Patents

Literature

215results about How to "Balanced ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meal replacement protein powder solid beverage for managing body weight

InactiveCN104287049AGuaranteed intakeIntake controlMilk preparationSugar food ingredientsFiberAdditive ingredient

The invention discloses a meal replacement protein powder solid beverage for managing the body weight and belongs to the field of nutrient foods. The solid beverage comprises the following components of soybean isolated protein, dried skim milk, whey protein concentrate, resistant dextrin, inulin, L-carnitine, a white kidney bean extract, a guarana extract, soy dietary fiber powder, pea fiber, oat fiber, erythritol, stevioside, phospholipid, Arabic gum, xanthan gum, pectin, alkalized cocoa powder, xylooligosaccharide and edible essence. By comprehensively considering the difference of nutrient components required by a human body at daytime and nighttime, the solid beverage disclosed by the invention is reasonable in formula matching and balanced in nutrition, and is the meal replacement solid beverage for supplementing the nutrients of the human body and controlling the body weight; the production process is simple and the drying is avoided; the damage to plant extracts and other components is prevented, so that the effects of nutrient components are guaranteed; besides, no sugar is added in the formula of the meal replacement protein powder solid beverage, so that the meal replacement protein powder solid beverage is suitable for being eaten by people with diabetes.

Owner:JIANGSU ALAND NOURISHMENT

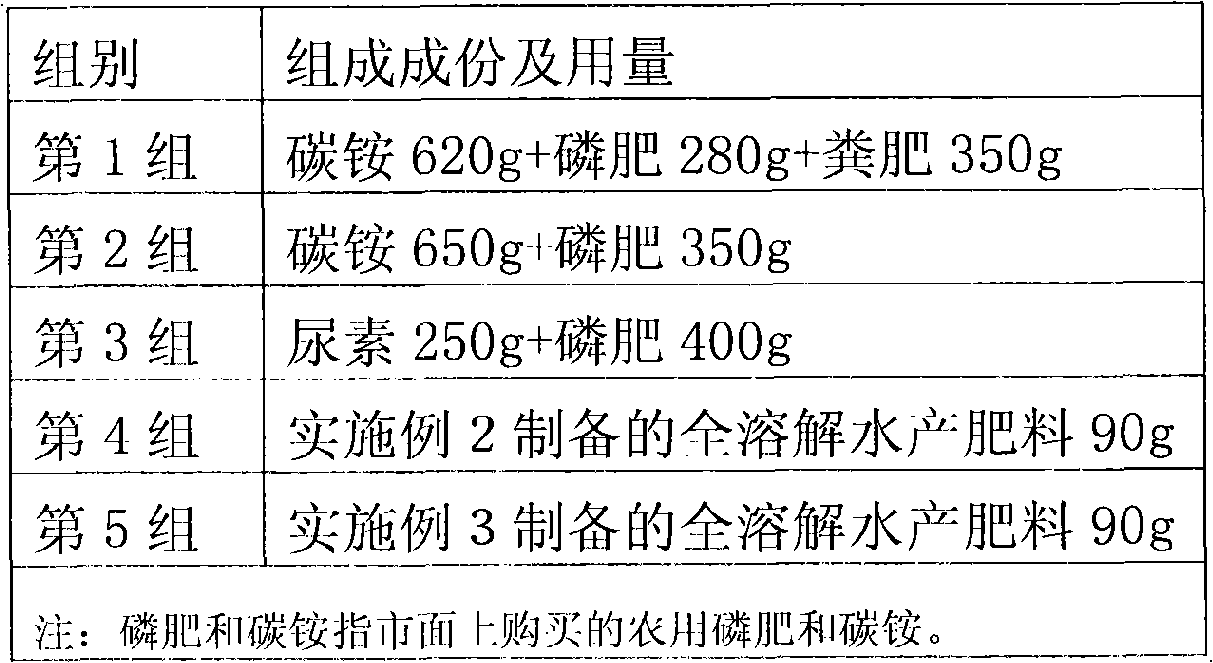

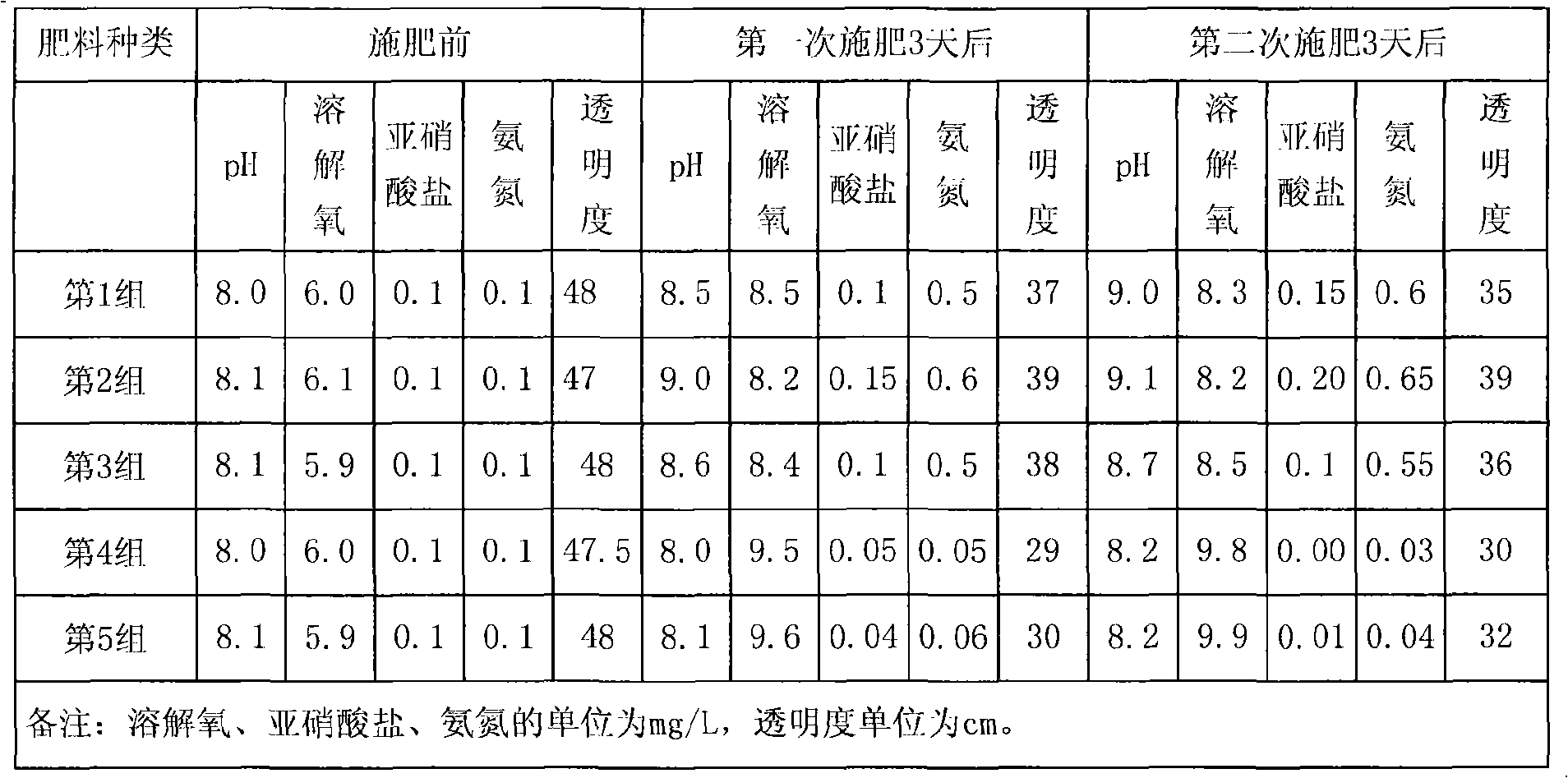

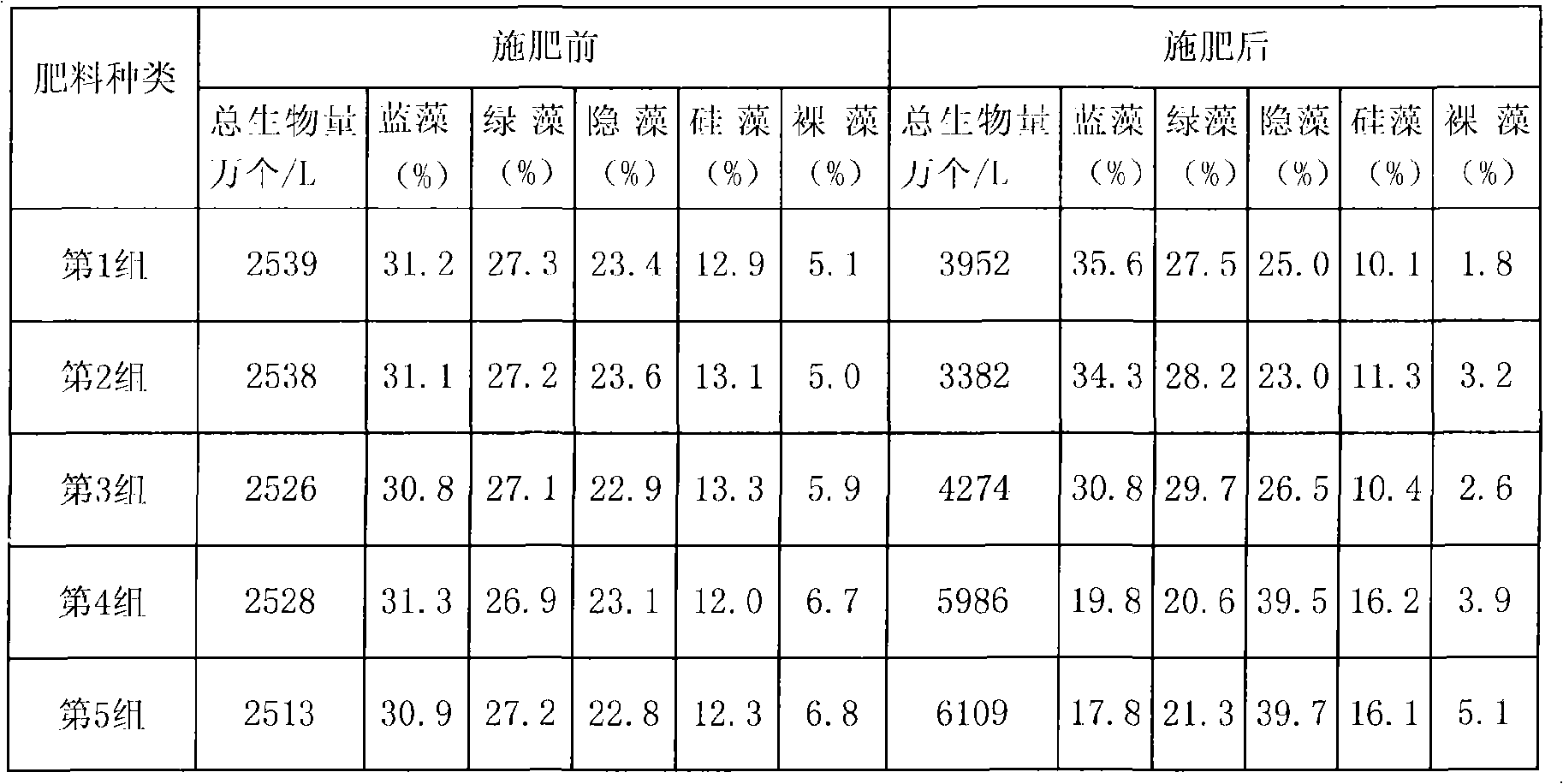

A fully soluble aquatic fertilizer and its preparation method

ActiveCN101550036AReduction factorImprove immunityClimate change adaptationAlkali orthophosphate fertiliserDiseaseTrace element composition

The present invention discloses a fully soluble aquatic fertilizer and its preparation method and pertains to aquaculture field. The aquatic fertilizer of the present invention comprises monoammonium phosphate 15-45%, sodium humate 12-20%, sodium silicate 5-12%, compound premix 8-13%, and urea 30-40%. The compound premix is mainly composed of trace elements. Firstly, the aquatic fertilizer of the present invention has comprehensive nutrition and balanced formula; secondly, the present invention has high dissolution speed and utilization rate; thirdly, the present invention features simple use method, small use amount, sufficient content, long lasting time and low cost; fourthly, the present invention can not only promote the mass propagation of food organisms of aquatic animals but also specifically cultivate helpful algae, improve water quality, increase dissolved oxygen, effectively avoid pond poisoning, reduce diseases, lower feed coefficient and enhance fish immunity; the present invention is green and environment-friendly, and has stable quality and no harm on human and animal and no pollution on environment.

Owner:邳州市鑫盛创业投资有限公司

Immune type protein powder solid beverage and preparation method thereof

ActiveCN104522832AImprove absorption rateHigh purityNatural extract food ingredientsFood ingredient functionsWhey proteinGamma-Aminobutyric acid

The invention discloses an immune type protein powder solid beverage and a preparation method thereof and belongs to the field of nutritional foods. The solid beverage comprises the following components: 70-85 percent of concentrated whey protein powder, 3-8 percent of pea protein, 5-15 percent of wheat protolysate, 2-4 percent of phospholipid, 1-3 percent of an acerola cherry extract, 1-5 percent of edible essence, 0.5-1.5 percent of a yeast extract, 0.5-1.5 percent of gamma-aminobutyric acid, 0.5-1.5 percent of coconut milk powder, 0.3-0.8 percent of silicon dioxide and 0.1-0.3 percent of stevioside. The invention also discloses the preparation method of the solid beverage. The solid beverage disclosed by the invention fully meets the demands of the human body, is scientific in prescription design, reasonable in nutrition arrangement and different in taste according to different customers, and can meet the special demands of different people on taste; the solid beverage is mellow in taste, convenient to use, stable in quality, simple in preparation method, easy to operate, suitable for large-scale industrial production, free of sugar in the prescription and suitable for diabetics to eat.

Owner:JIANGSU ALAND NOURISHMENT

Premixed fodder used specially for young milk-cow

InactiveCN1723792AImprove digestion and absorption rateImprove immune functionAnimal feeding stuffAccessory food factorsTrace elementRumen

Owner:陕西杨凌富仕特饲料股份有限公司

Method for producing multilayer coating film

ActiveUS20110108426A1Inhibition of saggingGood lookingDuplicating/marking methodsSynthetic resin layered productsAcrylic resinMonomer

The present invention relates to a method for producing a multilayer coating film, which comprises steps of applying a waterborne intermediate coating composition on an electrodeposited coating film to form an intermediate coating film; applying a waterborne base coating composition on the intermediate coating film to form a base coating film; applying a clear coating composition on the base coating film to form a clear coating film; and simultaneously baking and curing the intermediate coating film, the base coating film applied thereon, and the clear coating film further applied thereon in order to form a multilayer coating film, wherein the waterborne intermediate coating composition comprises an emulsion of a hydroxyl group-containing acrylic resin comprising 27 to 65% by weight of a styrene monomer, wherein the emulsion has a water-tolerance within a range of from 0.2 to 5 and a hexane-tolerance within a range of from 5 to 25; a hydroxyl group-containing polyester resin; a melamine resin; a carbodiimide; and an associative thickener, wherein the associative thickener comprises an urethane compound (A) represented by the formula (1), and an urethane compound (B) represented by the formula (2): R—(OA)m-O—C(═O)—NH—Y—NH—C(═O)—O-(AO)n—R (1) R—(OA)a-[O—C(═O)—NH—Y—NH—C(═O)—(OA)b]c-O—C(═O)—NH—Y—NH—C(═O)—O-(AO)d—R (2) wherein R independently represents a hydrocarbon group having 8 to 24 carbon atoms, Y independently represents a residue resulted from a removal of two isocyanate groups from a diisocyanate, OA independently represents an oxyalkylene group having 2 to 4 carbon atoms, AO independently represents an alkyleneoxy group having 2 to 4 carbon atoms, O represents an oxygen atom, C represents a carbon atom, N represents a nitrogen atom, m independently represents an integer of 20 to 500, n independently represents an integer of 20 to 500, a independently represents an integer of 1 to 100, d independently represents an integer of 1 to 100, b represents an integer of 40 to 500, c represents an integer of 1 to 5, b by c (or b×c) represents an integer of 150 to 2500, and R may be the same or different, and Y may be the same or different, wherein each of the urethane compounds (A) and (B) has at least 80% by weight of oxyethylene groups and ethyleneoxy groups relative to the total weight of the oxyalkylene groups and the alkyleneoxy groups, wherein weight ratio of the hydroxyl group-containing acrylic resin emulsion to the associative thickener is within a range of from 100 / 0.1 to 100 / 50 as a basis of the solid content, in order to provide the multilayer coating film with an excellent exterior appearance by a three coating and one baking (3C1B) procedure, wherein viscosity of the intermediate coating composition is controlled, and furthermore, ratio of hydrophilicity to hydrophobicity of the resin in the intermediate coating composition is controlled, in order to significantly suppress sagging of the waterborne intermediate coating composition during the coating procedure.

Owner:TOYOTA JIDOSHA KK +1

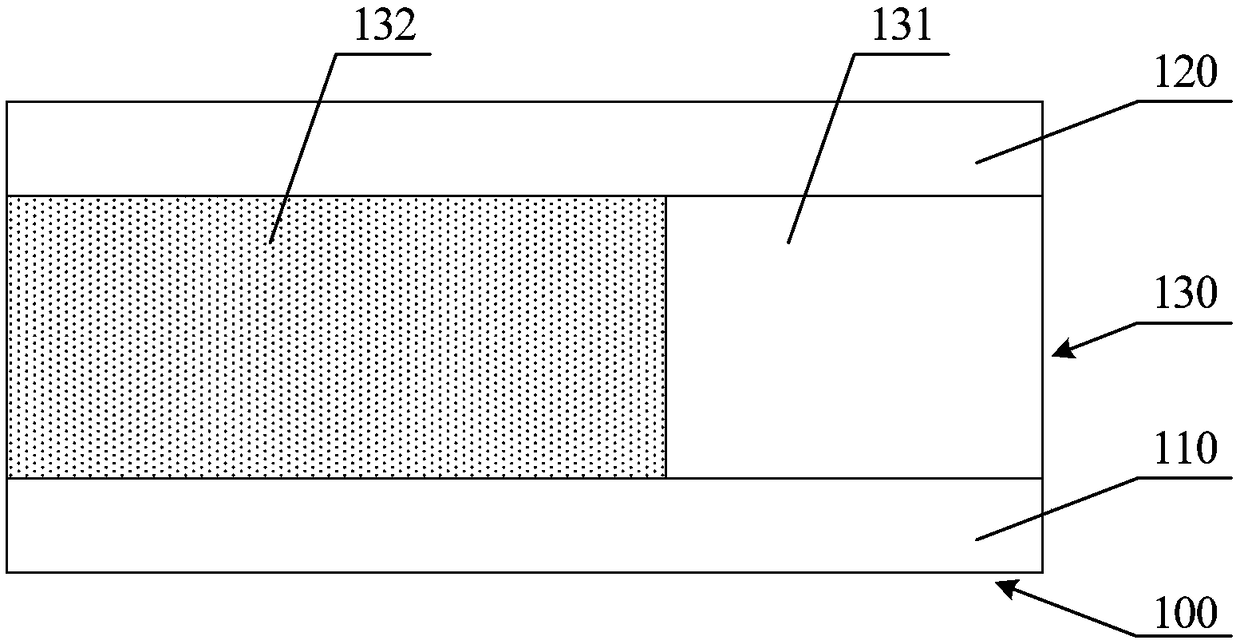

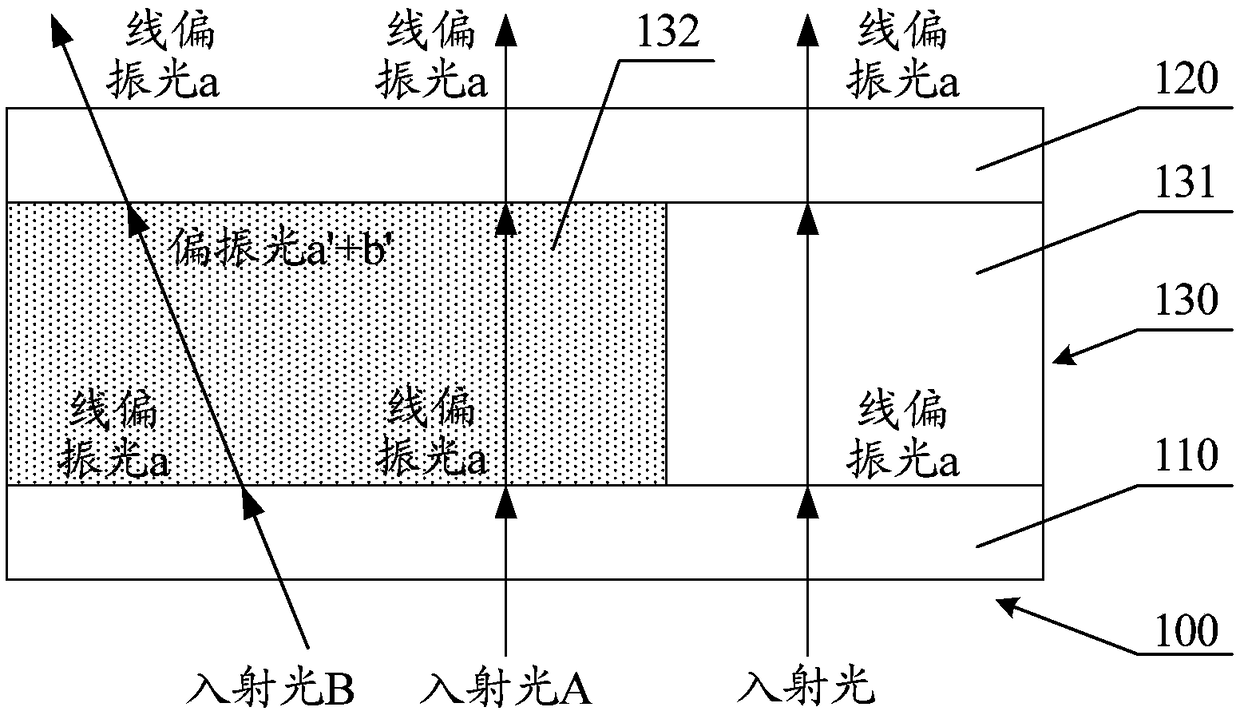

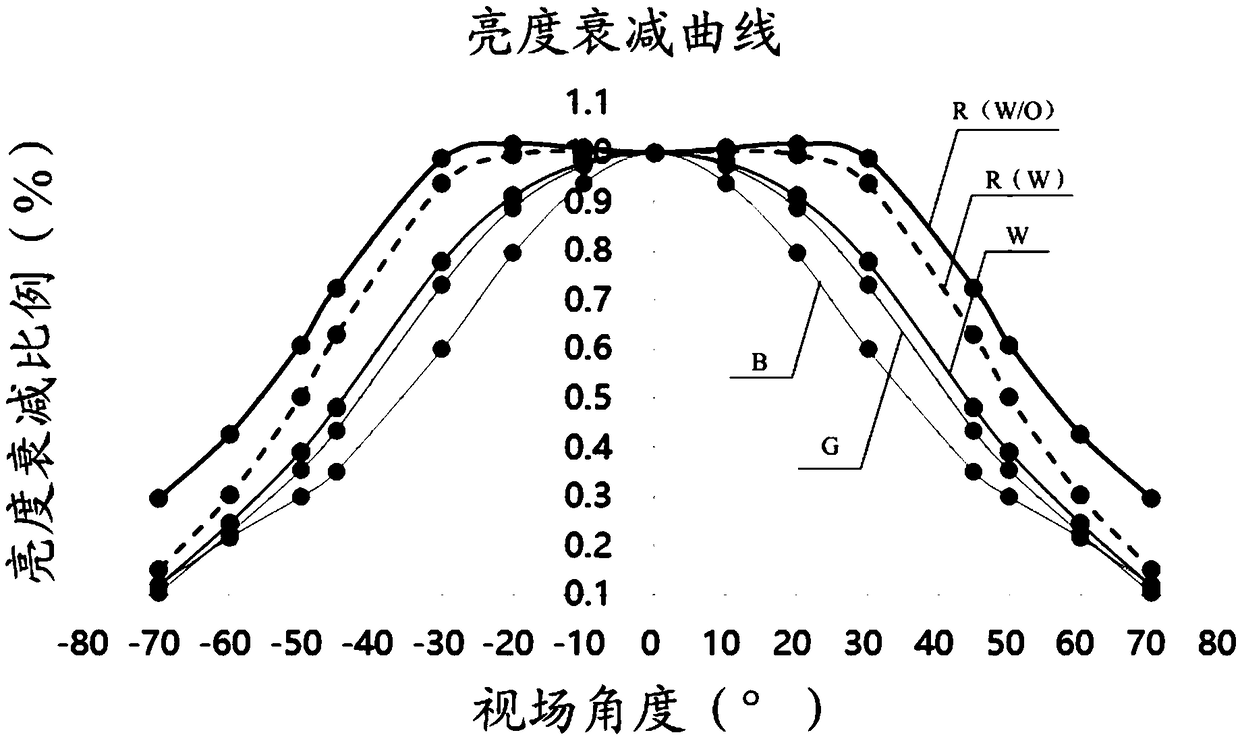

A polarization module and a display panel

ActiveCN109065600ASolve the problem of color castReduce brightnessSolid-state devicesNon-linear opticsPolarizerOptoelectronics

The embodiment of the invention discloses a polarization module and a display panel. The polarization module comprises a first polarizing plate arranged on the light entrance side and a second polarizing plate arranged on the light exit side, and a polarizing film layer arranged between the first polarizing plate and the second polarizing plate, wherein the polarizing film layer comprises a lighttransmitting region and a polarizing region; A first polarizer and a second polarizer are used for emitting incident polarized light as linearly polarized light in a specified polarization direction;A polarizing region is used for retarding a phase of linearly polarized light incident into the polarizing region in a direction different from an optical axis direction of the polarizing region suchthat the exiting polarized light includes a first polarized light in a first polarizing direction and a second polarized light in a second polarizing direction; A light-transmitting region is used fortransmitting light incident into the light-transmitting region. The embodiment of the invention solves the problem of color deviation of the existing display panel under different viewing angles without affecting the front efficiency of the OLED panel, the cathode resistance and the color gamut of the display picture.

Owner:BOE TECH GRP CO LTD +1

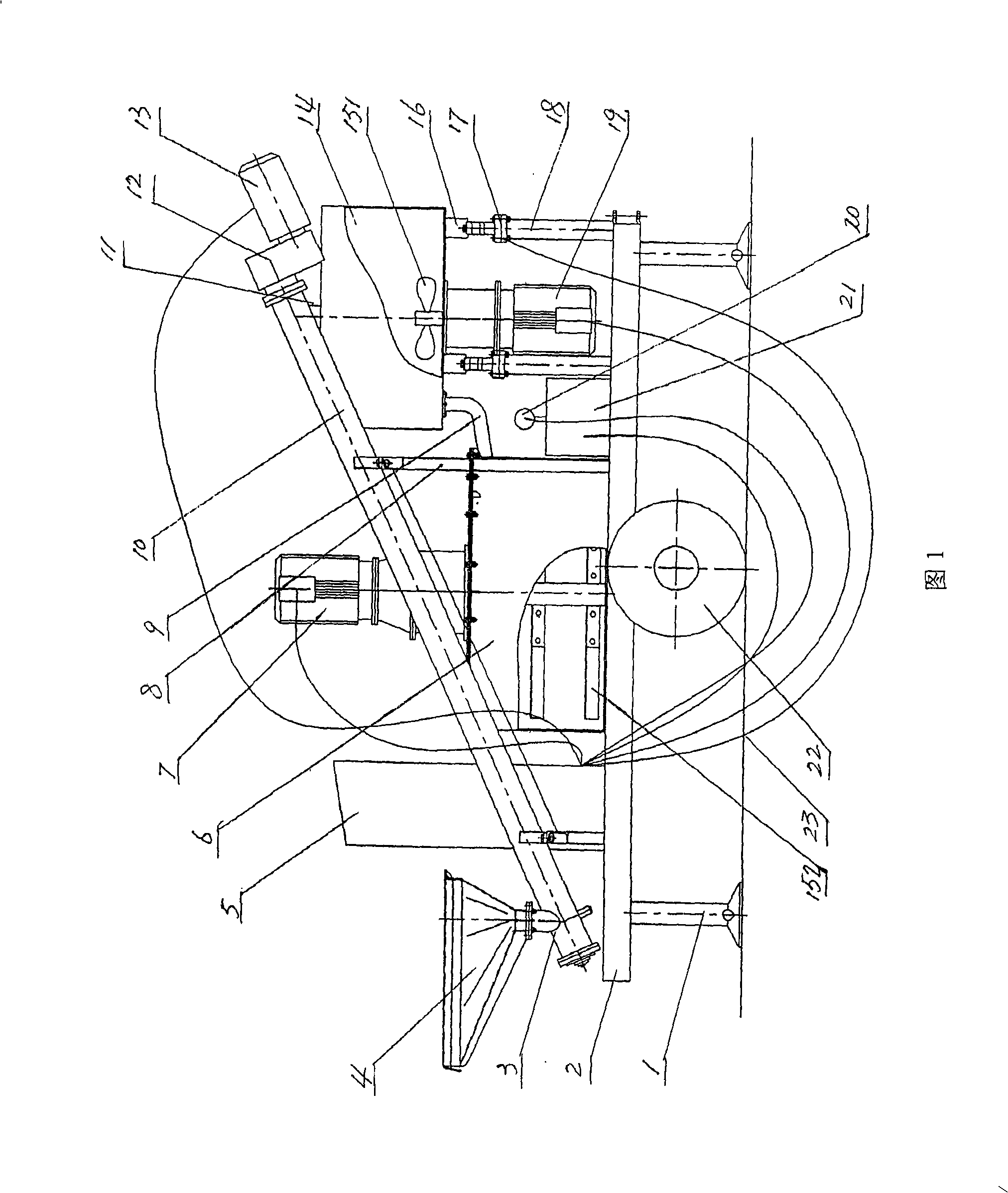

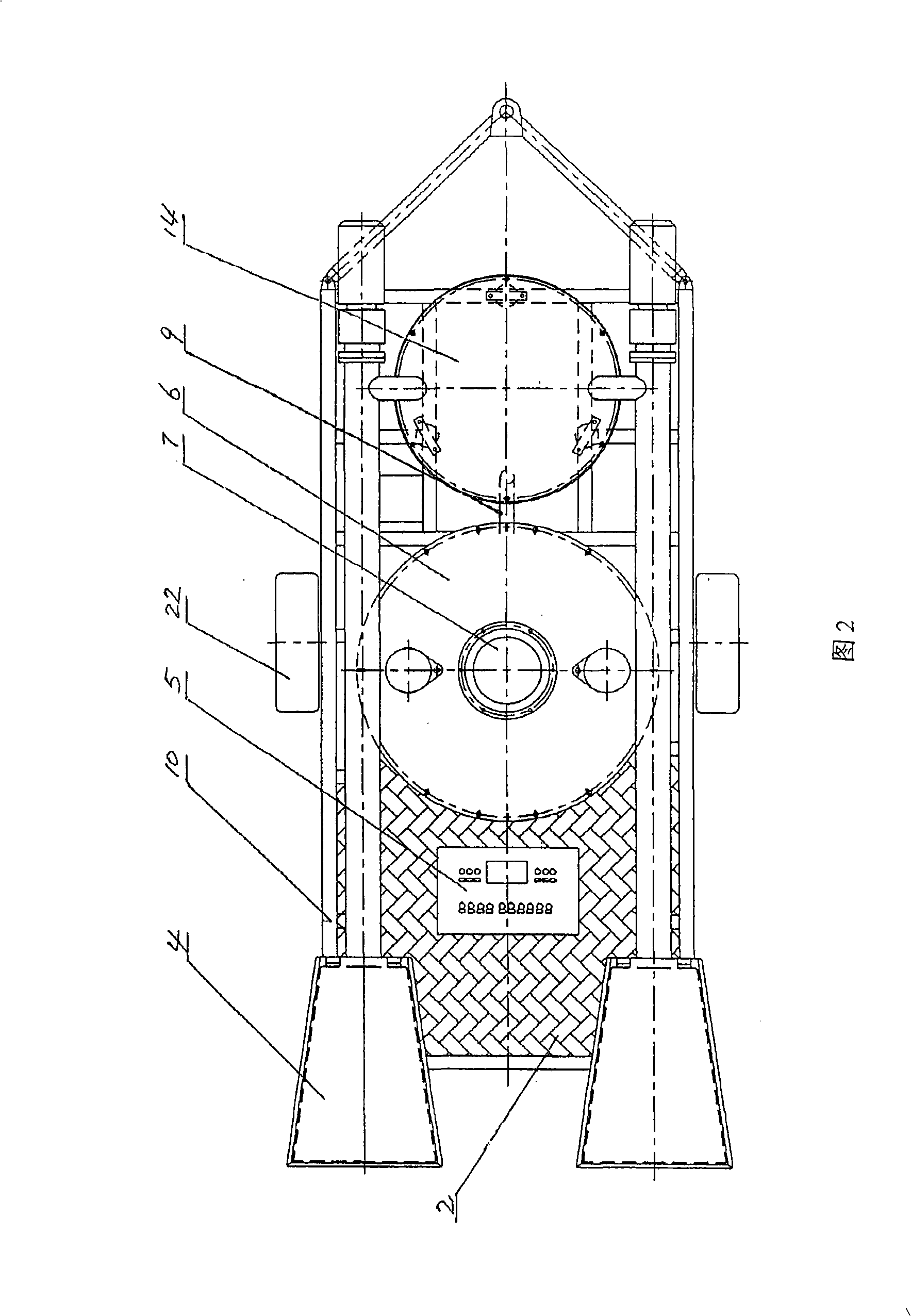

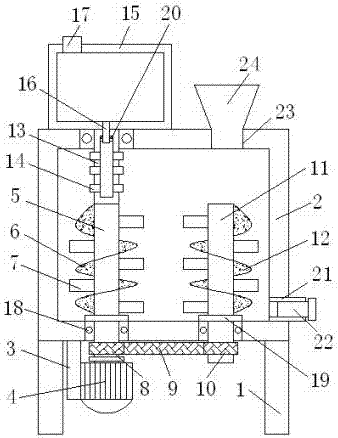

High-speed stirring-squeezing trolley

ActiveCN101352894AWell mixedQuality assuranceDischarging apparatusMixing operation control apparatusAutomatic controlVehicle frame

The invention discloses a high-speed stirring mud grouting trolley and is characterized in that: the high-speed stirring mud grouting trolley is provided with a frame, and the frame is equipped with a screw conveying mechanism, a high-speed stirring mechanism, a grout pump and a controller. The high-speed stirring mechanism is composed of a high-speed stirring drum, a bracket and a high-speed stirring motor. The inlet of the grout pump is communicated with the high-speed stirring drum by a pipeline. The bracket is provided with at least three pillars, and the lower ends of the pillars are fixed on a trolley board, while the upper ends thereof are connected with the bottom of the stirring drum by a weighting sensor. The output shaft of the high-speed stirring motor faces upwards and penetrates into the high-speed stirring drum, and the end of the output shaft is provided with blades. The screw conveying mechanism is fixed on the trolley board in an oblique manner in virtue of the bracket, the end of the the discharge hole of the screw conveying mechanism is communicated with the feeding hole of the high-speed stirring drum, and the feeding hole is provided with a feeding funnel. Automatic control of each part can be realized by the controller. The high-speed stirring mud grouting trolley of the invention not only can save time and improve production efficiency, but also can evenly mix grouting agents and can guarantee the quality of bridges. The high-speed stirring mud grouting trolley is suitable for preparing grouting agents and filling the grouting agents in pipelines.

Owner:贾铭铭 +1

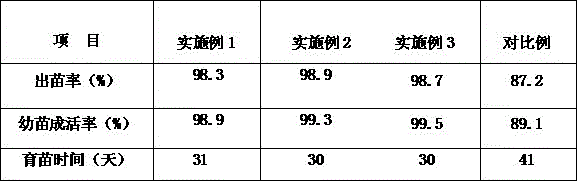

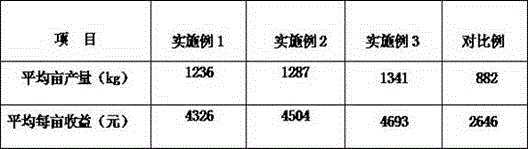

Method for planting high-yield high-quality blackcurrant

InactiveCN105875339APromote softeningPromote expansionBiocideGrowth substratesWarm waterSeed treatment

The invention discloses a method for planting high-yield high-quality blackcurrant. The method specifically comprises the steps of seed selection, seed processing, seed sowing, seedling transplantation and pest control. Seeds are soaked in potassium permanganate solution and then cleaned with clear water instantly, and stirring and soaking are conducted with warm water next, so that seed germination rate is effectively increased and seed germination time is shortened. An adopted seedling raising substrate is balanced in matching, and through interaction of different raw materials, release of nutrients of each raw material can be effectively improved, rich nutrients are provided for growth of seedlings, seedling emergence rate is increased, and robust growth of seedlings is promoted; furthermore, sterilization capacity is high, germ infringement can be effectively inhibited, the disease resistance of seedlings is improved, and the survival rate of seedlings is increased. An adopted pesticide is scientific and reasonable in formula, has efficient sterilization and pesticidal capacity, and can remarkably reduce paranthrene regalis butler attack rate.

Owner:蚌埠市宝煦家庭农场

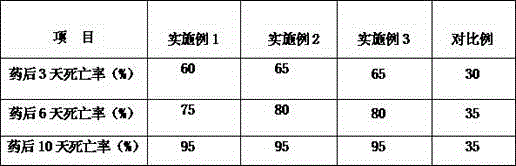

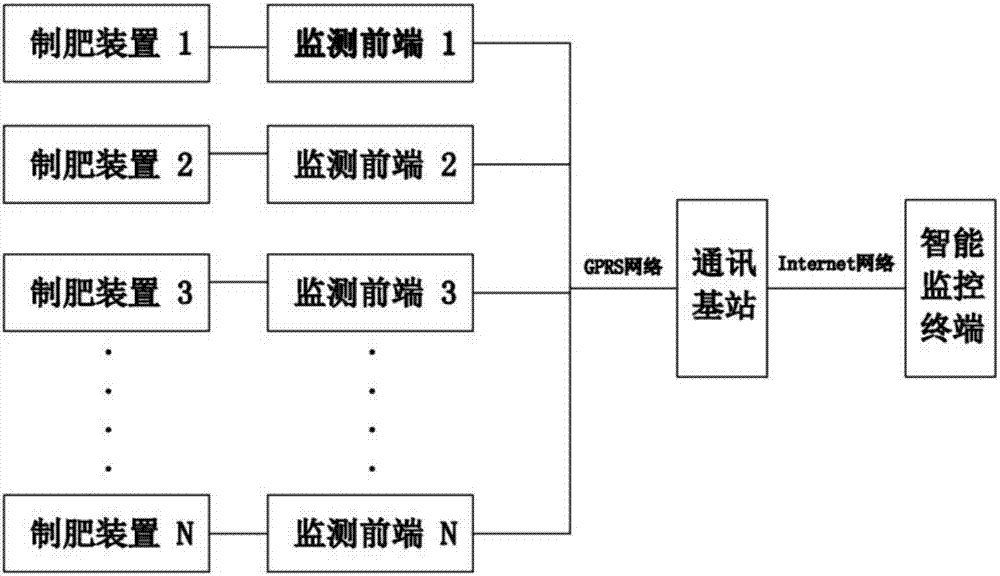

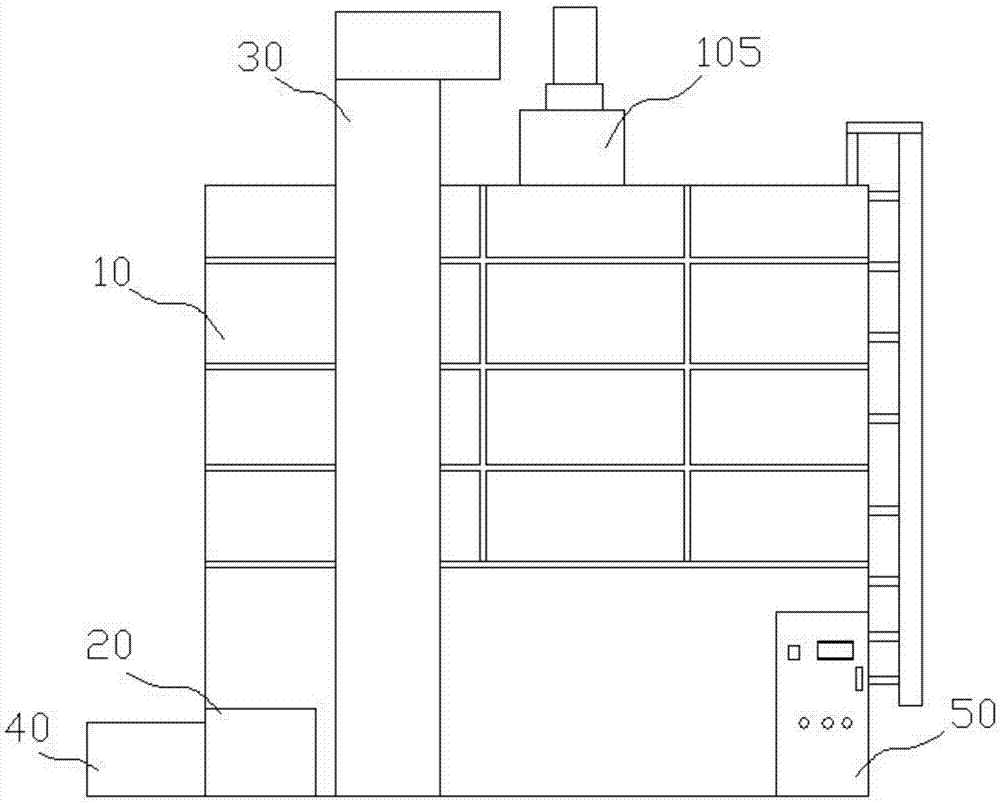

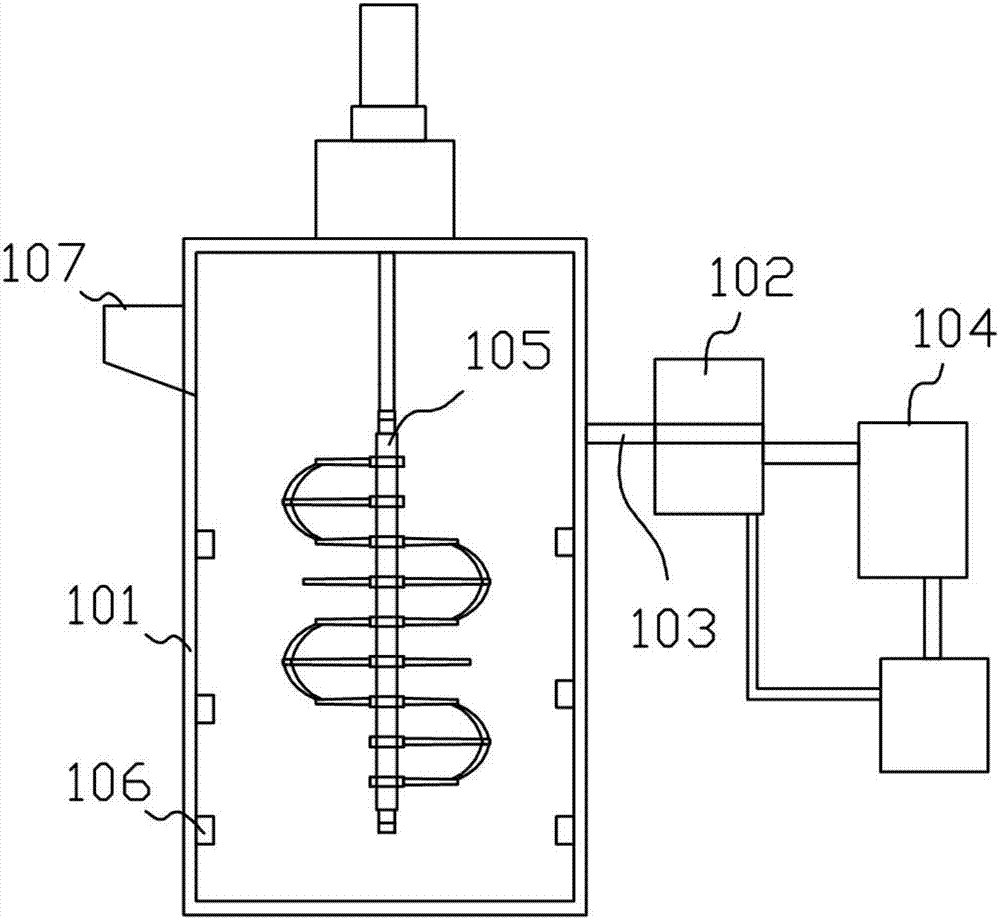

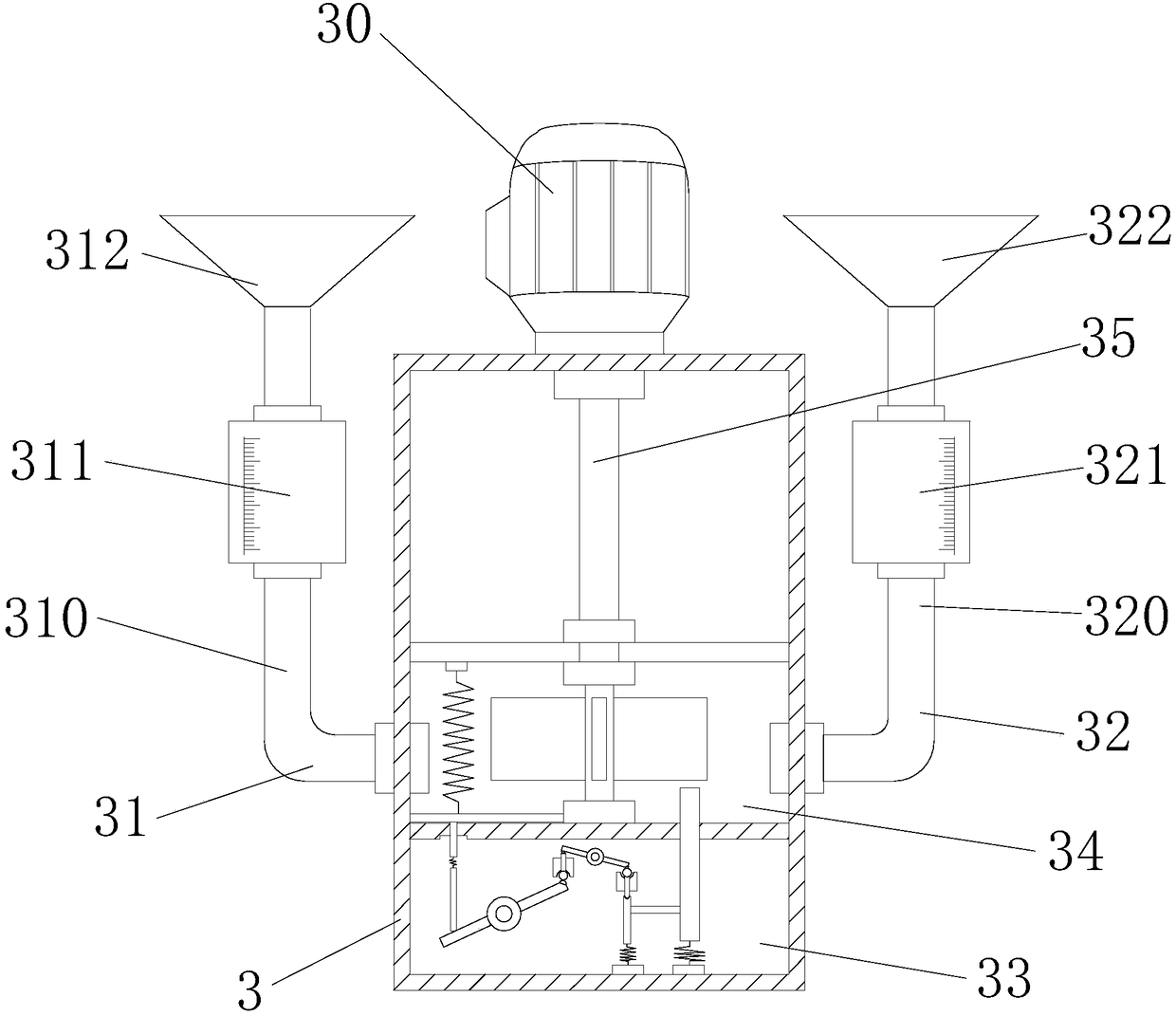

Internet-monitoring-based system for intelligently fermenting straws to prepare multiple-effect composite fertilizer

ActiveCN107037748ARealize automatic heat exchangeBalanced ratioProgramme controlCalcareous fertilisersInternet networkInternet monitoring

The invention provides an internet-monitoring-based system for intelligently fermenting straws to prepare multiple-effect composite fertilizer. The system comprises fertilizer preparing devices arranged at various straw processing points, monitoring front ends arranged on the fertilizer preparing devices, a communication base, and an intelligent monitoring terminal. The monitoring front ends are in communication and connection with the communication base through a GPRS network. The communication base communicates with the intelligent monitoring terminal through an Internet network. The monitoring front ends realize the monitoring, acquiring and transmitting of the running data inside the fertilizer preparing devices. The monitoring front ends transmit the measured real-time parameters of the fertilizer devices to the communication base through the GPRS network in which the communication base gathers the data of various points and transmits the data through the Internet network to the intelligent monitoring terminal. With the backstage remote control of the intelligent monitoring terminal, real time control over the fertilizer preparing devices at various points and the entire production process can be monitored without end. In addition, parameters can also be altered instantly and data are stored.

Owner:ANHUI JULI MACHINERY MFG

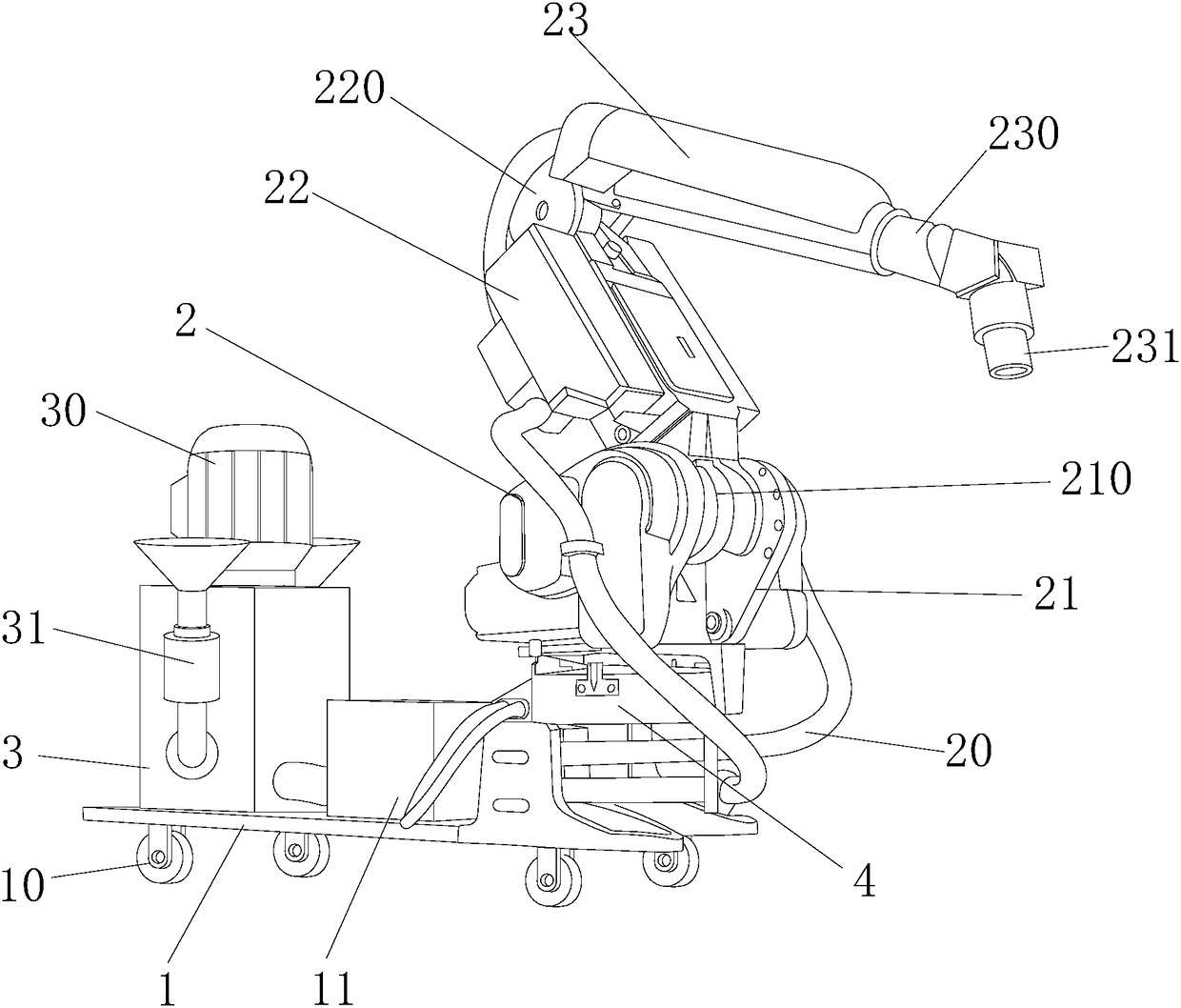

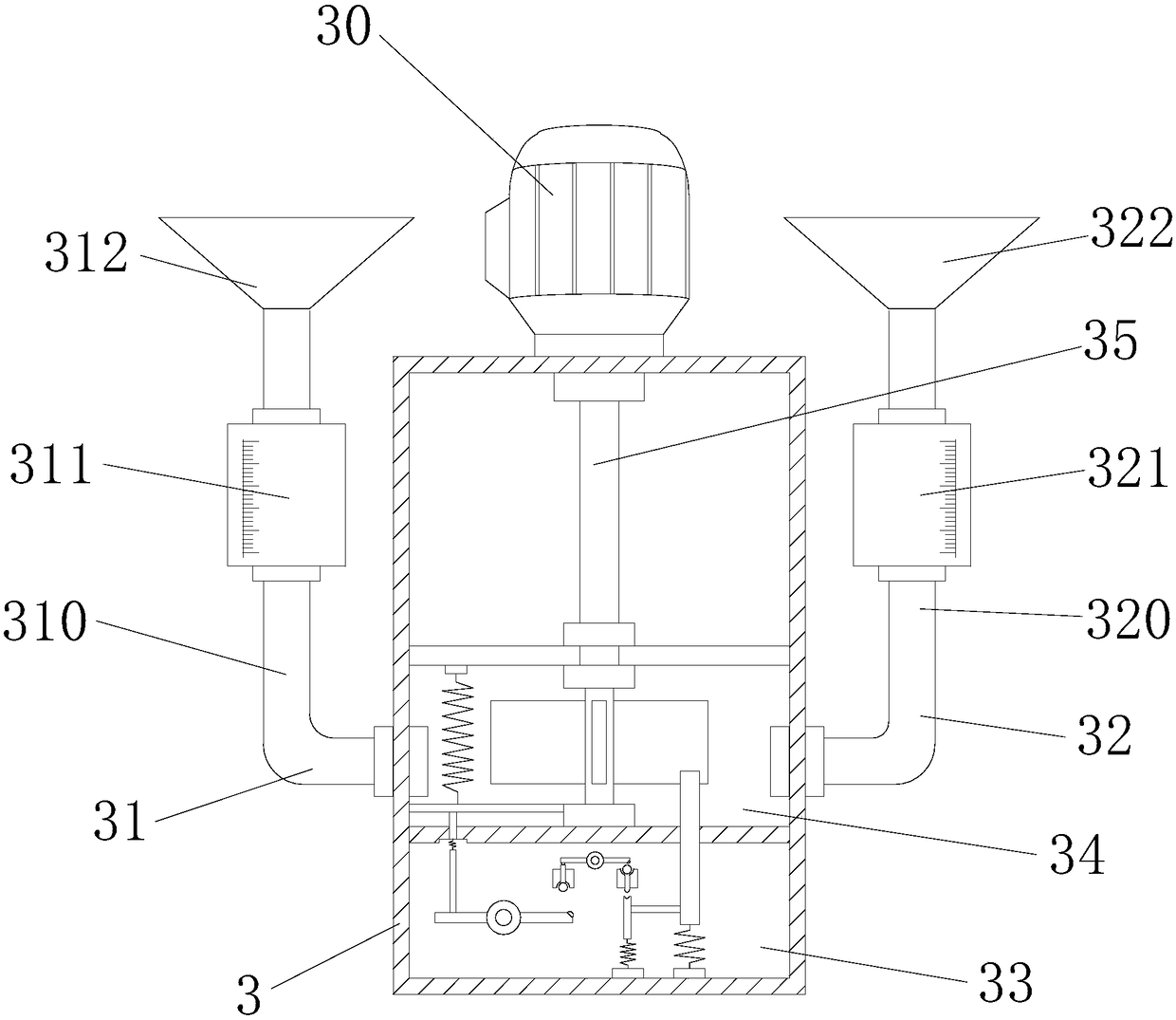

Novel self-moving spray robot

InactiveCN108160375APrecise ratioAvoid affecting the effect of smearingProgramme-controlled manipulatorSpraying apparatusAutomatic controlAgricultural engineering

The invention discloses a novel self-moving spray robot which structurally comprises a bottom bearing plate, a spraying moving support arm, a coating proportioning box and a rotary base; the sprayingmoving support arm is provided with a coating conveying conduit, a bottom moving main arm, a moving elbow joint and a moving wrist joint; the coating proportioning box is provided with a transmissionmotor, a coating proportioning mechanism, a water injection proportioning mechanism, a stirring device drive mechanism, an internal proportioning layer and a stirring device, so that when being used,equipment can autonomously drive an internal stirring mechanism to perform stirring while automatically performing proportioning, proportioning is uniform, and the coating smearing effect is avoided from being influenced; by automatically controlling internal quantitative proportioning and stirring, the manual proportioning procedure is saved, the proportioning error rate is lowered, and the problems of saving the time and the labor are solved.

Owner:曾清民

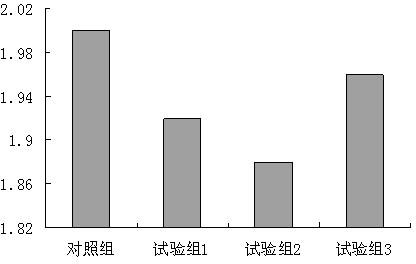

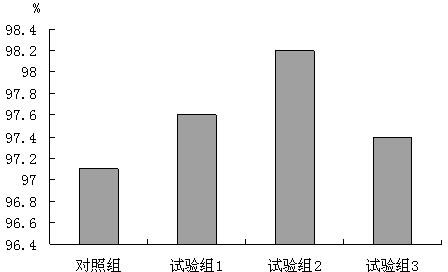

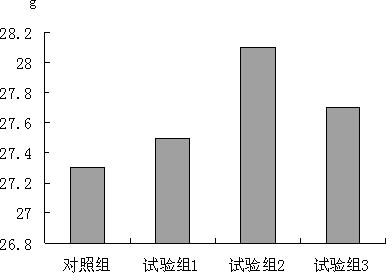

Compound premix for broilers and preparation method thereof

The invention relates to a compound premix formula for broilers and a preparation method thereof. The formula comprises the following components by weight percent: 2-3% of compound trace element, 0.2-0.5% of compound vitamin, 5-15% of compound additive, 15-30% of calcium hydrophosphate, 30-40% of limestone, 4-8% of salt, 0.1-0.5% of Ledaxiang, 0.5-1% of 1wt% maduramicin, 0.01-0.1% of attractant and the balance of zeolite powder. The preparation method comprises the following steps: weighing the components according to the weight ratio; and adding the components into a mixer, and mixing for 2-8 minutes to ensure that the degree of uniformity of the components reaches 5%, thus obtaining the finished product. The premix aims at the broiler growth nutritional characteristics, has scientific ratio and can be used for effectively increasing the broiler feed intake and the feed conversion ratio, reducing the feed to gain ratio and improving the survival rate and the production performance.

Owner:WUXI ZHENGDA POULTRY

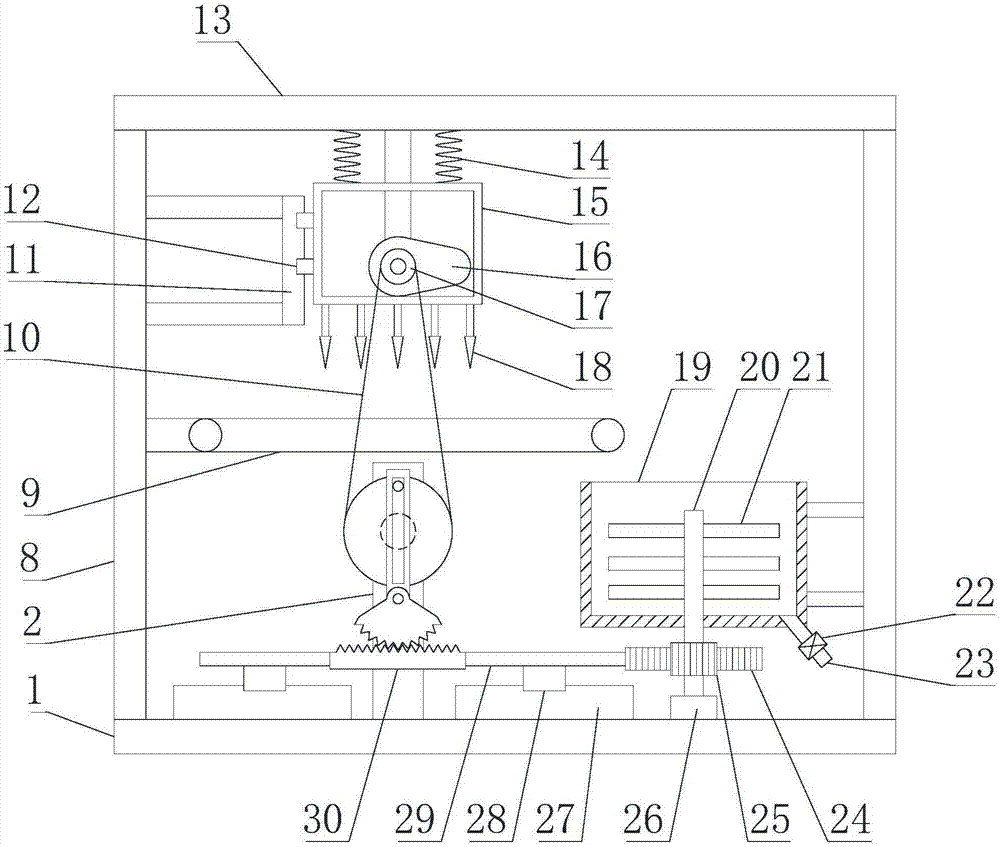

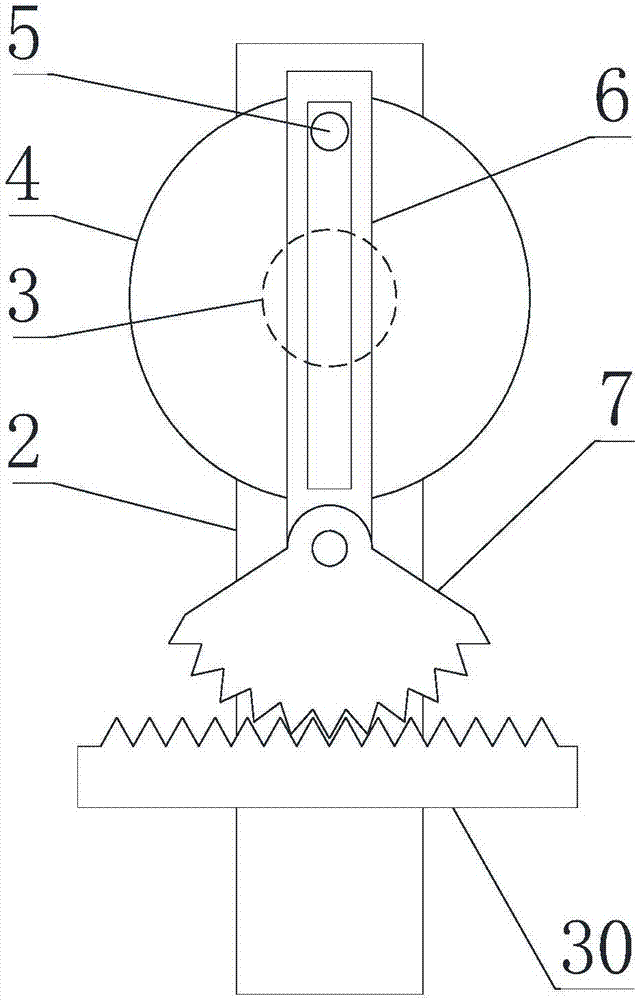

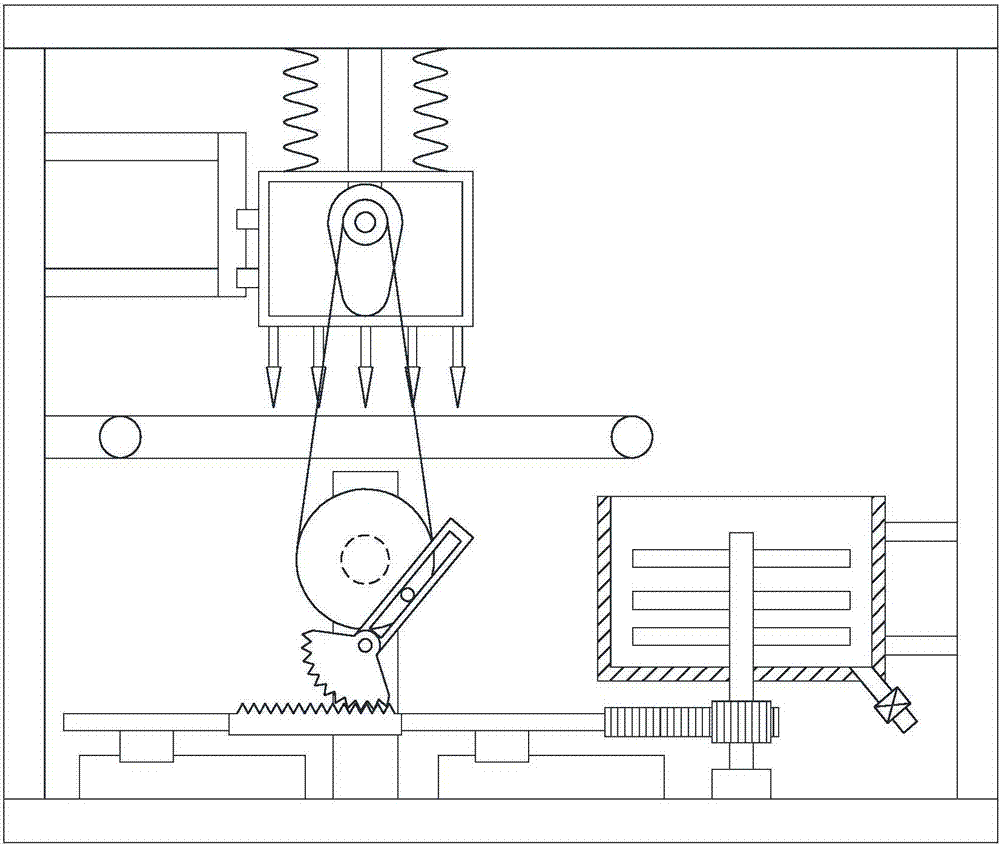

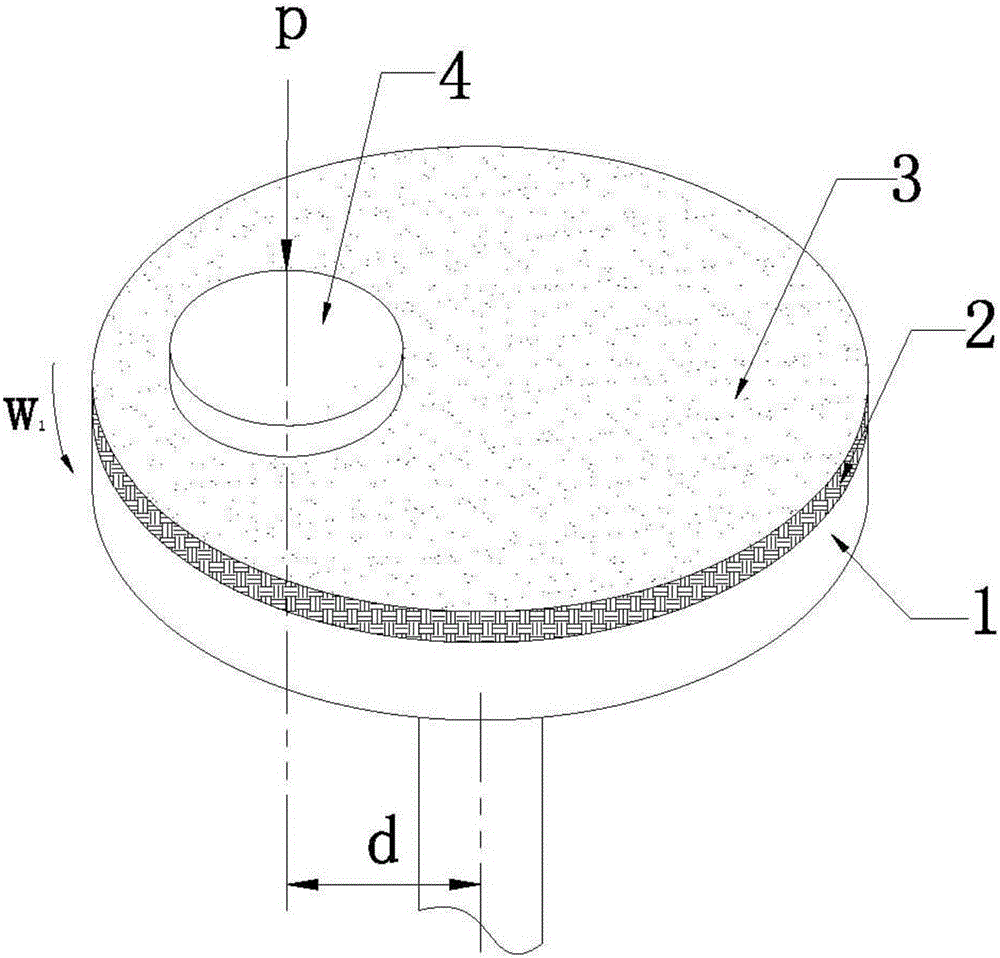

Integrated automatic cutting and mixing device for traditional Chinese medicinal materials

InactiveCN107029569AEvenly proportioned Chinese herbal medicinesConvenient delivery of medicinal materialsRotary stirring mixersTransportation and packagingMoving frameMotor shaft

The invention discloses an integrated automatic cutting and mixing device for traditional Chinese medicinal materials. The integrated automatic cutting and mixing device for traditional Chinese medicinal materials comprises a base. A support is arranged on the base, a speed reducing motor is mounted on the front end surface of the support, a motor shaft at the front end of the speed reducing motor is connected to a first belt pulley, a pin roll is arranged on the front end surface of the first belt pulley, a fan-shaped gear is also rotatably connected to the front end surface of the support, the fan-shaped gear is fixedly connected to a connecting rod, a straight notch is formed in the connecting rod, and the pin roll is matched with the straight notch in the connecting rod; two supporting plates are also arranged on the base, a top plate is arranged on the top of the supporting plates, a first slide rail is connected to the left supporting plate through a supporting rod, a moving frame is slidably connected to the first slide rail through a first slide block, the top of the moving frame is connected to the bottom of the top plate through a spring, and the bottom of the moving frame is fixedly connected to a slicer through the connecting rod. By cutting and mixing the traditional Chinese medicinal materials, the traditional Chinese medicinal materials are uniformly proportioned; various transmission modes are realized by one motor, so that the utilization ratio of energy sources is effectively increased.

Owner:张大化

Calcium, iron, zinc and selenium milk tea

InactiveCN101999460AEliminate hazardsMatching scienceMilk preparationFood preparationLiver and kidneyFerrous Gluconate

The invention discloses calcium, iron, zinc and selenium milk tea. The calcium, iron, zinc and selenium milk tea comprises the following raw materials in part by weight: 200 to 450 parts of papaya juice, 50 to 80 parts of red date juice, 400 to 600 parts of milk, 10 to 18 parts of tea leaf powder, 5 to 20 parts of Chinese wolfberry juice, 30 to 110 parts of lotus nut starch, 1 to 4 parts of emulsion stabilizer, 20 to 40 parts of white granulated sugar, 3 to 6 parts of calcium lactate, 2 to 3 parts of zinc gluconate, 0.4 to 1 part of ferrous gluconate and 0.0005 to 0.002 part of sodium selenite. The product has moderate fragrance and sweetness, mellow milky flavor, complete effects and economy, can be easily accepted by people, and has the effects of tonifying qi and enriching blood, maintaining beauty and keeping young, tonifying liver and kidney, replenishing vital essence to improve eyesight, relieving cough and promoting secretion, refreshing, moistening intestine and dryness, nourishing intestines and stomach, invigorating the circulation of blood, preventing and fighting cancer, resisting oxidation and aging, adjusting immunity, resisting fatigue, improving sleep, promoting growth and development, supplementing nutrition and the like.

Owner:凌一

Method for machining mirror surface of aluminum alloy

ActiveCN106826535AStable chemical propertiesImprove wear resistanceLapping machinesPolishing compositions with abrasivesSurface roughnessCorundum

The invention relates to the technical field of machining aluminum alloy, particularly to a method for machining mirror surface of an aluminum alloy. The method for machining mirror surface comprises a, coarse grinding, to be specific, placing an aluminum alloy workpiece to be grinded on a polishing disc, and coarsely grinding the workpiece by white corundum; b, coarse lapping, to be specific, coarsely lapping the aluminum alloy workpiece with a first grinding paste; c, a first fine lapping, to be specific, subjecting the aluminum alloy workpiece to the first fine lapping with a second grinding paste; d, a second fine lapped, to be specific, subjecting the aluminum alloy workpiece to the second fine lapping with a third grinding paste; e, ultrasonic cleaning; f, drying. The aluminum alloy workpiece is machined by the coarse grinding, the coarse lapping, the first fine lapping and the second fine lapped in different stages with different grinding paste. The method for machining mirror surface can gradually reduce the surface roughness of the aluminum alloy, and finally the surface roughness of aluminum alloy is less than 0. 025micron to meet requirements of superprecision machining mirror of the surface of the workpiece. The method for machining mirror surface has the advantages of simple process, high efficiency, convenient operation, little pollution to the environment and stable product quality.

Owner:上海皋奋工业铝型材有限公司

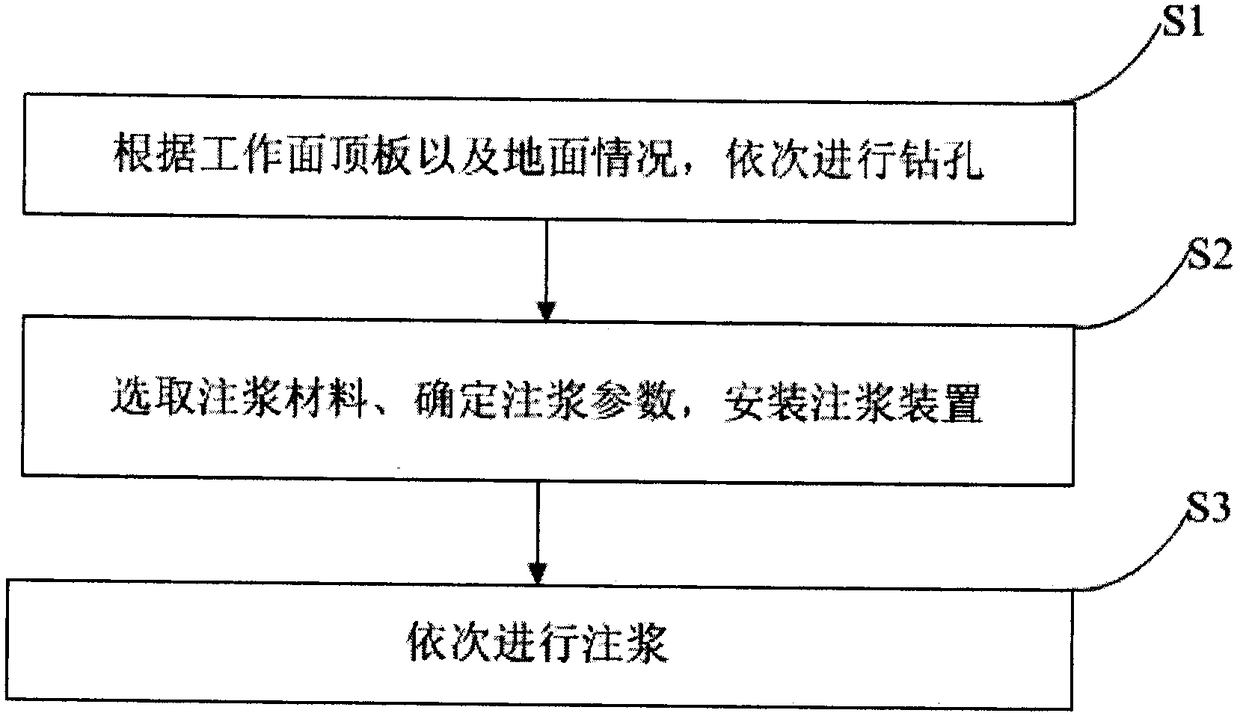

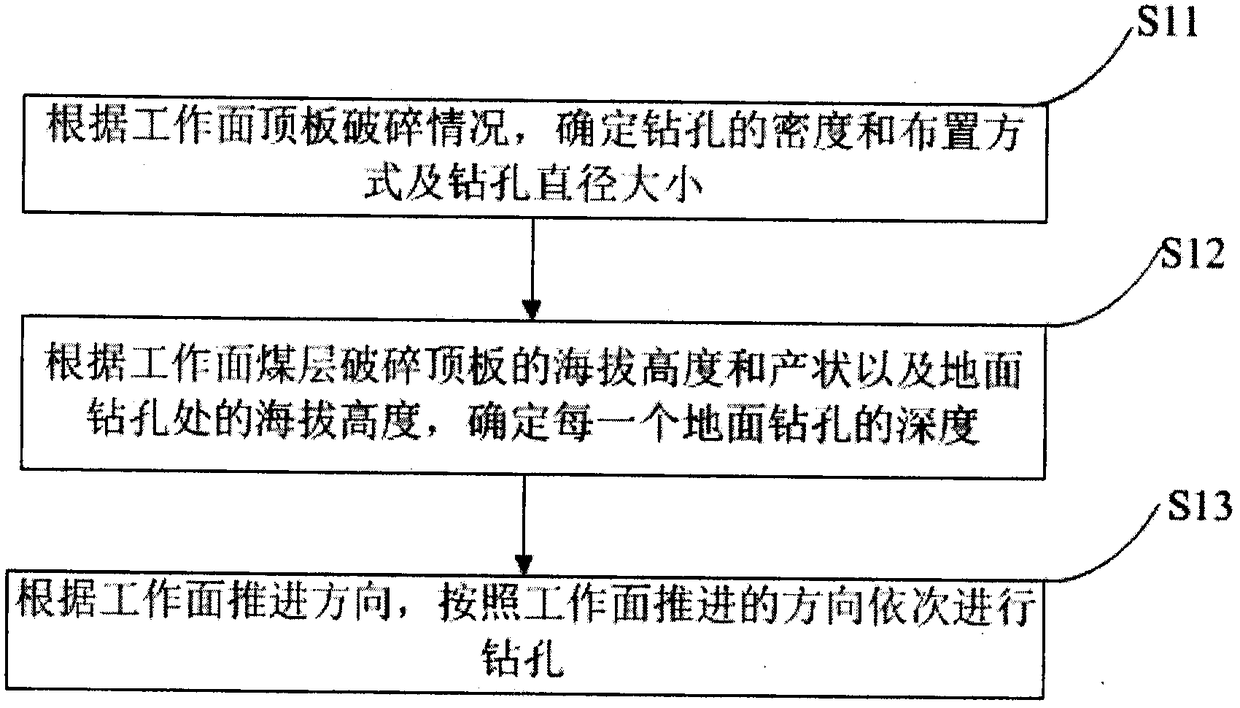

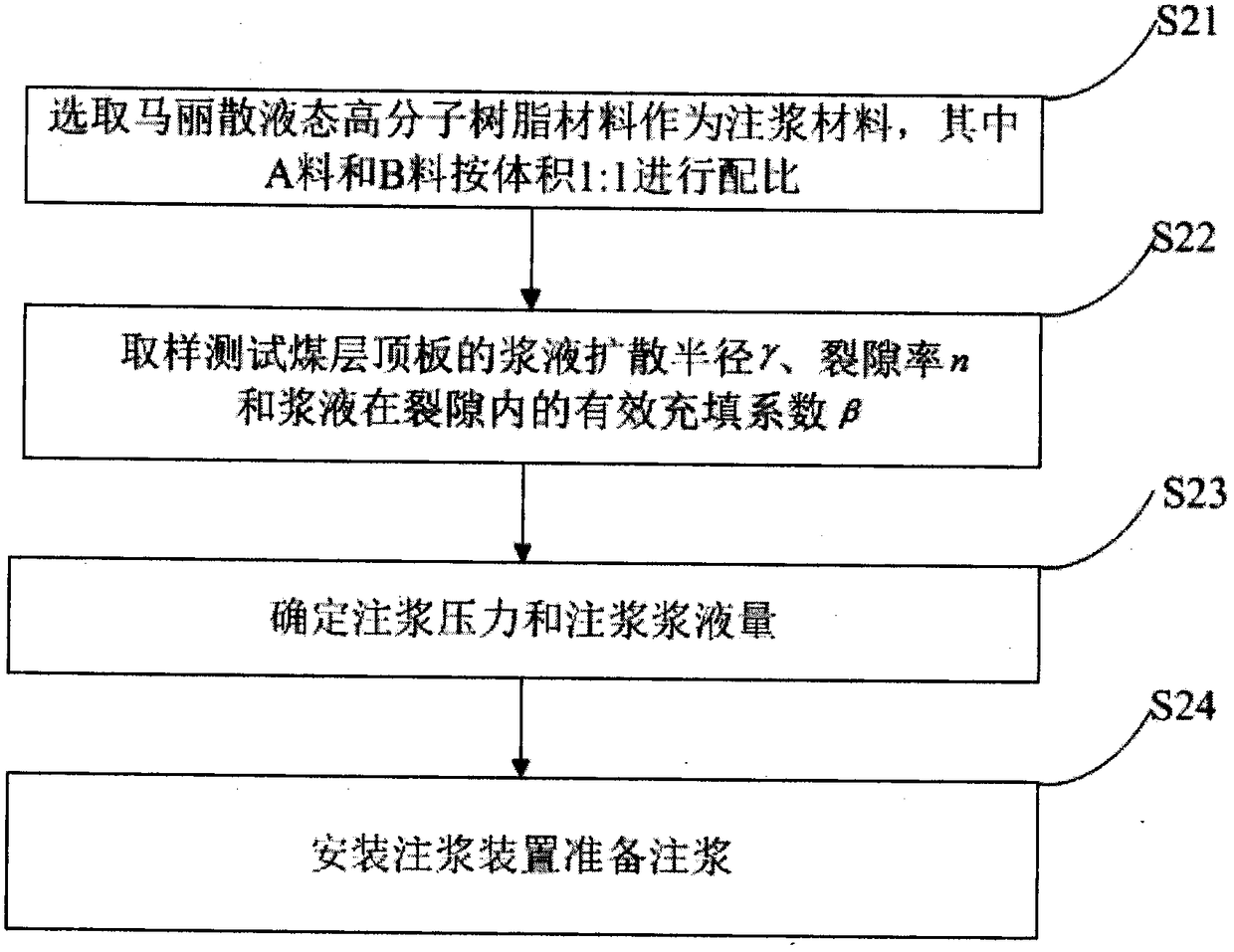

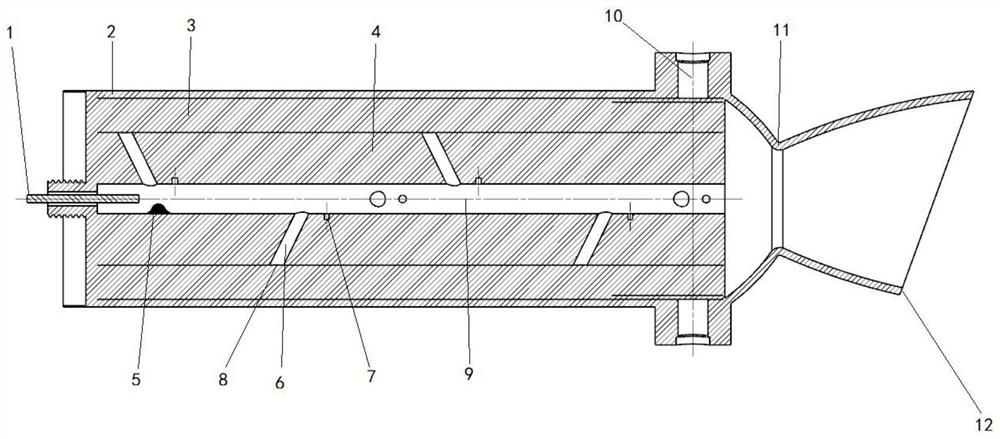

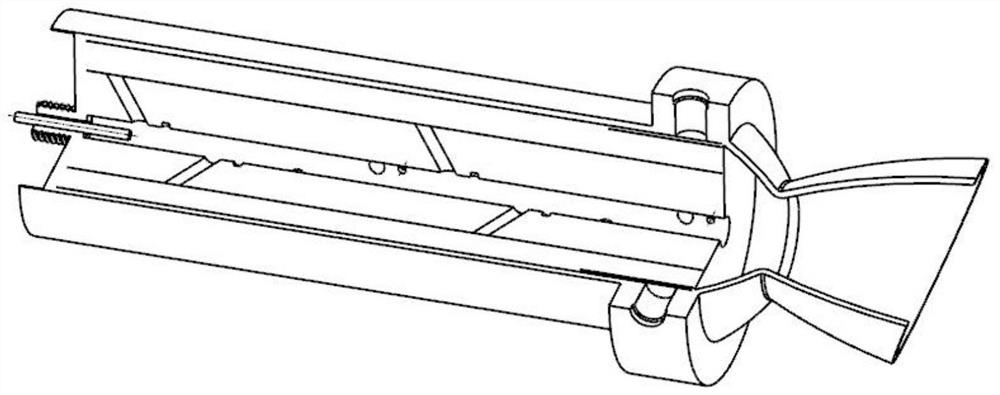

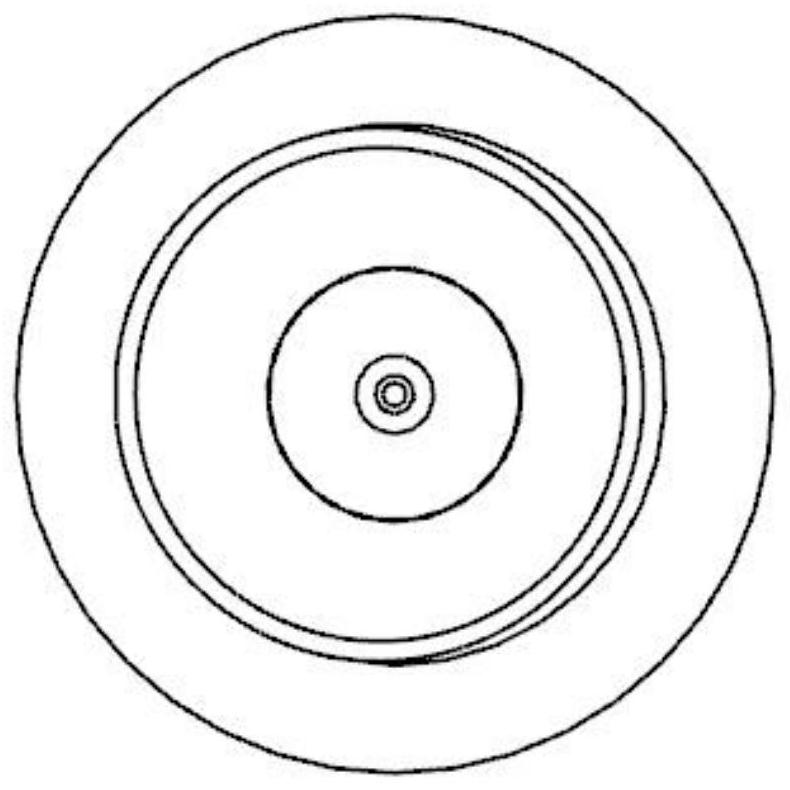

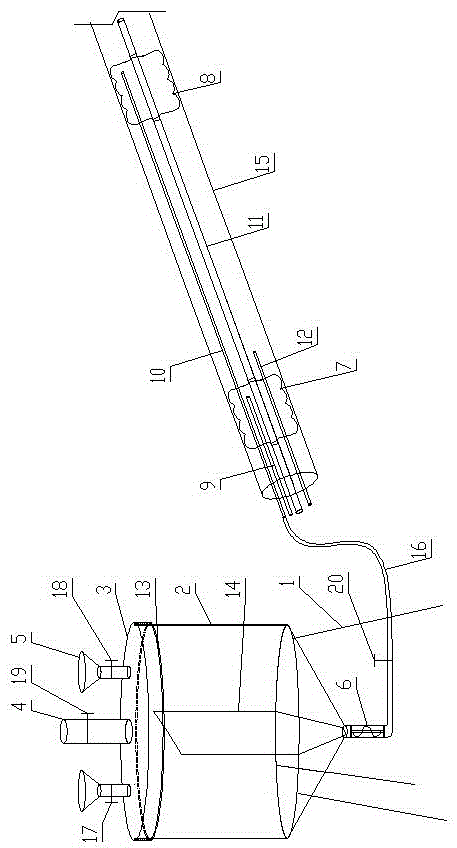

Grouting reinforcement method for broken top board in coal seam during surface drilling and grouting device

PendingCN108979590AGood effectExcellent mechanical propertiesUnderground miningSurface miningSlurryUltimate tensile strength

The invention provides a grouting reinforcement method for a broken top board in a coal seam during surface drilling and a grouting device. The method is large in operation space and does not need thespecial step of hole sealing, thereby reducing the technical difficulty of borehole grouting. Defects in the prior art are resolved such as great limit of underground grouting to drilling angles, small grouting range, great difficulty in hole sealing, outflow possibility of slurries and poor grouting effect. According to the broken top board in a coal seam and the ground condition, the grouting method comprises the following steps: setting borehole density, depth and diameter and orderly performing drilling operation; selecting proper grouting material and utilizing the grouting device to perform grouting operation. The grouting device utilizes a metering pump to suck raw material. The raw material is prepared at accurate ratio. By arranging a pressure gage and a flowmeter, grouting pressure and flow are stable and controllable. The slurry dispersion area is large. The grouting effect is good. Multi-hole grouting technology helps achieve all-round cover of the broken top board. The overall strength of super thick, relatively thick broken top boards in the coal seam are greatly increased.

Owner:ANHUI UNIV OF SCI & TECH

Small solid rocket engine

InactiveCN112211749ASimple structureImprove combustion effectRocket engine plantsCombustion chamberEngineering

The invention provides a small solid rocket engine, and relates to the technical field of rocket engines. A grain and a spray pipe in a combustion chamber are improved. The grain is divided into an oxidizing agent layer and a gunpowder layer, unstable and unsafe elements of the mixed grain can be effectively prevented by leading the grain into a gas channel through oxidizing agent holes and gunpowder holes, meanwhile, the oxidizing agent layer is arranged to play a certain thermal protection role on a combustion chamber shell, the oxidizing agent holes and the gunpowder holes are spirally andevenly arranged, the combustion process can be effectively controlled, staged combustion and complete combustion are achieved, and the combustion performance of the combustion chamber is improved. Inaddition, a rotatable flexible joint and a single-face expansion type spray pipe are designed at the engine spray pipe, the radial direction speed can be effectively controlled while the leakproofnessand the rotating stability of the spray pipe are guaranteed, vector control over the engine is achieved, and therefore the control over the launching range and direction of the engine is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

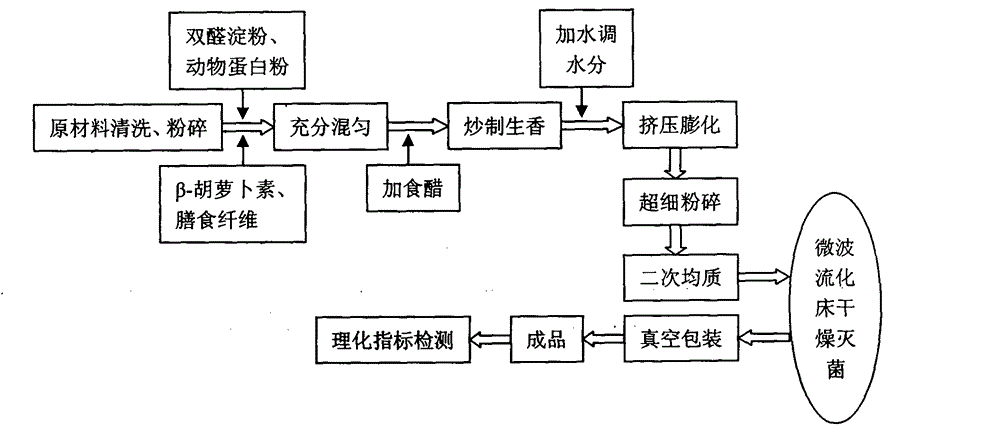

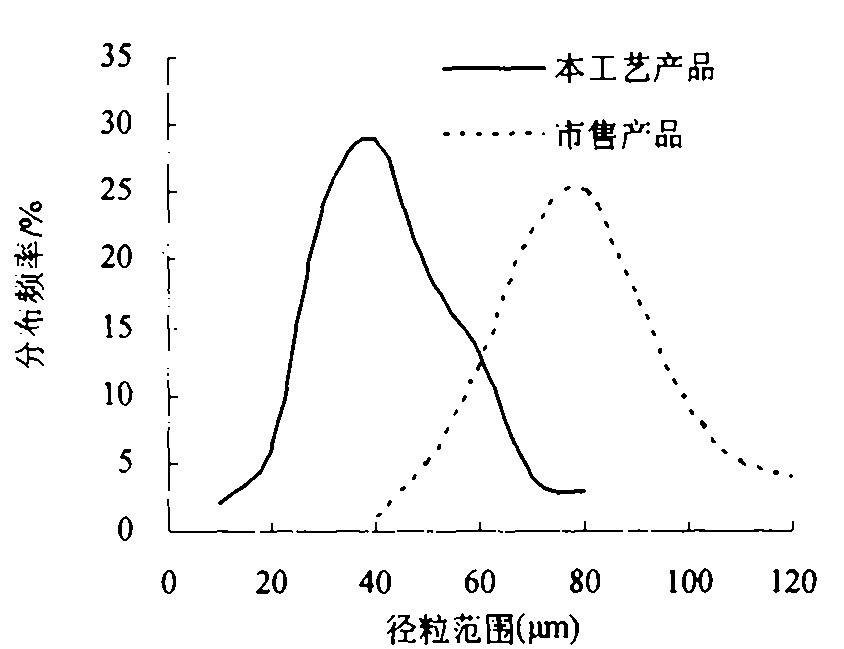

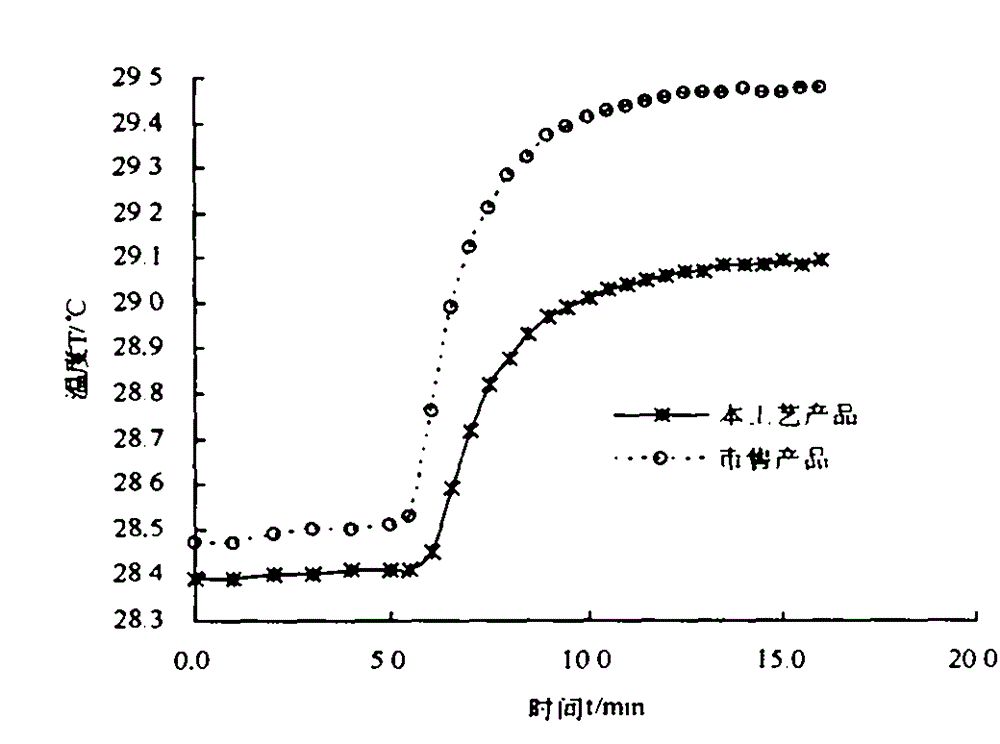

Preparation method of low heat nutritious instant rice paste

InactiveCN104872502AHigh retention rateSuitable for absorptionFood preparationBiotechnologyNutrition

The invention relates to a method for preparing low heat nutritious instant rice paste by taking cereals as raw materials. The method comprises the steps of: washing rice, low fat peanut kernels and the like; drying at a low temperature, after smashing, mixing the smashed rice and low fat peanut kernels and the like uniformly with dialdehyde starch, resistant starch, dietary fiber, beta-carotene and animal albumen powder according to a ratio, frying the mixture until the mixture emits sweet smell, adjusting moisture, extruding the mixture at the low temperature, performing ultrafine grinding and secondary homogenizing, and performing vacuum packing to obtain finished products after microwave fluid bed drying and sterilizing. Compared with the available similar products, the rice paste has the advantages that the crude protein is higher by 2.79%-10.45%, the crude protein in vitro digestibility coefficient is higher by 5.9%-10.3%, the amino acid is higher by 2.65%-8.63%, the crude fat is lower by 2.48%-3.96%, the dietary fiber is higher by 2.42%-3.79%, a food energy value and a bioenergy value are respectively lower by 8%-15% and 14%-26%, the VA is higher by 0.59%-0.87%. The low heat nutritious instant rice paste has the beneficial effects of unique flavor and high nutrition, easy absorption, strong satiety, good water absorption property and reconstituability without clustering, and convenient eating, and especially suits the middle aged and elderly people, diabetes and obese patients, and has wide market prospect.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Efficient trace element liquid fertilizer and preparation method thereof

InactiveCN105152756ASolve the problem that the moisture content is too high and difficult to useRich in organic matterFertilizer mixturesLivestock manureTrace element

The invention belongs to the field of agriculture and particularly discloses efficient trace element liquid fertilizer and a preparation method thereof. The efficient trace element liquid fertilizer is prepared on the basis of fermentation of livestock manure with high water content, a trace element solution and a composite additive are added to the livestock manure, the mixture is chelated and concentrated, and the efficient trace element liquid fertilizer is prepared. The content of the trace elements in the prepared efficient trace element liquid fertilizer is not lower than 100 g / L. Therefore, the efficient trace element liquid fertilizer has the advantages of high nutrition facts, balanced ratio, high stability, convenience in application and the like, effectively solves the problem that the livestock manure in rural areas is difficult to use due to overhigh water content at present and has broad application prospects.

Owner:江苏盐城环保产业工程研发服务中心

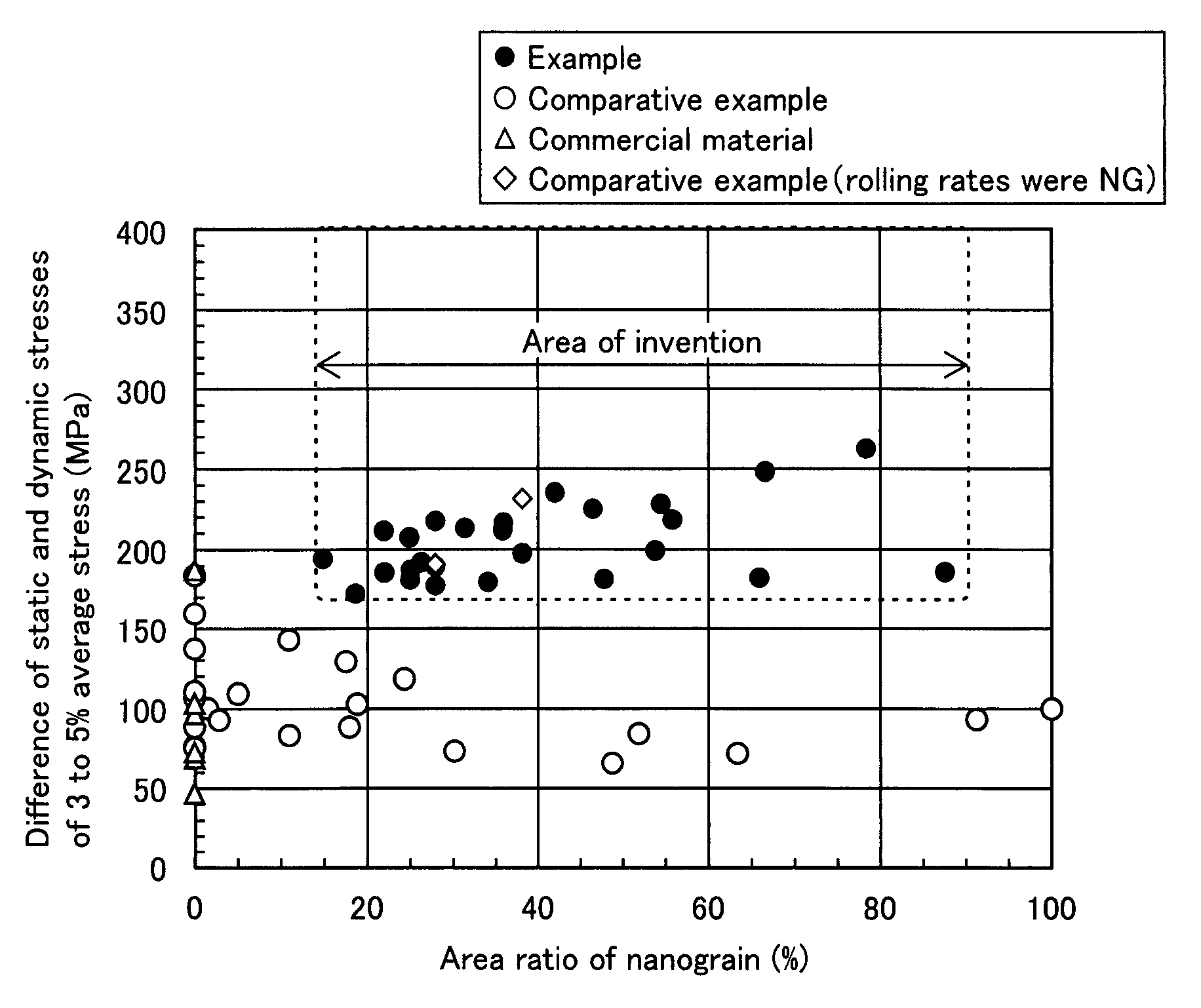

High strength steel sheet and method for production thereof

InactiveUS7754030B2Reduce amountHigh strengthFurnace typesHeat treatment process controlGranularityHigh intensity

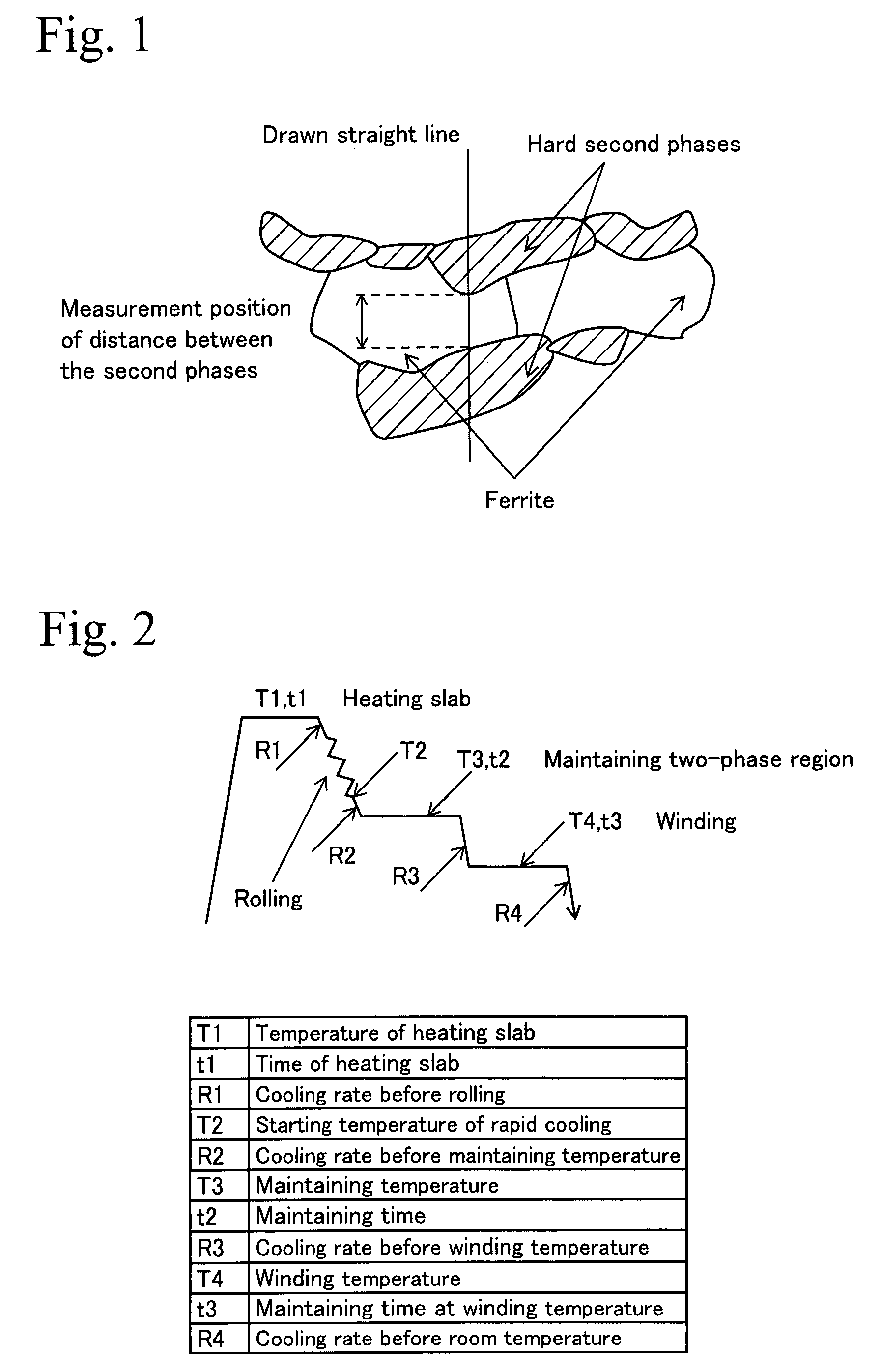

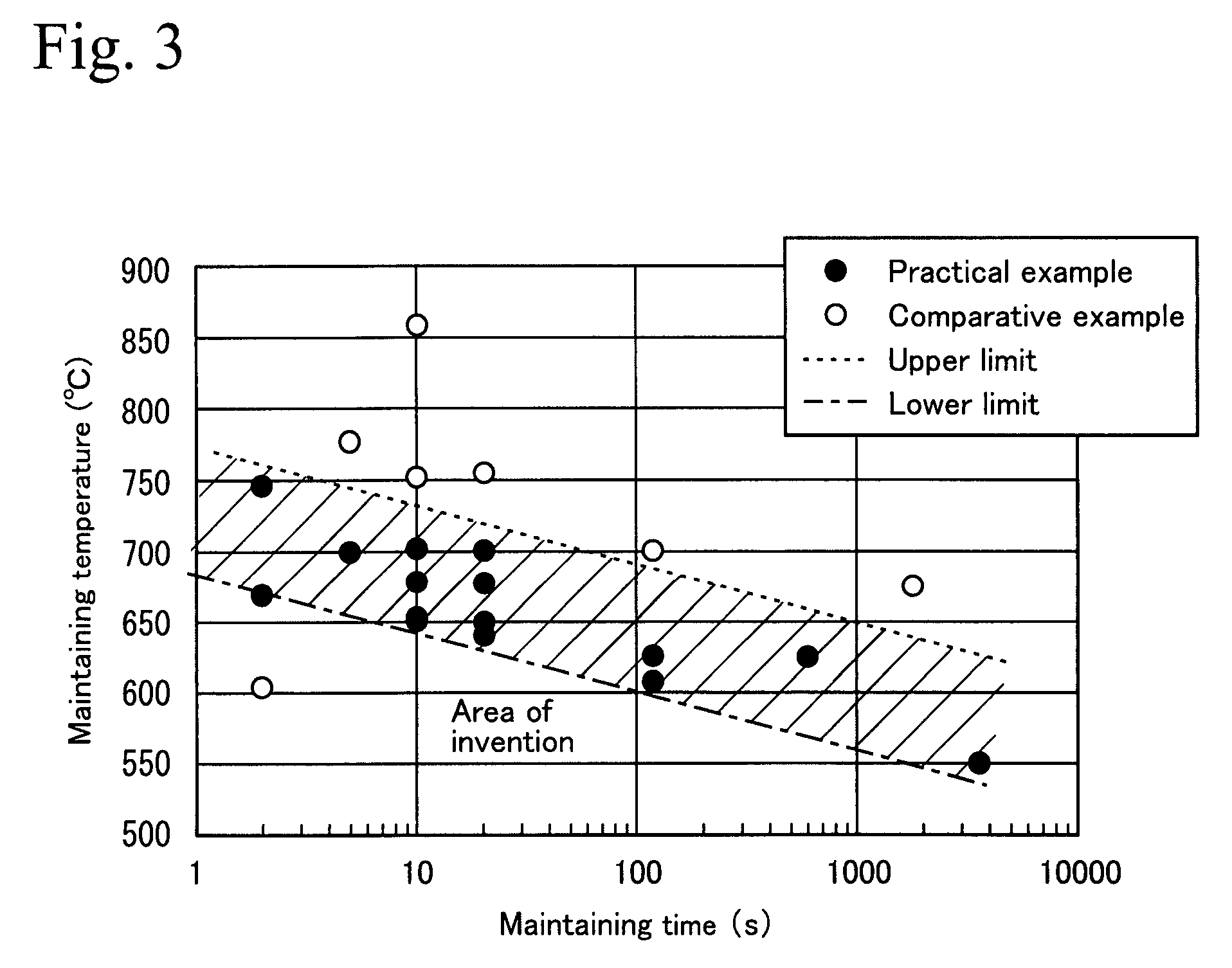

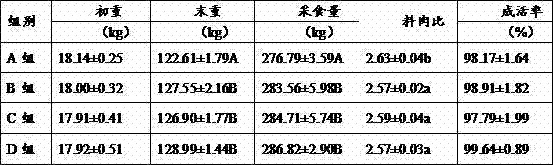

A high-strength steel sheet has a metal structure consisting of a ferrite phase in which a hard second phase is dispersed and has 3 to 30% of an area ratio of the hard second phase. In the ferrite phase, the area ratio of nanograins of which grain sizes are not more than 1.2 μm is 15 to 90%, and dS as an average grain size of nanograins of which grain sizes are not more than 1.2 μm and dL as an average grain size of micrograins of which grain sizes are more than 1.2 μm satisfy an equation (dL / dS≧3).

Owner:HONDA MOTOR CO LTD

Anti-heat-stress Chinese herbal medicine composite feedstuff additive for meat duck

ActiveCN102894212ANot easy to polluteImprove resistance to heat stressAnimal feeding stuffBiotechnologyFeed additive

The invention discloses an anti-heat-stress Chinese herbal medicine composite feedstuff additive for meat ducks. The feedstuff additive provided by the invention is prepared from a composition of a plurality of Chinese herbal medicines. With the feedstuff additive, meat duck discomfort caused by stress under high-temperature state can be relieved, and meat duck heat stress resistance can be improved.

Owner:GUANGDONG HAID GROUP

Effervescence tablet containing multiplex vitamin including iron, zinc and calcium, ring shaped preparation, and preparation method

InactiveCN1759825ABalanced ratioMeet the actual needs of daily nutritional supplementsMetabolism disorderInorganic active ingredientsEffervescent tabletVitamin C

Owner:JIANGXI HERBFINE HI TECH

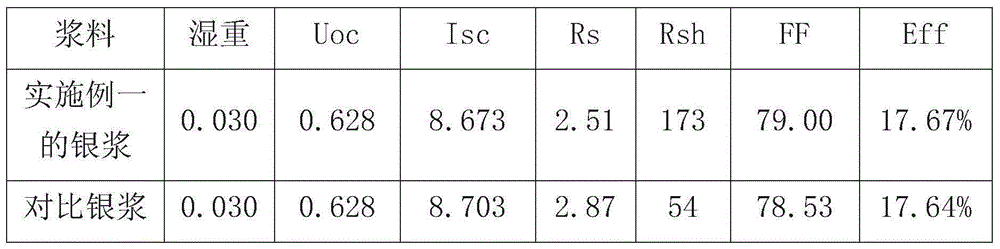

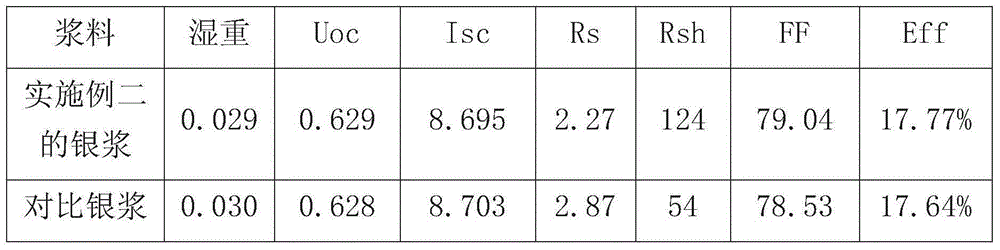

Environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste

InactiveCN104992747AEnhanced Fusion ContactIncrease contact resistanceNon-conductive material with dispersed conductive materialSemiconductor devicesAdhesiveBack surface field

The invention relates to a silicon solar cell back electrode raw material, in particular, an environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste. With the environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste of the invention adopted, the problems of poor printing performance, large series resistance and low photoelectric conversion efficiency of the components of a silicon solar cell back electrode can be solved. The environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste is composed of the following components in part by weight: 50 to 58 parts of silver aluminum mixed powder, 1 to 3 parts of lead-free glass powder, 0.1 to 1 part of inorganic additive, and 39 to 48 parts of organic adhesive; the fine degree of the silver paste is smaller than 15 micron; and the viscosity of the silver paste ranges from30 to 60Pa.s. According to the environmentally-friendly low-series resistance crystalline silicon solar cell back electrode silver paste of the invention, irregularly-shaped silver powder and spherical aluminum powder are adopted as the base materials of the silver paste; a uniform and compact silver conductive layer is formed on the back surface of a silicon wafer in a high-temperature sintering treatment process, and excellent ohmic contact can be realized between the silver conductive layer and an aluminum back surface field as well as between the silver conductive layer and the silicon wafer; and therefore, lower series resistance and higher photoelectric conversion efficiency can be realized, and the weldability and adhesion of a back electrode can be improved, and the series resistance of a cell sheet can be small, and conversion efficiency is high.

Owner:苏州柏特瑞新材料有限公司

Device used for evenly mixing and stirring concrete

InactiveCN107443579AEasy to mix and stirEasy to stir and mixCement mixing apparatusSold ingredients supply apparatusCouplingChemical engineering

The invention discloses a device for uniform mixing and stirring of concrete, which comprises supporting legs, the surface of the supporting legs is fixedly connected with a mixing room, the bottom of the mixing room is fixedly connected with a supporting rod, the surface of the supporting rod is fixedly connected with a motor, and the motor The output shaft of the first rotating shaft is fixedly connected with the first rotating shaft through a coupling, one end of the first rotating shaft penetrates and extends to the inside of the mixing chamber, the surface of the first rotating shaft is fixedly connected with the first helical stirring roller, and the surface of the first rotating shaft is fixedly connected with stirring rod. The device for uniform mixing and stirring of concrete, when stirring is required, the first rotating shaft drives the first spiral stirring roller to rotate to stir the mixture downward, and at the same time, the second rotating shaft drives the second spiral stirring roller to rotate upward to stir the mixture, achieving The effect of facilitating uniform mixing effectively solves the problem that the general concrete mixer has a slow mixing speed and is not convenient for uniform mixing, which affects work efficiency to a certain extent.

Owner:WUXI KONSTANT POWER TECH CO LTD

Whey protein solid beverage

InactiveCN107258927AHigh organic ferrous contentPromote decompositionWhey manufactureSolubilityAdditive ingredient

The invention discloses a whey protein solid beverage. The whey protein solid beverage is prepared from the following raw materials: concentrated whey protein powder, inulin, resistant dextrin, a flavoring agent, vitamin A acetate, vitamin C, vitamin E acetate, thiamine hydrochloride, riboflavin, pyridoxine hydrochloride, vitamin B12, folic acid, calcium pantothenate, ferrous fumarate, zinc sulfate, maltodextrin, natural strawberry essence, silicon dioxide and stevioside. According to the whey protein solid beverage disclosed by the invention, the raw materials have high protein content and contain various types of vitamins, so that the absorption of proteins can be accelerated, the water solubility is relatively high and the mouthfeel is more fine and smooth. The whey protein solid beverage disclosed by the invention has the effects of supplementing physical ability, nutrients and various types of the vitamins, protecting eyesight and the like. The whey protein solid beverage has simple and reasonable raw material composition, natural components and a proper proportion; when being brewed with water, the whey protein solid beverage is more uniformly dispersed and is convenient for oral administration; the whey protein solid beverage is a solid beverage suitable for people.

Owner:深圳瑞森健康科技有限公司

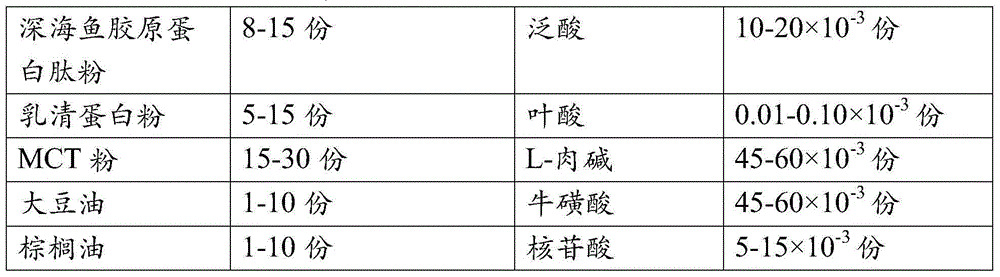

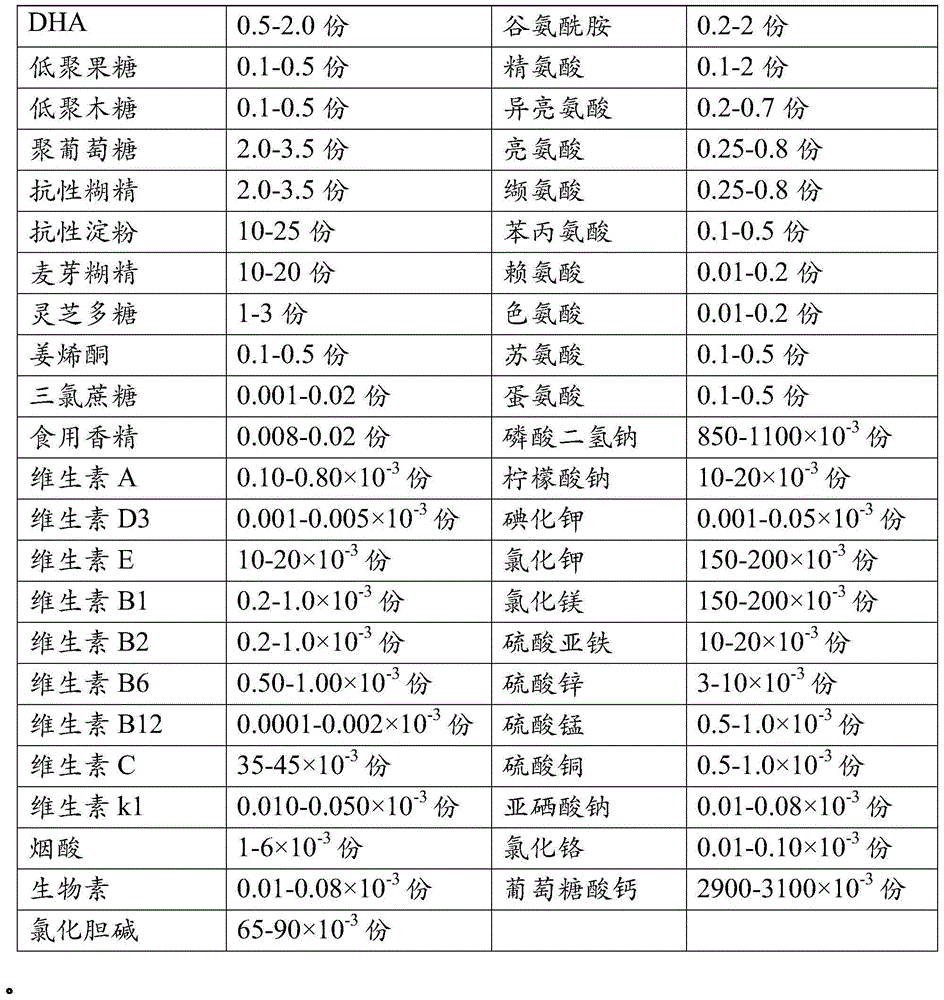

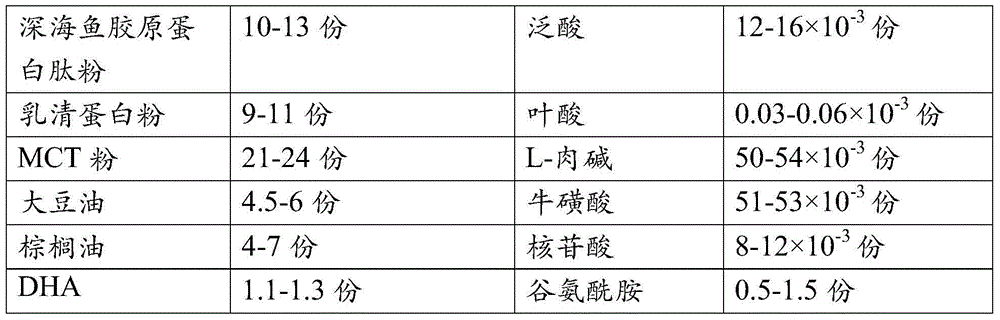

Total-nutrient formula food for tumor patient and preparation method thereof

ActiveCN104814375ABalanced ratioPromote absorptionOligosaccharide food ingredientsFood preparationNutrientOncology

The invention discloses total-nutrient formula food for a tumor patient and a preparation method thereof. By adding branched chain amino acid, nutrients are balanced in proportion and rapid to absorb, the growth, transfer and reoccurrence of tumor can be effectively prevented, the resistance of the tumor patient to the tumor treatment can be improved, and the life time of the tumor patient can be prolonged.

Owner:ZHEJIANG HAILISHENG BIOTECH +2

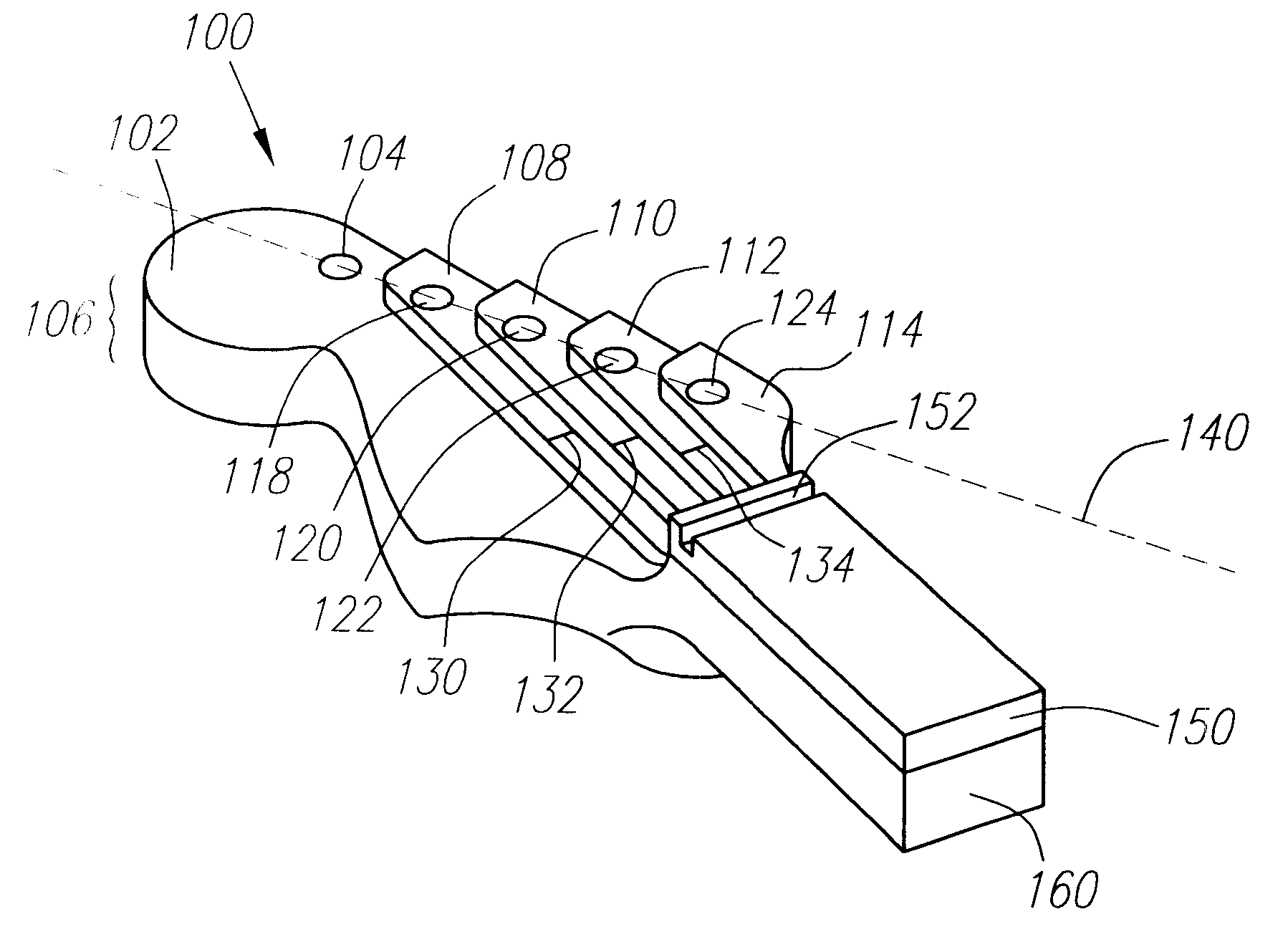

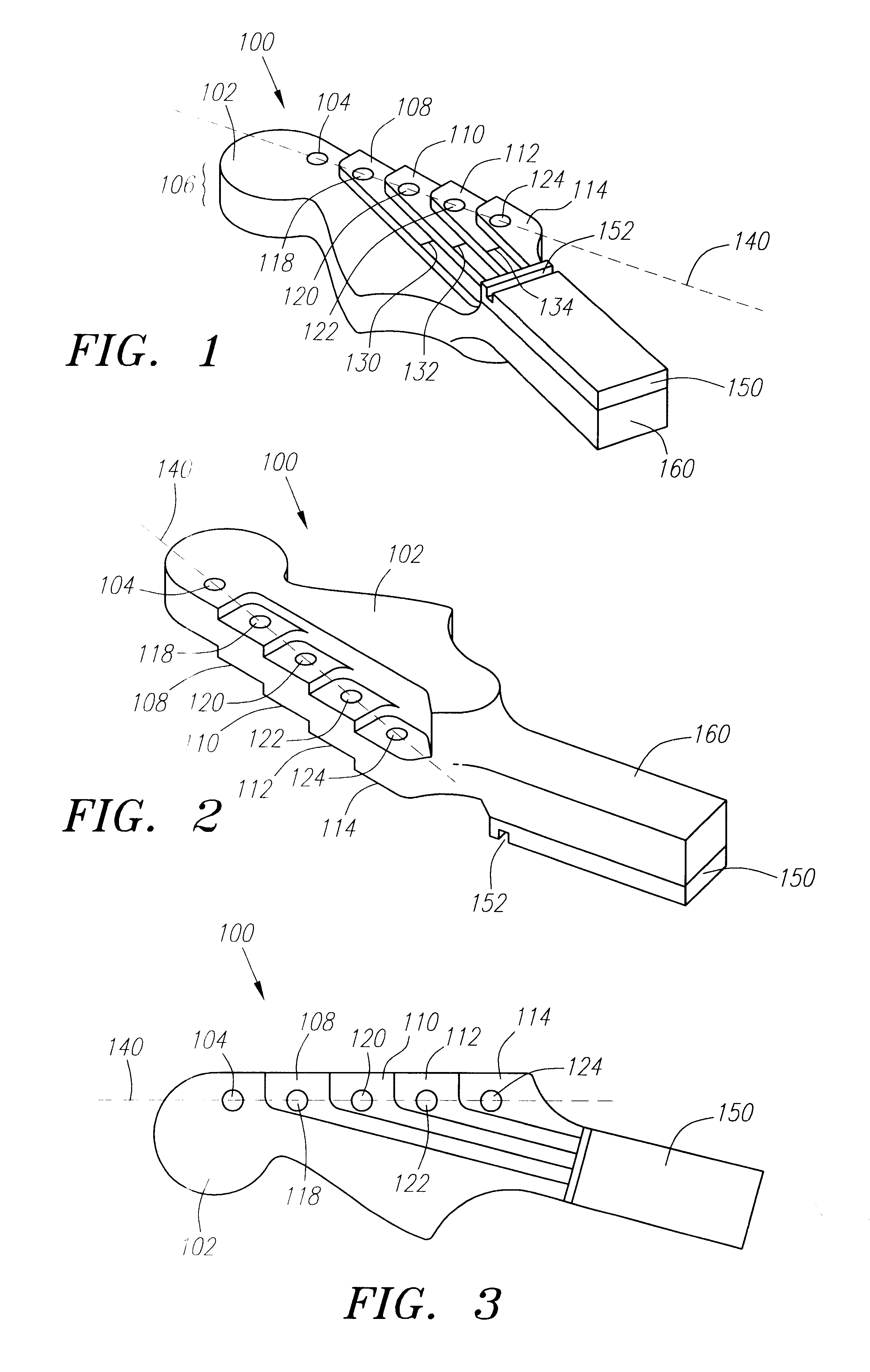

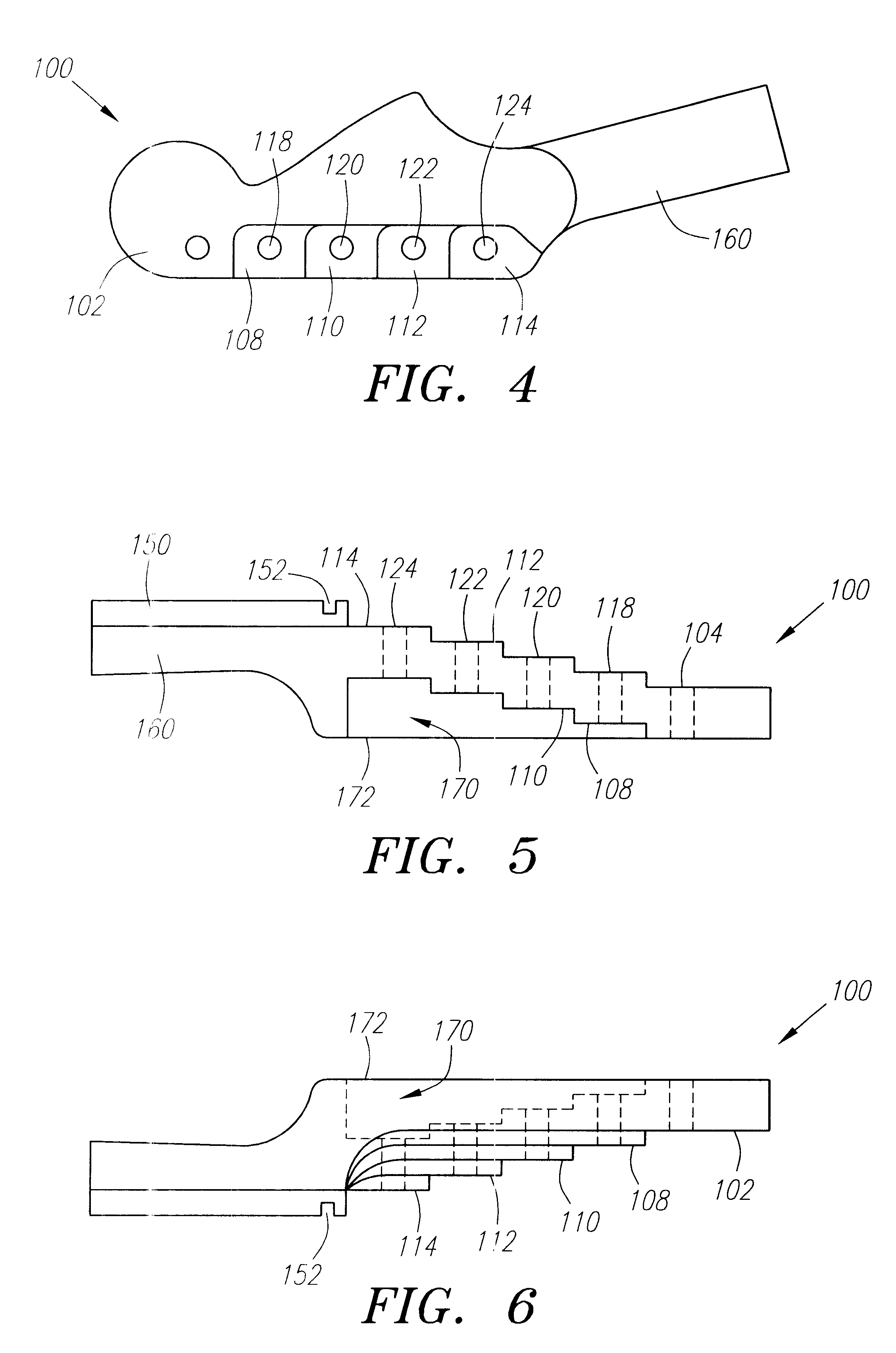

Multi-planar headstock for stringed musical instruments

A multi-plane headstock provides different planes to which strings of a stringed musical instrument may be attached to control the tension on the string and the angle at which the string breaks from the plane of the strings over the fingerboard. Advantageous musical characteristics are provided to such stringed musical instruments by implementation of the multi-planed headstock of the present invention in greater selectability and adjustability of stringed musical instrument characteristics, as well as increased internal harmony of the instrument.

Owner:PEN 5 GUITARS

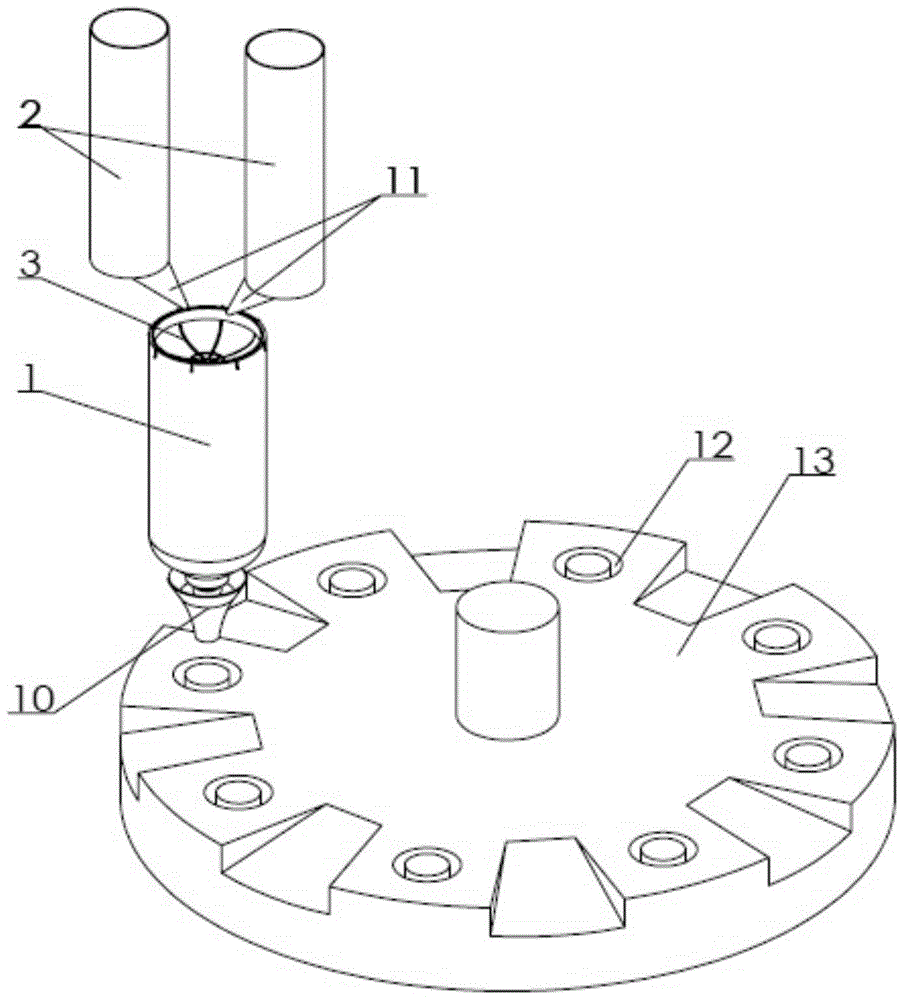

Mixed feeding device of metallurgical powder

The invention discloses a mixed feeding device of metallurgical powder. The device is characterized in that the device comprises a receiving cylinder and injection cylinders. The receiving cylinder is a revolution body; ribs that are embedded inside the cylinder and are distributed circumferentially are arranged at an upper opening; a discharging port is formed at the axis position in the bottom of the receiving cylinder and a fusiform flow adjusting body is arranged at the discharging port; the flow adjusting body is connected with a support inside the receiving cylinder by a screw rod extending upwardly and is connected with a support inside a funnel by a screw rod extending downwardly; and the cross section area of the upper opening of the funnel is larger than that of the discharging port. At least two injection cylinders are arranged; and injection openings are formed in the bottoms of the injection cylinders and point at the axis of the receiving cylinder. According to the invention, powder flowing out of the discharging port is dispersed and then is gathered in the funnel, is mixed and then flows into a compression acupoint, so that diameter matching of powder particles becomes balanced and mixing can be carried out fully, so that consistency of the compressed finished products is improved.

Owner:重庆九瑞金属材料有限公司

Fertilizer special for lettuce and preparation method thereof

InactiveCN104326810ALeaf color dark greenCrisp and tenderCalcareous fertilisersAlkali orthophosphate fertiliserDiseaseAdditive ingredient

The invention discloses a fertilizer special for lettuce and a preparation method thereof. The fertilizer consists of the following ingredients by mass: 21-23 parts of decomposed pig manure, 19-21 parts of potassium dihydrogen phosphate, 17-19 parts of water hyacinth green manure, 16-18 parts of potassium sulfate, 15-17 parts of a calcium magnesium phosphate fertilizer, 12-14 parts of iron ammonium phosphate, 10-13 of a phosphate-solubilizing bacteria fertilizer, 9-11 parts of manganese sulfate, 7-9 parts of forchlorfenuron, 4-6 parts of borax, 2-4 parts of ammonium molybdate, 1-3 parts of a stem strengthening agent, 2-4 parts of Thiram wettable powder, and 50-60 parts of water. The fertilizer provided by the invention is rich in nutrients, has balanced ratio, can promote dark green lettuce leaves, has crisp and tender texture, and fresh, tender and faint scent taste, and can improve lettuce resistance to diseases and pests, thus significantly enhancing the yield and quality of lettuce.

Owner:胡伟东

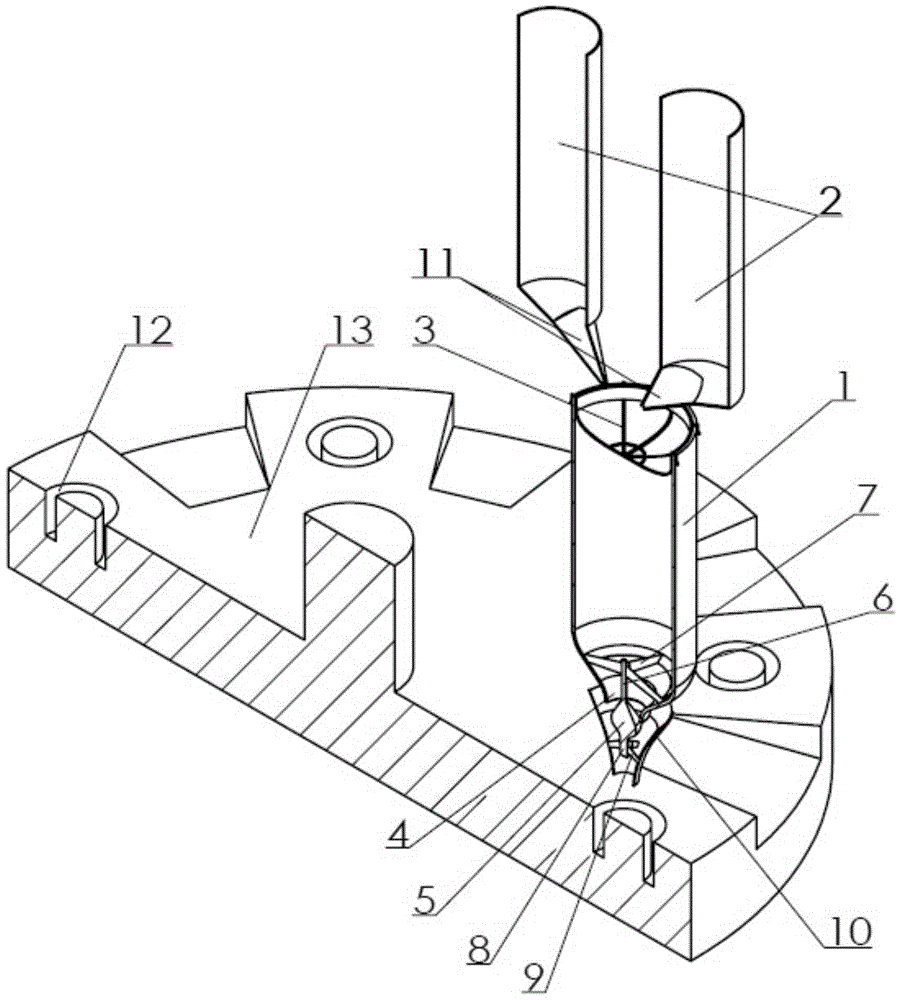

Polyurethane long-distance rapid fixed-point hole sealing device and method for underground drilling of coal mine

The invention provides a polyurethane long-distance rapid fixed-point hole sealing device for underground drilling of a coal mine. The polyurethane long-distance rapid fixed-point hole sealing device comprises supporting legs, a material injection barrel, a barrel cover, a pressure air connection pipe, feeding funnels, a powerless pipeline mixer, a first polyurethane foaming bag, a second polyurethane foaming bag, a pressure measuring or extraction pipe, a first material injection pipe, a second material injection pipe and a slurry injection pipe, wherein the barrel cover is horizontally arranged at the top of the material injection barrel; the material injection barrel is internally vertically provided with a separation plate for separating the inner part of the material injection barrel into a material storage chamber a and a material storage chamber b; the pressure air connection pipe and the two feeding funnels are arranged on the barrel cover; the upper end of the powerless pipeline mixer is arranged at the center of the bottom of the material injection barrel; and an inlet of the powerless pipeline mixer is communicated with the material storage chamber a and the material storage chamber b. The invention further discloses a hole sealing method. With the adoption of the polyurethane long-distance rapid fixed-point hole sealing device provided by the invention, the labor intensity of workers can be greatly alleviated; the polyurethane long-distance rapid fixed-point hole sealing device has the advantages of light weight, convenience for carrying, simplicity in operation and the like; after hole sealing work is finished, a plastic thin film in the material injection barrel is removed to finish the work, so that the procedure of washing the material injection barrel is avoided and the device is convenient and rapid.

Owner:HENAN POLYTECHNIC UNIV

Feed for grass carp

InactiveCN104431539AImprove digestion utilizationIncrease profitAnimal feeding stuffVitamin CDigestion

The invention relates to a feed for grass carp. The feed is mainly prepared from the following raw materials in percentage by mass: 30-35% of bean pulp, 0.3-0.4% of fine ground limestone, 8-10% of cottonseed meal, 10-15% of domestic fish meal, 2-3% of bentonite, 8-10% of rice bran meal, 10-15% of flour, 10-12% of high protein flour, 0.1-0.2% of lysine, 0.1-0.2% of vitamin C, 0.5-0.7% of an adhesive, 0.02-0.05% of bacillus subtilis, 0.3-0.5% of a fish premix and 0.3-0.5% of a Yikang XP-aquatic product. The feed provided by the invention contains various energy, proteins and amino acid substances required by growth of fishes and is balanced in proportion. By adding the Yikang XP-aquatic product, the feed digestibility utilization ratio is improved and the digestion-absorption function and the immune coordinating capacity of the fishes are maintained and improved. By adding VC, the disease resistance of grass carp is improved. By adding bacillus subtilis to adjust the microecological balance of the intestinal tract of the grass carp, the feed utilization ratio is improved.

Owner:TIANJIN MODERN TIANJIAO AQUATIC FEED CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com