Feed blending system

A technology of batching system and feed, applied in mixer accessories, cleaning hollow objects, mixers and other directions, can solve the problems of poor quality of feed products, no crushing function, limited mixing effect, etc., and achieve good feed quality, high degree of automation, The effect of particle size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

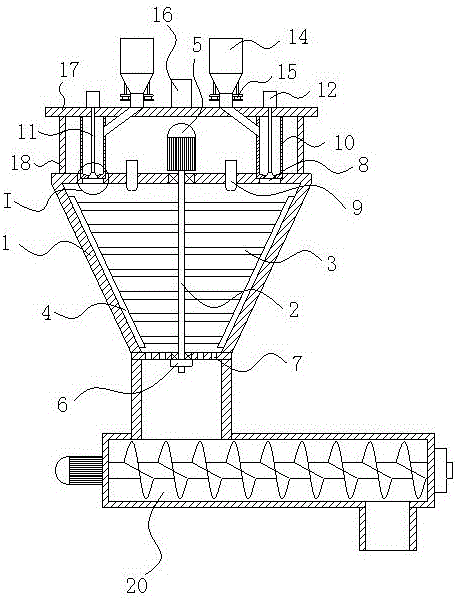

[0015] Attached below Figure 1~4 The present invention is further described.

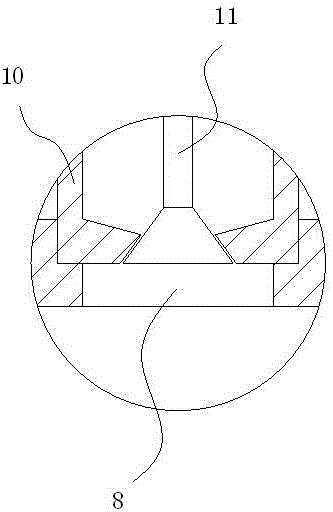

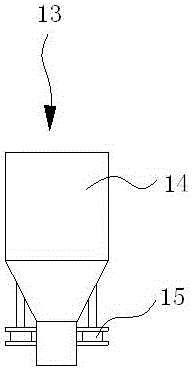

[0016] A feed batching system, comprising a cylindrical mixing chamber 1, the radius of the upper shell of the mixing chamber 1 is greater than the radius of the lower shell, the mixing chamber 1 is provided with a stirring device, the stirring device includes a stirring shaft 2, a stirring shaft 2 A plurality of stirring blades 3 are arranged from top to bottom, and the stirring radius of the stirring blades 3 gradually decreases. Fixed on the shell at the upper end of the mixing chamber 1, the other end of the stirring shaft 2 passes through the shell at the lower end of the mixing chamber 1 to connect a bearing end cover 6, and the stirring shaft 2 and the shell of the mixing chamber 1 are fixedly connected by bearings; the mixing chamber The lower shell of 1 is provided with a sieve hole 7, and the upper shell is provided with a plurality of raw material inlets 8 and additive inlets 9, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com