Patents

Literature

431 results about "Feed quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

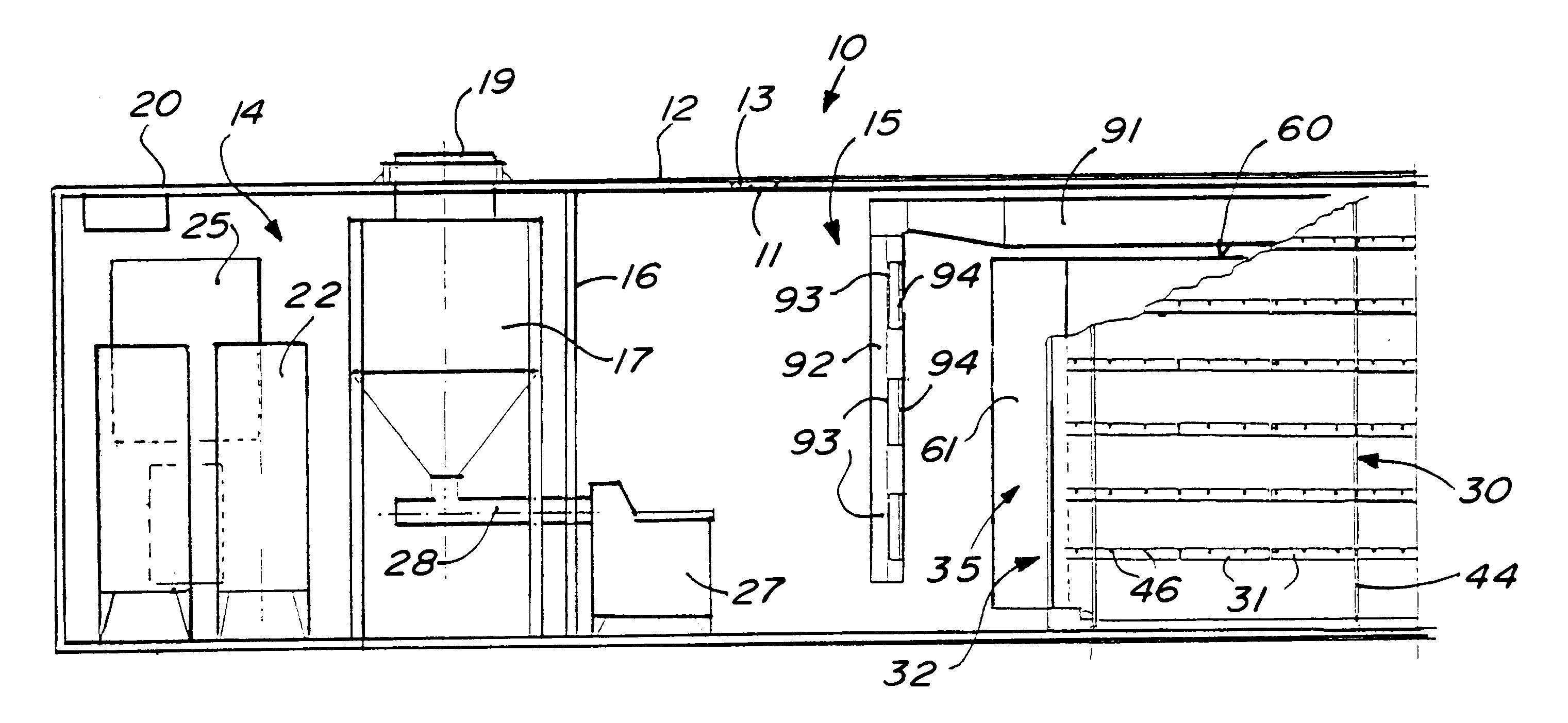

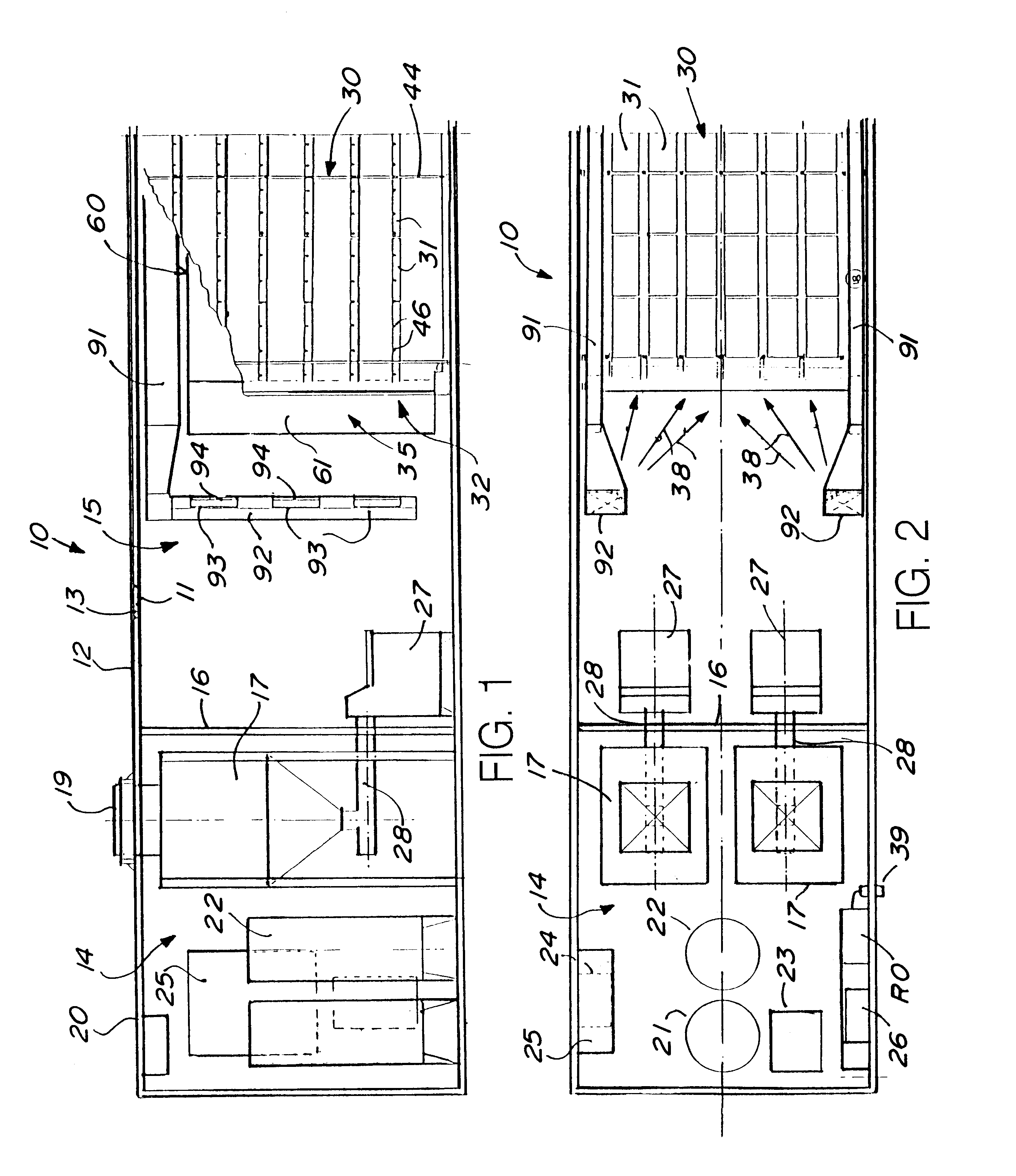

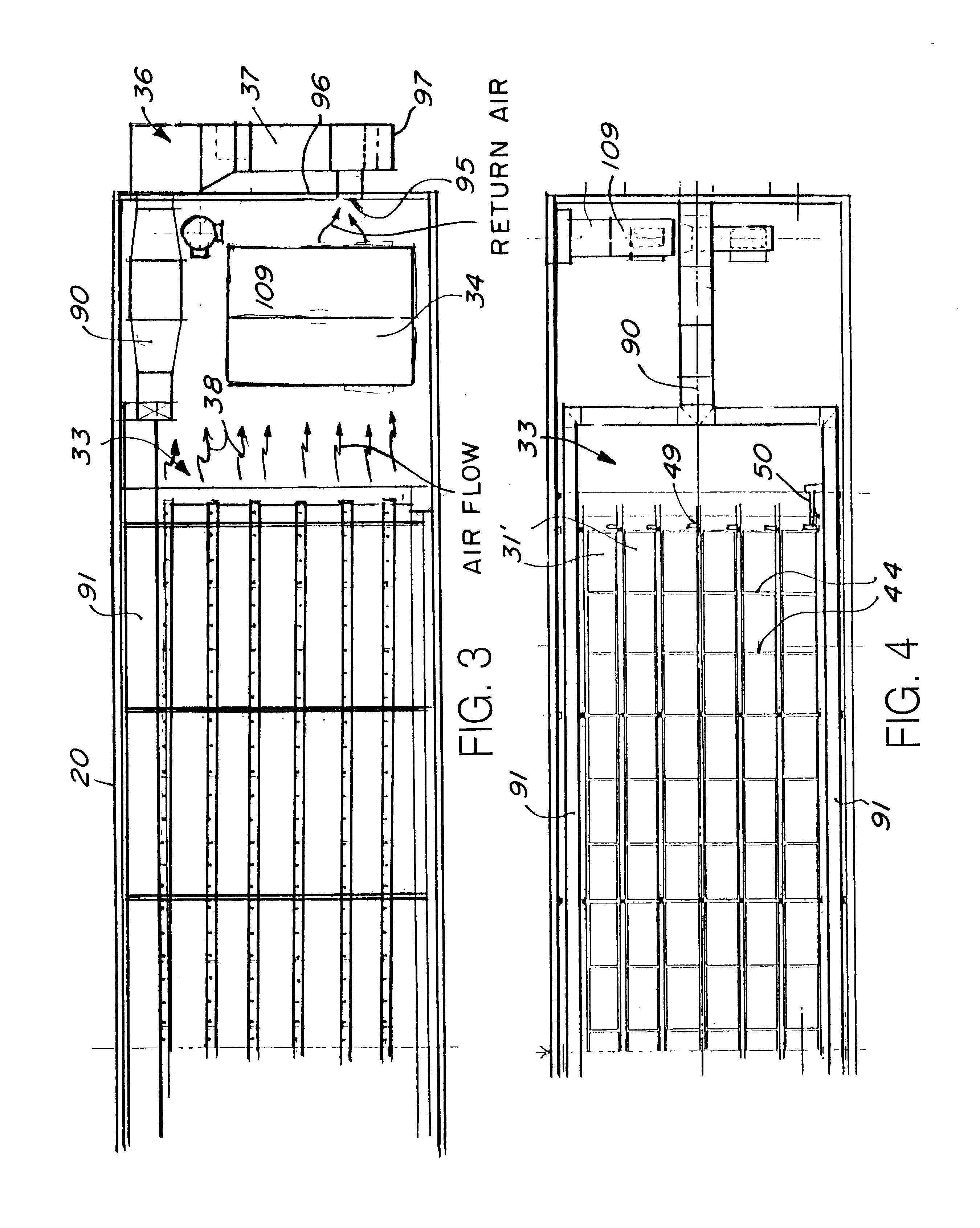

Hydroponic growing enclosure and method for the fabrication of animal feed grass from seed

InactiveUS6578319B1Easy to useAgriculture gas emission reductionCultivating equipmentsSprouted SeedsEngineering

Owner:COLE ROBERT +1

Efficient full-day cubed feed for barn feeding cattle and production method thereof

InactiveCN101385514AAvoid investmentAvoid production performance anomaliesFood processingAnimal feeding stuffDiseaseSodium Bentonite

The present invention relates to a yard feeding cattle efficient total ration blocky feed and a production method thereof. The yard feeding cattle efficient total ration blocky feed consists of 37 percent to 60 percent of crushed or cut forage grass, 38 percent to 60 percent of yard feeding cattle concentrate complemental feed and 2 percent to 3 percent of bentonite which are mixed in a mixer, the water content of a product is controlled within 14 percent, and finally, the prepared raw material is pressed and molded in a ring die waferer. The present invention leads total mixed ration (TMR) to be blocks, compared with the TMR in bulk, the present invention has the advantages that the present invention has stable feed quality, reduces the forage grass waste in the process of feeding and the labor intensity, improves the labor ration and can be fit for large scale industrialized production; the present invention improves the grain ration palatability obviously, effectively prevents the flocks and herds from being fussy, improves the dry matter feed intake and the weight grain of the ruminant and reduces the feed cost to save the feed grains; the present invention has balanced nutrition, thereby being good for improving the feed utilization rate and reducing the occurrence of various kinds of stress diseases of animals; the present invention is convenient for being stored and transported, etc.

Owner:李爱华

Method for controlling amine solvent regeneration system

InactiveCN101642629ARealize automatic controlReduce investmentAmino compound purification/separationDispersed particle separationControl systemReboiler

The invention provides a method for controlling an amine solvent regeneration system, belongs to the technical field of amine solvent recovery, and comprises an amine recovery tower. The method is characterized in that a heat supply regulating valve of a tower bottom reboiler is related to system pressure; and a distilled line regulating valve of a tower top product is related to the gas-phase temperature of the tower top. The method can meet the requirement on purification degree of an amine solvent product on the tower bottom only by presetting a system pressure value and a tower top gas-phase temperature vale; and the control system can trace variations of feeding flow rate, feeding quality and feeding temperature to realize automatic regulation and obtain perfect tower bottom products.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Livestock and poultry meat quality modifier, and preparation method thereof

ActiveCN102232468APromote absorptionGood curative effectFood processingAnimal feeding stuffSteepingAnimal science

The invention belongs to the field of feedstuff additives, and relates to a livestock and poultry meat quality modifier, and a preparation method thereof. The modifier is characterized in that: crushed and sieved tangerine peel, cinnamon, hot pepper, and clove are adopted as main materials; bean pulp, corn flour and wheat bran are adopted as auxiliary materials; the materials are processed through steps of water-steeping, pH value regulating, sterilizing, and cooling; the materials are then inoculated with probiotics for fermentation; after fermentation, the materials are dried, such that themodifier is obtained. The meat quality modifier is used as a livestock and poultry feedstuff additive. The addition amount of the modifier in the feedstuff is 0.02% to 0.5% by weight. The modifier can be used for replacing antibiotic medicines and hormone medicines used in current livestock and poultry productions. With the modifier, livestock and poultry digestions can be promoted, livestock andpoultry production performances can be improved, livestock and poultry meat qualities and flavors can be improved, and livestock and poultry product added values can be increased. The modifier also has advantages of no toxic and side effect, no pollution, no residue. The modifier causes no drug resistance. With the modifier, livestock and poultry meat production requirements of high-efficiency, high-quality and health can be satisfied.

Owner:BEIJING KEEPYOUNG TECH

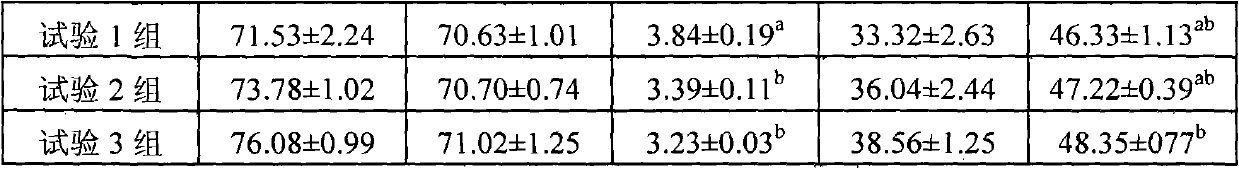

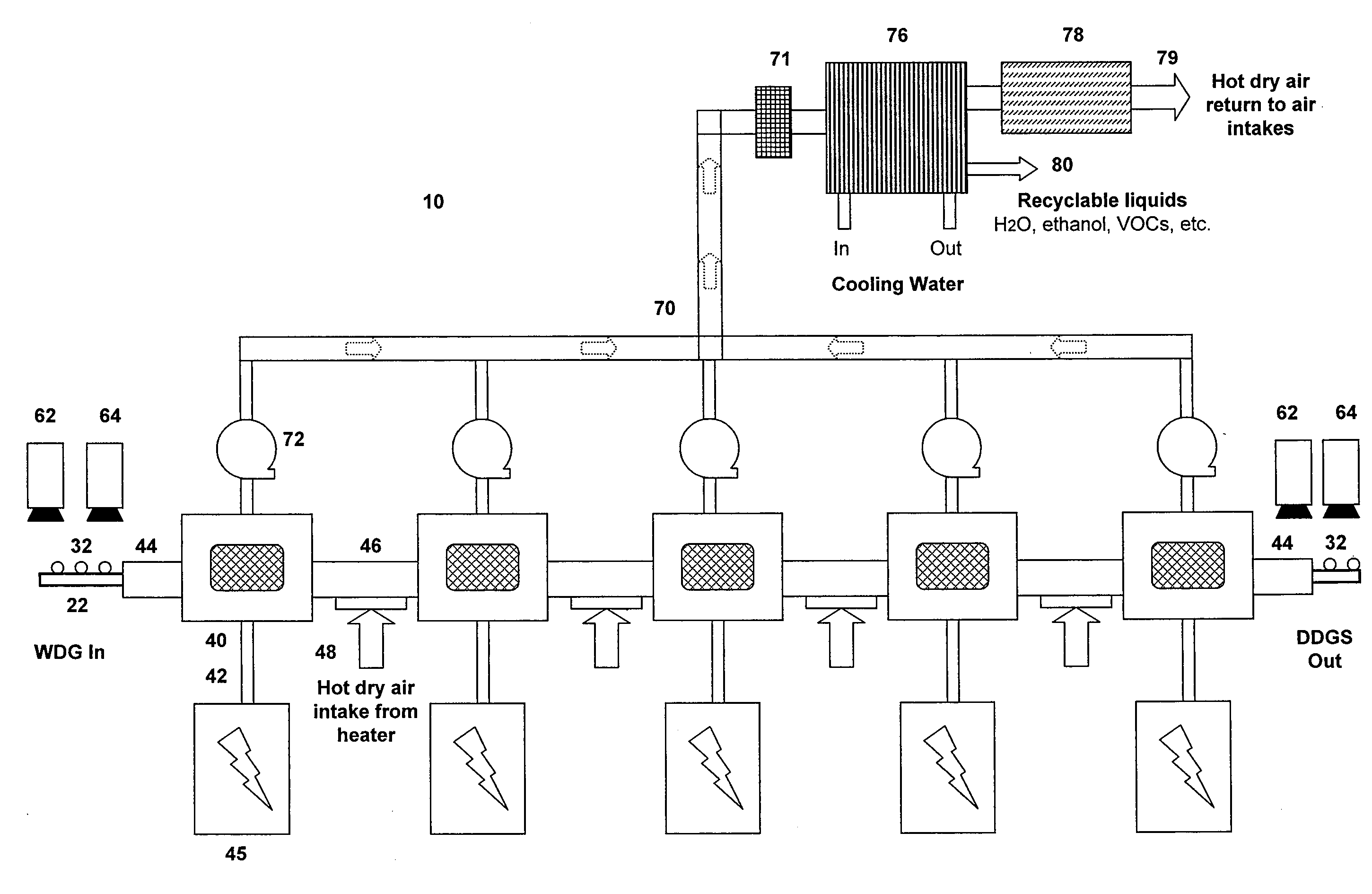

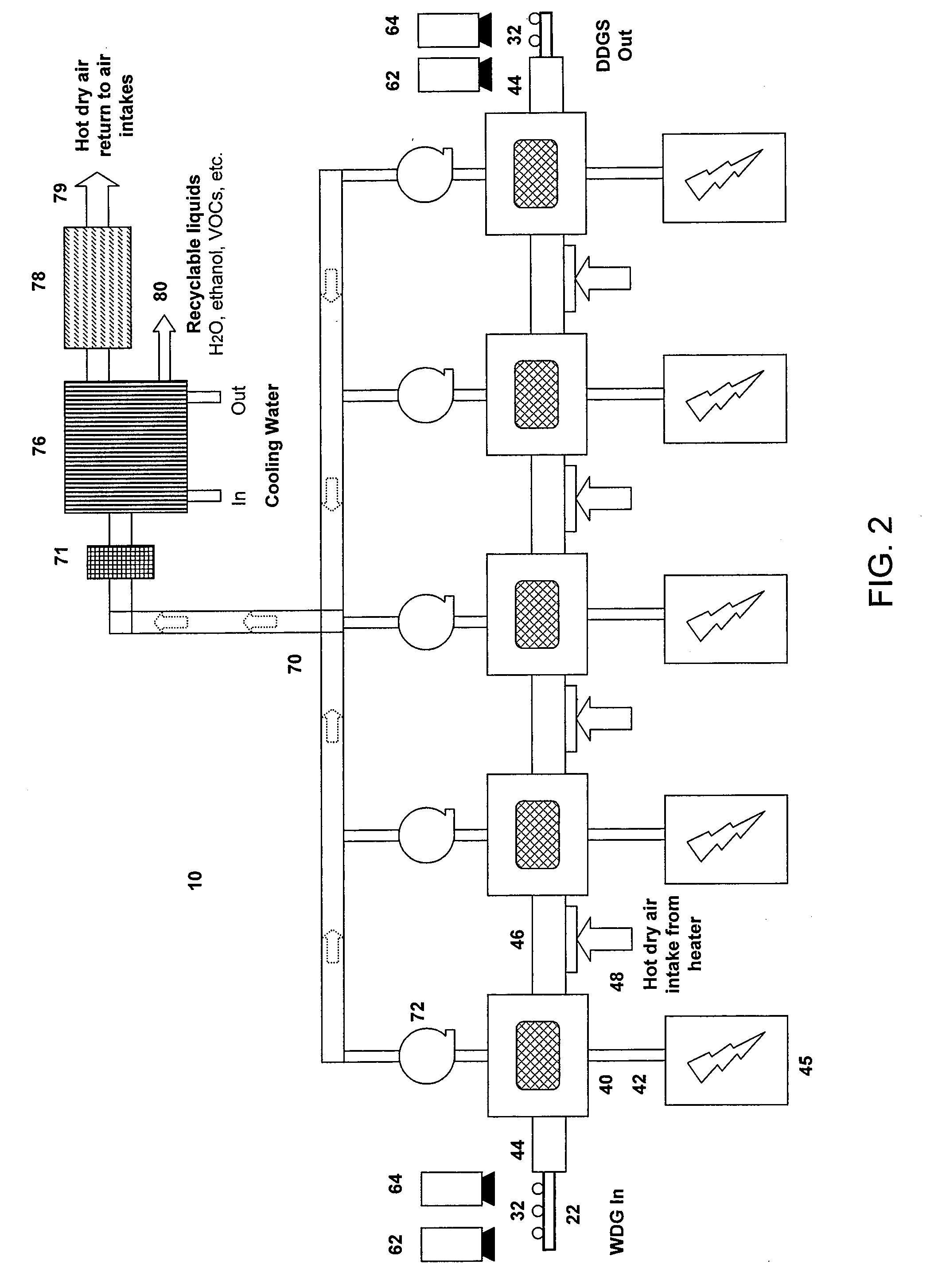

Animal Feed Product From Distillers' Grain

The present invention concerns systems, apparatus, methods and compositions for production of improved animal feeds from by-products of ethanol production or similar facilities, such as DDG or DDGS. In preferred embodiments, the methods may comprise initial removal of water by mechanical devices, pelletizing the material, and further water removal by microwave treatment. Optionally, various supplements such as enzymes, vitamins, minerals or other nutrients may be added. In more preferred embodiments, the action of the enzymes in breaking down complex molecules in the mixture is enhanced by microwave treatment. Most preferably, the mixtures are maintained at relatively low temperatures to preserve enzyme activity and / or nutrient and feed quality.

Owner:CELLENCOR INC

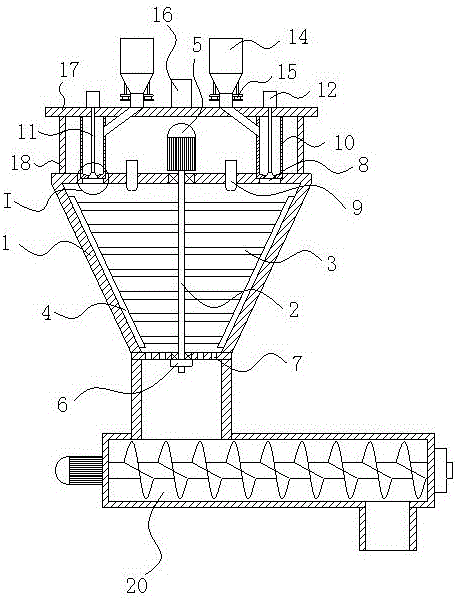

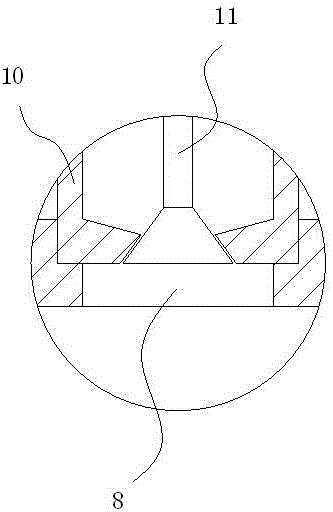

Feed blending system

InactiveCN106582369AQuality improvementAvoid stickingRotary stirring mixersTransportation and packagingProcess engineeringScrew conveyor

The invention relates to the field of feed processing machinery and aims to provide a feed blending system which is high in automation level and having mixing and smashing functions. The feed blending system comprises a mixing bin, radius of an upper-end shell of the mixing bin is greater than that of a lower-end shell, a stirring device is arranged in the mixing bin and comprises a stirring shaft, multiple stirring blades are arranged on the stirring shaft from top to bottom, the ends of the stirring blades are connected with a scraping plate, one end of the stirring shaft is connected with a motor, sieve holes are formed in the lower-end shell of the mixing bin, multiple raw material inlets and an additive inlet are arranged on the upper-end shell, a raw material barrel is arranged above a raw material inlet of the mixing bin and communicated with a raw material bin through a conveying pipeline, and a spiral conveyor is arranged at the lower end of the mixing bin. The feed blending system is high in automation level, has the functions of both mixing and smashing and is high in quality of feed blended by the system.

Owner:云南龙谷生物科技有限公司

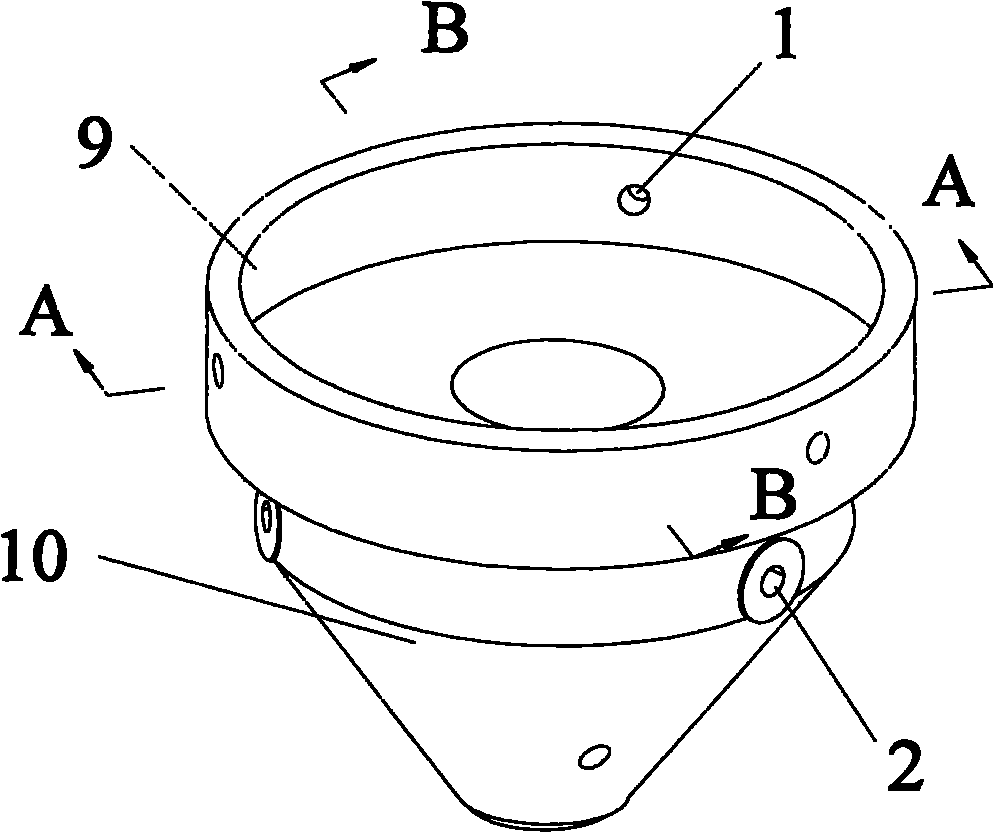

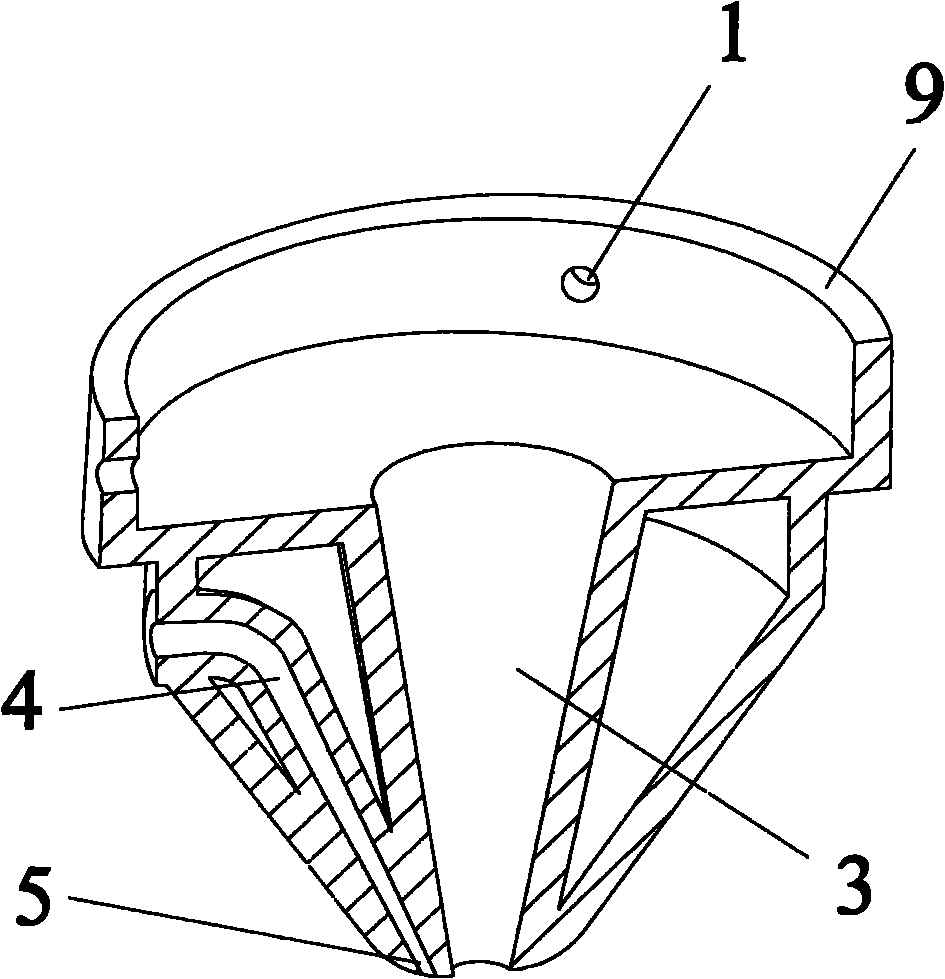

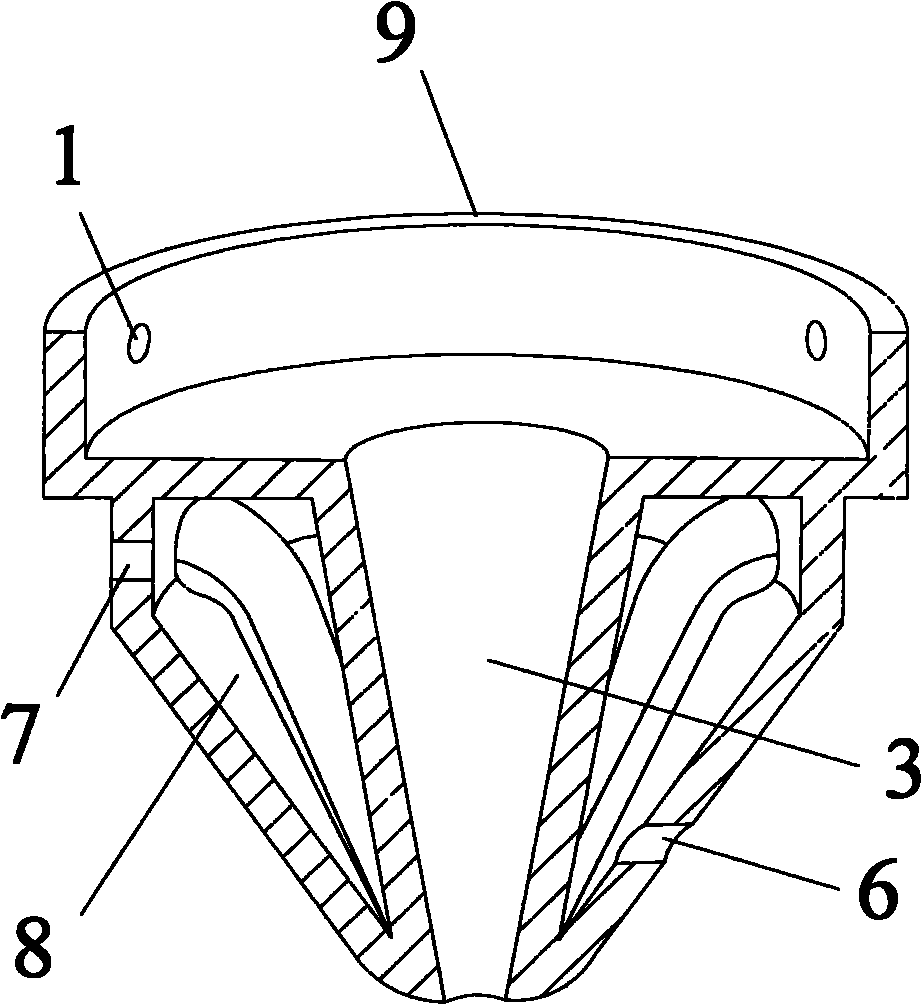

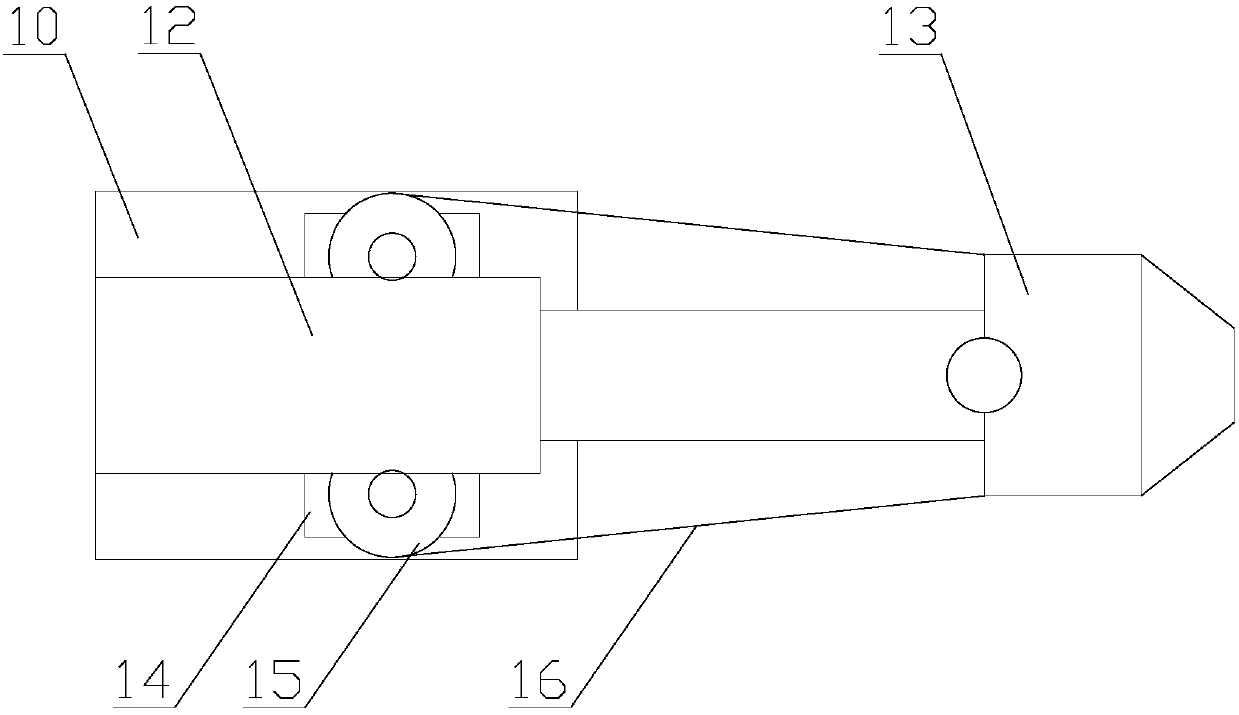

Laser cladding nozzle convenient for cooling and manufacturing method thereof

InactiveCN101942659AImprove cooling effectGood powder delivery effectMetallic material coating processesLaser beam welding apparatusAfter treatmentCooling effect

The invention discloses a laser cladding nozzle convenient for cooling, comprising a nozzle wick and a connector which is connected above the nozzle wick and is externally connected with a laser system, wherein the nozzle wick is provided with a light beam channel, cooling cavities and a plurality of powder feeding channels; the cooling cavities are formed by the periphery of the light beam channel and the periphery of each powder feeding channel; the outer side wall of the upper end of the nozzle wick is provided with powder inlets communicated with the powder feeding channels and a water outlet communicated with the cooling cavities respectively; the lower end of the nozzle wick is provided with powder outlets communicated with the powder feeding channels and a water inlet communicated with the cooling cavities; and the water inlet and the water outlet are respectively connected with a cooling system externally. The invention also discloses a manufacturing method of the nozzle, comprising the steps of model drawing, slicing treating, rapid forming, after-treatment, etc. The nozzle has simple structure, high cooling effect and better powder feeding quality and is directly manufactured by the rapid forming method, thus design of the nozzle is free from limitation of the traditional processing methods and the structure of the nozzle is further diversified.

Owner:SOUTH CHINA UNIV OF TECH

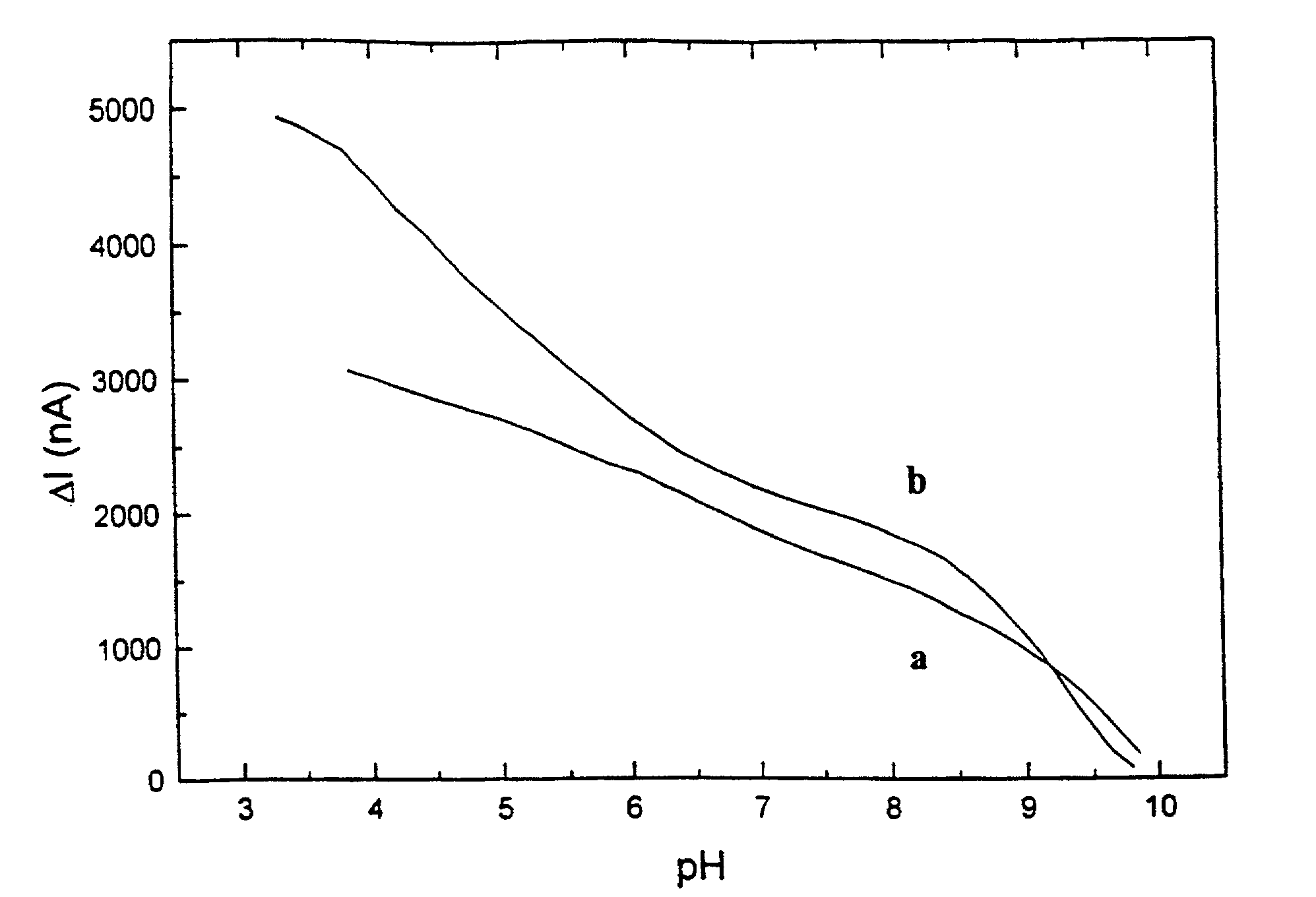

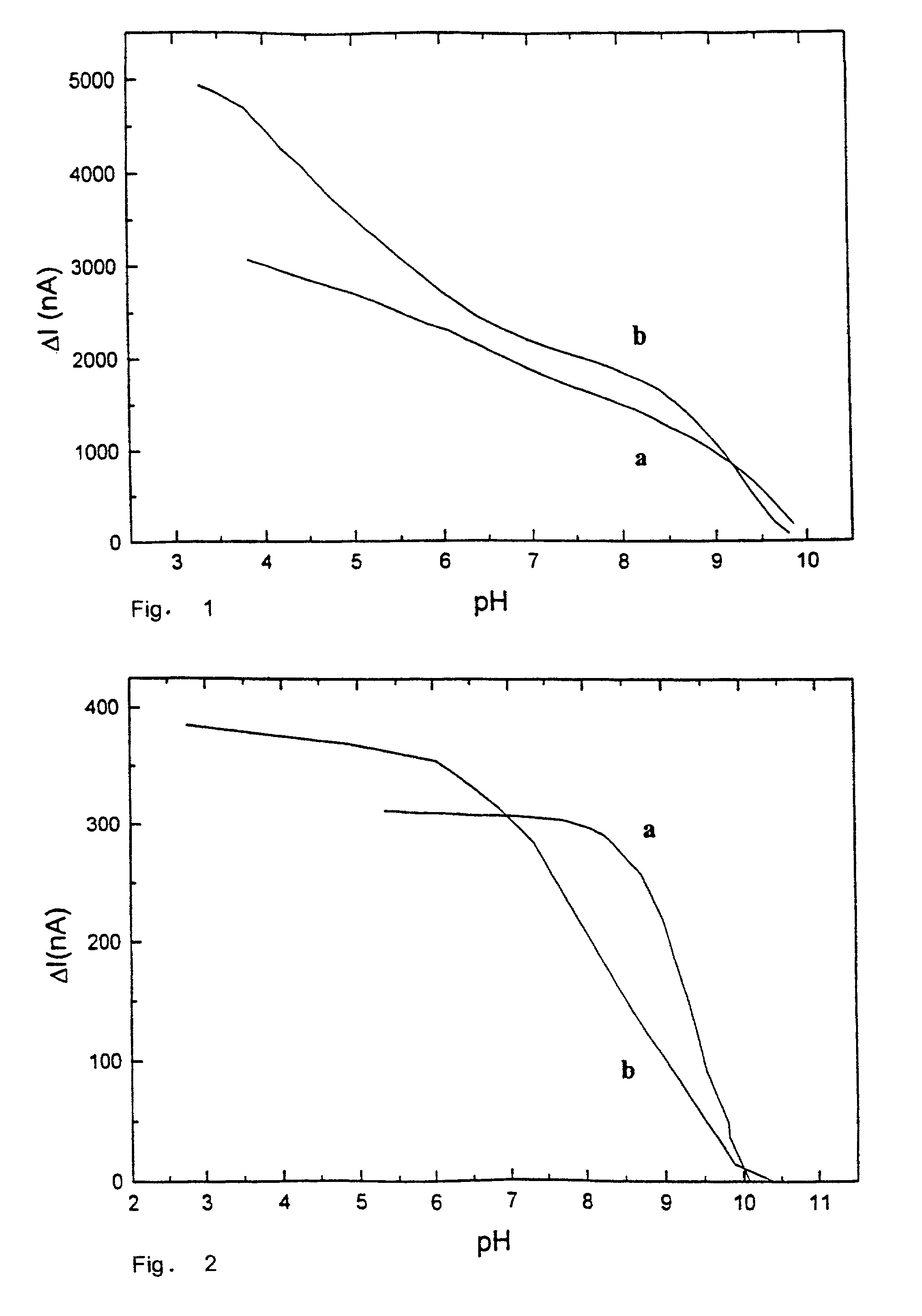

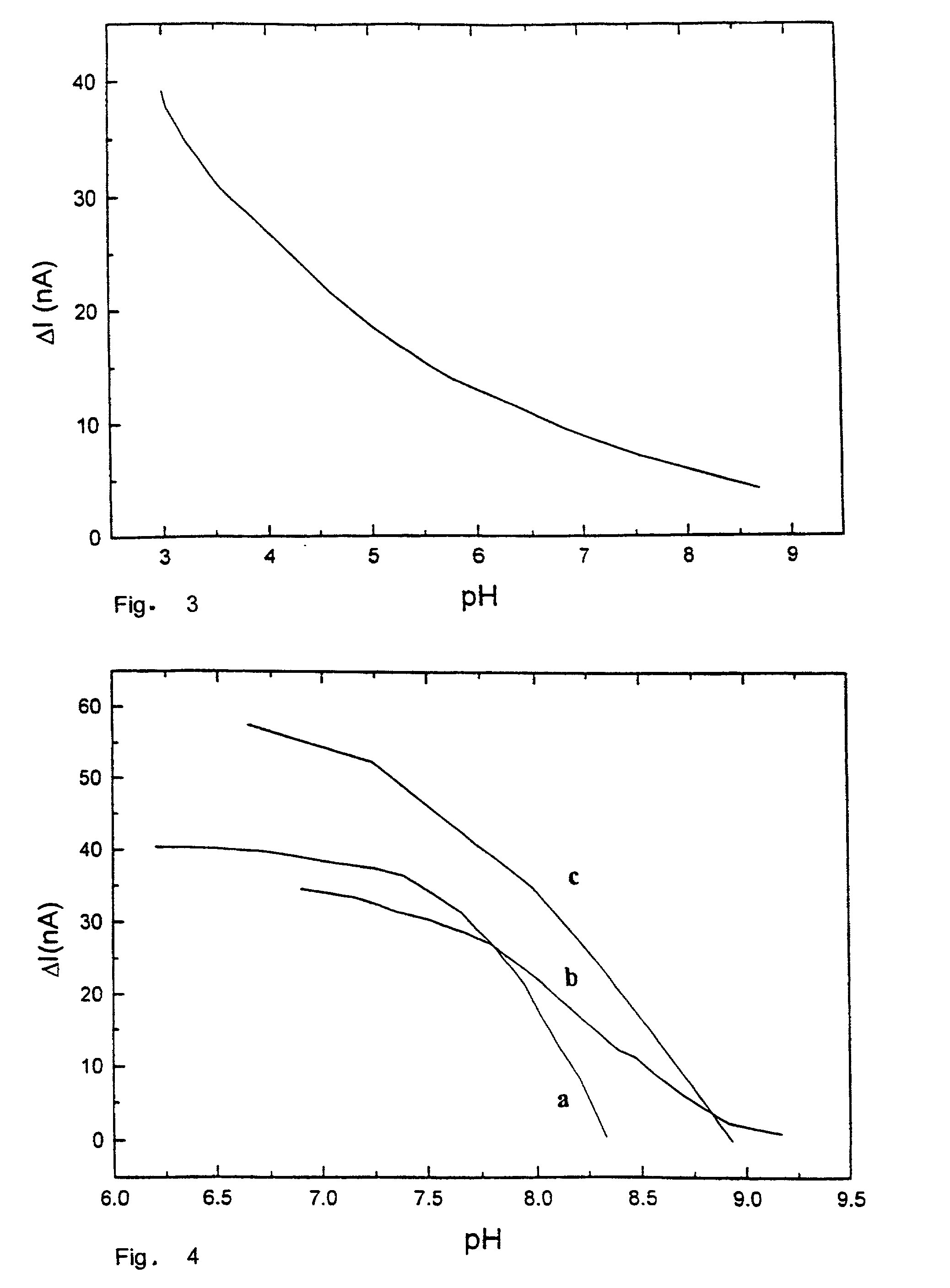

pH-sensitive amperometric biosensor

InactiveUS7041209B1Accurate detectionImmobilised enzymesBioreactor/fermenter combinationsProtonationElectrochemical biosensor

The present invention describes a new electrochemical biosensor comprising (i) a biocatalyst producing a pH change when interacting with the analyte to be determined and (ii) a compound exhibiting different redox properties both in its protonated and non-protonated forms (pH-sensitive redox compound). The elements described above are integrated in a biosensor system composed of a working electrode and a reference electrode connected to an ammeter. When the analyte is present, the system produces a current change that is proportional to the concentration of the analyte. The biosensors described herein can be used in the accurate detection of a wide range of analytes. They can be used in diagnostics, industrial processes, food and feed quality control, biotechnology, pharmaceutical industry, environmental monitoring and so on.

Owner:SAICOM

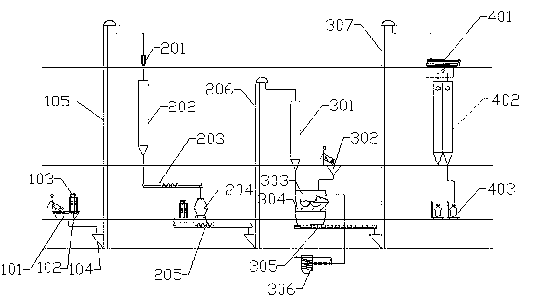

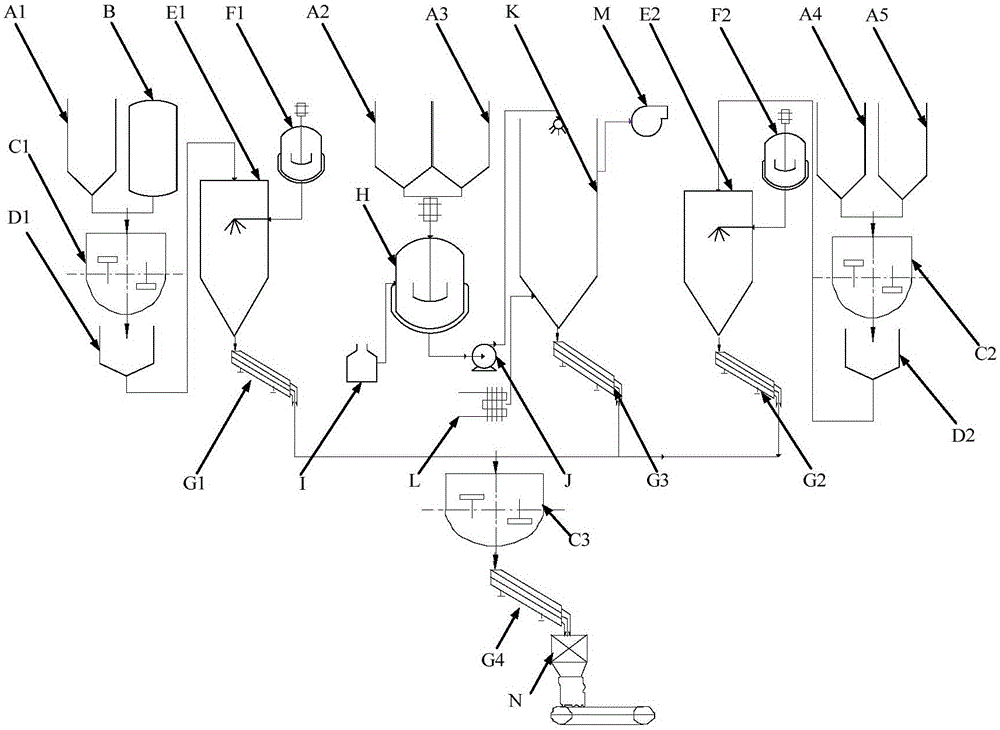

Biologically fermented feed as well as preparation method and special device thereof

The invention relates to a biologically fermented feed as well as a preparation technology and a special device thereof. The preparation technology comprises the steps of: pre-cleaning, grinding, mixing, inoculating, packaging and fermenting raw materials, is simple and convenient to operate, and realizes the mechanical continuous production. In the formulation of the biologically fermented feed, leftovers of agricultural and sideline products, with the low price, such as apple pomace, jujube powder, peanut shells, distillers dried grains with soluble (DDGS), spray corn husks and other biological matrixes are adopted, and the biologically fermented feed is prepared by adding a premix and bacteria liquid into the leftovers, mixing and fermenting. The prepared biologically fermented feed is stable in quality, good in palatability, comprehensive in nutritive value, high in living bacterium content and easy to store and transport, can be directly fed as daily ration of livestock and poultry, and can replace 20-30% of a complete formula feed, thus saving grains in deed and reducing the breeding cost.

Owner:潍坊天普阳光饲料科技有限公司

Constant-tension wire moving mechanism with automatic wire feeding function

ActiveCN102357692AAchieve recyclingImprove machining accuracyElectrical-based machining electrodesProcessing accuracyTension control

The invention discloses a constant-tension wire moving mechanism with an automatic wire feeding function, which comprises a wire release and retract device, a tension regulation device and an automatic wire feeding device. The constant-tension wire moving mechanism is characterized in that: a first-stage tension regulation device and a second-stage tension regulation device are arranged between the wire release and retract device and the automatic wire feeding device; automatic wire breakage and wire feed are realized by setting the automatic wire feed mechanism, automatic retrieving of broken wires and waste wires can be realized, the operation is convenient, time and labor force are saved, the wire feeding efficiency and production efficiency are improved, and the wire feeding quality is increase; two stages of tension control are realized by setting the first-stage tension regulation device and the second-stage tension regulation device, changes of preceding stage wire coil tension are effectively controlled, the constant tension of the metal wire is ensured, and the processing accuracy of parts is improved.

Owner:北京安德建奇数字设备股份有限公司

Meat chicken feed and processing method thereof

InactiveCN101991012AAddressing Anti-Nutritional ProblemsImprove digestibilityAnimal feeding stuffAccessory food factorsAnimal scienceFeed conversion ratio

The invention discloses meat chicken feed and a processing method thereof. The feed comprises the following components in percentage by weight: 58 percent of corn, 3 percent of wheat flour, 5 percent of bean pulp, 5 percent of vegetable meal, 5 percent of cotton meal, 5 percent of colza cake, 5.8 percent of peanut cake, 5 percent of bulked soybean, 2.8 percent of corn protein powder, 1.0 percent of lard oil, 1.2 percent of rock flour, 1.5 percent of calcium hydrophosphate, 0.21 percent of edible salt, 0.53 percent of lysine, 0.12 percent of methionine, 0.14 percent of threonine, 0.2 percent of composite bio-enzyme preparation, and 0.5 percent of premix. The processing method comprises: crushing and / or grinding the components of the feed; feeding the raw materials into a mixer for mixing; and packaging the mixed feed in bags. By adding an additive, the feed conversion rate and feed quality stability of the feed are improved and the use amount of mixed meal proteins is reduced; therefore, the cost of the feed is reduced, and the growth performance of the meat chickens can be maintained or improved.

Owner:HENAN MUHE GROUP FEED

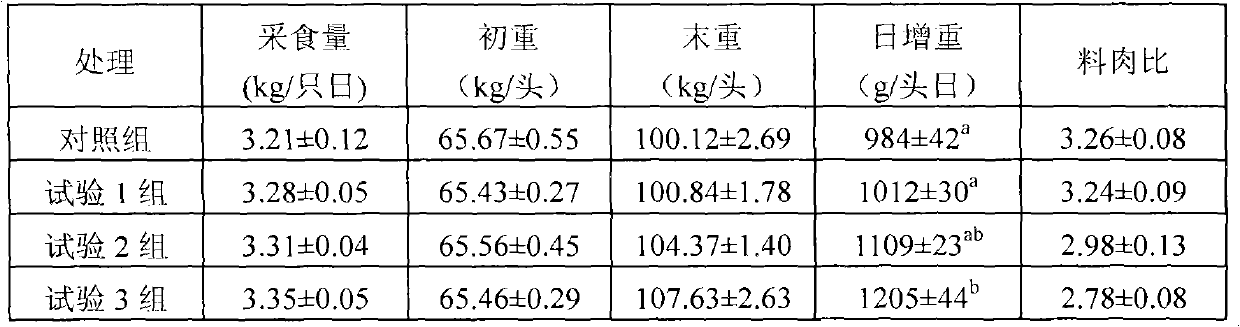

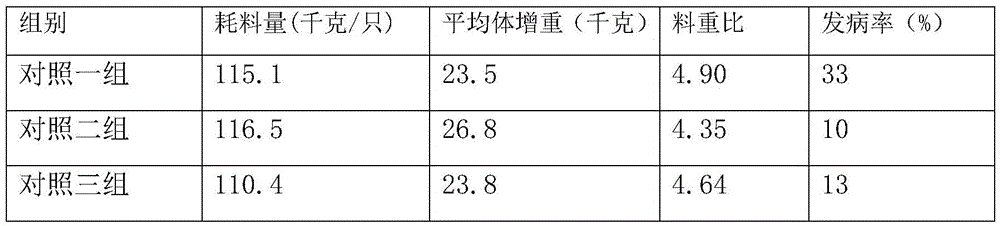

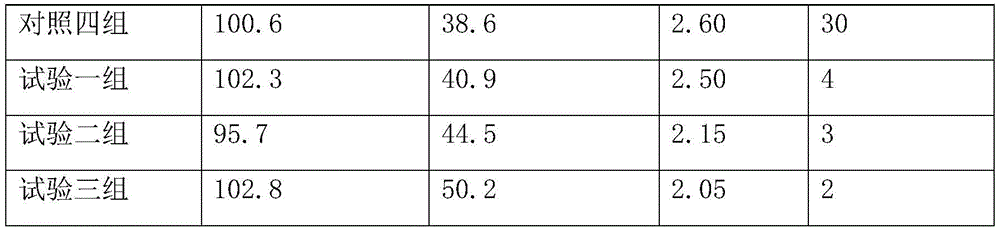

Multi-strain microorganism pig feed additive and production method thereof

The invention relates to a multi-strain microorganism pig feed additive and a production method thereof. According to the additive, bacillus subtilis, lactobacillus delbrueckii, saccharomyces cerevisiae, candida and photosynthetic bacteria are inoculated into a fermentation culture medium according to a ratio of 2:1:1:1:2, and are prepared into a finished product through solid fermentation. The microorganism preparation is reasonably matched, various microorganisms in the preparation can bring respective effects into play and depend on one another, the overall advantage of the microorganism preparation can be brought into play, the growth development and the improvement of the anti-disease capability of a host are facilitated, and the feed additive is safe to use and can improve the immunity of animals, prevent and resist diseases, prompt animal growth, improve the feed utilization rate and improve the feed quality.

Owner:河南旭瑞食品有限公司

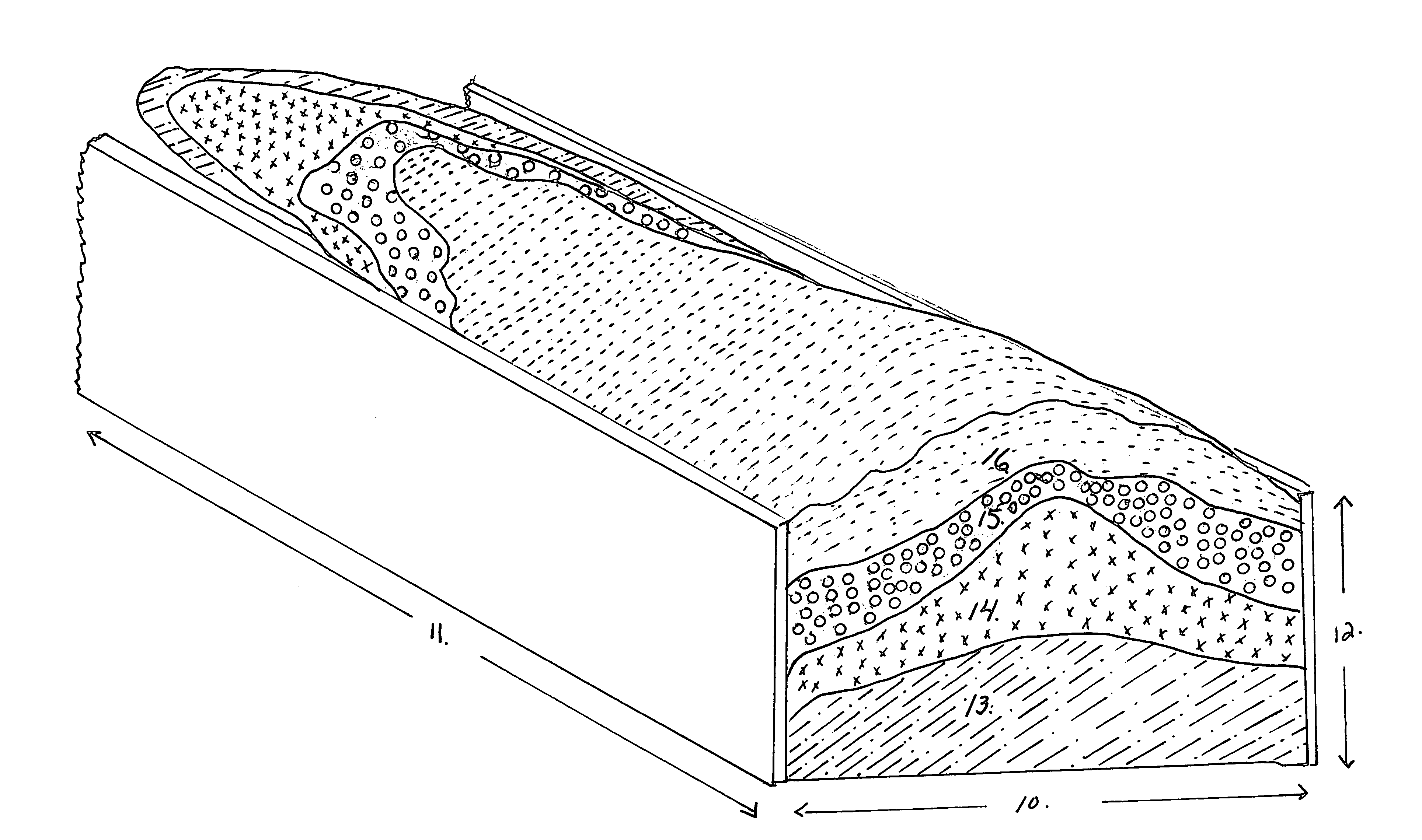

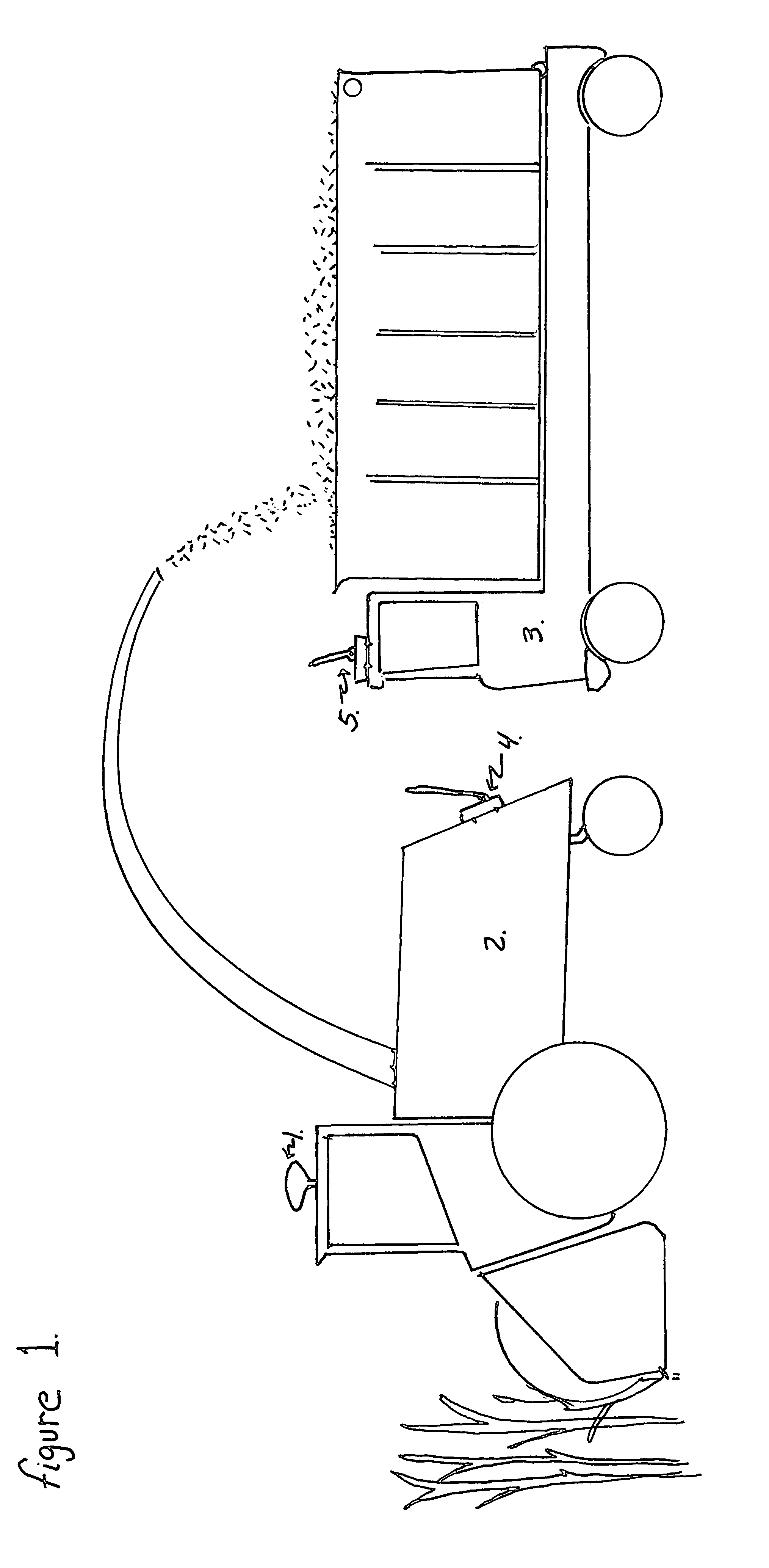

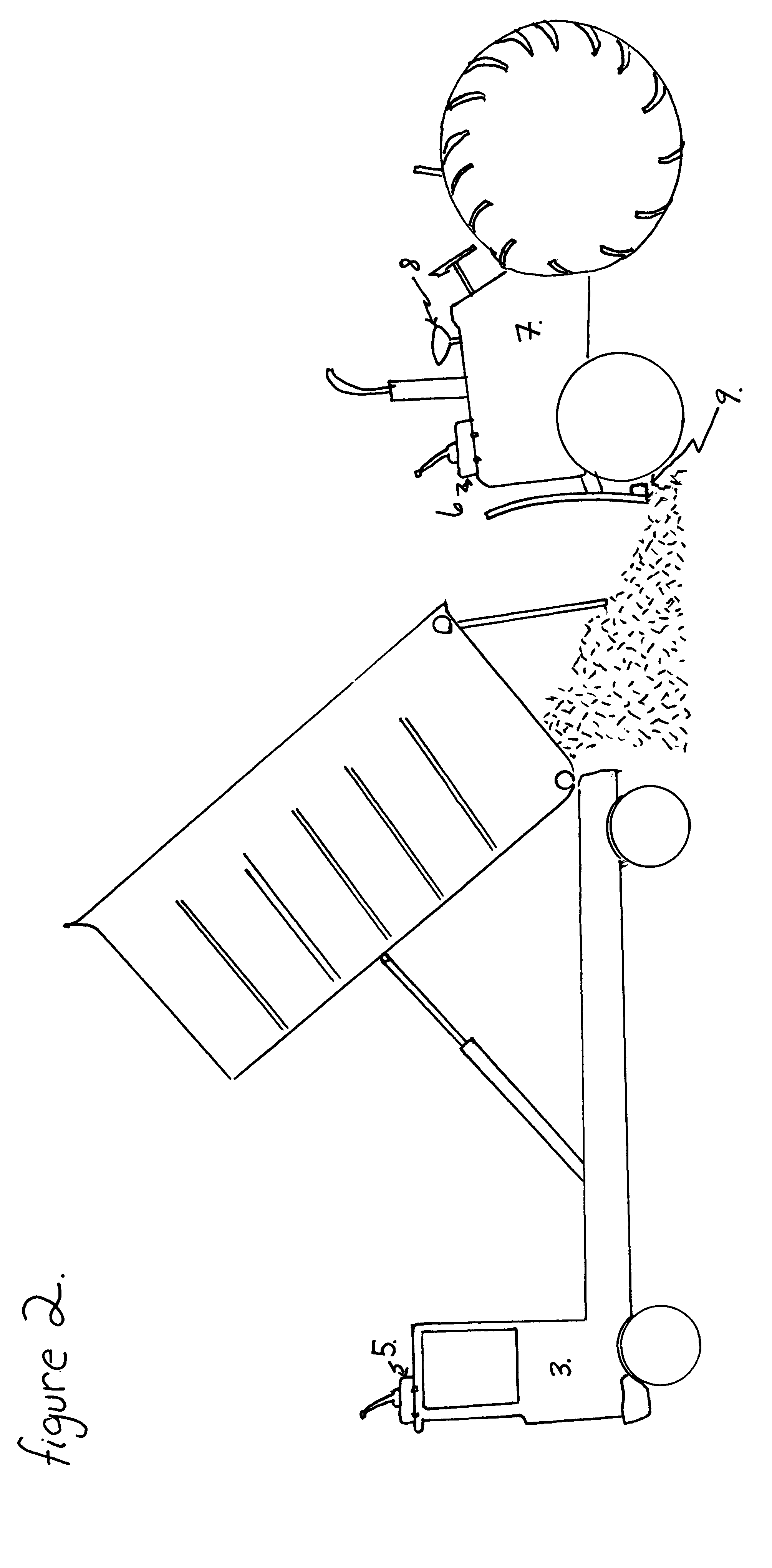

System and method for identifying individual loads of chopped forage in storage

ActiveUS7996134B2Navigational calculation instrumentsAnalogue computers for trafficAgricultural scienceLoad following power plant

Owner:HARVEST TEC

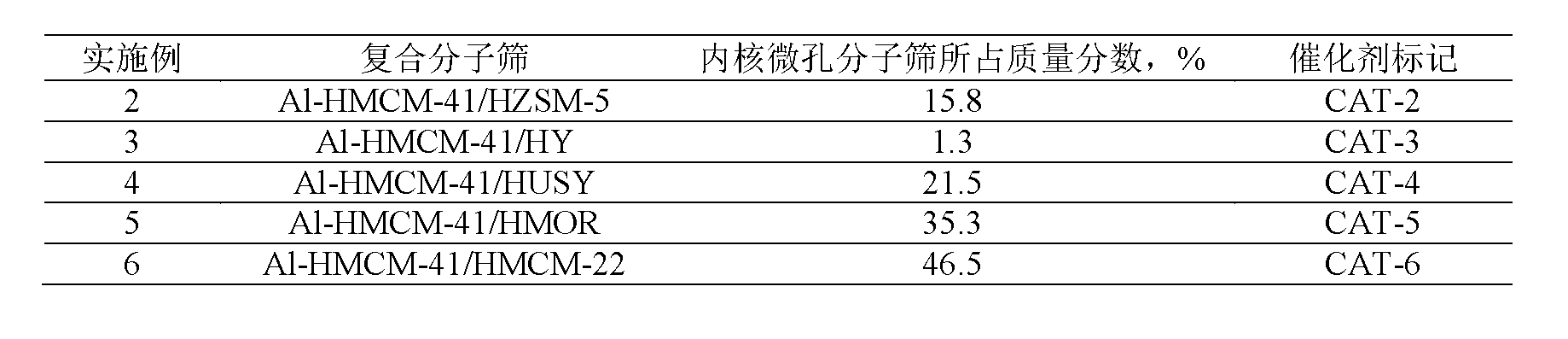

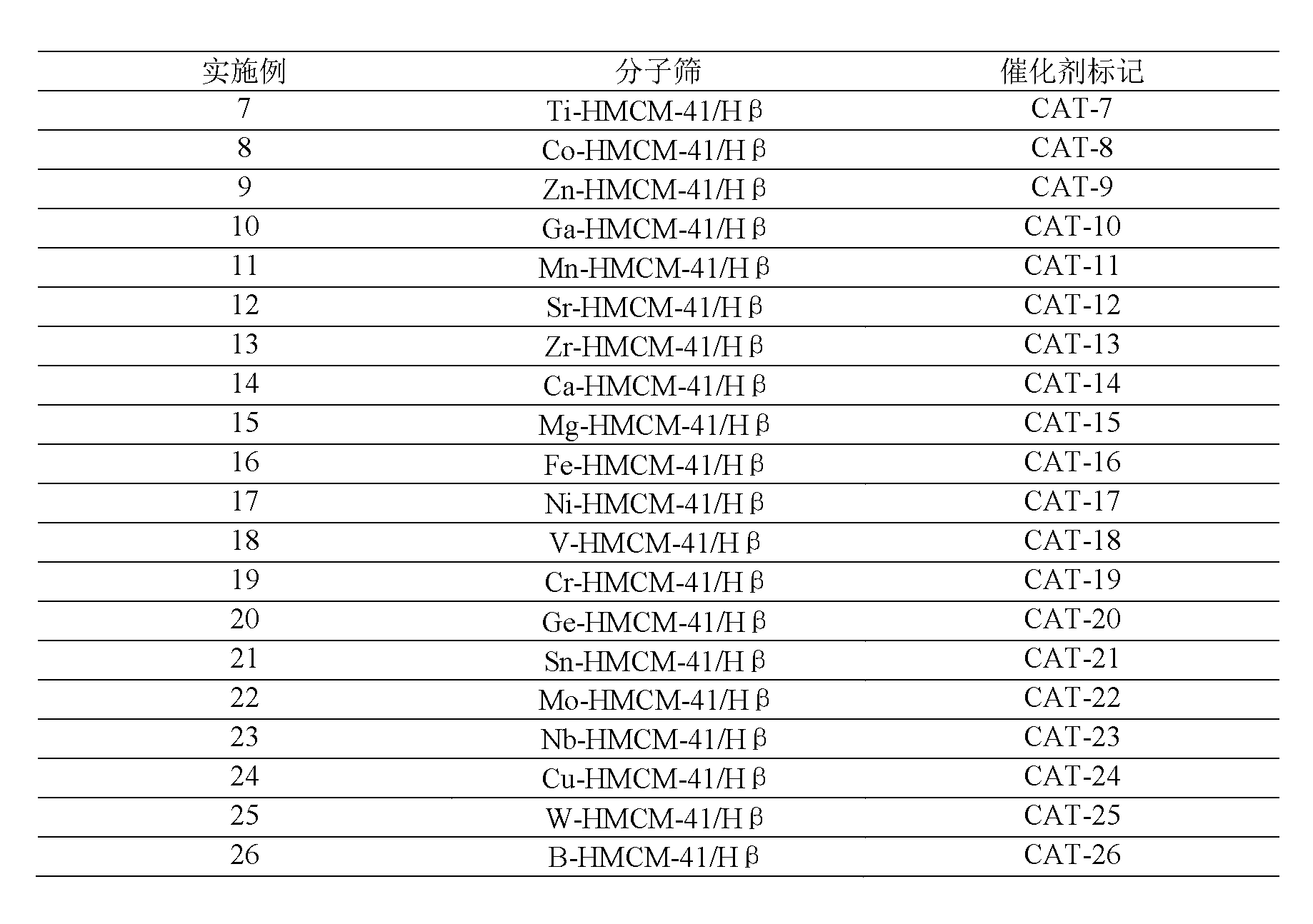

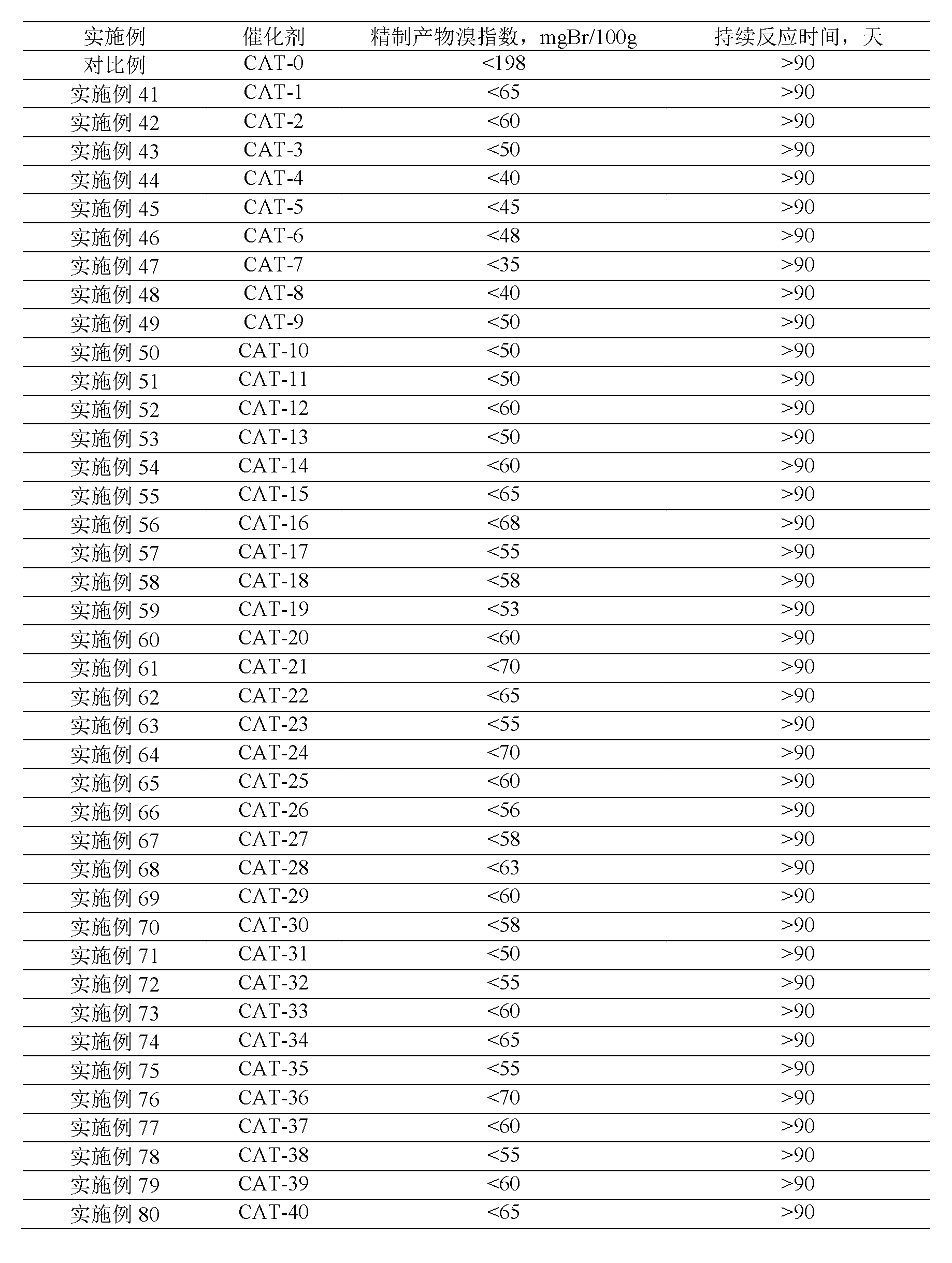

Catalyzer for preparing low carbon olefinic hydrocarbon through hydrocarbons catalytic oxidation cracking

ActiveCN101116827AReduce surface area carbonImprove conversion rateCatalytic crackingMolecular sieve catalystsCatalytic oxidationCracking reaction

A catalyst preparing light olefins from hydrocarbon catalytic oxidation cracking is provided. Weight percentage compositions of components in the catalyst are as follows: 10-100 percent by weight of an active component, and 0-90 percent by weight of a carrier, wherein the active component comprises oxygen-carrying type metal oxide and acid catalytic material. Weight percentage compositions of components in the active component are as follows: 10-99 percent by weight of the oxygen-carrying type metal oxide, and 1-90 percent by weight of the acid catalytic material. The hydrocarbon oil raw material is contacted with the above catalyst, proceeds with catalytic oxidation cracking reaction under the conditions of 500-800 DEG C, the water-oil ratio of 0-1.5 and the feeding quality space velocity of 1-500 h-1, and separates reaction logistics to obtain the target product of light olefins. The catalyst not only improves the conversion of raw materials, but also improves the yield and selectivity of ethylene, propylene and butane to different extent, and simultaneously reduces the carbon deposition on the catalyst surface.

Owner:CHINA PETROLEUM & CHEM CORP +1

Piglet feed

InactiveCN101692876APromote healthy growthPrevent growth arrestFood processingAnimal feeding stuffYeastDigestion

The invention discloses a piglet feed comprising the following components in percentage by weight: 20.0 percent of corn flour, 10.4 percent of wheat bran, 55.0 percent of fermented soybean meal, 10.0 percent of domestic fish meal, 3.0 percent of yeast powder, 1.0 percent of bone meal, 0.54 percent of edible salt, 0.02 percent of copper sulphate, 0.01 percent of ferrous sulphate, 0.01 percent of furacilinum, 0.01 percent of terramycin and 0.01 percent of multi-vitamin. The invention has the advantages of optimizing the feed quality, improving the feed stability, strengthening the digestion, the absorption and the utilization ratio of nutrients, promoting the piglet healthy growth, effectively controlling phenomena, such as diarrhoea, growth cessation and the like and solving the general emergent problems of piglets at present, such as poor ingestion, slow biting, easy diarrhea, high death rate, low productivity and the like.

Owner:姜波

Method for removing micro-quantity alkene in aromatic hydrocarbon

ActiveCN103012034ASimple processDoes not consume hydrogenChemical recyclingChemical modification purification/separationAlkyl transferSolid acid

The invention discloses a method for removing micro-quantity alkene in aromatic hydrocarbon. The method comprises the following steps of: contacting and reacting the aromatic hydrocarbon with a solid acid catalyst under the condition of temperature of 30-350 DEG C, pressure of 0.1-12MPa and feeding quality airspeed of 0.1-15 h<-1>, so that micro-quantity alkene in the aromatic hydrocarbon undergoes adsorbing, overlapping and alkylation reaction so as to remove the micro-quantity alkene in the aromatic hydrocarbon. The method is simple in process procedure, free of oxygen consumption and low in device investment and operation expense; and the catalyst is good in activity stability, the device is long in stable operation time, the aromatic hydrocarbon loss is small, the frequent switching operation between reactor reaction and regeneration is avoided, and the catalyst can be regenerated, so that a great deal of waste catalyst is prevented from being buried, and the environment is less polluted.

Owner:ZHEJIANG UNIV OF TECH

Microbial inoculum for preparing feed and application thereof

The invention discloses a microbial inoculum for preparing feed and application thereof. The active components of the microbial inoculum comprise Lactobacillus plantarum, Lactobacillus kimchii, Lactobacillus farciminis and Lactobacillus pentosus. The four inocula in the lactic acid bacteria composite system of the microbial inoculum of the invention have high synergetic effect, can rapidly reproduce, colonize and dominate in an unpasteurized natural raw material, effectively control microbiota in silage, rapidly generate a large amount of lactic acid, reduce the pH value of the feed to about 4.0, reduce the dry matter loss and the feed quality decline caused by growth of contaminated microbes in the silage period to the farthest extent, reduce the generation of ammonia nitrogen, and improve the fermentation quality of the silage. Compared with control, the lactic acid production amount and speed in the alfalfa silage taking the microbial inoculum of the invention as an additive are obviously increased, and the protein content, the dry matter content and the like of the obtained alfalfa feed are obviously improved.

Owner:CHINA AGRI UNIV

Sugar cane byproduct cattle feed capable of promoting digestion

InactiveCN105475643AChange structureReduce crystallinityFood processingAnimal feeding stuffShootDigestion

The invention discloses a sugar cane byproduct cattle feed capable of promoting digestion, which is characterized by being prepared by treating bagasse with continuous steam puffing technology, mixing with fresh sugar cane shoot leaves, adding an inorganic or organic nitrogen source to serve as a nitrogen source, converting into proteins by probiotic silage or microbial treatment, and compounding with multiple traditional Chinese medicine components. By puffing bagasse and sugar cane shoot leaves and spraying cane molasses, the palatability is improved; and by adding the multiple traditional Chinese medicine components, the digestion of the poultry and livestock is promoted and the immunity of the poultry and livestock is improved. The feed cost is lowered, the feed quality is improved, the prepared feed can be used for cattle breeding, the sugar byproducts, namely sugar cane shoot leaves, bagasse and molasses are effectively utilized, the wastes are changed into values, and the economical benefits are improved.

Owner:GUANGZHOU SUGARCANE IND RES INST +1

Production of modified polysaccharides

InactiveUS6639126B1Improve abilitiesSuppression of activityOther foreign material introduction processesFermentationBiotechnologyPullulanase

The invention alters the physical characteristics of storage polyglucans including starch. Methods are provided to modify the polyglucan biosynthesis pathway by simultaneously altering the activity of a pullulanase debranching enzyme and the activity of another polypeptide in the polyglucan biosynthesis pathway. Compositions of the invention include transgenic plants and seeds having a modified polyglucan structure and / or content and elevated phytoglycogen levels. Additional compositions include a grain with increased energy availability for improved feed quality and industrial uses. Further compositions include a polyglucan with improved functional properties useful in a wide range of food and industrial applications.

Owner:PIONEER HI BRED INT INC

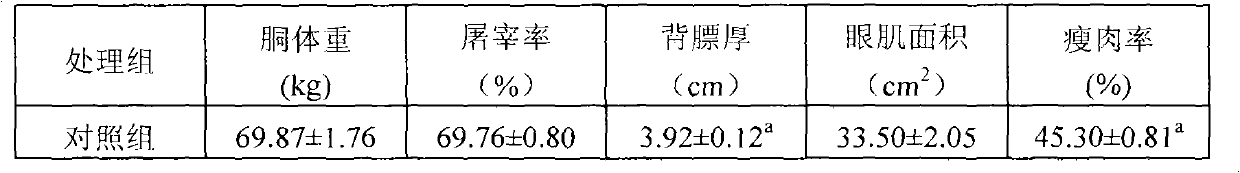

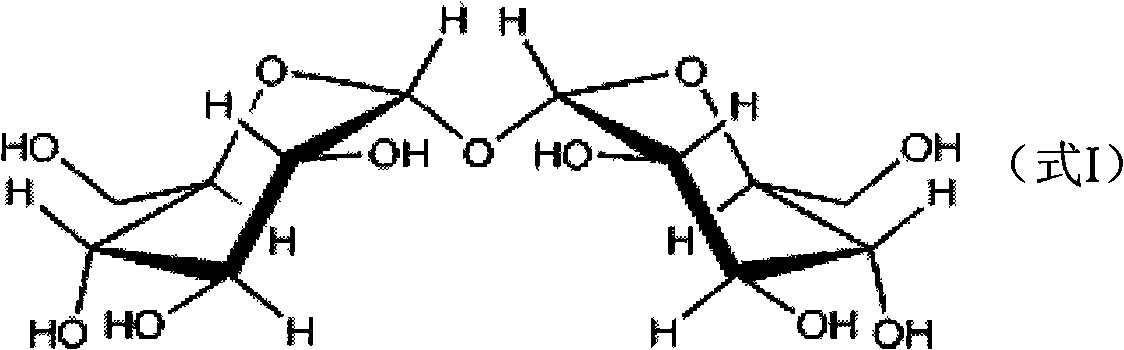

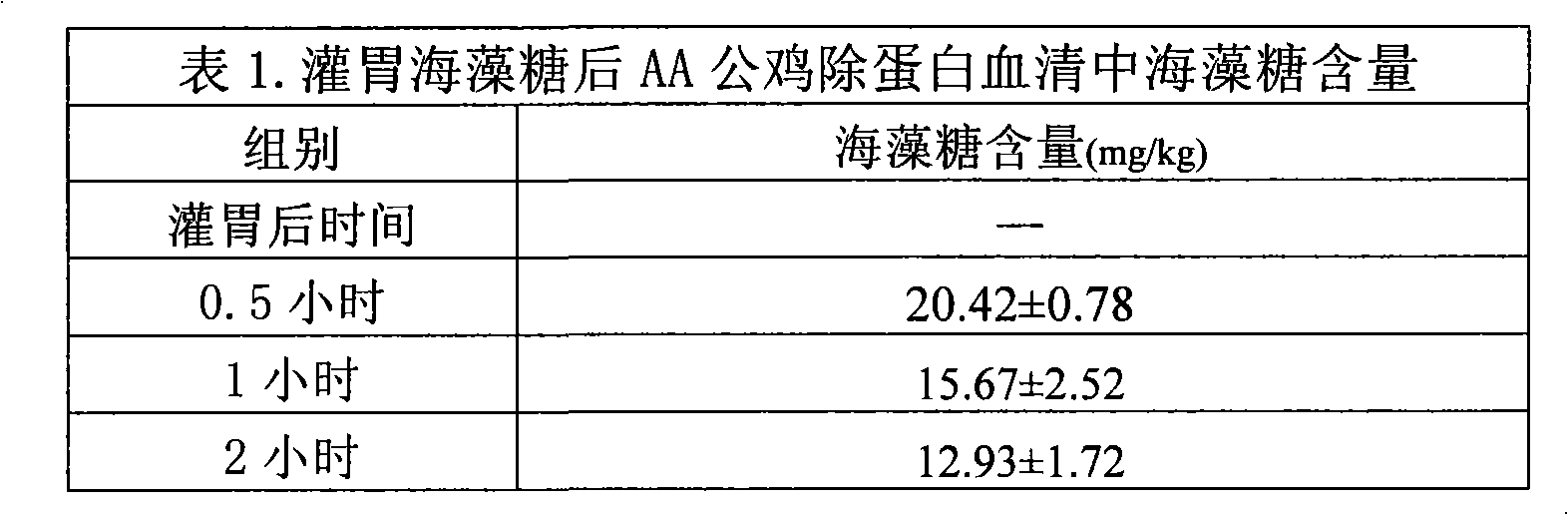

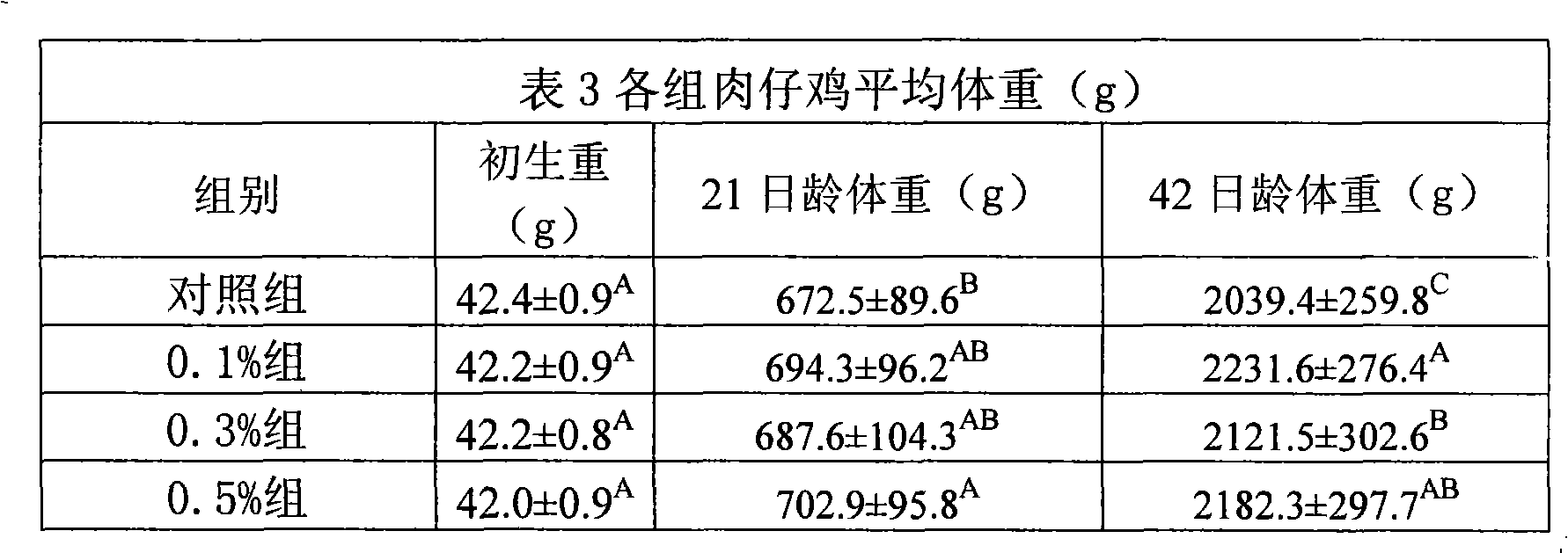

Application of fucose serving as animal feed additive

InactiveCN101513221AImprove qualityIncrease production capacityAnimal feeding stuffAccessory food factorsAnimal productFodder

The invention discloses the application of fucose serving as an animal feed additive. The addition final concentration of the fucose is 0.01-2% (weight percentage content). The fucose is added into animal feed, which can increase the feed quality and growth performance and slaughtering performance of poultry. The fucose can be widely applied to the animal husbandry production and processing industries of domesticated animal products.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

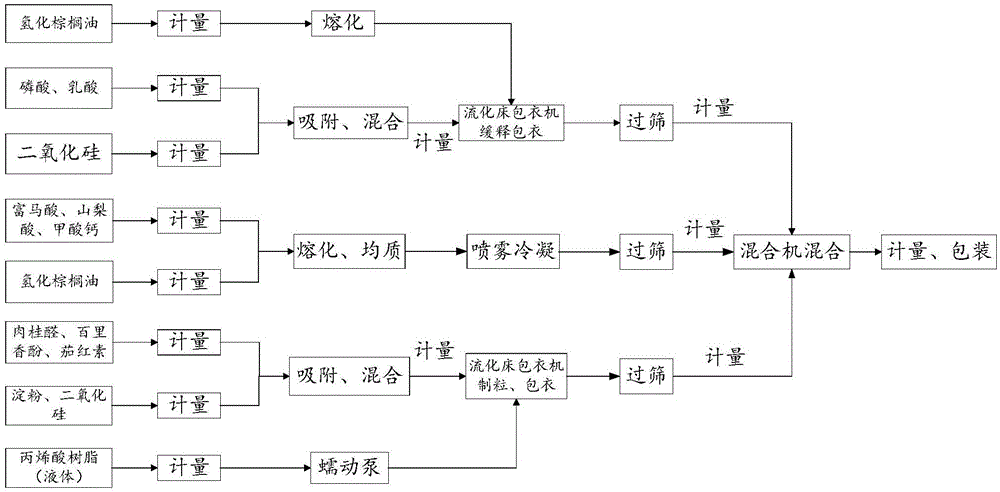

Formula and processing method of feed additive for improving production performance of animals and guaranteeing health of alimentary canals

ActiveCN105076717ASegmented release works wellEasy to useAnimal feeding stuffFood additivePhosphoric acid

The invention relates to a formula and processing method of a feed additive for improving the production performance of animals and guaranteeing the health of alimentary canals. The formula of the feed additive comprises an acidity adjusting agent, plant essential oil and auxiliary materials. The processing method adopting the formula comprises the steps of slow release treatment of phosphoric acid and lactic acid, fat burial treatment of the acidity adjusting agent and fixed-point release treatment of the plant essential oil. The formula and the processing method of the feed additive, disclosed by the invention, are adopted, so that products present good sectional release effects in different solutions after being treated by using technology equipment, wherein about 70% of the products are released in stomachs, about 15% of the products are released in small intestines and about 15% of the products are released in large intestines. Through the optimized combination of a formula technique and a processing technology technique, under the circumstance that the food consumption of the animals and the stability of the feed quality are not influenced, various effective components of the products separately exert effects in the stomachs, the small intestines and the large intestines, so that the use effect and the use value of the products are improved.

Owner:上海美农生物科技股份有限公司

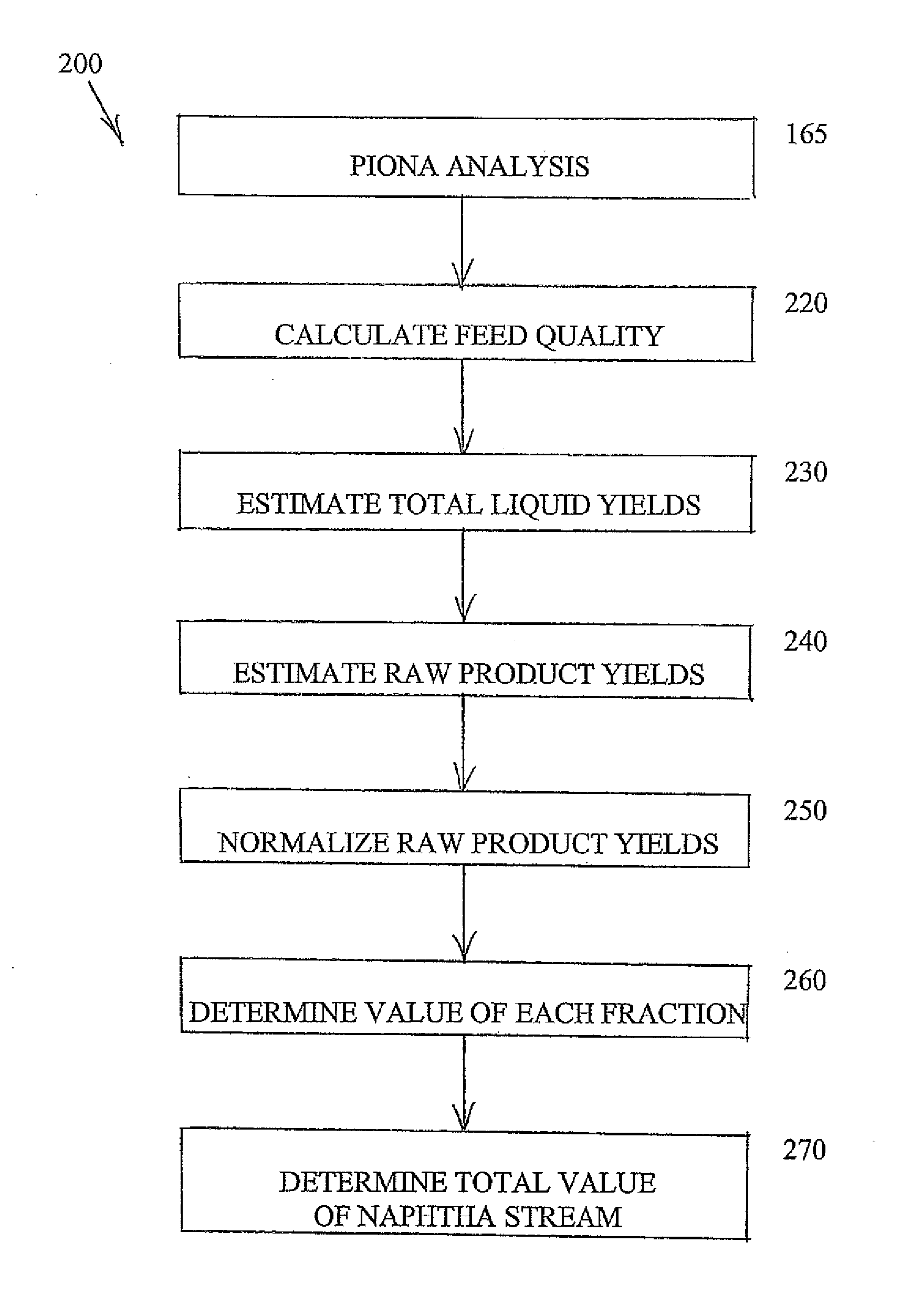

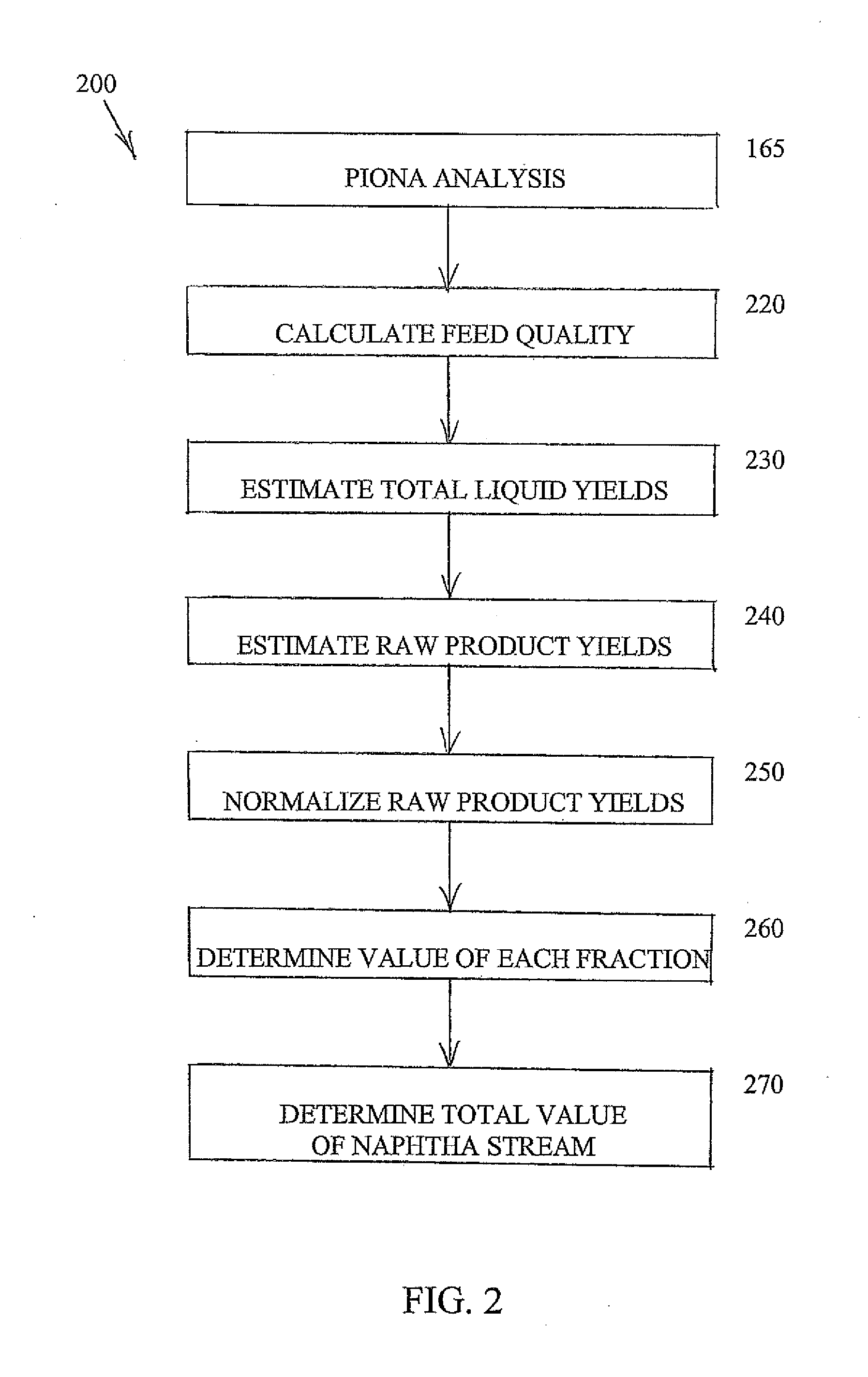

Relative valuation method for naphtha streams

A system and a method for determining the relative value of a naphtha product includes reforming the naphtha into fractions at a predetermined constant research octane number (RON), conducting PIONA analysis on the reformate, after which modules or steps are performed to assign the feed quality, assign the total liquid yields, assign raw product yields, normalize the assigned raw product yields, assign a value to one or more fractions, and calculate a total value of the naphtha stream. The method is repeated on samples of different crude oils in order to provide relative values at the predetermined RON for comparison purposes.

Owner:SAUDI ARABIAN OIL CO

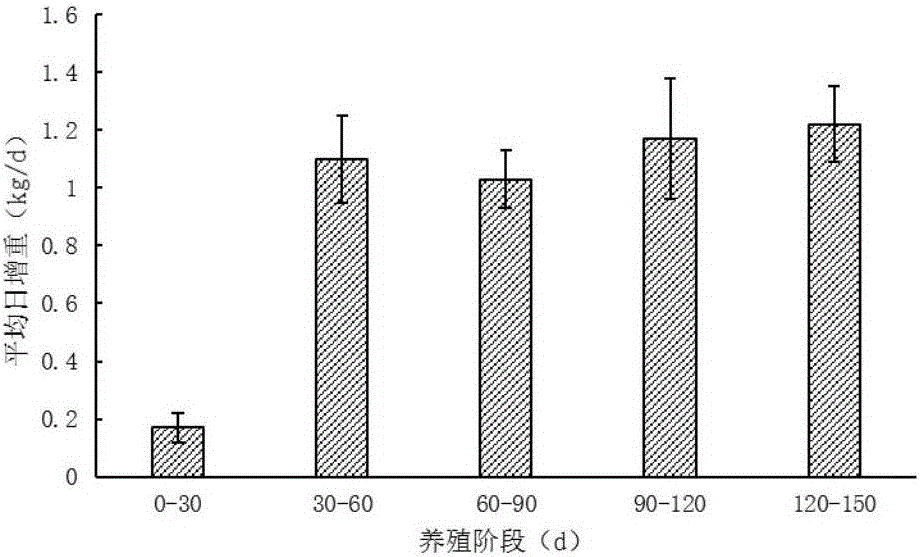

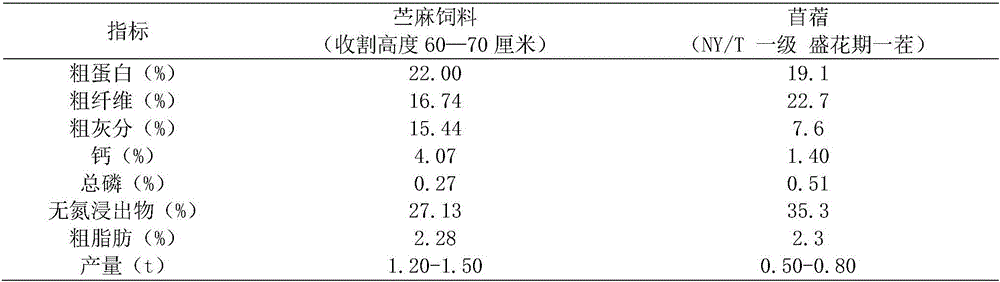

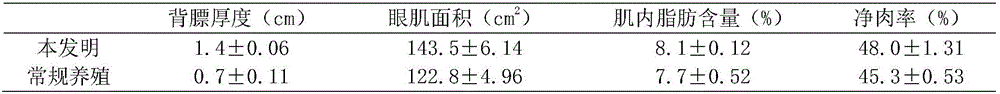

Method for preparing ramie ensilage feed

The invention discloses a method for preparing ramie ensilage feed. The method comprises steps of preparation of a fermentation liquid and preparation of ensilage feed. With the adoption of a suitable cultivation method, compound lactobacillus flora more beneficial to ensilage of a ramie by-product, namely, ensilage is cultivated within short time and is blended with crop straw such as wheat straw, rice straw, corn stalk and the like which are the easiest to obtain in a ramie production region to form ensilage feed with comprehensive and rich nutrients, efficient ensilage of fresh ramie plants is realized, the ensilage time is remarkably shortened, loss of nutrients is reduced, the feed quality is improved, and the method is applicable to yearly production and use of the ramie ensilage feed. The ramie ensilage feed prepared with the method can reduce consumption of concentrated feed by 25% and can effectively improve the beef quality without reducing the production performance of beef.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

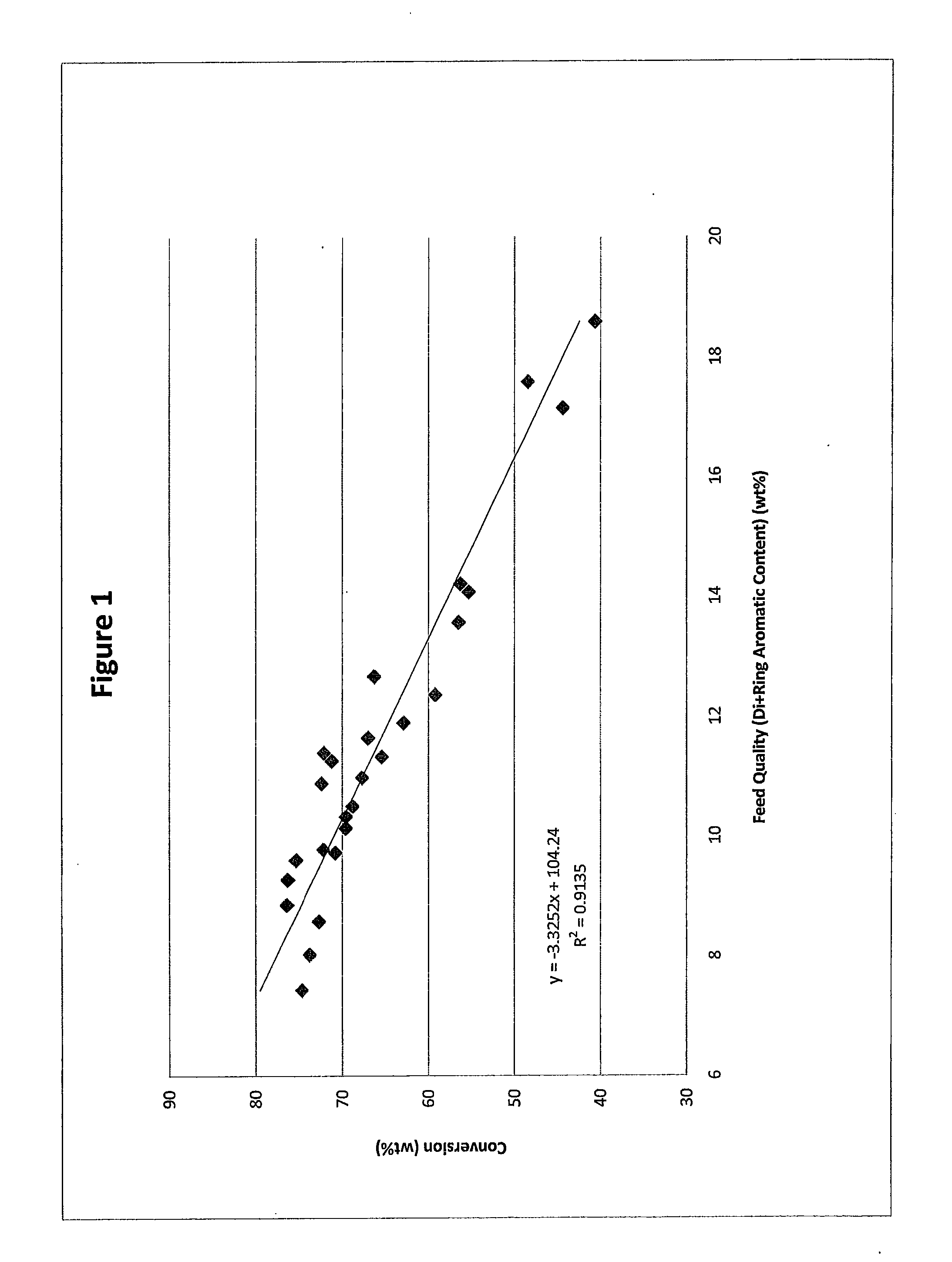

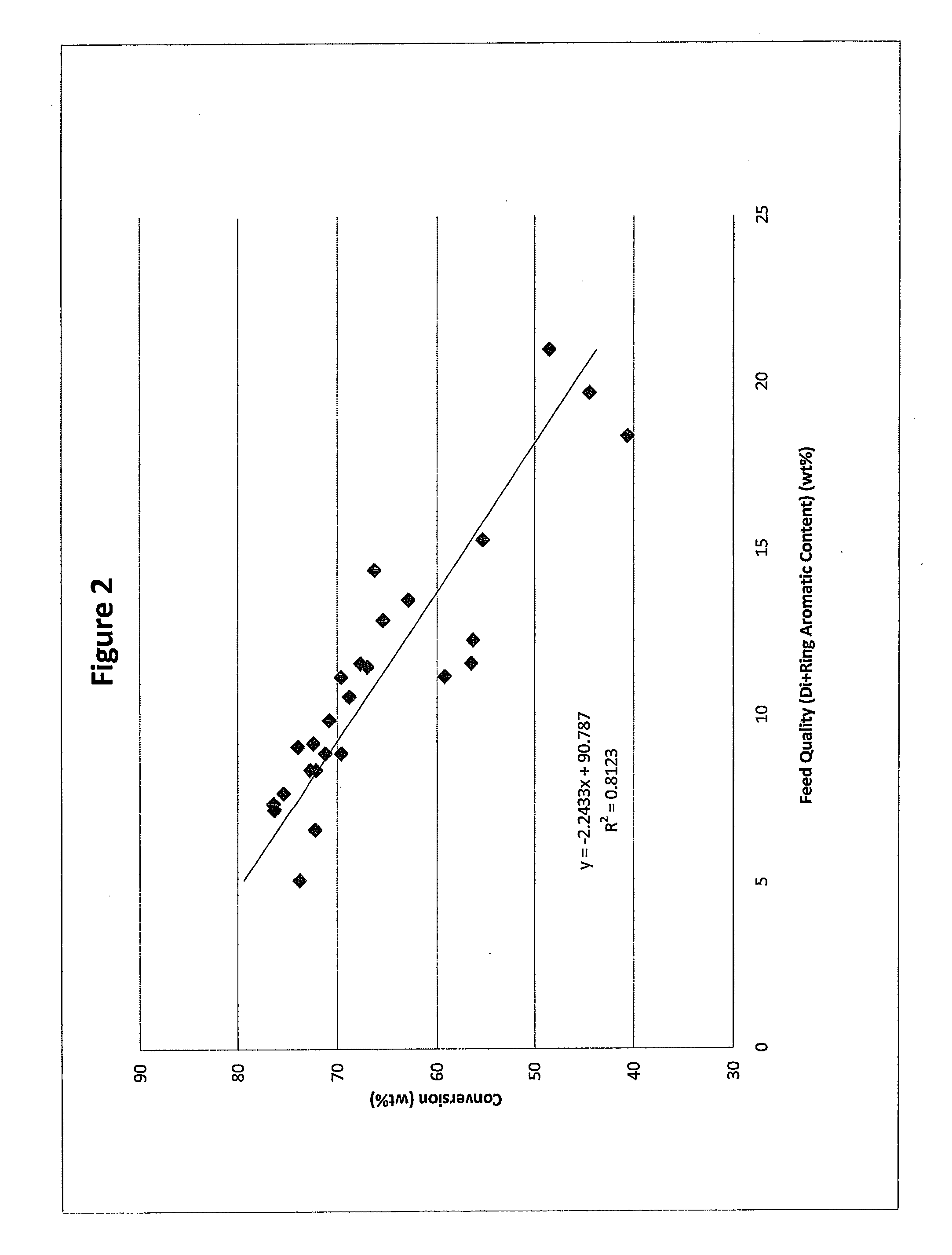

Methodology to determine feed quality (di+ring aromatic content) of FCC and hydrocracking feeds

ActiveUS20110308996A1Improve feeding qualityGood quality feedCatalytic crackingHydrocarbon oil crackingNaphthaAPI gravity

A method of upgrading naphtha and diesel yields from fluid catalytic cracking and hydrocracking units by improving a feed quality of a petroleum feedstock, product or fraction mixture. The method of improving the feed quality of the petroleum feedstock, product or fraction mixture occurs by first determining the API Gravity of a petroleum feedstock, product or fraction mixture. A temperature at which about fifty percent of the petroleum feedstock, product or fraction boils (T50) is then determined. The feed quality for the petroleum feedstock, product or fraction mixture as determined from the API Gravity and the T50 for the feedstock, product or fraction mixture is then estimated followed by adjusting the petroleum feedstock, product or fraction mixture to achieve a higher feed quality.

Owner:PHILLIPS 66 CO

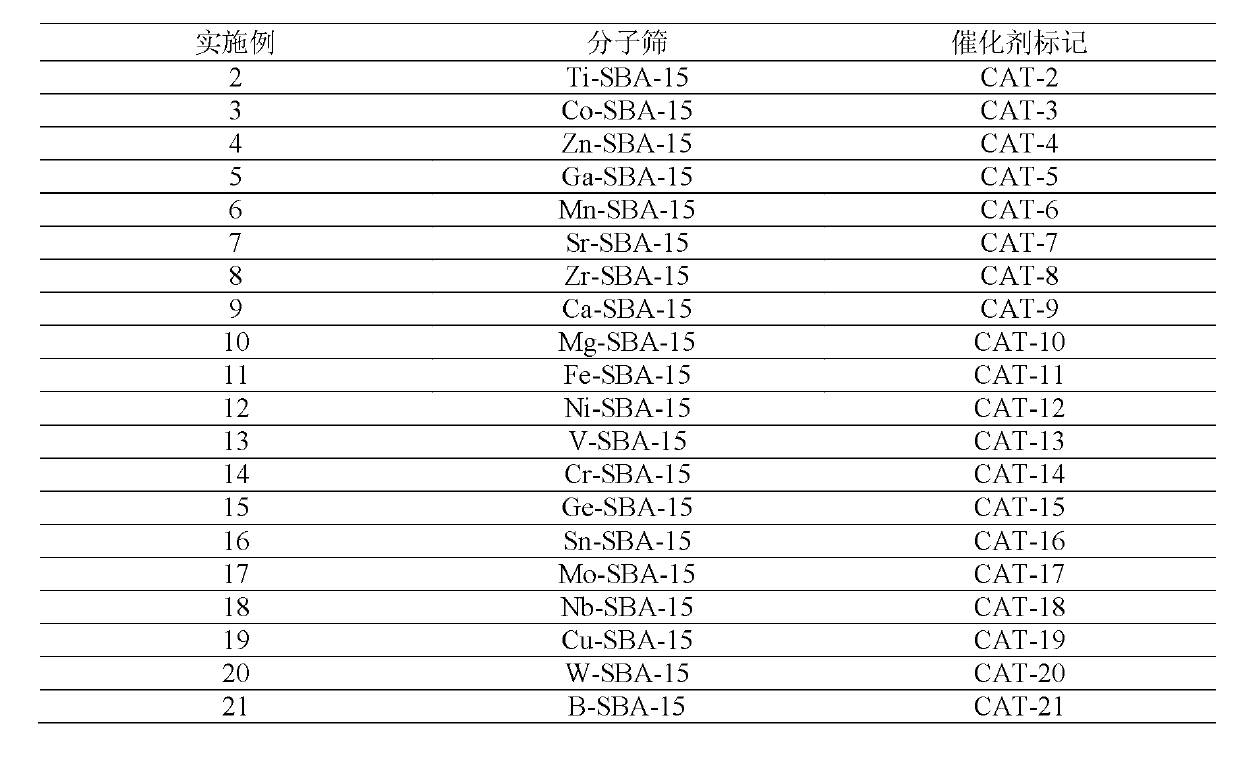

Method for removing olefin in aromatic hydrocarbon by M-SBA-15 type mesoporous molecular sieve

ActiveCN102992932ASimple processDoes not consume hydrogenChemical modification purification/separationMolecular sieveFeed quality

The invention discloses a method for removing olefin in aromatic hydrocarbon by an M-SBA-15 type mesoporous molecular sieve. The method comprises the step of carrying out contact reaction of aromatic hydrocarbon with a solid acid catalyst to obtain aromatic hydrocarbon without olefin at 30-350 DEGC, at a pressure of 0.1-10MPa, and at an air speed of 0.1-15 / h for feed quality, wherein the aromatic hydrocarbon is aromatic hydrocarbon generated by reforming generated oil, reforming aromatic hydrocarbon or steam cracking. The method is simple in process flow, free of hydrogen consumption and low in device investment and operating cost. The catalyst activity is good in stability, the stable operation of the device is long and the aromatic hydrocarbon loss is small, so that the frequency switching operation between reaction and regeneration of a reactor is avoided. The catalyst is reproducible, so that a great amount of dead catalysts is not buried, therefore, the environmental influence is small.

Owner:ZHEJIANG UNIV OF TECH

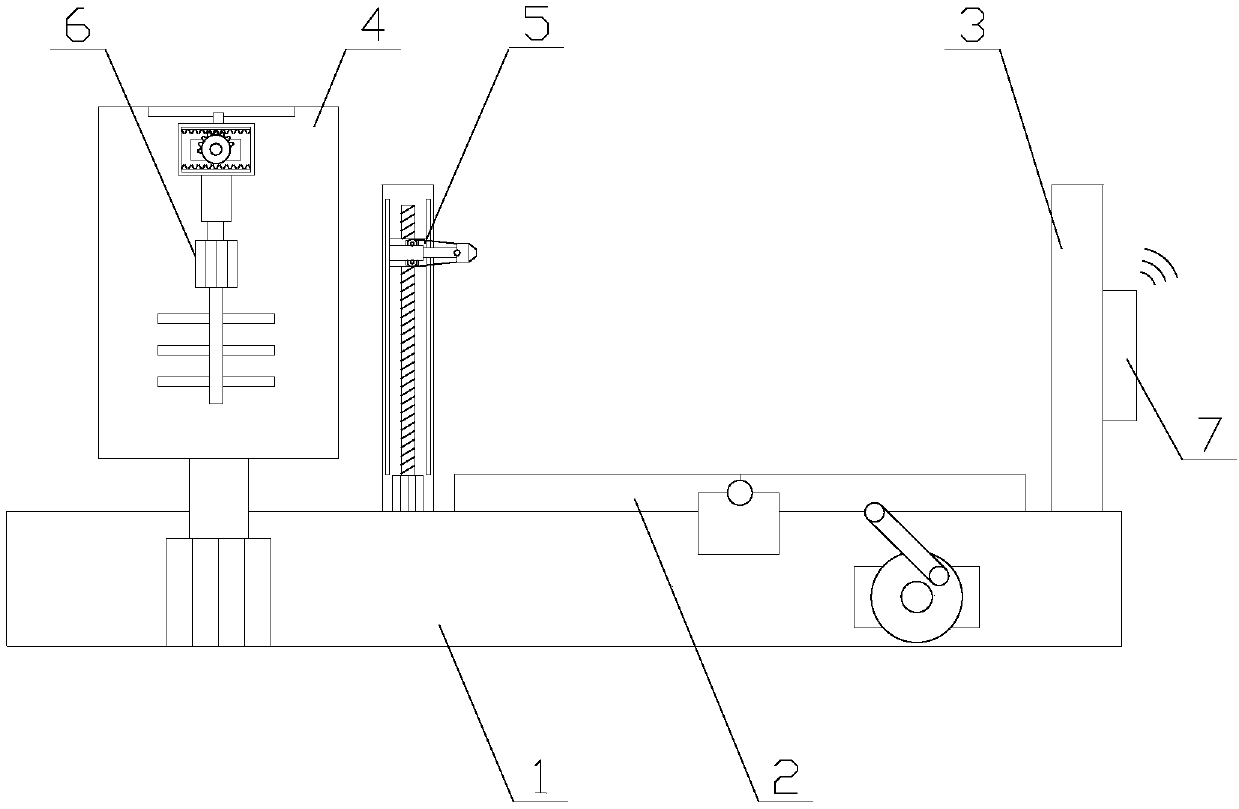

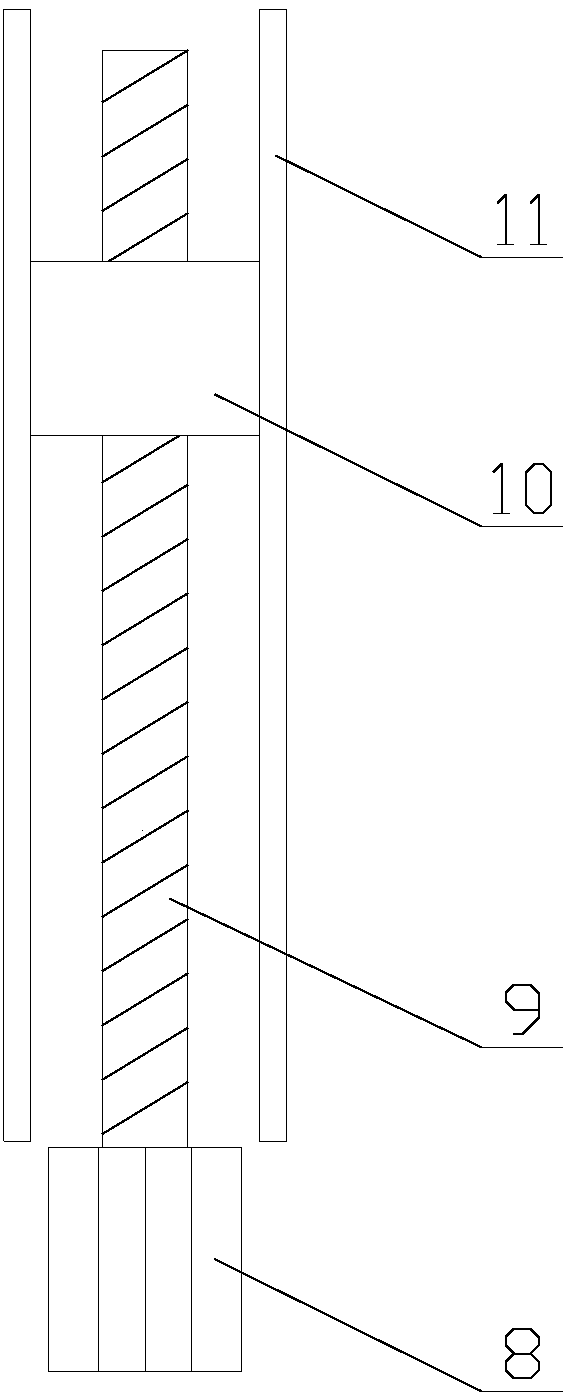

Internet of things based intelligent device for livestock breeding

ActiveCN107593493APromote absorptionIncrease exerciseRotating receptacle mixersShaking/oscillating/vibrating mixersLivestock breedingThe Internet

The invention relates to an internet of things based intelligent device for livestock breeding. The device comprises a base, a base plate, two partition plates, a stirrer, a cleaning mechanism, a stirring mechanism and a center control mechanism, the cleaning mechanism comprises a lifting assembly and an angle adjustment assembly, the angle adjustment assembly comprises an electric push rod, a spray head and two adjusting units, the stirring mechanism comprises a reciprocating assembly and a rotating assembly. In the internet of things based intelligent device for livestock breeding, by meansof the cleaning mechanism, the spray range can be enlarged through up-down movement, stretching and angle adjustment, and then spray is more uniform; by cleaning livestock, the livestock bodies and breeding environment are kept clean, the manual labor cost is lowered, and convenience is achieved; by means of the stirring mechanism, stirring is conducted to be more uniform, nutrients of feed are distributed more uniformly, the feed feeding quality is greatly improved, absorption by the livestock is convenient, growth is better, and in this way, the practicability and reliability of the breedingdevice are improved.

Owner:青岛意联汇智工业设备有限公司

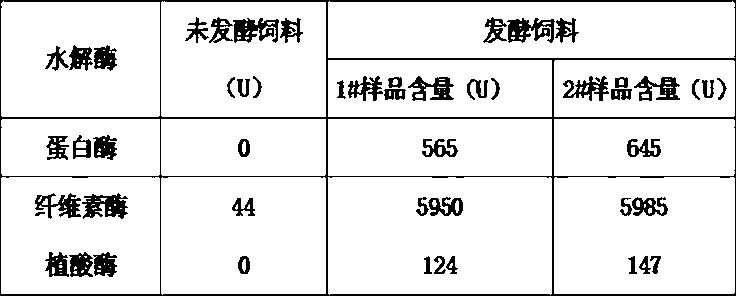

Method for solid-state fermenting of soybean meal

The invention relates to a method for solid-state fermenting of soybean meal. The method comprises four steps such as strain selection, seed liquid preparation, fermentation broth preparation and solid-state fermentation. Compared with the method in the prior art, the method of the present invention has the following characteristics that solid-state fermentation is performed on soybean meal by combining Bacillus subtilis, Saccharomyces cerevisiae and Lactobacillus plantarum; during the fermentation process, the Bacillus subtilis secretes protease to degrade crude protein into small peptides, a large amount of the Saccharomyces cerevisiae grow to synthesize bacterial protein, and a large amount of the Lactobacillus plantarum breed to secrete organic acids so as to improves the flavor of the fermented soybean meal, improve the nutritive value, promote the digestion and absorption of the nutrients; and according to the fermented product, the feeding quality of the fermented soybean meal and the efficiency of the fermented soybean meal are substantially improved, and the characteristics of remarkable economy, remarkable environmental protection and high efficiency are provided.

Owner:上海邦成生物工程有限公司

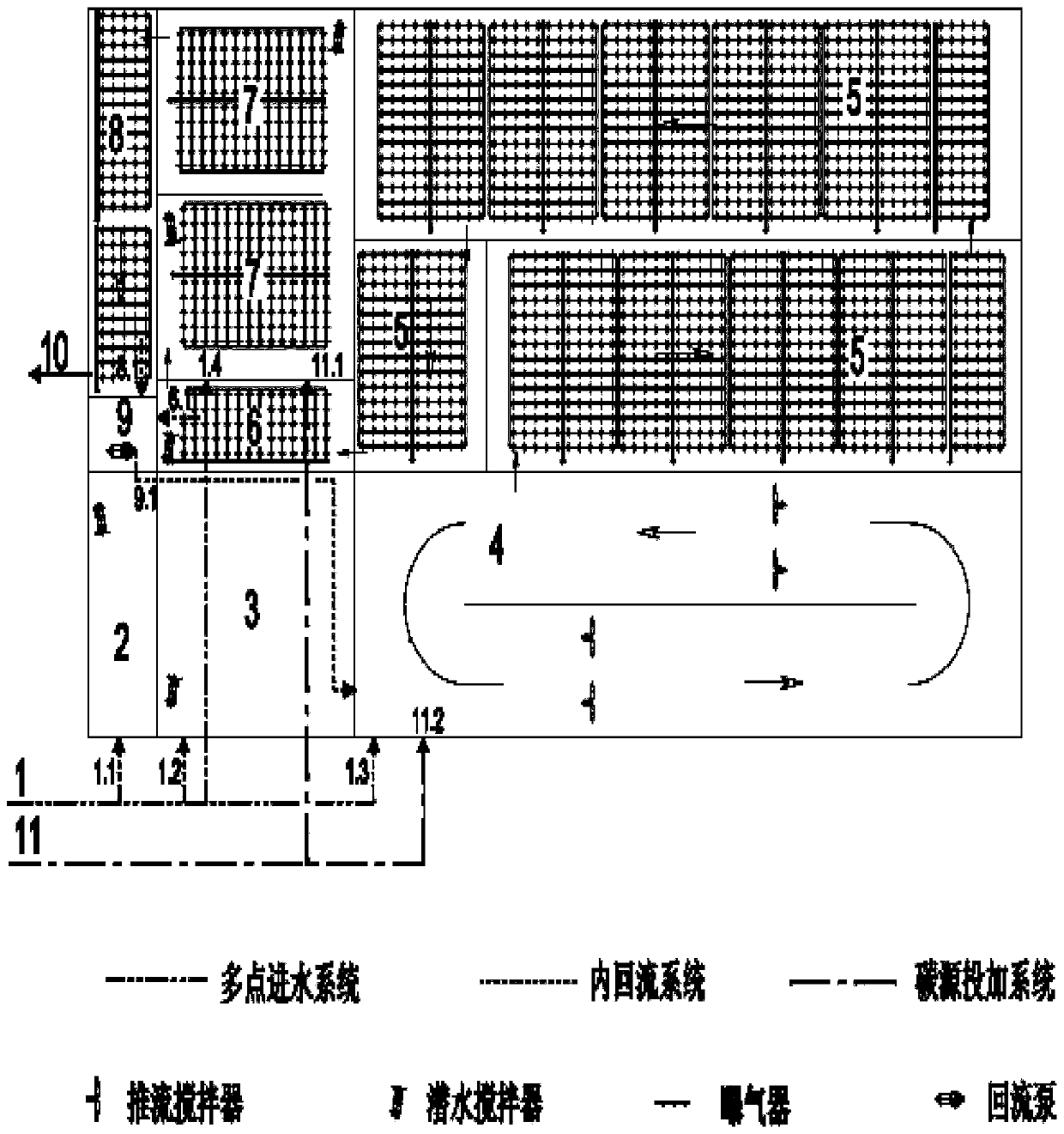

Reinforceable denitrification nitrogen removal and phosphorus removal system based on multi-point water feeding and multi-mode operation

PendingCN109879421AGuaranteed degree of anaerobicReduce adverse effectsWater contaminantsTreatment with aerobic and anaerobic processesWater qualityOxygen

The invention relates to a reinforceable denitrification nitrogen removal and phosphorus removal system based on multi-point water feeding and multi-mode operation, and belongs to the technical fieldof sewage treatment. The system comprises a pre-anaerobic pool, an anaerobic pool, a first anaerobic pool, a first oxic pool, a deoxygenation pool, a second anaerobic pool, a second oxic pool, an external carbon source adding system and a mixed liquid inner backflow system, wherein the pre-anaerobic pool, the anaerobic pool, the first anaerobic pool, the first oxic pool, a deoxygenation pool, thesecond anaerobic pool and the second oxic pool are sequentially connected. By aiming at the general phenomena of sewage treatment of high feeding CODcr and feeding TN concentration change, low C-N ratio and high-standard discharge, the deoxygenation pool and the second anaerobic pool are switched between two states of the oxic state and the anaerobic state so as to cope with the feeding quality change; the reasonable allocation and efficient utilization of the carbon source are realized through multi-point water feeding and external carbon source adding point optimization. The system has the advantages that the effluent quality is high; the carbon source utilization rate is high; the flexibility is high; the production operation cost is low, and the like.

Owner:北控水务(中国)投资有限公司

Aroma type spirit distiller grain comprehensive utilization method

The invention belong to wine brewing waste material comprehensive utilization field and aims at providing an efficiency method for applying the aroma type spirit distiller grains. The method comprises following steps: a. cleaning the aroma type spirit distiller grains, and smashing the mass in a machine; b. drying the products in step a in a drier to control the water content of 6-15%; c. grinding the products in step b on a mill and peeling the rice hulls and the other components; d. feeding the grinded aroma type spirit distiller grains in a sieving machine for separation. The products on the sieve contain a lot of rice hulls for fuel. The burned rice hulls are used for producing carbon white. The sieved products are used for preparing feeds. The method has little equipment investment, low production cost, high feed quality, high rice hull combustion rate and stable rice hull dusts and can adequately use the aroma type spirit distiller grains.

Owner:SICHUAN YIBIN WULIANGYE GROUP +1

Composite biological protein feed stuff and manufacture method thereof

InactiveCN101248831ASave foodSave on long-distance transportationFood processingAnimal feeding stuffCelluloseBiotechnology

The invention discloses compound biological protein feed and a preparation method thereof. The protein feed is made by mixing and stirring the following materials with microbial strains, fermenting, baking and crushing. The feed comprises the following materials by the weight percentages as follows: chaff 30%-55%, rice pericarp 3%-15%, and edible mushroom leftover germ bran 40%-60%. The weight ratio of the materials to the microbial strains is (90-95):(5-15). In the invention, the chaff, the edible mushroom leftover germ bran and the rice pericarp are complexly fermented to complement each other's advantages, xylogen and cellulose are degraded by 70% or so, mycoprotein is increased by 25-28%, thereby meeting the quality requirement for grain feed, and meanwhile increasing diseases suppressing and growth promoting factors, such as various vitamins, minerals, and a plurality of organized enzymes. Therefore, the protein feed is safe and environment-friendly, and can meet the growth and development requirements of livestock and poultry without addition of grain for energy.

Owner:张嘉闻

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com