Patents

Literature

43 results about "Geocomposite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The basic philosophy behind geocomposite materials is to combine the best features of different materials in such a way that specific applications are addressed in the optimal manner and at minimum cost. Thus, the benefit/cost ratio is maximized. Such geocomposites will generally be geosynthetic materials, but not always. In some cases it may be more advantageous to use a nonsynthetic material with a geosynthetic one for optimum performance and/or least cost. As seen in the following, the number of possibilities is huge — the only limits being one's ingenuity and imagination.

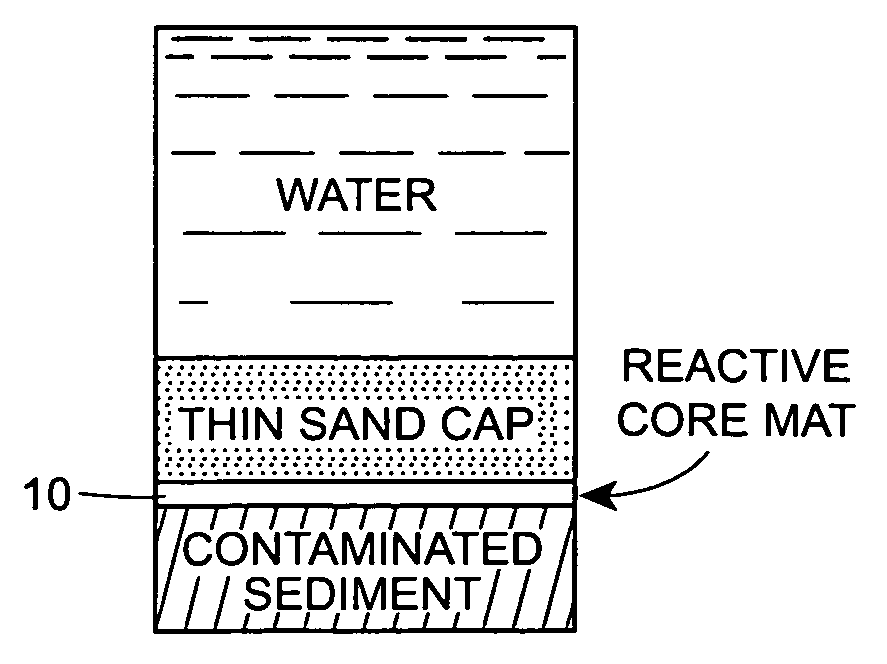

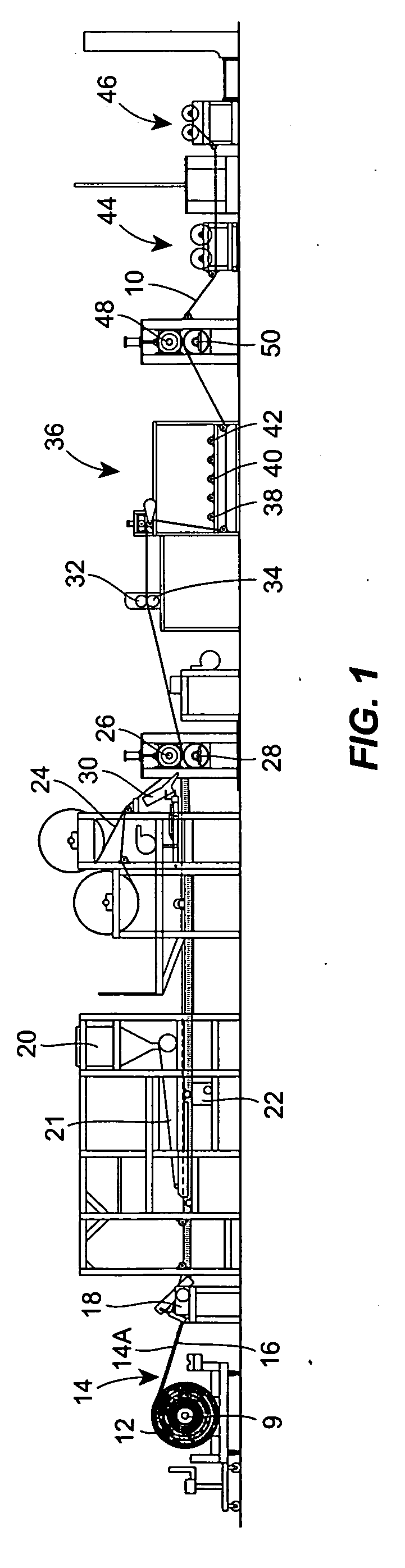

Contaminant-reactive geocomposite mat and method of manufacture and use

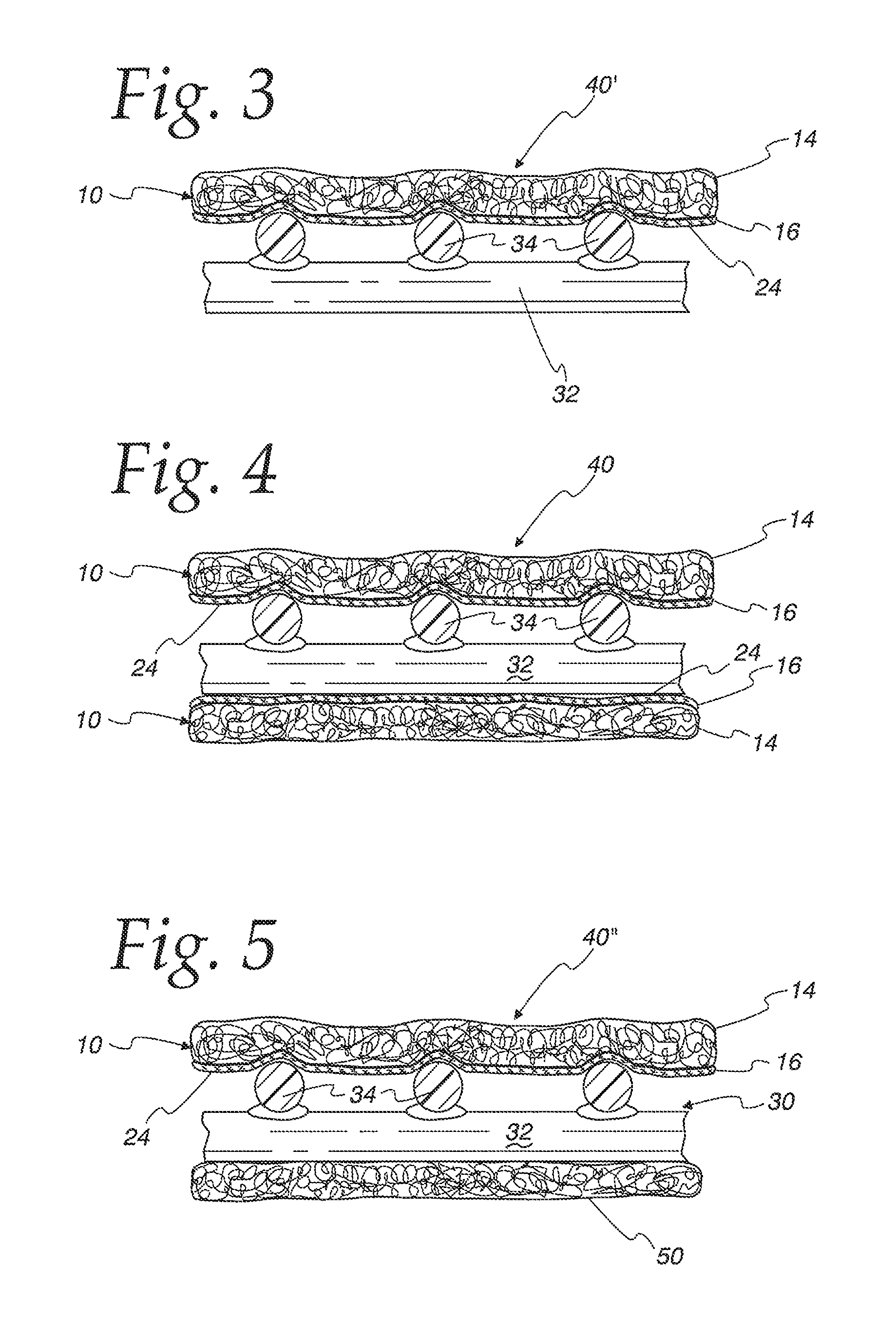

InactiveUS20070206994A1Minimize breakageHollow inflatable ballsHollow non-inflatable ballsPorosityFiber

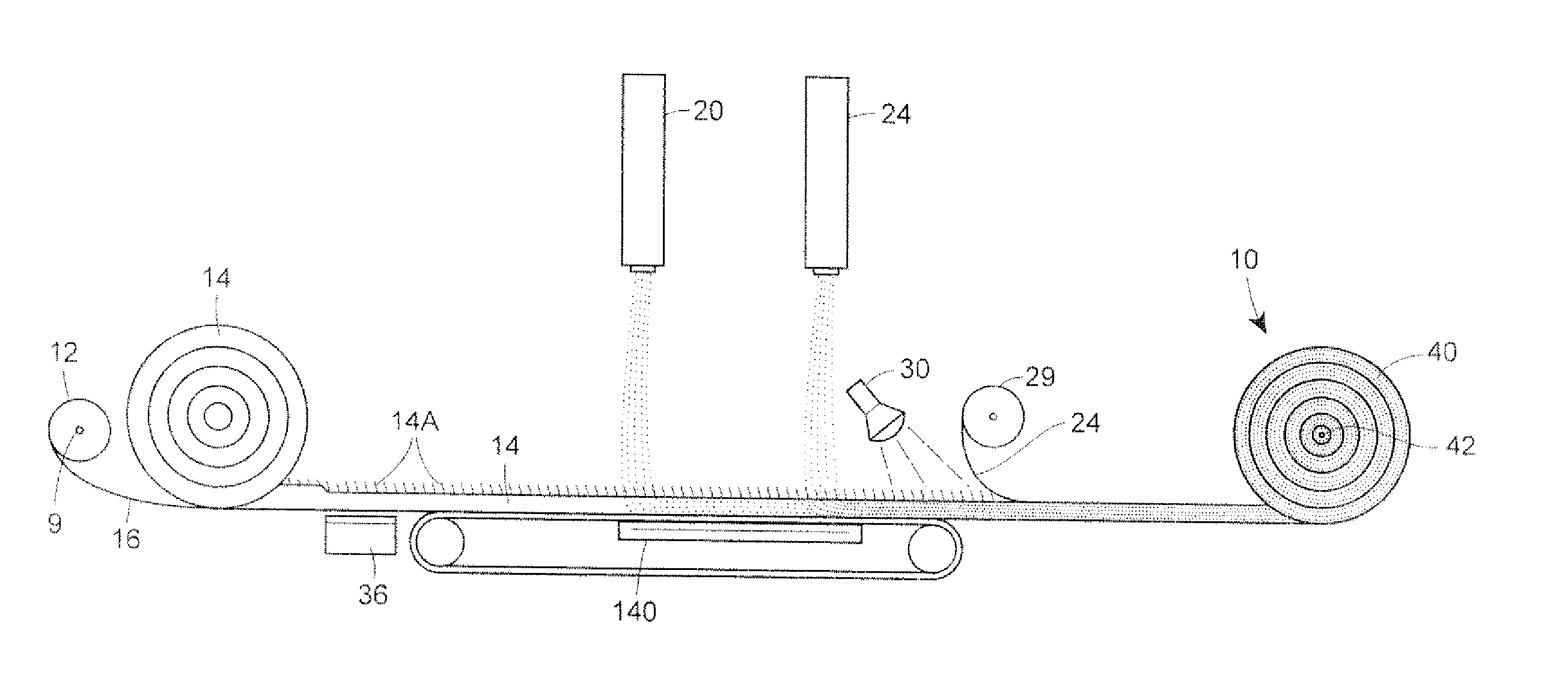

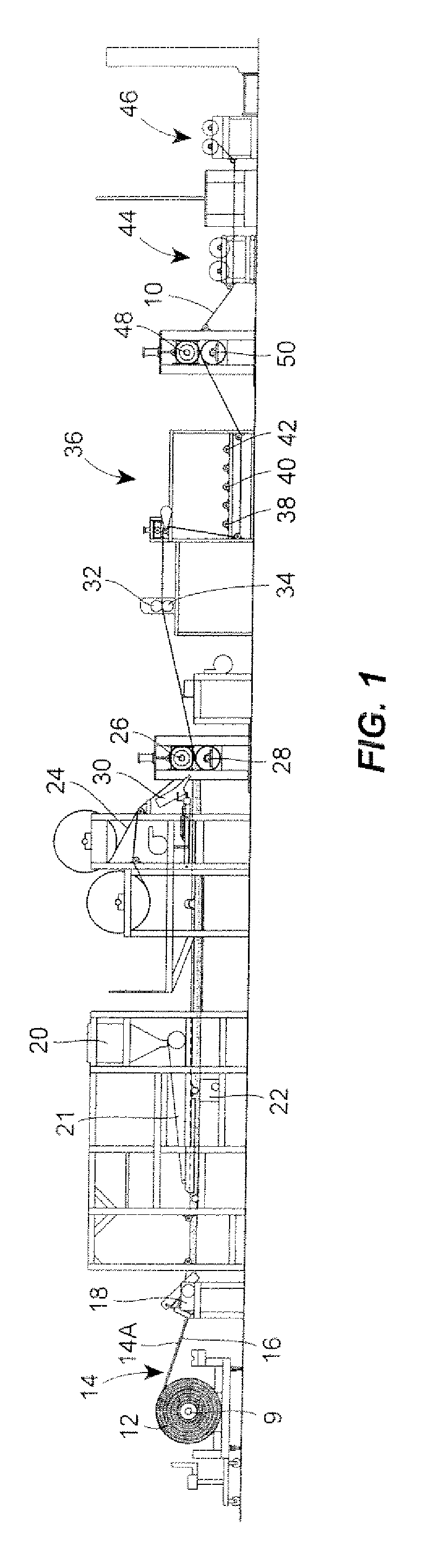

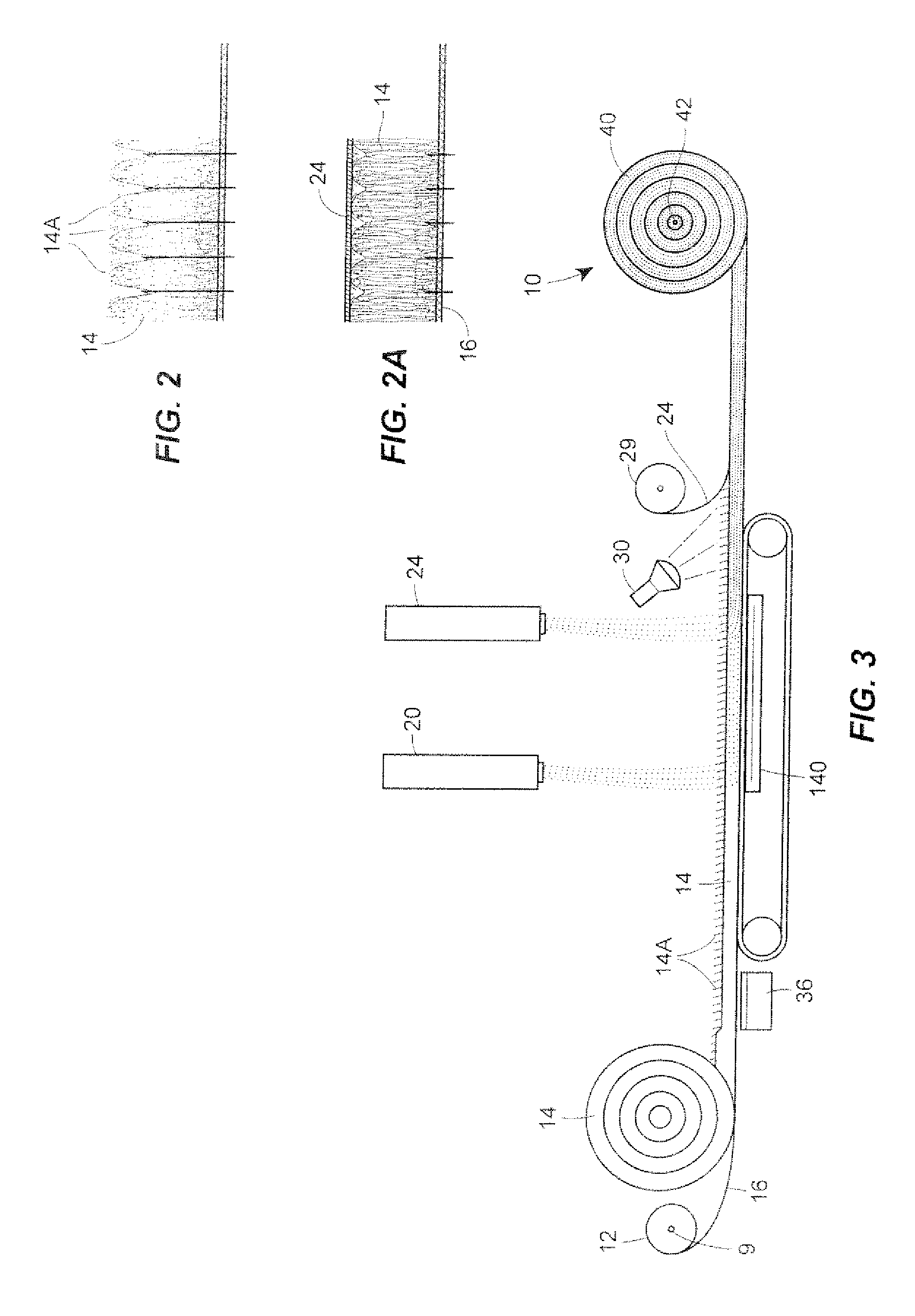

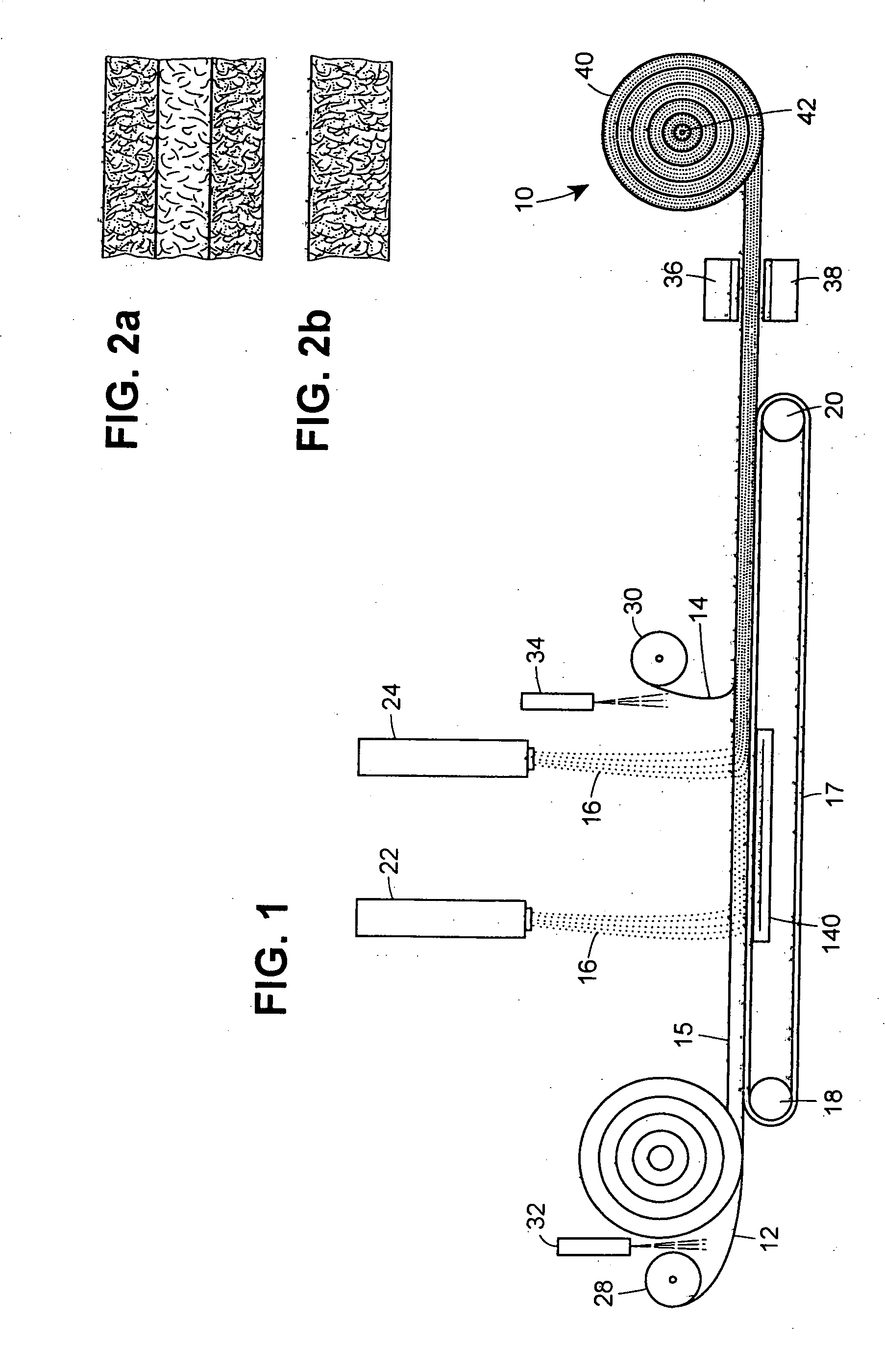

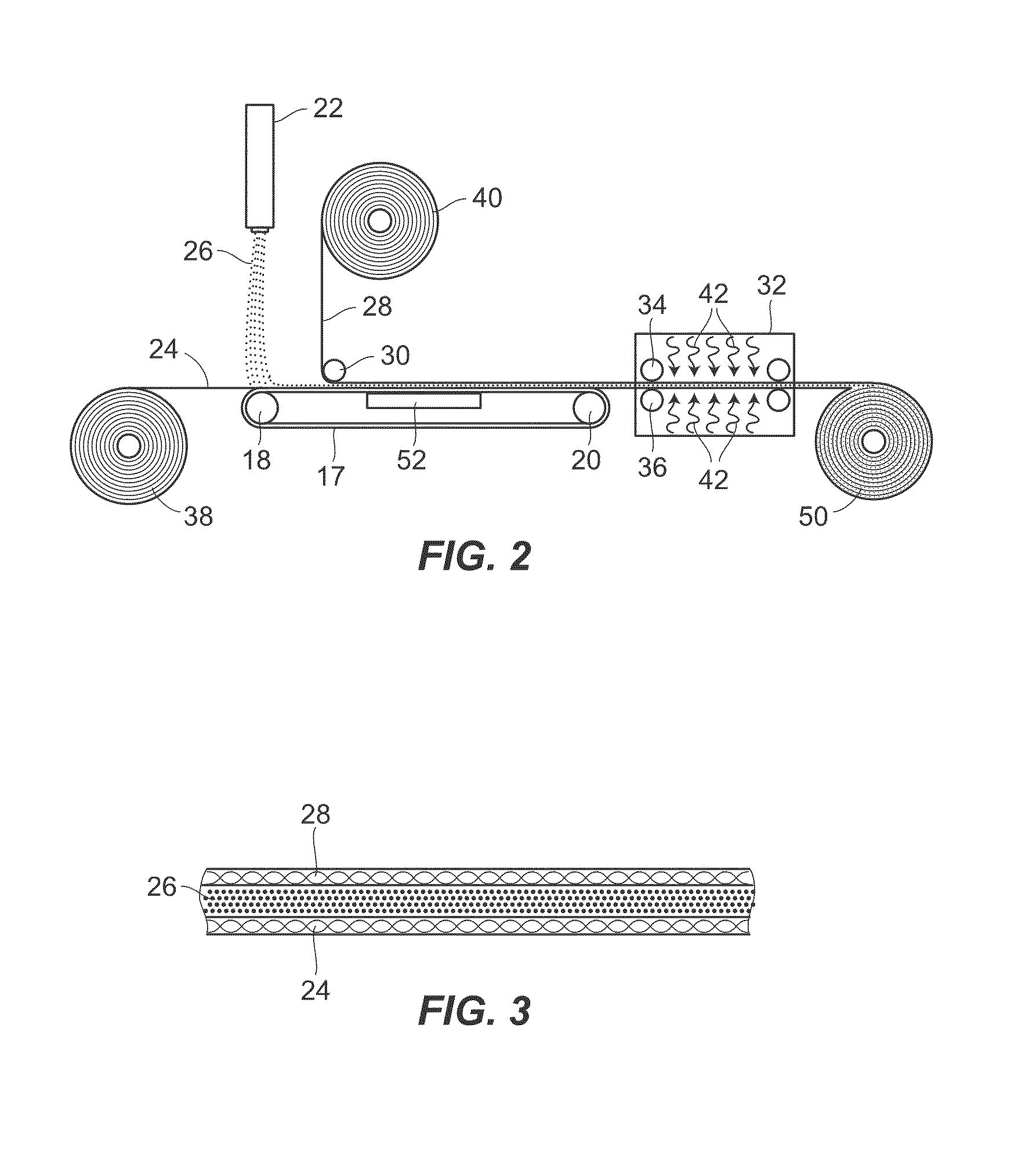

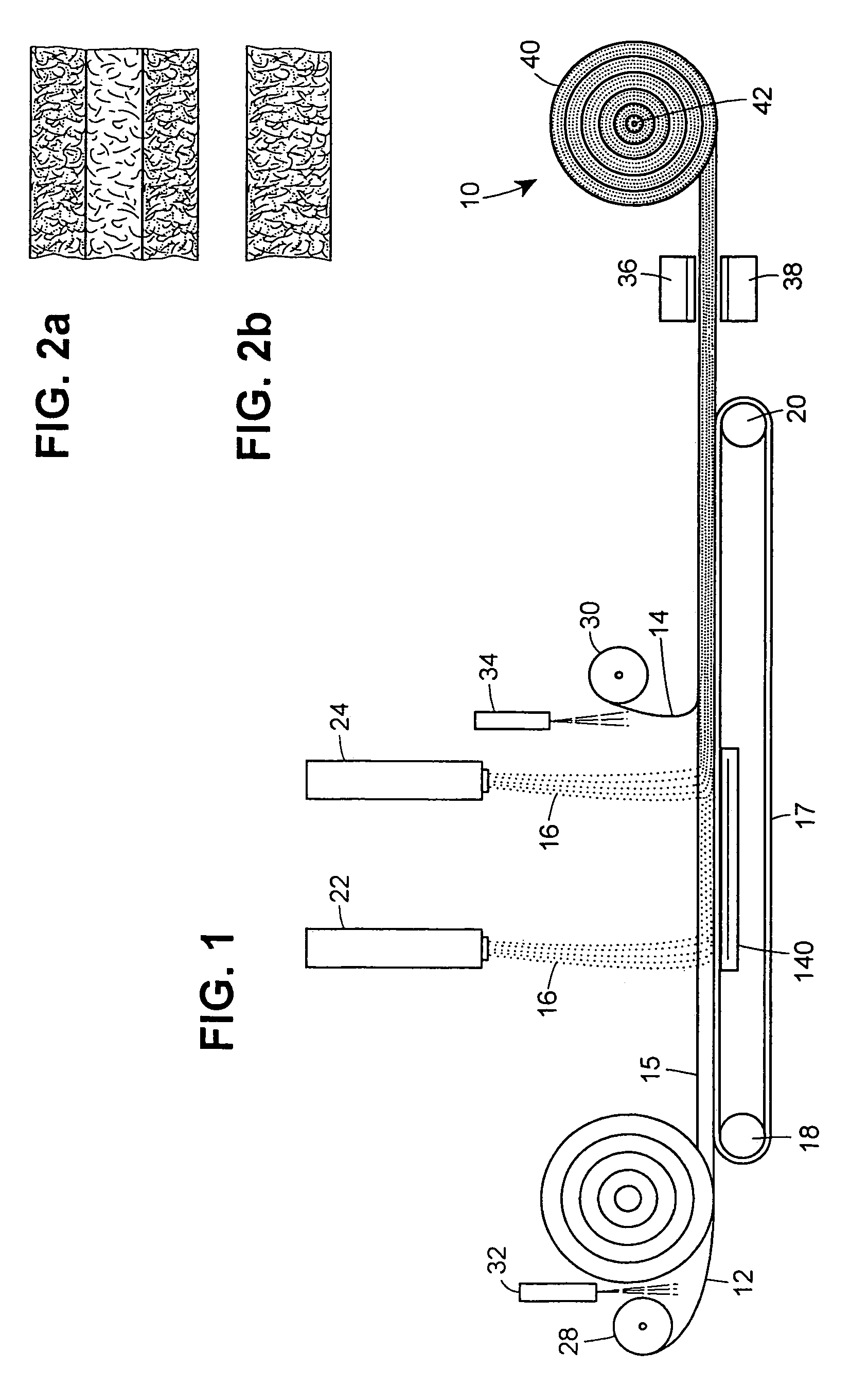

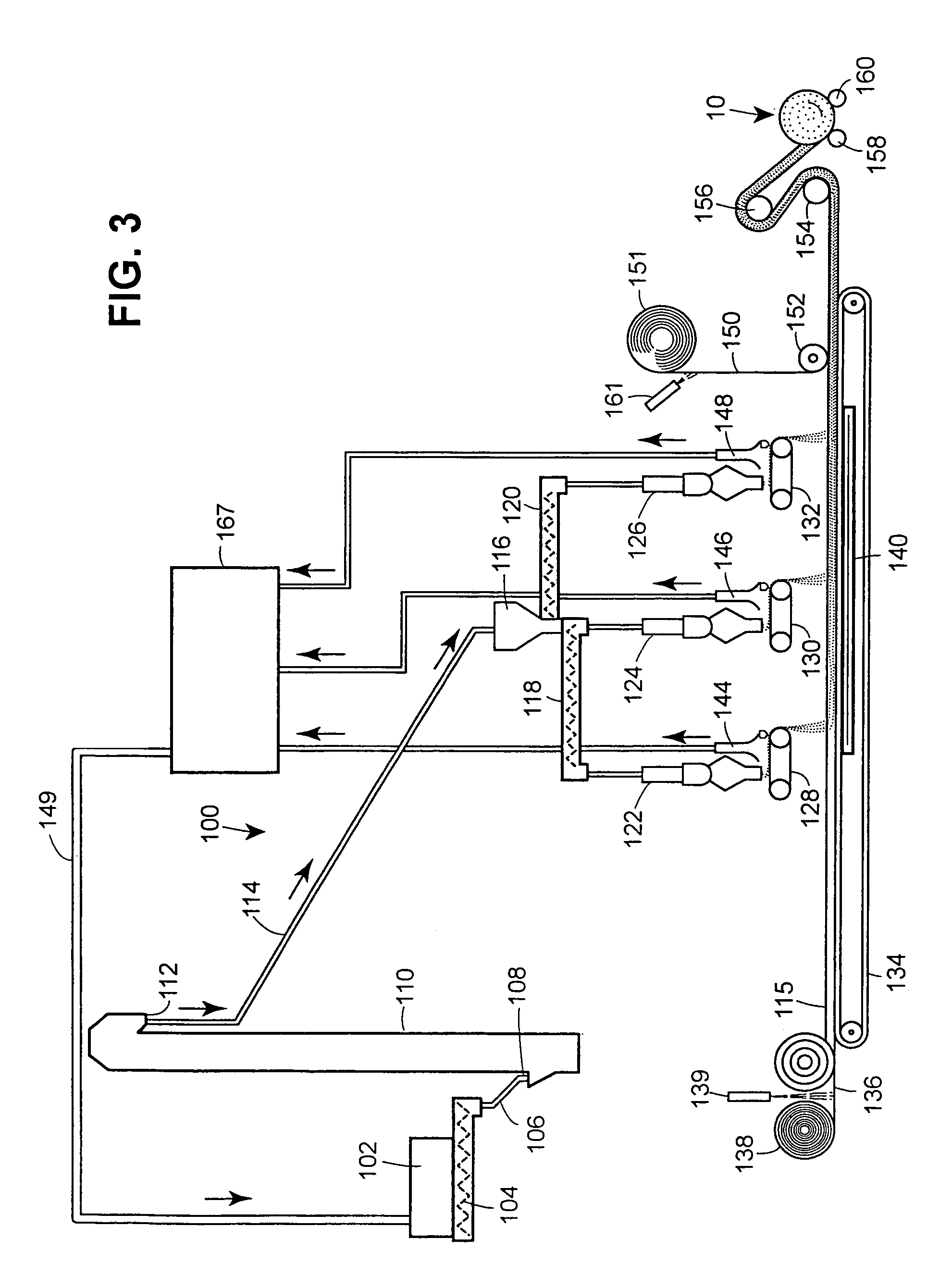

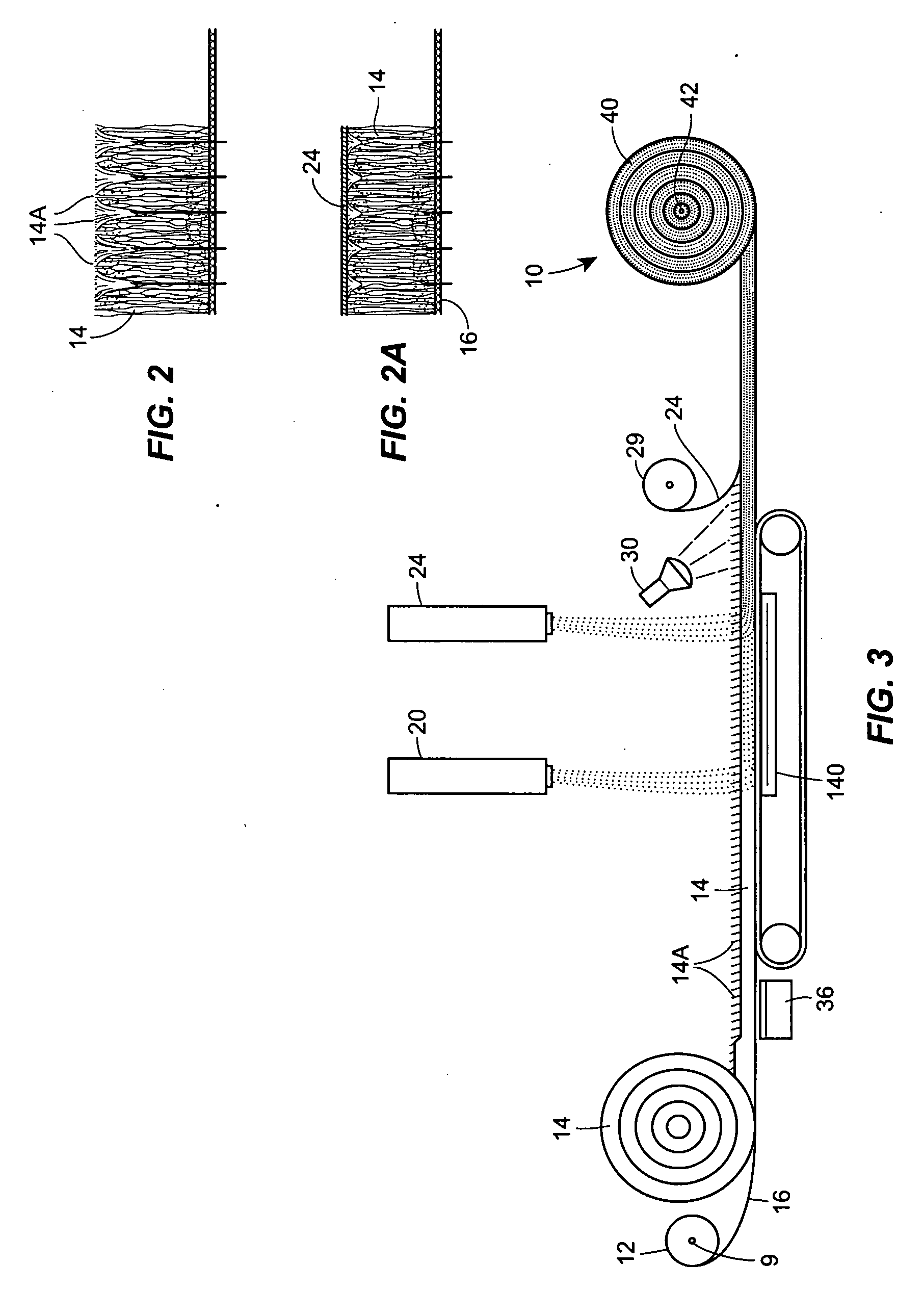

Reactive geocomposite mats, and their method of manufacture, for treating contaminants in sediment, soil or water that allow the passage of essentially non-contaminated water therethrough. The geocomposite mat includes a pre-formed woven or non-woven geotextile, that is needlepunched to an outer geotextile sheet layer to provide a high loft, structurally secured, pre-formed geotextile having a thickness of about 6 mm to about 200 mm, and having, a porosity sufficient to receive a powdered or granular contaminant-reactive material, contaminant-sorptive material, or a contaminant-neutralizing material (hereinafter collectively referred to as “contaminant-reactant material” or “contaminant-reactive material”) throughout its thickness, or in any portion of the thickness across its entire major surface(s). The powdered or granular contaminant-reactive material is disposed within the pores of the previously formed, high loft geotextile mat to surround the fibers, e.g., by vacuum or vibrating the high loft mat while in contact with the contaminant-reactive material to allow the powdered or granular contaminant-reactive material to flow by gravity into the pores of the previously formed, needlepunched geotextile. A liquid-permeable outer geotextile sheet then is secured to the filled geotextile, preferably by heating upwardly extending fibers of the pre-formed geotextile mat to prevent the powdered or granular material from escaping from the geotextile during transportation and installation.

Owner:AMCOL INTERNATIONAL CORPORATION

Contaminant-reactive geocomposite mat and method of manufacture and use

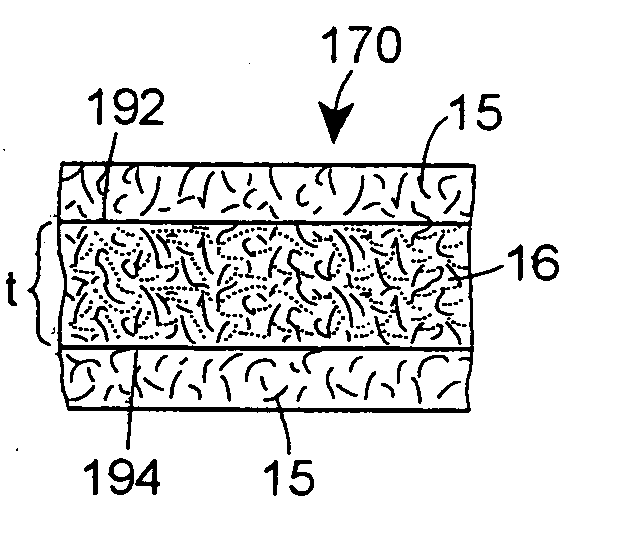

Reactive geocomposite mats, and their method of manufacture, for treating contaminants in soil or water that allow the passage of essentially non-contaminated water therethrough. The geocomposite mat includes a pre-formed woven or non-woven geotextile, having a thickness of about 6 mm to about 200 mm, and having, a porosity sufficient to receive a powdered or granular contaminant-reactive material, contaminant-sorptive material, or a contaminant-neutralizing material (hereinafter collectively referred to as “contaminant-reactant material” or “contaminant-reactive material”) throughout its thickness, or in any portion of the thickness across its entire major surface(s). The powdered or granular contaminant-reactive material is disposed within the pores of the previously formed, high loft geotextile mat to surround the fibers, e.g., by vacuum or vibrating the high loft mat while in contact with the contaminant-reactive material to allow the powdered or granular contaminant-reactive material to flow by gravity into the pores of the previously formed geotextile and vibrational forces. Liquid-permeable cover sheets are adhered to the upper and lower major surfaces of the filled geotextile to prevent the powdered or granular material from escaping from the geotextile during transportation and installation.

Owner:AMCOL INTERNATIONAL CORPORATION

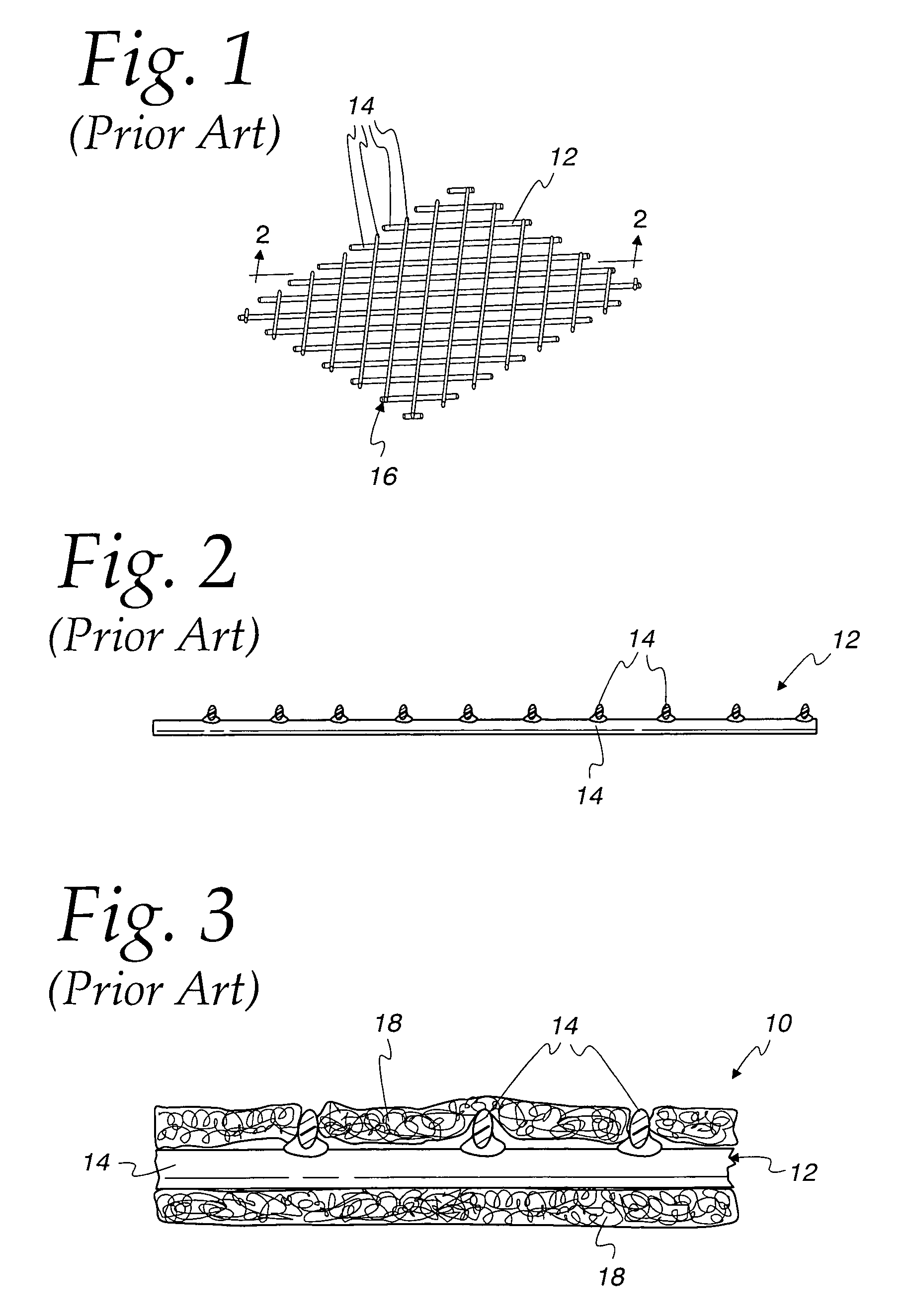

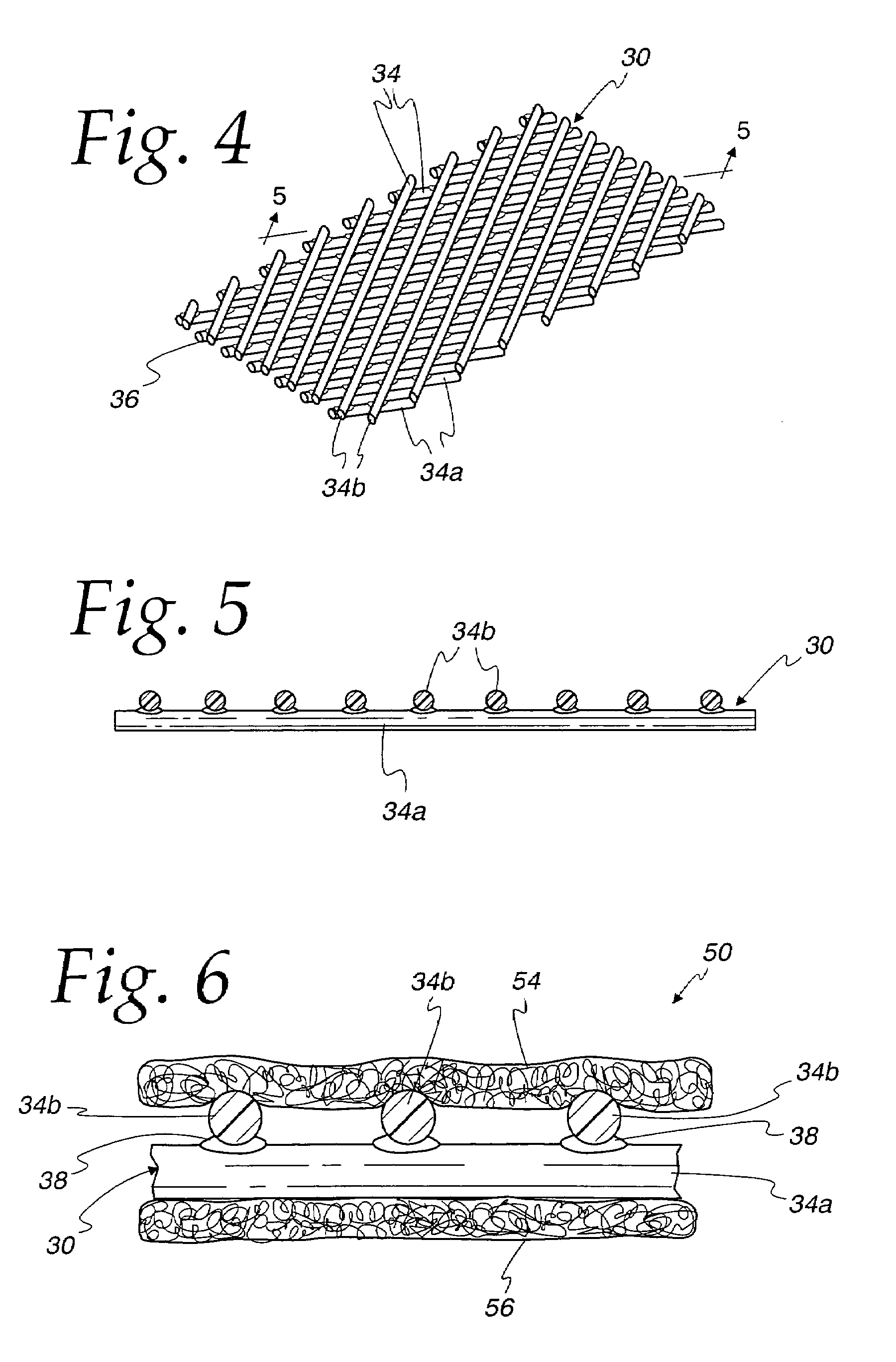

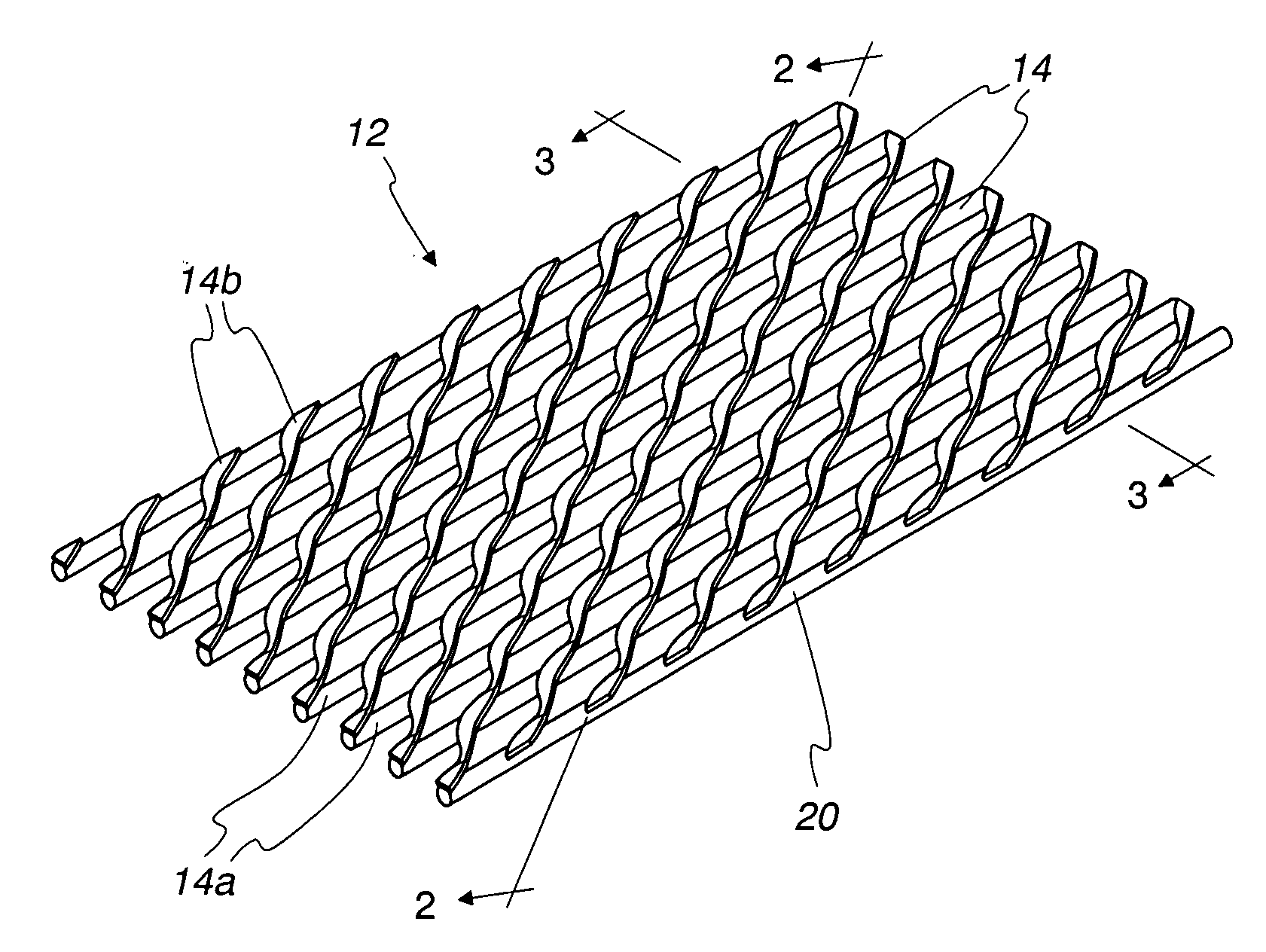

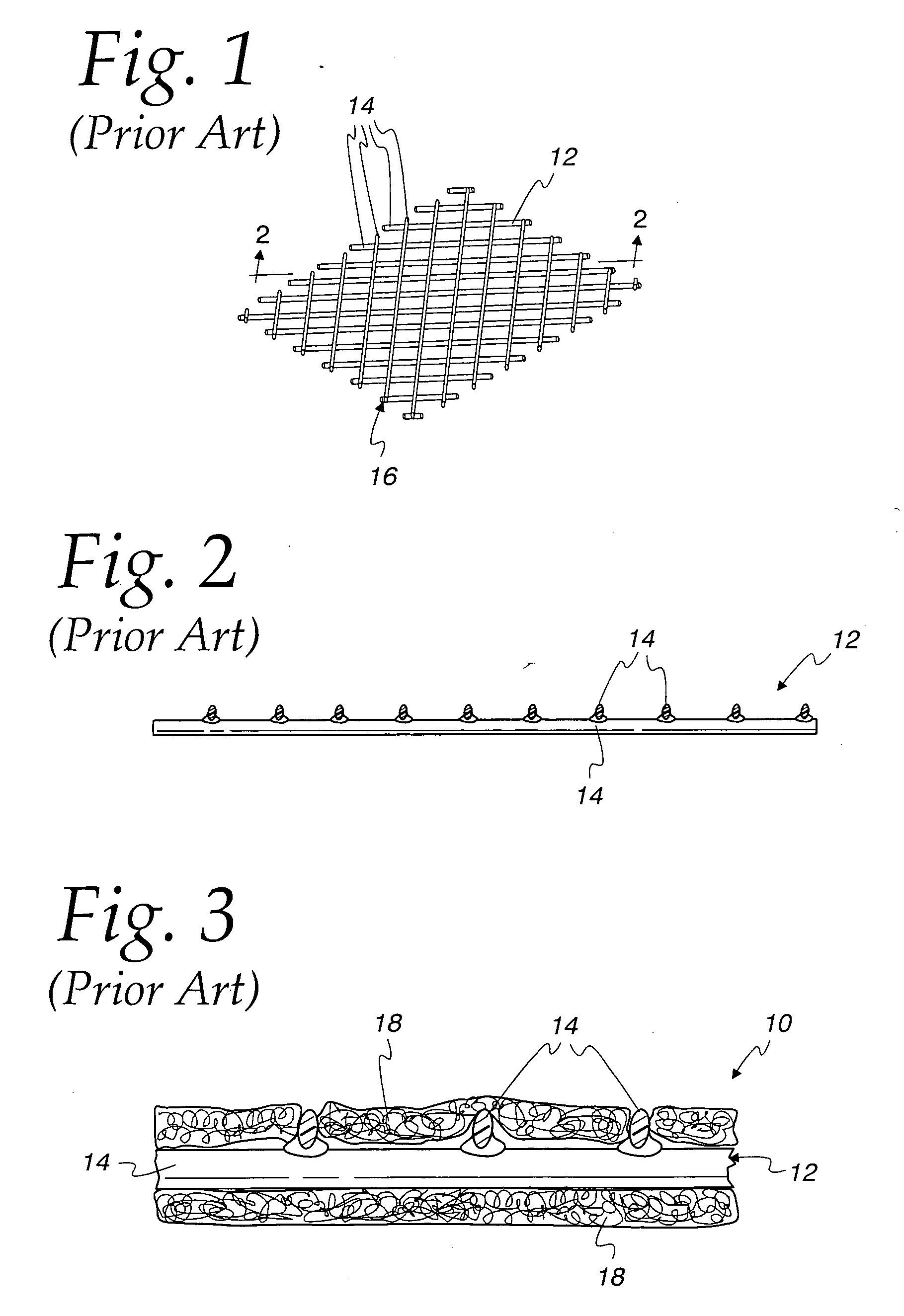

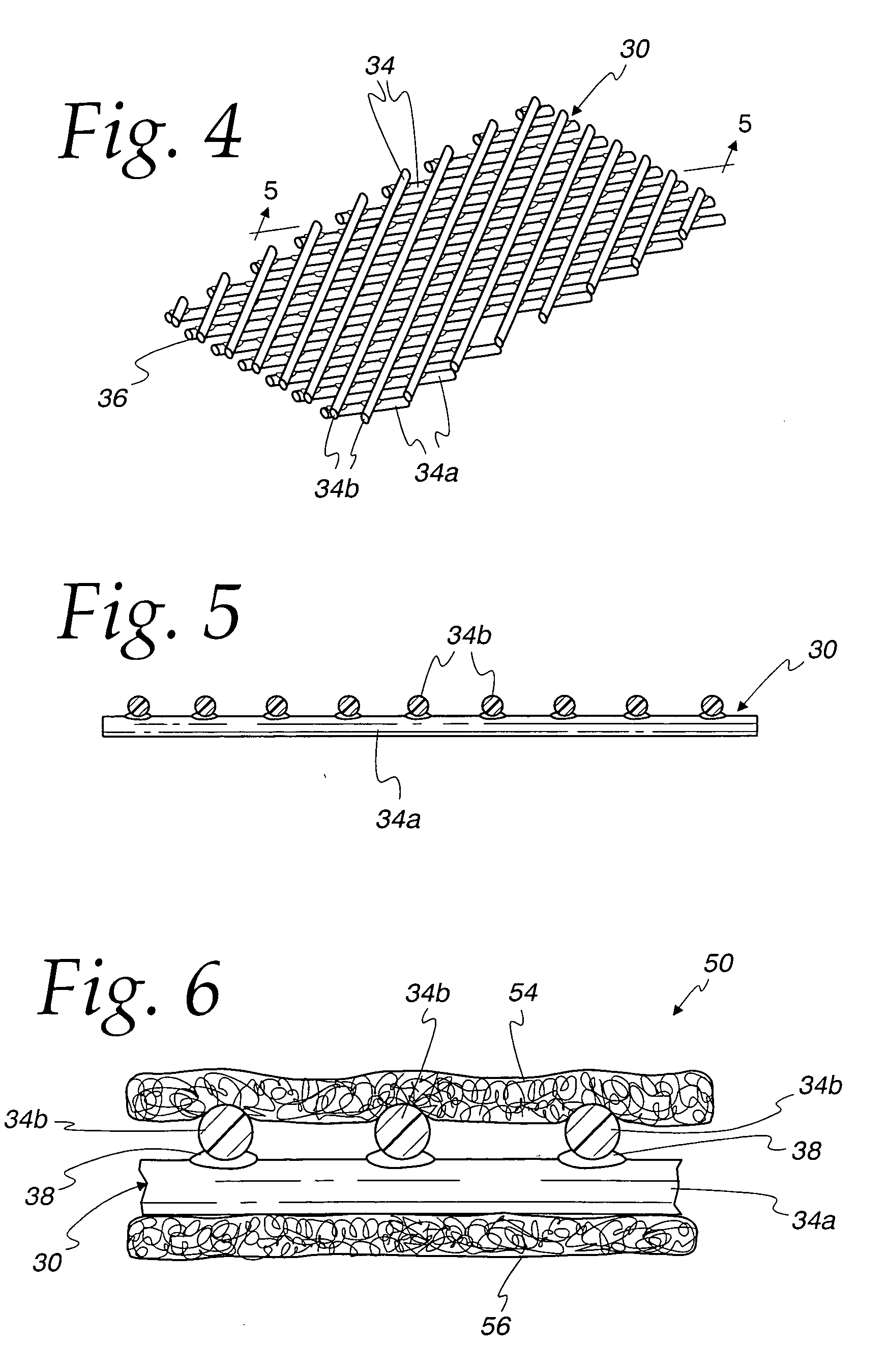

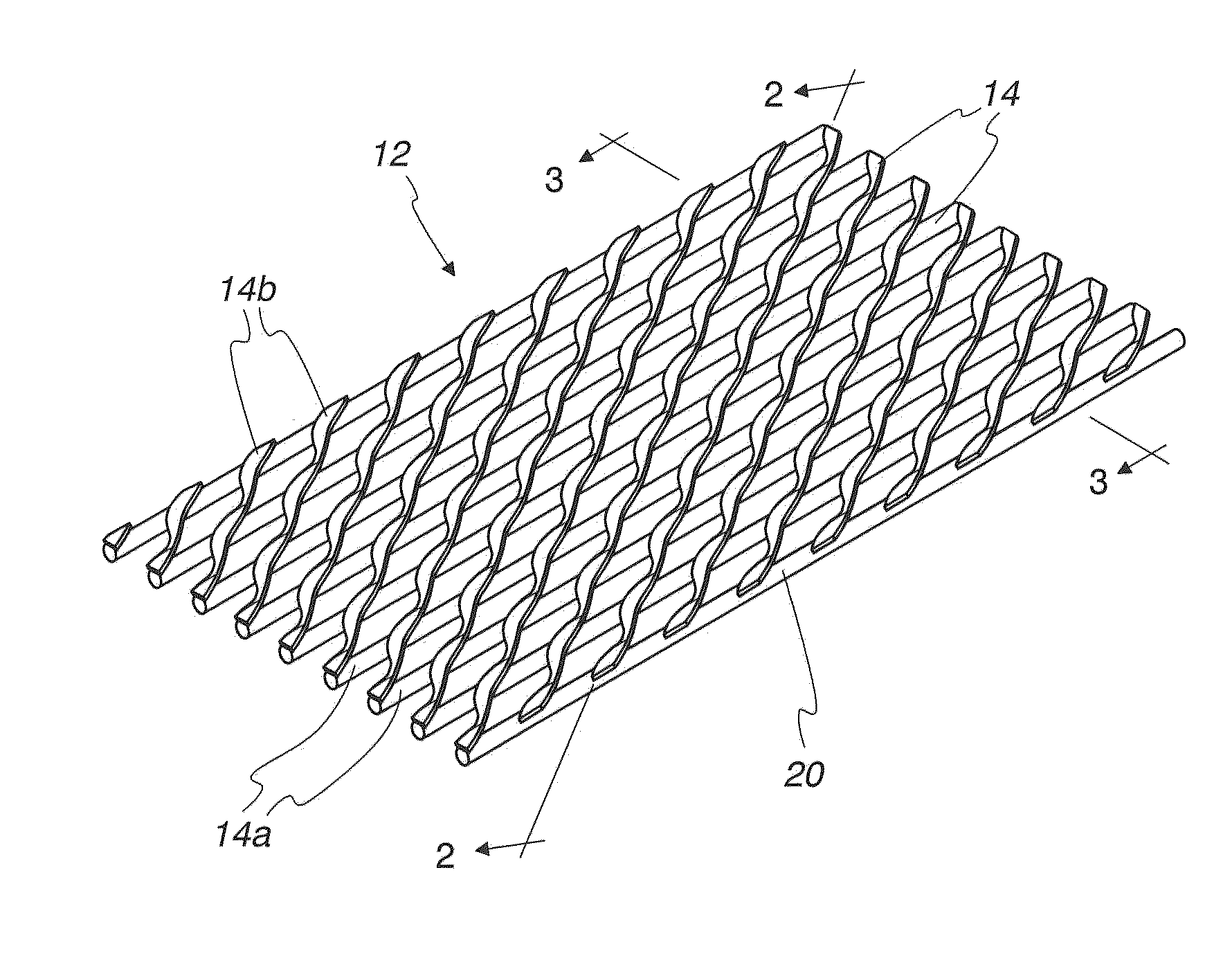

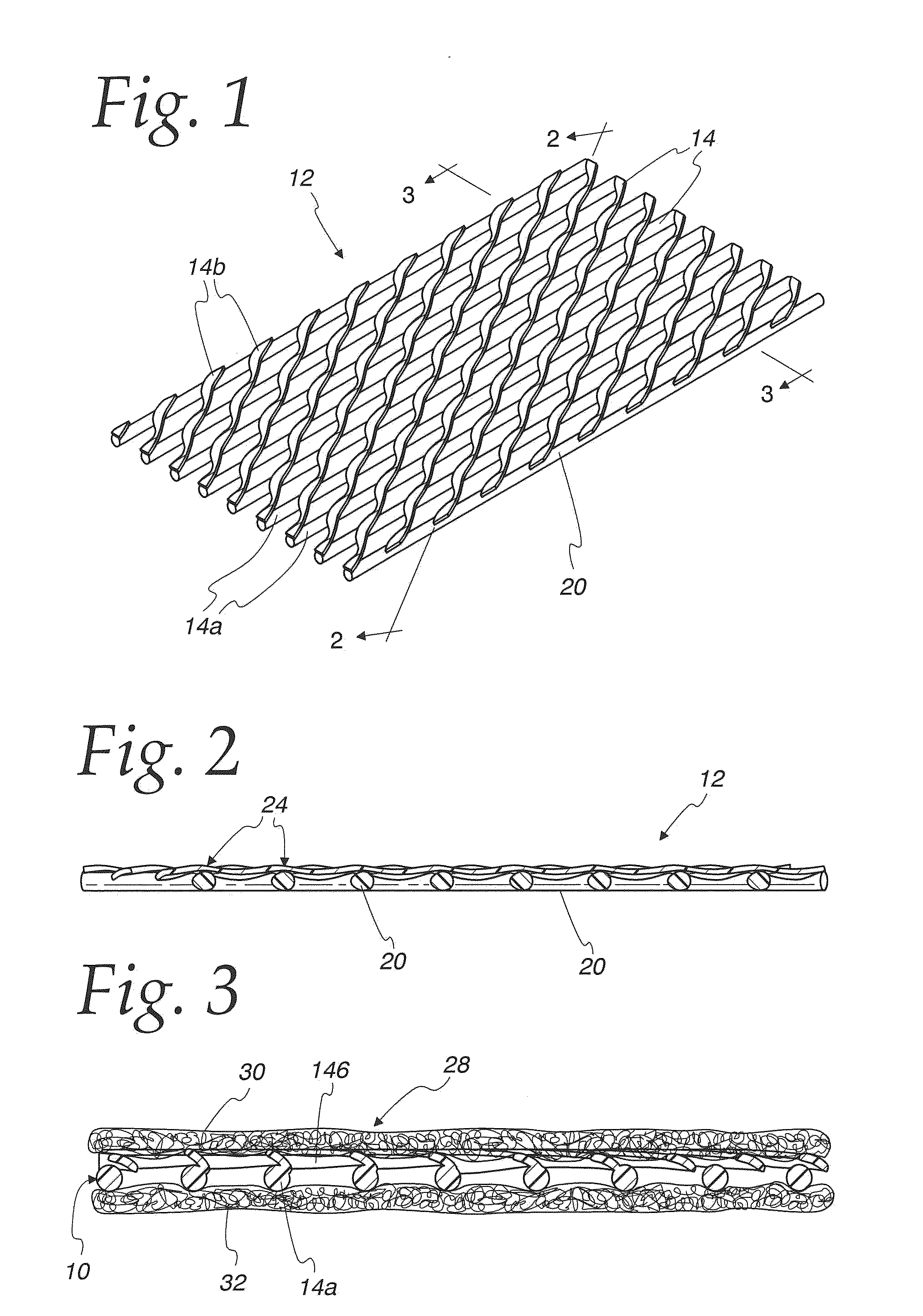

Geonet for a geocomposite

A geocomposite for use in a landfill, including a geonet and a geotextile bonded to at least one side of the geonet. The geonet includes a first plurality of substantially parallel strands, and a second plurality of substantially parallel strands disposed on top of the first plurality of strands, the second plurality of strands being at an angle relative to the first plurality of strands. The first and second plurality of strands are substantially incompressible and secured to one another at crossover locations, and are substantially round in cross-section.

Owner:GSE ENVIRONMENTAL

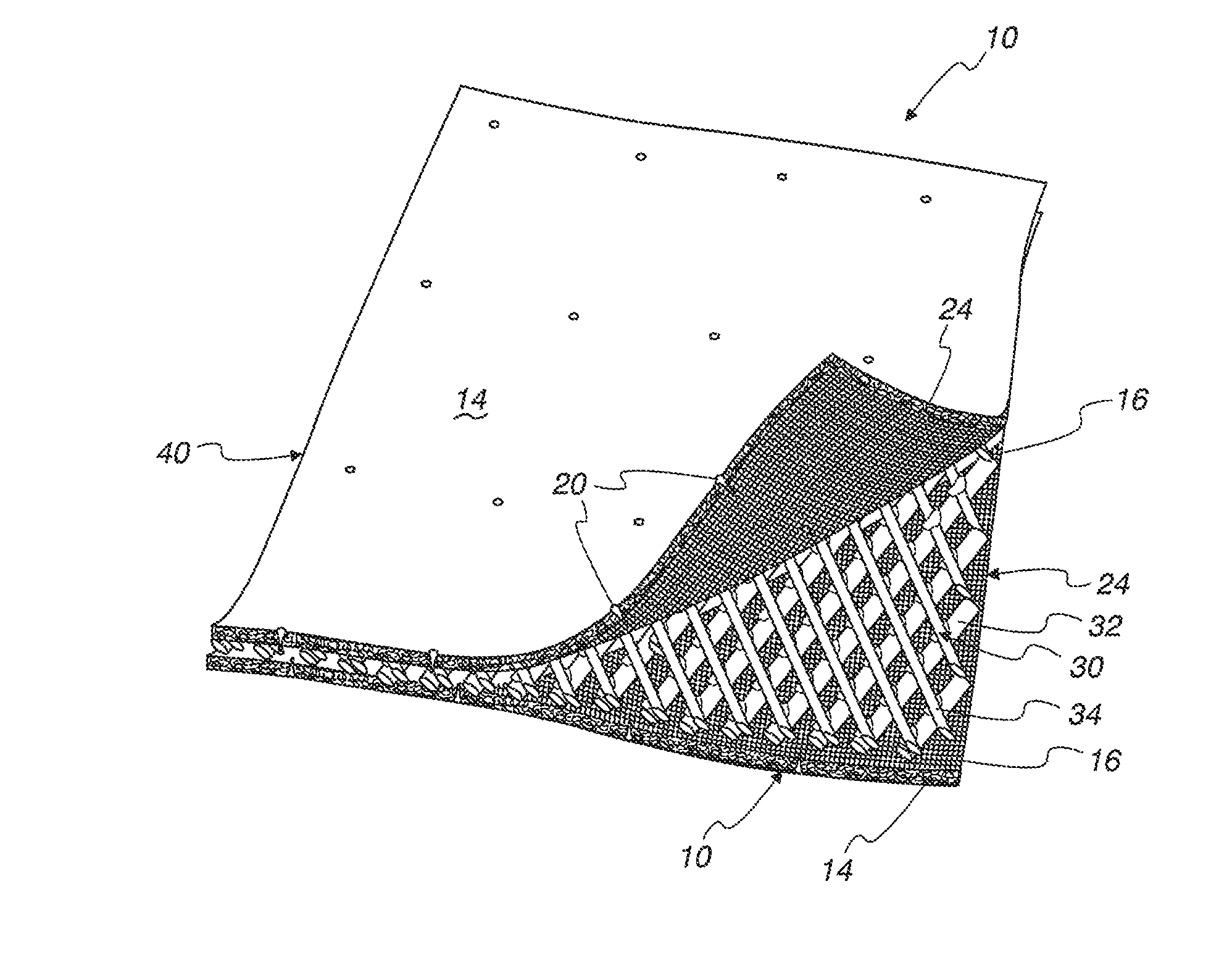

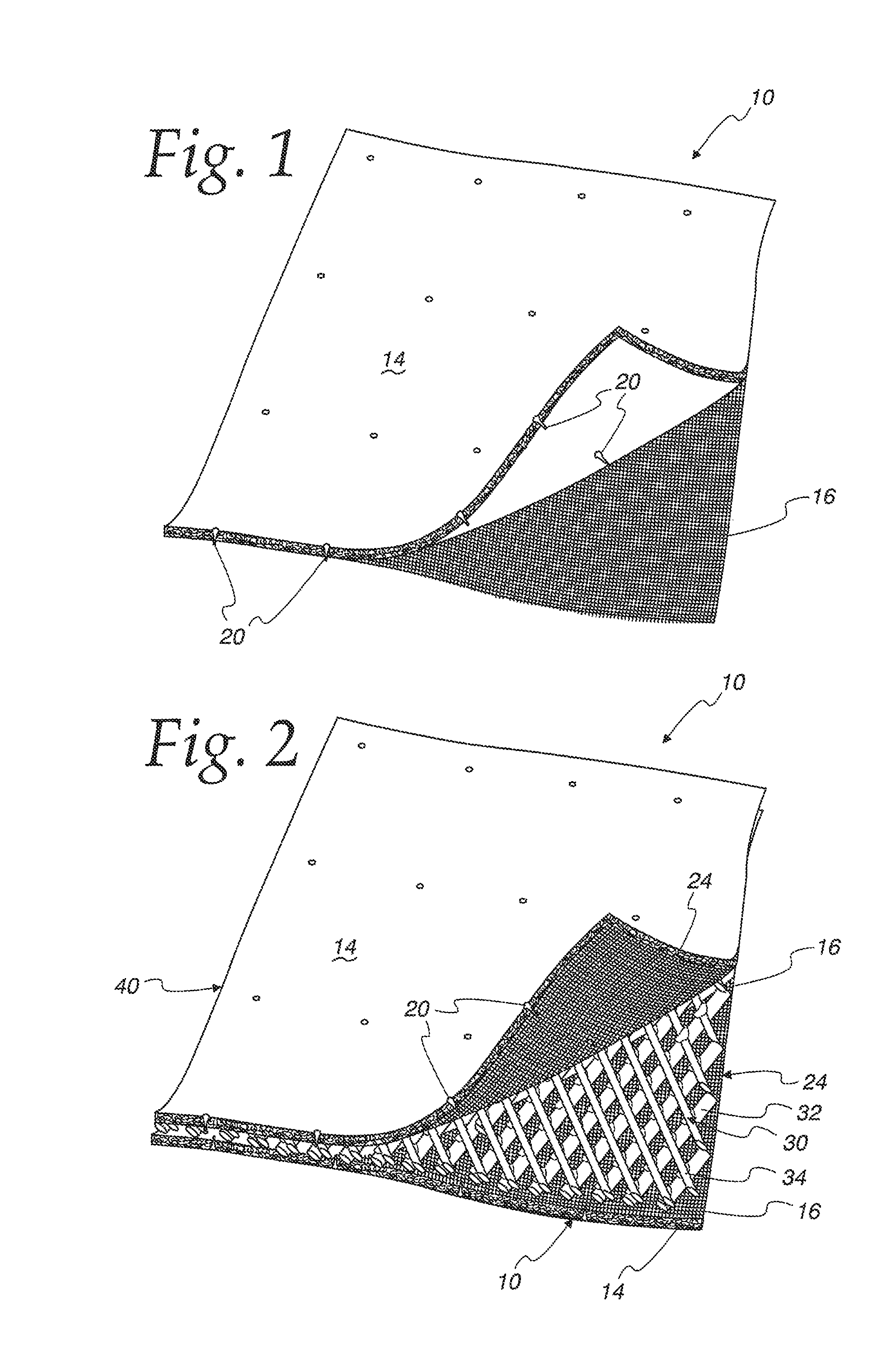

Self Healing Salt Water Barrier

ActiveUS20110177736A1Prevent penetrationProtective equipmentSynthetic resin layered productsCross-linkSelf-healing

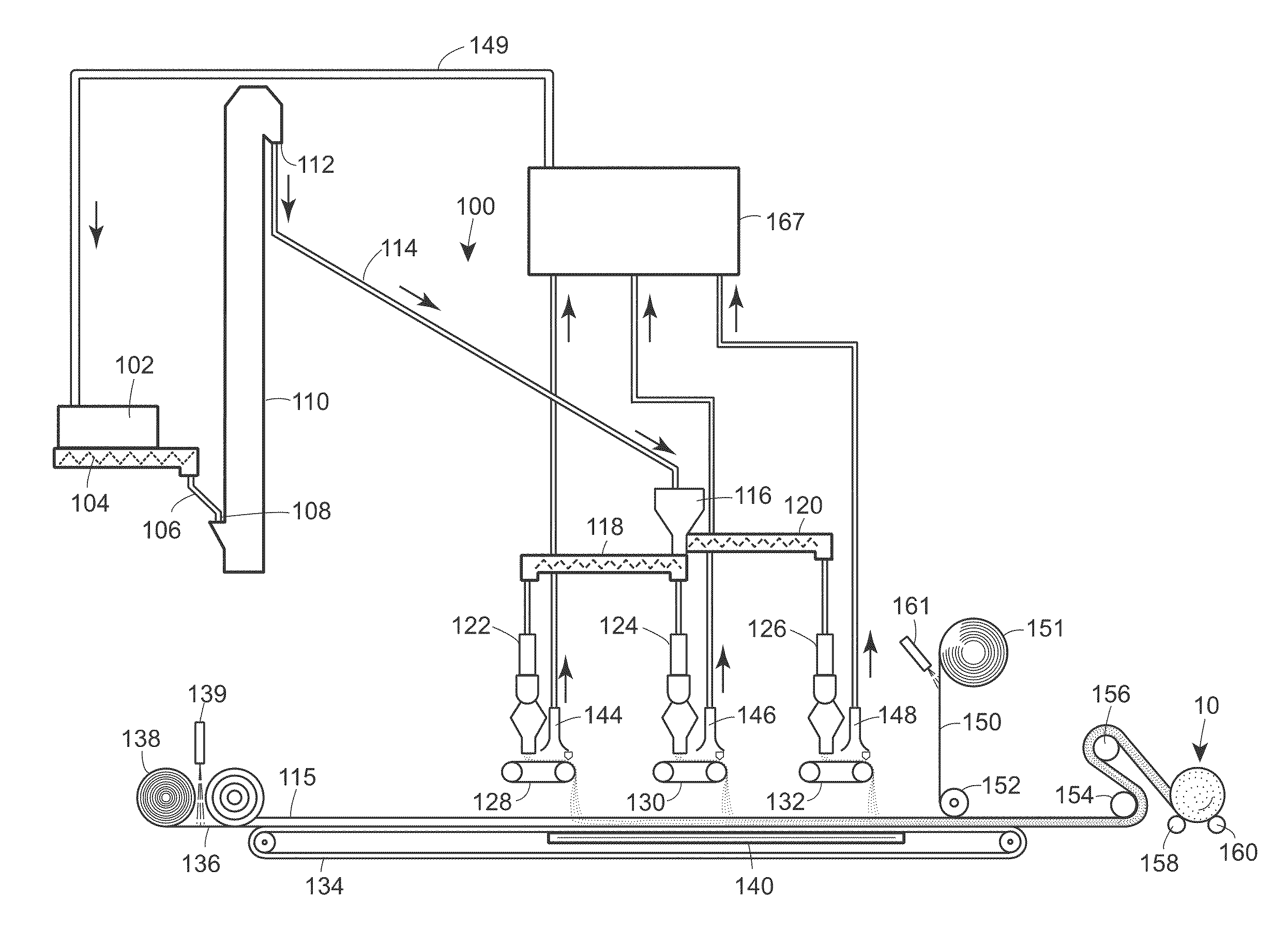

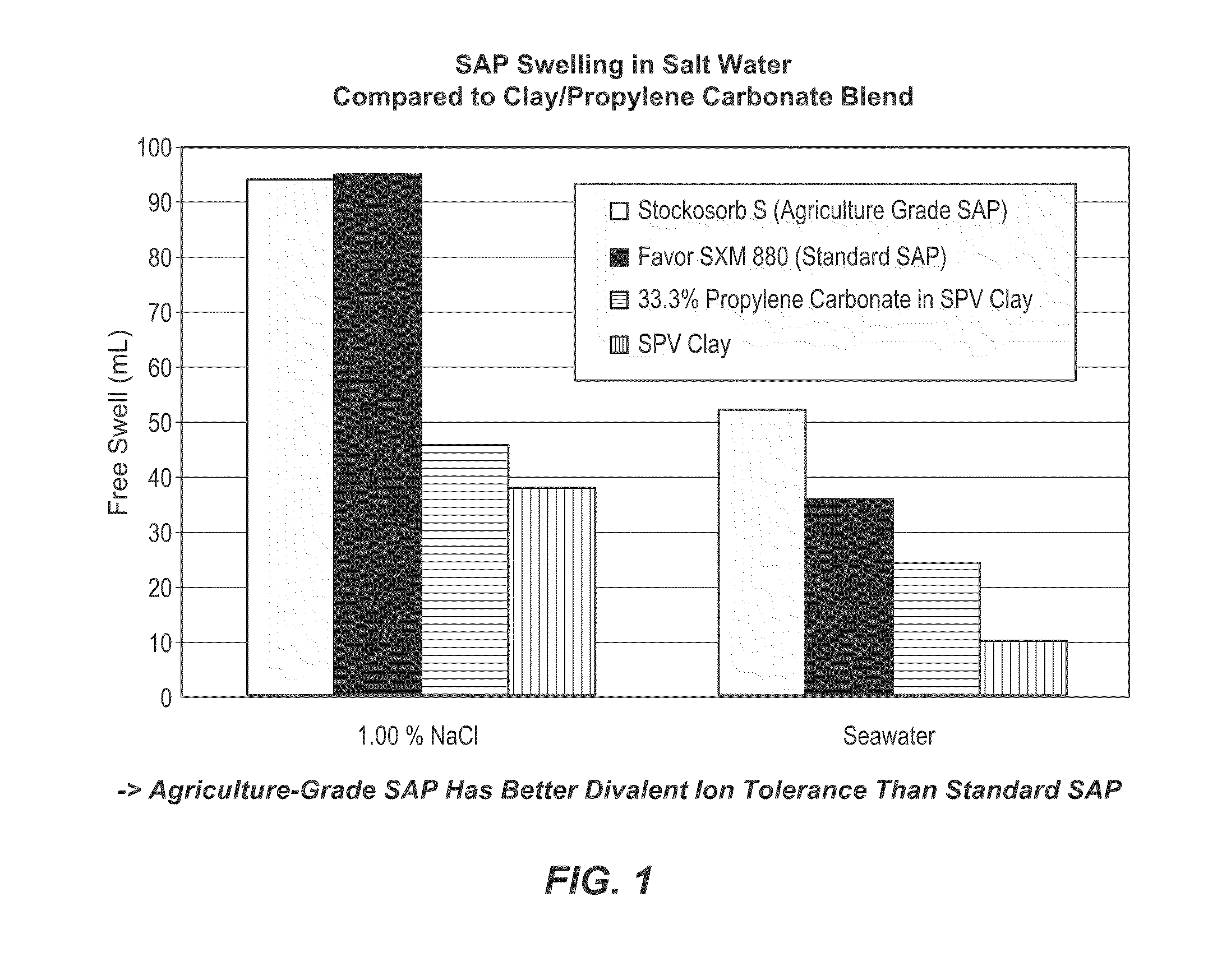

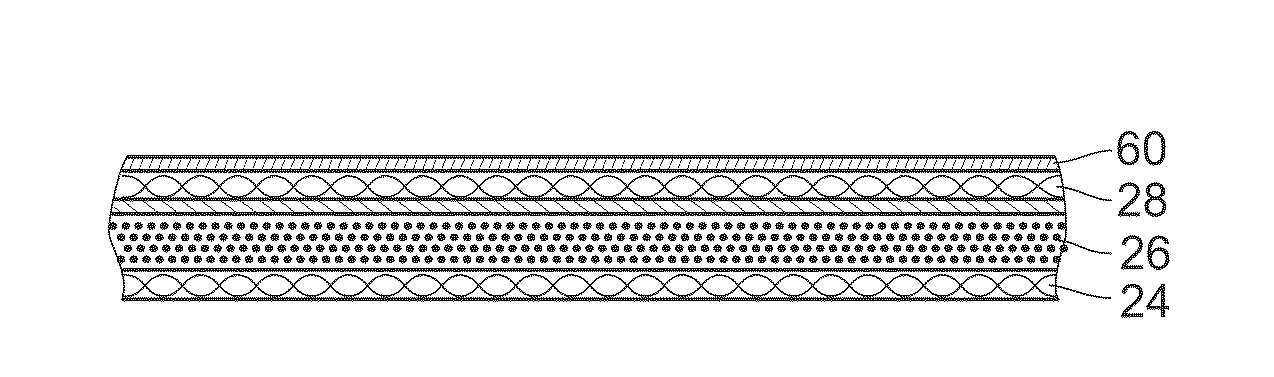

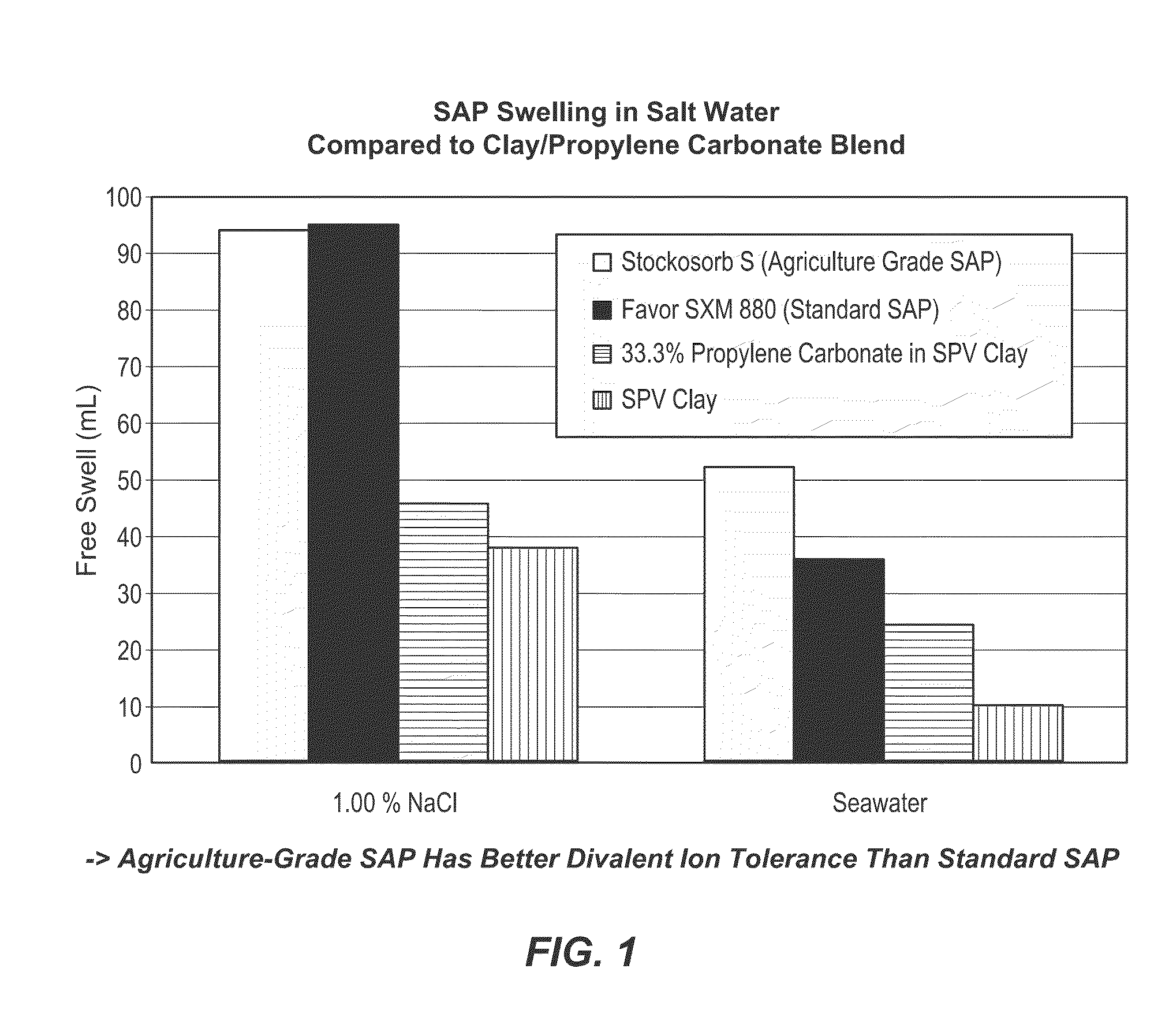

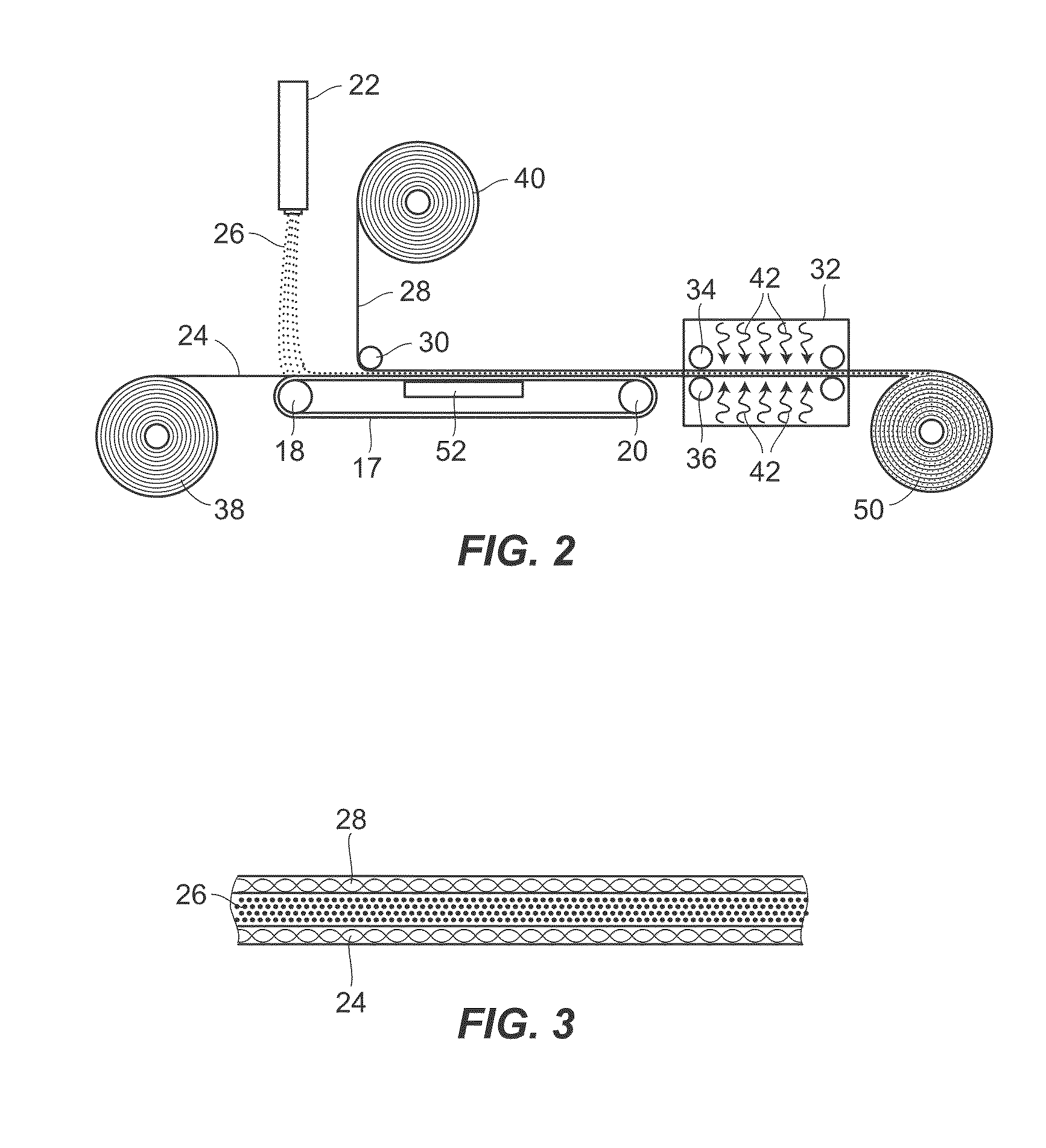

Geocomposite articles that can provide a barrier against high conductivity water e.g., ocean water, are described and their method of manufacture, for waterproofing surfaces that contact high conductivity water. The geocomposite article mat includes a woven or non-woven geotextile sheet or mat containing a powdered or granular partially cross-linked acrylamide / acrylate / acrylic acid copolymer across its entire major surface(s). The powdered or granular copolymer has an unexpectedly high free-swell when hydrated with High Conductivity water, such as ocean water. A liquid-impermeable cover sheet is adhered to the upper major surfaces of the filled copolymer-carrying geotextile to provide a primary high conductivity water barrier layer that, if ruptured, is sealed by the swell of an underlying layer of water-insoluble, partially cross-linked acrylamide / acrylic acid copolymer.

Owner:AMCOL INTERNATIONAL CORPORATION

Self healing salt water barrier

ActiveUS20140302735A1Prevent penetrationSynthetic resin layered productsProtective foundationCross-linkSelf-healing

Geocomposite articles that can provide a barrier against high conductivity water e.g., ocean water, are described and their method of manufacture, for waterproofing surfaces that contact high conductivity water. The geocomposite article mat includes a woven or non-woven geotextile sheet or mat containing a powdered or granular partially cross-linked acrylamide / acrylate / acrylic acid copolymer across its entire major surface(s). The powdered or granular copolymer has an unexpectedly high free-swell when hydrated with High Conductivity water, such as ocean water. A liquid-impermeable cover sheet is adhered to the upper major surfaces of the filled copolymer-carrying geotextile to provide a primary high conductivity water barrier layer that, if ruptured, is sealed by the swell of an underlying layer of water-insoluble, partially cross-linked acrylamide / acrylic acid copolymer.

Owner:AMCOL INTERNATIONAL CORPORATION

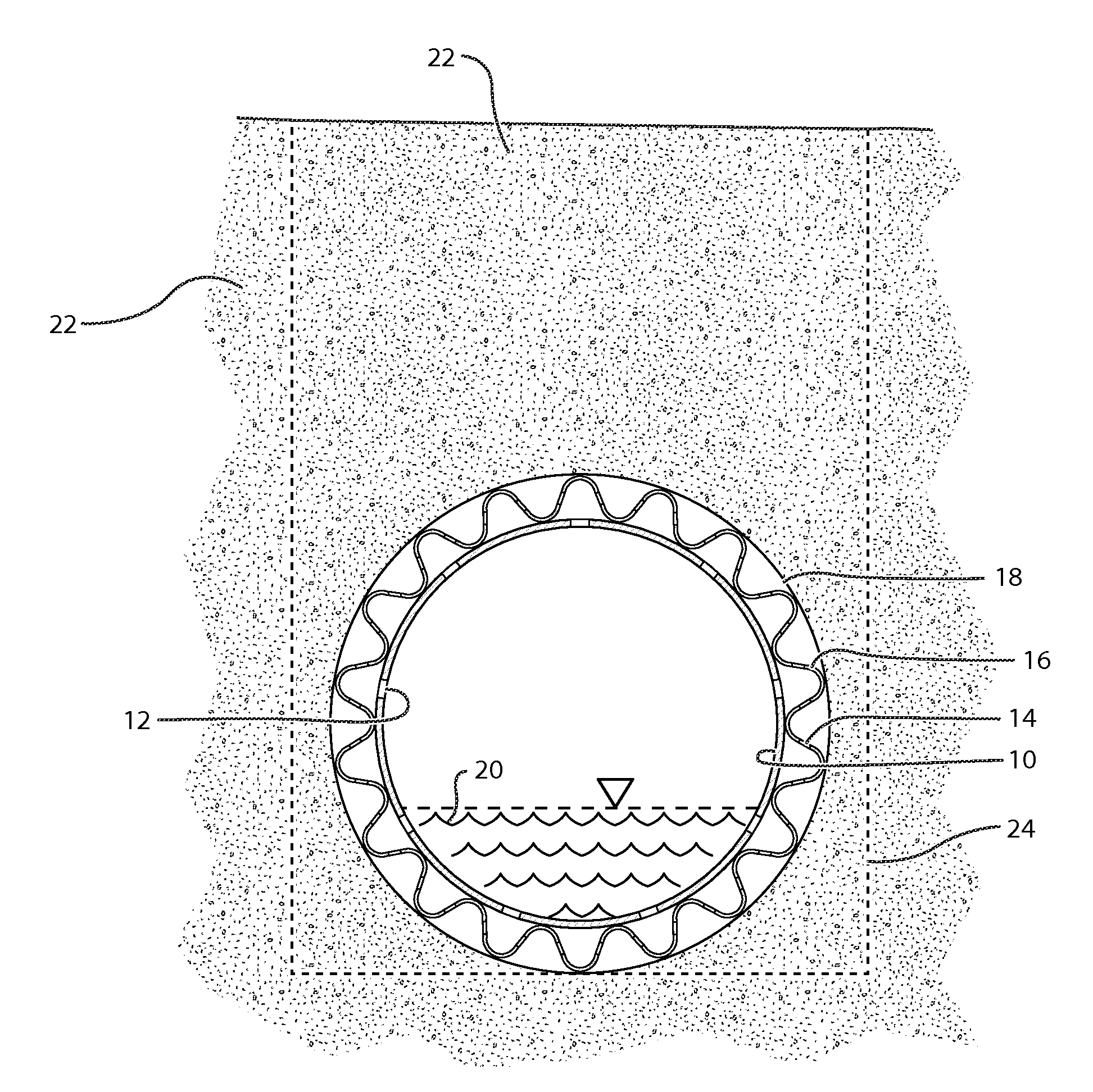

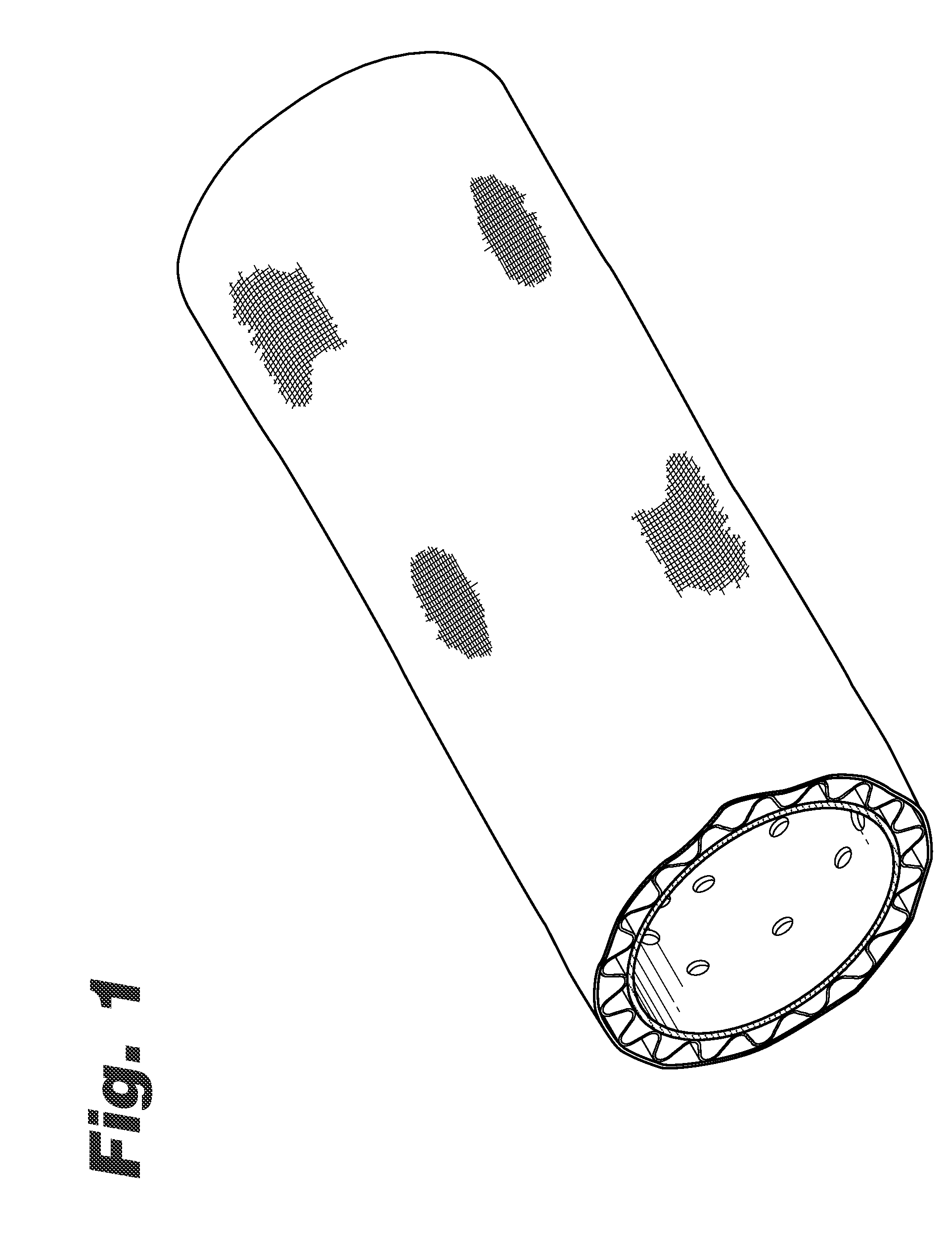

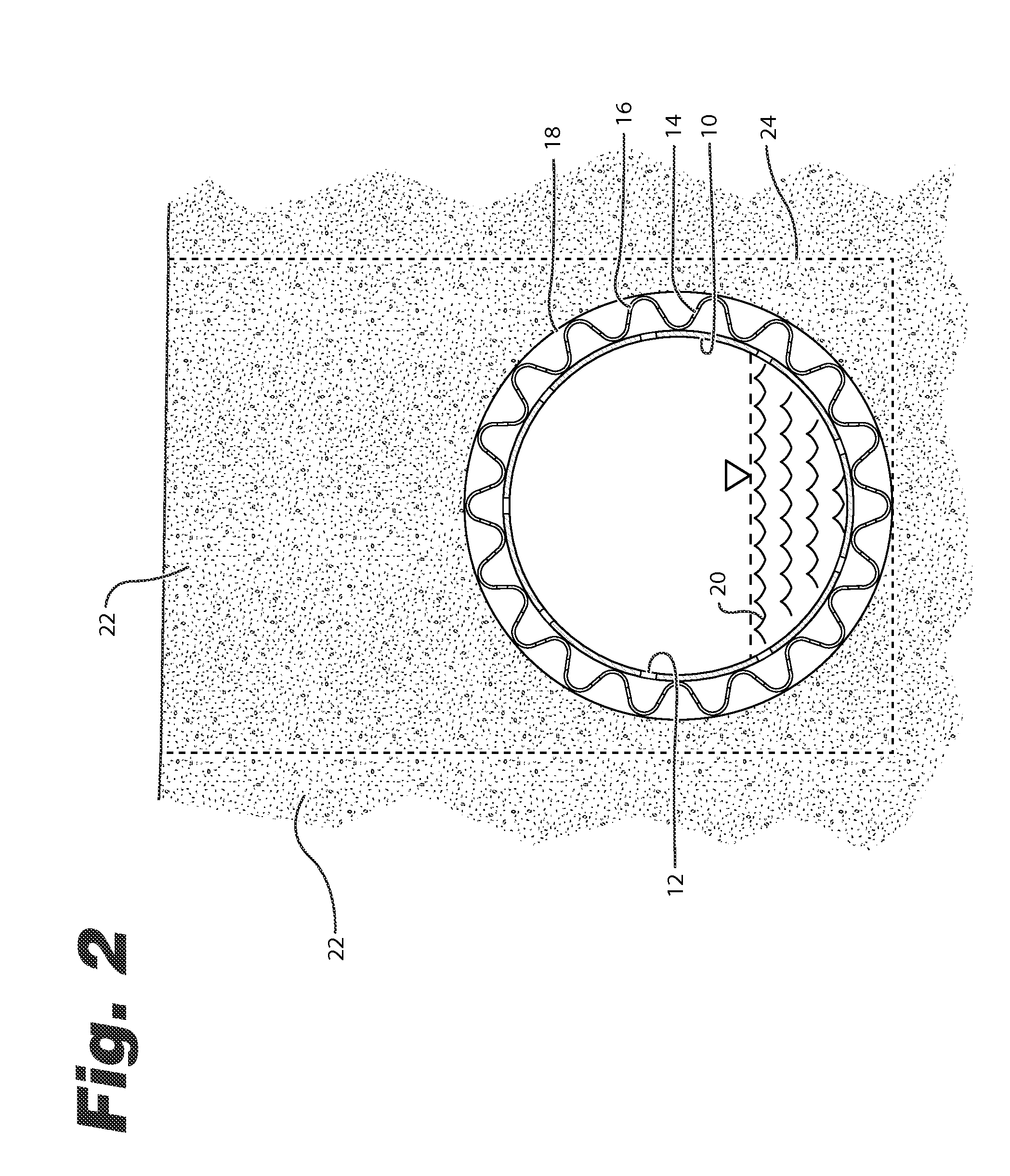

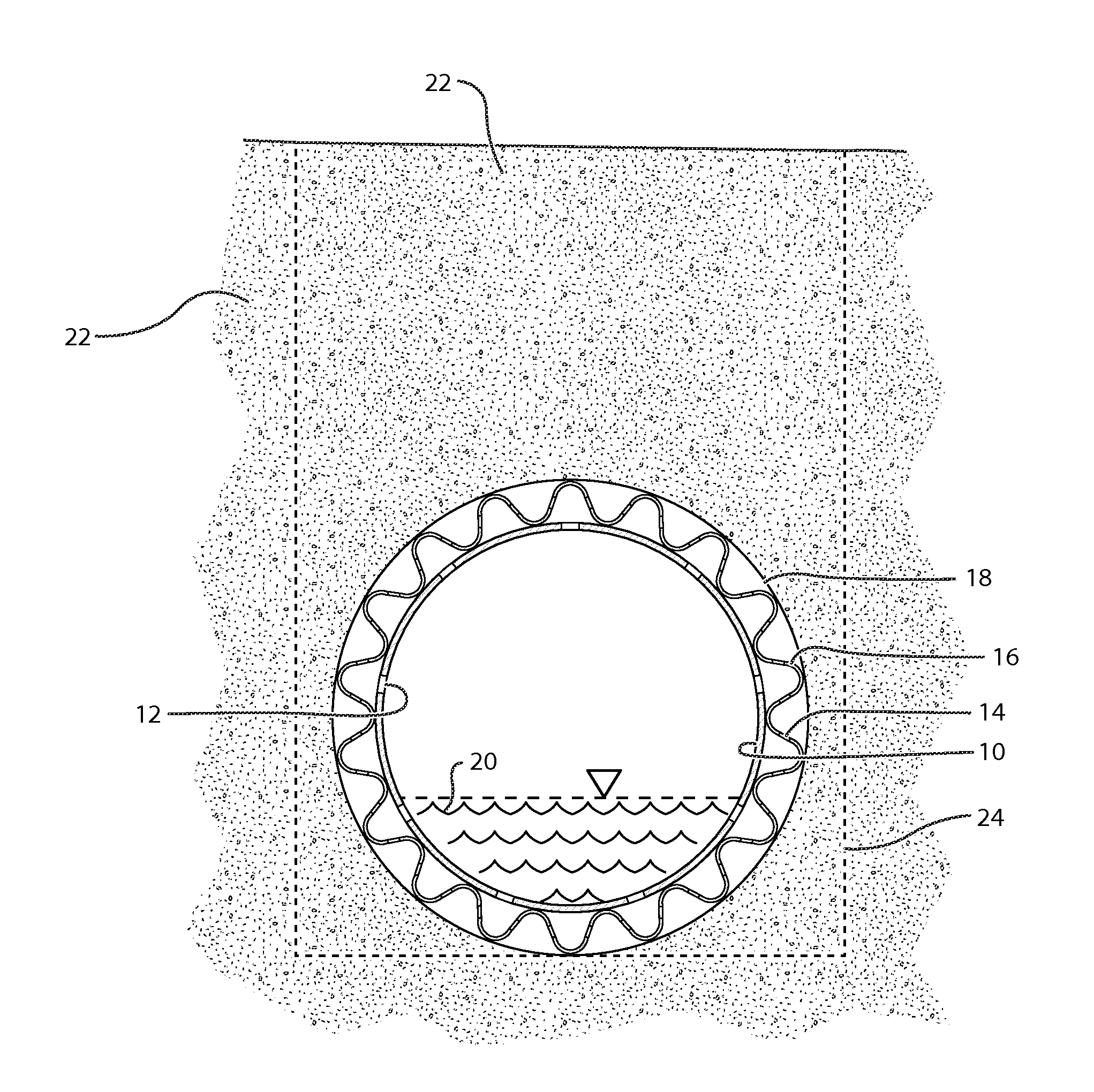

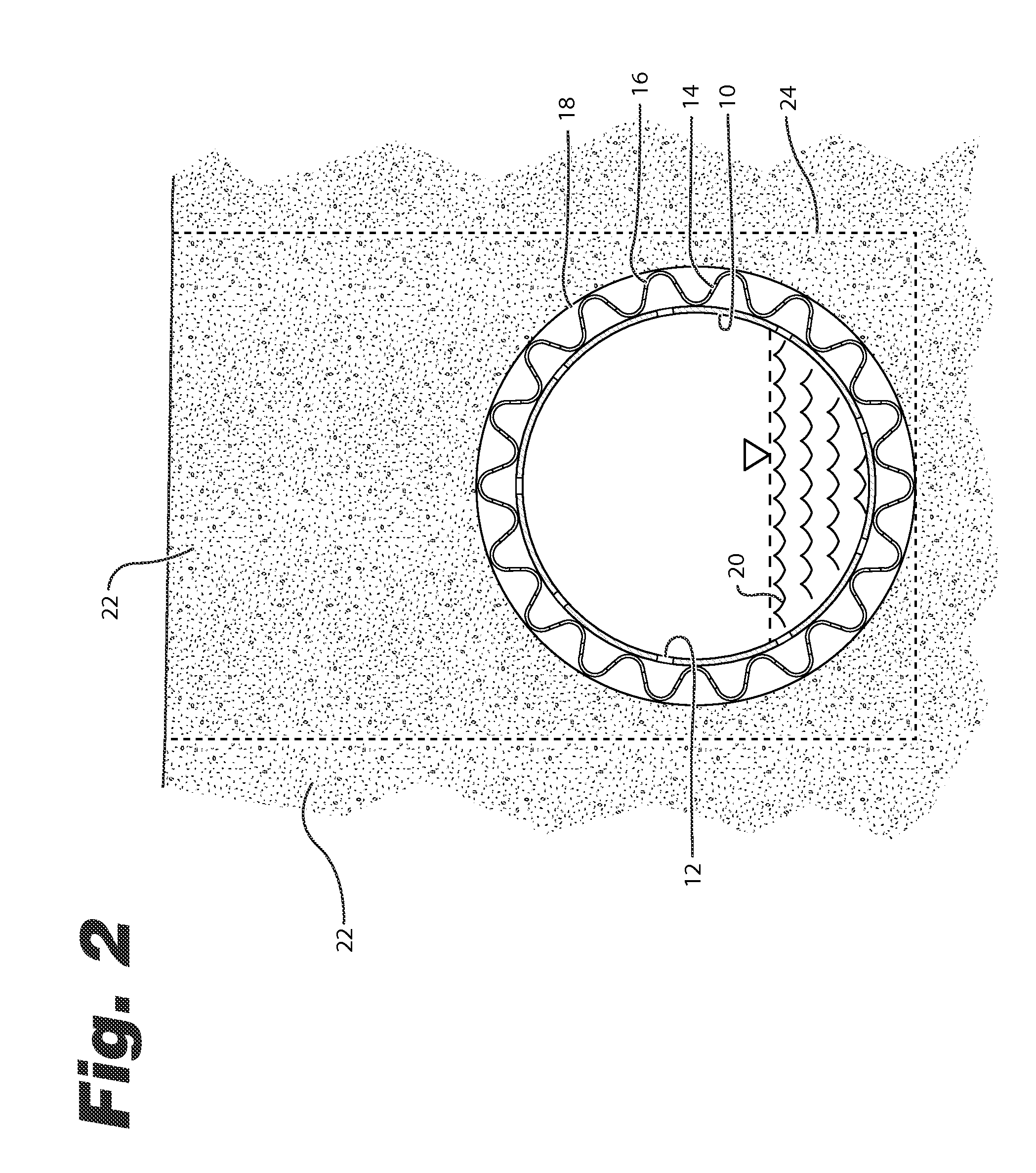

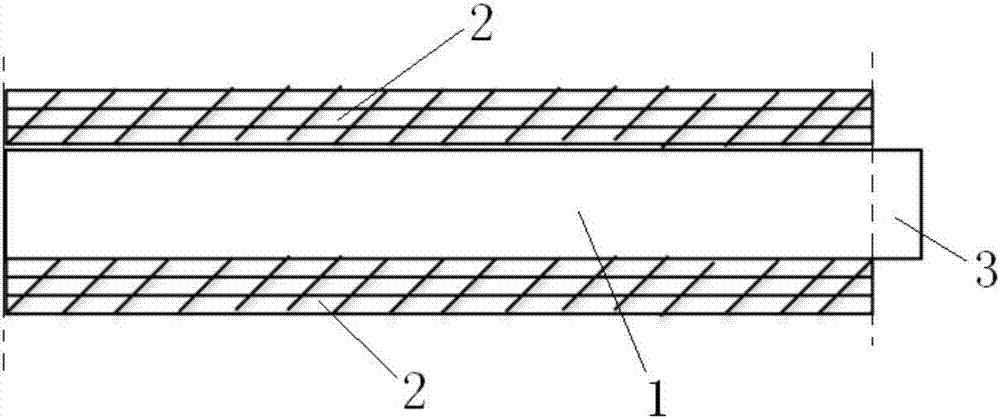

Soil drainage system

A soil drainage system which comprises a core pipe (10) having a plurality of perforations (12). A geocomposite core jacket (14) having a plurality of perforations (16) surrounds the core pipe (10). A geotextile filter fabric (18) wraps around and surrounds the geocomposite core jacket (14). The geotextile filter fabric (18) is permeable to water (20) or other fluids and filters out soil particles (22), or other particles, whereby the water (20) readily permeates the geotextile filter fabric (18), the geocomposite core jacket (14) and the core pipe (10) to provide for a rapid and improved flow of the water (20) and subsequent drainage of the water (20) through the core pipe (10).

Owner:SAMARA EMILE A

Geonet for a geocomposite

A geonet having a length substantially greater than its width and including no more than first and second layers of strands. A first plurality of substantially parallel strands extends in the lengthwise direction and defines the first layer of strands, and a second plurality of substantially parallel strands is disposed on top of, and at an angle relative to, the first plurality of strands and defines the second layer of strands. The first and second plurality of strands are substantially incompressible and secured to one another at crossover locations. Geocomposites include geotextile bonded to at least one side of the geonet. The geonets / geocomposites are laid in geotechnical construction sites in the direction of expected drainage flow.

Owner:GSE ENVIRONMENTAL

Geonet for a geocomposite

ActiveUS20070104543A1High densitySolid waste disposalSynthetic resin layered productsEngineeringGeocomposite

A geocomposite for use in a landfill, including a geonet and a geotextile bonded to at least one side of the geonet. The geonet includes a first plurality of substantially parallel strands, and a second plurality of substantially parallel strands disposed on top of the first plurality of strands, the second plurality of strands being at an angle relative to the first plurality of strands. The first and second plurality of strands are substantially incompressible and secured to one another at crossover locations, and are substantially round in cross-section.

Owner:GSE ENVIRONMENTAL

Contaminant-reactive geocomposite mat and method of manufacture and use

Reactive geocomposite mats, and their method of manufacture, for treating contaminants in sediment, soil or water that allow the passage of essentially non-contaminated water therethrough. The geocomposite mat includes a pre-formed woven or non-woven geotextile, that is needlepunched to an outer geotextile sheet layer to provide a high loft, structurally secured, pre-formed geotextile having a thickness of about 6 mm to about 200 mm, and having, a porosity sufficient to receive a powdered or granular contaminant-reactive material, contaminant-sorptive material, or a contaminant-neutralizing material (hereinafter collectively referred to as “contaminant-reactant material” or “contaminant-reactive material”) throughout its thickness, or in any portion of the thickness across its entire major surface(s). The powdered or granular contaminant-reactive material is disposed within the pores of the previously formed, high loft geotextile mat to surround the fibers, e.g., by vacuum or vibrating the high loft mat while in contact with the contaminant-reactive material to allow the powdered or granular contaminant-reactive material to flow by gravity into the pores of the previously formed, needlepunched geotextile. A liquid-permeable outer geotextile sheet then is secured to the filled geotextile, preferably by heating upwardly extending fibers of the pre-formed geotextile mat to prevent the powdered or granular material from escaping from the geotextile during transportation and installation.

Owner:AMCOL INTERNATIONAL CORPORATION

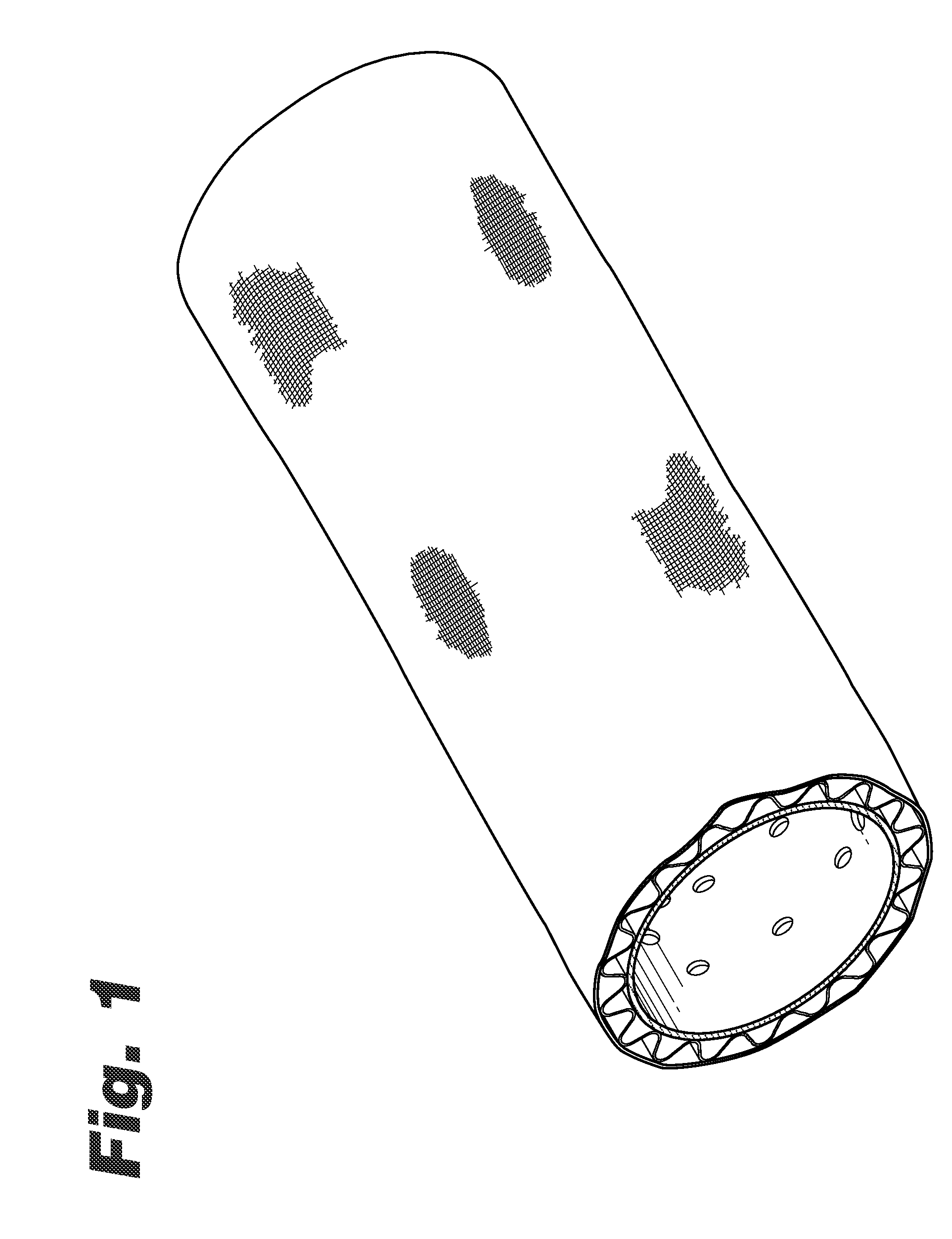

Bioremediation mat and method of manufacture and use

InactiveUS7419593B2High loftContaminated soil reclamationProtective foundationPorosityBioremediation

Bioremediation geocomposite articles, and their method of manufacture, for treating (digesting) contaminats in soil or water. The bioremediating geocomposite mat includes a woven or non-woven geotexile, having a thickness of about 6 mm to about 200 mm. In the preferred embodiment, outer layers of the geocomposite article have a porosity sufficient to receive a powdered or granular contaminant-reactive material, contaminat-sorptive material, or a contaminant-neutralizing material in at least outer portions of the thickness across its entire major surface(s) for better contact of the bacteria with contaminants held by the powdered or granular material. In the most preferred embodiment, liquid-permeable cover sheets are adhered to the upper and lower major surfaces of the bacterial-containing geotextile article to prevent a powdered or granular material from escaping from the geotextile during transportation and installation.

Owner:AMCOL INTERNATIONAL CORPORATION

Soil drainage system

A soil drainage system which comprises a core pipe (10) having a plurality of perforations (12). A geocomposite core jacket (14) having a plurality of perforations (16) surrounds the core pipe (10). A geotextile filter fabric (18) wraps around and surrounds the geocomposite core jacket (14). The geotextile filter fabric (18) is permeable to water (20) or other fluids and filters out soil particles (22), or other particles, whereby the water (20) readily permeates the geotextile filter fabric (18), the geocomposite core jacket (14) and the core pipe (10) to provide for a rapid and improved flow of the water (20) and subsequent drainage of the water (20) through the core pipe (10).

Owner:SAMARA EMILE A

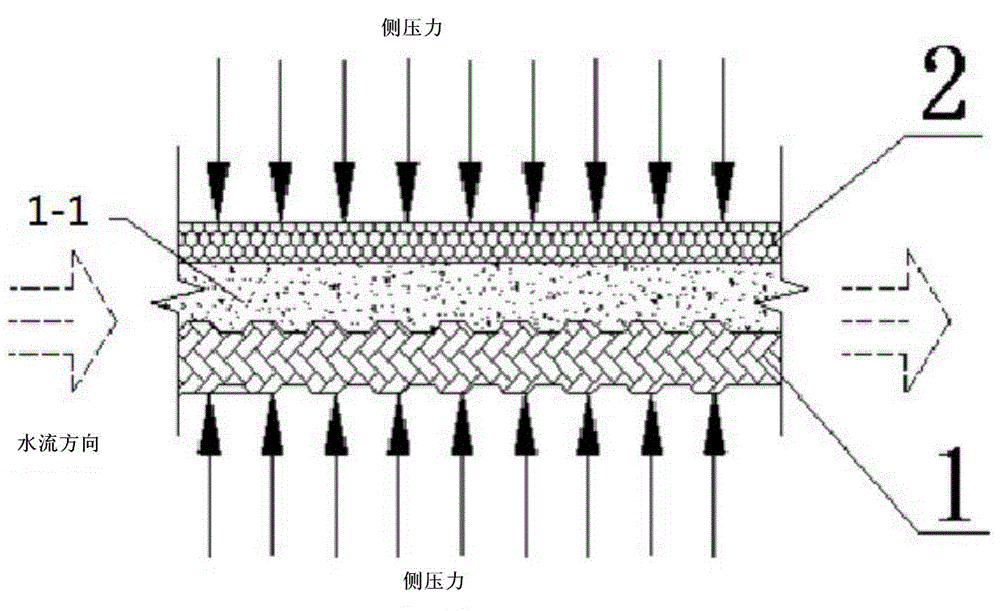

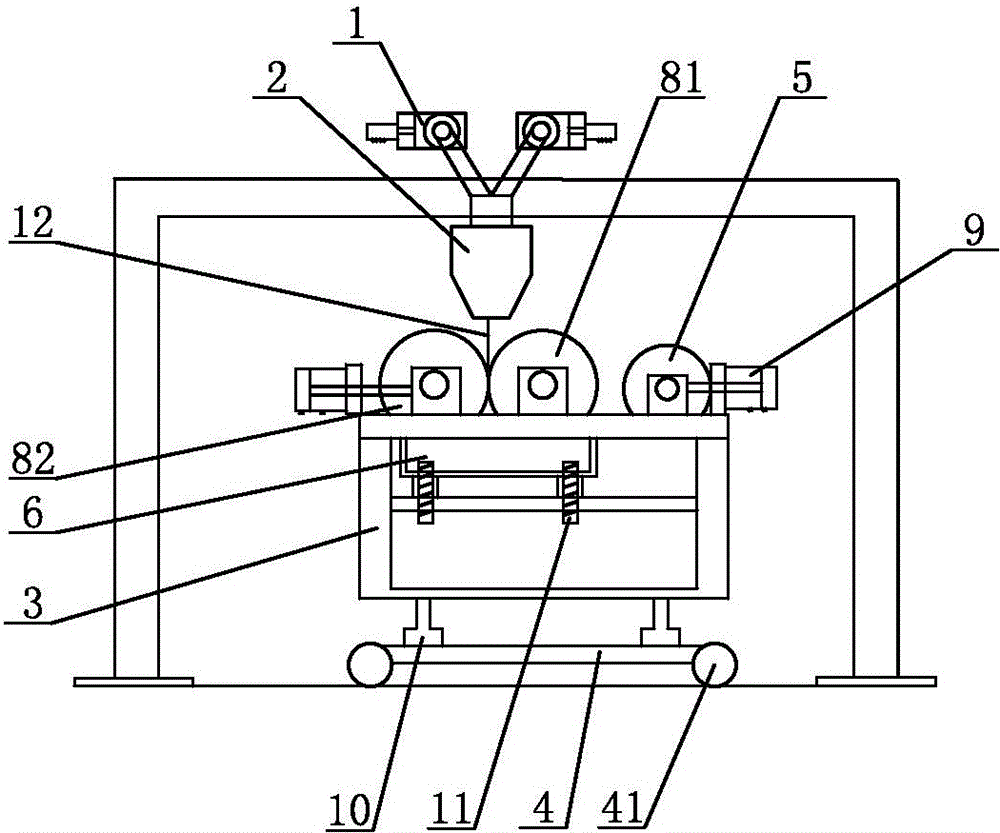

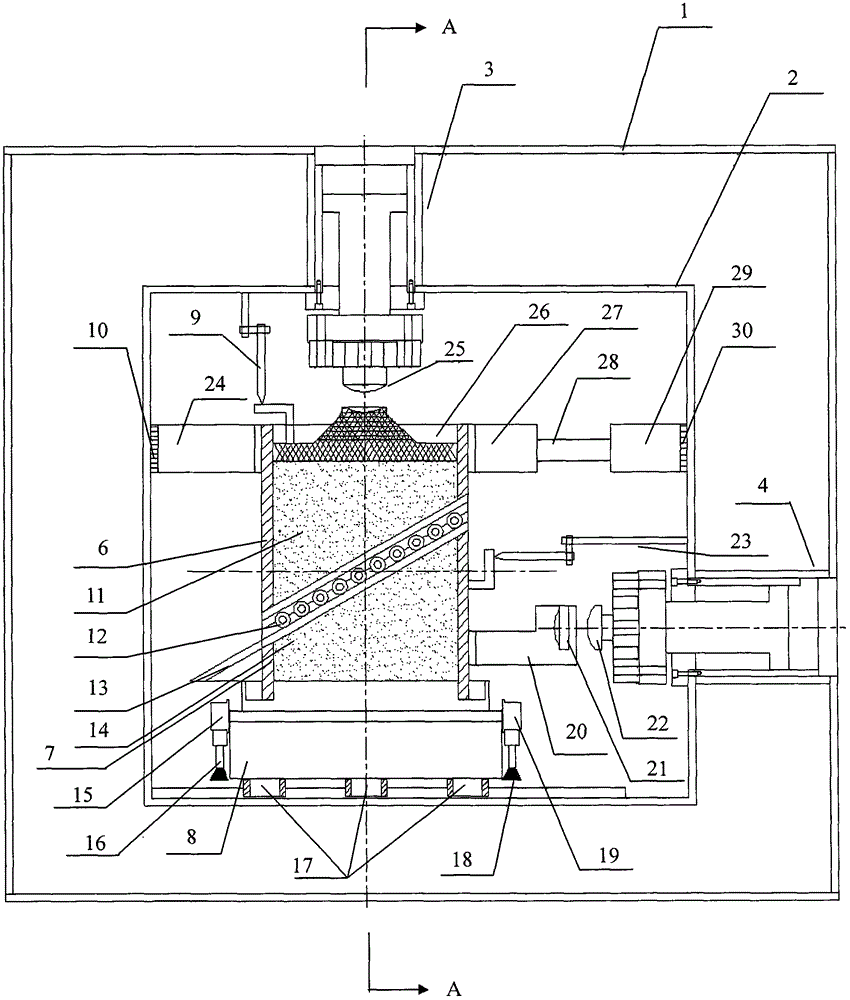

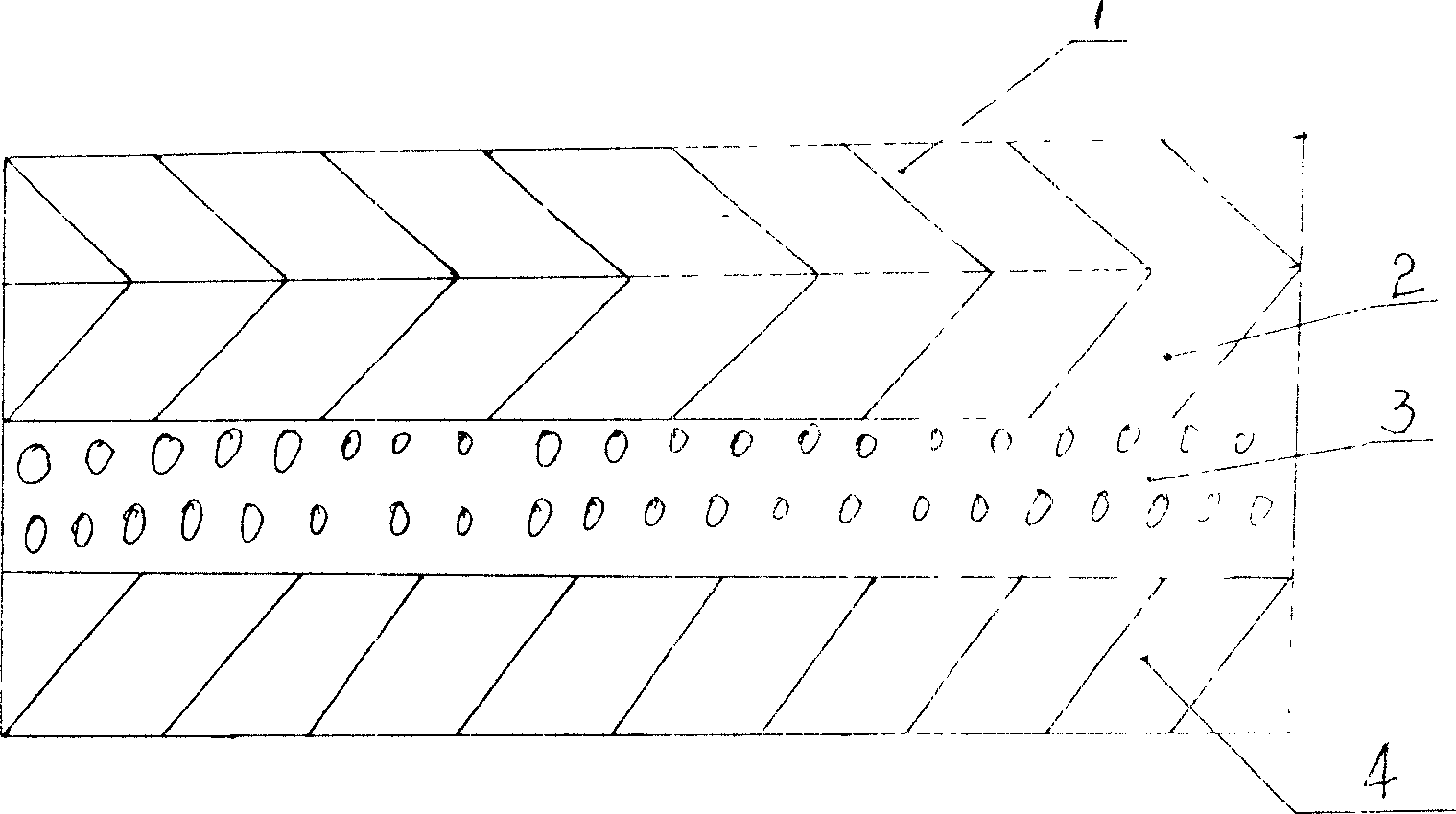

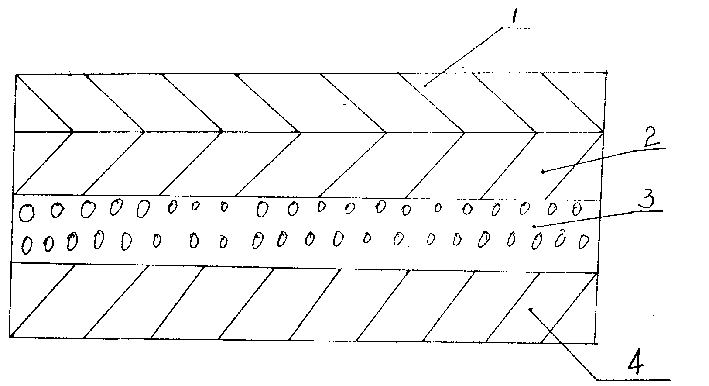

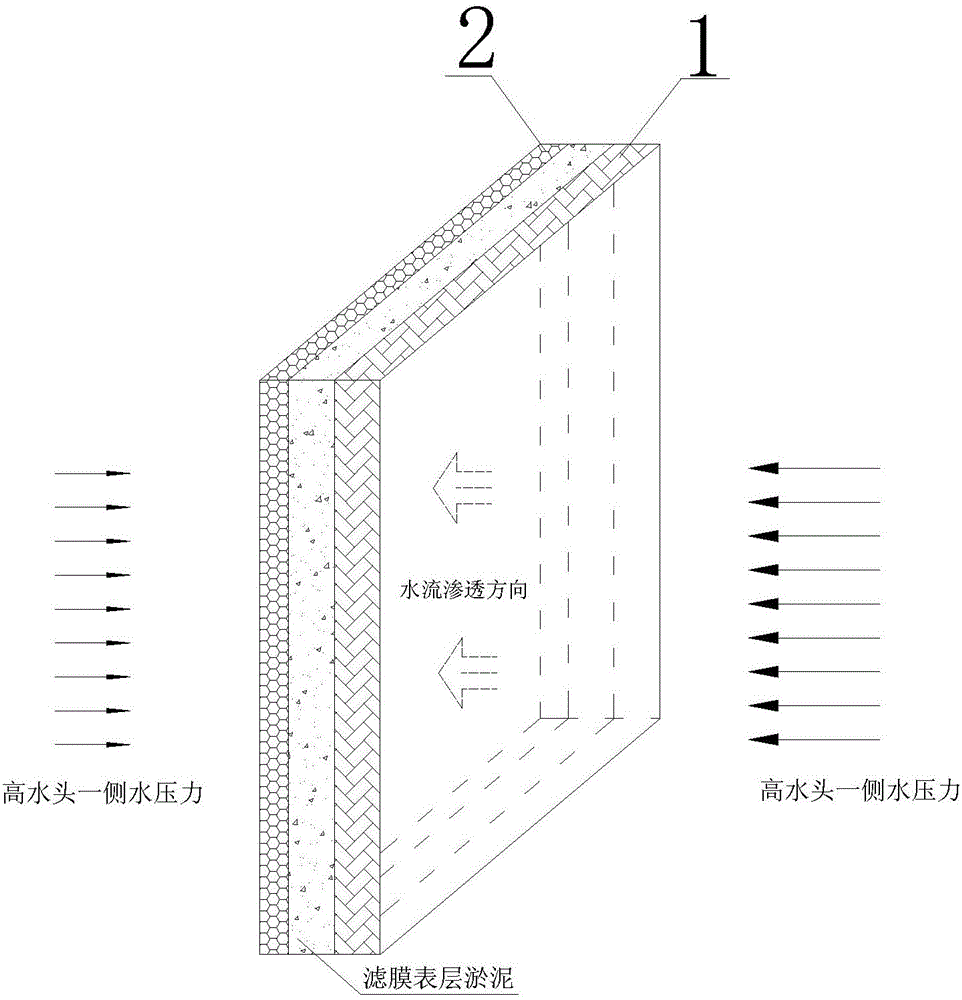

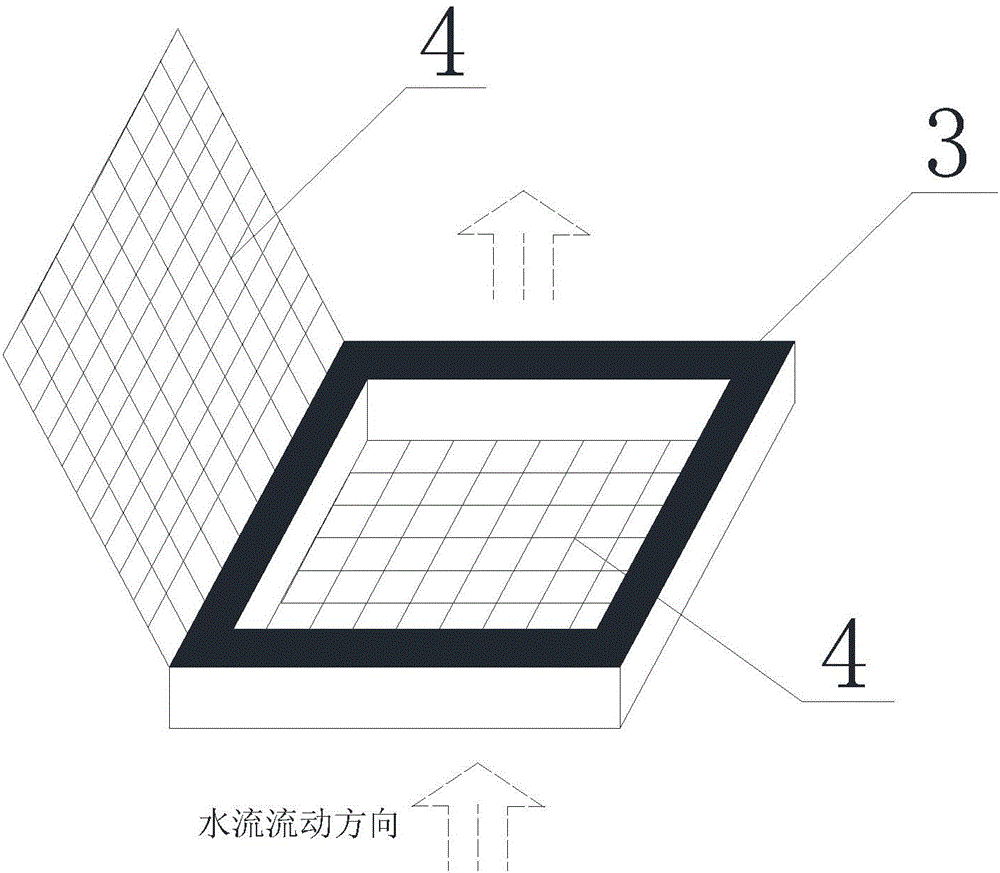

Geotechnical composite drainage material filter membrane horizontal seepage clogging discounting test device and test method thereof

PendingCN104614297AImprove water tightnessImprove air tightnessPreparing sample for investigationPermeability/surface area analysisSurface layerSoil horizon

The invention relates to a geotechnical composite drainage material filter membrane horizontal seepage clogging discounting test method. The method comprises the following processes: filter membrane sample manufacturing comprises taking out geotechnical composite drainage material non-disturbance sample in clogging from a soil layer, and manufacturing a sample containing deposited clay on the surface layer of the filter membrane according to a specific sample preparation method, wherein the discounting of the geotechnical composite drainage material filter membrane horizontal seepage coefficient caused by sedimentation clogging after being used in the soil layer can be really simulated through the sample preparation; and meanwhile, a set of horizontal seepage coefficient test device is researched, the device can be used for simulating and testing the horizontal seepage coefficient of the filter membrane in different hydraulic gradient and different lateral pressure coefficient conditions, the sample prepared by using the above method and the unused filter membrane sample are used for performing contrast test to obtain a filter membrane clogging discounting index. The invention firstly provides the method and corresponding device for quantitatively testing the geotechnical composite drainage material filter membrane horizontal seepage clogging discounting, the device is simple, the operation is simple and easy to implement, and the measurement precision is high; the device can be used for testing the geotechnical composite drainage material filter membrane horizontal seepage coefficient.

Owner:GUANGXI UNIV

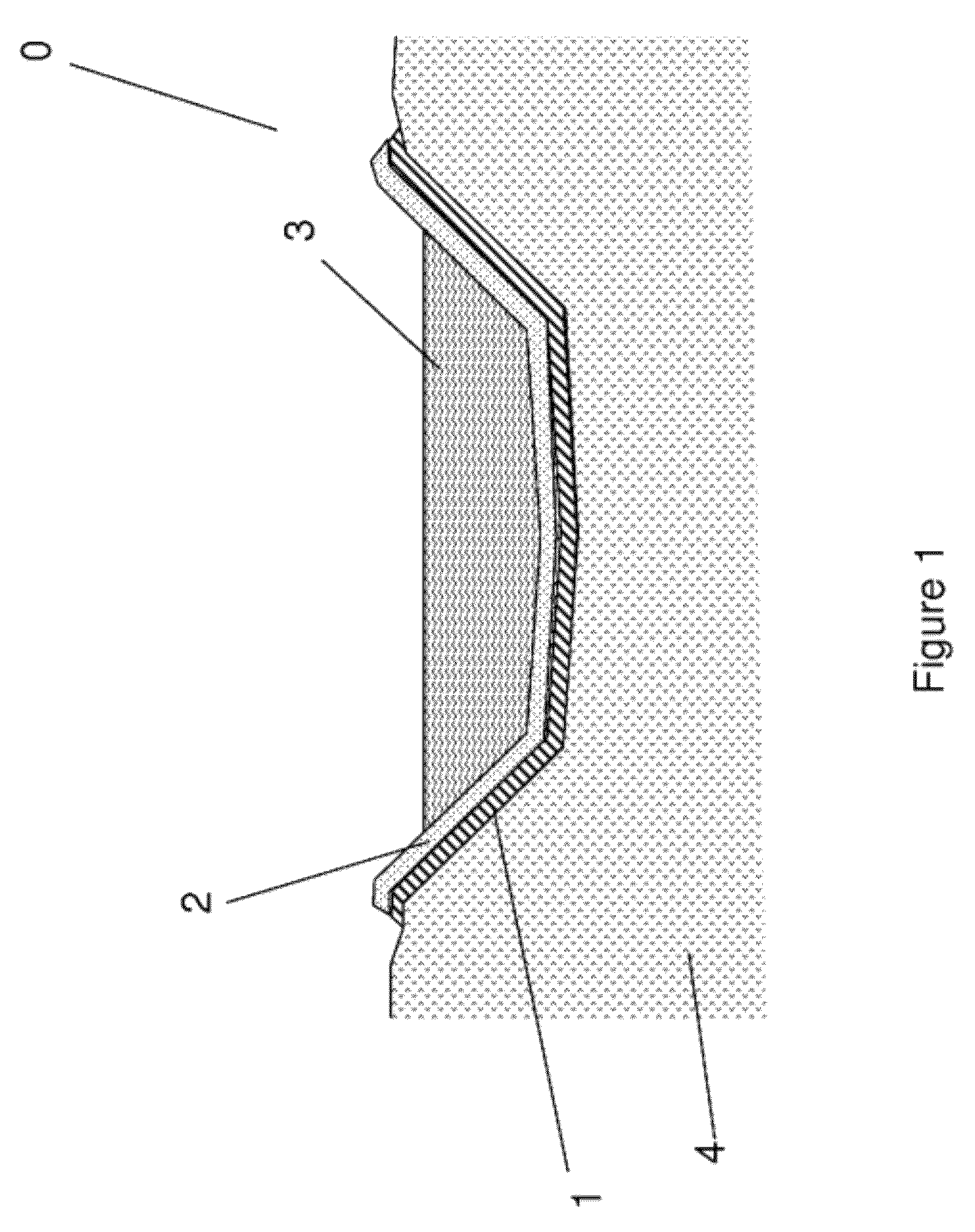

Geocomposite enabling leak detection by electrical scan, and method for use

ActiveUS8970201B2Avoid cloggingMaterial analysis by electric/magnetic meansProtective foundationElectricityConductive textile

A geocomposite for positioning under a geomembrane comprising at least one first geotextile covered by at least one second geotextile at least one electrically conductive textile being positioned between the second geotextile and the first geotextile. The conductive textile having a module for connecting to a phase of an electric generator. The geocomposite being in the form of one or several strips at the edges of which the second geotextile, the first geotextile and the electrically conductive textile are separate from each other, the geocomposite comprising perforated ringed mini-drains positioned parallel with each other on the first geotextile and covered with the second geotextile.

Owner:AFITEX INT

High-friction geo-textiles for increasing the stability of landfill drainage layers and other high-friction angle installations, and related methods

InactiveUS20070183852A1Improve the immunityImprove featuresLayered productsEmbankmentsSlope angleEngineering

The present invention relates generally to geo-textiles having an increased resistance to the negative effects of shear forces in installations or layered structures which can be adapted and arranged to utilize geo-textiles. Geo-textiles of the invention comprise at least one high-friction compound, such as one or more high-friction polymers, and methods for making and utilizing them. The high-friction characteristics of components of the invention provide increased resistance to the negative effects of shear forces in layered installations which employ them. Geo-textiles of the invention may have one or more high-friction compounds provided on either or both surfaces. Geo-textiles according to the invention are particularly useful in sloped installations where at least a portion of the layered structure is at a slope angle of greater than 4 degrees, and can be interposed between one or more of geo-membranes, geo-grids, geo-cells, geocomposite laminates and conventional geo-textiles.

Owner:TENAX INT

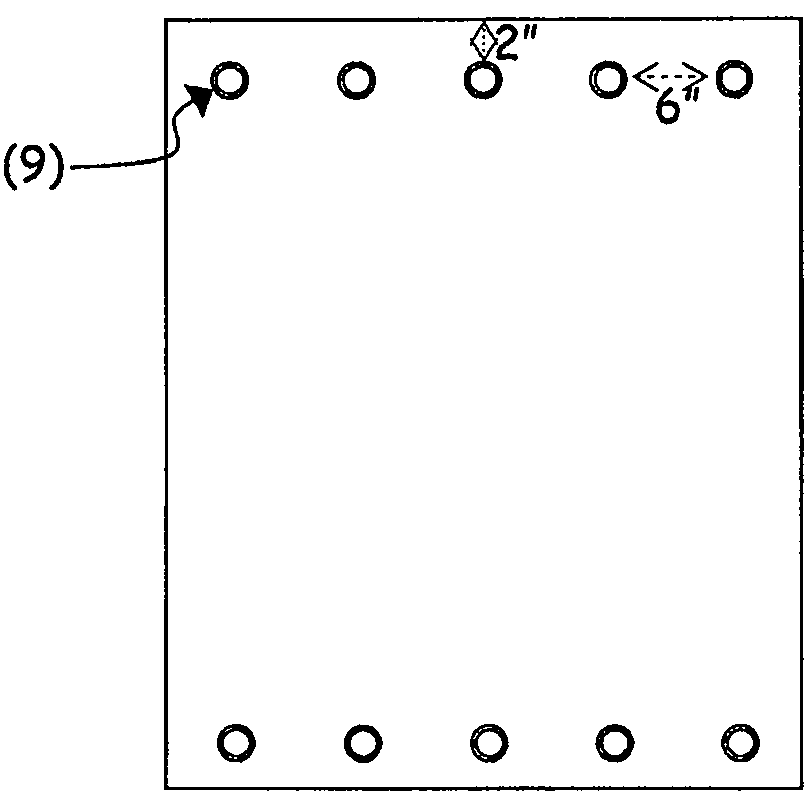

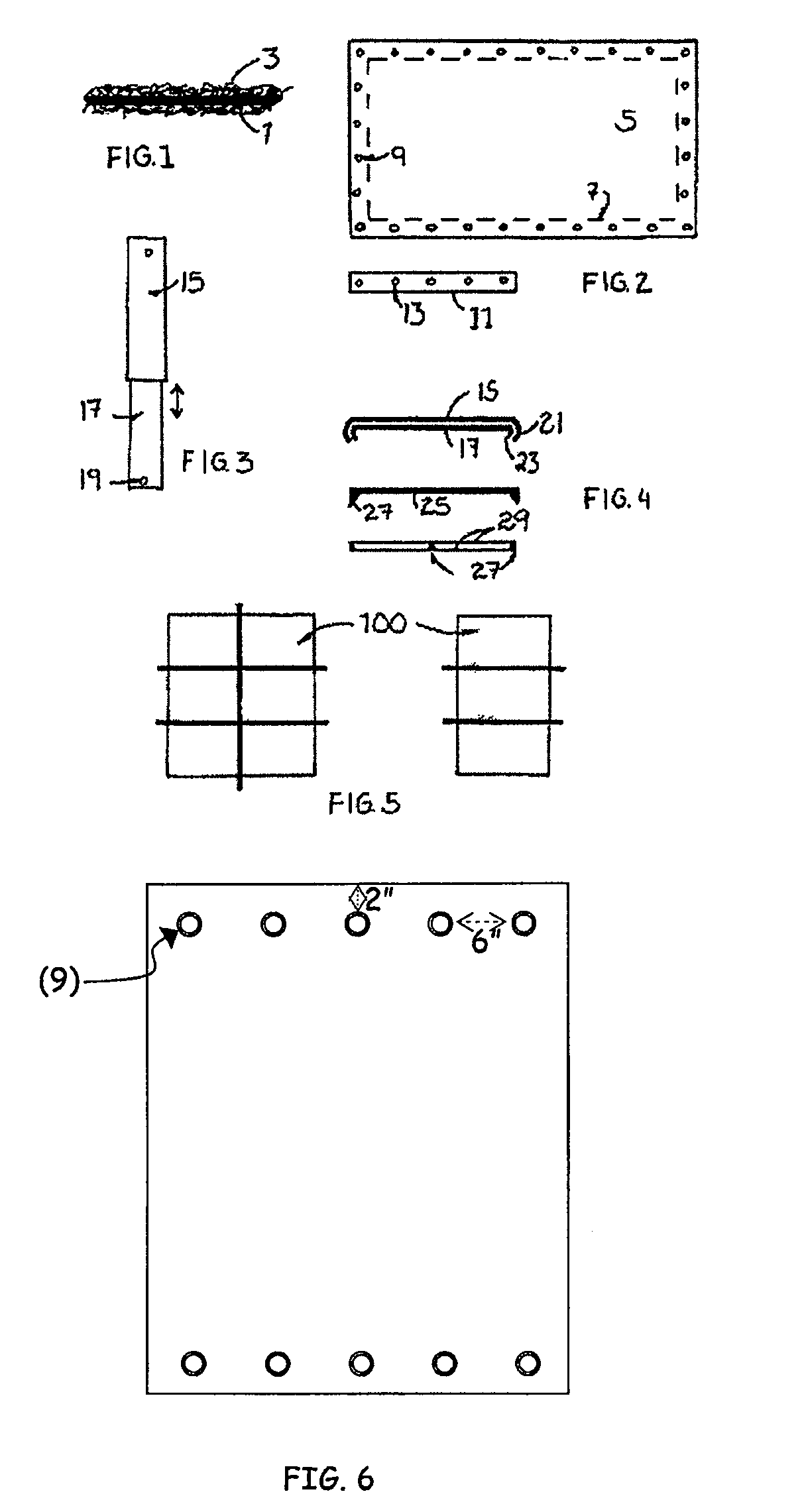

Hurricane panel

InactiveUS20090193730A1Easy to storeEasy to set upHuman health protectionHurricane shuttersEngineeringGeocomposite

A hurricane panel configured to cover a building opening that is made of a geocomposite having an impermeable core and surrounded by both sides with batting, and anchoring means for attachment to a building.

Owner:PRUET RICK +2

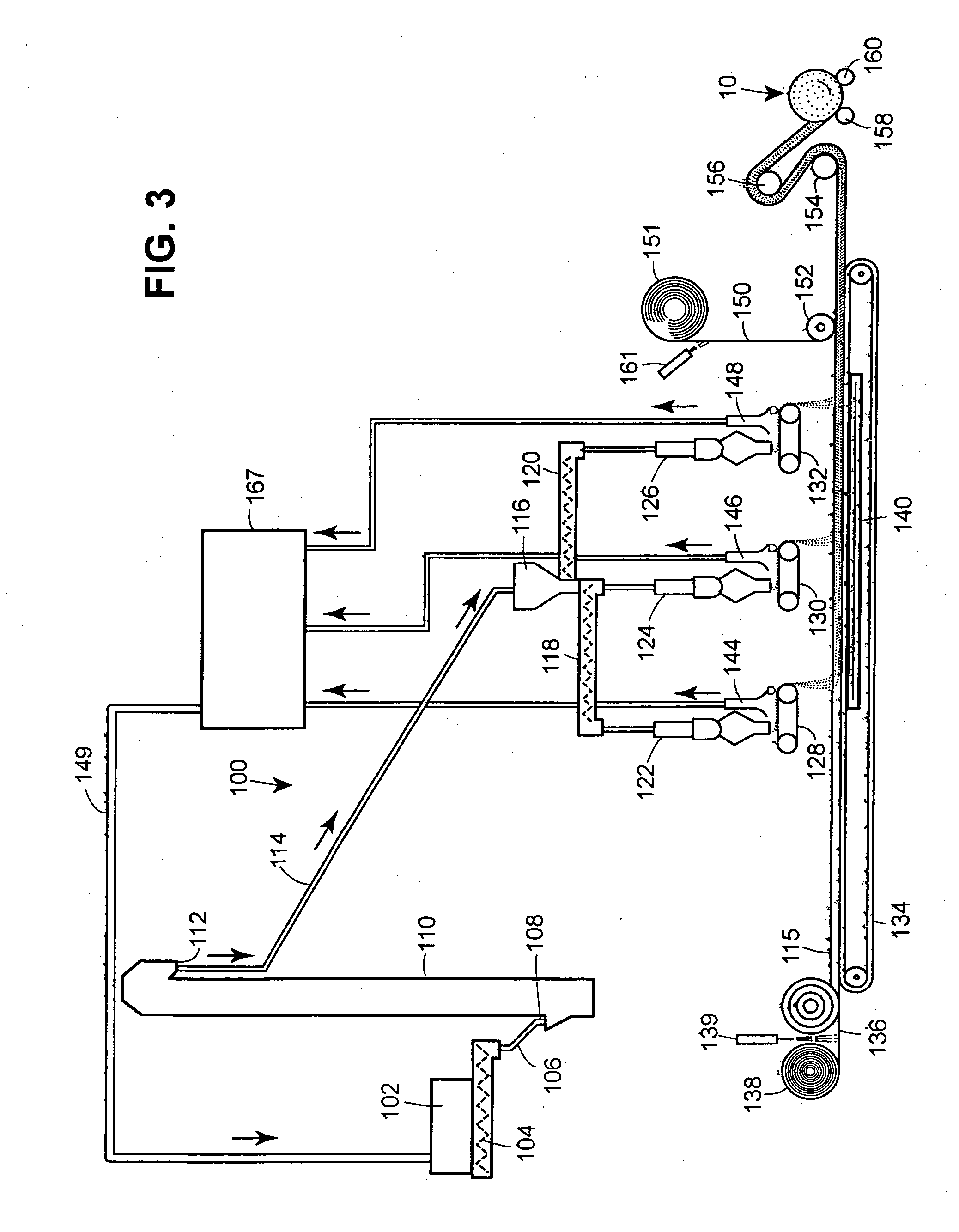

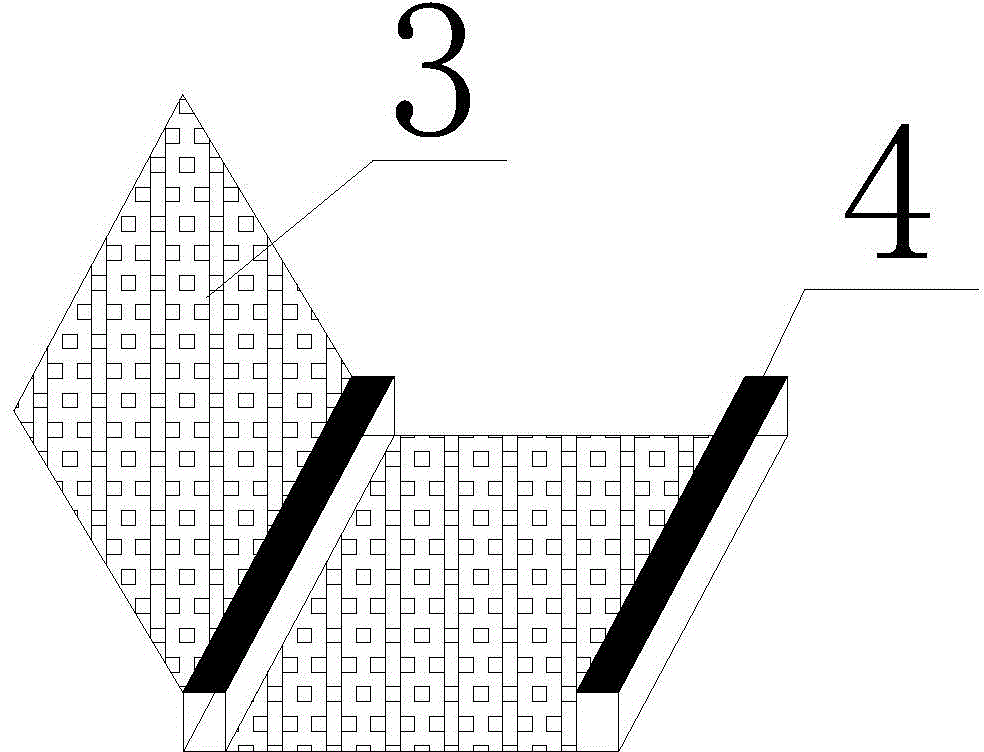

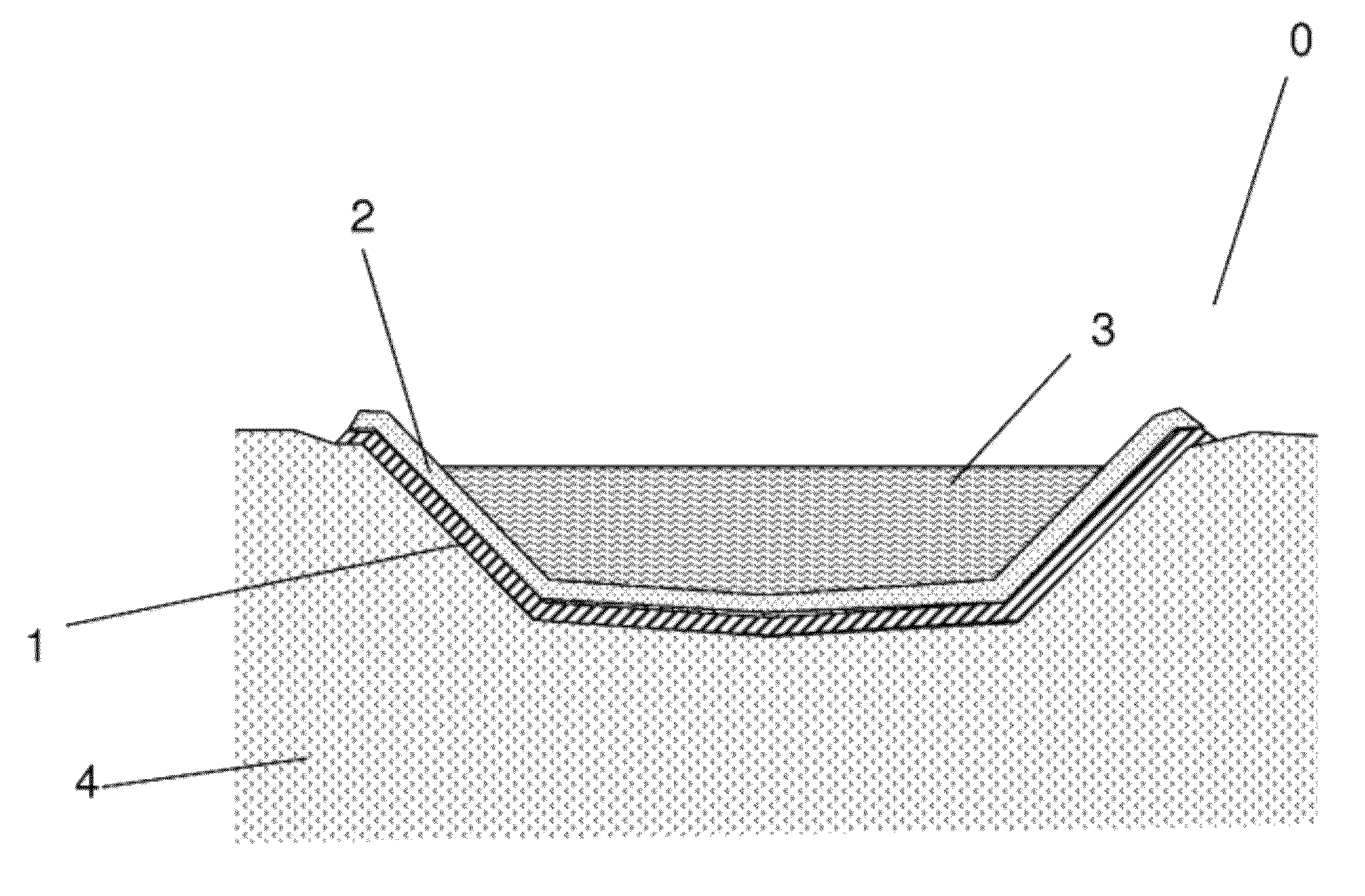

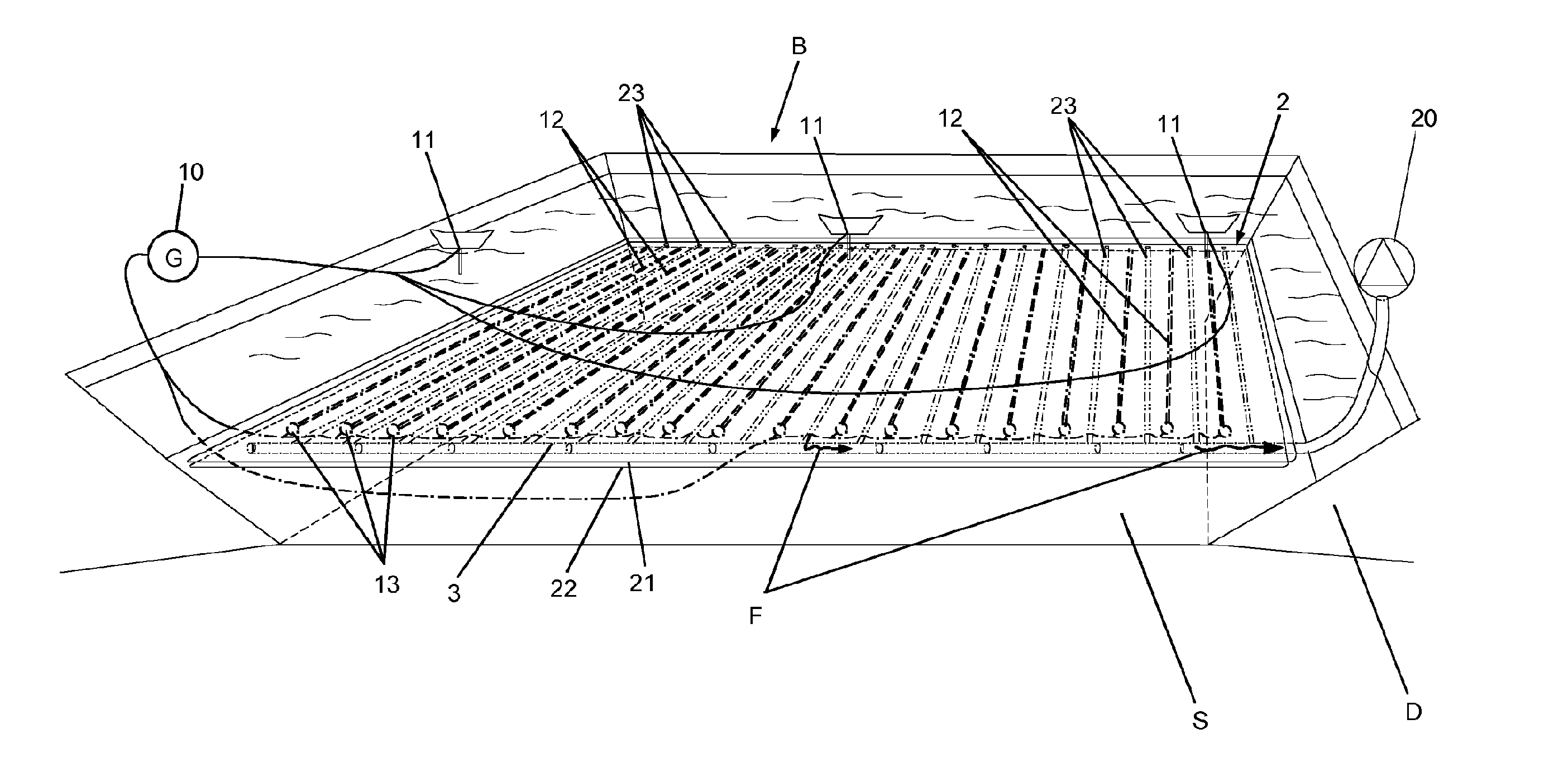

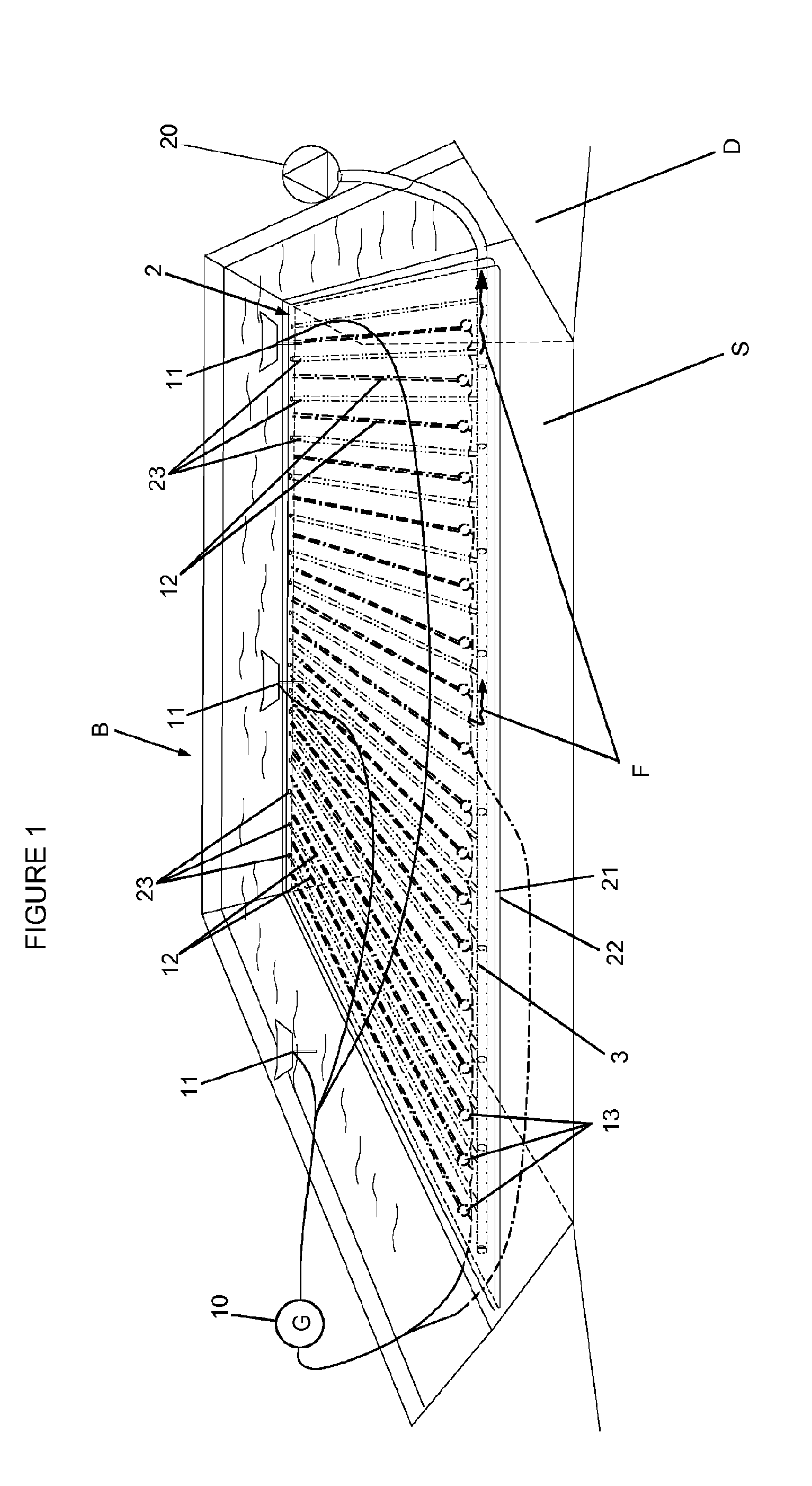

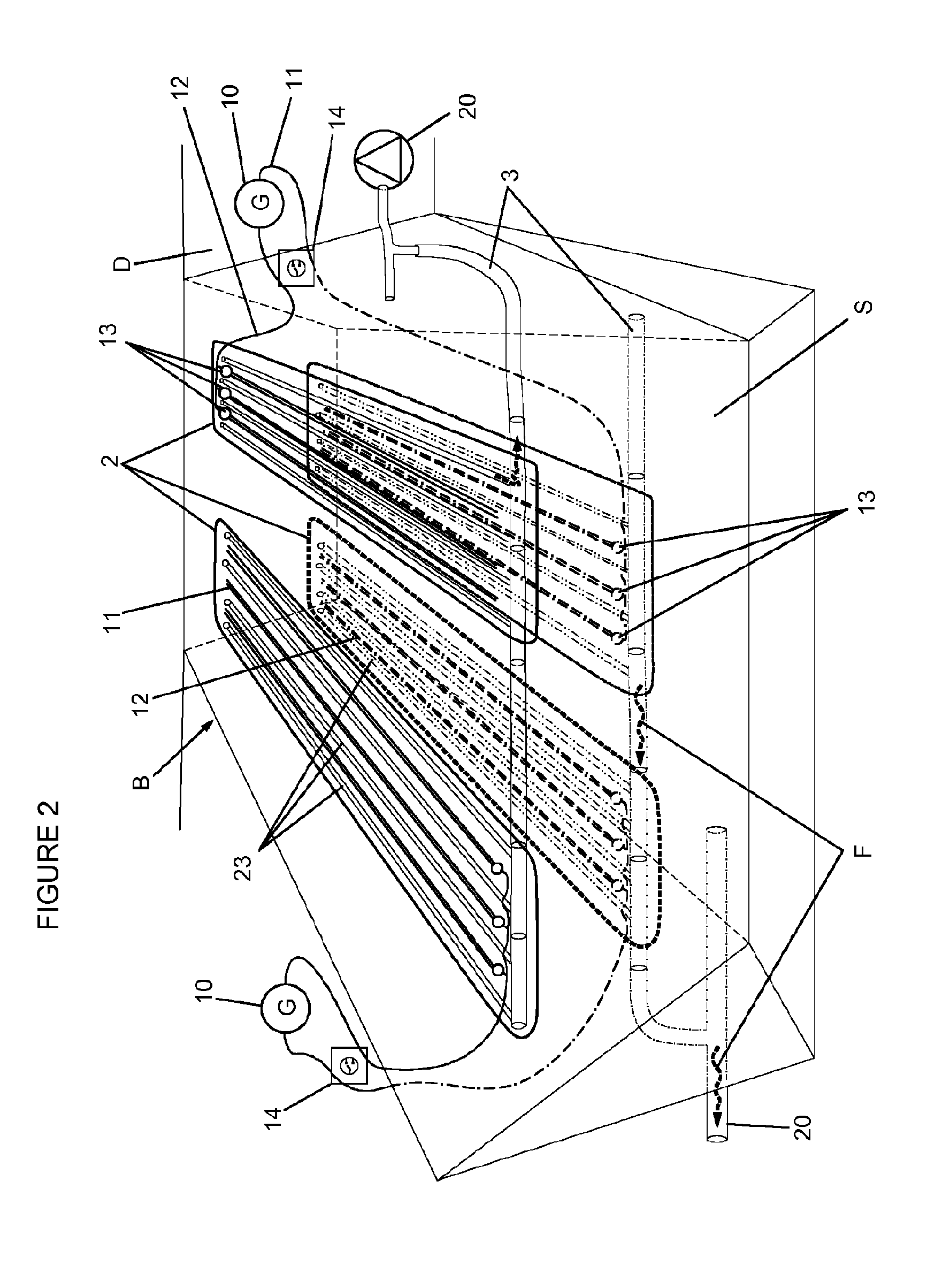

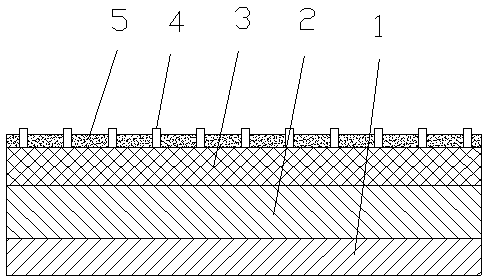

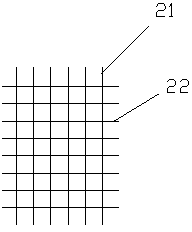

Soil-treatment system, geocomposite for such a system, and soil consolidation method

InactiveUS20160311003A1Optimize allocationAvoid corrosionWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningElectricitySoil treatment

The present invention concerns a soil-treatment method and system, comprising at least one electricity generator (10) and at least two electrodes (11, 12), as well as at least one pumping device (20), characterised in that the system comprises at least one geocomposite (2) that contains at least one portion of at least one of said electrodes (11, 12) and which includes at least one filtering layer (21) and / or at least one draining layer (22), and in that at least one portion of at least one of said electrodes (11, 12) comprises carbon.

Owner:AFITEX INT

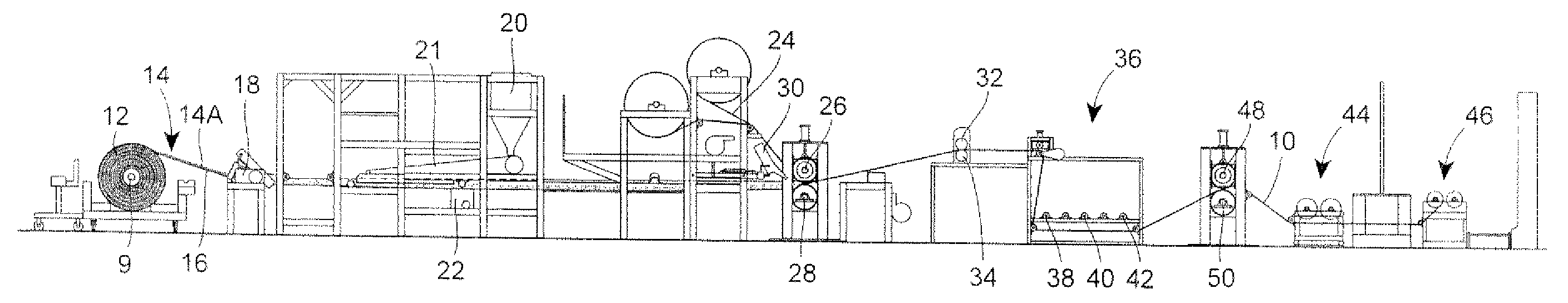

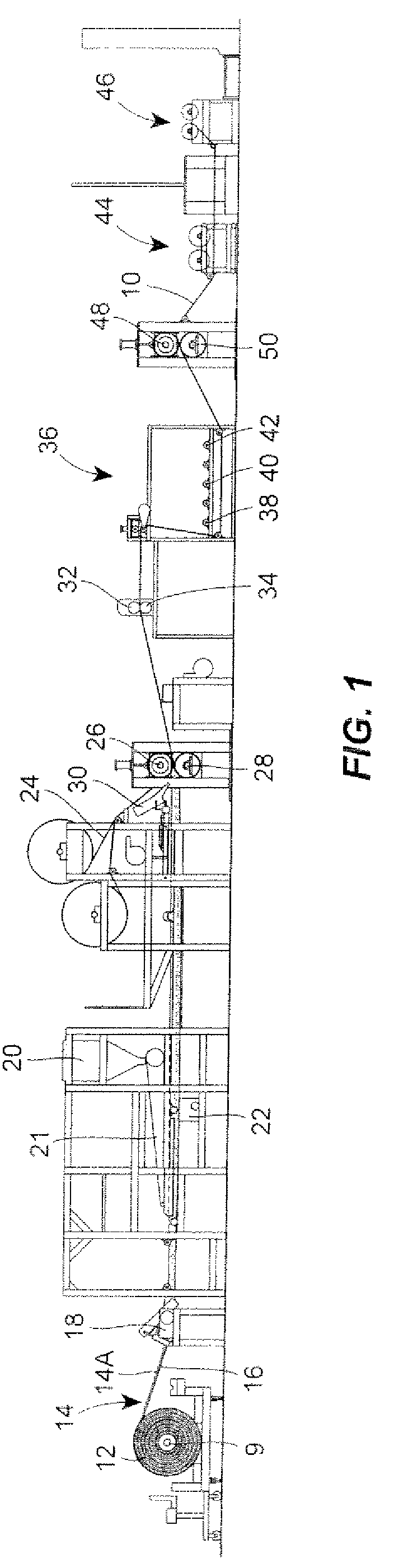

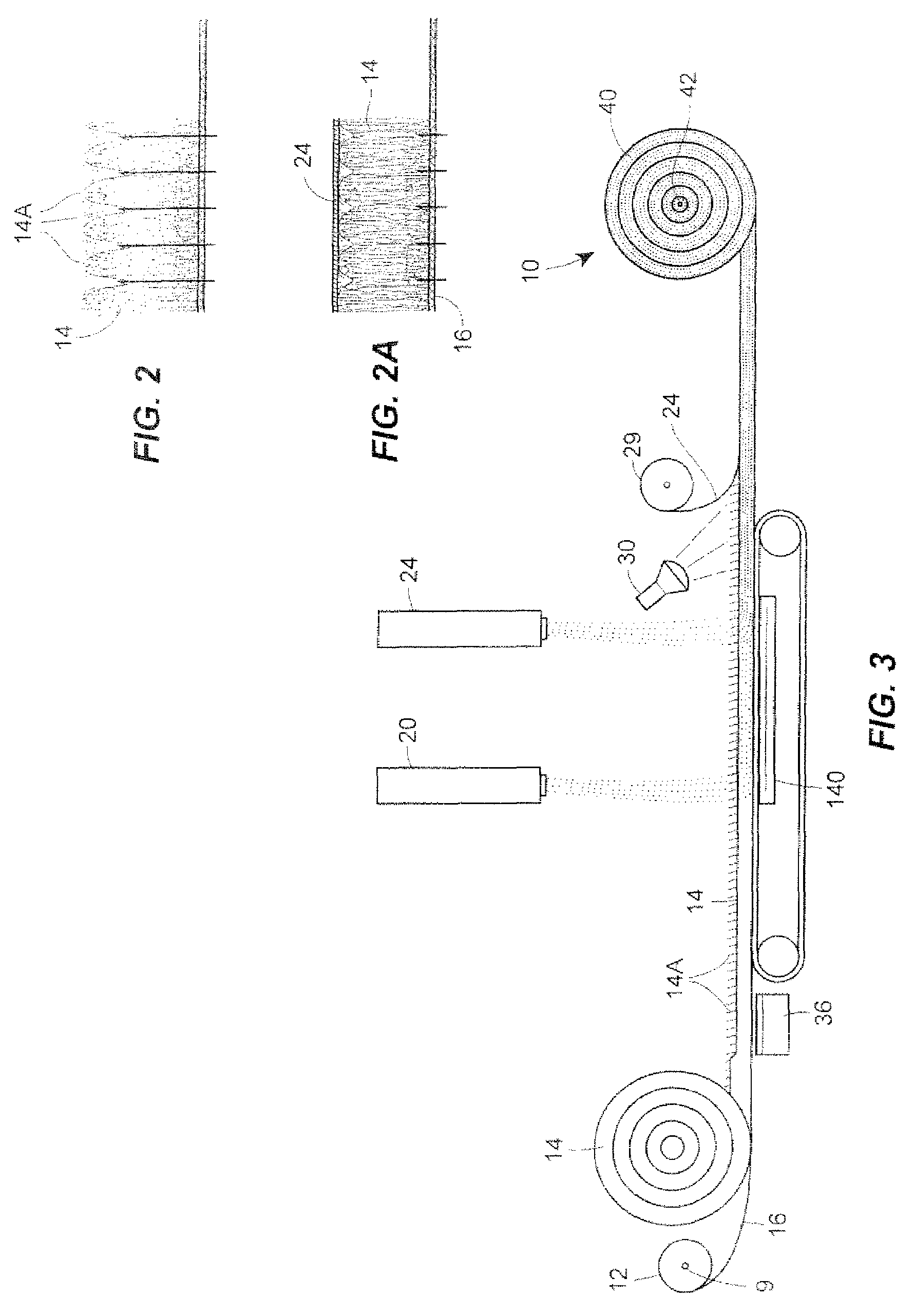

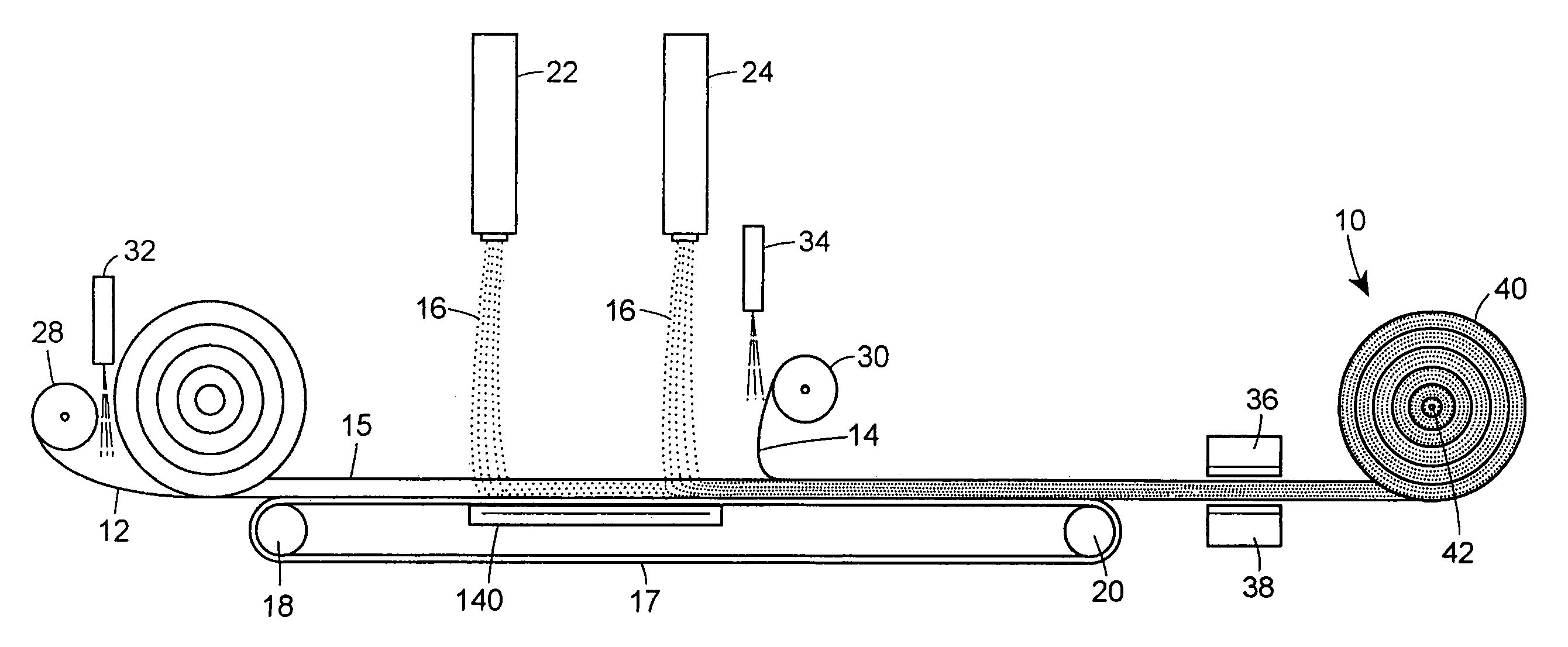

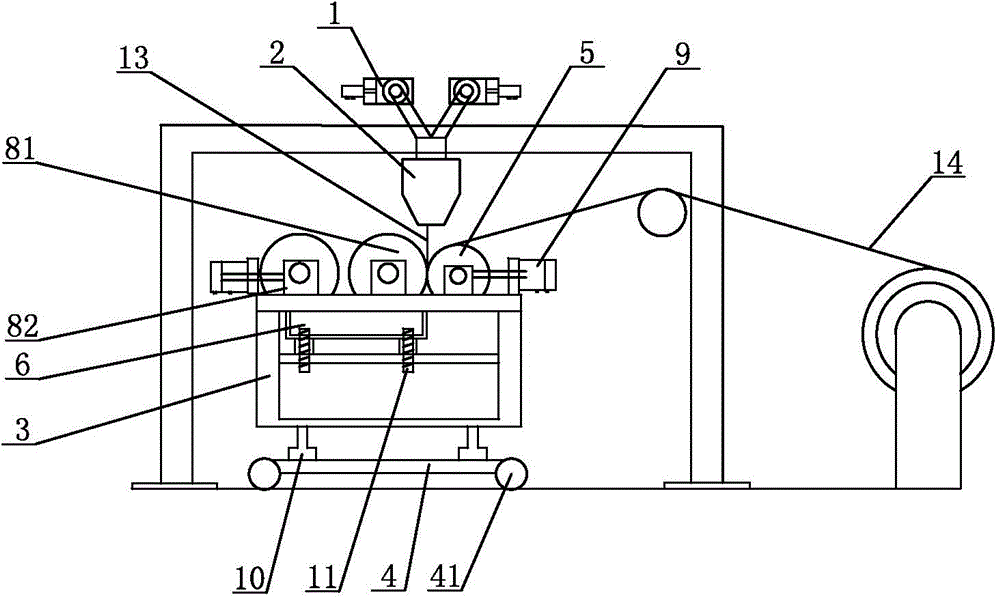

Extrusion casting machine calendering apparatus

ActiveCN104875317AFree from pressure gap restrictionsThe distance is easy to adjustGeomembraneEngineering

The present invention discloses an extrusion casting machine calendering apparatus, which comprises an extruder, a die, a calendering rack, a base, a calendering roller set, a glue roller and a water tank, wherein the calendering roller set and the glue roller are arranged on the calendering rack, the water groove is arranged below the calendering roller set, the die is arranged above the calendering roller set and is connected with the extruder, the calendering rack is arranged above the base, and a stretching device is arranged between the base and the calendering rack. With the equipment of the present invention, the produced geomembrane sheet thickness range is wide, the geomembrane and the geotechnological composite material can be concurrently produced, and the defect that the membrane blowing method can not produce the composite material is overcome.

Owner:CHANGZHOU DALI PLASTICS MACHINERY

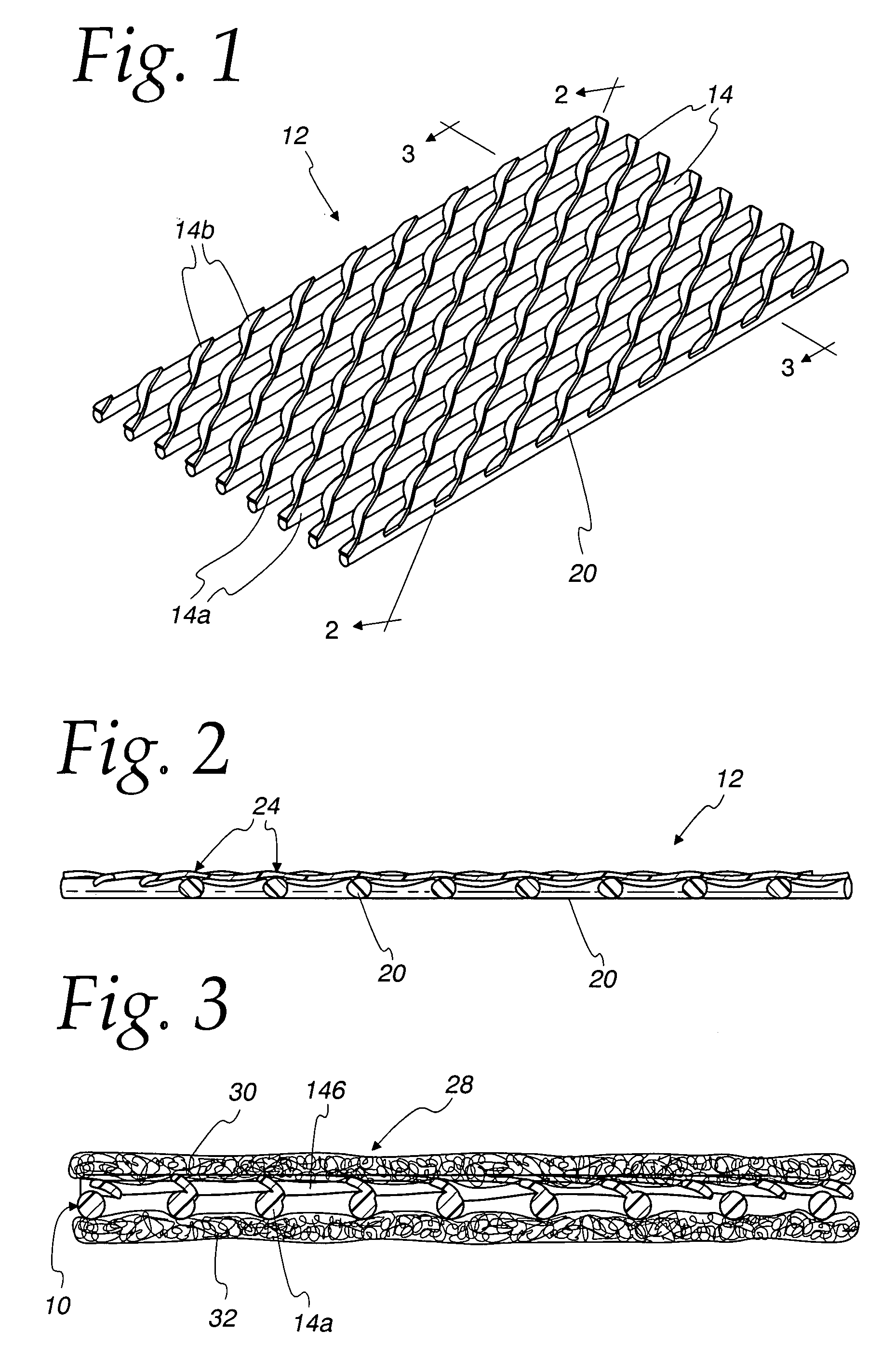

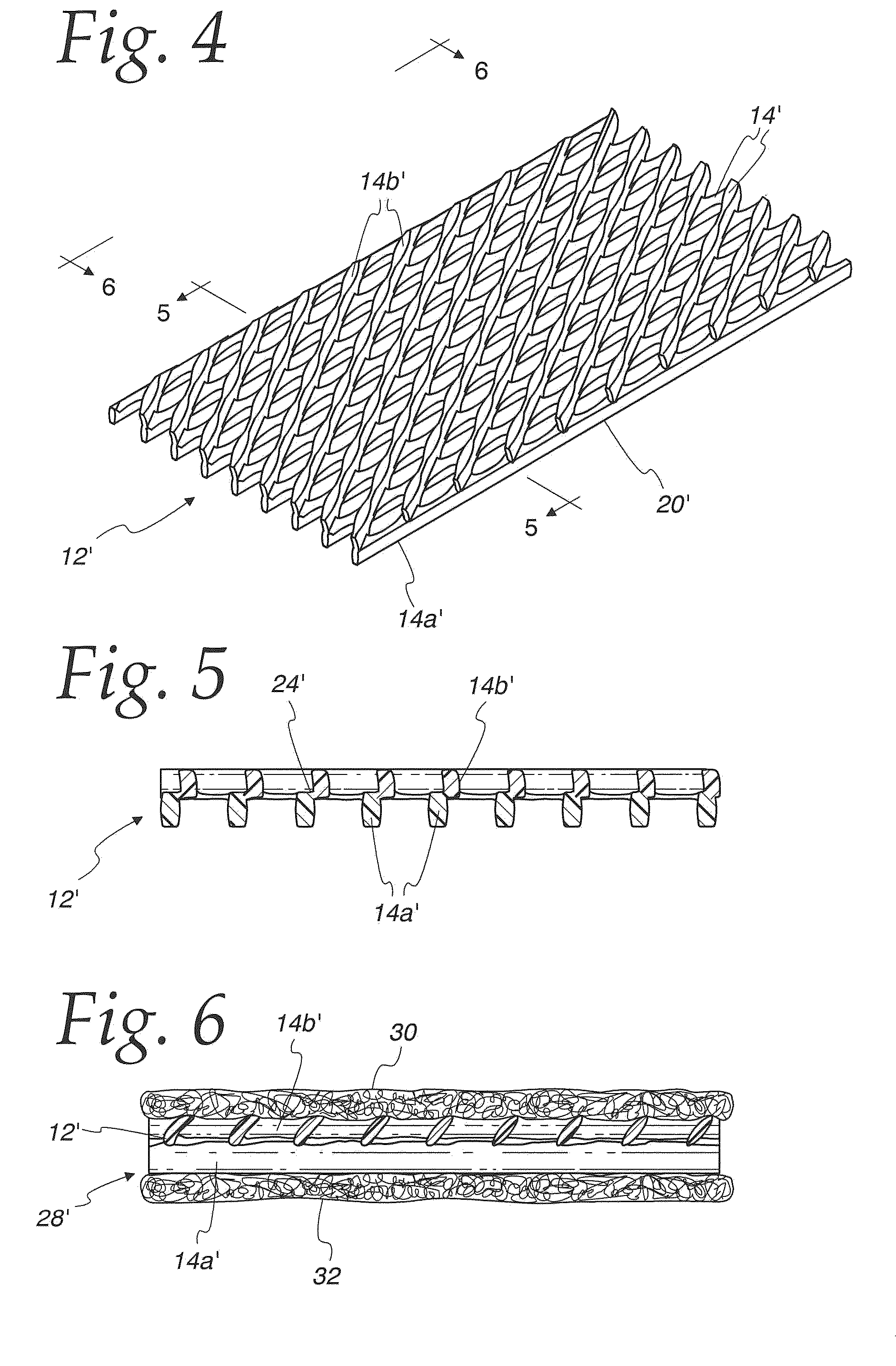

Geosynthetic composite for filtration and drainage of fine-grained geomaterials

A geocomposite with a geonet and a geotextile. The geotextile has a nonwoven fabric layer and a woven fabric layer, with the nonwoven fabric connected by needle-punching to the woven fabric whereby fibers of the nonwoven fabric extend through and beyond the woven fabric, and the woven fabric and fibers of the nonwoven fabric extending through the woven fabric are bonded to one side of the geonet.

Owner:GSE ENVIRONMENTAL

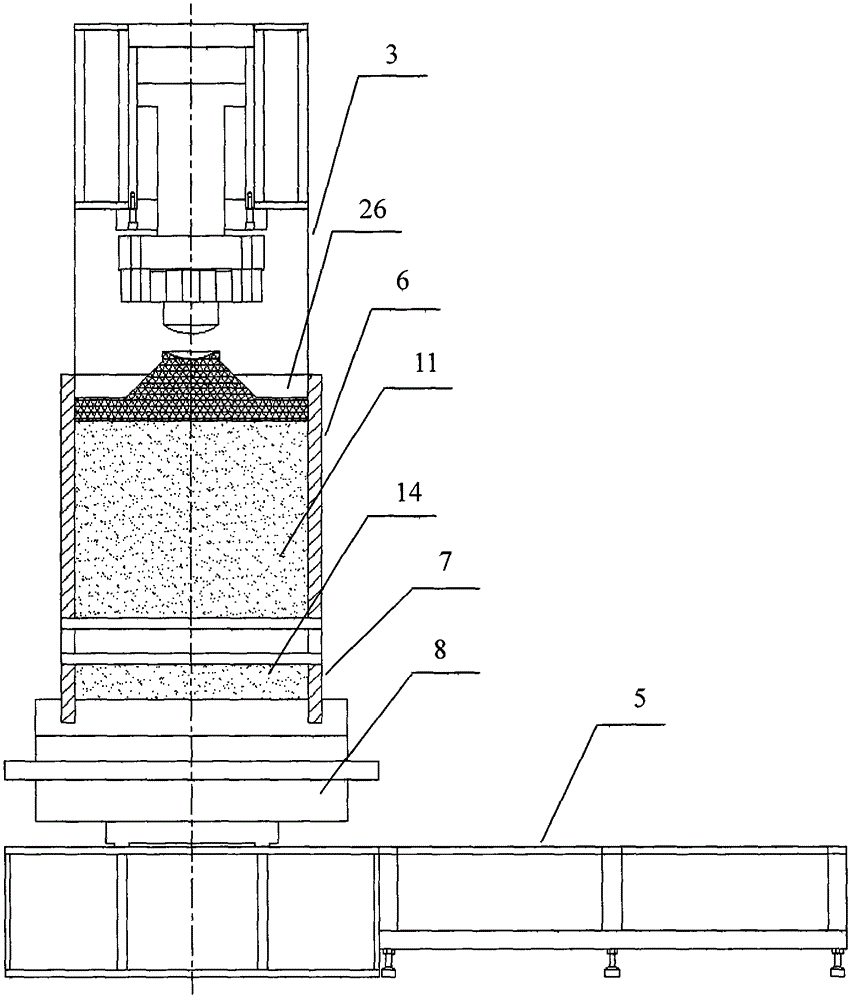

Geosynthetic material contact surface friction strength test method

InactiveCN105004666AEasy to manufactureHigh measurement accuracyUsing mechanical meansMaterial analysisGeomembraneShear stress

The invention relates to a geosynthetic material contact surface friction strength test method, which is characterized by employing a test device to acquire geosynthetic material contact surface friction strength parameters. The device comprises a reaction frame (1), a loading frame (2), a first servo motor (3), a second servo motor (4), a sample carrying platform (5), an upper shear box (6), a lower shear box (7), a rail car (8), a horizontal slide rail (17), a horizontal loading shaft (22), and a vertical loading shaft (25), etc. Through the interaction of a geosynthetic material and a geologic body under the action of different vertical loads, normal stress and shear stress on an oblique section can be obtained, thereby acquiring friction strength parameters. The method provided by the invention can be used for acquiring the friction strength parameters between various geosynthetic materials including geotechnical fabrics, geomembranes, geotechnical cloth, geogrids, geotechnical pads, geotechnical special materials, geocomposites and the like in civil engineering or geological engineering and geologic bodies.

Owner:云南武易高速公路建设指挥部 +1

Contaminant-reactive geocomposite mat and method of manufacture and use

InactiveUS20090208290A1Minimize breakageHollow inflatable ballsHollow non-inflatable ballsFiberPorosity

Reactive geocomposite mats, and their method of manufacture, for treating contaminants in sediment, soil or water that allow the passage of essentially non-contaminated water therethrough. The geocomposite mat includes a pre-formed woven or non-woven geotextile, that is needlepunched to an outer geotextile sheet layer to provide a high loft, structurally secured, pre-formed geotextile having a thickness of about 6 mm to about 200 mm, and having, a porosity sufficient to receive a powdered or granular contaminant-reactive material, contaminant-sorptive material, or a contaminant-neutralizing material (hereinafter collectively referred to as “contaminant-reactant material” or “contaminant-reactive material”) throughout its thickness, or in any portion of the thickness across its entire major surface(s). The powdered or granular contaminant-reactive material is disposed within the pores of the previously formed, high loft geotextile mat to surround the fibers, e.g., by vacuum or vibrating the high loft mat while in contact with the contaminant-reactive material to allow the powdered or granular contaminant-reactive material to flow by gravity into the pores of the previously formed, needlepunched geotextile. A liquid-permeable outer geotextile sheet then is secured to the filled geotextile, preferably by heating upwardly extending fibers of the pre-formed geotextile mat to prevent the powdered or granular material from escaping from the geotextile during transportation and installation.

Owner:AMCOL INTERNATIONAL CORPORATION

Geonet for a geocomposite

A geonet having a length substantially greater than its width and including no more than first and second layers of strands. A first plurality of substantially parallel strands extends in the lengthwise direction and defines the first layer of strands, and a second plurality of substantially parallel strands is disposed on top of, and at an angle relative to, the first plurality of strands and defines the second layer of strands. The first and second plurality of strands are substantially incompressible and secured to one another at crossover locations. Geocomposites include geotextile bonded to at least one side of the geonet. The geonets / geocomposites are laid in geotechnical construction sites in the direction of expected drainage flow.

Owner:GSE ENVIRONMENTAL

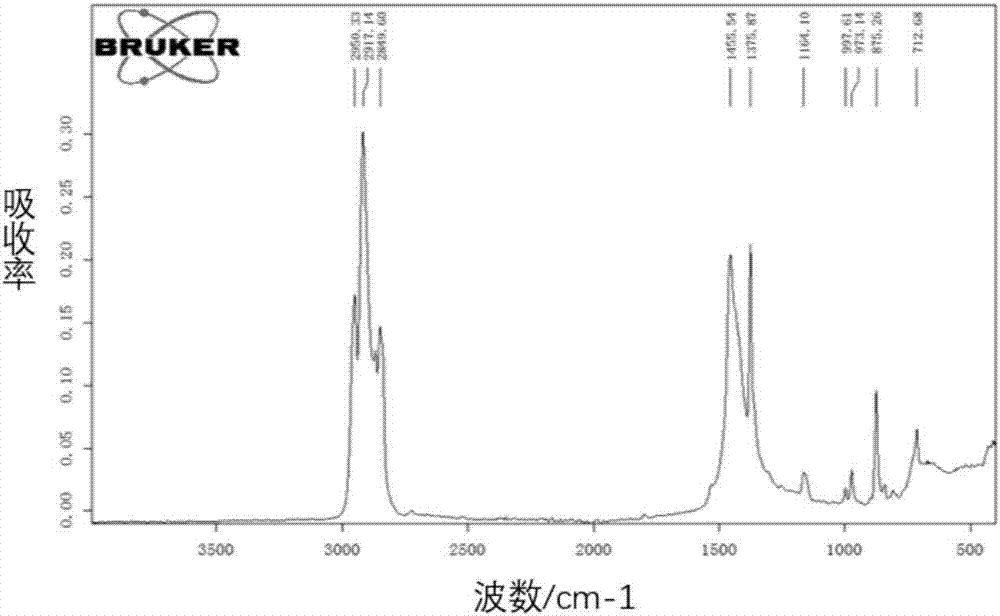

Thermoplastic polyolefin earthwork composite material and preparation method thereof

ActiveCN106891593AGood flexibilityGood extensibilitySynthetic resin layered productsLaminationExtensibilityBursting strength

The invention provides a thermoplastic polyolefin earthwork composite material and a preparation method thereof and belongs to the technical field of water-power engineering. The thermoplastic polyolefin earthwork composite material is used for solving the problem that the present impermeable material cannot be applied to the water-power engineering for a long time. The thermoplastic polyolefin earthwork composite material includes a thermoplastic polyolefin layer and a geo-fabric layer which are compounded with each other. The composite material has high flexibility, extensibility and durability of rubbers and excellent fusing processing characteristics of thermoplastic plastics, contains no plasticizer, has excellent ultraviolet light aging resistance, high anti-puncturing strength, high anti-burst strength, high hydrostatic pressure resistance and excellent thermal welding performance, is capable of bearing water pressure impact 200m or above, can be directly exposed and applied to the newly constructed and repaired hydraulic and hydro-power engineering for preventing seepage, such as dams, reservoirs, embankments, cofferdams, water channels, tunnels and nuclear power plants, and has the service life as same as the service life of the constructions.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

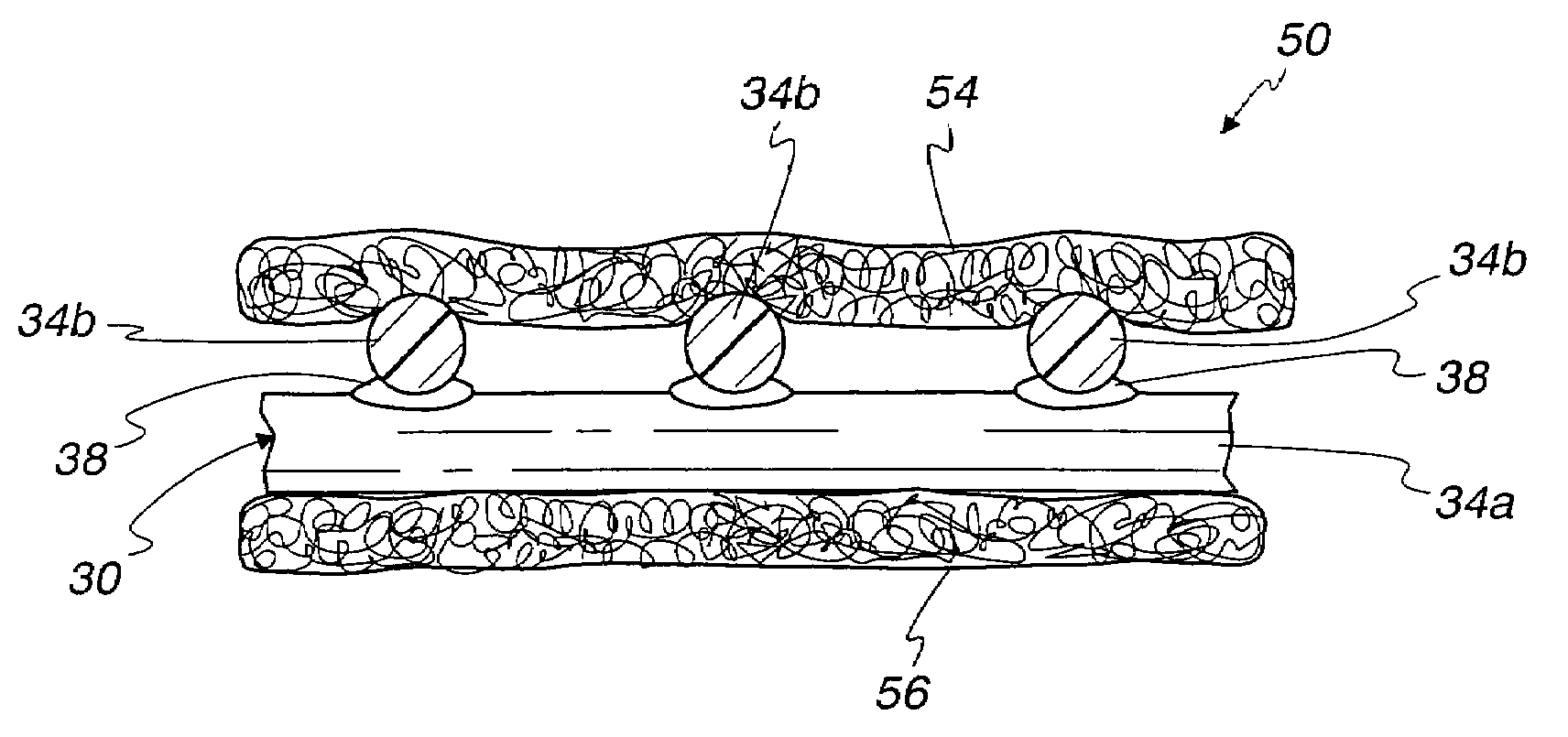

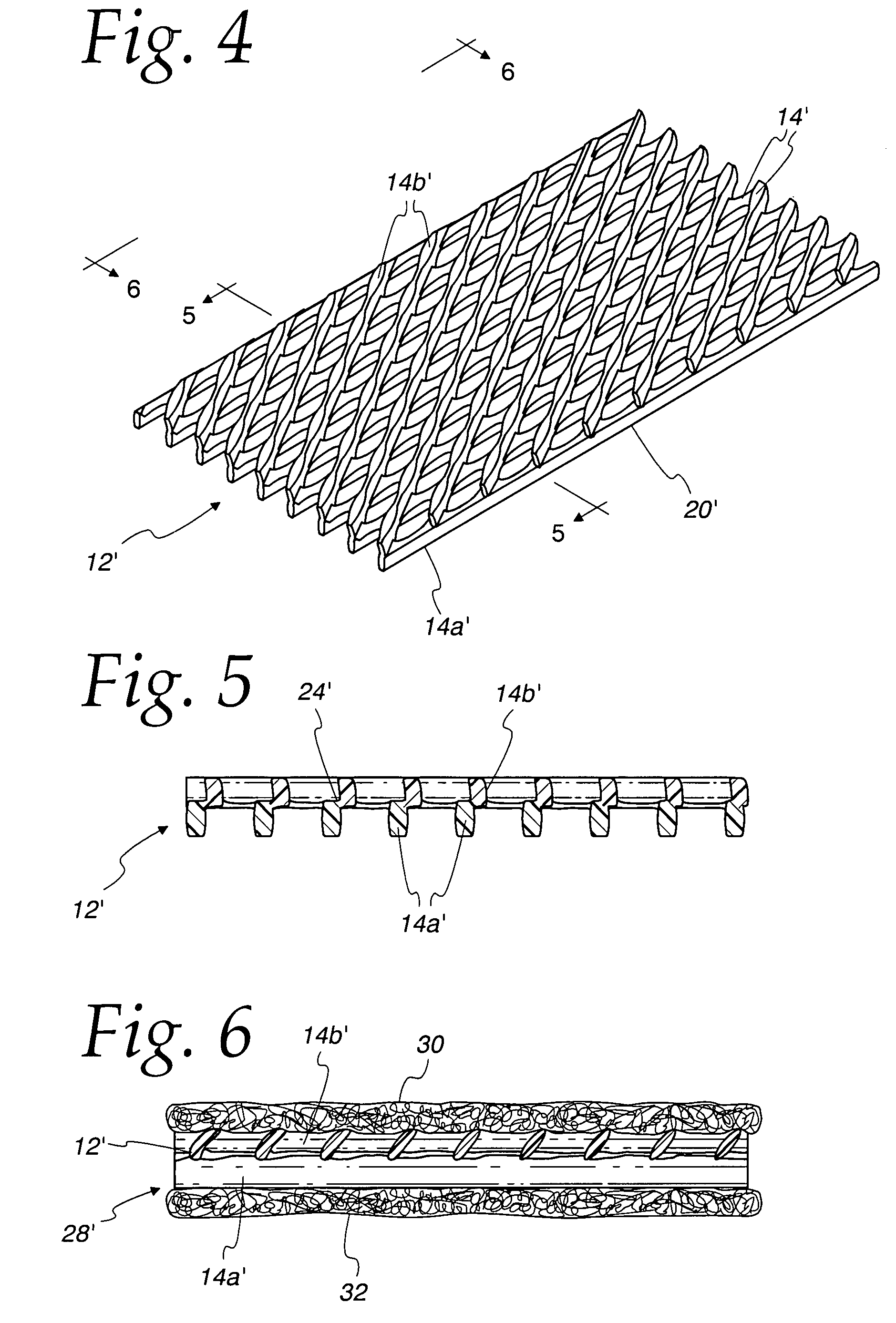

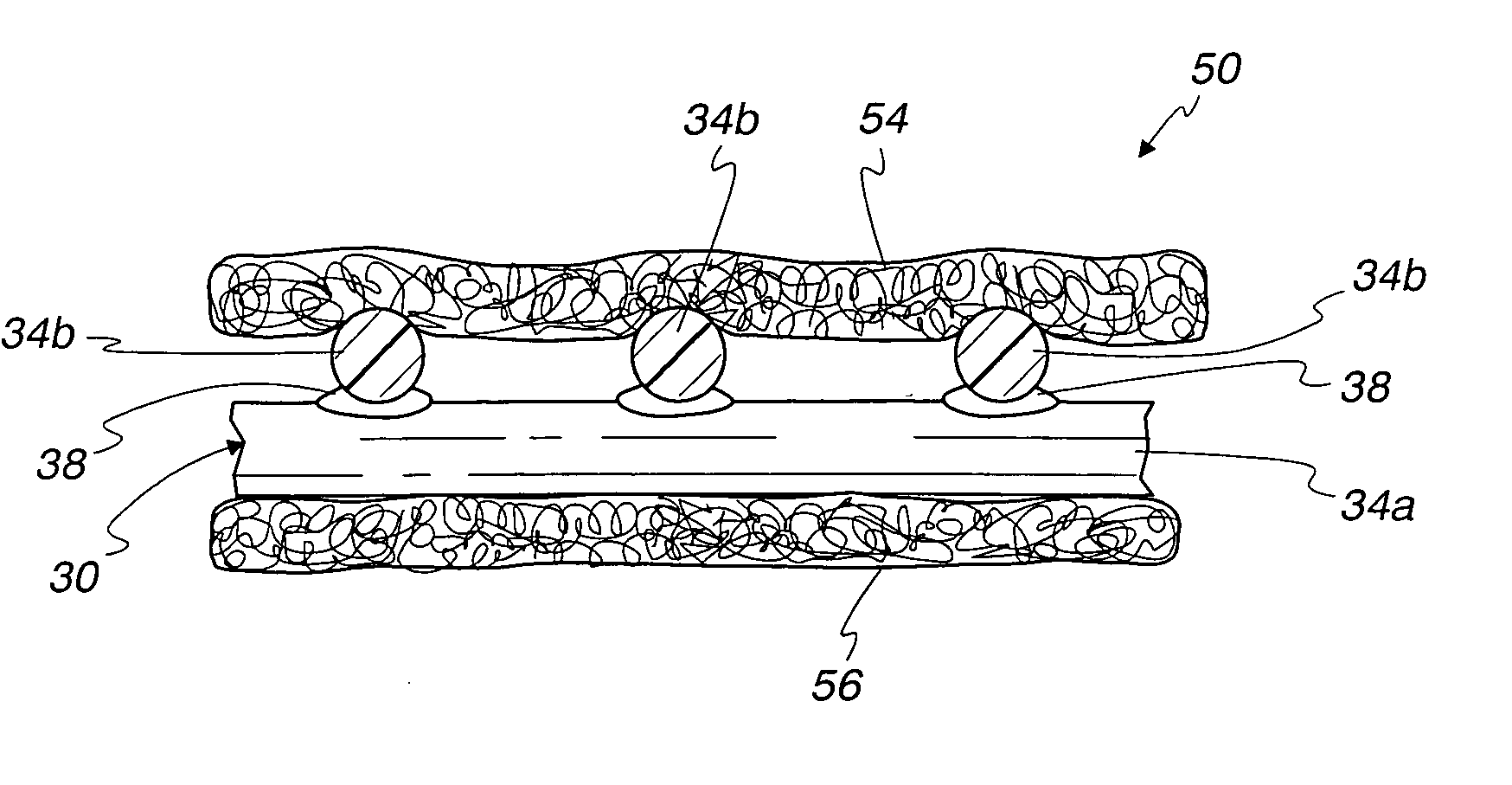

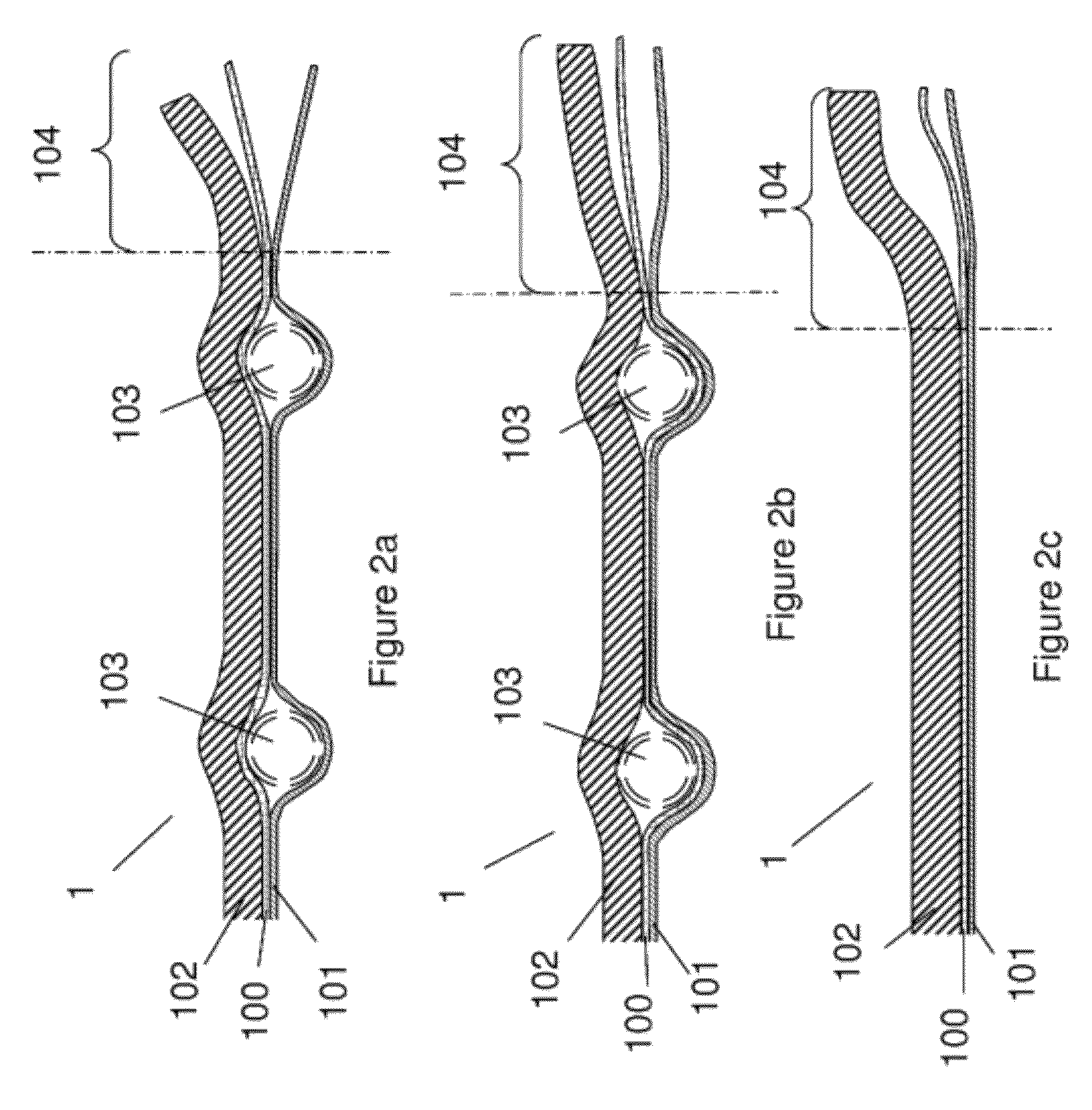

Fuzzy woven layers, geocomposite laminates incorporating them, and related methods

InactiveUS8039081B2Secure attachmentImprove featuresAdhesive processes with surface pretreatmentSoil drainagePermittivityVoids in mineral aggregate

Void-maintaining laminates comprising fuzzy woven or fuzzy membrane layers are provided. Laminates of the present invention comprise at least one sheet-like core element, typically comprising void spaces or channels and, bonded thereto, at least one layer of fuzzy woven composite for use in geotechnical applications. The superior adhesion or bonding of the respective layers to one another, and its contribution to the structural integrity of void spaces or channels, enables the construction and positioning of drainage composites having the desirable characteristics of high permittivity and high transmissivity. Numerous embodiments of the invention are possible. Fuzzy geocomposites of the invention can be used, for example, underneath buildings, foundations, roadways and other paved structures, or in landfills or other types of geotechnical installations to replace or complement conventional drainage materials such as sand, stone and gravel. Methods for making the fuzzy geocomposites are also provided.

Owner:IANNIELLO PETER J

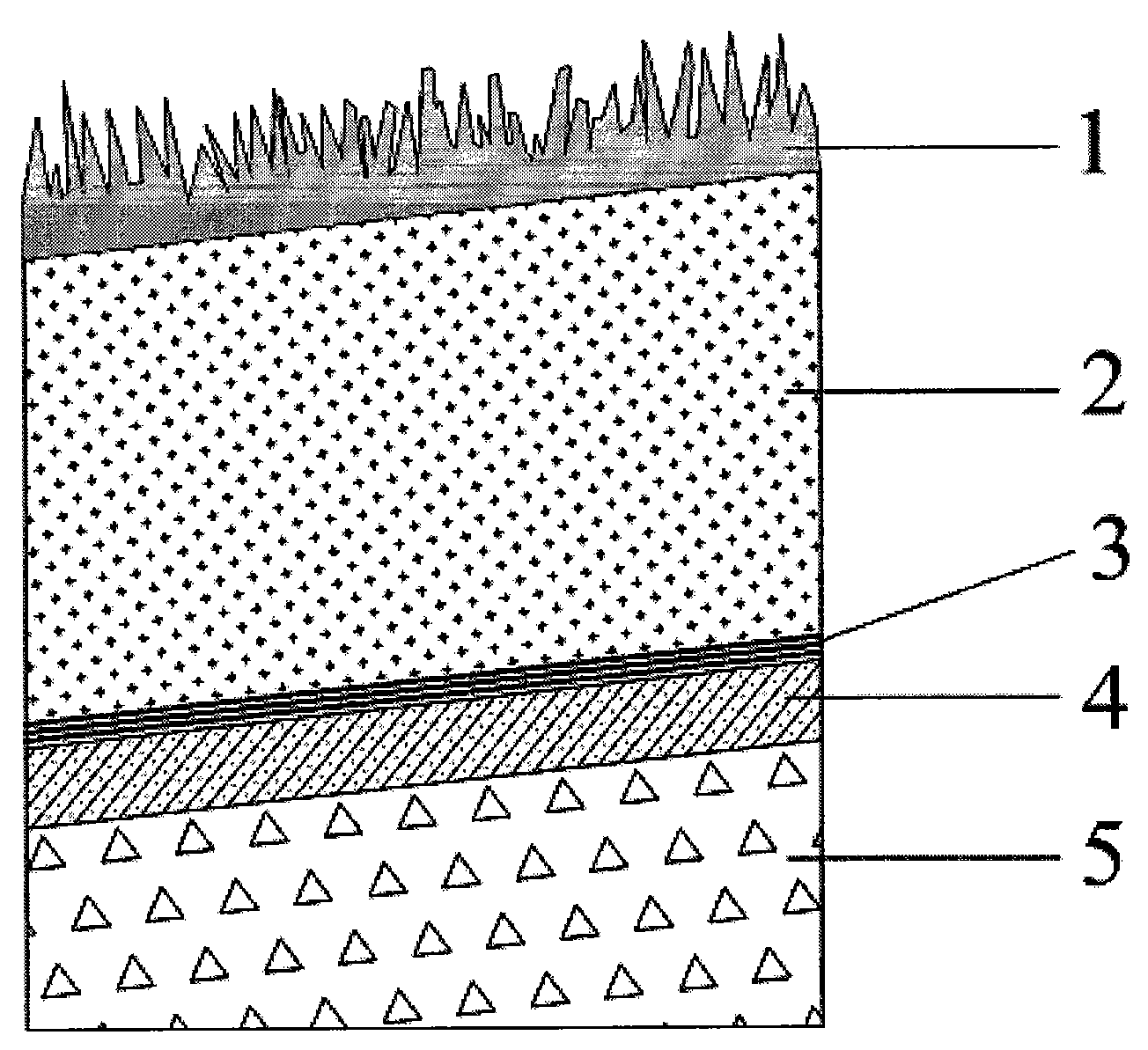

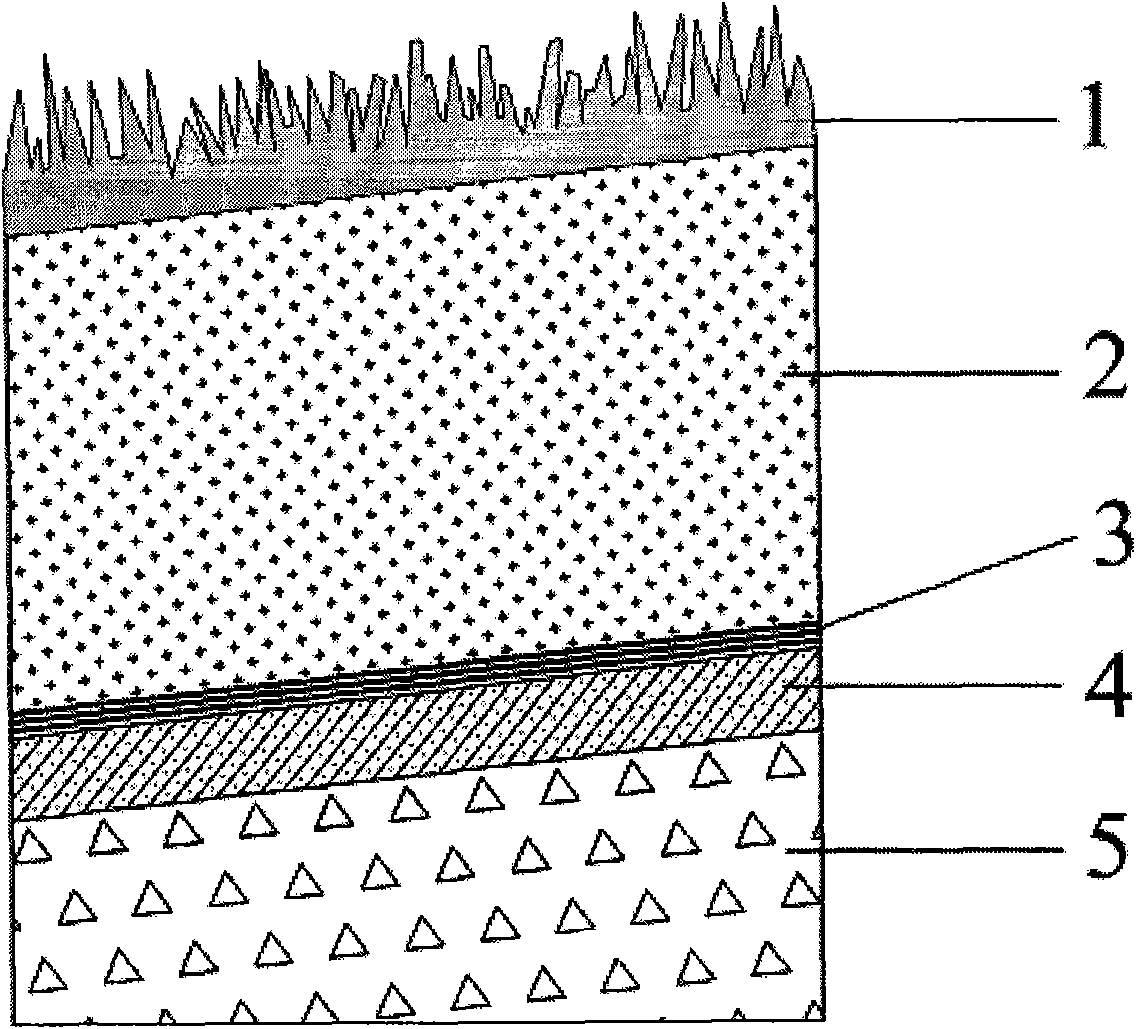

Geocomposite evapotranspiration plugged structure of refuse landfill

InactiveCN101811125ASimple structureImprove water resistanceLandfill technologiesSolid waste disposalVegetationLitter

The invention relates to a geocomposite evapotranspiration plugged structure of a refuse landfill, which comprises an adjustment soil layer, a vegetation growth soil layer and a vegetation layer which cover the refuse from bottom to up, wherein a layer of geocomposite bentonite pad is laid between the adjustment soil layer and the vegetation growth soil layer. The geocomposite evapotranspiration plugged structure can obviously enhance water retention capability of an evapotranspiration covered soil layer, lower rainfall infiltration amount after the landfill is sealed, and expand the application of the evapotranspiration plugged structure in sub-humid-humid areas.

Owner:SHANGHAI UNIV

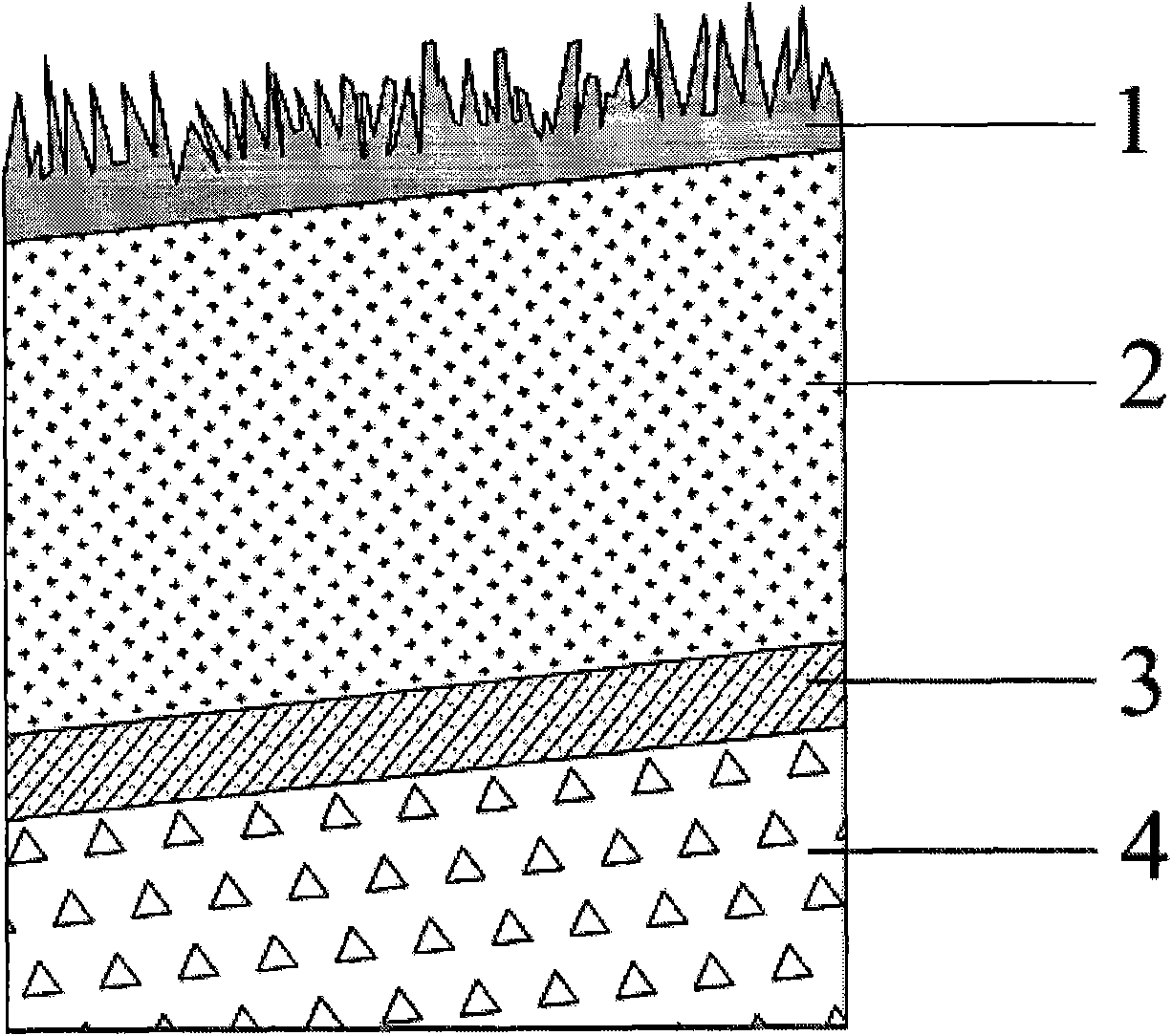

Earthworking composite material and its manufacture method

This invention relates to a soil mechanics compound material and its manufacturing method characterizing that the structure of the material is formed by one layer of soil mechanic film, an upper layer soil fabric, a layer of bentonite and lower layer soil fabric from top to the bottom. The bentonite is placed between the two soil fabrics by chemical adheres, the soil film is combined with the upper soil fabric. The method is first of all to finish the high temperature high pressure heat compound of the film and the upper soil fabric, then to coat adhesion agent and spread bentonite between the bottom surface of the upper fabric and the top surface of lower fabric then to be extruded to formation.

Owner:郎荣良

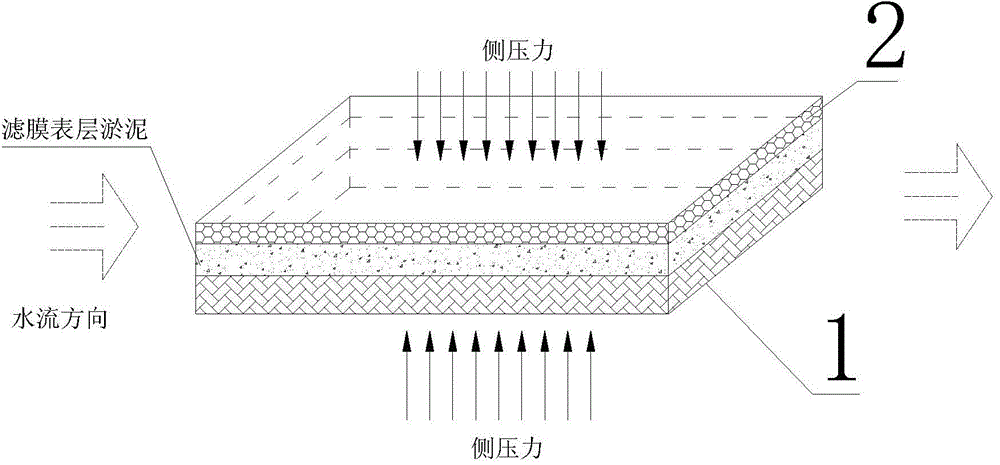

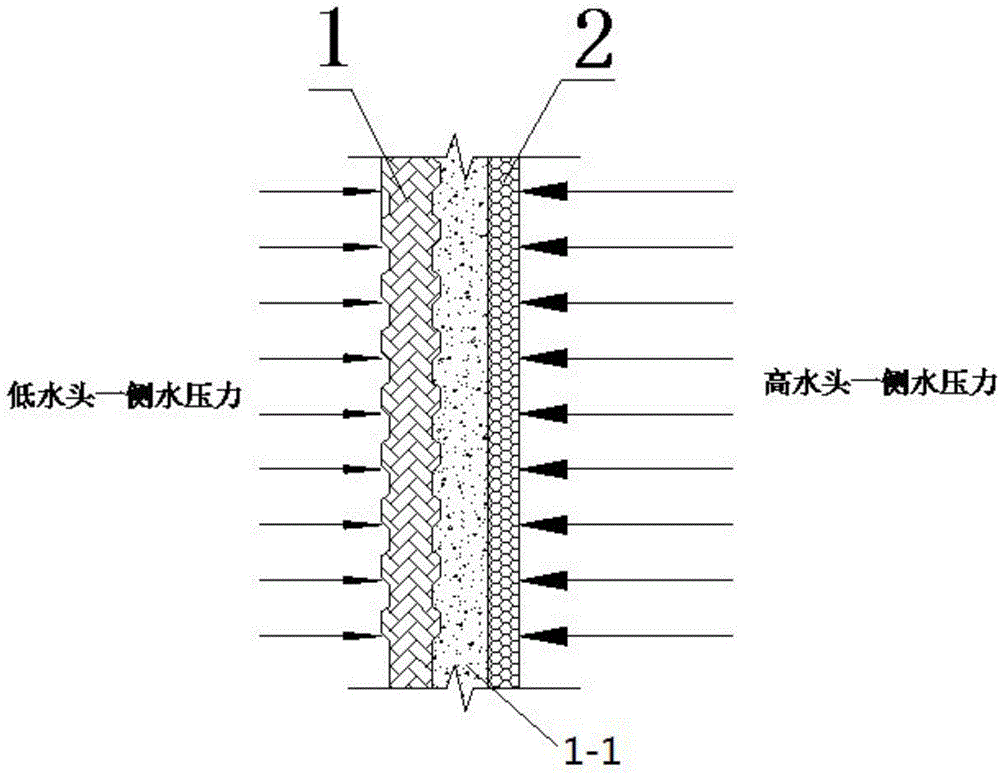

Vertical permeability clogging and reduction testing device of geocomposite drainage material filter membrane and detection method thereof

PendingCN104655543AImprove water tightnessImprove air tightnessPreparing sample for investigationPermeability/surface area analysisTest sampleMembrane surface

The invention belongs to the technical field of geosynthetic testing, and relates to a vertical permeability clogging and reduction testing device of a geocomposite drainage material filter membrane. In the processes of the method, a filter membrane test sample contains filter membrane surface depositing soil and is made by taking a geocomposite drainage material that clogging occurs after use out of a soil layer in accordance with a preset sample making method. The test sample is subjected to a contrast test with a filter membrane test sample which is not used by virtue of a researched vertical permeability coefficient testing device (the device can be used for testing filter membrane vertical permeability coefficients under conditions of different hydraulic gradients and different lateral pressure coefficients), so as to obtain filter membrane clogging and reduction indexes. The invention provides a method and a corresponding device for the quantitative test of clogging and reduction of the geocomposite drainage material filter membrane for the first time; and the device has the advantages of being simple, easy and simple in operation and high in measurement precision, and is suitable for testing the vertical permeability coefficient of a geocomposite composite material.

Owner:GUANGXI UNIV

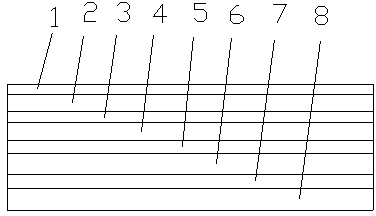

Plastic geocomposite film having high anti-seepage performance

InactiveCN103660475AImprove anti-seepage performanceHigh tensile strengthSynthetic resin layered productsWoven fabricsPolyesterPlastic film

The invention discloses a plastic geocomposite film having high anti-seepage performance. The plastic geocomposite film includes a first anti-seepage plastic thin film layer, a first reinforcing geotextile layer, a second anti-seepage plastic thin film layer, a second reinforcing geotextile layer, a third anti-seepage plastic thin film layer, a third reinforcing geotextile layer, a fourth anti-seepage plastic thin film layer and a fourth reinforcing geotextile layer which are successively arranged; the first reinforcing geotextile layer, the second reinforcing geotextile layer, the third reinforcing geotextile layer and the fourth reinforcing geotextile layer are each formed by weaving a reinforcing fiber; the reinforcing fiber is prepared by composite twisting of 100-120 nylon fibers, 75-85 polyester fibers and 85-100 cotton fibers. According to the above method, the plastic geocomposite film has simple and reasonable structure, and has relatively high tensile strength and anti-seepage performance.

Owner:CHANGZHOU HEXIANG PLASTIC

Geosynthetics with transponder technology

Synthetic geomaterials, such as geotextiles, geocomposites or geogrids (woven, knitted or of monolithic strips), characterized in that the synthetic geomaterial comprises at least one transponder applied thereon for storing and for calling up data related to product and / or state and condition and / or project.

Owner:TENCATE GEOSYNTHETICS AUSTRIA GES +1

Novel plastic geocomposite film

InactiveCN103660476ASimple structureIncrease roughnessSynthetic resin layered productsFiberCarbon fibers

The invention discloses a novel plastic geocomposite film including an anti-seepage plastic film layer. One side face of the anti-seepage plastic film is provided with a tensile reinforcing layer; the tensile reinforcing layer comprises warp yarns and weft yarns, the warp yarns and the weft yarns are all high-strength blended yarns, and the high-strength blended yarns are each formed by compositing 50-60 cotton fibers and 30-40 carbon fibers; the outer side face of the tensile reinforcing layer is provided with a rough structural layer, and the rough structural layer comprises base cloth and a plurality of hard components distributed on the outer side face of the base cloth. According to the above method, the plastic geocomposite film has simple and reasonable structure, allows the side face used for paving to have higher roughness, has good stability after paving, does not generate a slippage phenomenon, and especially can more reflect the advantages when being paved on a slope.

Owner:CHANGZHOU HEXIANG PLASTIC

Self healing salt water barrier

ActiveUS9995014B2Prevent penetrationCoastlines protectionProtective foundationCross-linkWater insoluble

Geocomposite articles that can provide a barrier against high conductivity water e.g., ocean water, are described and their method of manufacture, for waterproofing surfaces that contact high conductivity water. The geocomposite article mat includes a woven or non-woven geotextile sheet or mat containing a powdered or granular partially cross-linked acrylamide / acrylate / acrylic acid copolymer across its entire major surface(s). The powdered or granular copolymer has an unexpectedly high free-swell when hydrated with High Conductivity water, such as ocean water. A liquid-impermeable cover sheet is adhered to the upper major surfaces of the filled copolymer-carrying geotextile to provide a primary high conductivity water barrier layer that, if ruptured, is sealed by the swell of an underlying layer of water-insoluble, partially cross-linked acrylamide / acrylic acid copolymer.

Owner:AMCOL INTERNATIONAL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com