A silo tank for preventing mold at the bottom of silage material and its construction method

A technology for silage ponds and silage materials, which is applied in the field of silage ponds and its construction, can solve the problems that silage materials are prone to mildew, affect the food safety of livestock, and reduce the quality of silage feed, and achieve simple structure, low cost and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

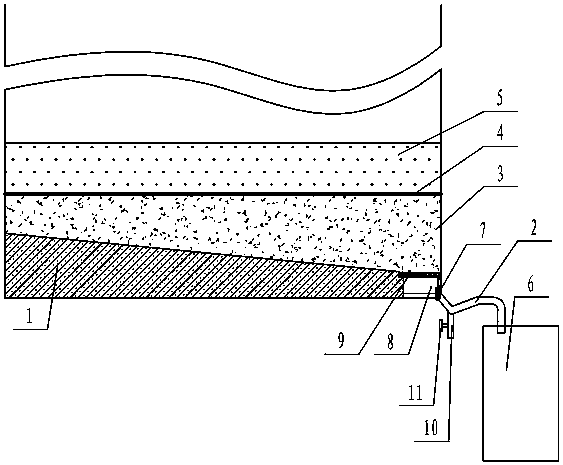

[0032] Embodiment 1: as Figure 1~Figure 2 Shown, a kind of silage pond that prevents the moldy bottom of silage material, comprises silage pond 1 and drainage pipe 2, spreads sandy soil layer 3, plastic film 4 and hay layer 5 successively at the bottom of silage pond 1 from bottom to top, and in silage pond 1 One side of the bottom of the pool 1 is provided with a sump 8, and the sump 8 is provided with a partition 9 with a through hole. The sump 8 is connected with the drain pipe 2, and the drain pipe 2 directly discharges the silage solution to the silage solution for collection. In the pool 6, the plastic film 4 is provided with a through hole covering the film surface, and the bottom surface of the silage pool 1 is set as an inclined plane, and the inclined plane is inclined to the side of the liquid collection tank 8, the inclination is 0.5~1:100, and the thickness of the hay layer 5 is The thickness of the plastic film 4 is 0.04mm, the thickness of the sand layer 3 is 3...

Embodiment 2

[0037] Embodiment 2: a kind of construction method of the silage tank that prevents the moldy bottom of silage material, this method comprises the following steps:

[0038] (1) Build the four walls of the silage pond with concrete;

[0039] (2) The bottom surface is paved with concrete, and the bottom surface is laid as an inclined surface with an inclination of 0.5~1:100, and a liquid collection tank is installed on the lower side of the inclined surface, and the bottom surface of the liquid collection tank is inclined in the middle;

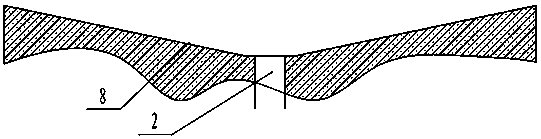

[0040] (3) Install the drain pipe with V-shaped structure in the middle of the sump, with the inner side of the V-shaped facing up, and set the filter screen at the inner end of the drain pipe, and the outlet end of the drain pipe with V-shaped structure facing the outside of the side wall of the silage tank;

[0041] (3) Cover the liquid collecting tank with a partition with a through hole, the diameter of the through hole of the partition is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com