Contaminant-reactive geocomposite mat and method of manufacture and use

a geocomposite mat and contaminant-reactive technology, applied in the field of contaminant-reactive geocomposite mat and method of manufacture and use, can solve the problem of restricting the aqueous flow through the mat by pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

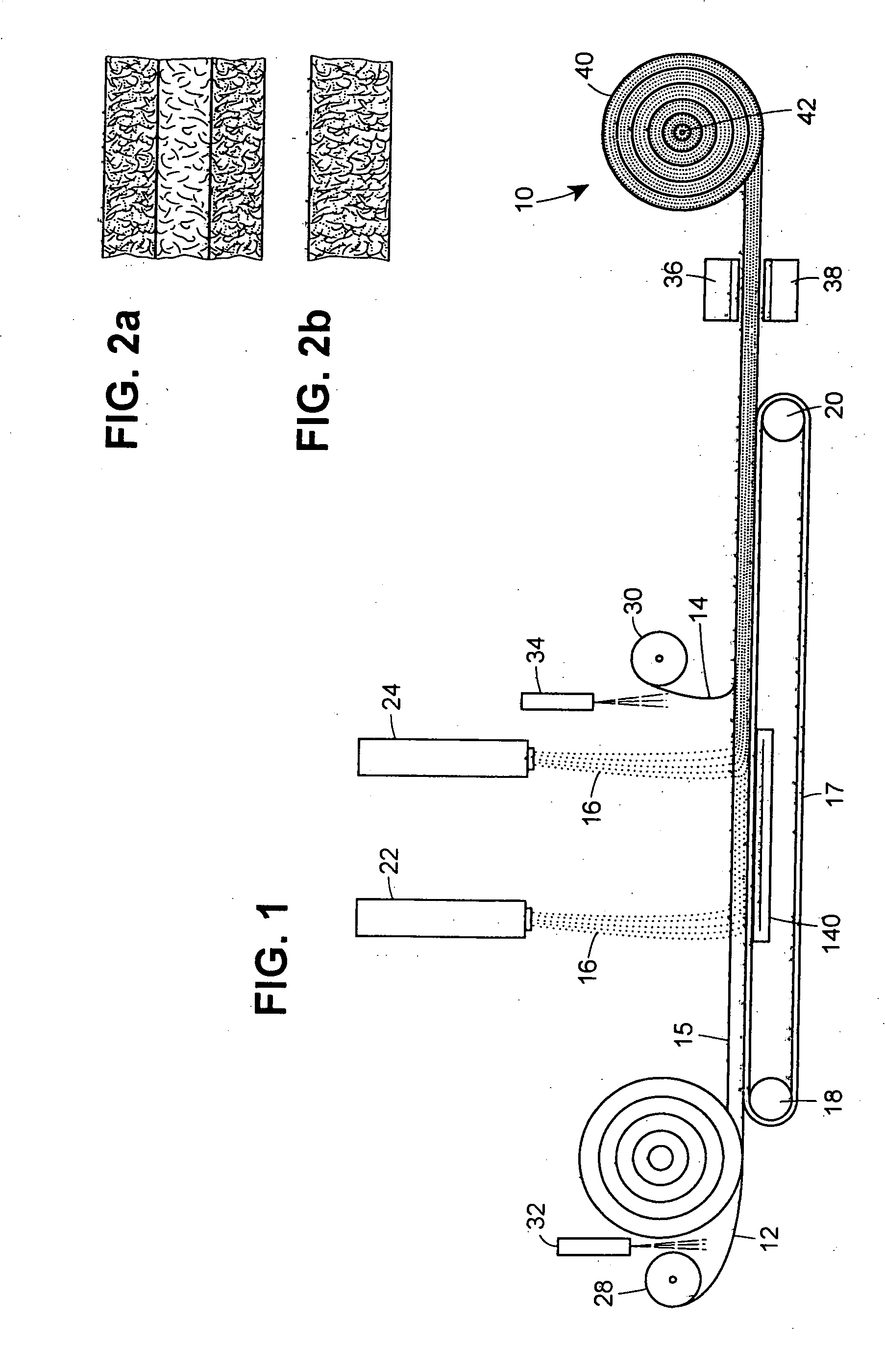

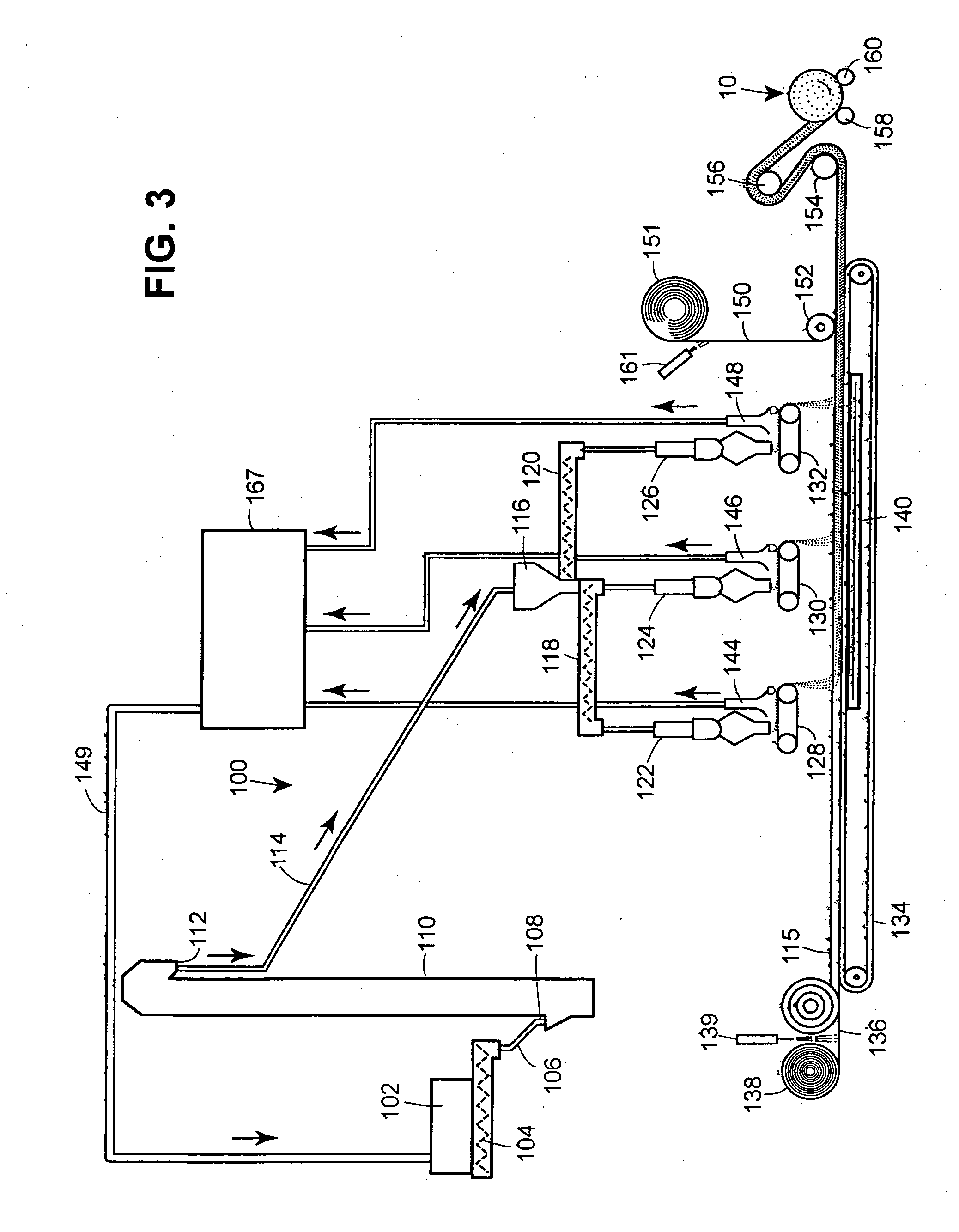

[0020] Turning now to FIG. 1, there is shown a schematic diagram for manufacturing the geocomposite articles 10 described herein, including many optional features any one or more of which can be included in the manufacturing process to provide various characteristics and properties to the geocomposite articles.

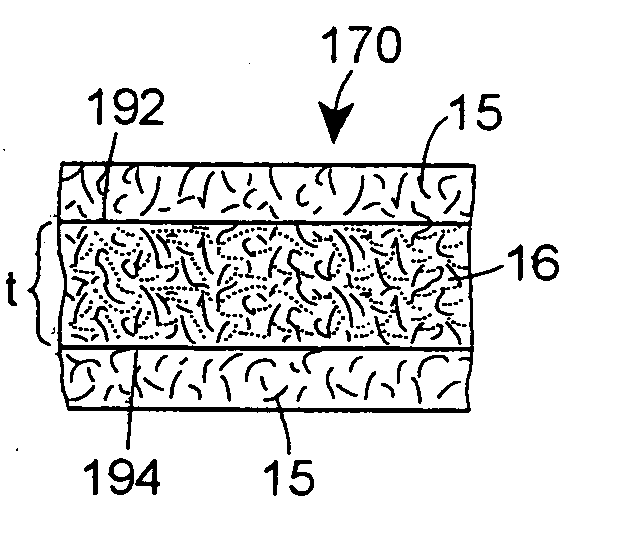

[0021] The geocomposite article 10 is manufactured to include a layer of woven or non-woven liquid-permeable sheet material 12 and 14 on both major exterior surfaces; various reinforcing material can be included within the interior and / or exterior of the article to provide structural reinforcement or to provide various degrees of article rigidity; portions of the high loft geotextile 15, along its upper and / or lower major surfaces can be left with low concentrations of, or without, a powdered or granular material so that a portion of the article is very porous to allow for venting of gases captured by the article from below; and powdered or granular materials such as a contam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com