Patents

Literature

588 results about "Needle penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

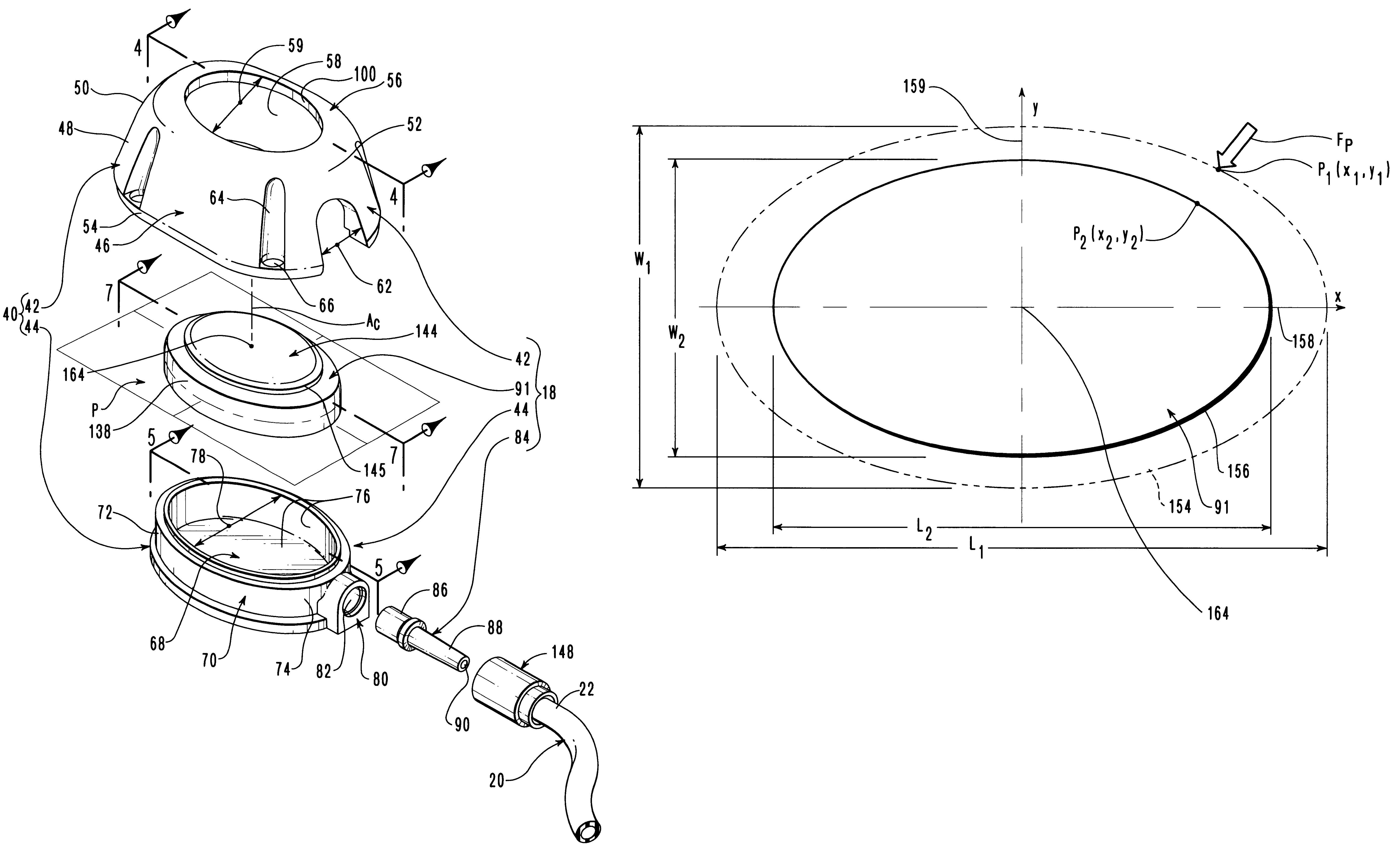

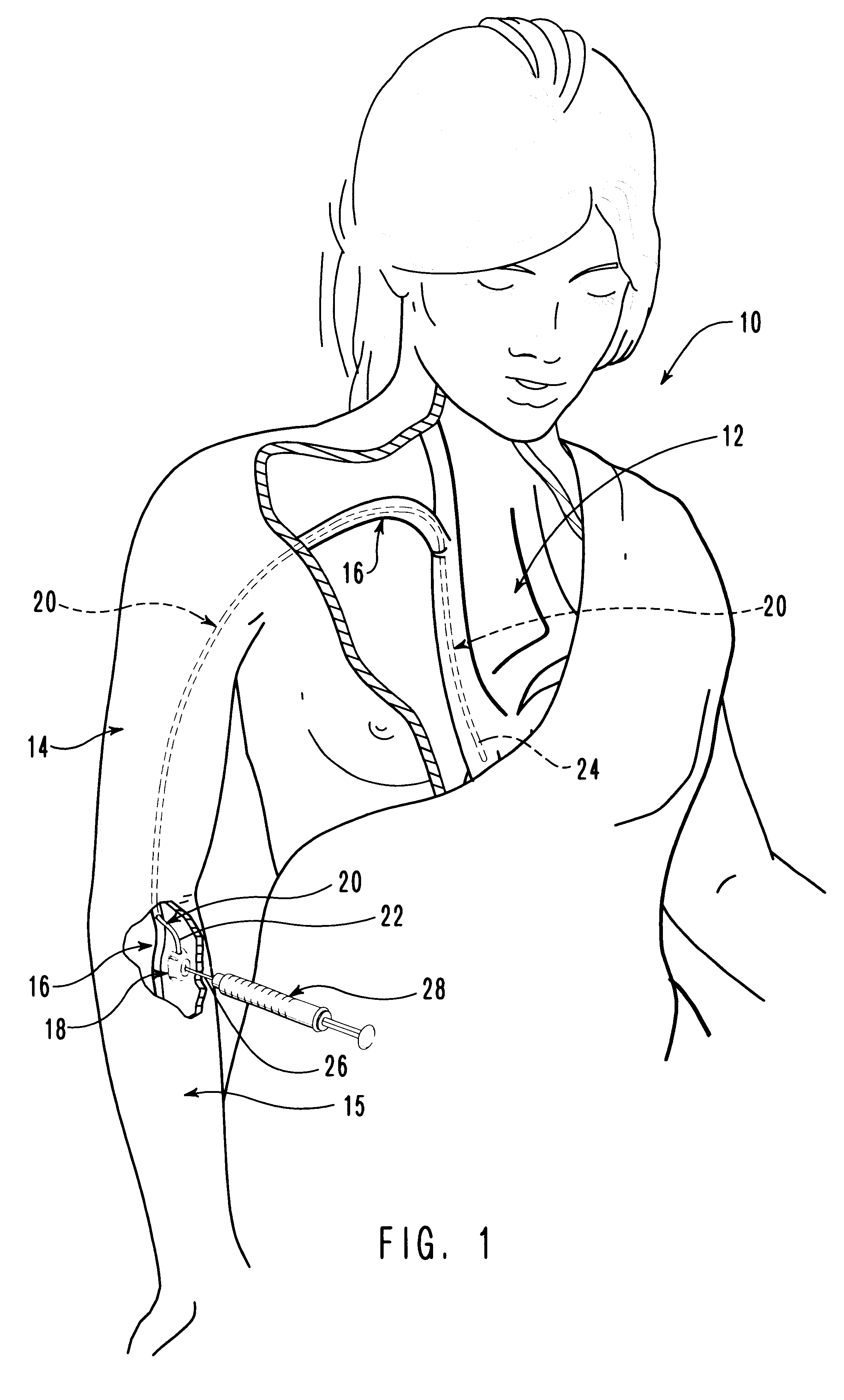

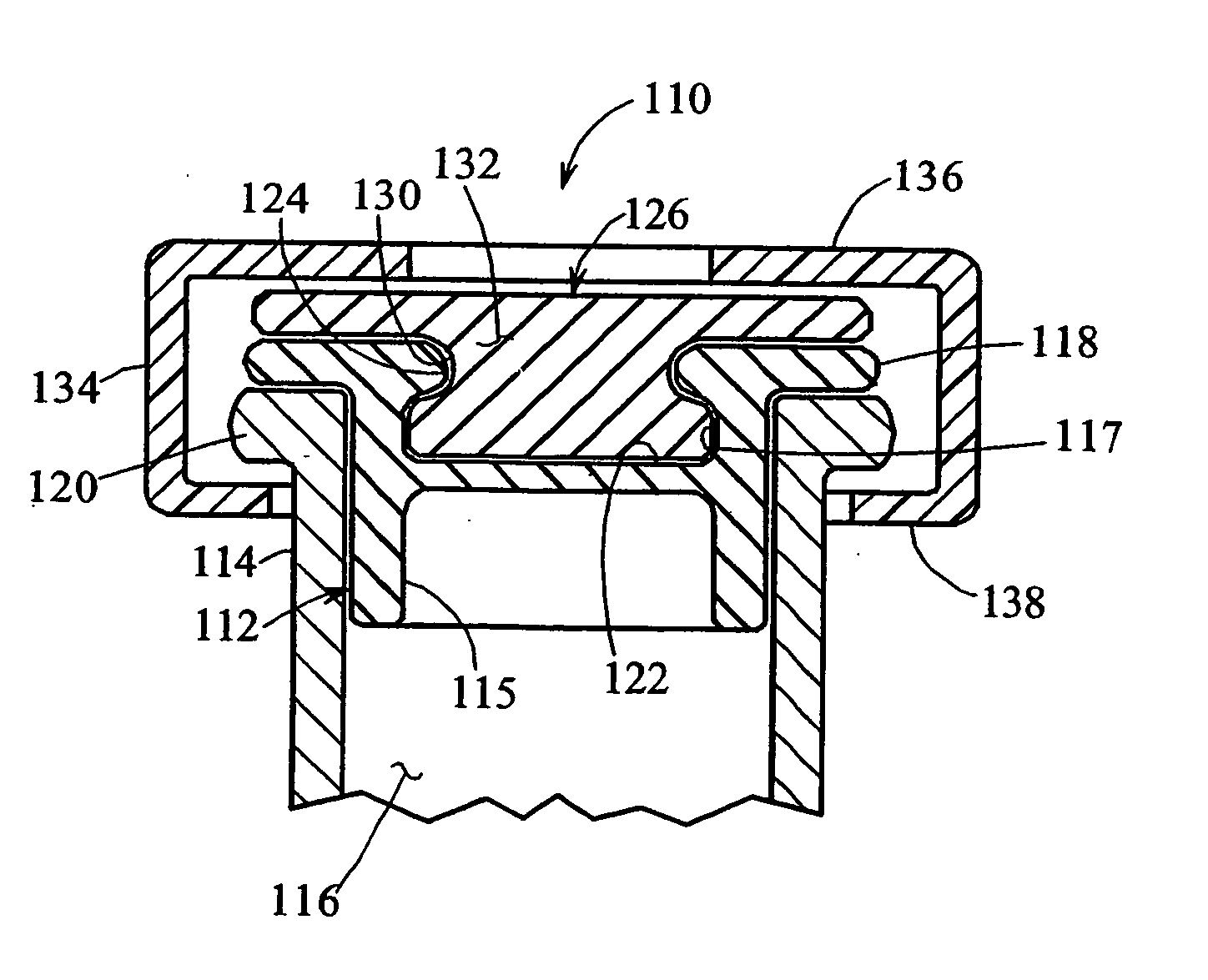

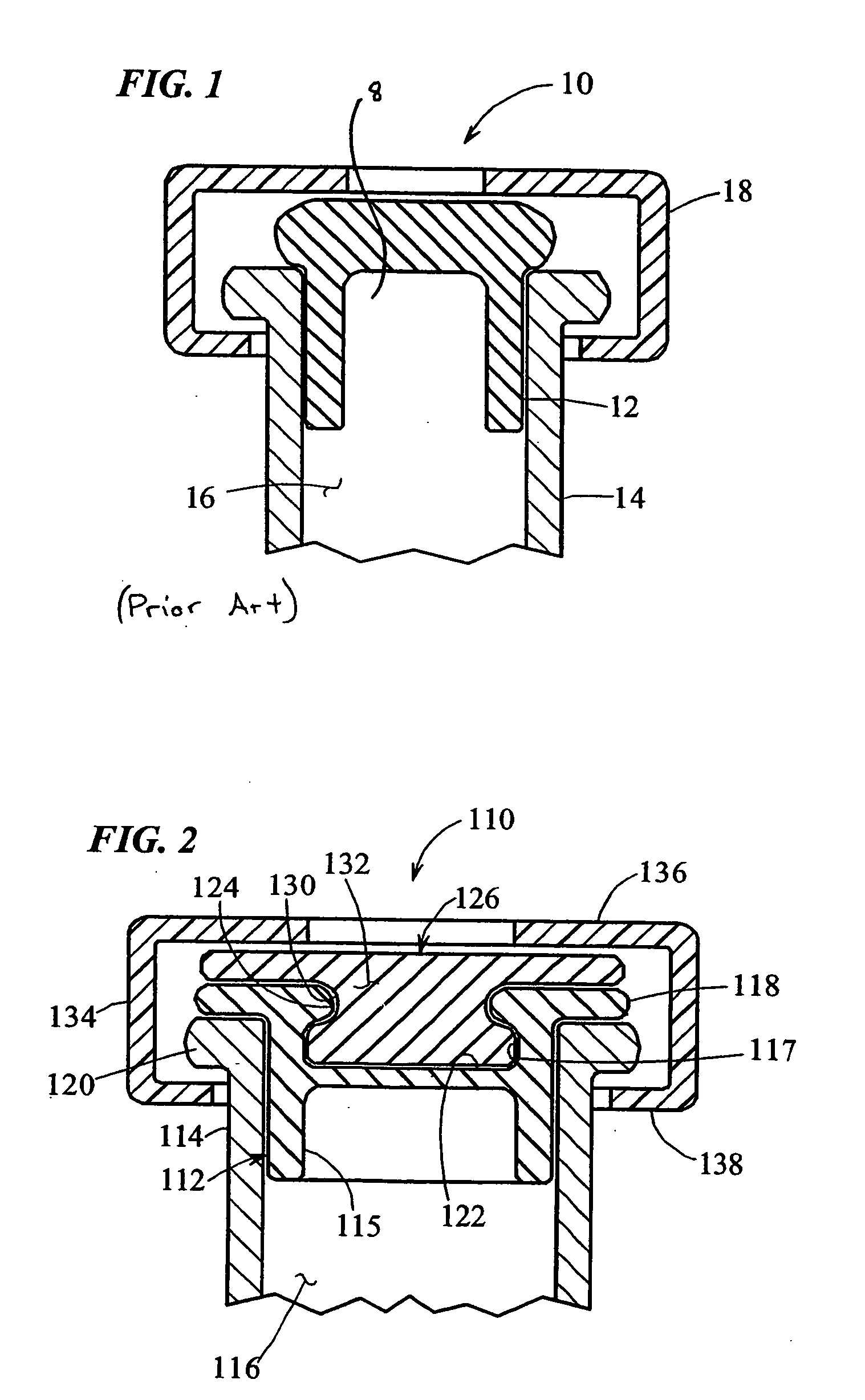

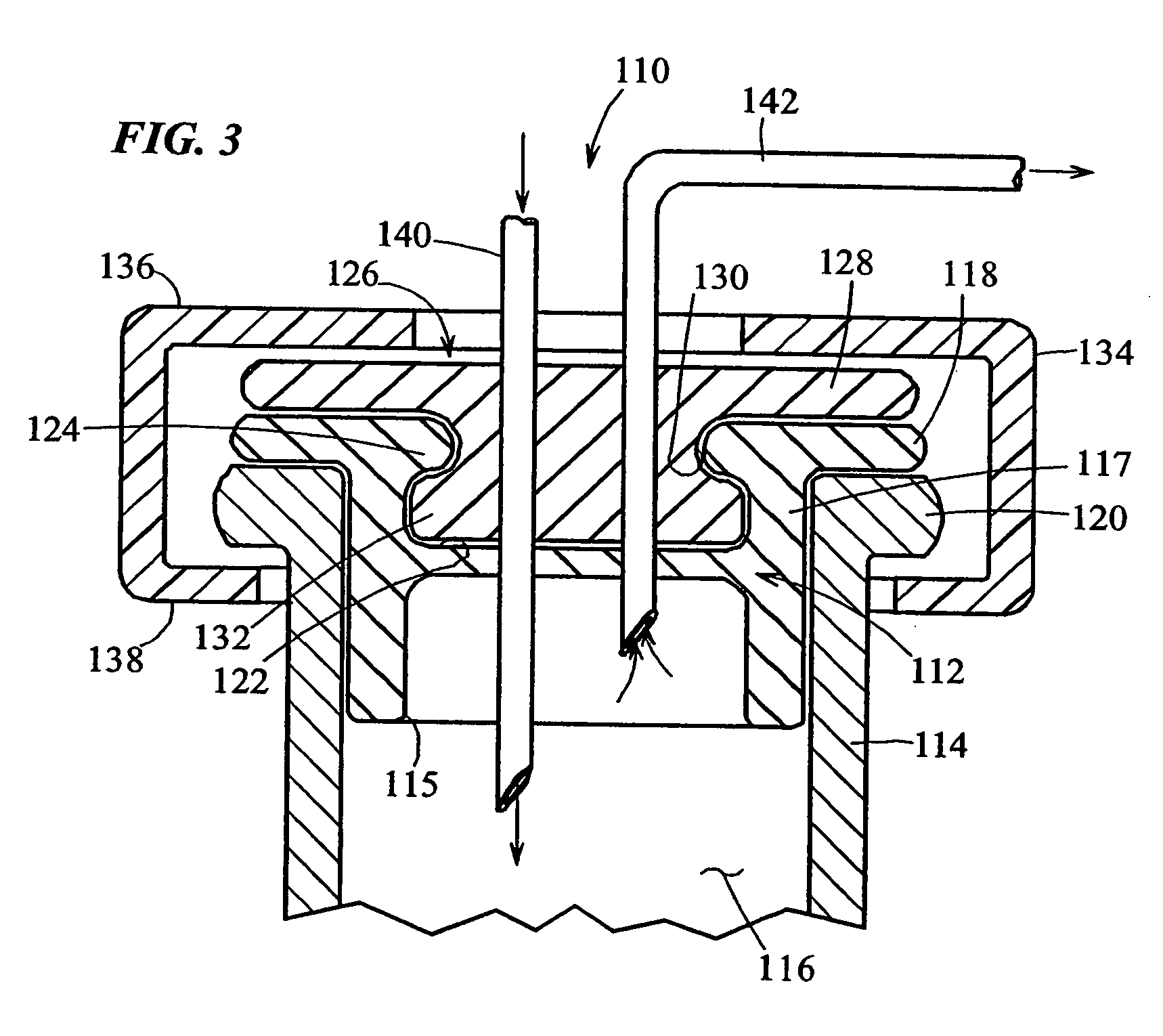

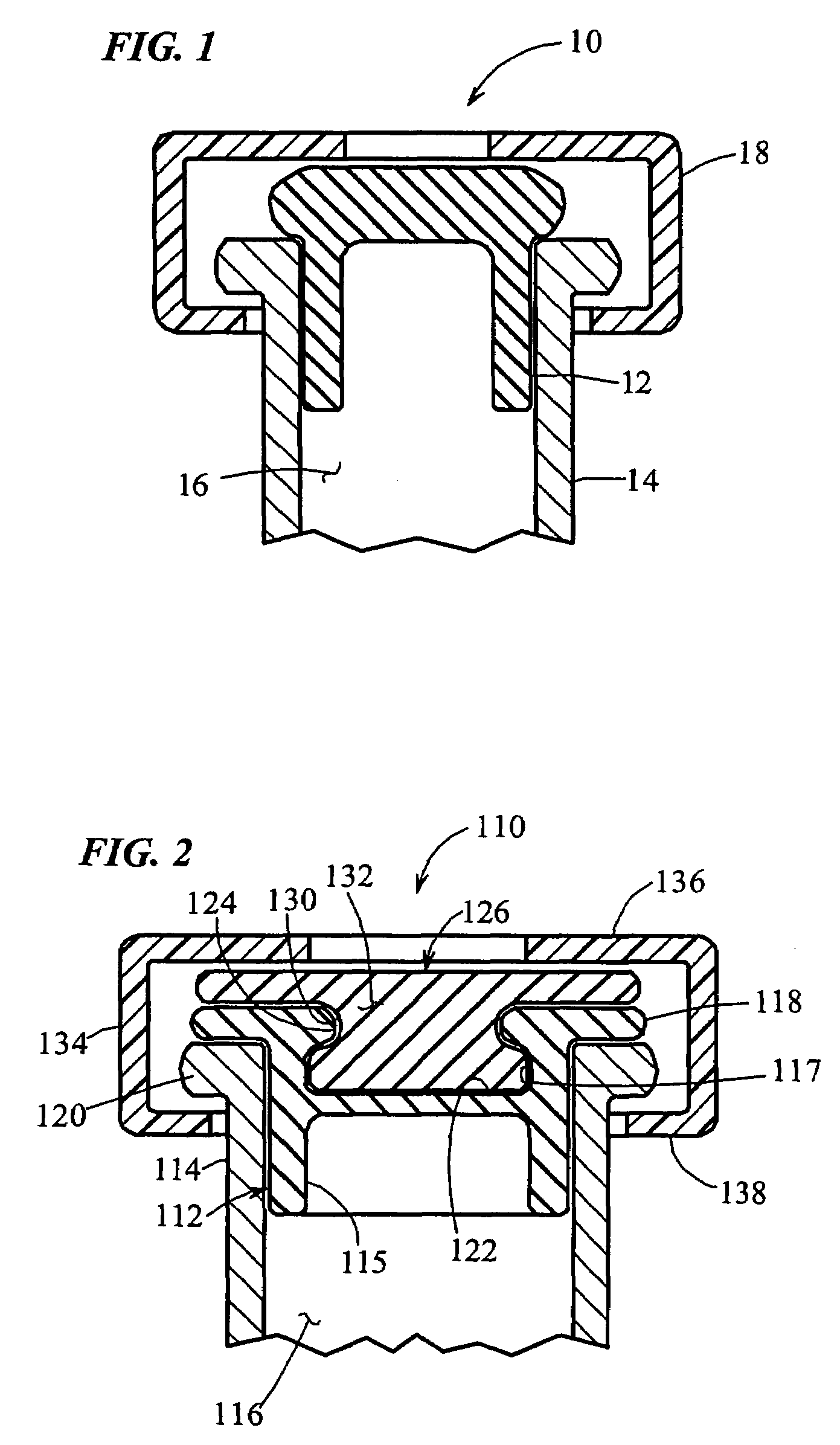

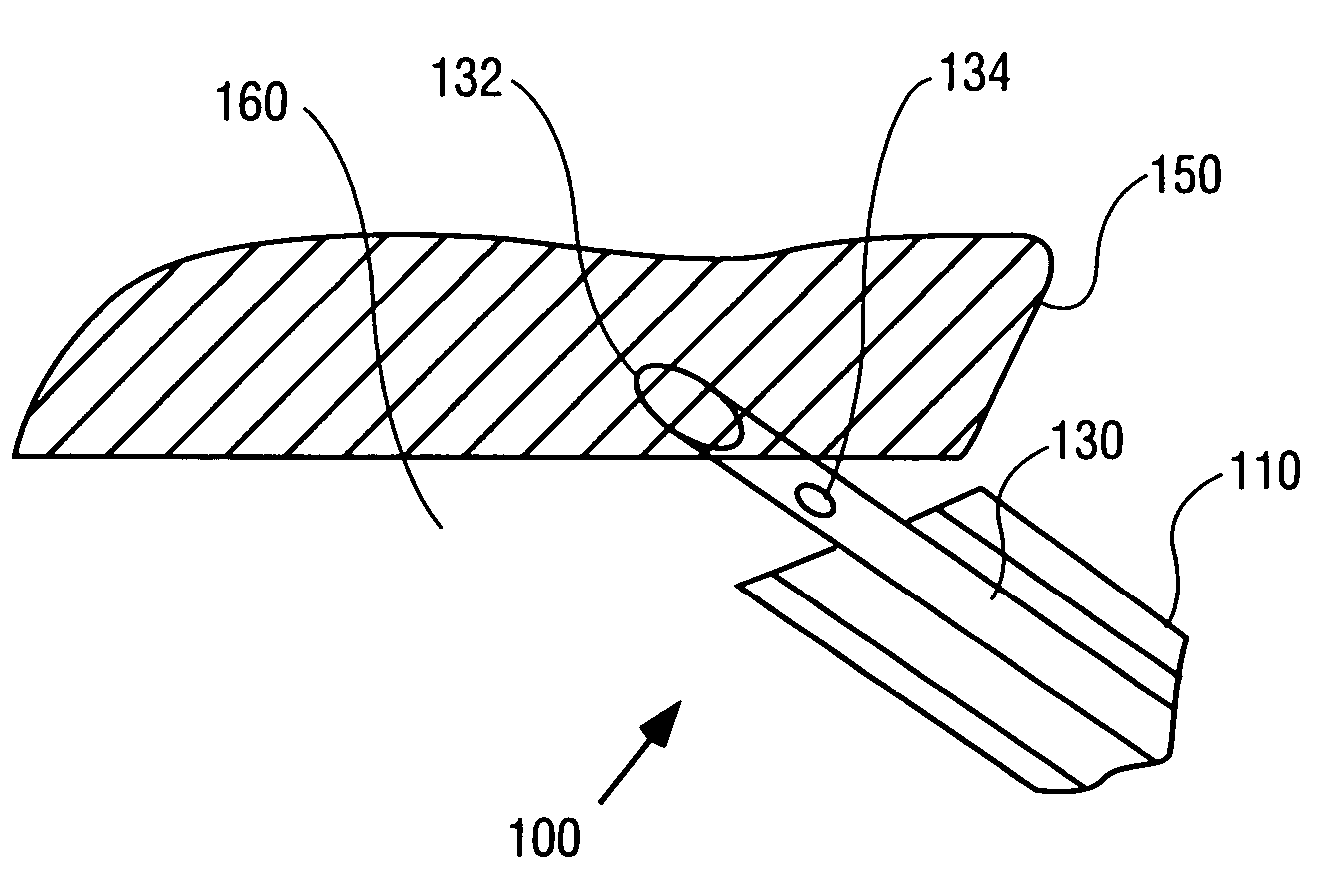

Vascular access port with elongated septum

InactiveUS6213973B1Large target areaPreventing buckling of the septumSurgeryMedical devicesNeedle penetrationHydrostatic pressure

An elongated access port has a needle-impenetrable housing enclosing a fluid reservoir. The housing includes a base having a floor with an upstanding encircling sidewall and a cap having a top wall with a depending encircling skirt. The skirt of the cap receives the sidewall of the base. An access aperture extends through the top wall of the cap to communicate with the fluid reservoir. The access aperture is encircled by a continuous rim having an elongated shape in the plane of the access aperture. The rim of the access aperture may be elliptical, oval, polygonal, or parabolic-ended. An elastomeric, needle-penetrable, generally planar septum is disposed in the access aperture with the periphery of the septum in sealing engagement with the rim of the access aperture. Prior to installation, the septum has a periphery with a cross section in the plane of the septum that is geometrically proportional to and larger than the shape of the access aperture. Installation causes the periphery of the septum to be displaced inwardly by the rim of the access aperture in a direction parallel to the plane of the septum. In view of the relative shapes of the rim of the access aperture and the periphery of the septum, this produces substantially uniform hydrostatic pressure in regions of the installed septum that are subjected in use of the access port to needle penetrations. Opposite faces of the periphery of the septum are urged toward each other between the cap of the housing and the top of the sidewall of the base of the housing.

Owner:CR BARD INC

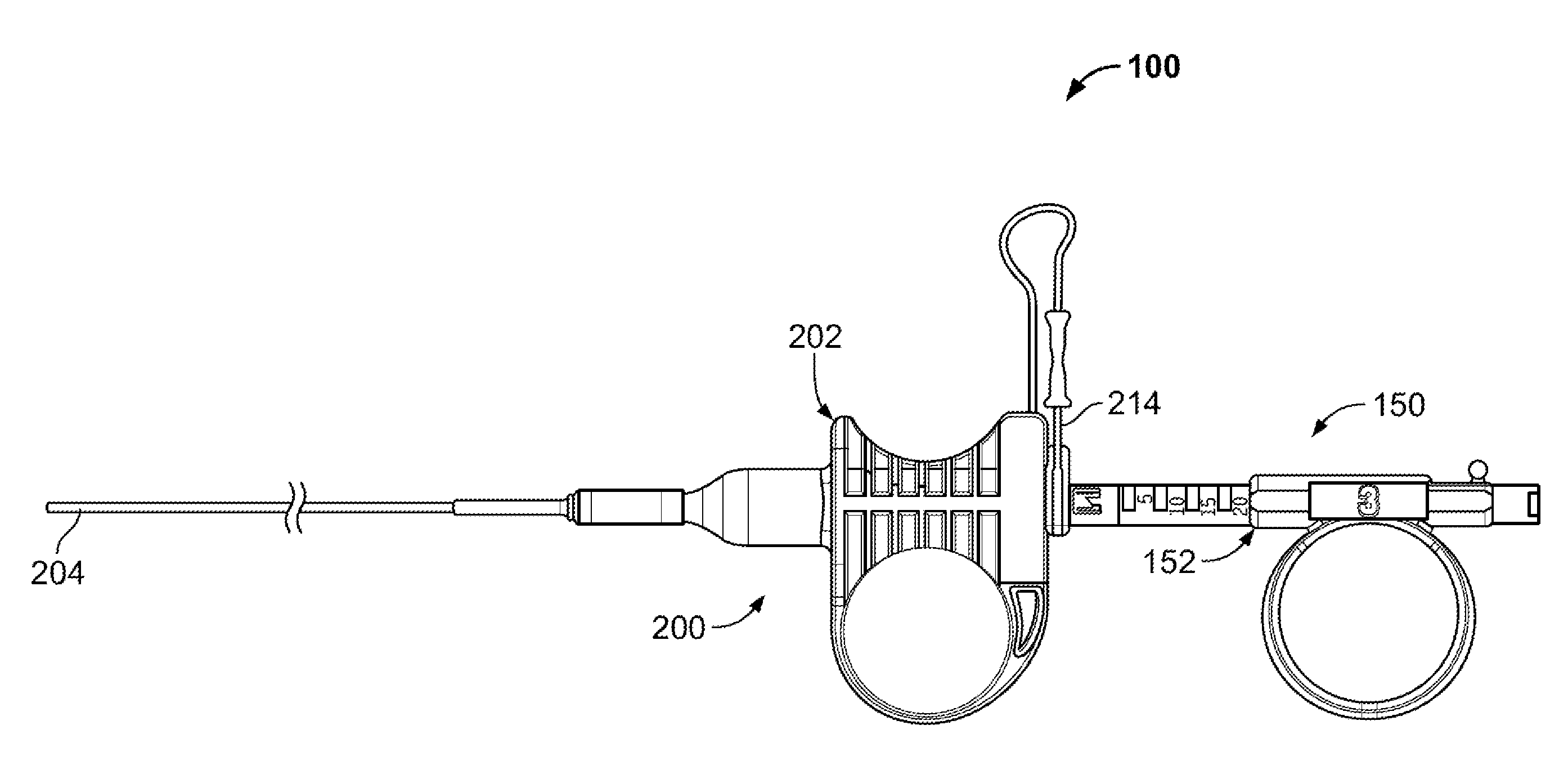

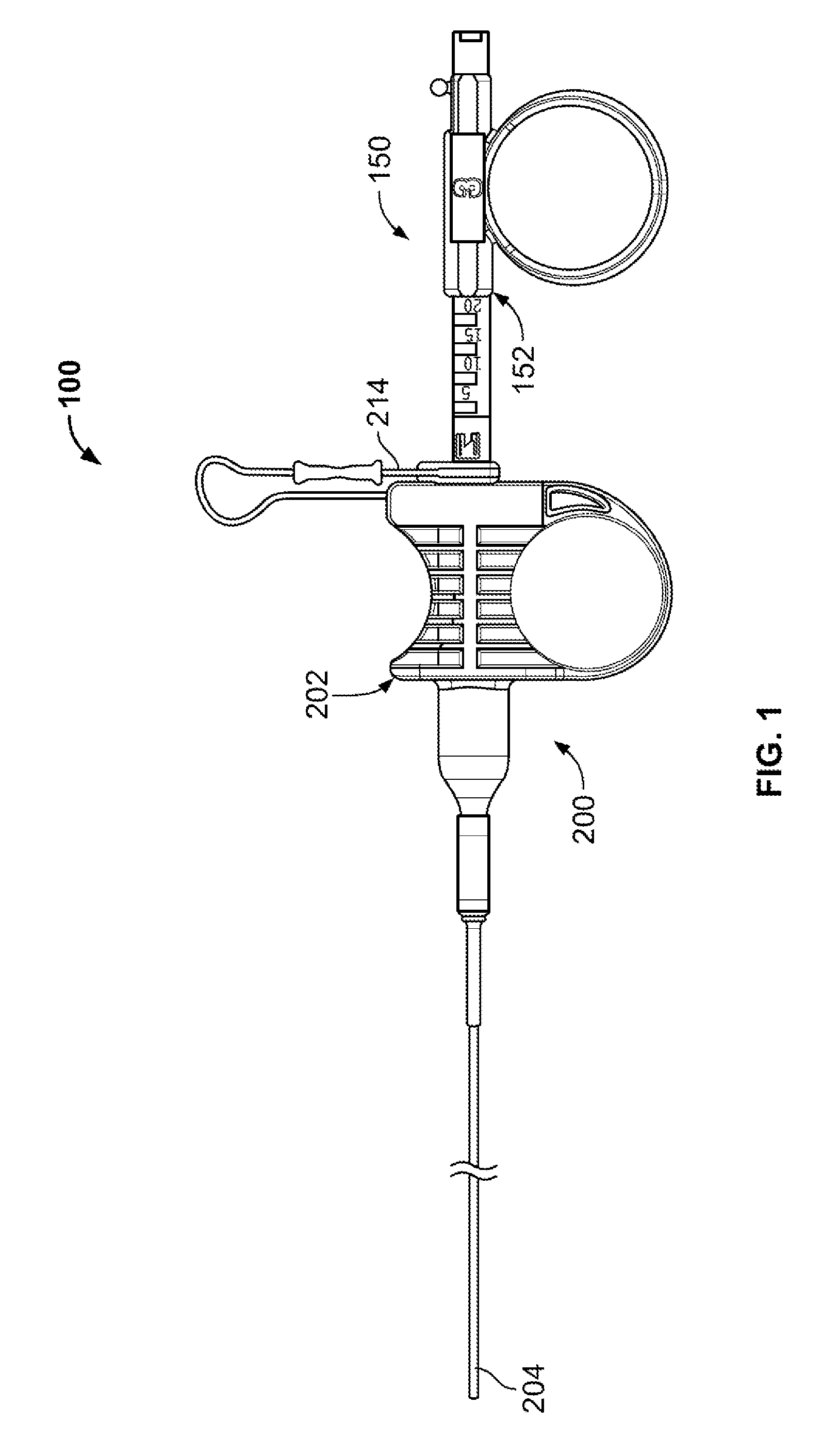

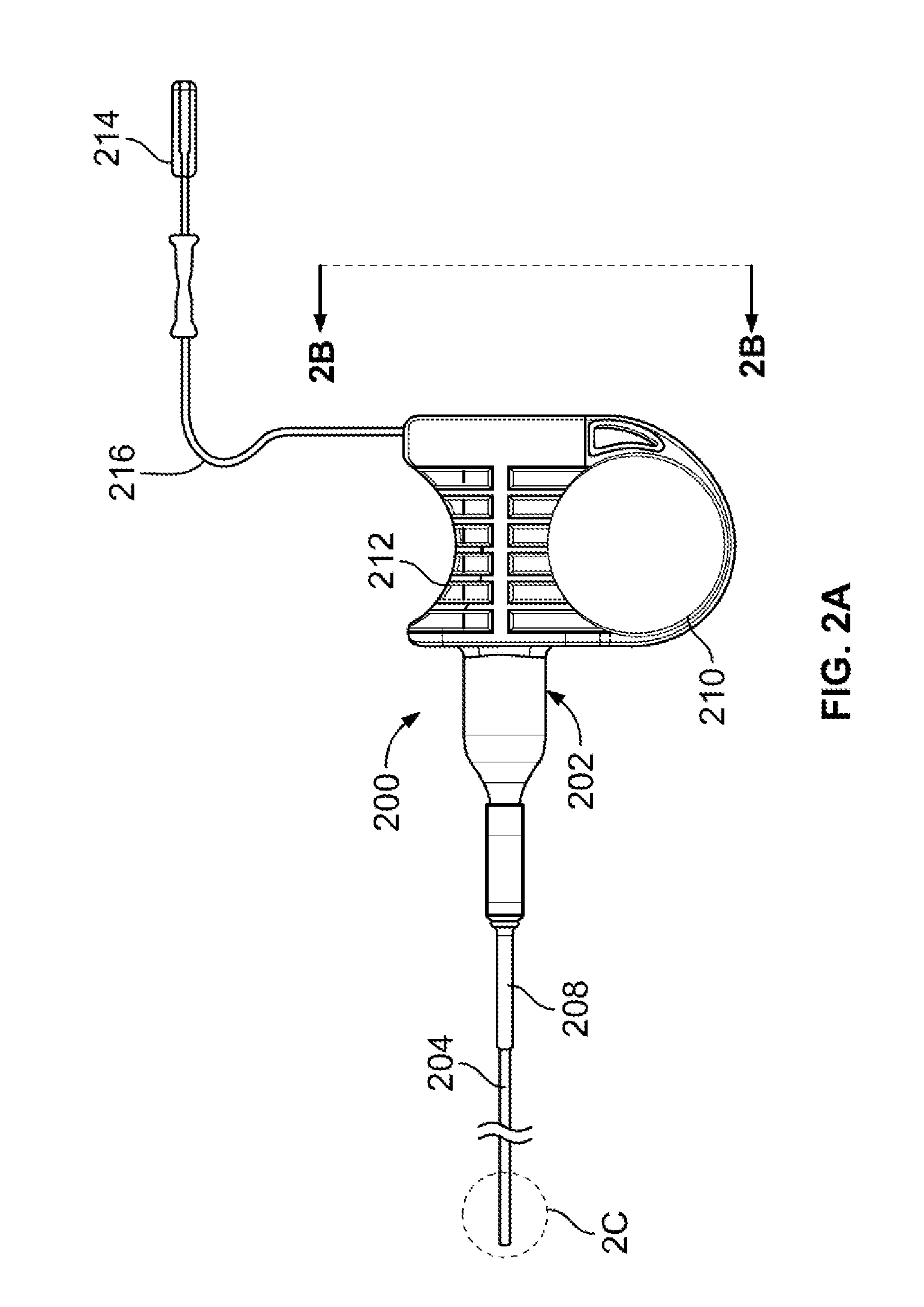

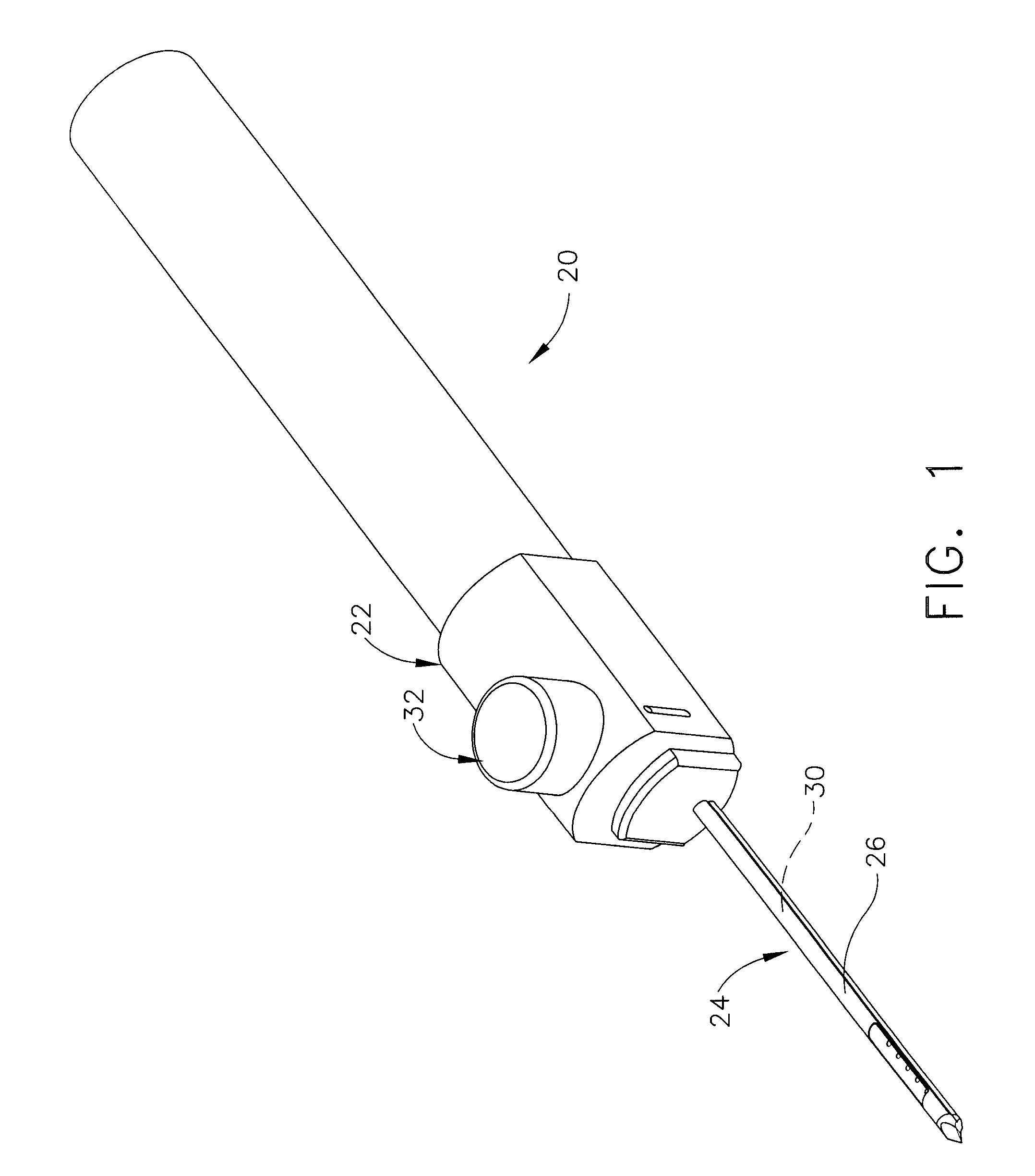

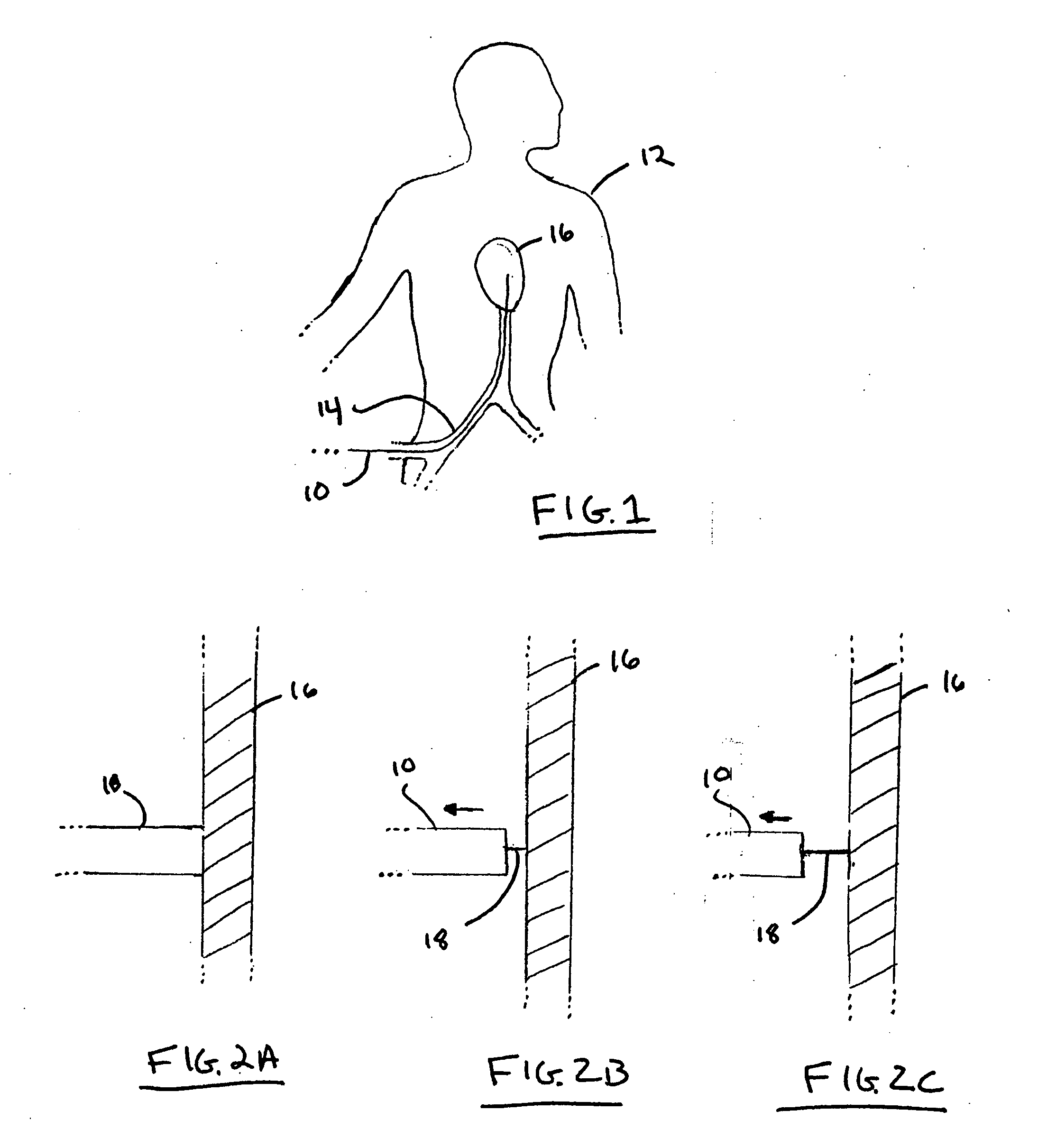

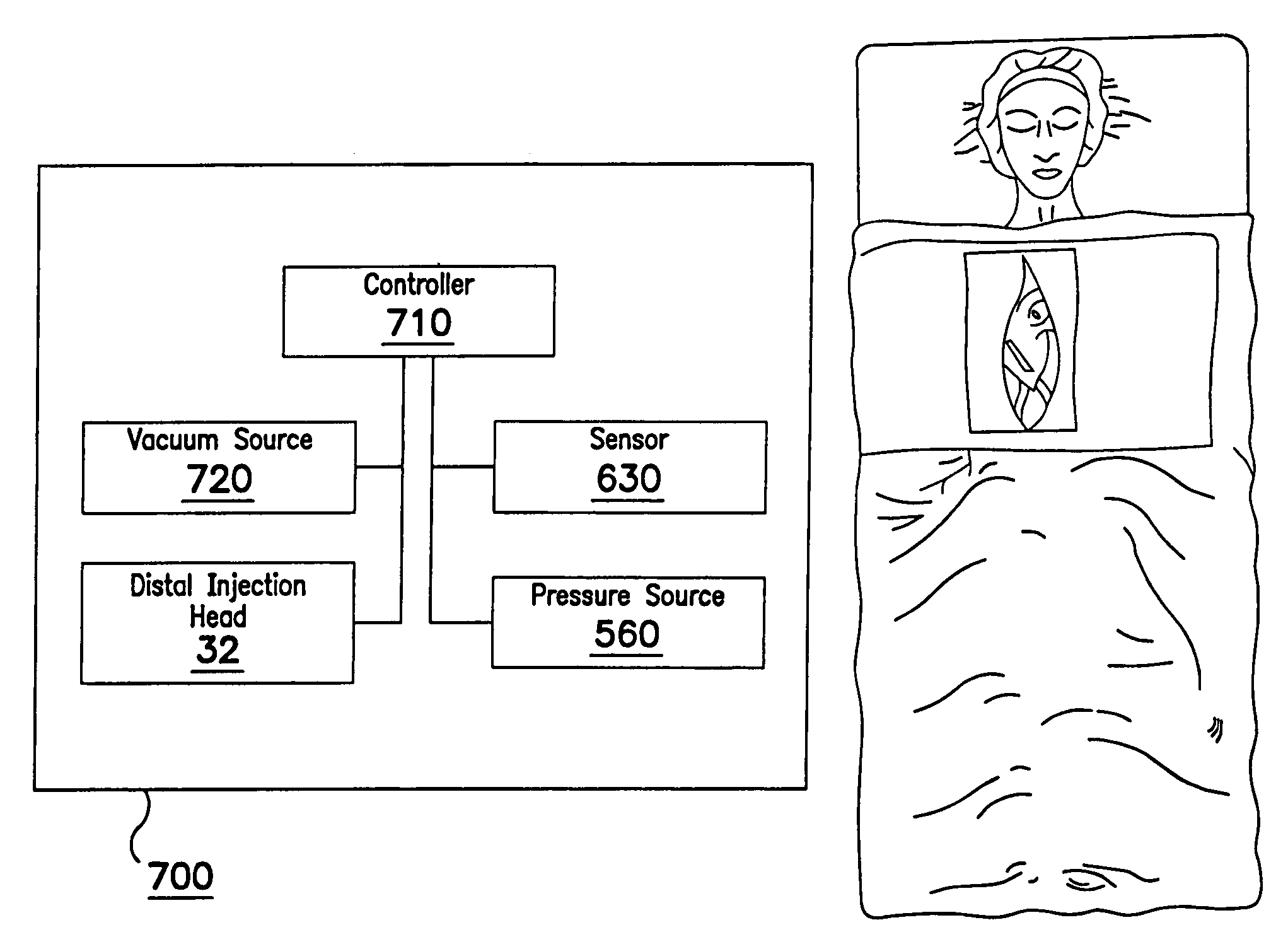

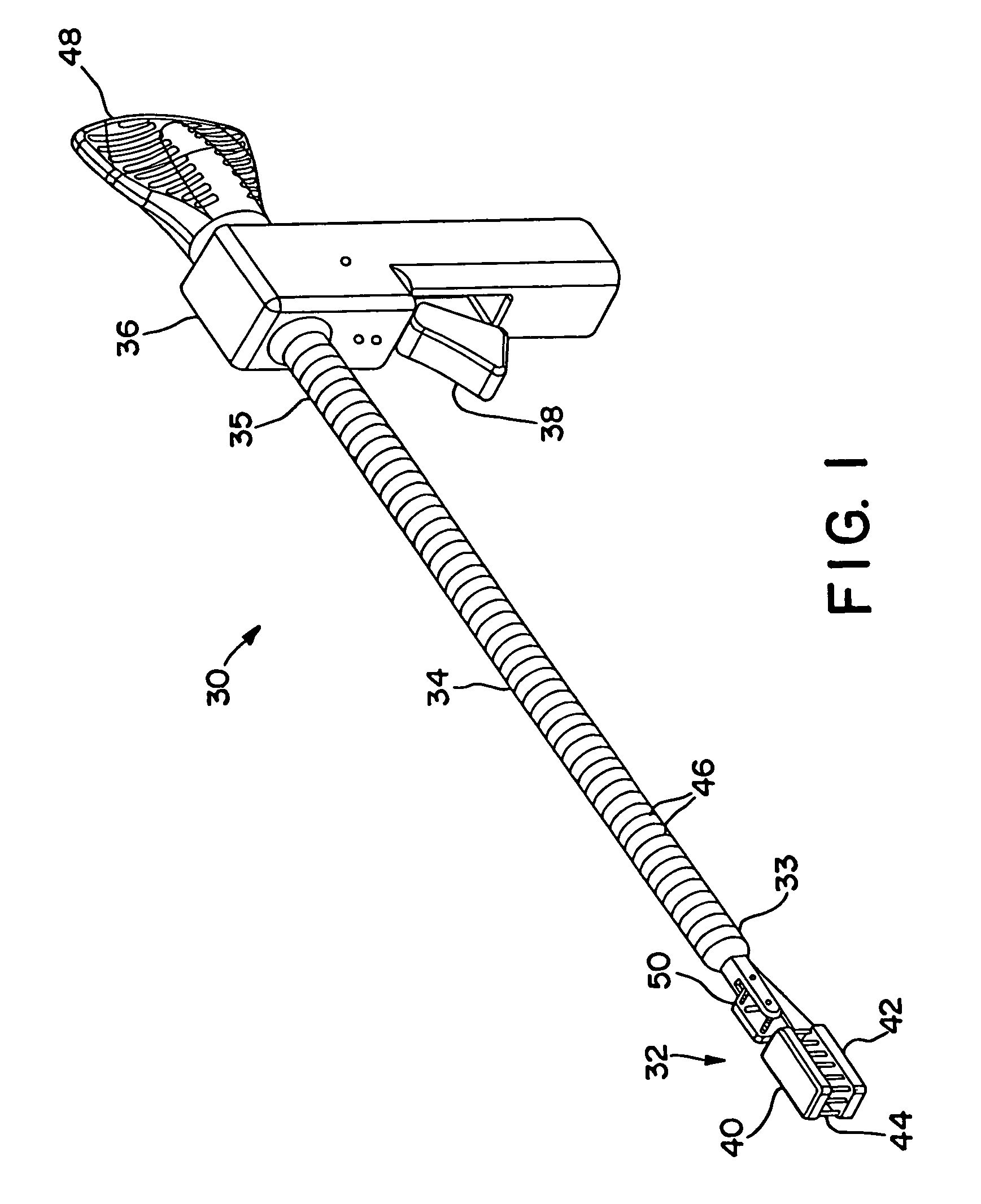

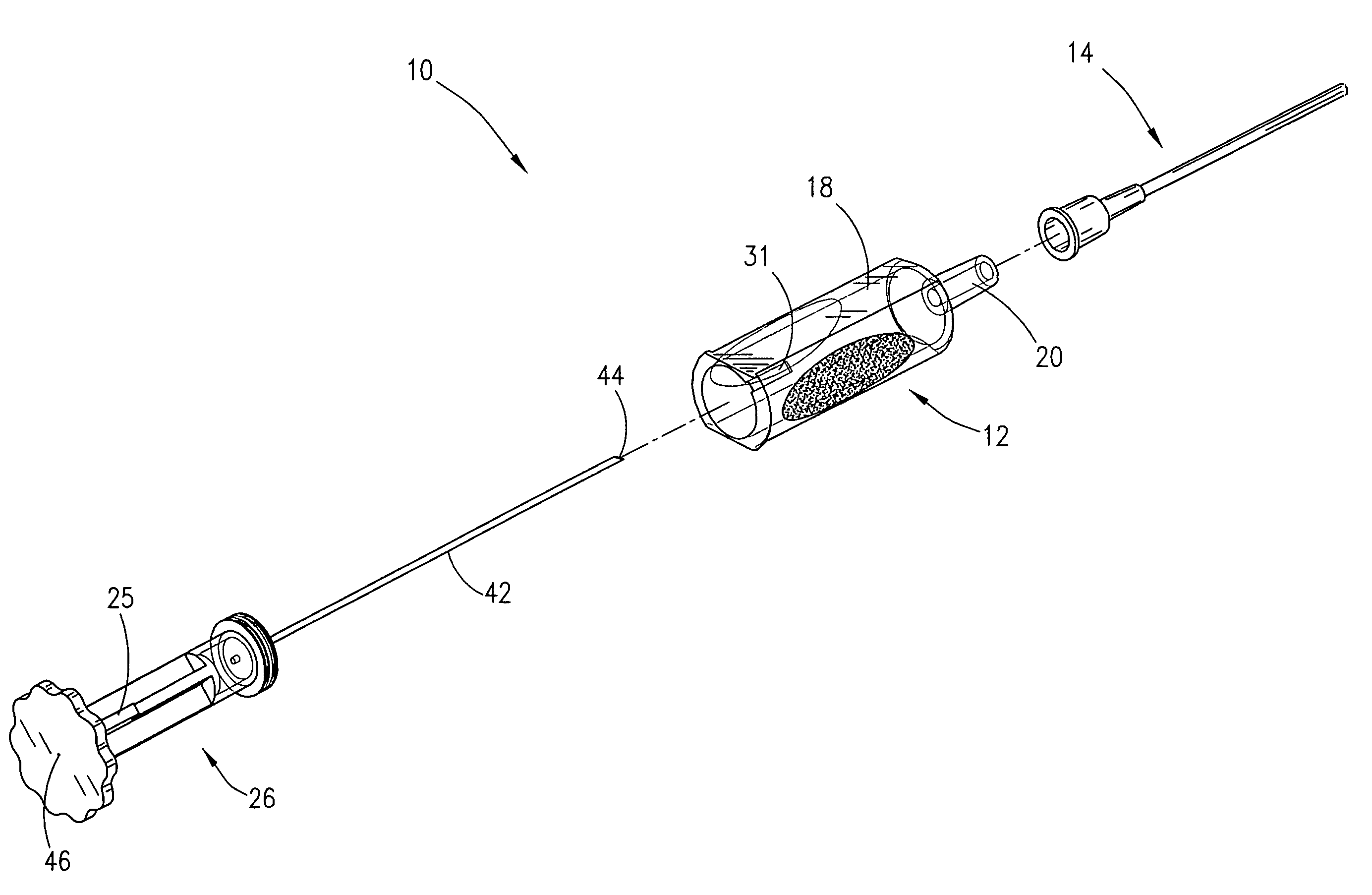

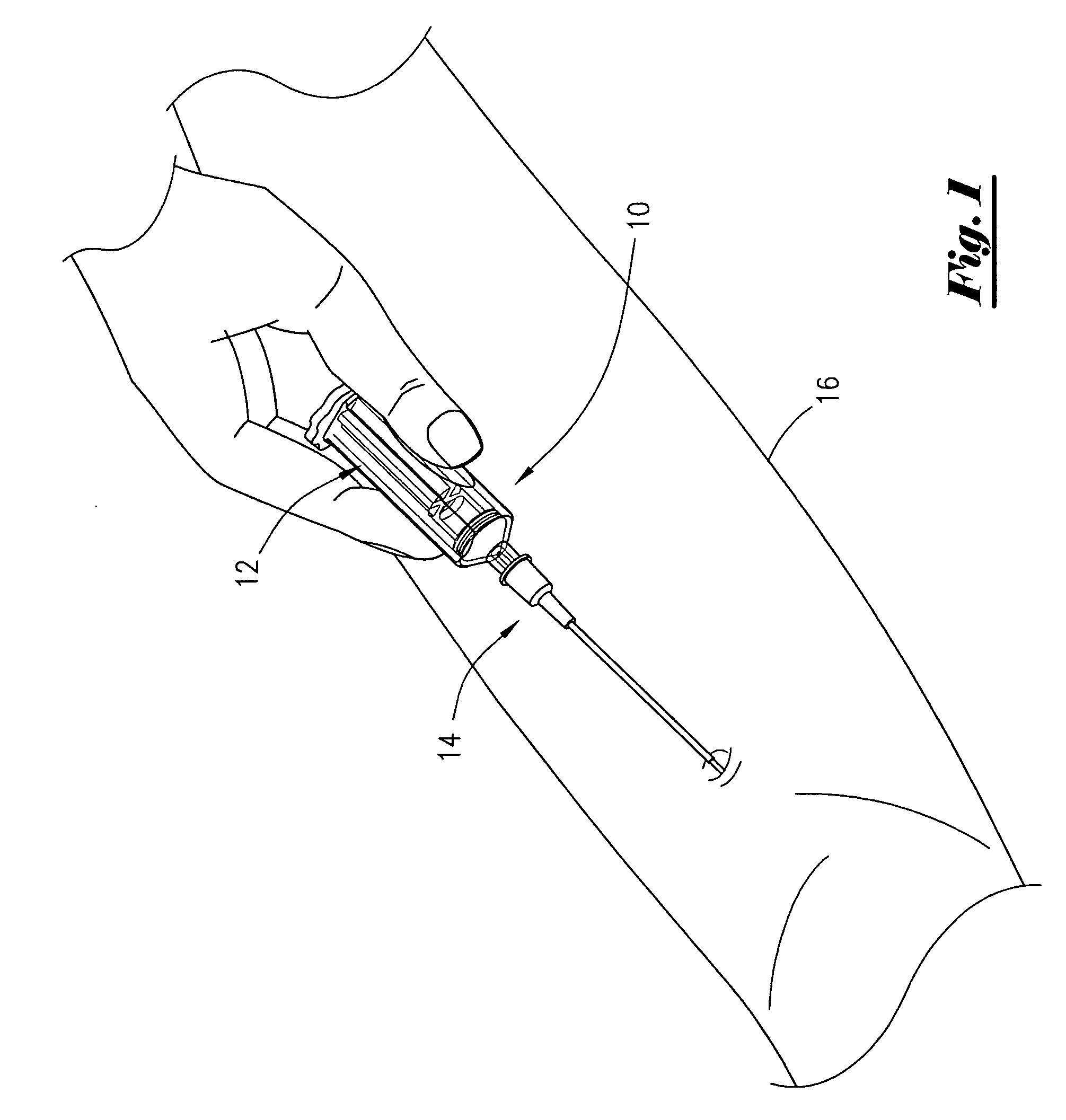

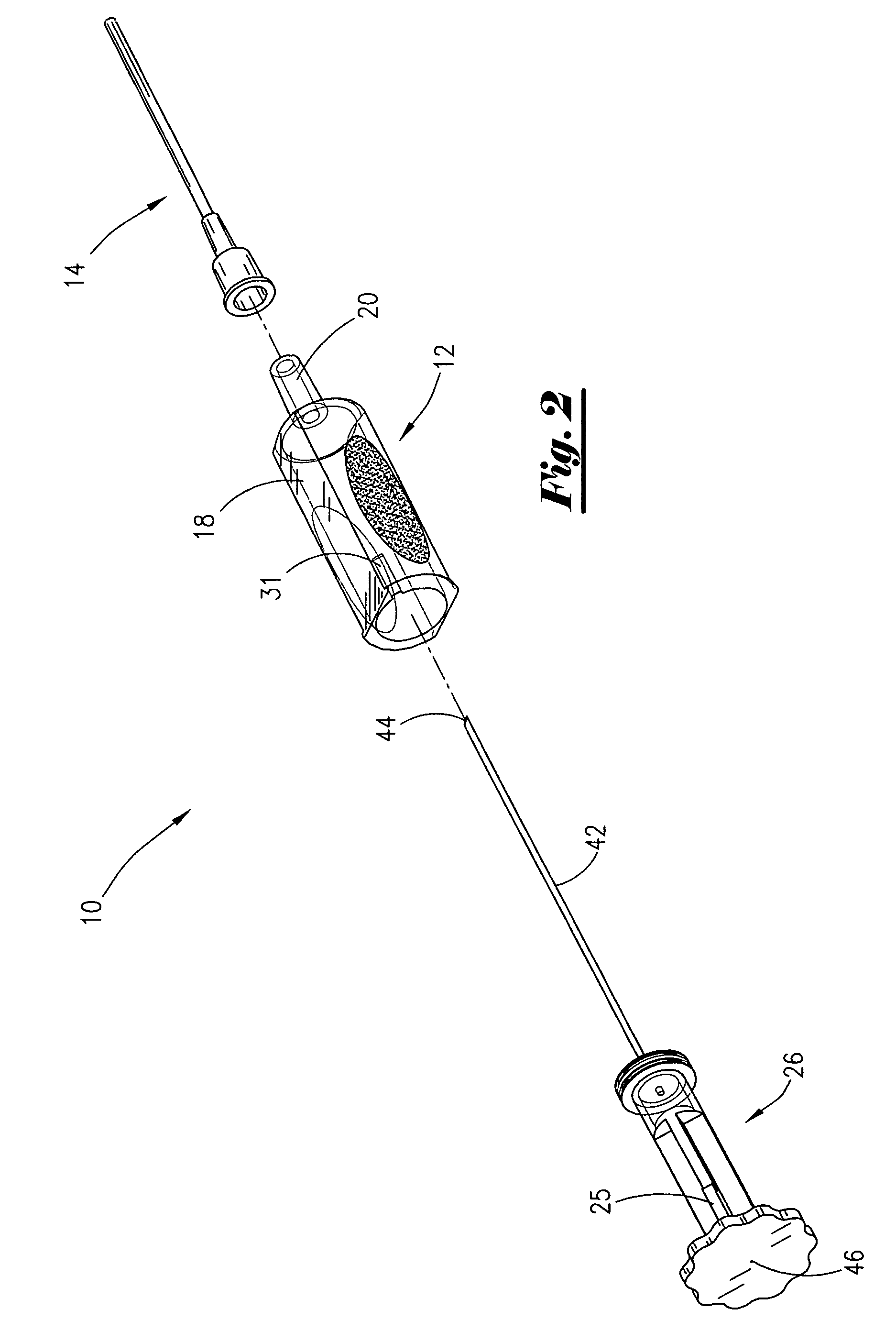

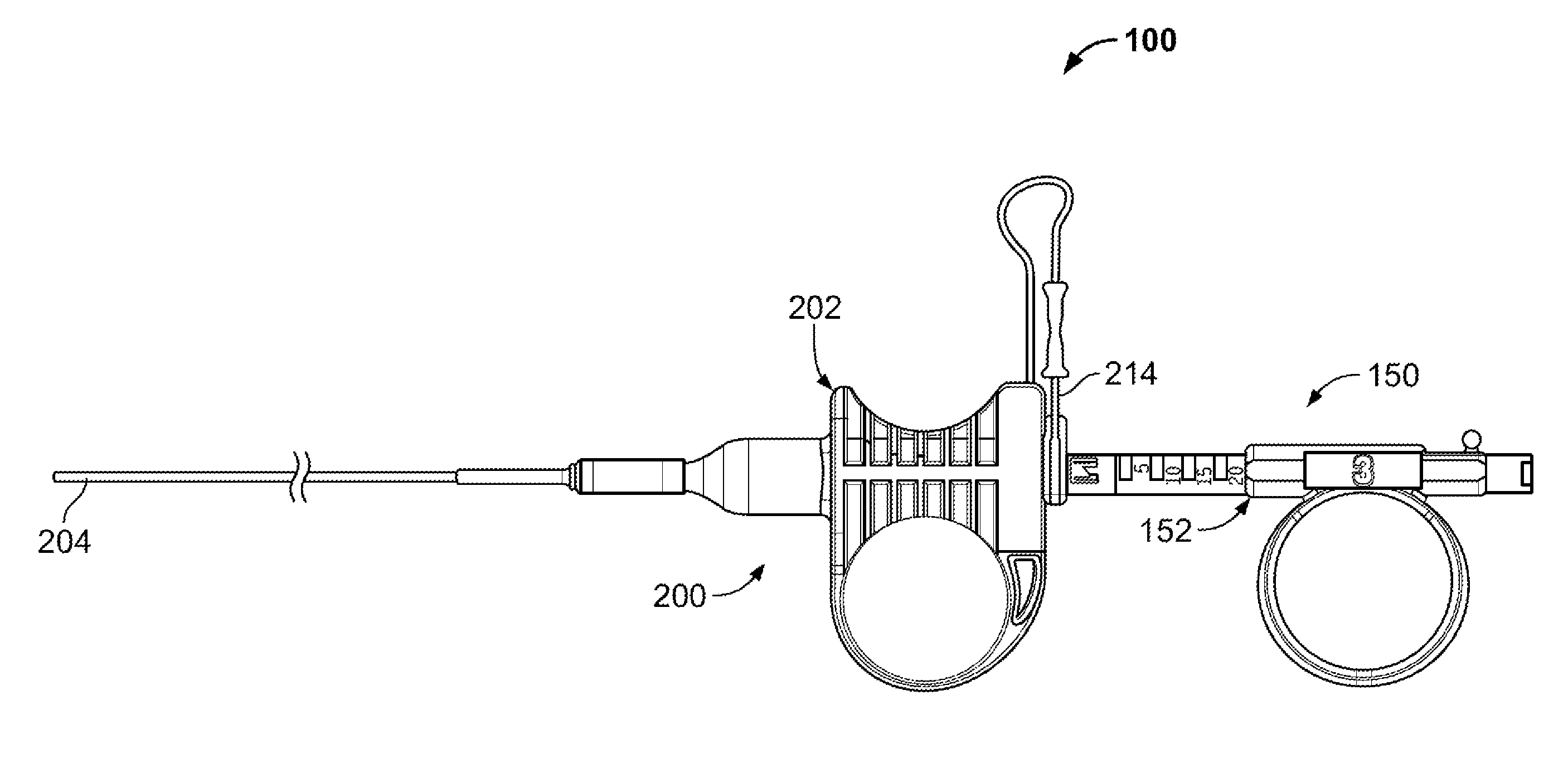

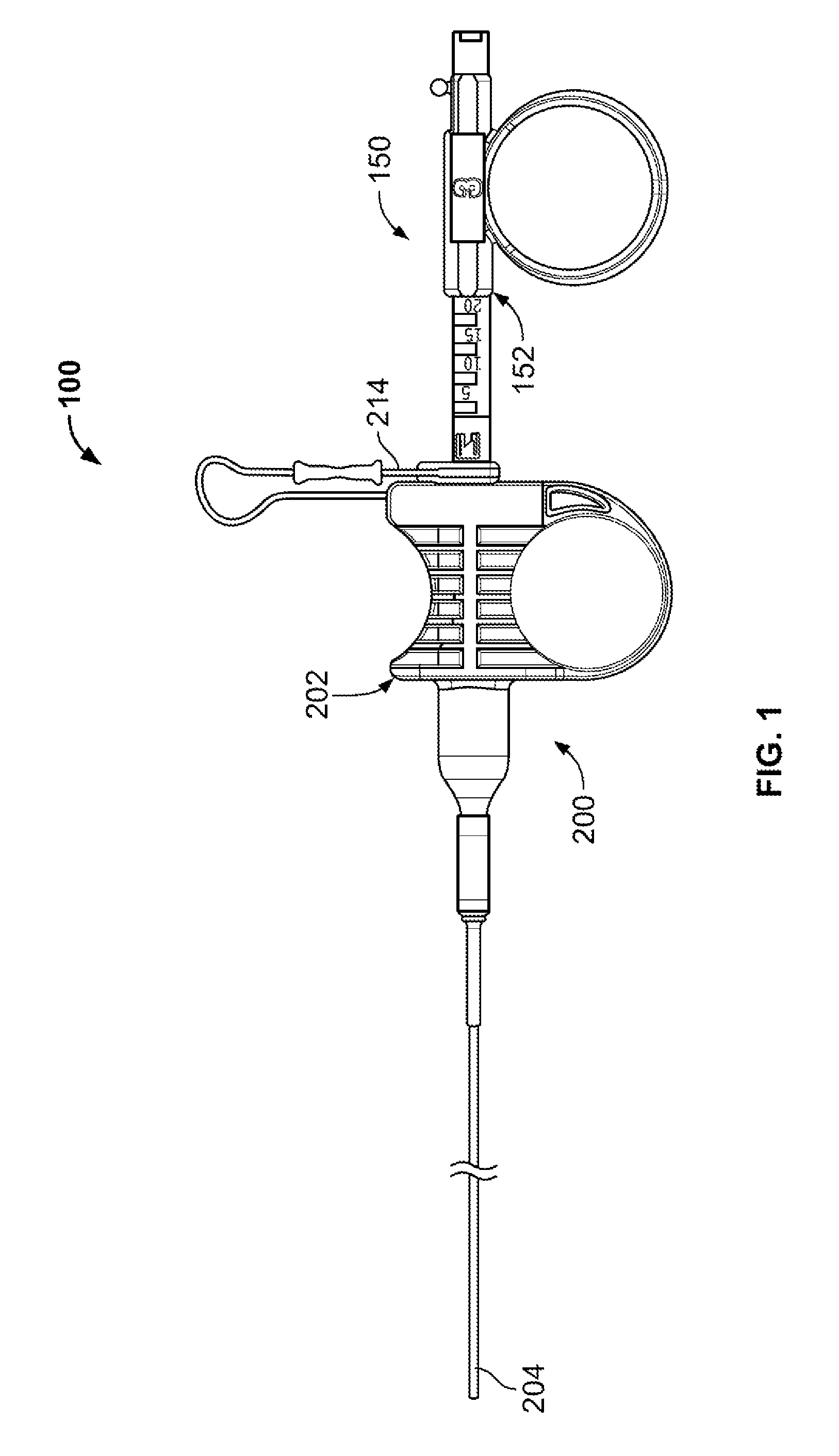

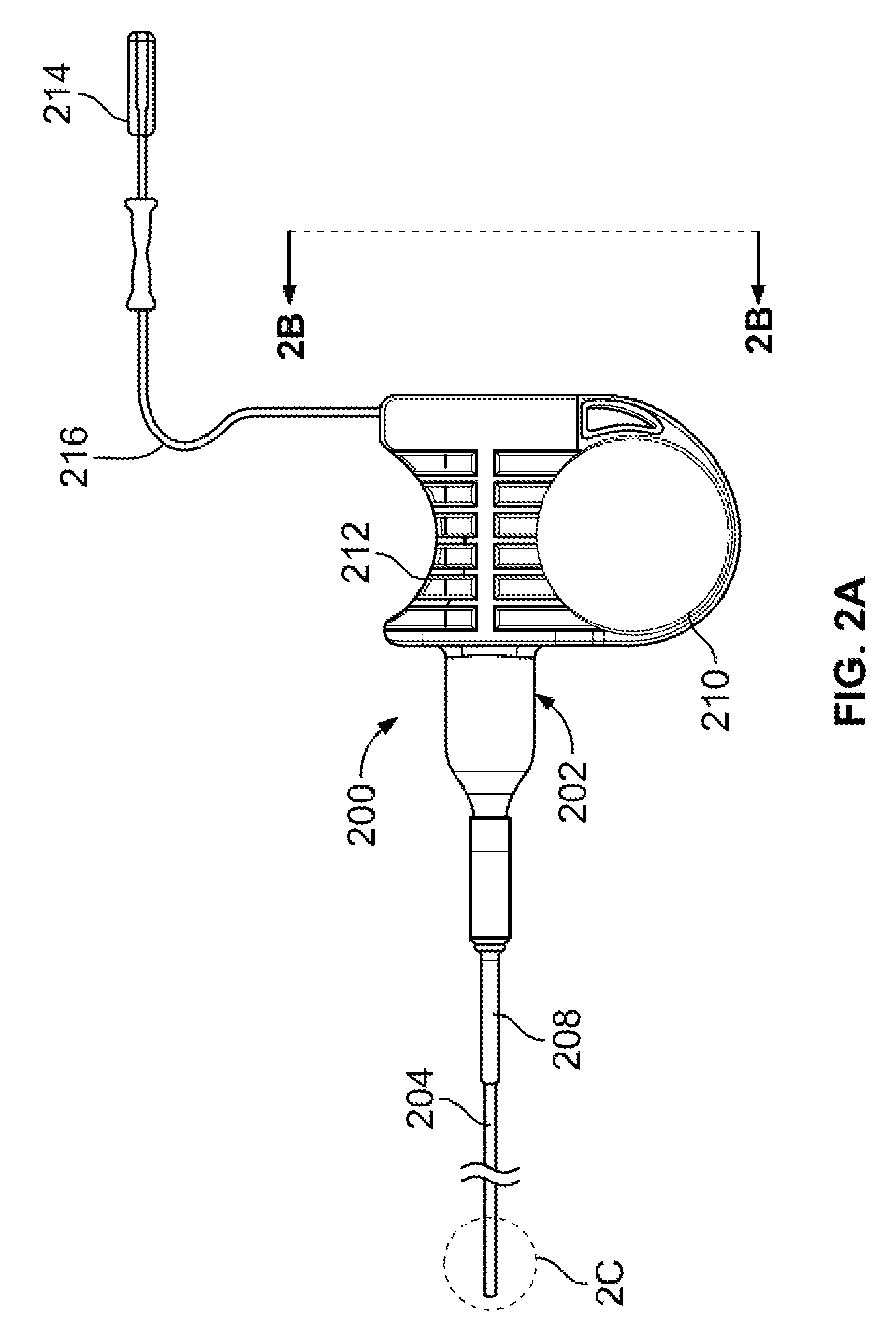

Tissue sampling devices, systems and methods

ActiveUS20100312141A1Minimize unintended injuryHigh strengthBronchoscopesGuide wiresNeedle penetrationMedicine

Methods, devices, and systems are described herein that allow for improved sampling of tissue from remote sites in the body. A tissue sampling device comprises a handle allowing single hand operation. In one variation the tissue sampling device includes a blood vessel scanning means and tissue coring means to excise a histology sample from a target site free of blood vessels. The sampling device also includes an adjustable stop to control the depth of a needle penetration. The sampling device may be used through a working channel of a bronchoscope.

Owner:BRONCUS MEDICAL

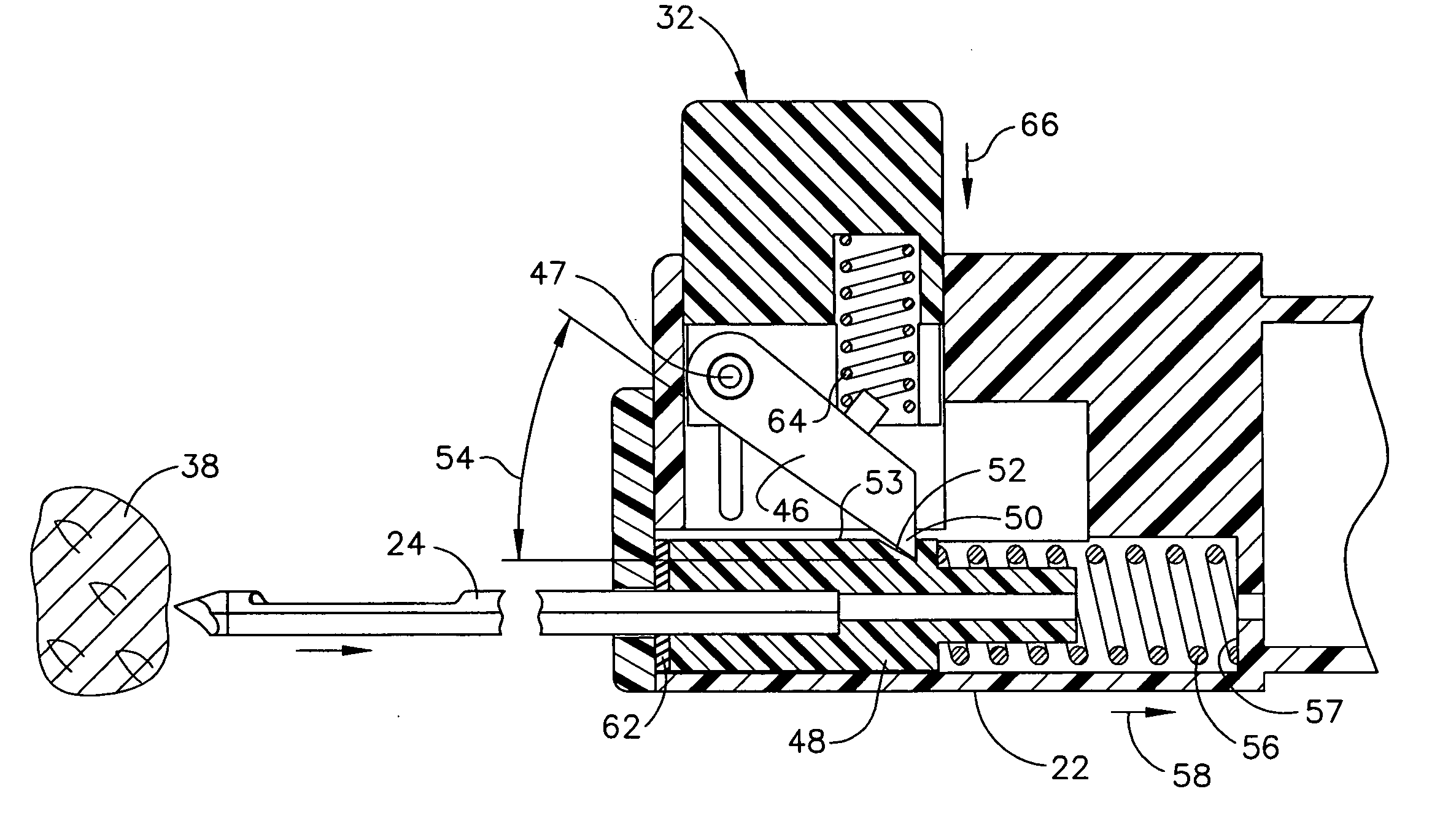

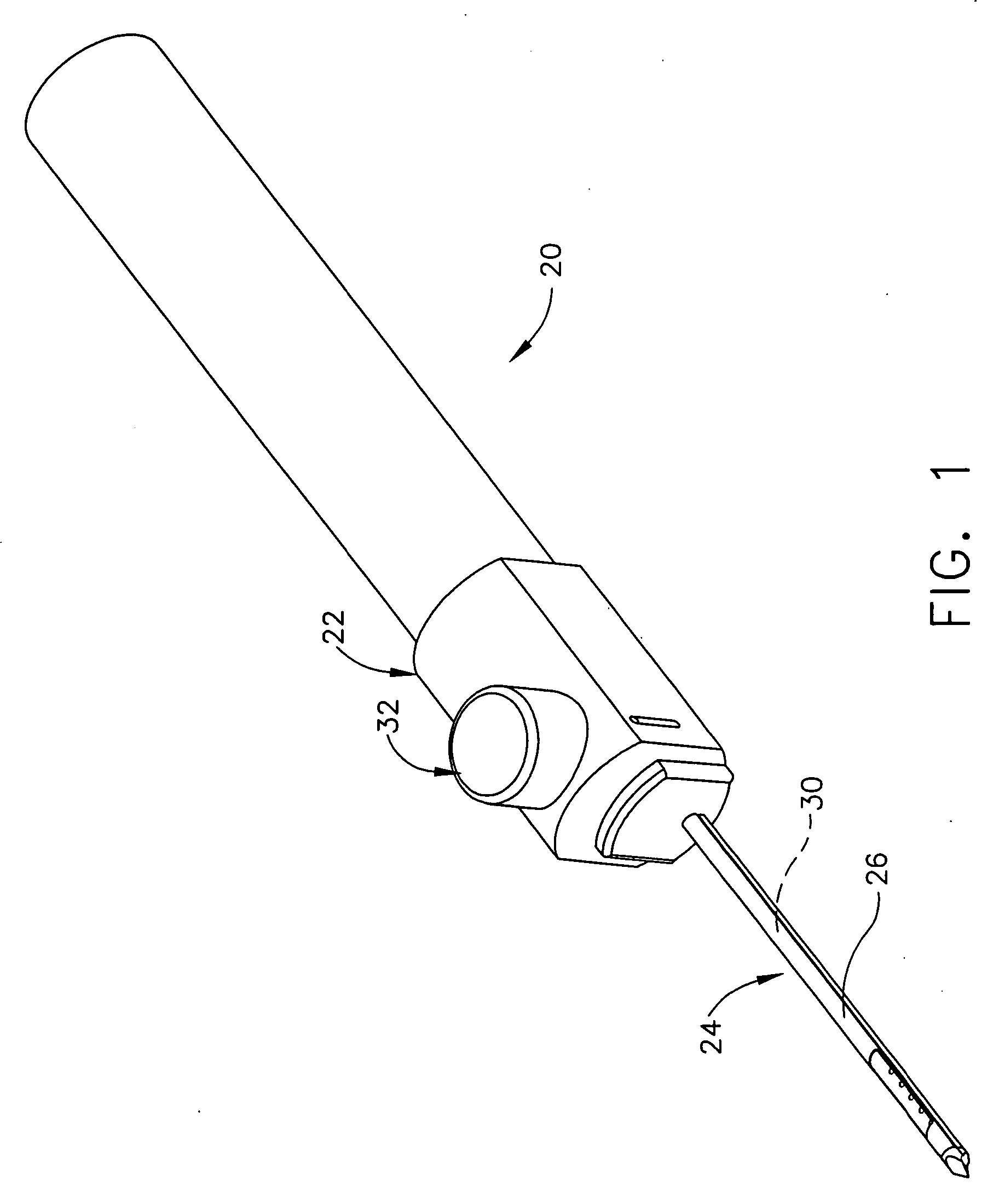

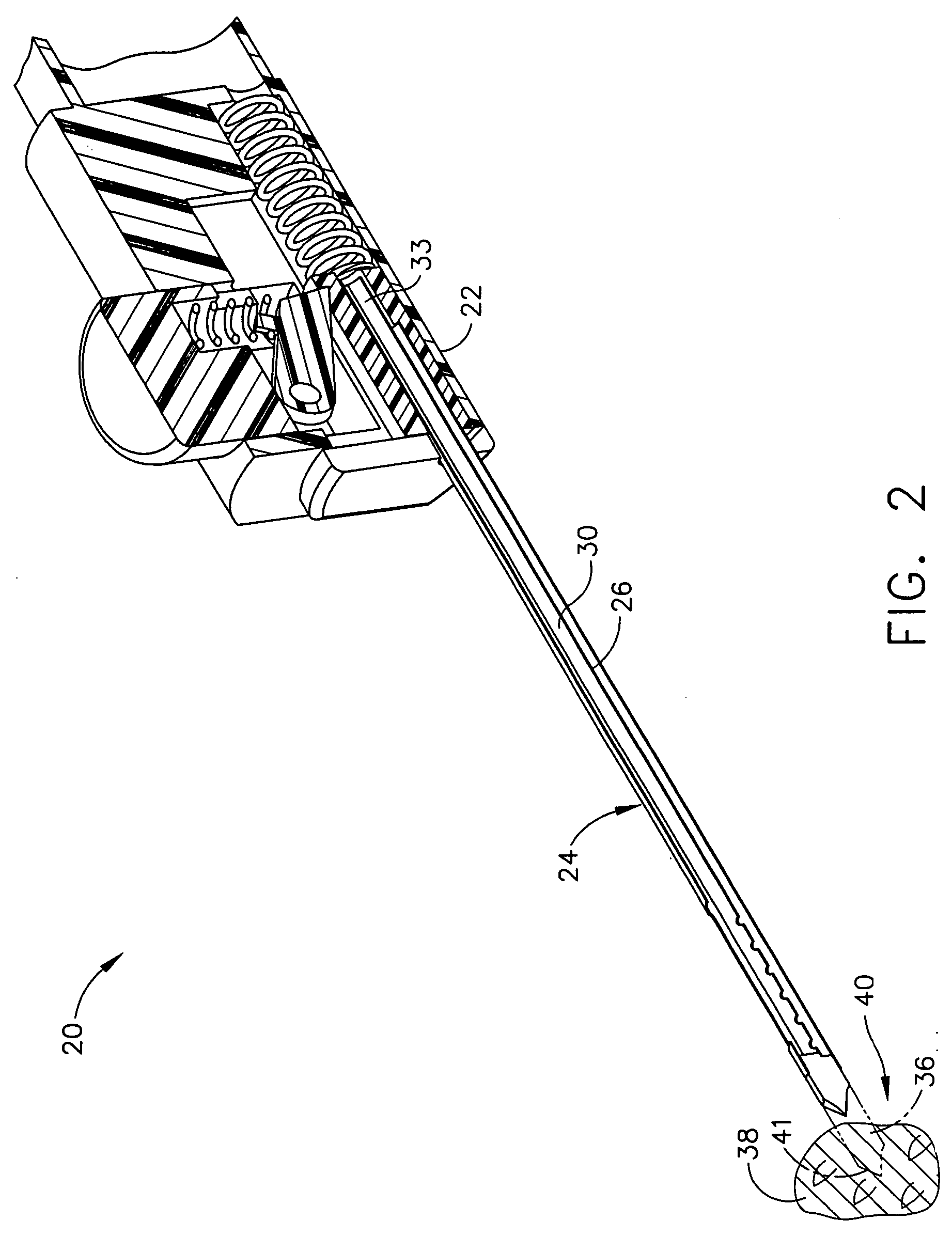

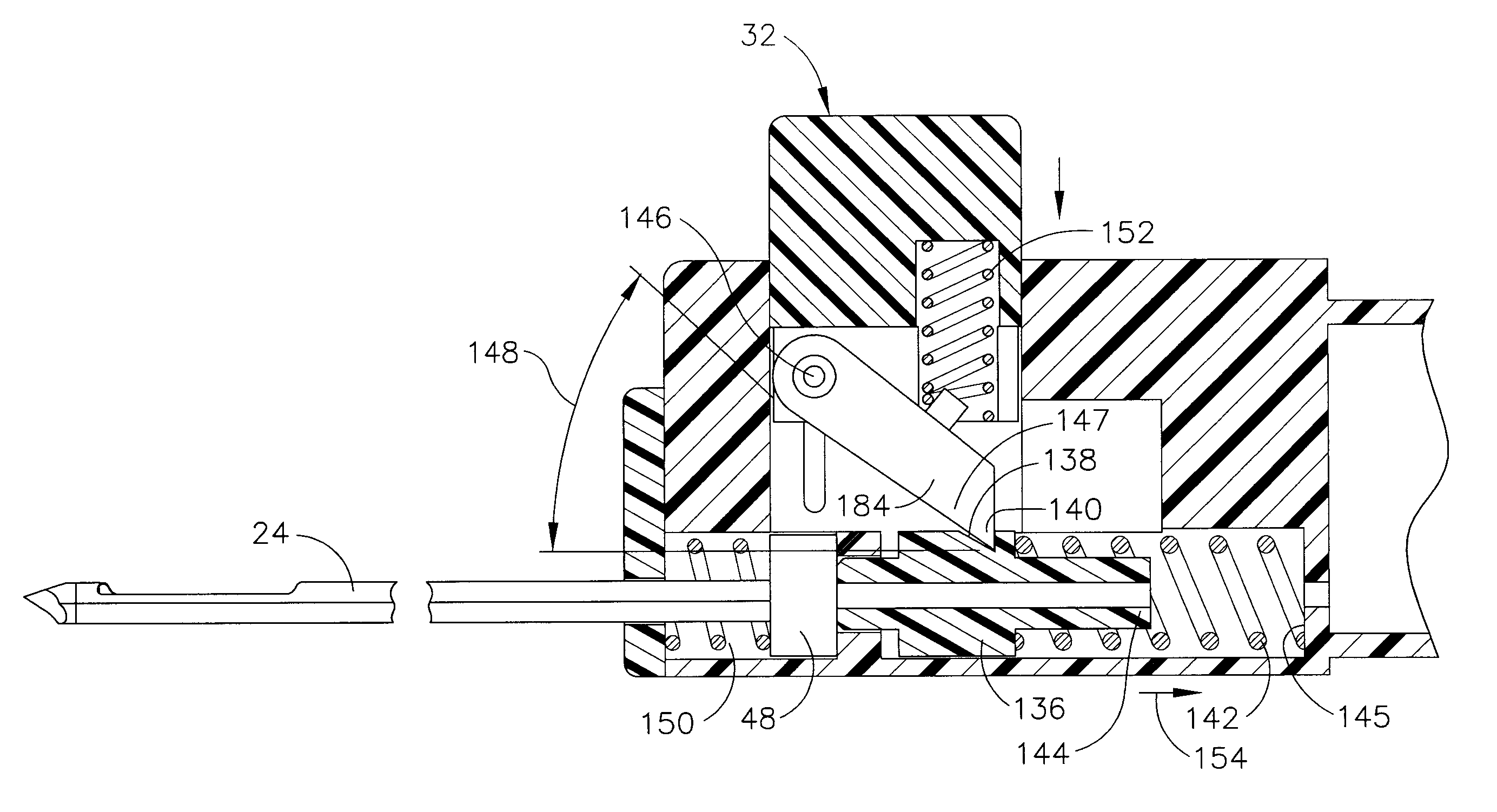

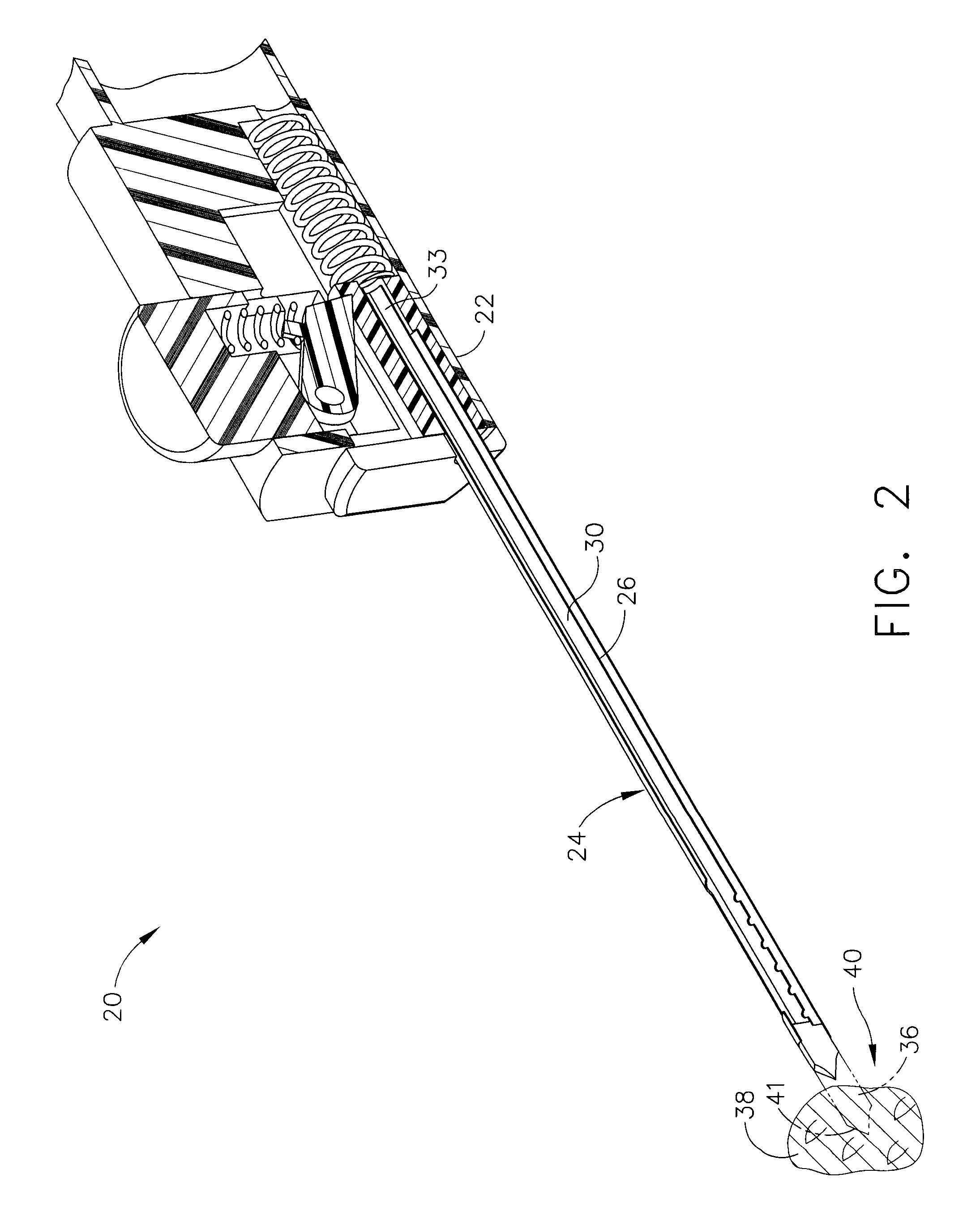

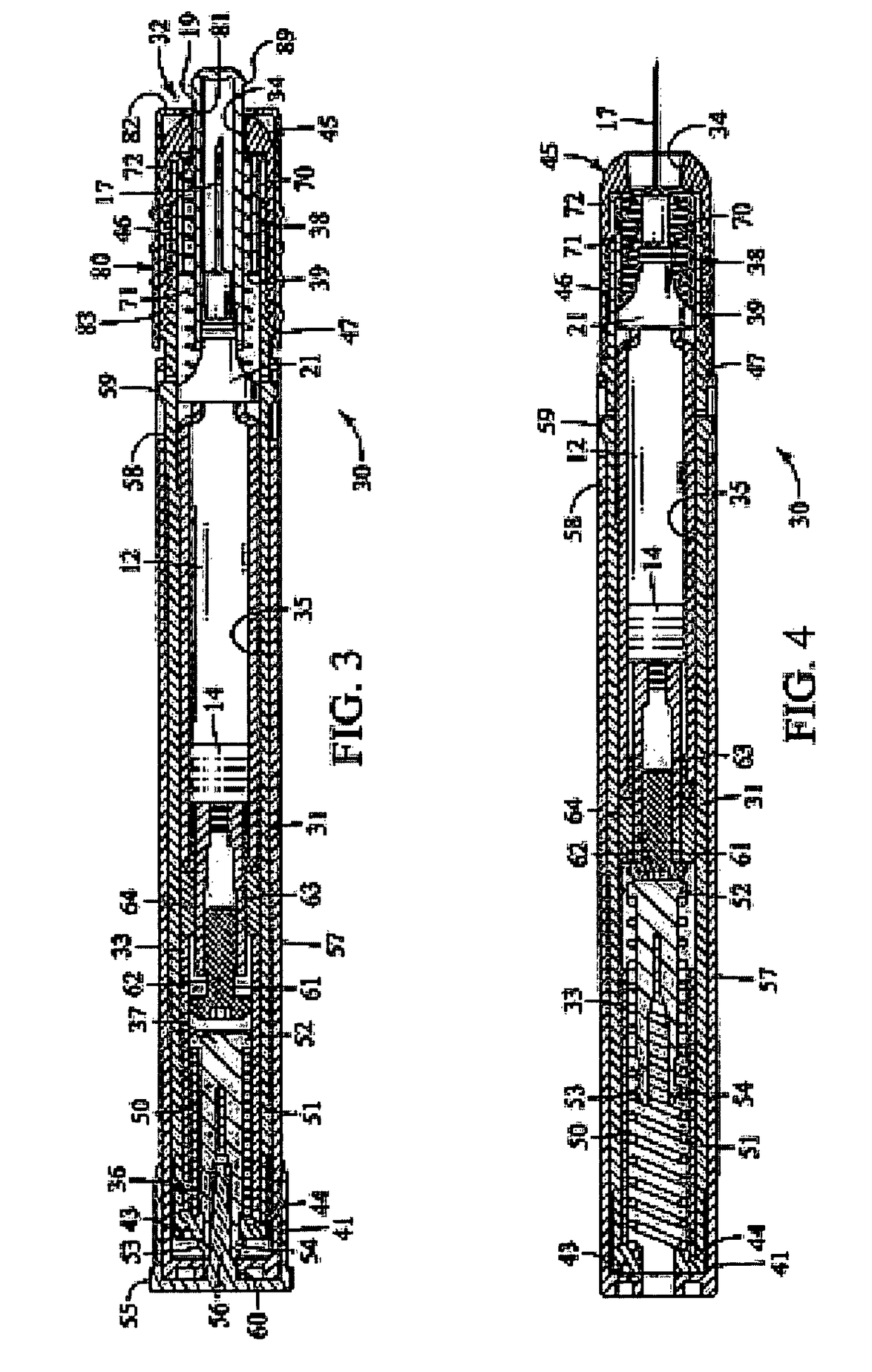

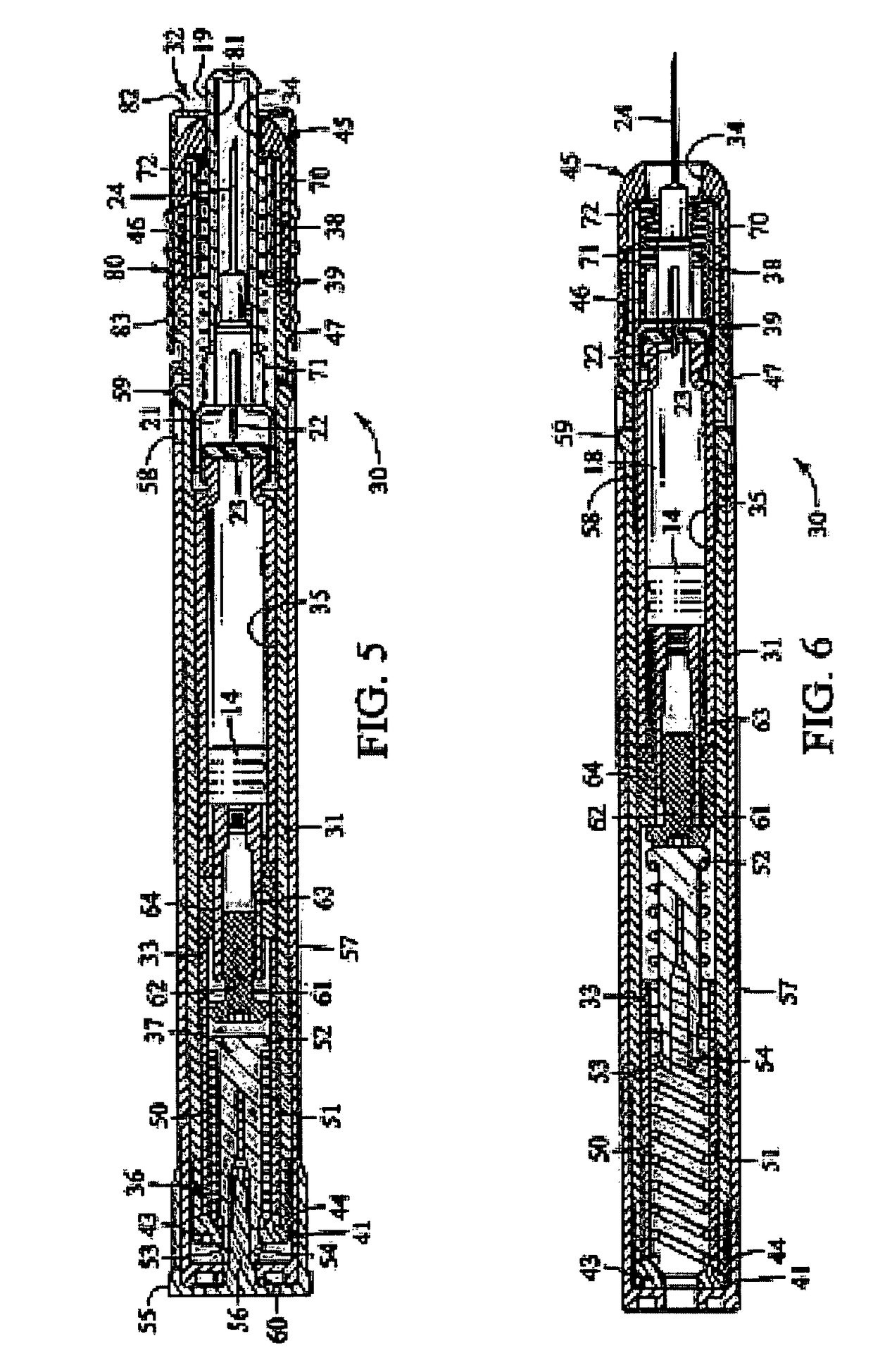

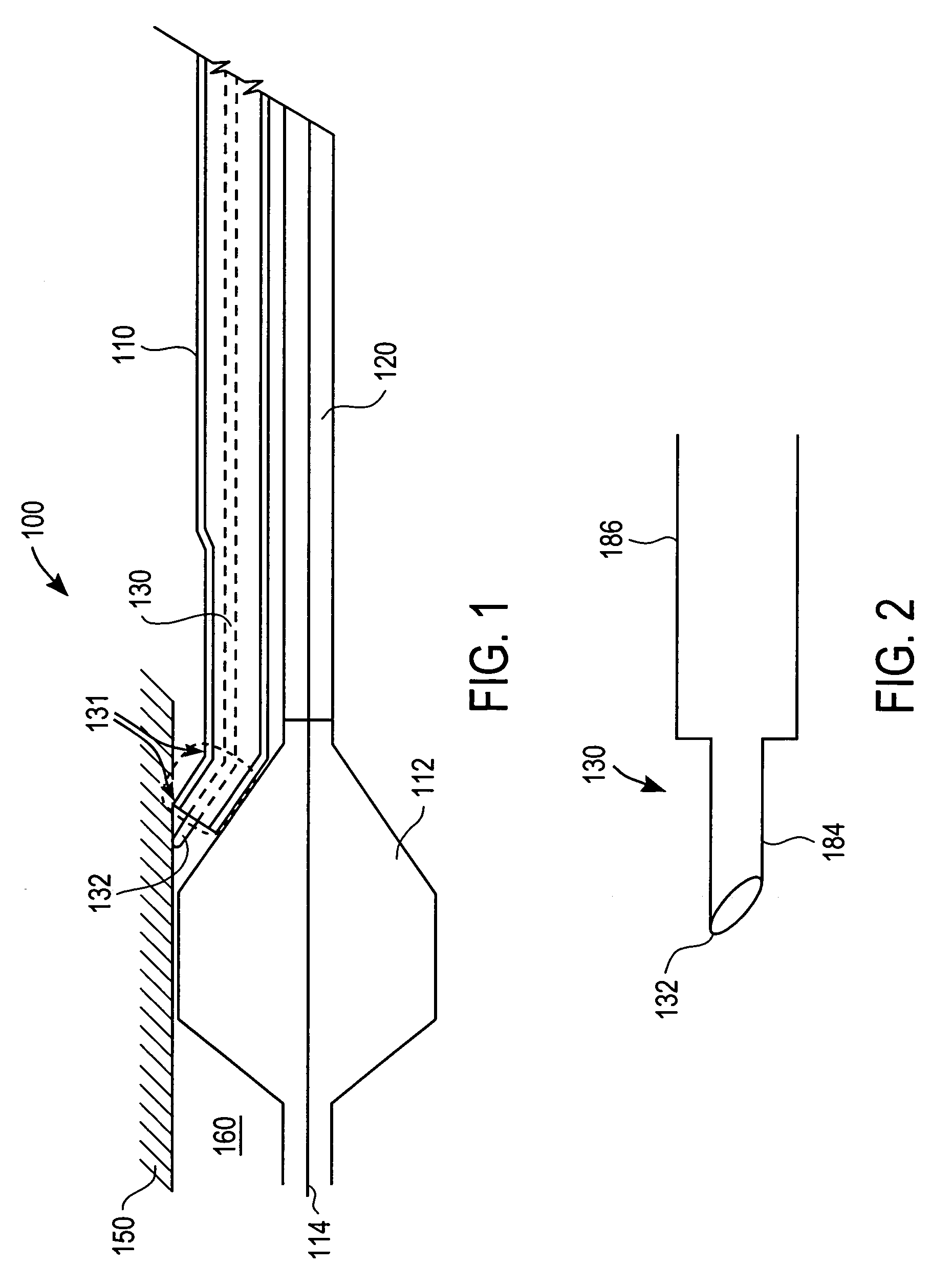

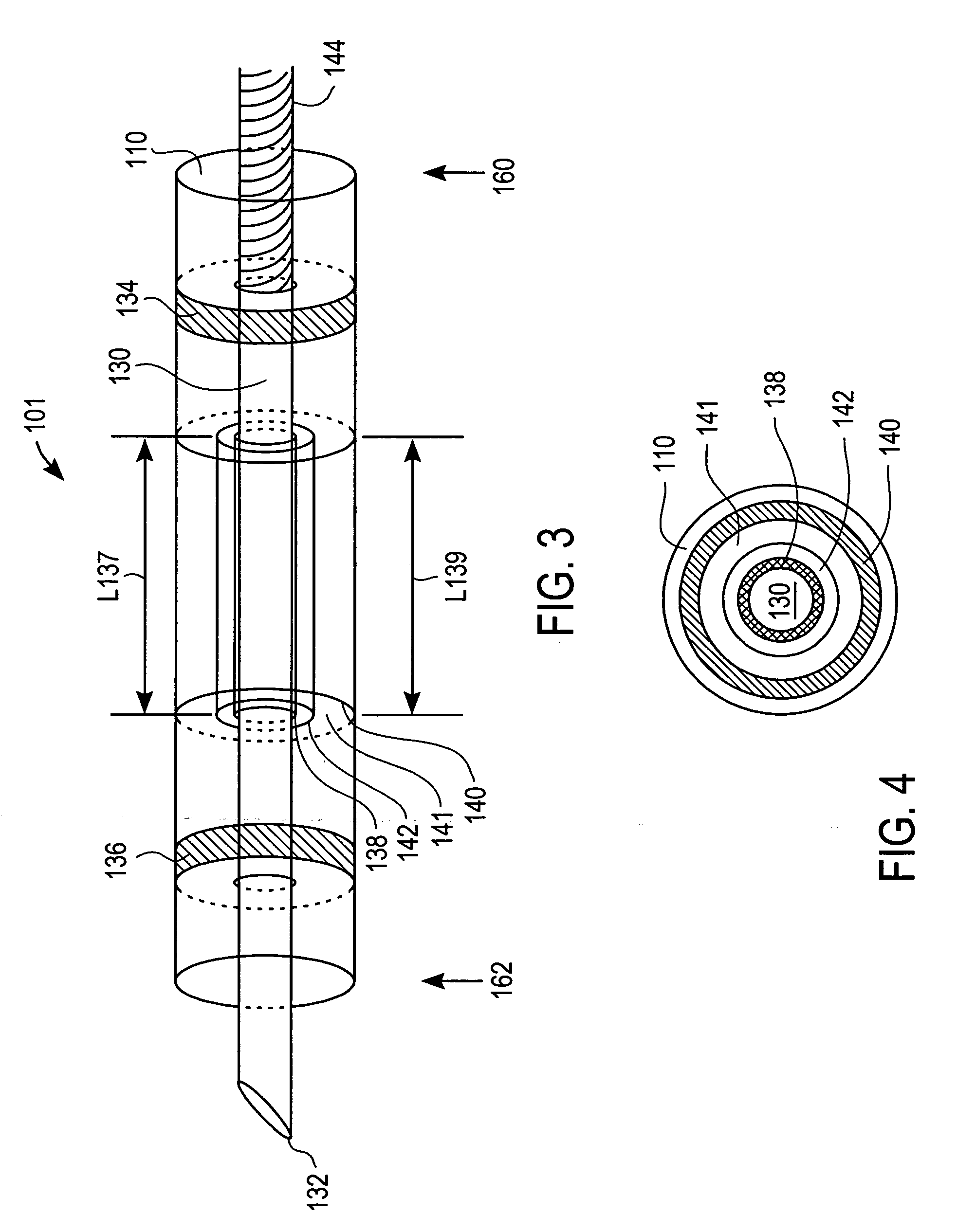

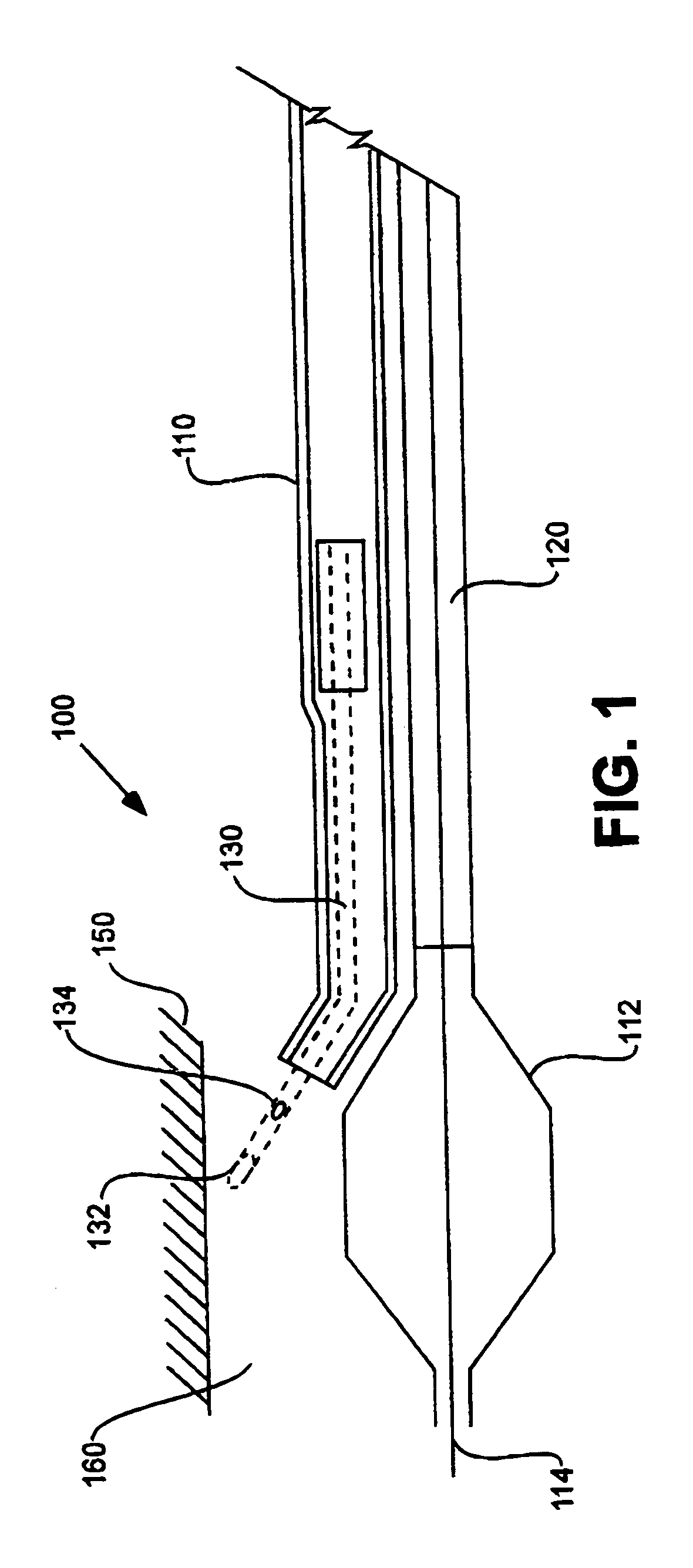

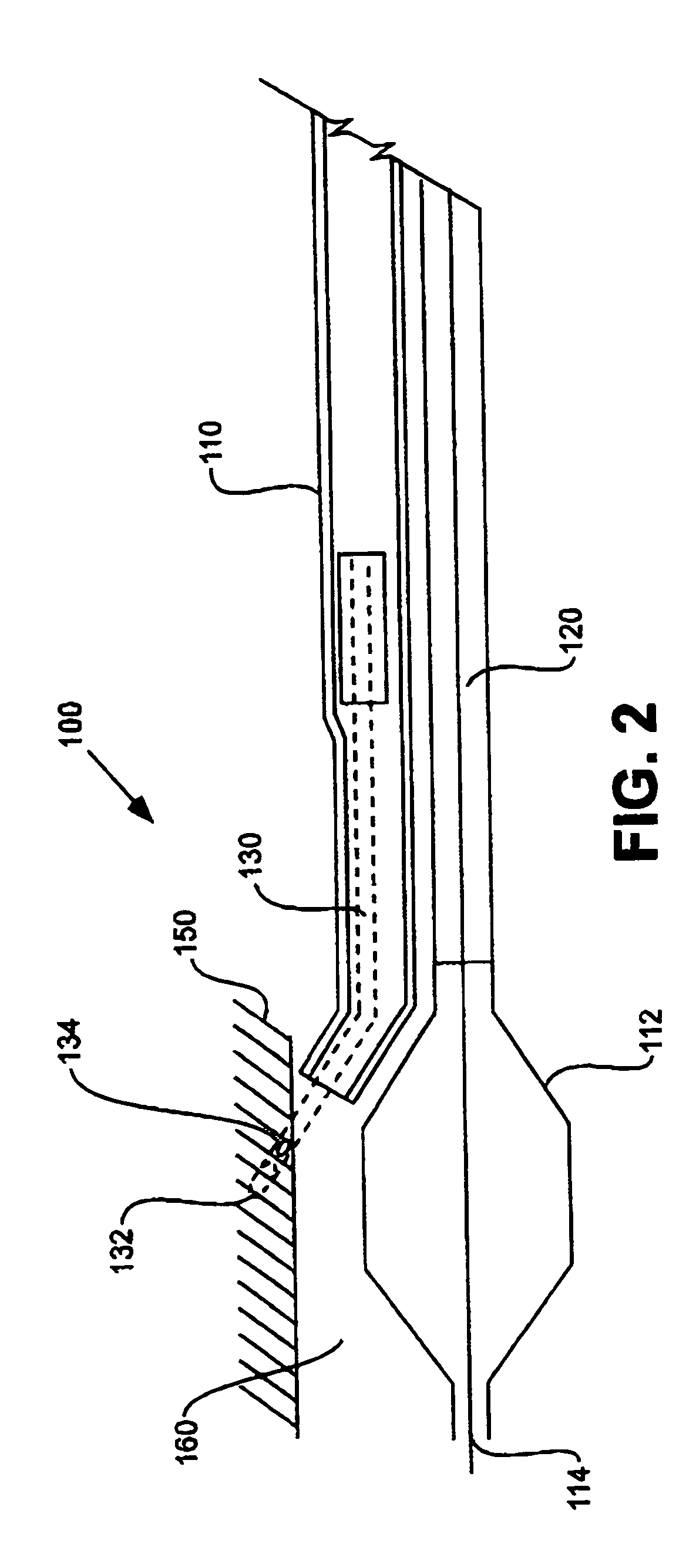

Biopsy instrument with improved needle penetration

InactiveUS20060155210A1Improve permeabilityPiercing especially dense tissueSurgical needlesVaccination/ovulation diagnosticsNeedle penetrationBiopsy instruments

The present invention provides a biopsy instrument with improved needle penetration for piercing dense tissue. The device may comprise a needle slidably retained in a housing. The device may further comprise an actuation member that may be adapted to communicate longitudinal motion to the needle in a first direction. The device may further include a propulsion element that provides the needle with return motion in a second direction. The device may be fired multiple times to create repeating reciprocal motion. In one version, the device may reciprocate several times as a result of a single engagement of the actuation member.

Owner:DEVICOR MEDICAL PROD

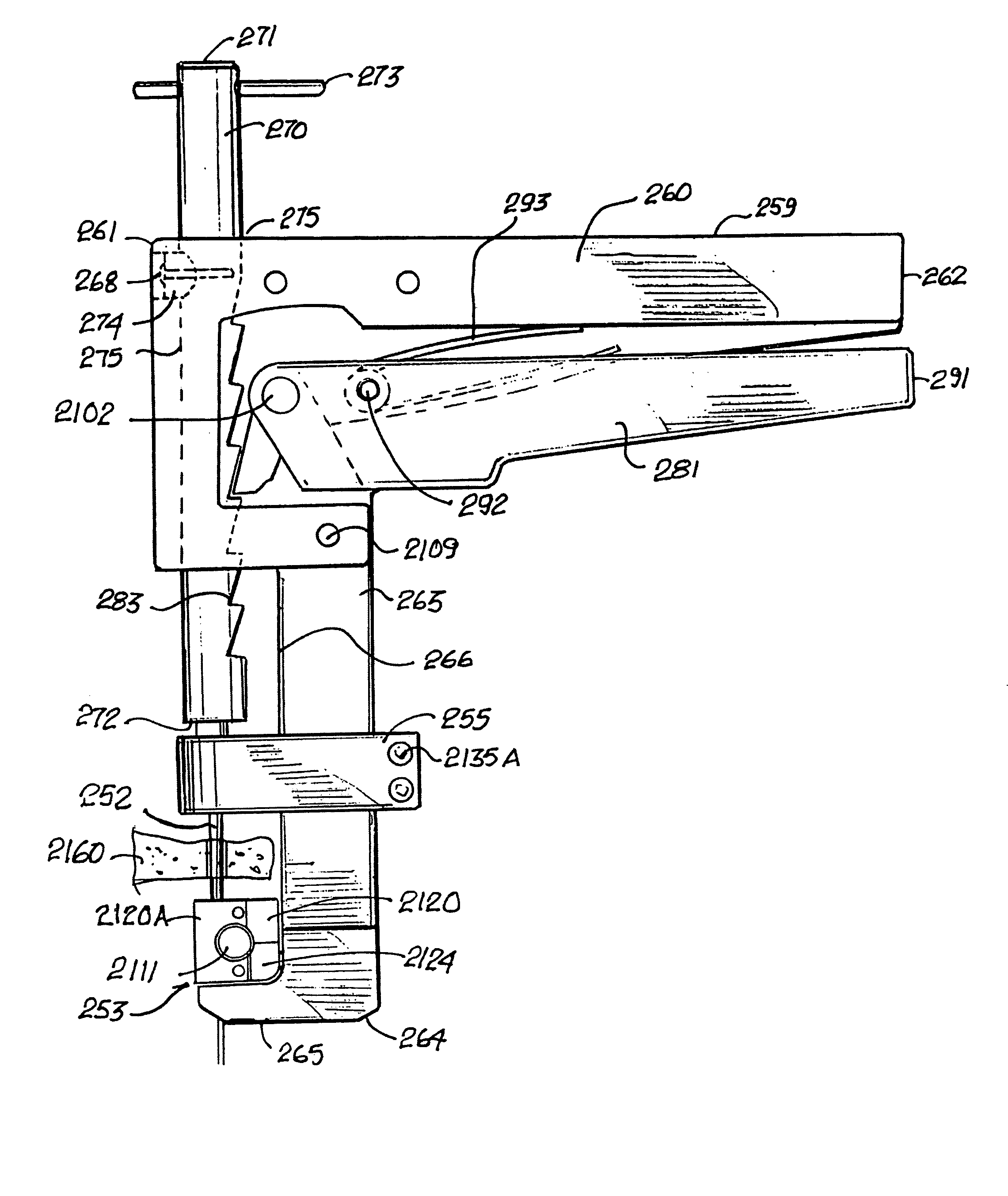

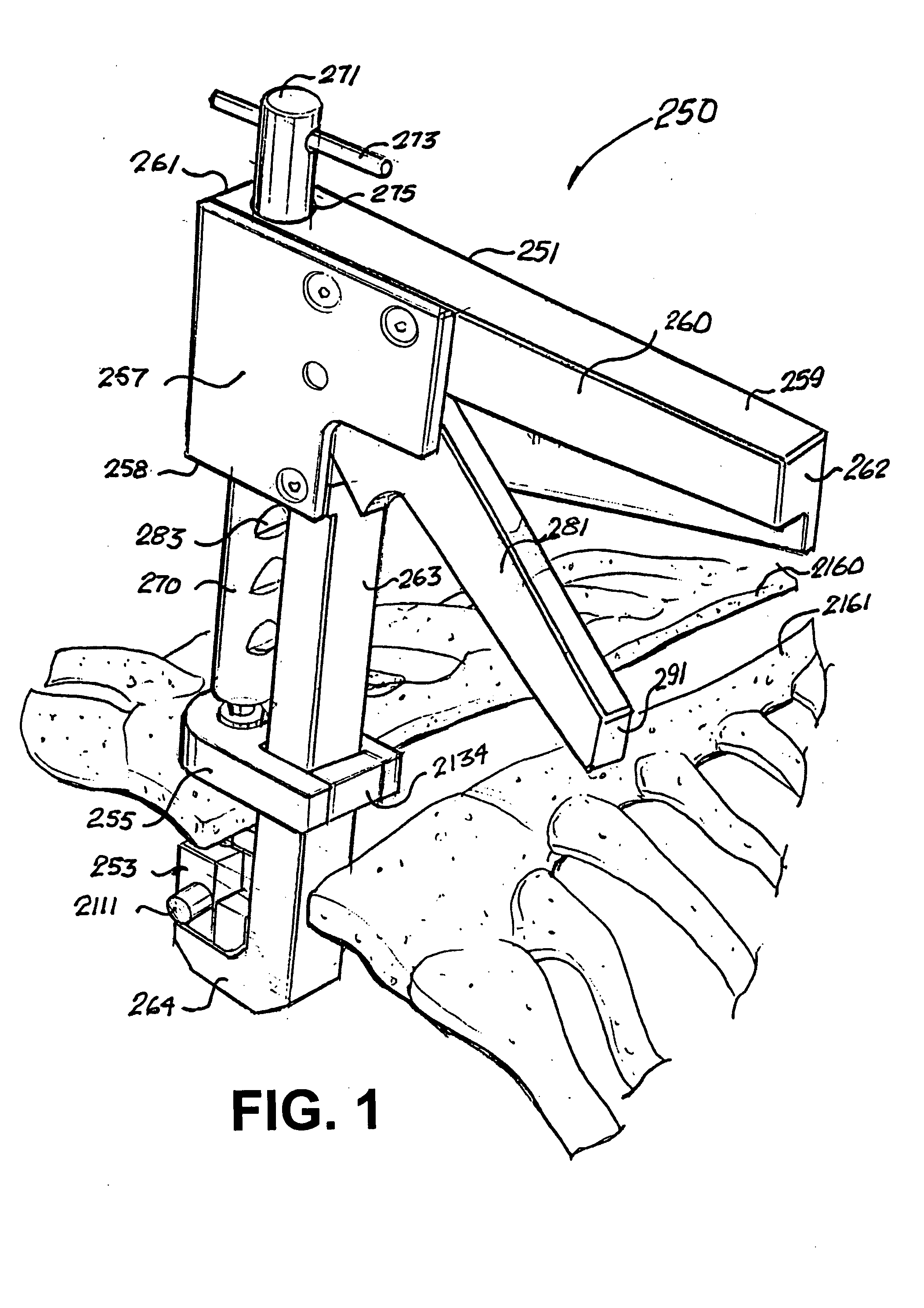

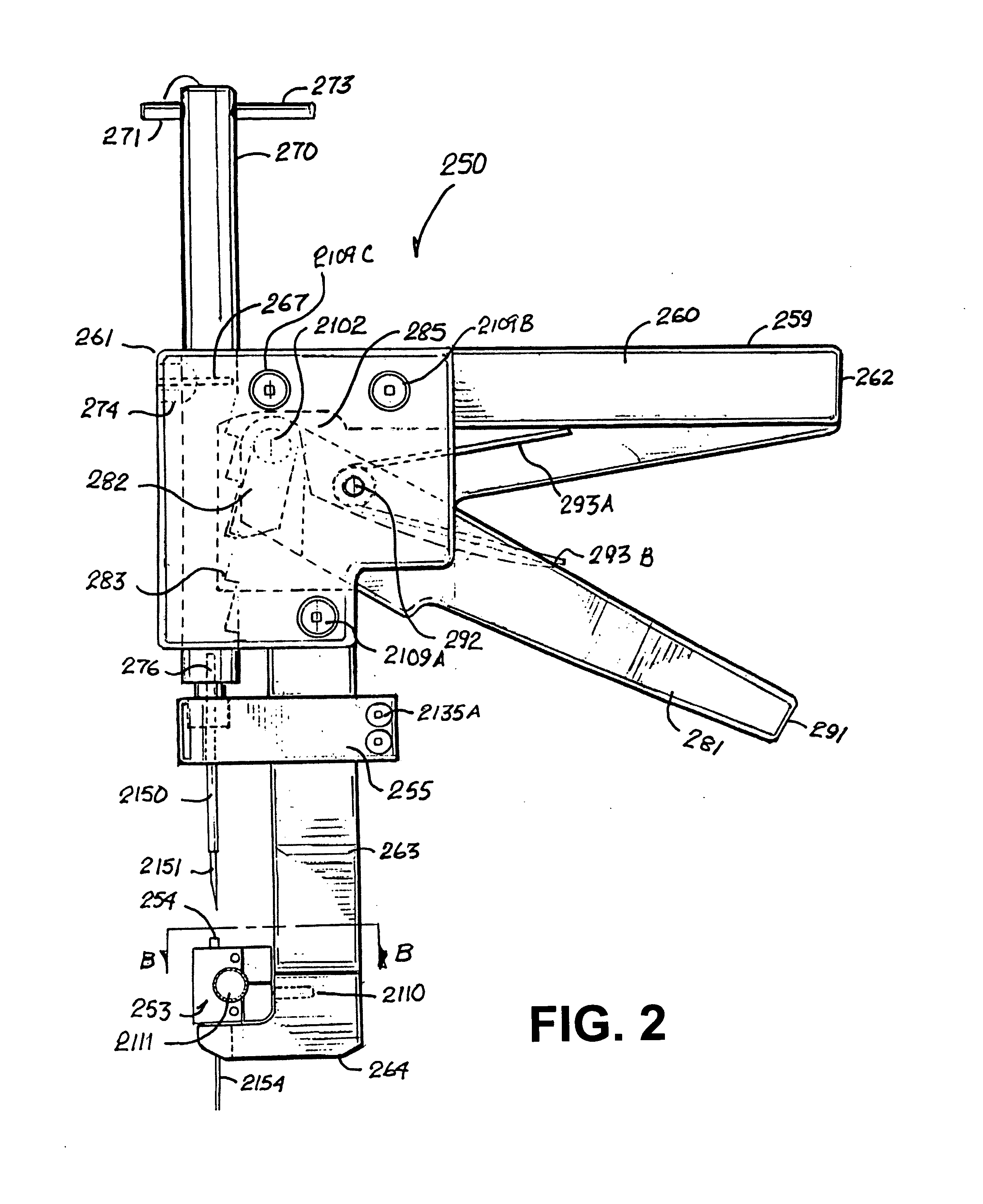

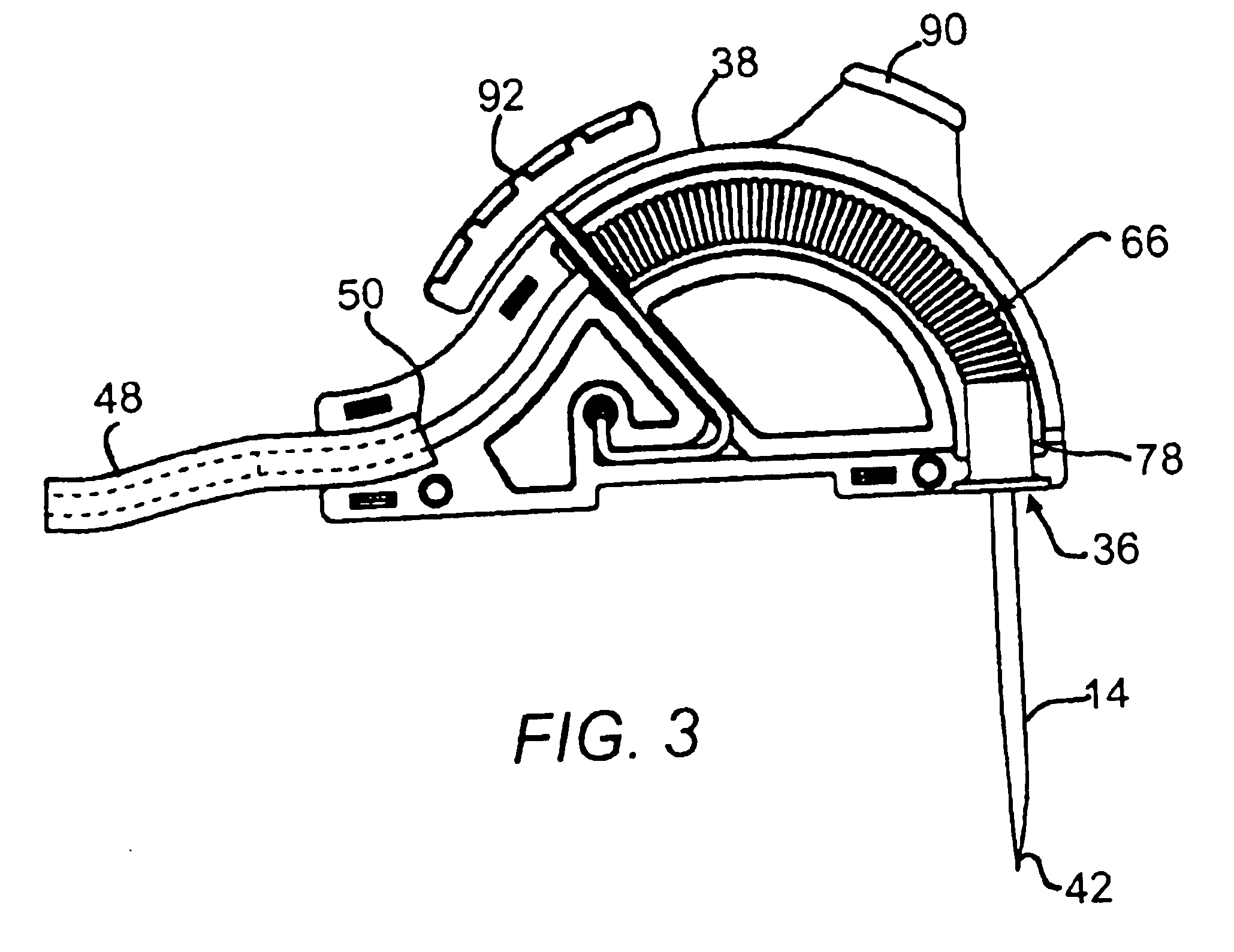

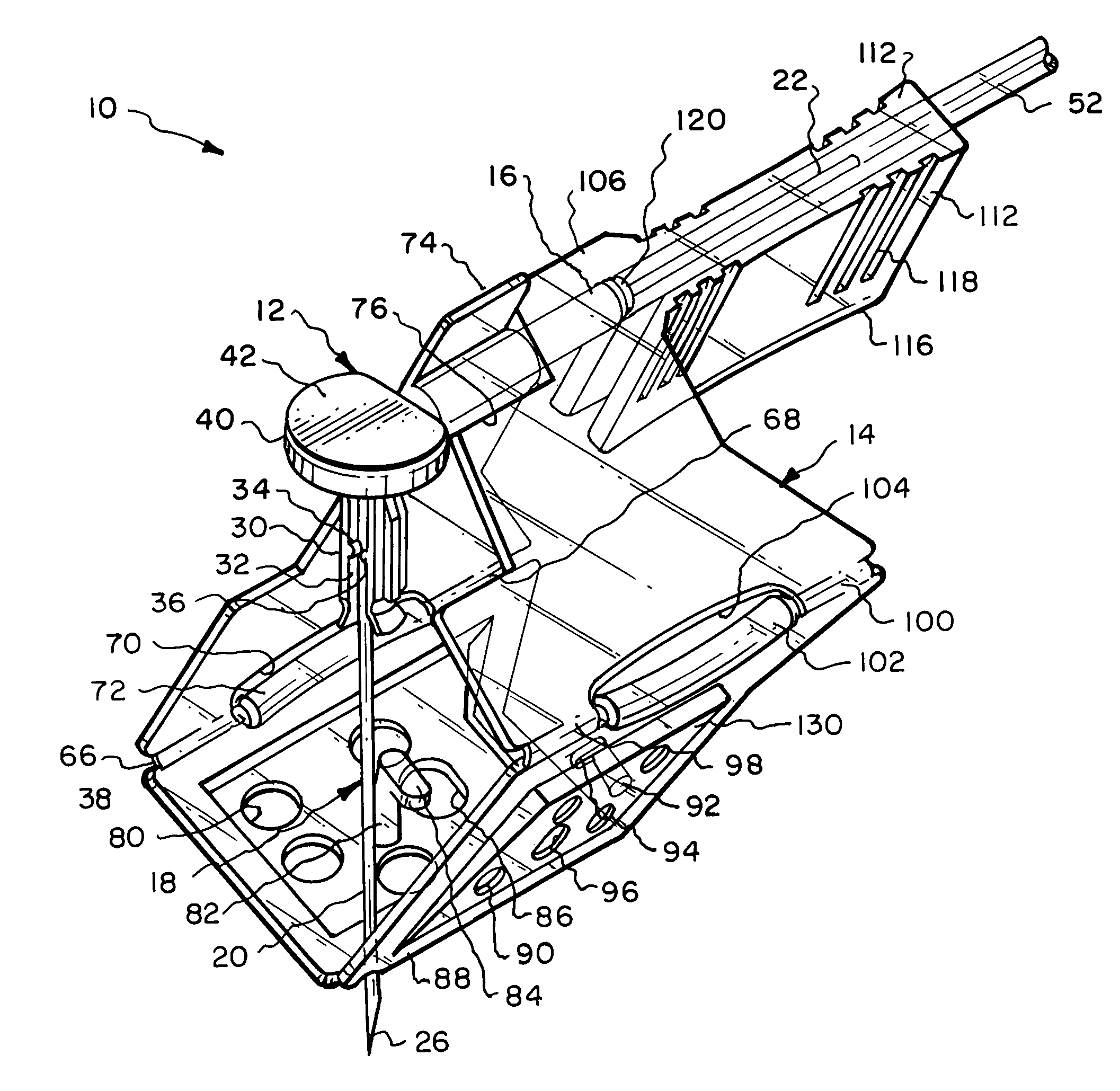

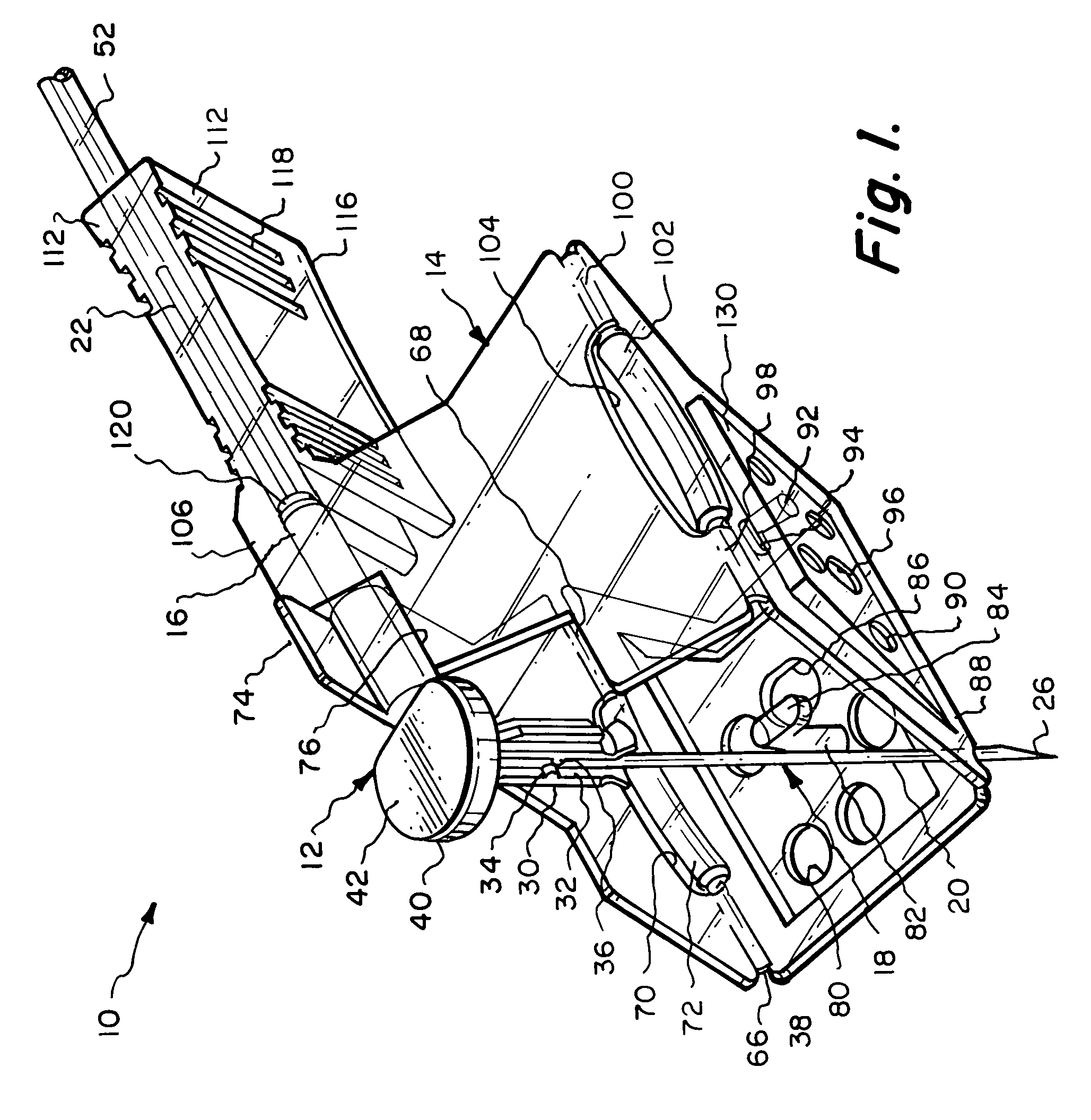

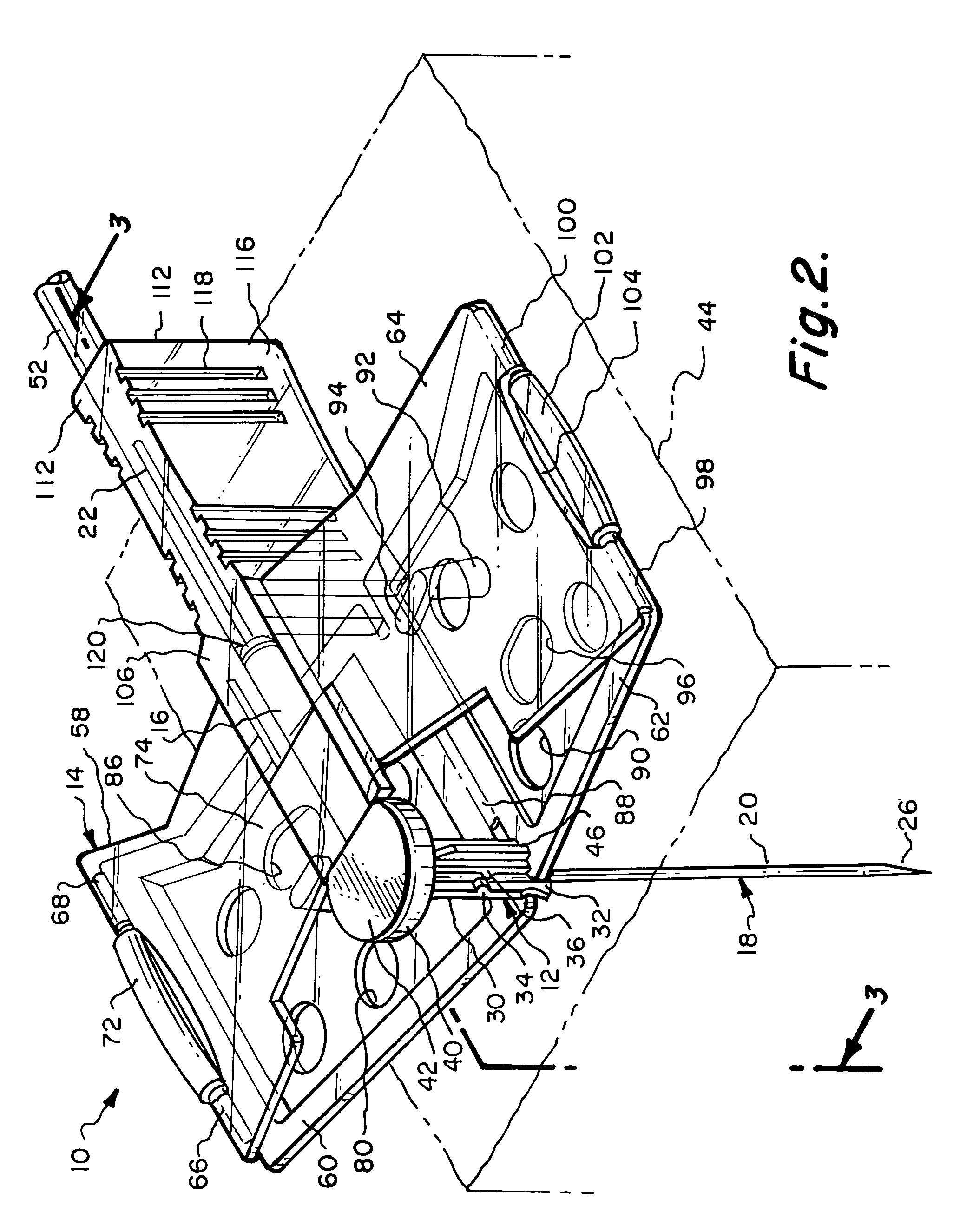

Suture apparatus and method for sternal closure

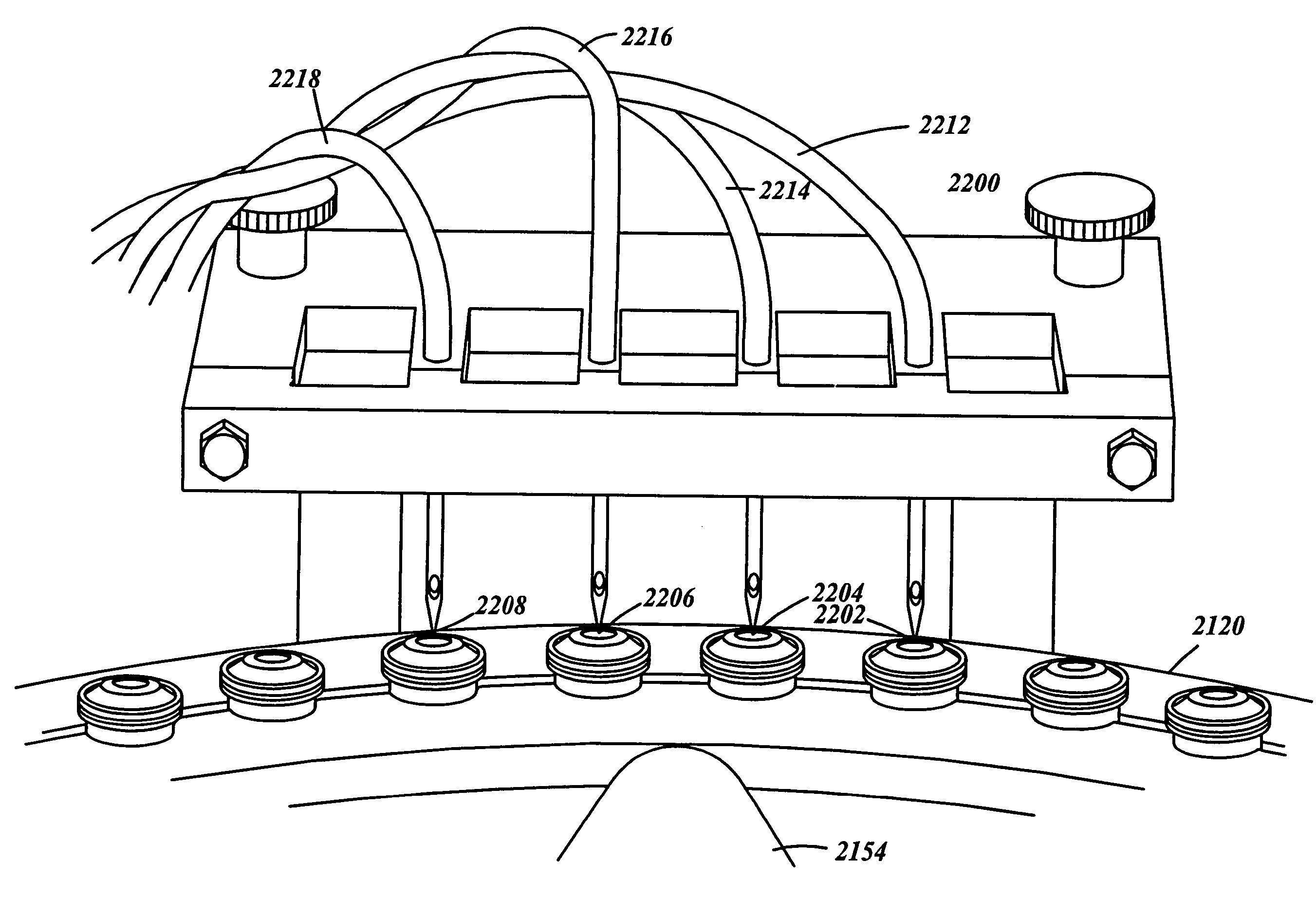

InactiveUS20050055037A1Precise and predictable placementRelieve pressureSuture equipmentsInternal osteosythesisNeedle penetrationEngineering

A needle driving apparatus for sternal closure following sternotomy. Accessory elements include: 1) a straight surgical needle absent attached suture and 2) a separate suture carrying small cylinders at opposing ends. Apparatus provides a dual capability of 1) needle penetration of sternum from top surface and 2) precise positioning of cylinder at undersurface of sternum. The apparatus is a handled framework supporting a rachet type drive assembly which includes a lever, a pawl, biasing springs and a toothed arm which carries a needle. A framework extension carries a socketed fixture. The fixture precisely positions a cylinder and its suture in the socket. When the lever is taken up by hand, motion is imparted to the arm and needle. The needle penetrates the sternum, then the cylinder, where it becomes locked therein by friction. Retrograde extraction of needle (using a conventional needle driver) delivers the suture by shuttle action to its desired position, atop the sternum. Repetition on the procedure described, on the opposing side of the sternum completes the placement of a single suture.

Owner:FATHAUER WILLIAM FREDERICK JR

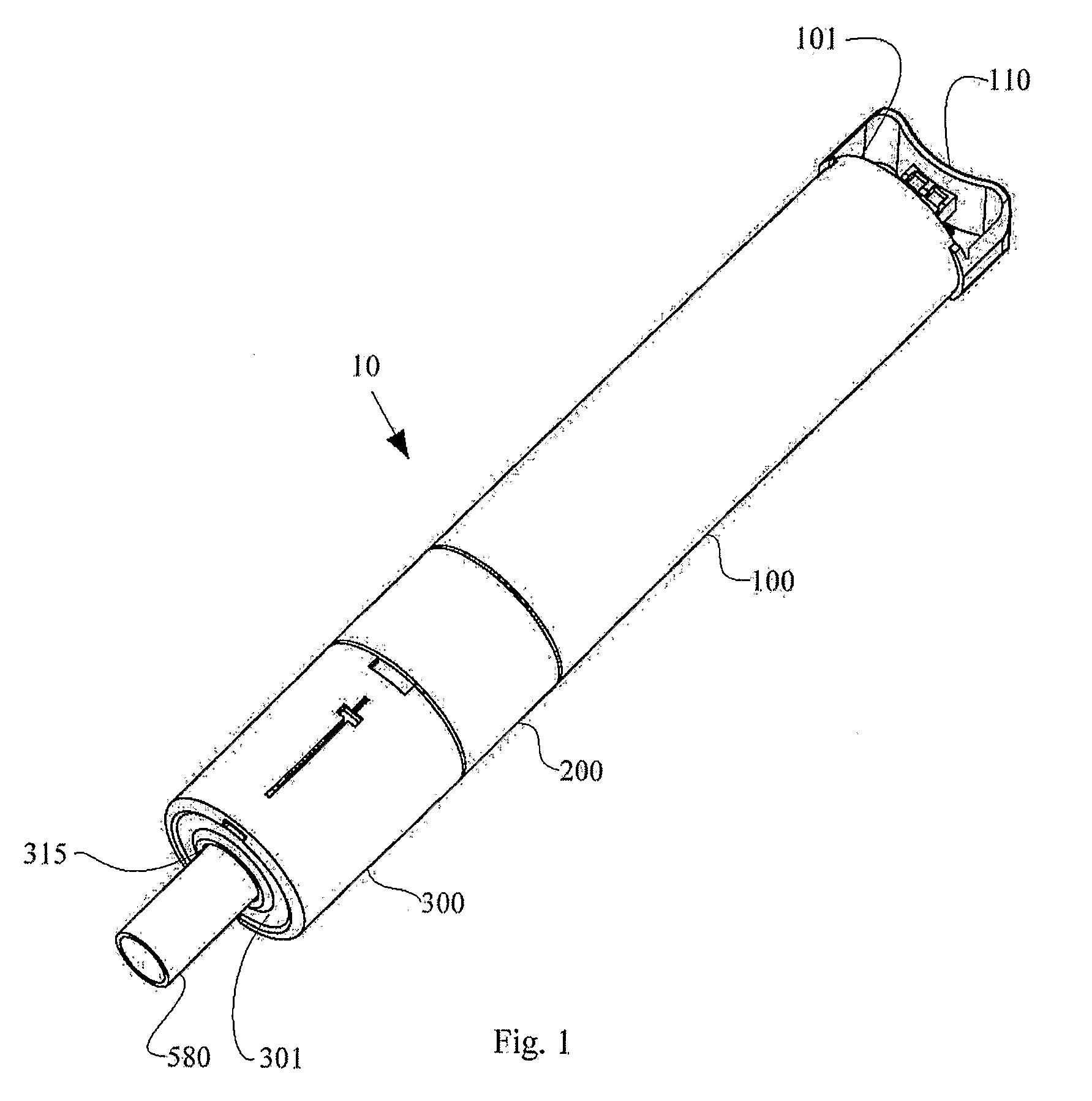

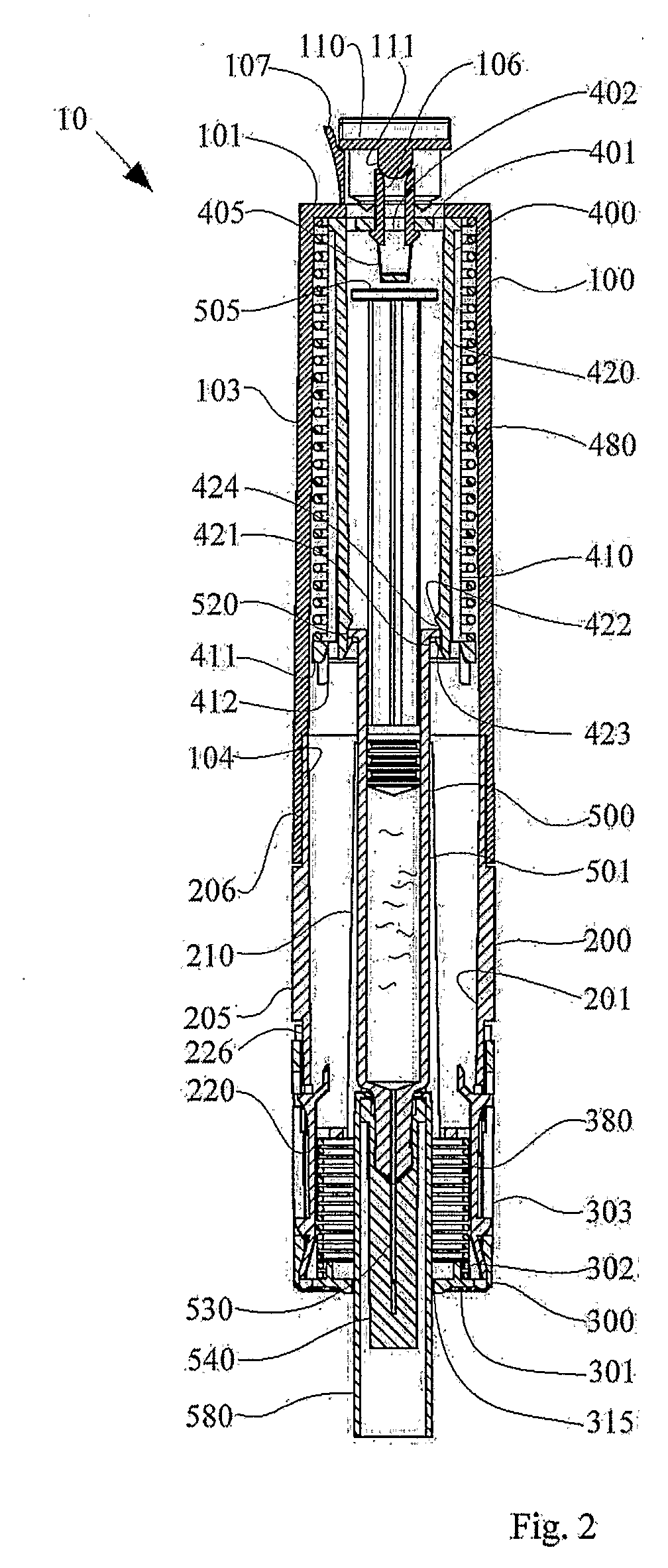

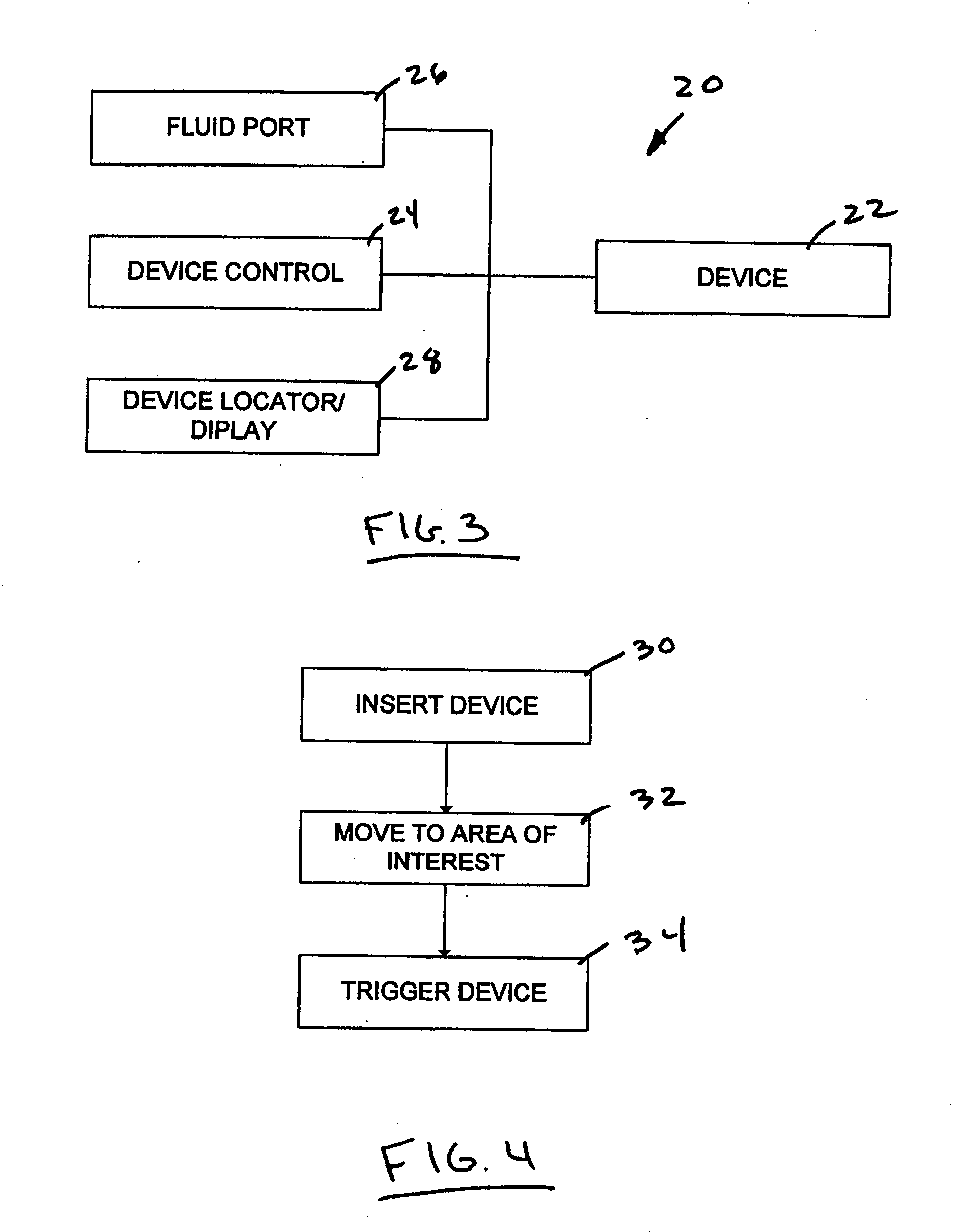

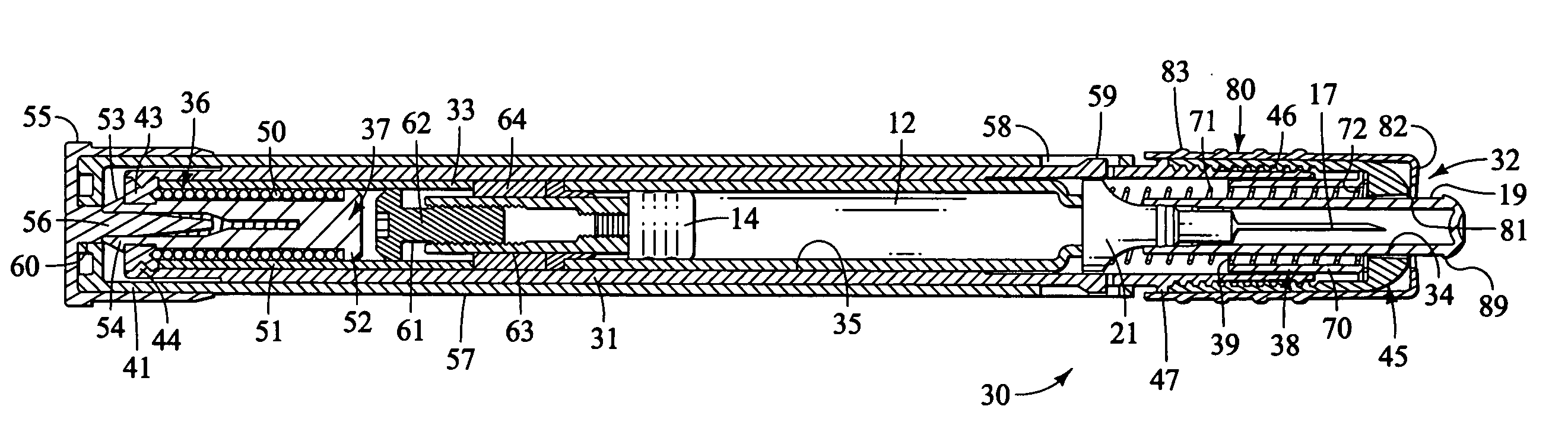

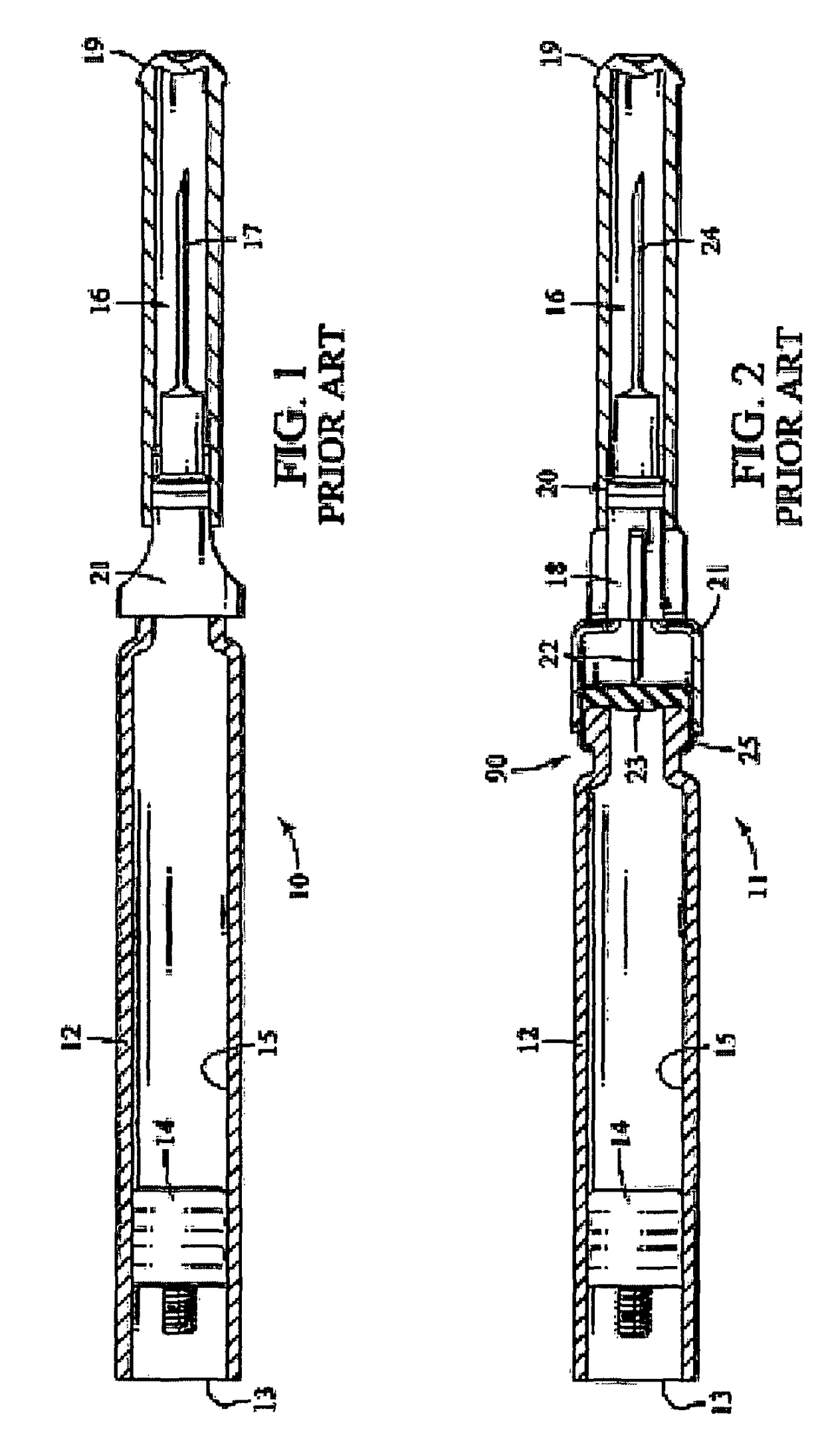

Medicine injection devices and methods

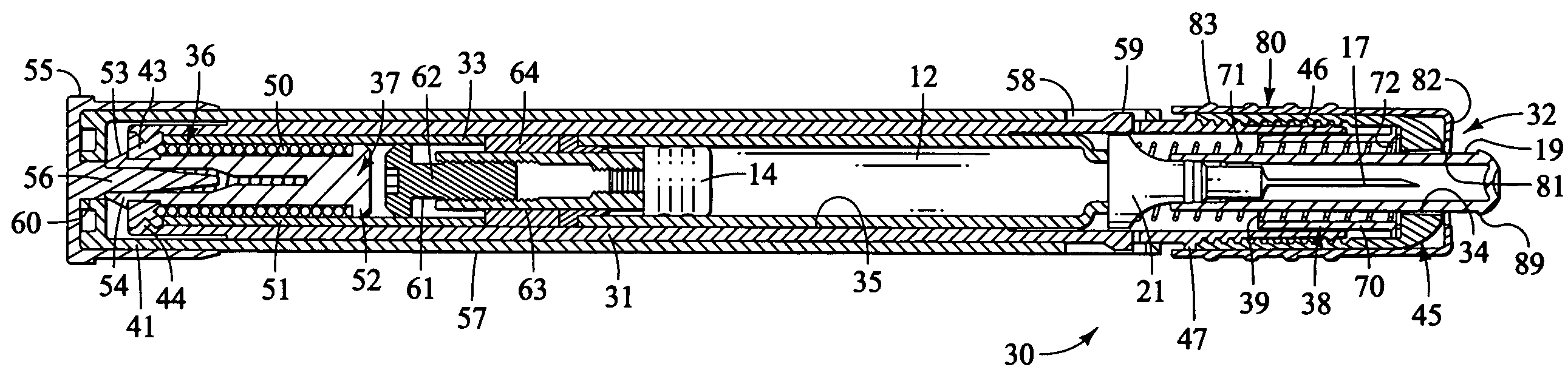

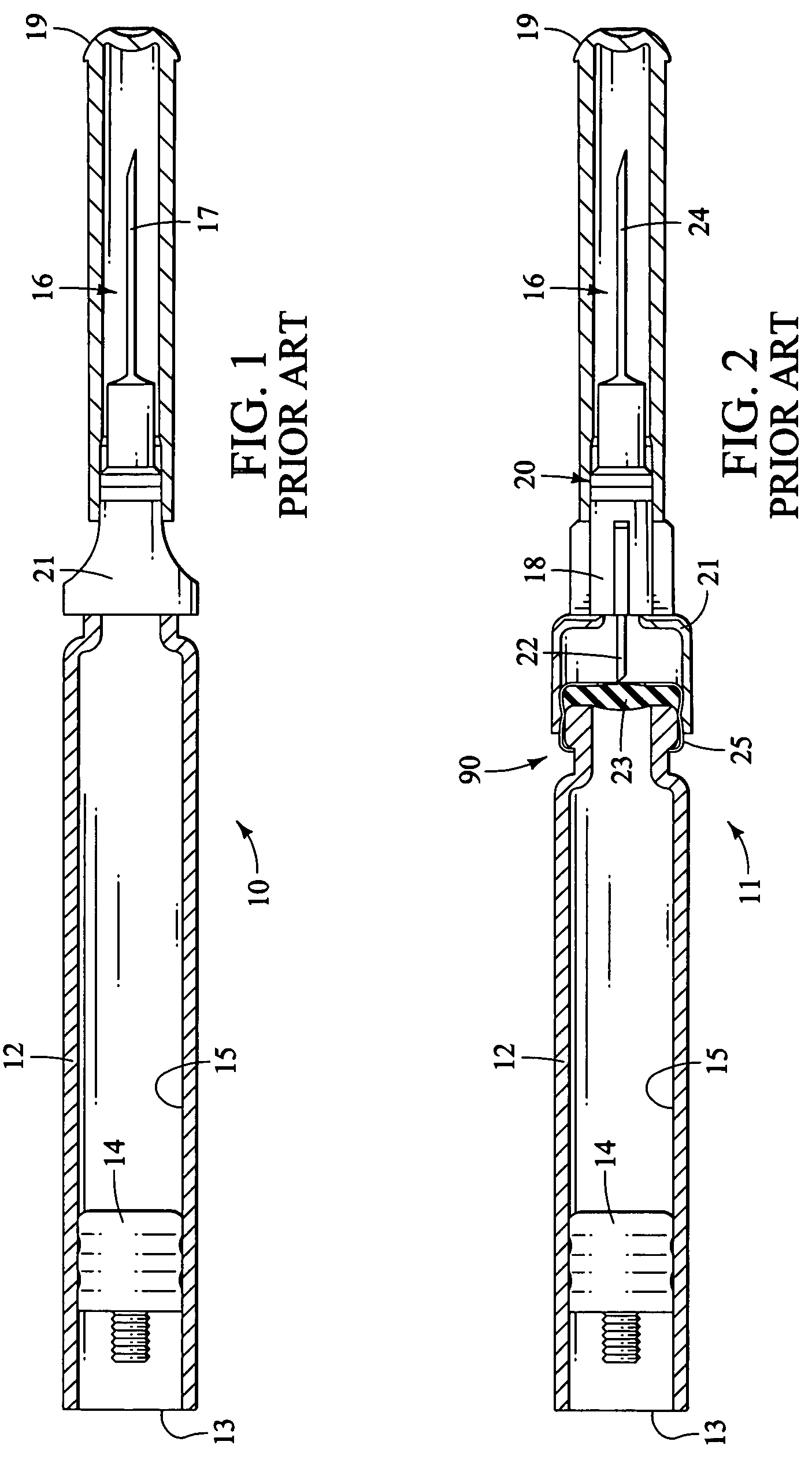

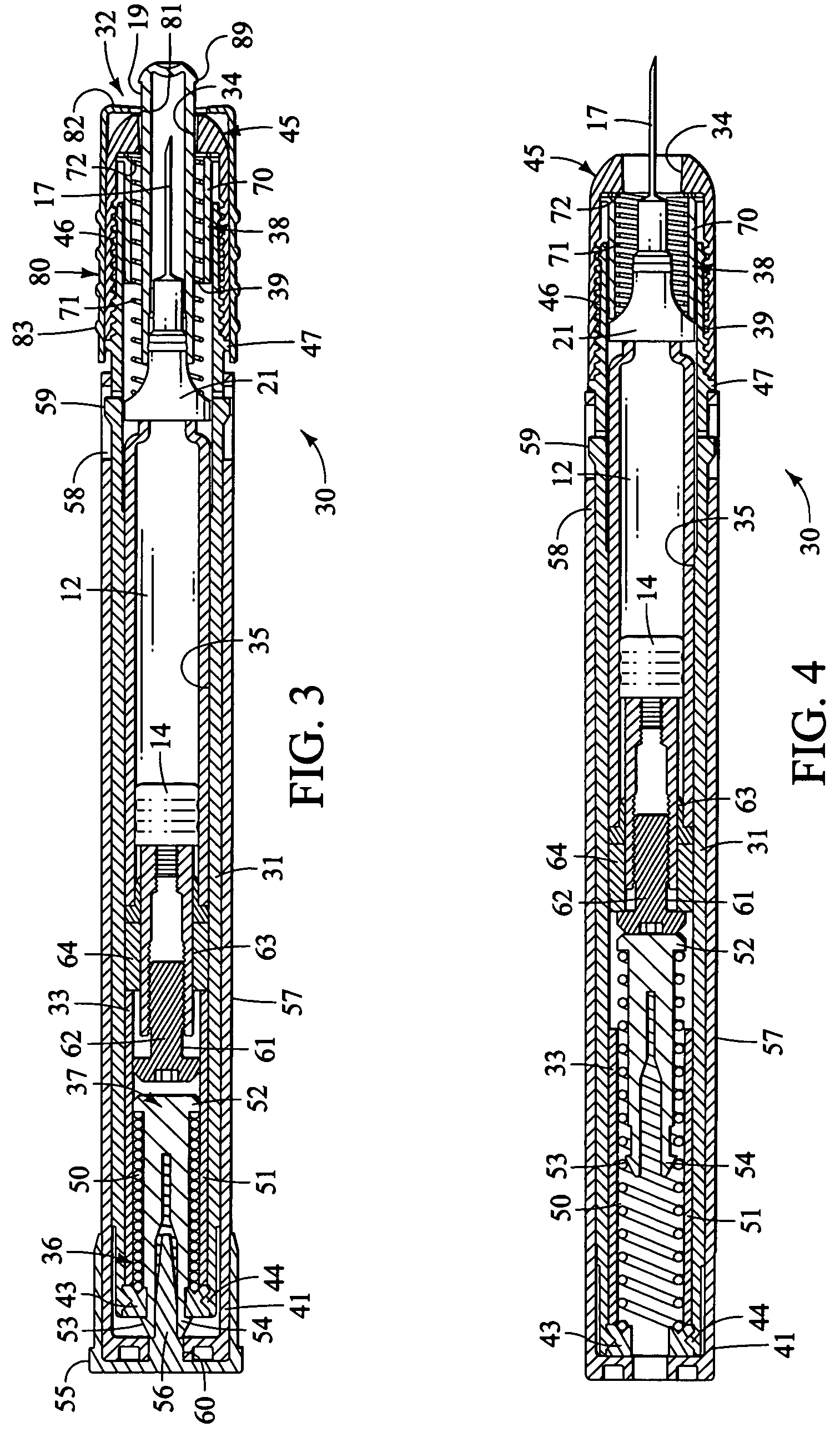

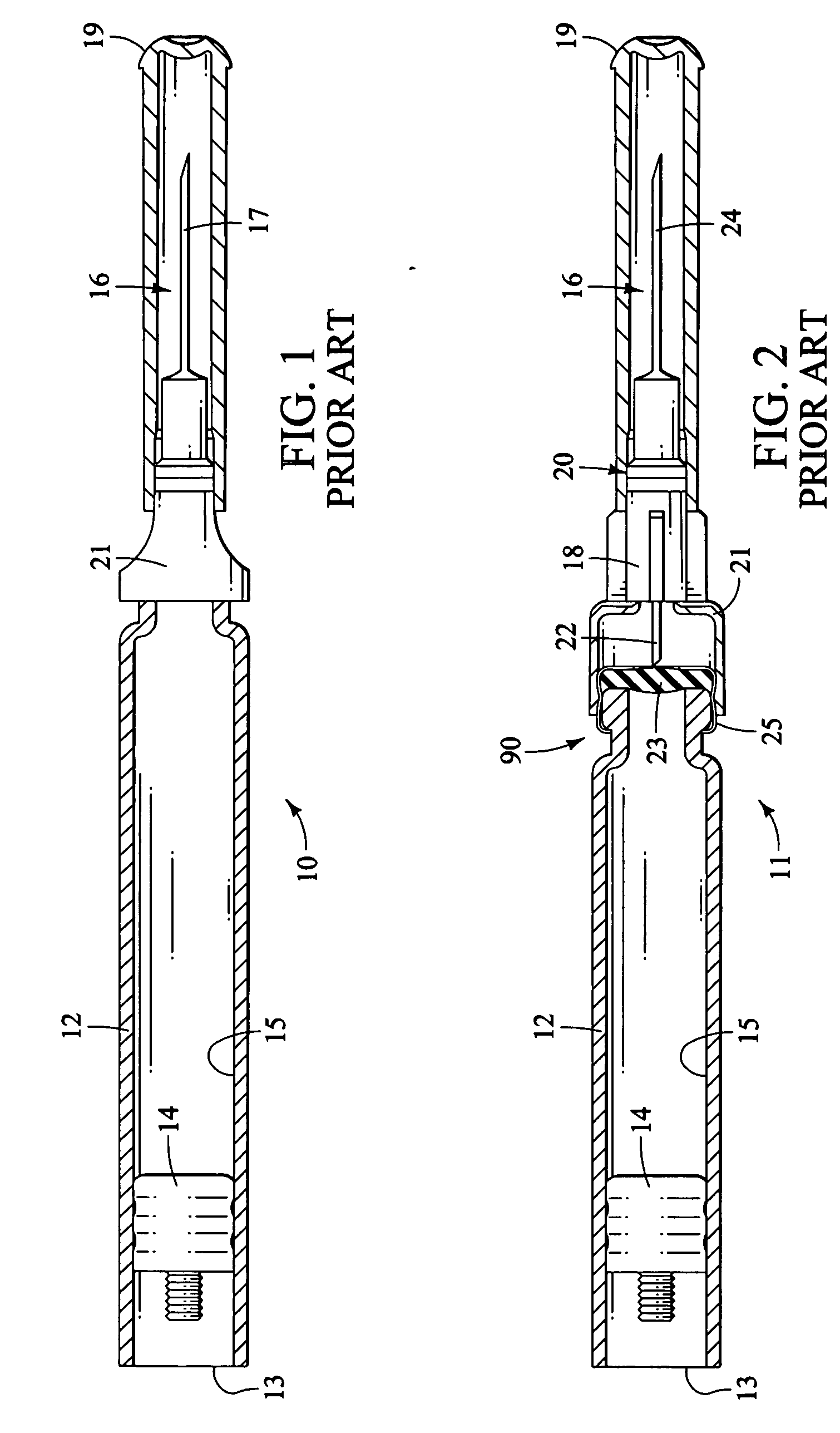

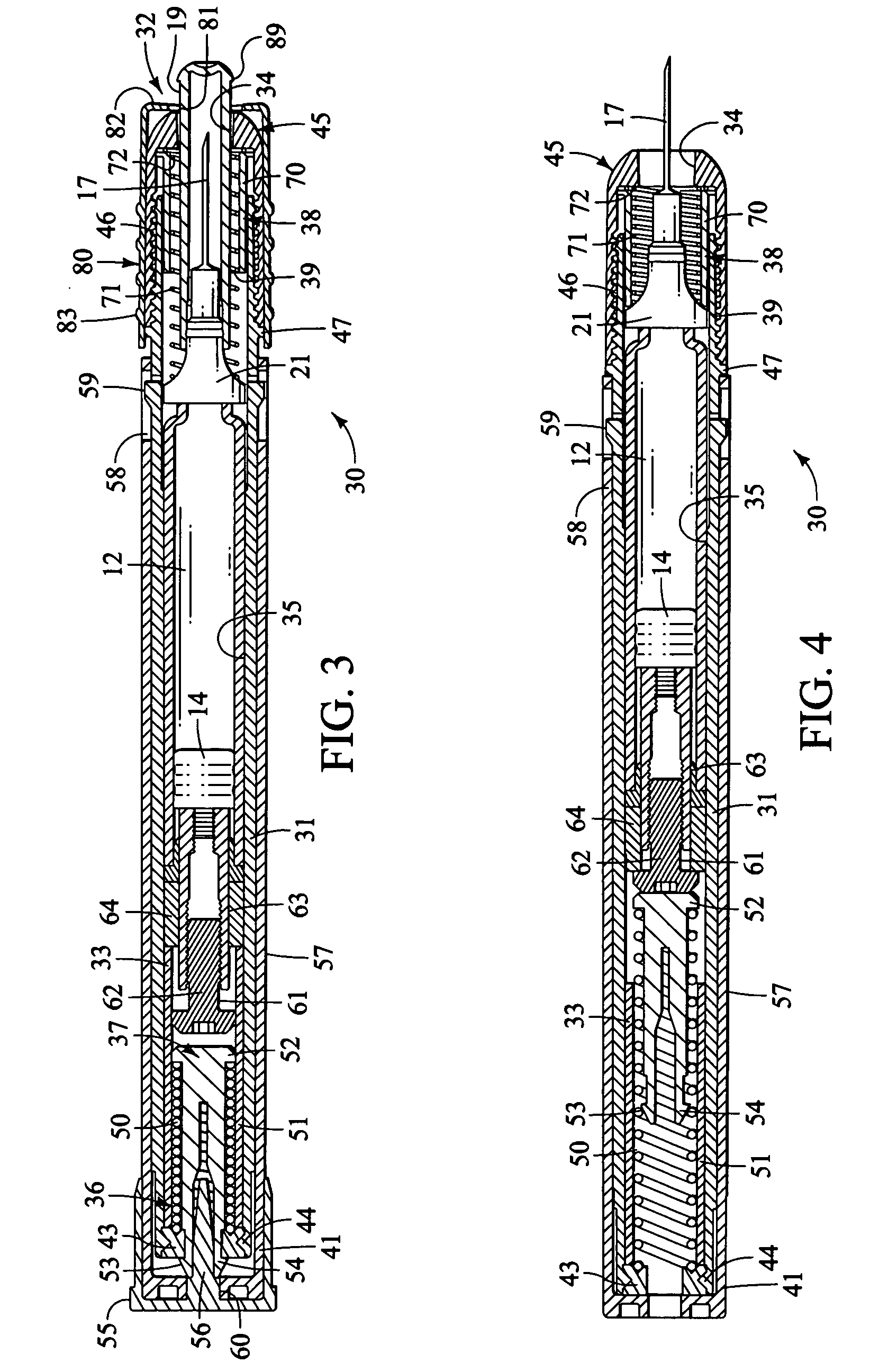

A reloadable medicine injector and methods are described in which a barrel with a receiving cavity is adapted to slidably receive a syringe subassembly for axial movement therein. Upon removal of a safety and release of a syringe driver, the syringe driver moves forward and injects the syringe needle. A plurality of penetration controls are shown for controlling injection needle penetration depth. The penetration controls have an abutment and various lengths to provide different needle penetration depth positions. In one form of penetration control a sleeve is used against which the syringe or related parts contact. In another form the front return spring is used as a penetration control. A cushioning ring may be used to reduce syringe breakage. A load distribution and guide ring may be used to distribute loading applied to the syringe and help guide the moving syringe.

Owner:WASHINGTON BIOTECH CORP +1

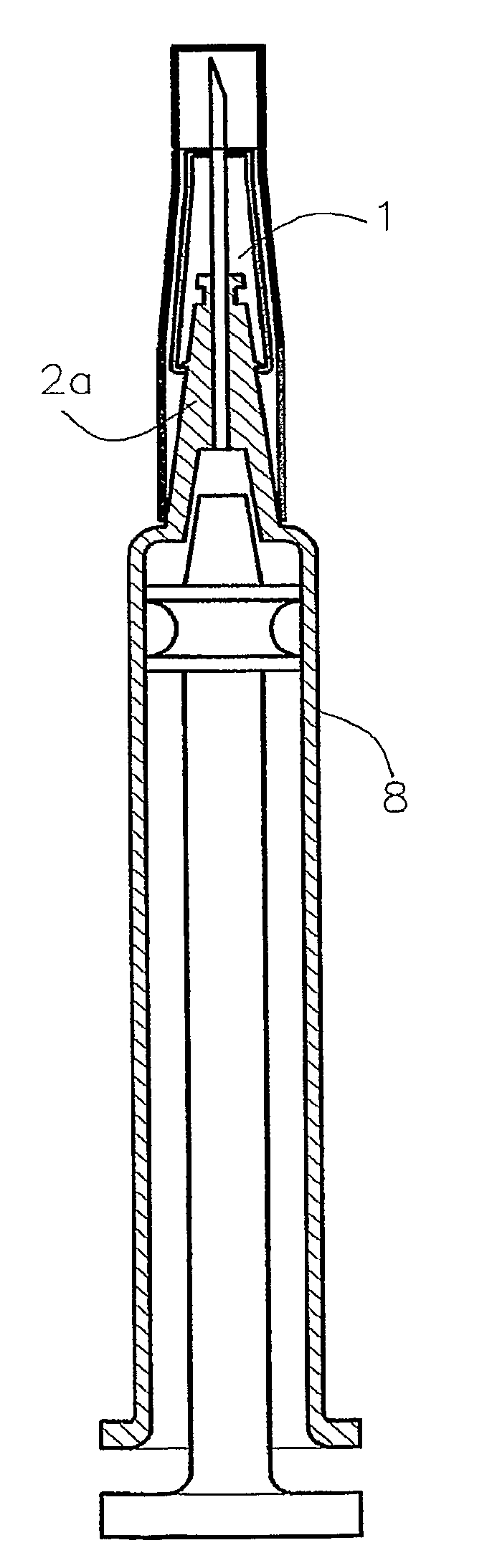

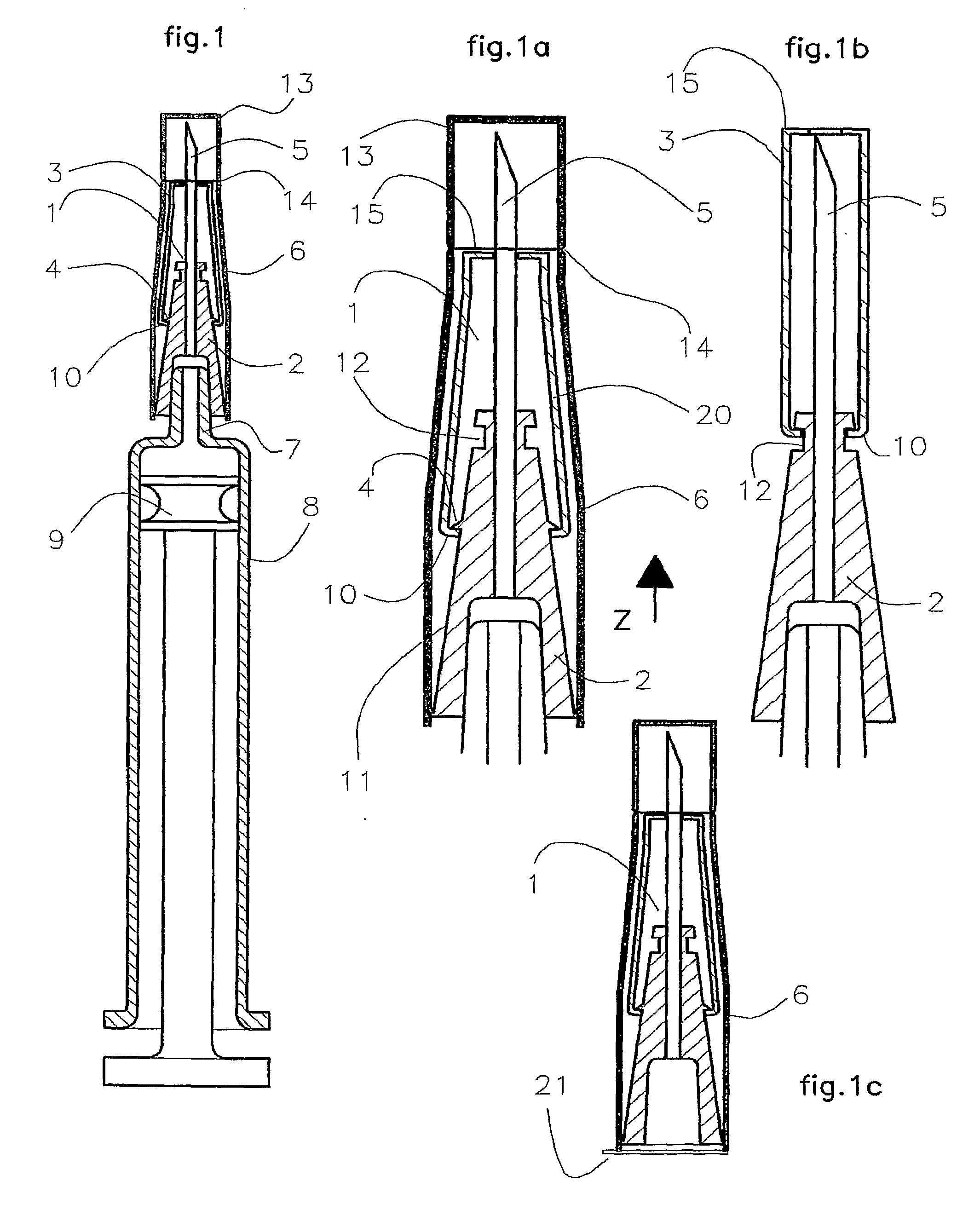

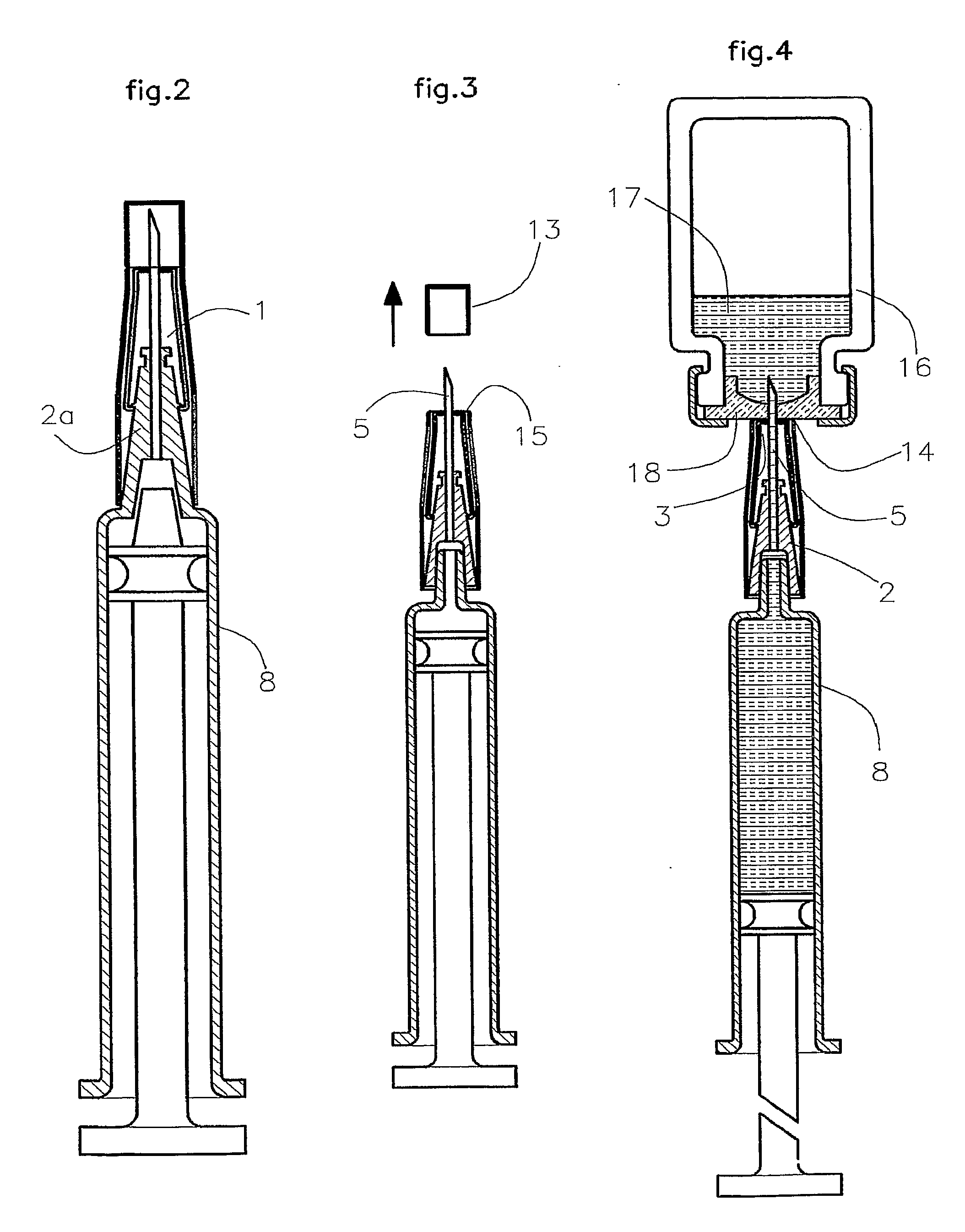

Automatic Injector

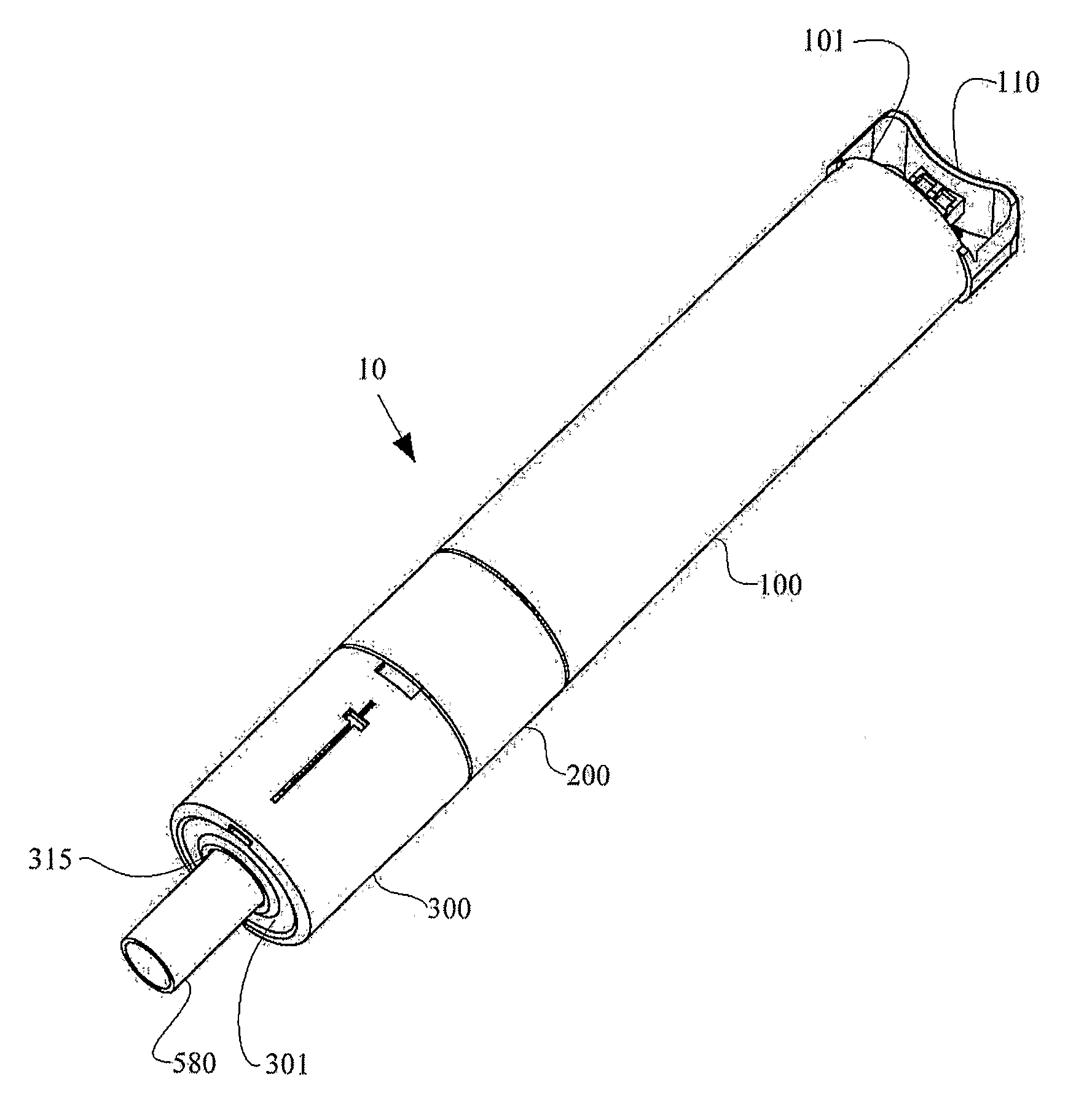

An injector is automatic in that the needle insertion into the injection site (e.g., a patient's skin) is triggered by the user or caregiver, the insertion is automatic, the following delivery is automatically initiated upon needle insertion, and the needle is shielded automatically after the end of delivery. Preferably the user does not see the needle prior to, during, or after injection. The injector includes a proximal and distal housings and a needle shield arranged to slide on the distal housing. The injector has a driver arranged to move the syringe to cause the needle penetration, to inject the drug, and subsequently to release the shield. The syringe needle is shielded and the shield locked automatically after delivery is completed. The patient does not experience any injector force on the tissue during injection. The injector has built in patient safety features.

Owner:TSALS IZRAIL +1

Biopsy instrument with improved needle penetration

InactiveUS7470237B2Piercing especially dense tissueSurgical needlesVaccination/ovulation diagnosticsNeedle penetrationBiopsy instruments

The present invention provides a biopsy instrument with improved needle penetration for piercing dense tissue. The device may comprise a needle slidably retained in a housing. The device may further comprise an actuation member that may be adapted to communicate longitudinal motion to the needle in a first direction. The device may further include a propulsion element that provides the needle with return motion in a second direction. The device may be fired multiple times to create repeating reciprocal motion. In one version, the device may reciprocate several times as a result of a single engagement of the actuation member.

Owner:DEVICOR MEDICAL PROD

Biopsy and injection catheters

InactiveUS20050222518A1Surgical needlesVaccination/ovulation diagnosticsNeedle penetrationRelative motion

Medical devices are delineated that may include a needle, a catheter and a sheath. Such devices may be used to take a biopsy from a patient and / or inject fluid into a patient, particularly in the patient's heart tissue. One or more ports may be located between the ends of the needle to facilitate the desired medical procedure. A relative motion restrictor may be included to restrict relative movement during needle deployment between the catheter and the sheath. Additionally, a driver may be employed to deploy the needle with one or more of a predefined force, acceleration and velocity to ease needle penetration.

Owner:MYTOGEN

Sealed containers and methods of making and filling same

Disclosed is a uniquely configured medicament vial assembly which includes a storage vial, a stopper member and a securing ring. The vial assembly is configured to improve healthcare worker safety by providing a shielded gripping location to aid in the reduction of accidental needle sticks. The storage vial has a body portion which defines an interior chamber for storing a predetermined medicament and a neck portion through which medicament is received into and withdrawn from the interior chamber. The stopper member is inserted into the mouth of the vial and establishes a first seal. The securing ring is engaged with the mouth of the vial and adapted and configured for retaining the stopper member within the vial mouth and effectuating a second seal. The securing ring is formed from a thermoplastic and / or elastic material. Preferably, the securing ring is formed by molding the thermoplastic and / or elastic material over a portion of the storage vial and stopper member when engaged within the vial mouth.

Owner:MEDINSTILL DEV

Medicine injection devices and methods

A reloadable medicine injector and methods are described in which a barrel with a receiving cavity is adapted to slidably receive a syringe subassembly for axial movement therein. Upon removal of a safety and release of a syringe driver, the syringe driver moves forward and injects the syringe needle. A plurality of penetration controls are shown for controlling injection needle penetration depth. The penetration controls have an abutment and various lengths to provide different needle penetration depth positions. In one form of penetration control a sleeve is used against which the syringe or related parts contact. In another form the front return spring is used as a penetration control. A cushioning ring may be used to reduce syringe breakage. A load distribution and guide ring may be used to distribute loading applied to the syringe and help guide the moving syringe.

Owner:WASHINGTON BIOTECH CORP +1

Huber needle with anti-rebound safety mechanism

InactiveUS6918894B2Alleviates the above-referenced deficienciesAvoid injurySurgeryMedical atomisersNeedle penetrationSyringe needle

A safety needle device for protecting a user against a needle-stick injury. This needle device includes a needle housing having a distal housing opening. A needle is disposed within the needle housing and has a distal needle portion which extends away therefrom through the distal housing opening. An elongate sheath assembly surrounds the needle within the needle housing. A trigger member retains the sheath assembly within the needle housing against a force urging the sheath assembly towards the distal housing opening. The trigger member is sized and configured to release the sheath assembly from retention to allow the sheath assembly to transition towards and out of the distal housing opening via the force. This causes the sheath assembly to enclose the distal needle portion and protect the user against the needle stick injury.

Owner:ACACIA INC

Kits containing medicine injection devices and containers

A reloadable medicine injector and methods are described in which a barrel with a receiving cavity is adapted to slidably receive a syringe subassembly for axial movement therein. Upon removal of a safety and release of a syringe driver, the syringe driver moves forward and injects the syringe needle. A plurality of penetration controls are shown for controlling injection needle penetration depth. The penetration controls have an abutment and various lengths to provide different needle penetration depth positions. In one form of penetration control a sleeve is used against which the syringe or related parts contact. In another form the front return spring is used as a penetration control. A cushioning ring may be used to reduce syringe breakage. A load distribution and guide ring may be used to distribute loading applied to the syringe and help guide the moving syringe.

Owner:VERUS PHARMA +1

Oligomerization of olefin waxes using metallocene-based catalyst systems

InactiveUS20110082323A1Decreased needle penetrationHigh kinematic viscosityOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionNeedle penetrationWax

This disclosure provides for olefin wax oligomer compositions, methods of producing olefin wax oligomer composition, and methods for oligomerizing olefin waxes. This disclosure encompasses metallocene-based olefin wax oligomerization catalyst systems, including those that include a metallocene and an aluminoxane, a metallocene and a solid oxide chemically-treated with an electron withdrawing anion, and a metallocene, a solid oxide chemically-treated with an electron withdrawing anion, and an organoaluminum compound. The olefin wax oligomers prepared with these catalyst systems can decreased needle penetrations, increased viscosity, and an increased drop melt, making them useful as an additive in candles, stone polishes, liquid polishes, and mold release formulations.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Device with needle penetrable and laser resealable portion and related method

A device and method are provided for needle penetrating and filling a chamber with a predetermined substance, and laser resealing a resulting needle hole in the device. A needle penetrable and laser resealable portion of the device is pierceable with a needle to form a needle aperture therethrough to fill the chamber through the needle, and is laser resealable to hermetically seal the needle aperture by applying laser radiation at a predetermined wavelength and power thereto. The needle penetrable and laser resealable portion defines a predetermined wall thickness in an axial direction thereof, and includes a thermoplastic that substantially prevents the formation of particles released into the chamber from the needle penetrable and laser resealable portion during penetration by and withdrawal of the needle. The thermoplastic includes a predetermined amount of pigment that allows the thermoplastic to substantially absorb laser radiation at the predetermined wavelength, substantially prevent the passage of radiation through the predetermined wall thickness thereof, and hermetically seal a needle aperture formed in the needle penetration region thereof in a predetermined time period.

Owner:MEDICAL INSTILL TECH

Asphalt compositions and products comprising tall oil derived materials, and methods for making and using same

InactiveUS8034172B2Working-up pitch/asphalt/bitumen by chemical meansCoatingsSolubilityNeedle penetration

Asphalt compositions and products in which the binder comprises tall oil materials possibly previously subjected to distillation, and / or oxidation, and / or combined with a polymer, the tall oil materials having a softening point in the range of 75 F to 400 F, a Needle Penetration value (0.1 mm) at 25 C of at least 1, a Rotational Viscosity at 275 F in the range of 650 cps to 8,000 cps, and a water solubility of less than 10 percent.

Owner:PVS MERIDIAN CHEM

Apparatus And Method For Injecting A Pharmaceutical

InactiveUS20080195056A1Easy to operateResist slippageAutomatic syringesMedical devicesNeedle penetrationInjection site

A method and apparatus for administering a pharmaceutical. The method employs a delivery device including a housing, a pharmaceutical containing needled syringe movable within the housing, an activation button disposed at one of the housing, and wherein the housing is flared radially outward at the other end and designed to allow visibility of the needled syringe. A skin-contacting surface of the housing at the flared end is designed to limit slippage along the skin, and at least one injection targeting guide is provided. When the device is sited for injection, and without pressing the delivery device housing toward the injection site with any predetermined force by the one hand holding the housing, the activation button may be plunged with the other hand toward the housing to trigger an advancing assembly within the device that first automatically advances the needled syringe to insert a needle into the injection site, and that second automatically advances the syringe piston to force pharmaceutical through the inserted needle.

Owner:BISHOP STEVEN +4

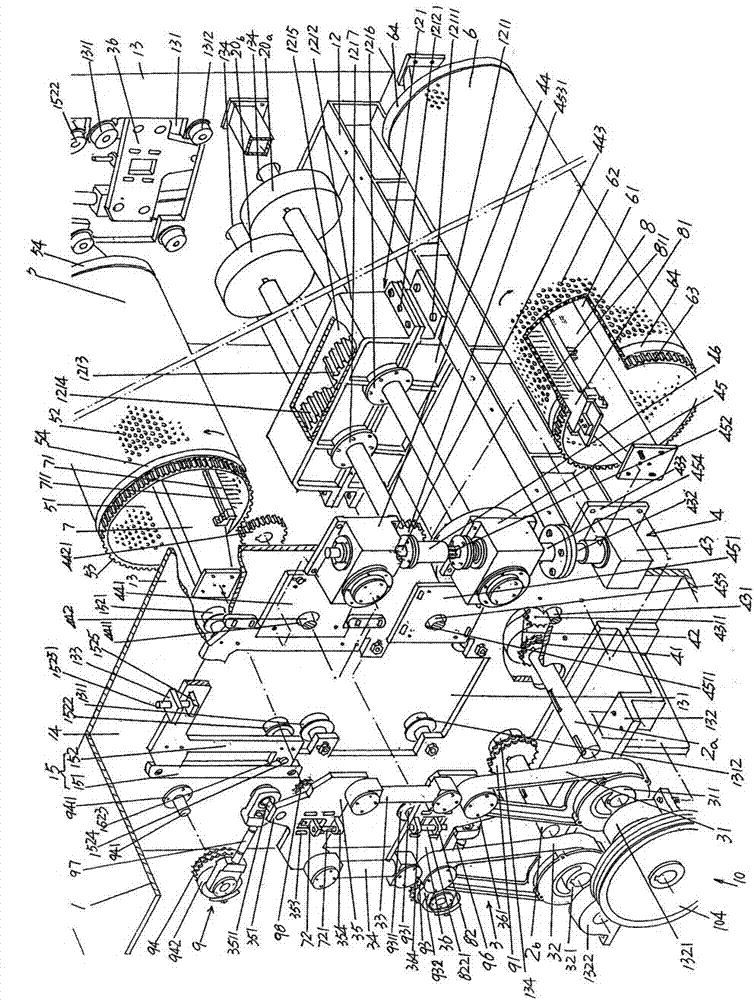

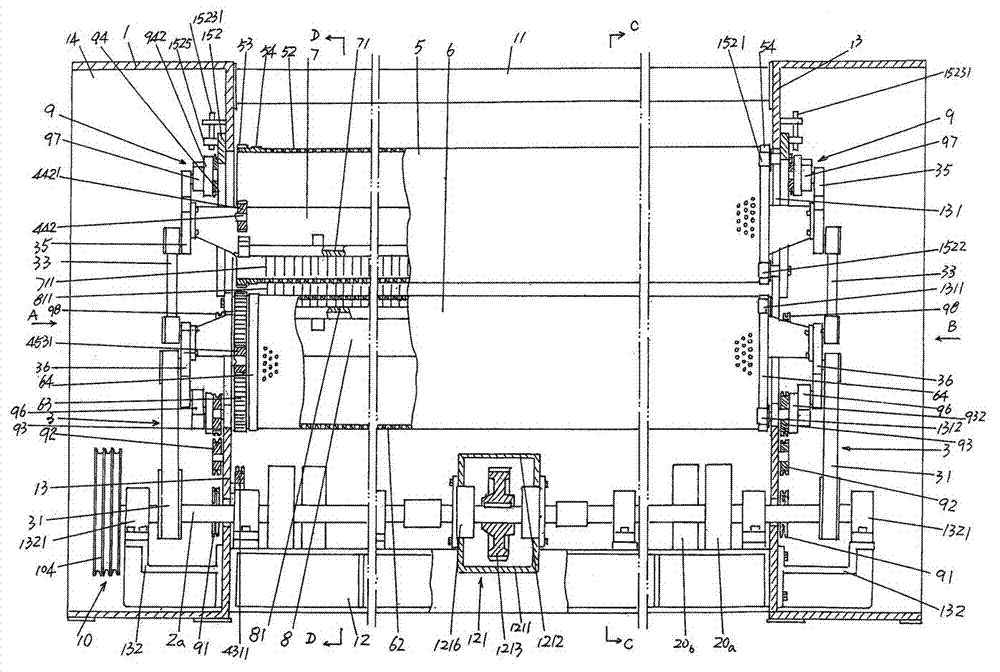

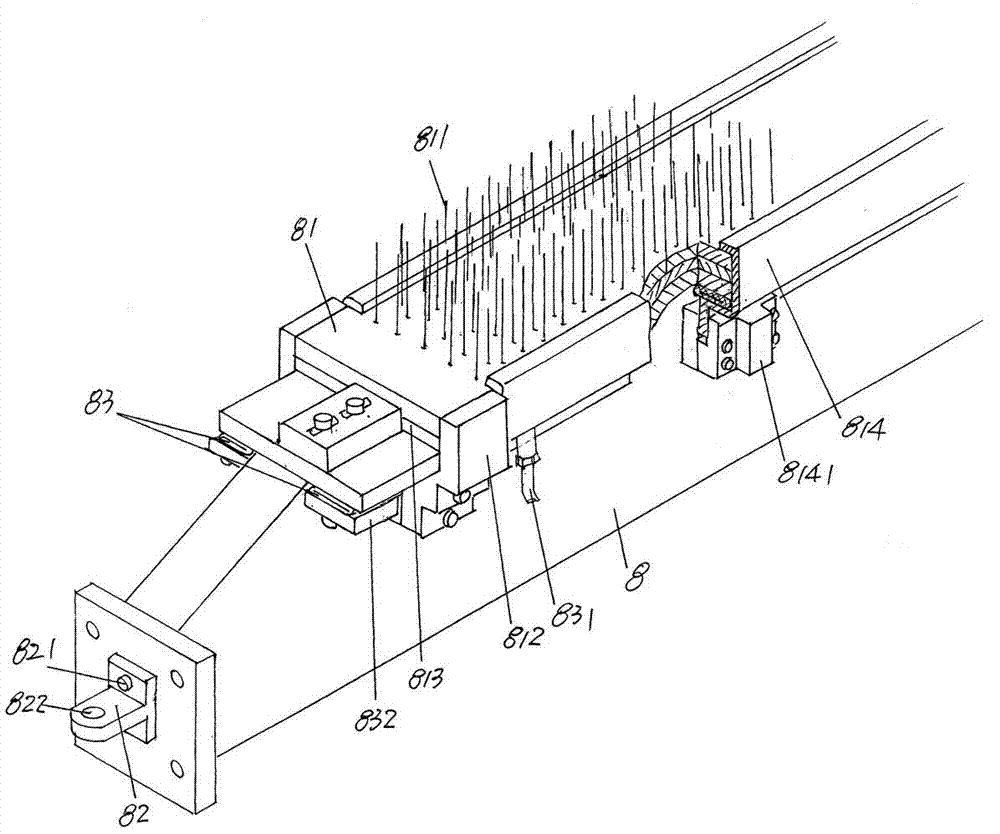

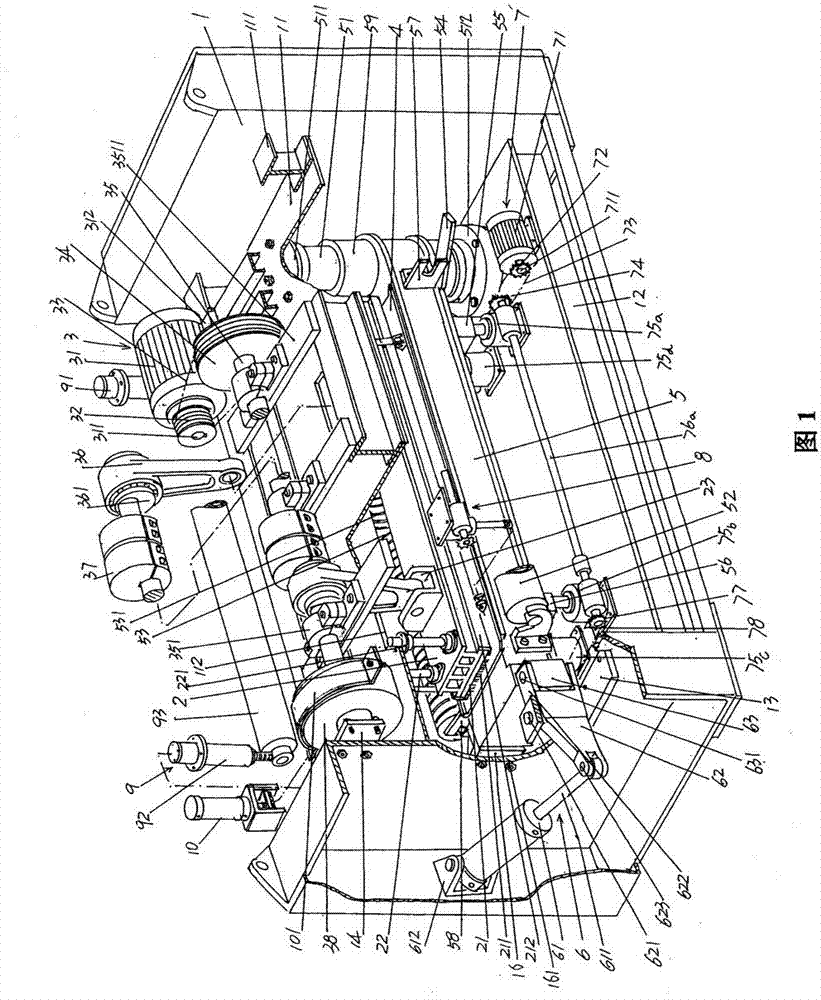

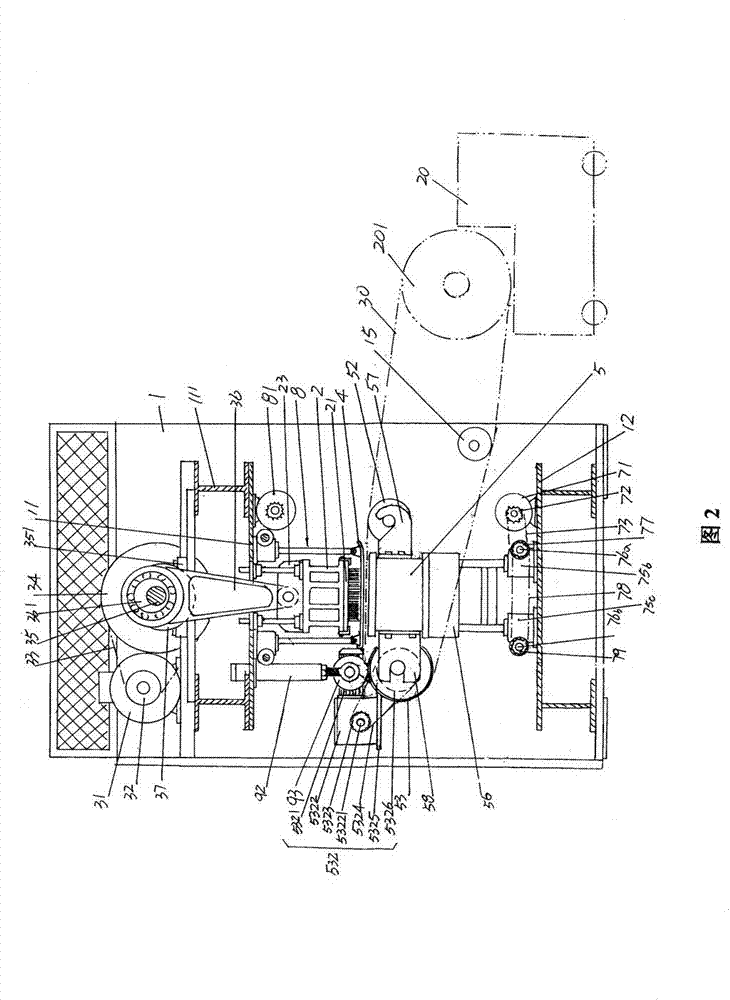

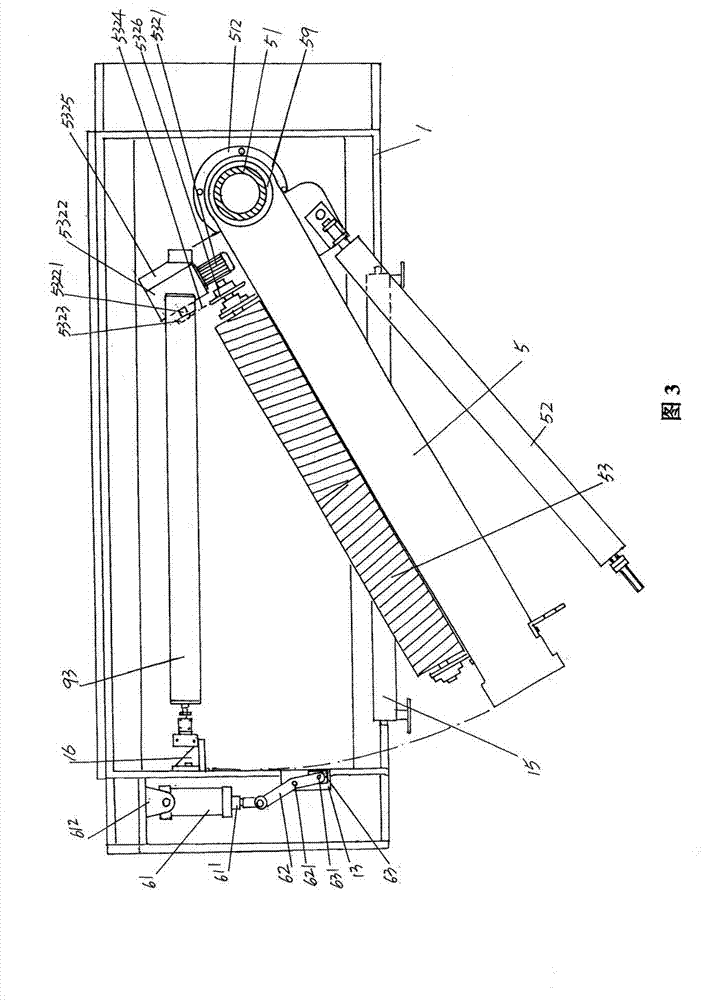

Roller type needling machine

ActiveCN102808290BSaving zero draftGuaranteed zero draftNeedling machinesNeedle penetrationWall plate

A drum-type needling machine belongs to the field of non-woven machinery. It includes a pair of chassis, a needle beam is set on the chassis wallboard of the pair of chassis to penetrate into the relief cavity, and a transmission box is arranged in the middle of the lower cross frame of the chassis; the first and second main shafts are supported between the pair of chassis; a pair of Connecting rod mechanism; roller driving mechanism, connected with the first main shaft; upper roller and lower roller, supported between a pair of chassis, cooperate with the roller driving mechanism; upper needle beam and lower needle beam, fixed on the middle part of the upper needle beam Needle board, the upper needle board is arranged with upper needles, the lower needle board is fixed in the middle of the lower needle beam, and the lower needle board is arranged with lower needles; a pair of connecting rod swing traction mechanisms are arranged in the chamber of a pair of chassis, It is connected with the link mechanism in the box cavity and is also connected with the second main shaft in transmission; the power transmission mechanism arranged on the case is connected with the first main shaft in transmission. Advantages: It helps to improve production efficiency, shorten the process flow, save energy consumed by needle looms; improve the grade of non-woven products.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

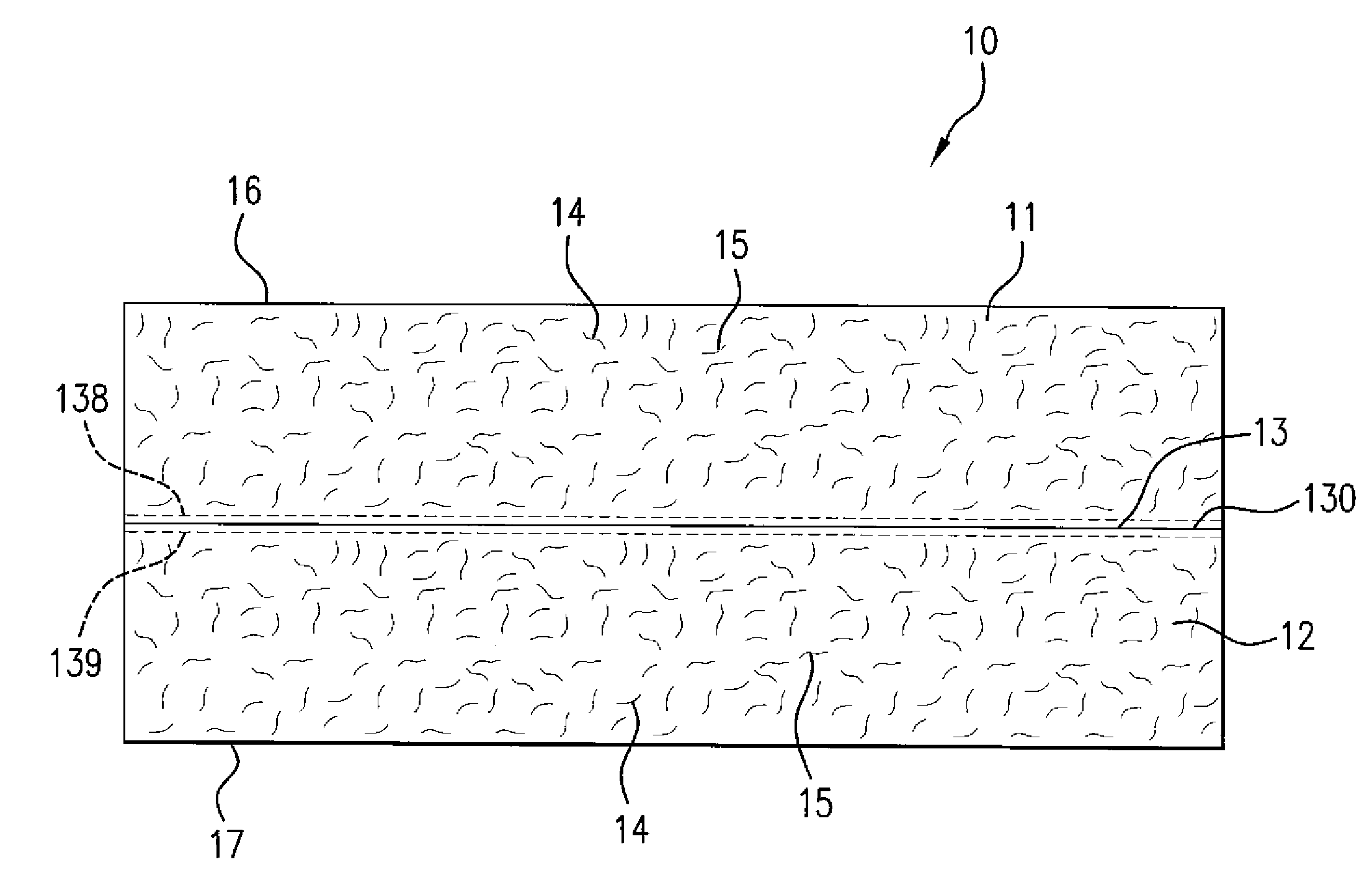

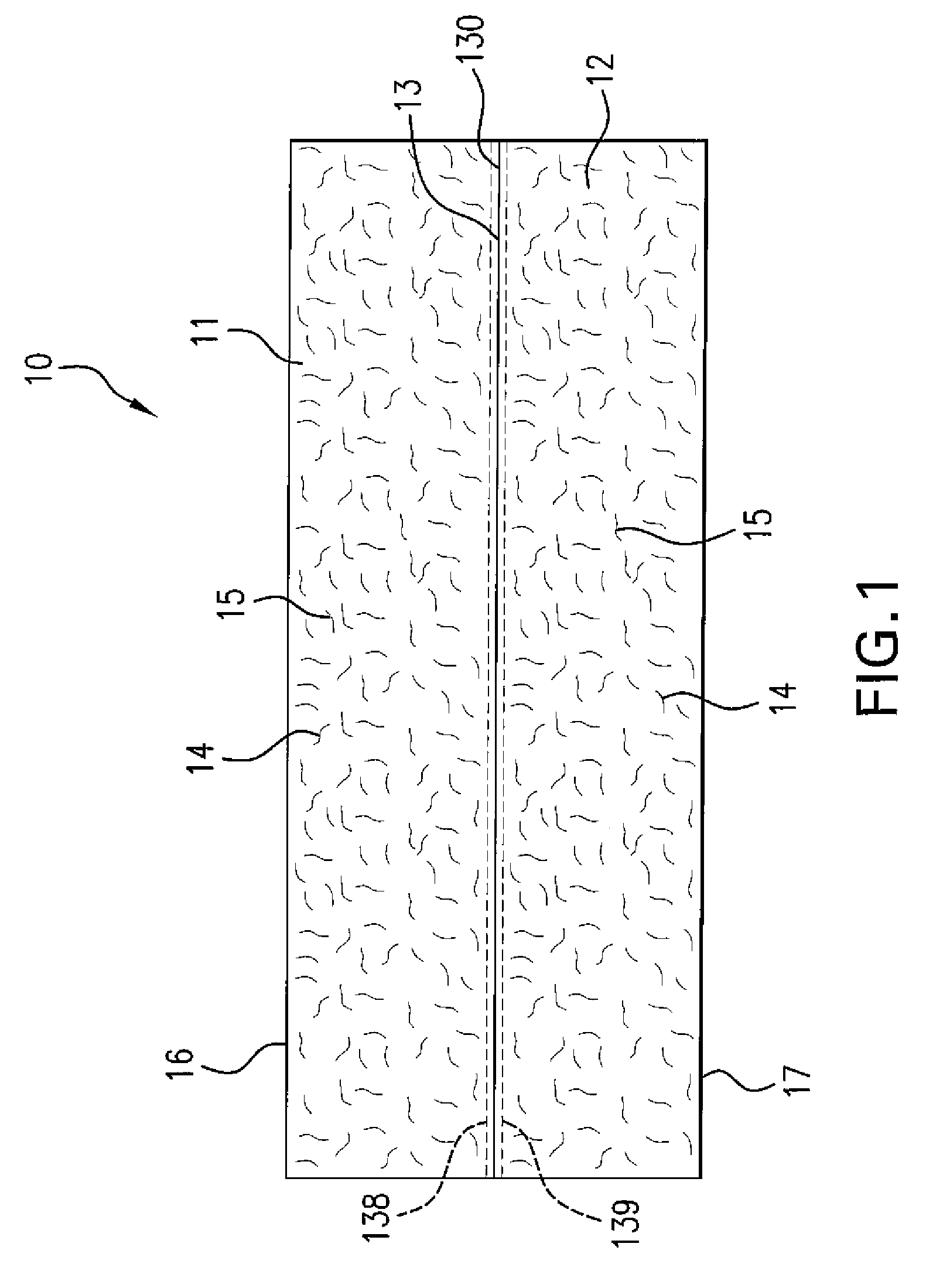

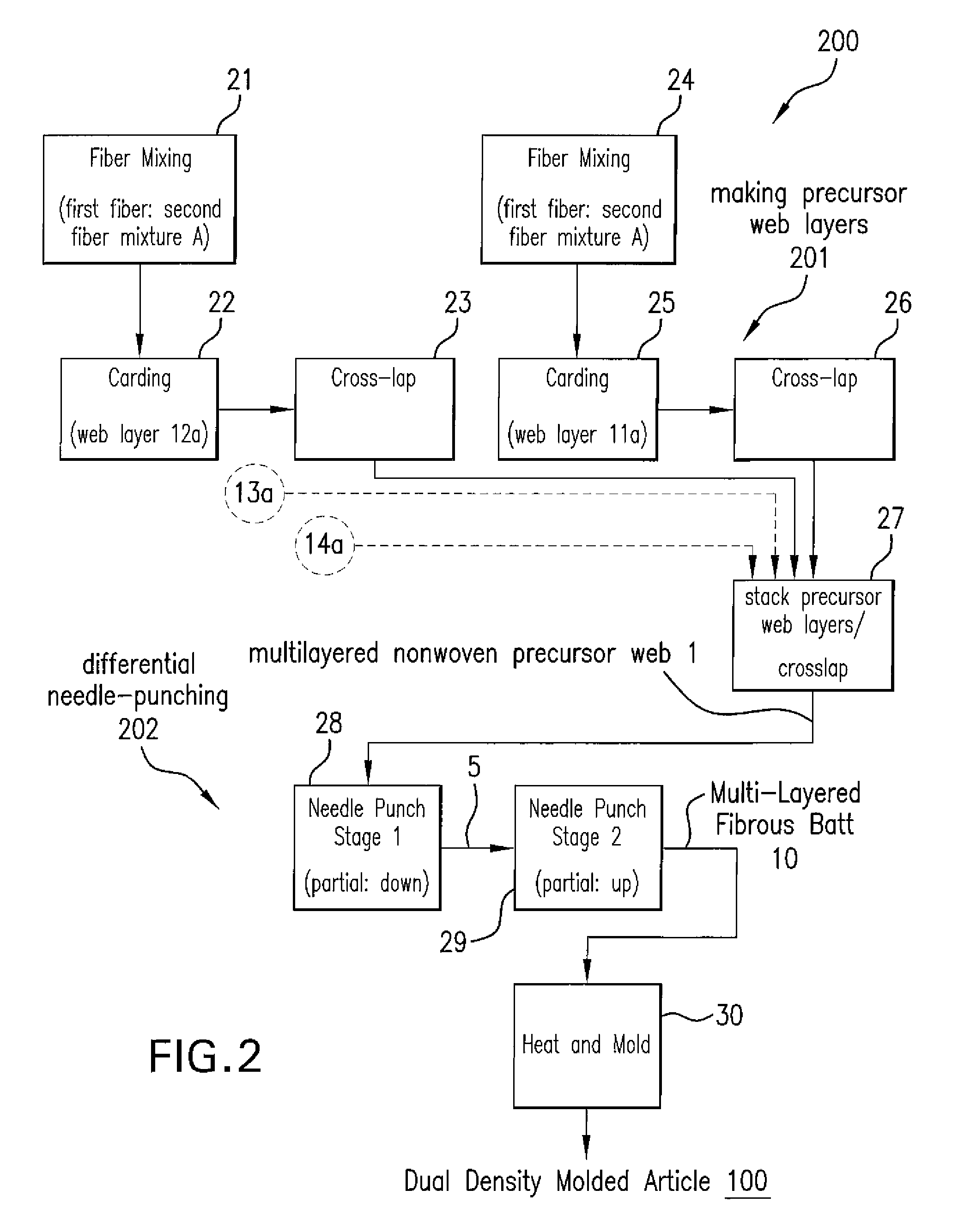

Nonwoven multilayered fibrous batts and multi-density molded articles made with same and processes of making thereof

InactiveUS7928025B2Reduce complexityLow costSynthetic resin layered productsNeedling machinesFiberNeedle penetration

Owner:AVINTIV SPECIALTY MATERIALS INC +1

Asphalt compositions and products comprising tall oil derived materials, and methods for making and using same

InactiveUS20100147190A1Working-up pitch/asphalt/bitumen by chemical meansCoatingsNeedle penetrationSolubility

Asphalt compositions and products in which the binder comprises tall oil materials possibly previously subjected to distillation, and / or oxidation, and / or combined with a polymer, the tall oil materials having a softening point in the range of 75 F to 400 F, a Needle Penetration value (0.1 mm) at 25 C of at least 1, a Rotational Viscosity at 275 F in the range of 650 cps to 8,000 cps, and a water solubility of less than 10 percent.

Owner:PVS MERIDIAN CHEM

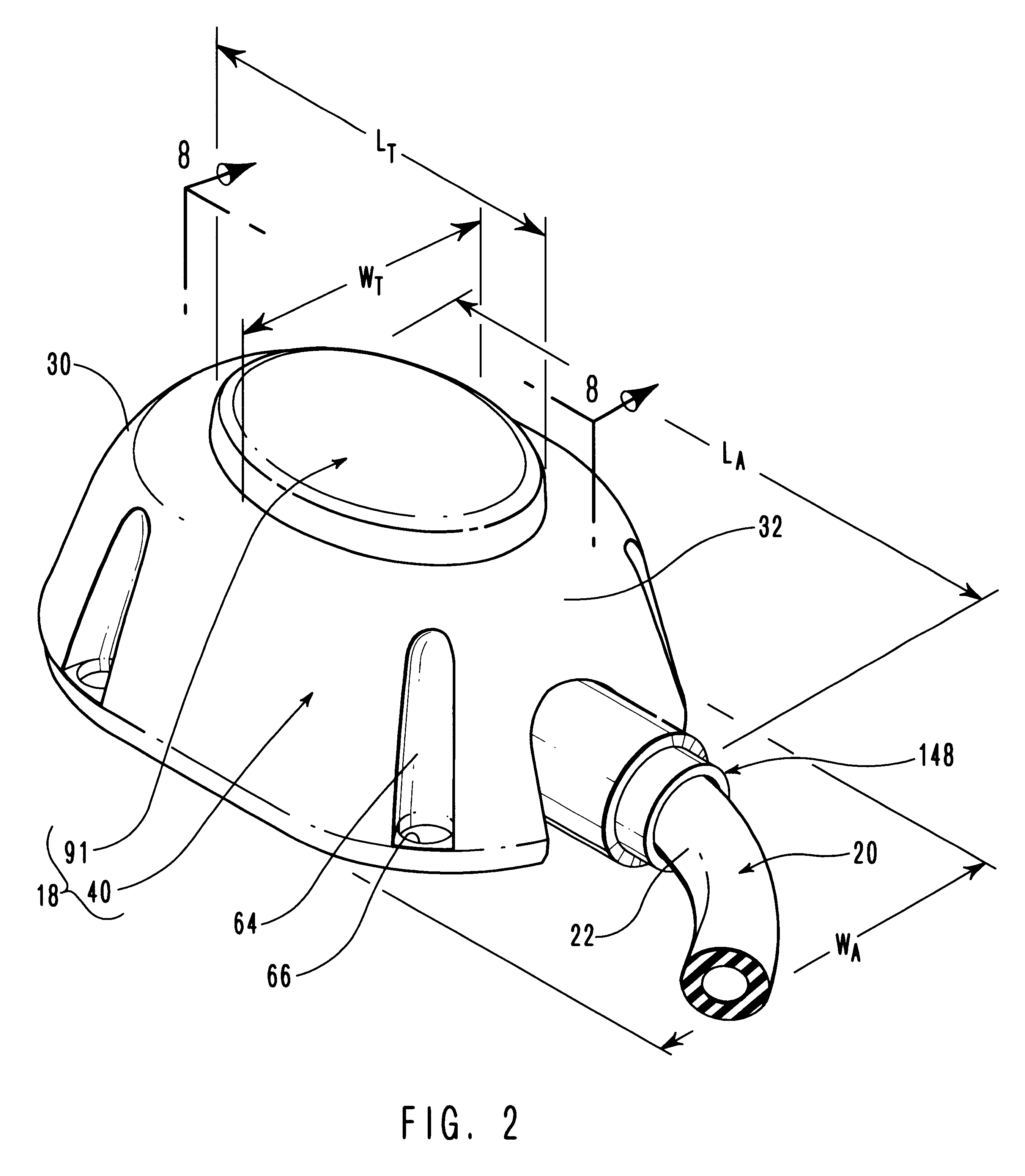

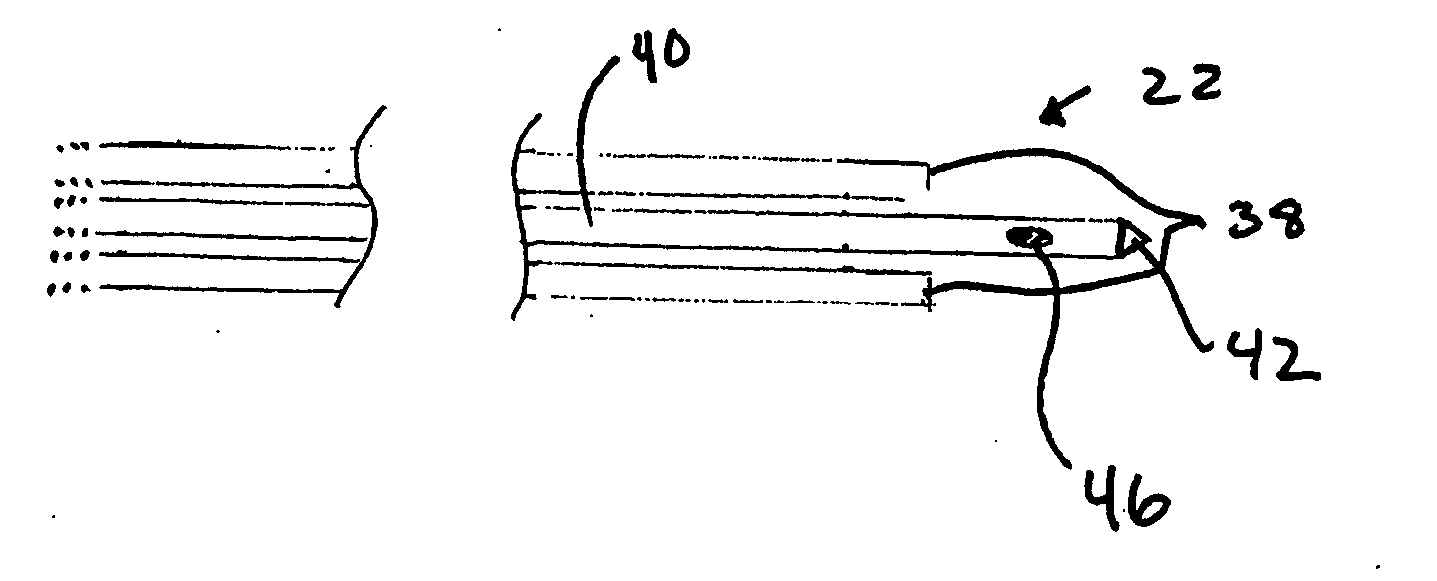

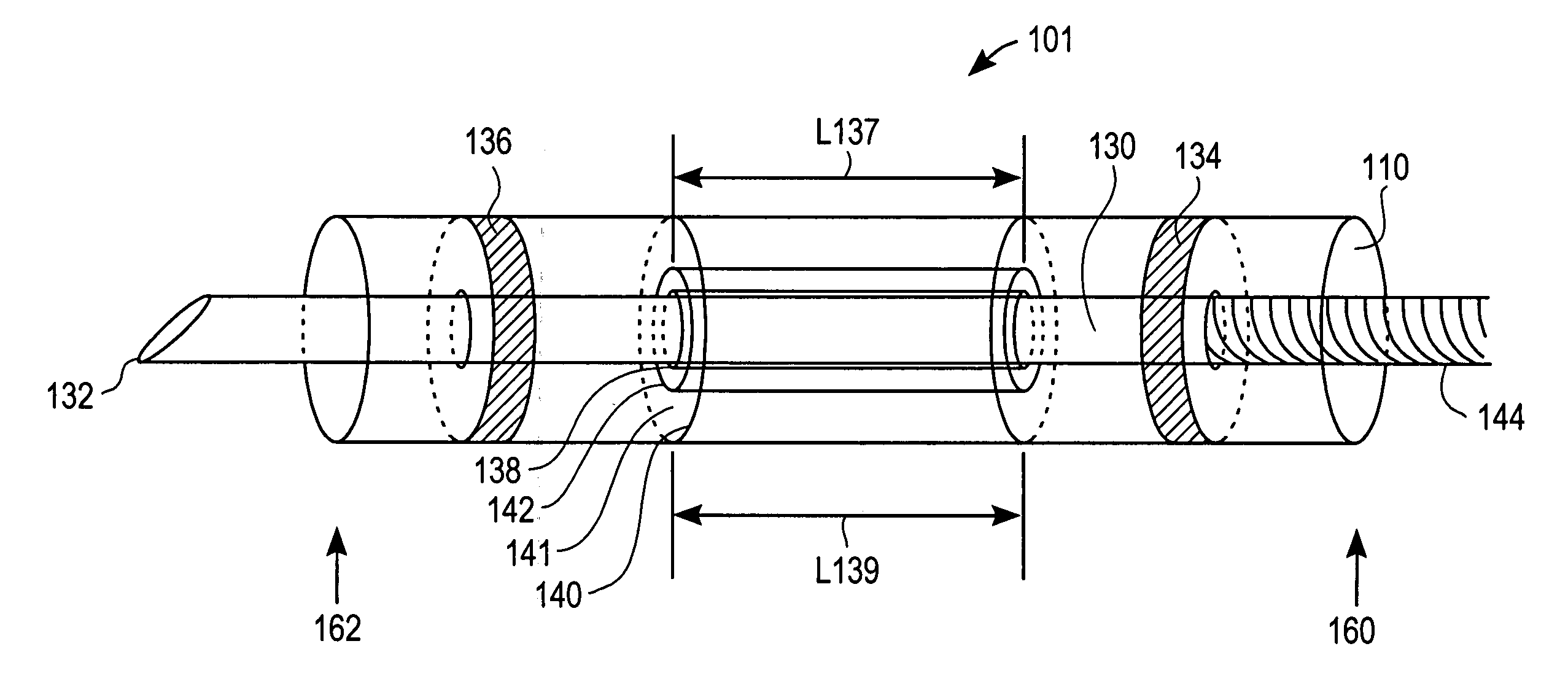

Method and apparatus for introducing an intravenous catheter

A catheter insertion apparatus with visual indication of needle penetration of a blood vessel and placement of the catheter cannula within the blood vessel, using blood vessel pressure to indicate needle penetration by the presence of blood within a transparent chamber within the apparatus and the displacement of a plunger to create a negative pressure on the cannula and thus allowing blood to be visible within the catheter hub thereby indicating the introduction of the cannula into the blood vessel.

Owner:WEXLER TOBY J

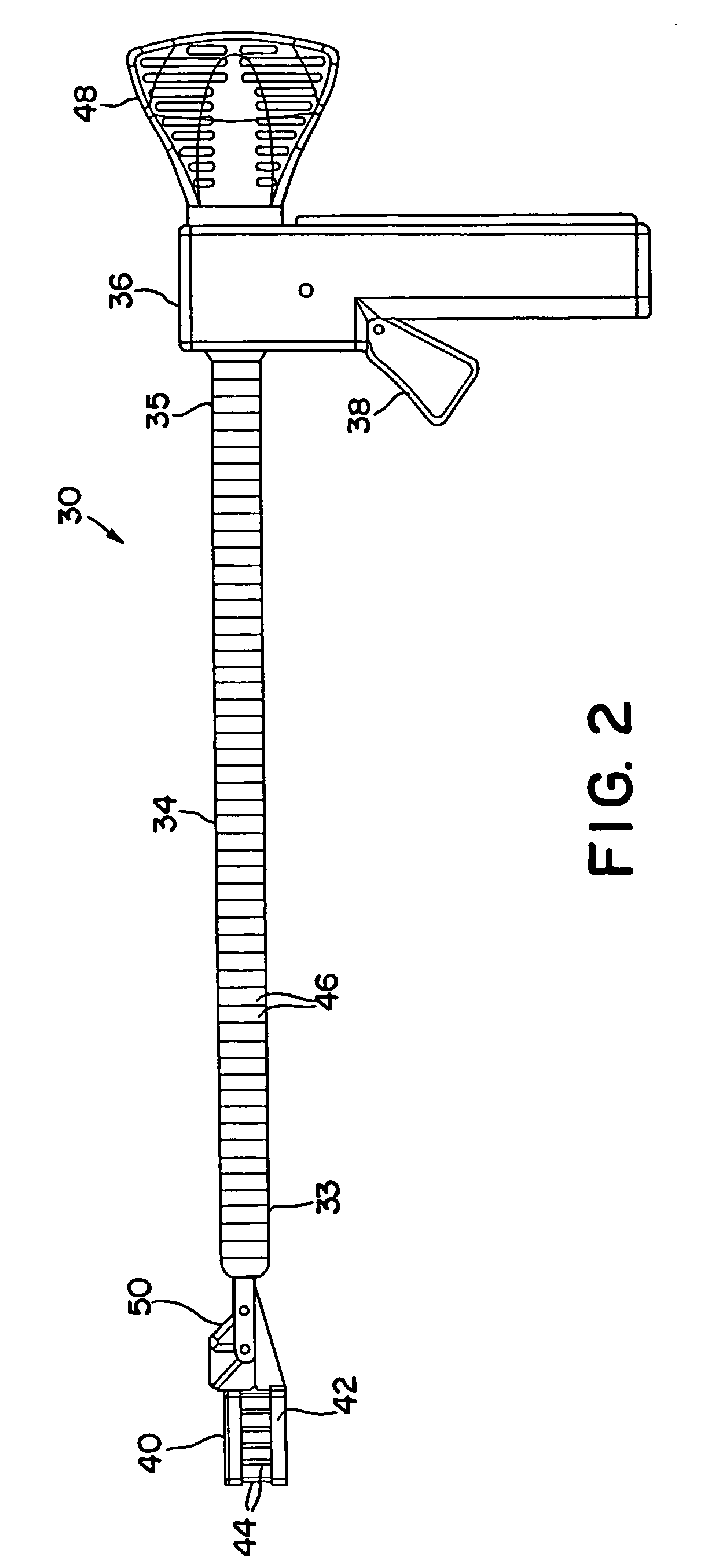

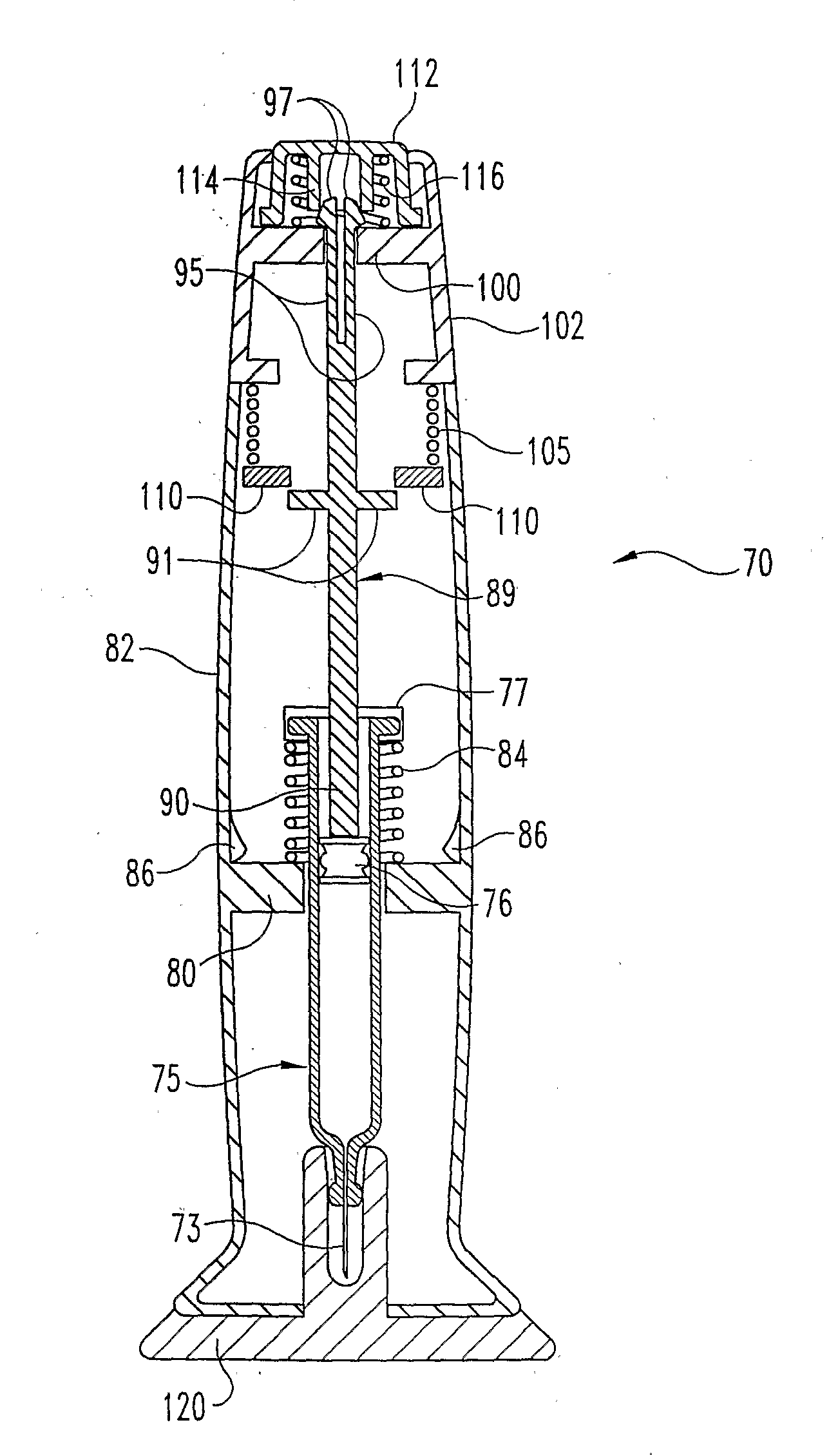

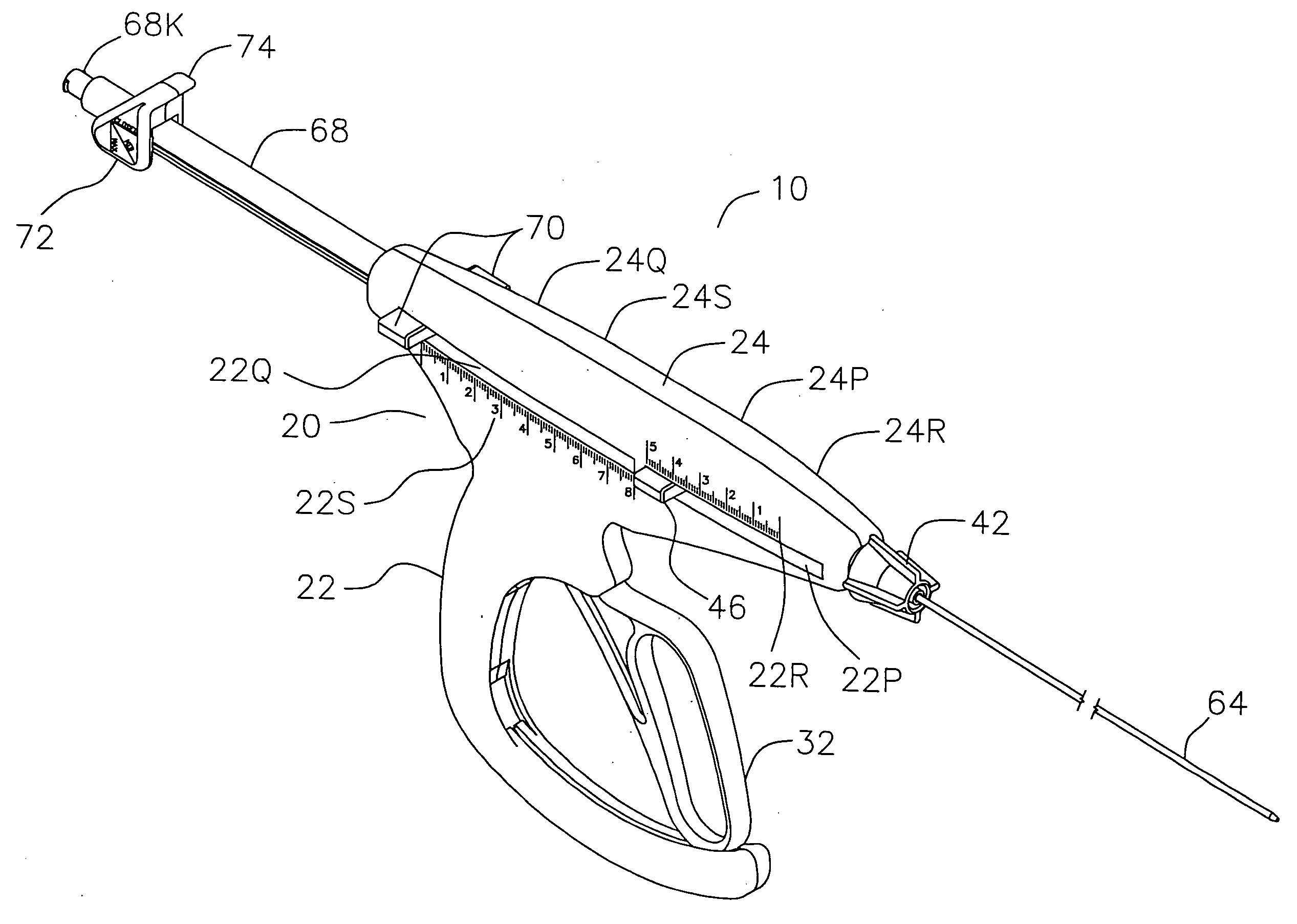

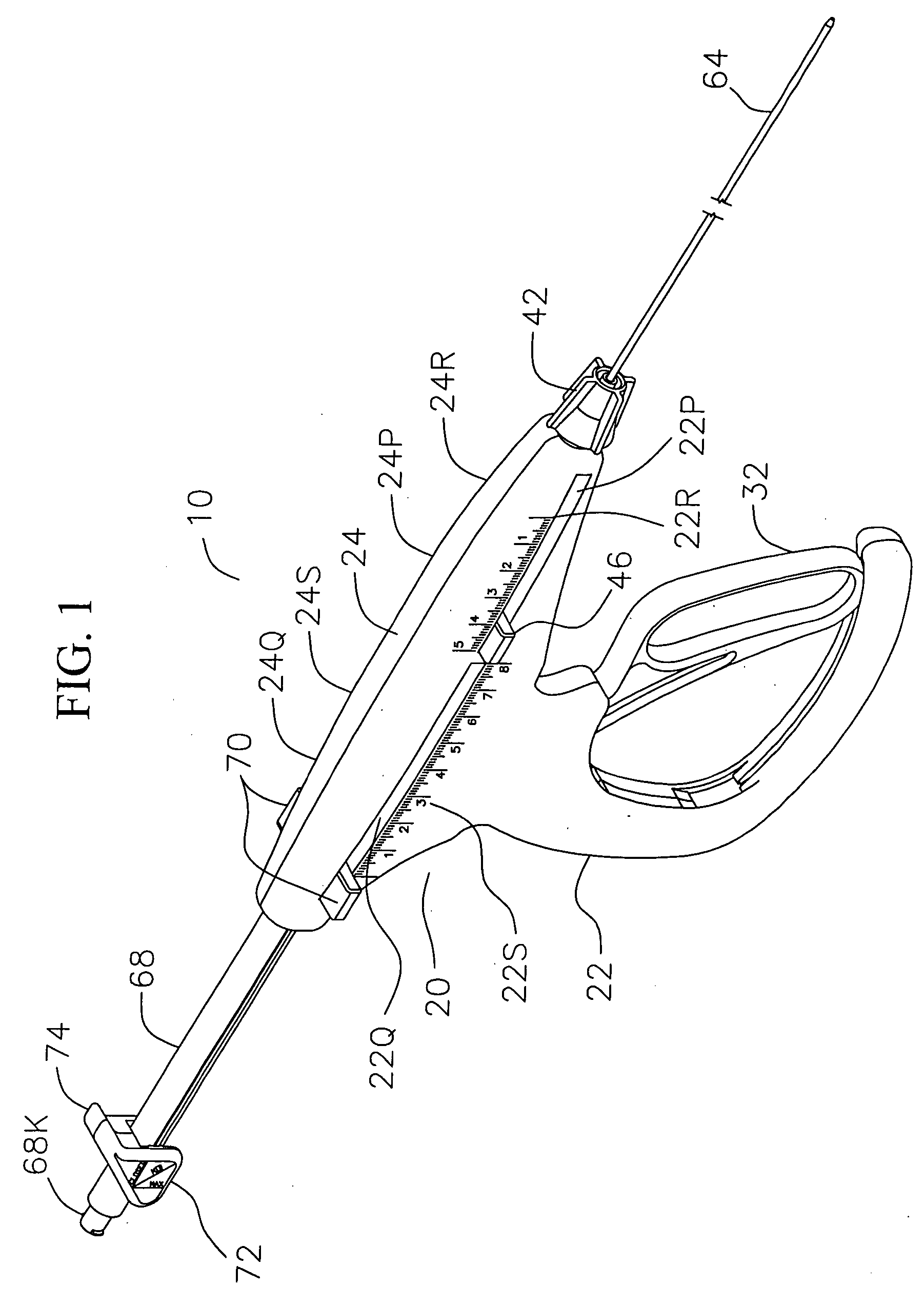

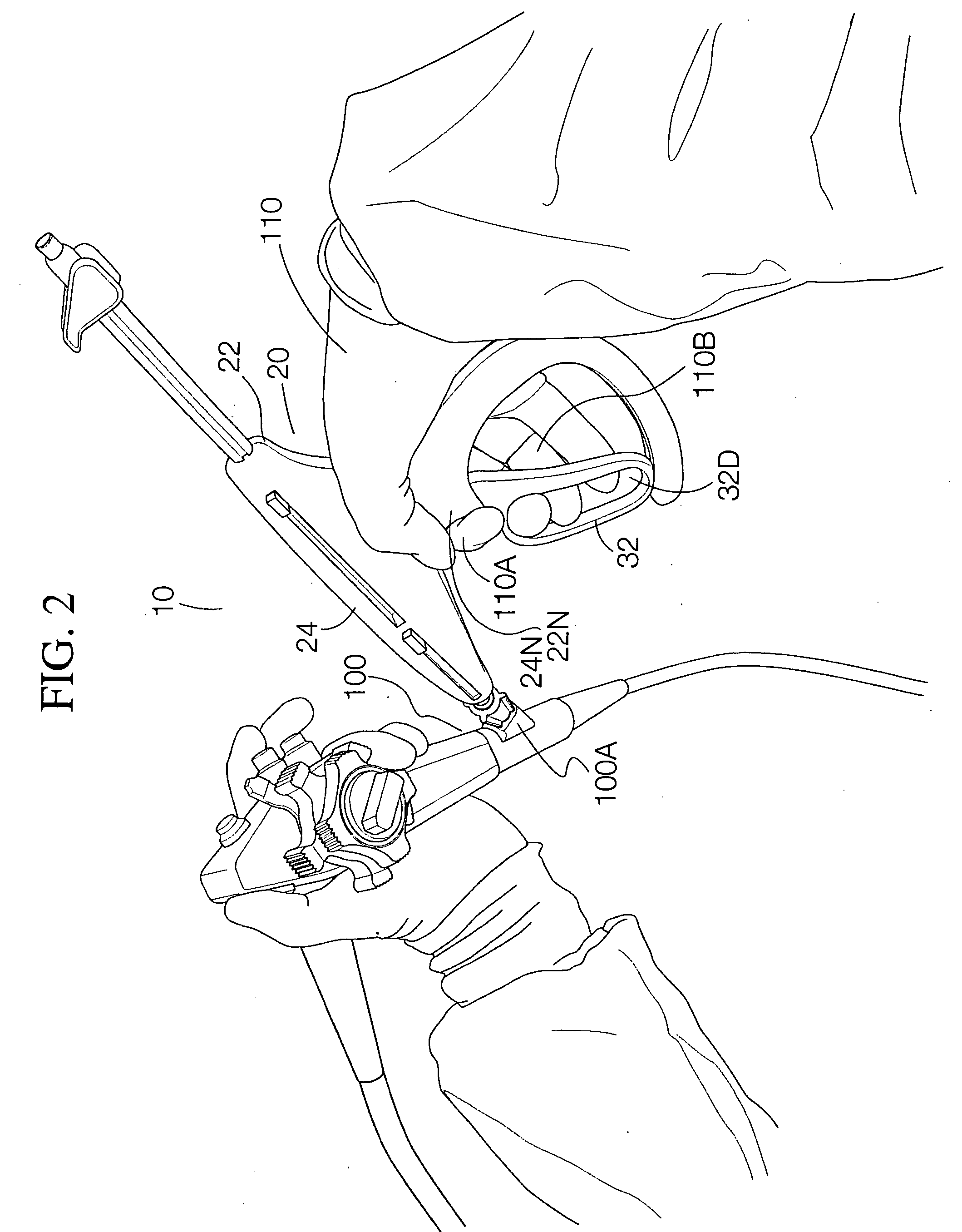

Ergonomic needle tissue harvesting instrument not requiring a stylet

A medical diagnostic instrument for the ergonomic effective and safe harvesting of specimen at targeted remote tissue sites includes a pistol grip style handle with a hand activated lever and a specialized elongated flexible double tube needle shaft inside of a protective sheath for use, in a preferred embodiment, within an endoscope. The length of needle shaft is adjusted using locking buttons. Moving another set of buttons sets the needle penetration depth. With a squeeze of the lever, a novel thin band drive mechanism advances the needle shaft out of its sheath, through adjacent tissue and into the targeted site. The double tube needle shaft incorporates a pointed distal tip attached to an innermost “grater” needle, which has sharp edged tissue cutting holes or “grating” features that are exposed by retracting back an overlying cover tube. Sliding back the cover tube is achieved via a cam. The sharp cutting surfaces of the grater tube communicate directly with a vacuum source attached near the handle. Oscillation of the vacuum augmented grater tube back and forth within the targeted tissue yields small pieces of tissue for harvest. When adequate amounts of tissue are drawn into the grater tube, the cover tube is re-advanced over the distal grater tube, the needle shaft is retracted back into the sheath and the instrument along with the harvested specimen are removed from the patient.

Owner:LSI SOLUTIONS

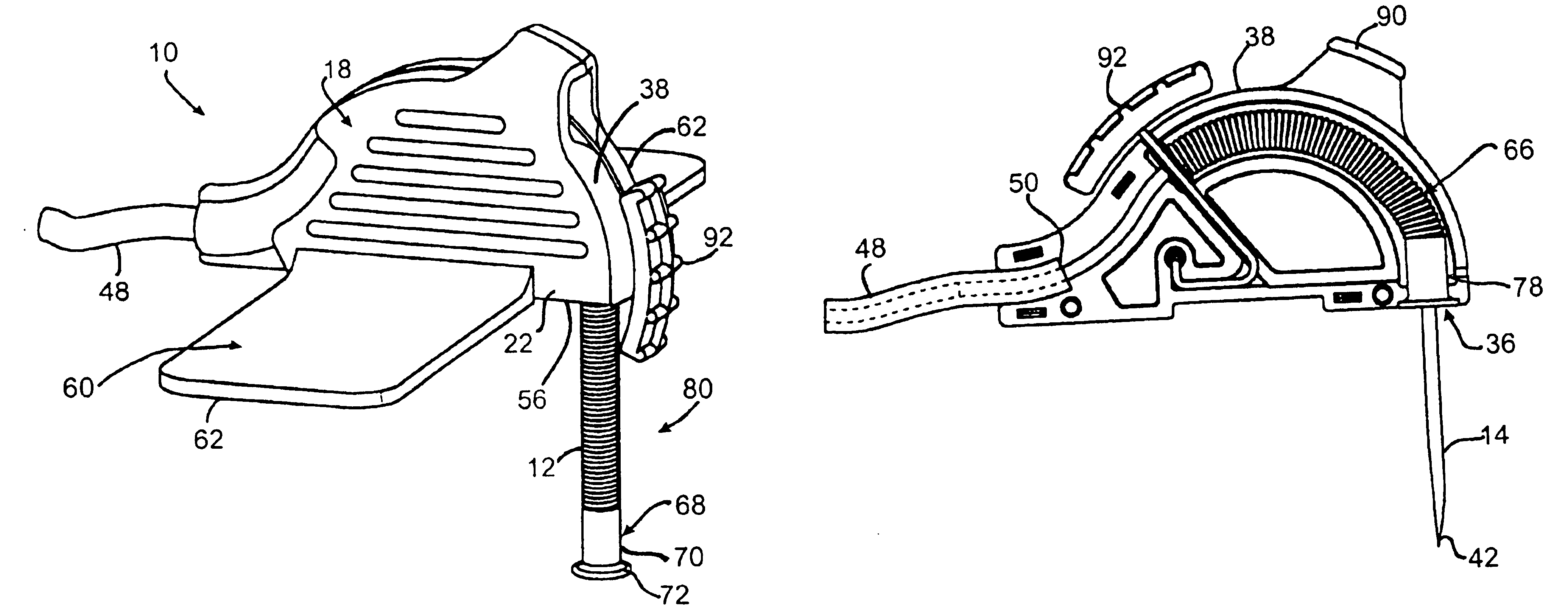

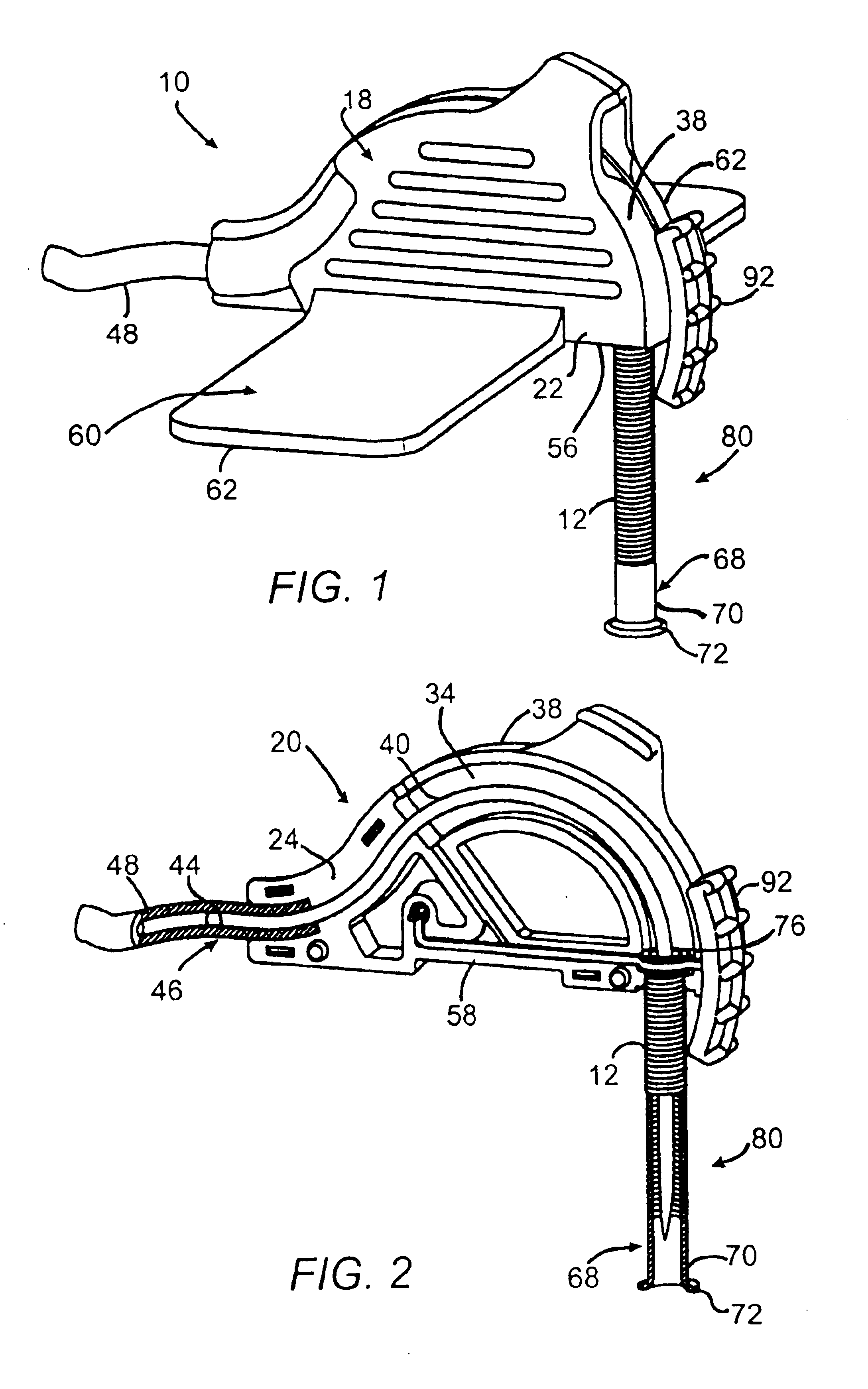

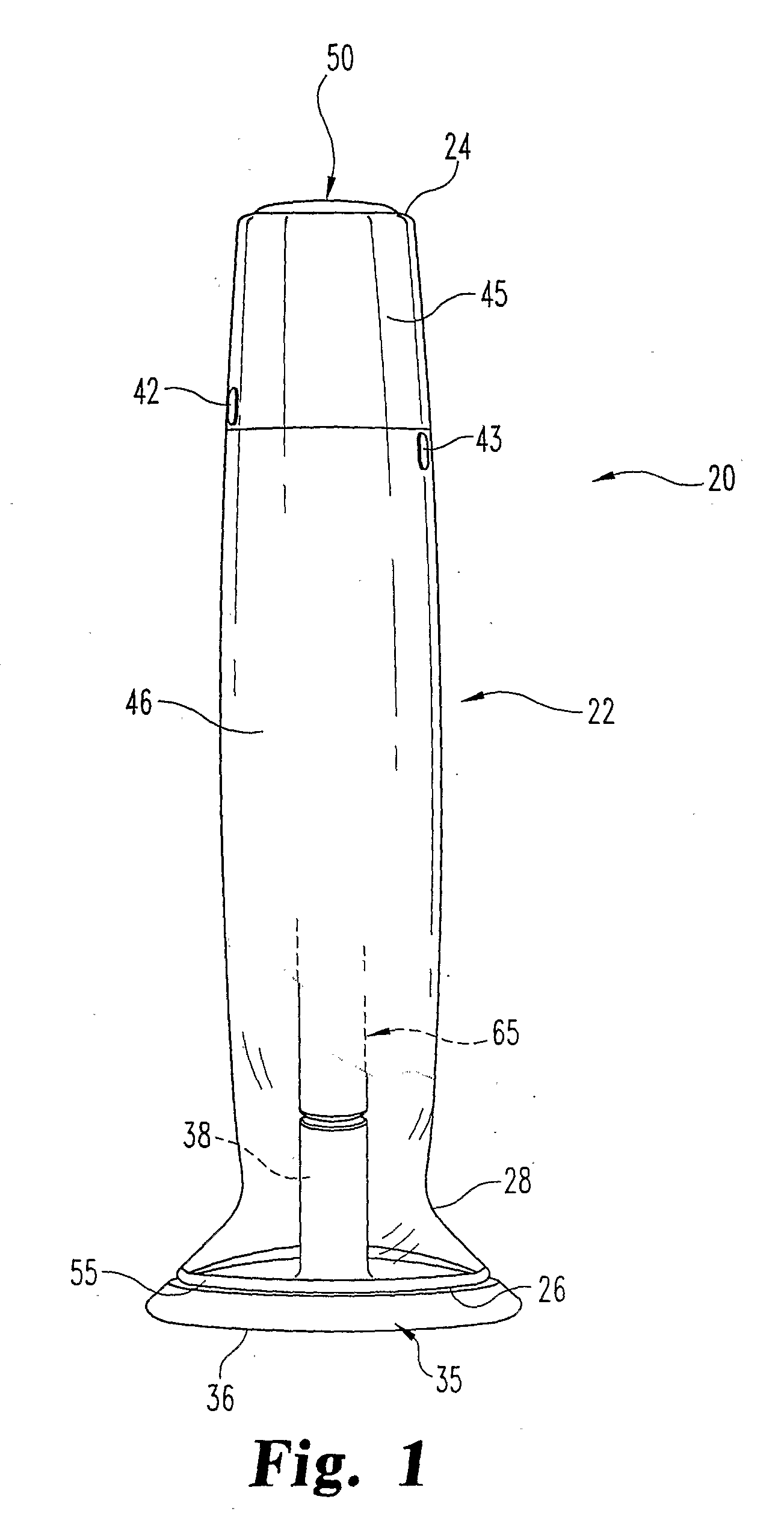

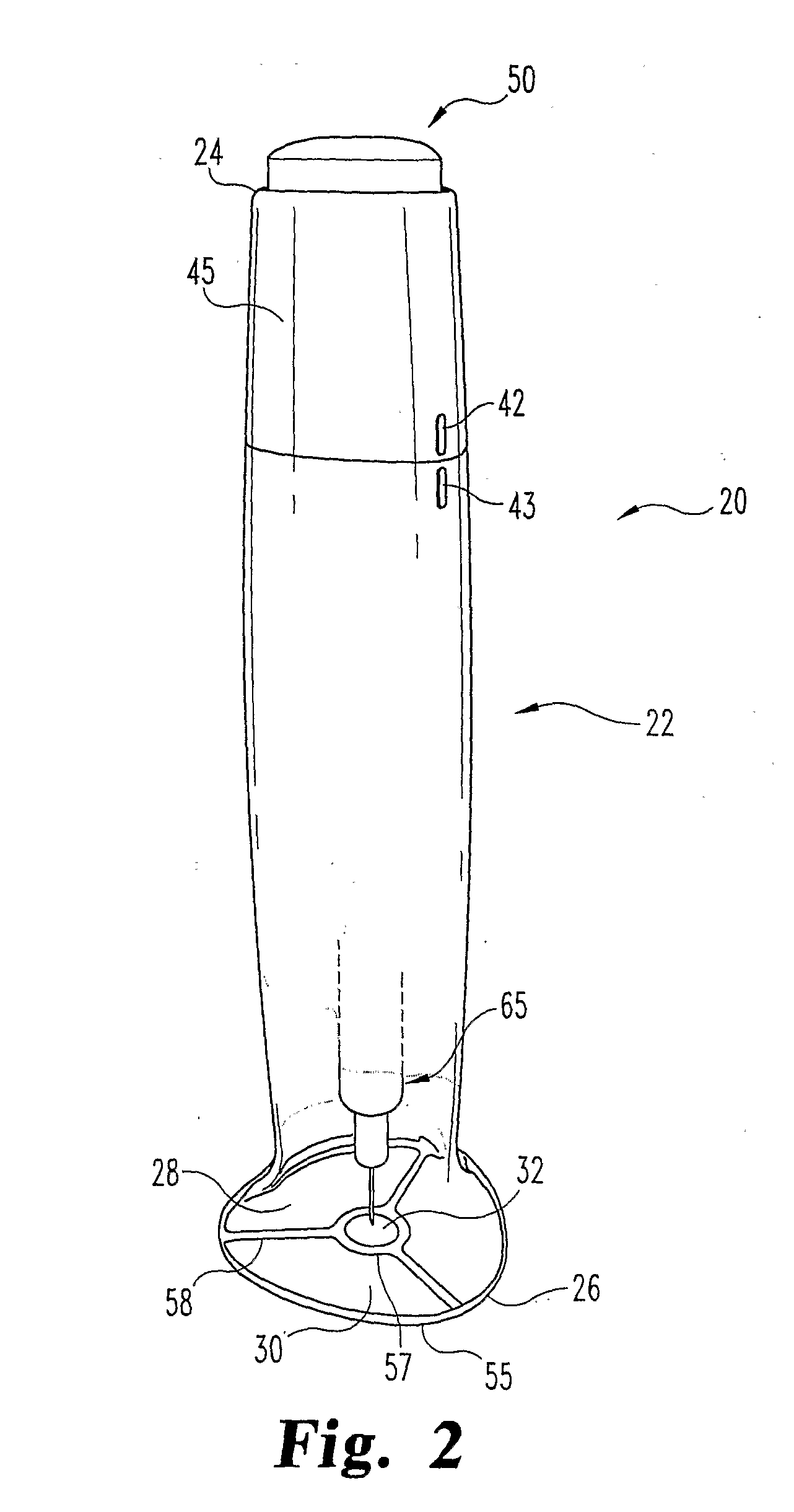

Huber needle safety enclosure

ActiveUS7776016B1Prevent rocking movementPrevent movementMedical devicesInfusion needlesNeedle penetrationHypodermic needle

A safety enclosure which is designed for a hypodermic needle that is located in the shape of an approximate right angle (Huber needle). A safety enclosure has a needle housing within which the Huber needle is mounted. The needle housing is mounted in conjunction with a panel unit. The panel unit is composed of a series of planar panels which are edge connected together defining an enclosed area. The panel unit can be movable from a basically transverse position to an elongated position. When in the transverse position, the panel unit is to be mounted with adhesive tape onto the skin of a patient with the sharp end of the needle being inserted within the body of the patient. When the panel unit is in the elongated position, the needle is withdrawn from the body of the patient and the sharpened end of the needle is covered by the panels thereby preventing undesired needlestick injury to the medical practitioner that is installing and removing the enclosure.

Owner:CR BARD INC

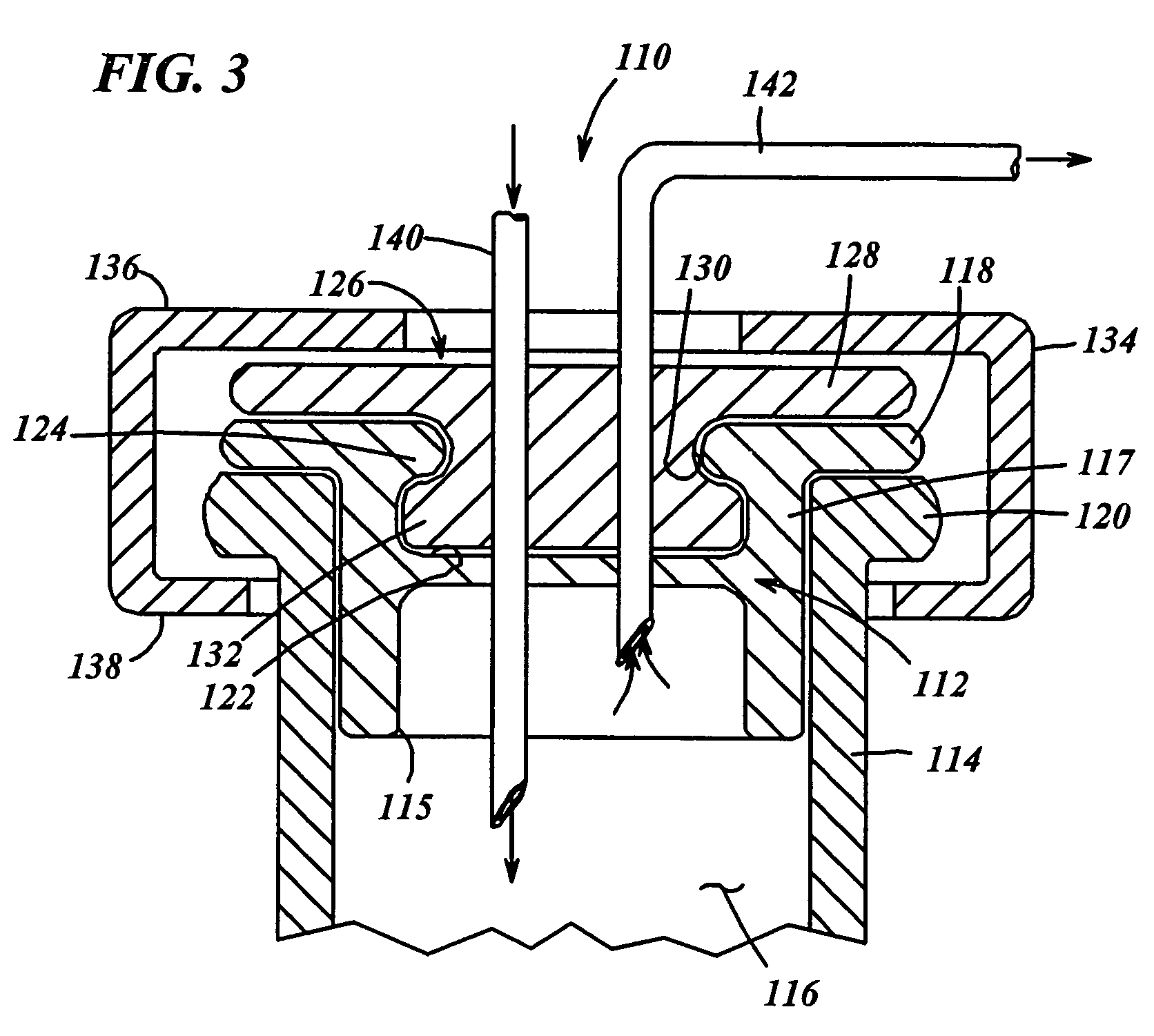

Systems and methods for detecting tissue contact and needle penetration depth

A system for detecting tissue contact and penetration depth. The system comprises a needle sheath having a needle sheath inner diameter and a needle sheath outer diameter. A first conductive region is disposed on the needle sheath inner diameter. A needle having a needle insulation layer on the outer diameter upon which a second conductive region is disposed within the first conductive region. A dielectric layer is disposed between the first conductive tube and the second conductive tube. A capacitance sensor is coupled to the first conductive region and the second conductive region.

Owner:ABBOTT CARDIOVASCULAR

Tissue sampling devices, systems and methods

ActiveUS8517955B2Minimize unintended injuryHigh strengthBronchoscopesGuide wiresNeedle penetrationMedicine

Methods, devices, and systems are described herein that allow for improved sampling of tissue from remote sites in the body. A tissue sampling device comprises a handle allowing single hand operation. In one variation the tissue sampling device includes a blood vessel scanning means and tissue coring means to excise a histology sample from a target site free of blood vessels. The sampling device also includes an adjustable stop to control the depth of a needle penetration. The sampling device may be used through a working channel of a bronchoscope.

Owner:BRONCUS MEDICAL

Knotless needling machine

The utility model relates to an endless needle punching machine, which belongs to the technical field of non-woven machinery. It includes the frame, the upper part of which is fixed with an upper top plate, the bottom is fixed with a base plate, and a pair of upper beams are fixed on the upper top plate; the needle beam and the needle beam driving mechanism are fixed on the bottom of the needle beam and the needle bed is arranged with needles; Pinhole plate; movable beam; movable beam opening and closing mechanism; movable beam lifting adjustment mechanism; features: the right end of the movable beam is set on the vertical shaft, and the vertical shaft is fixed between the upper top plate and the base, and the left end of the movable beam is formed as a free end. The opening and closing mechanism of the crossbeam includes a working cylinder, a pressing arm and a pressing block; an idler roller is arranged on the side of the movable crossbeam facing the pressing block, a tension roller is arranged on the other side, and a limit rod is fixed on the side of the right end of the movable crossbeam. Advantages: it can ensure the locking and opening of the movable beam; when the limit rod set on the movable beam is obstructed by the vertical shaft, the limit opening degree of the movable beam is limited; the movable beam can be lifted and lowered smoothly; the overall structure is simple.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

Safety Needle

ActiveUS20090012478A1Protect from harmInfusion syringesInfusion needlesNeedle penetrationSyringe needle

This invention relates to a safety needle to prevent needle stick injuries. The invention provides a safety needle accessory comprising a hollow needle having a base end and a sharp end, a hub surrounding the base end of the needle and having a connector for connection to an injection device, a sleeve surrounding the hub and slidable relative to the hub in an axial direction, an elastically deformable member, and a pack having a closed end covering the sharp end of the needle and an open end exposing the connector of the hub and which is releasably mounted over the needle, hub and sleeve. The sleeve is slidable in a first axial direction from a first position in which the needle is fully or partially covered by the sleeve to a second position in which the needle is exposed, via an intermediate position between the first and second positions in which the sharp end of the needle projects from the sleeve, and in a second axial direction from the second position to a third position in which the needle is fully covered by the sleeve. The deformable member is deformed by the sleeve sliding from the first to the second position and the force for sliding from the second to the third position is provided by the stored elastic energy in the deformable member. The closed end of the pack has a removable cap at a position on the pack such that removal of the cap exposes the sharp end of the needle but not the sleeve when the sleeve is in the intermediate position.

Owner:SALVUS TECH LTD

Systems and methods for detecting tissue contact and needle penetration depth

Systems and methods for determining tissue contact and penetration depth are provided. In one aspect, the system includes a needle and a pressure measurement assembly. The needle, in one exemplary embodiment, includes a first end and a second end with at least one aperture located a predetermined distance from the first end. The pressure measurement assembly is connected with a portion of the needle to measure pressure of fluid flowing through the needle. The pressure measurement assembly measures a first pressure when the needle contacts tissue and a second difference in pressure when the needle penetrates the tissue and the aperture becomes occluded.In an alternative aspect, the system includes a needle and a sensor. The sensor, in another exemplary embodiment, is coupled with a portion of the needle to detect tissue contact pressure on the sensor as the needle penetrates tissue and makes contact with the sensor. The sensor is located a predetermined distance from the first end of the needle.

Owner:ABBOTT CARDIOVASCULAR

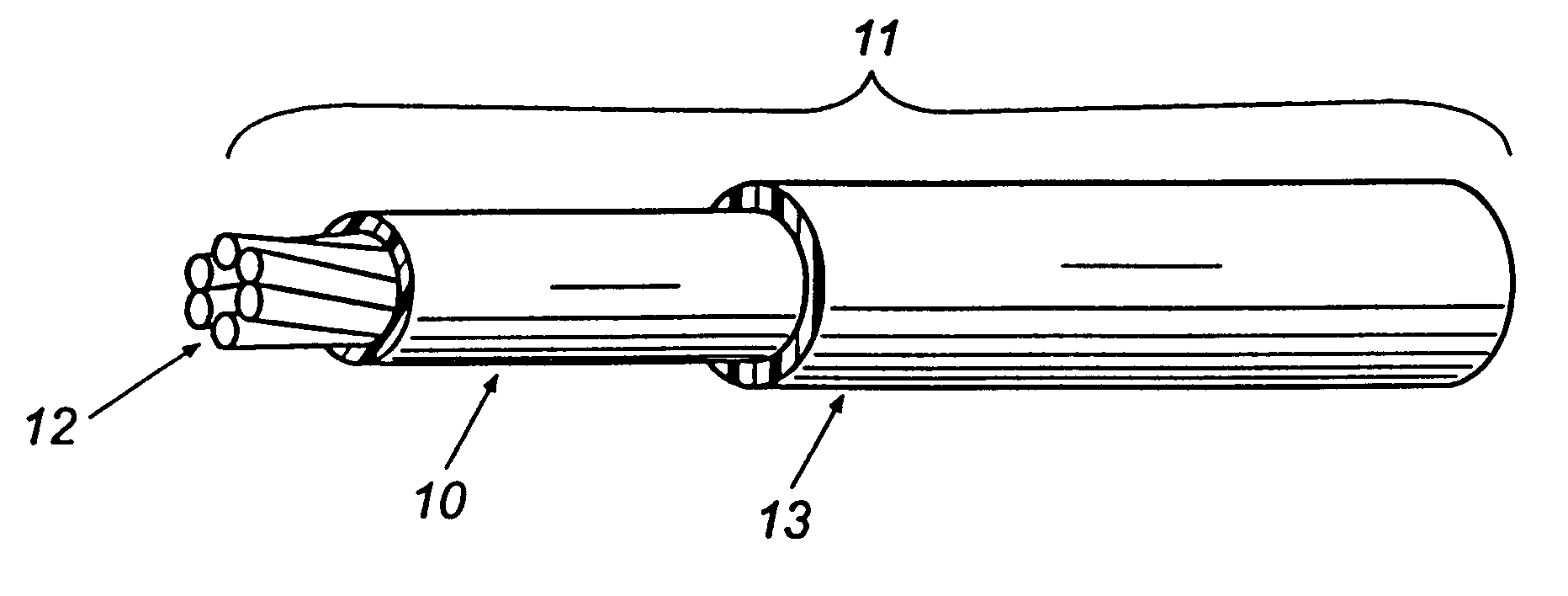

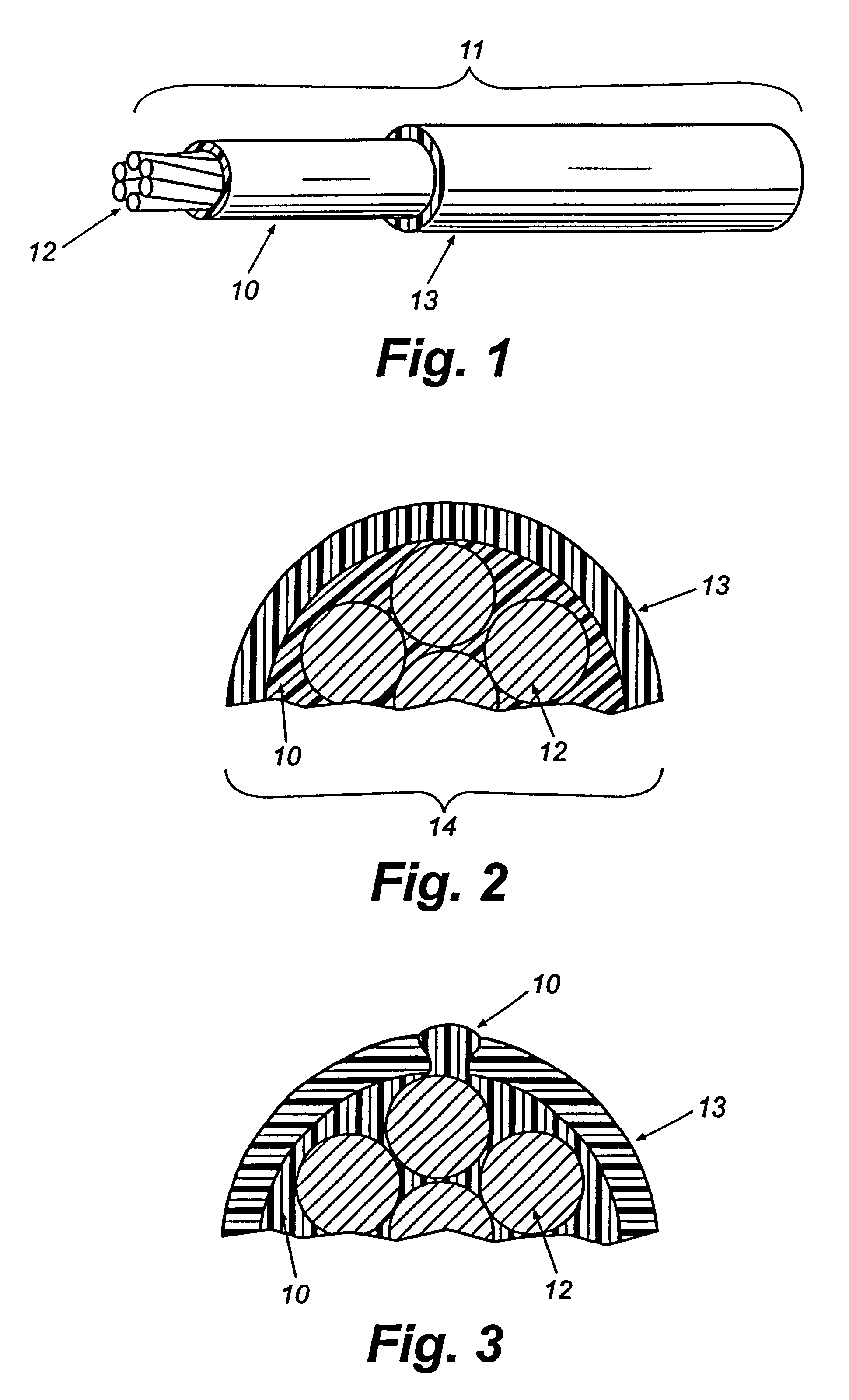

Electrical cable having a self-sealing agent and method for preventing water from contacting the conductor

InactiveUS6359231B2Plastic/resin/waxes insulatorsClimate change adaptationNeedle penetrationElectrical conductor

An electrical cable with a stranded central conductor encircled by insulation including a material which provides self-sealing properties to the cable present at least between the adjacent edges of the stranded conductor and the insulation. Preferably, the material is a polymeric material which is flowable at a temperature at least as low as 25° C. and has a 100 gram needle penetration value greater than 100 tenths of a millimeter at 25° C.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

Contaminant-reactive geocomposite mat and method of manufacture and use

InactiveUS20070206994A1Minimize breakageHollow inflatable ballsHollow non-inflatable ballsPorosityFiber

Reactive geocomposite mats, and their method of manufacture, for treating contaminants in sediment, soil or water that allow the passage of essentially non-contaminated water therethrough. The geocomposite mat includes a pre-formed woven or non-woven geotextile, that is needlepunched to an outer geotextile sheet layer to provide a high loft, structurally secured, pre-formed geotextile having a thickness of about 6 mm to about 200 mm, and having, a porosity sufficient to receive a powdered or granular contaminant-reactive material, contaminant-sorptive material, or a contaminant-neutralizing material (hereinafter collectively referred to as “contaminant-reactant material” or “contaminant-reactive material”) throughout its thickness, or in any portion of the thickness across its entire major surface(s). The powdered or granular contaminant-reactive material is disposed within the pores of the previously formed, high loft geotextile mat to surround the fibers, e.g., by vacuum or vibrating the high loft mat while in contact with the contaminant-reactive material to allow the powdered or granular contaminant-reactive material to flow by gravity into the pores of the previously formed, needlepunched geotextile. A liquid-permeable outer geotextile sheet then is secured to the filled geotextile, preferably by heating upwardly extending fibers of the pre-formed geotextile mat to prevent the powdered or granular material from escaping from the geotextile during transportation and installation.

Owner:AMCOL INTERNATIONAL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com