Earthworking composite material and its manufacture method

A geotechnical composite material and manufacturing method technology, applied in excavation, infrastructure engineering, construction and other directions, can solve the problems of uneven top and bottom of bentonite layer, affecting the effect of clay pad to prevent liquid leakage, inconvenient use, etc., and achieve good results. , good leakage, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

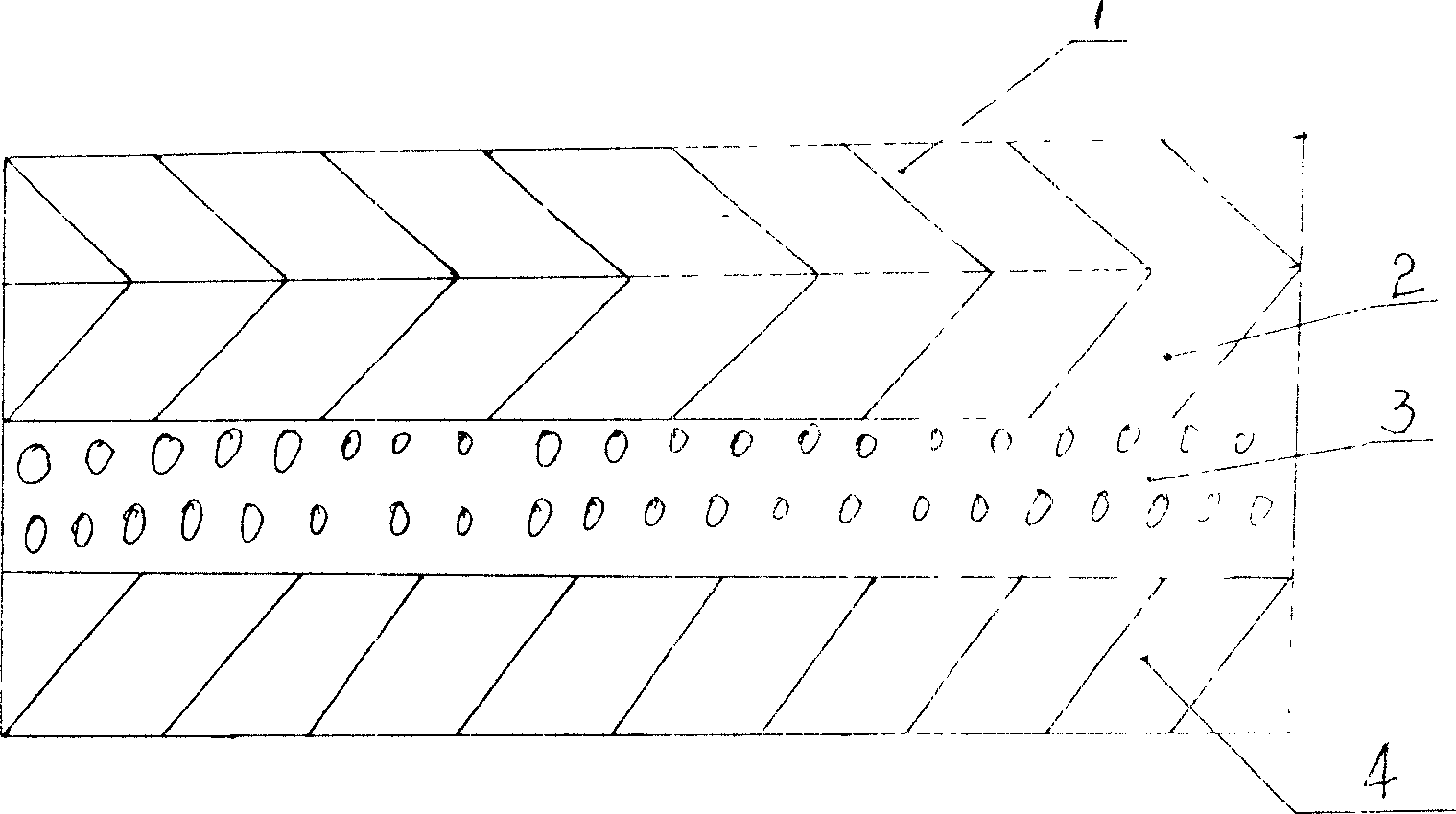

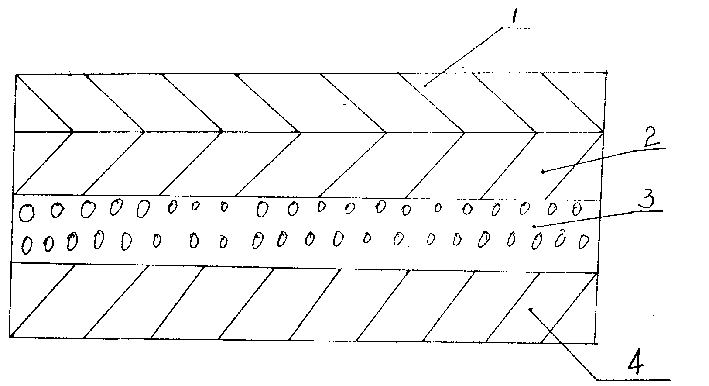

[0008] refer to figure 1 , the geotechnical composite material consists of a layer of geomembrane (1), an upper layer of geotextile (2), a bentonite layer (3), and a lower layer of geotextile (4) from top to bottom. The upper surface of the upper geotextile (2) is composited with the geomembrane (1), and the lower surface of the upper geotextile (2) is coated with an adhesive to adhere to the lower surface of the bentonite layer (3) below it. The surface, the upper surface of the lower geotextile (4) is also coated with an adhesive to adhere to the lower surface of the bentonite layer (3) located thereon, by chemical bonding between the two layers of geotextiles (2), (4) ) between the bentonite layer (3) and the geomembrane (1) compounded with the upper geotextile (2), both of which prevent the leakage of liquid gas.

[0009] The manufacturing method of this geotechnical composite material is to first complete the high-temperature and high-pressure thermal compounding of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com