High-speed stirring-squeezing trolley

A high-speed mixing and low-speed mixing technology, which is applied in cement mixing devices, clay preparation devices, and mixing operation control devices, etc., can solve the problems of inability to guarantee the quality of bridges, railways and bridges, affecting the quality of bridges, railways and bridges, and taking a long time. The effect of small human factors, elimination of water clumps, and uniform ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

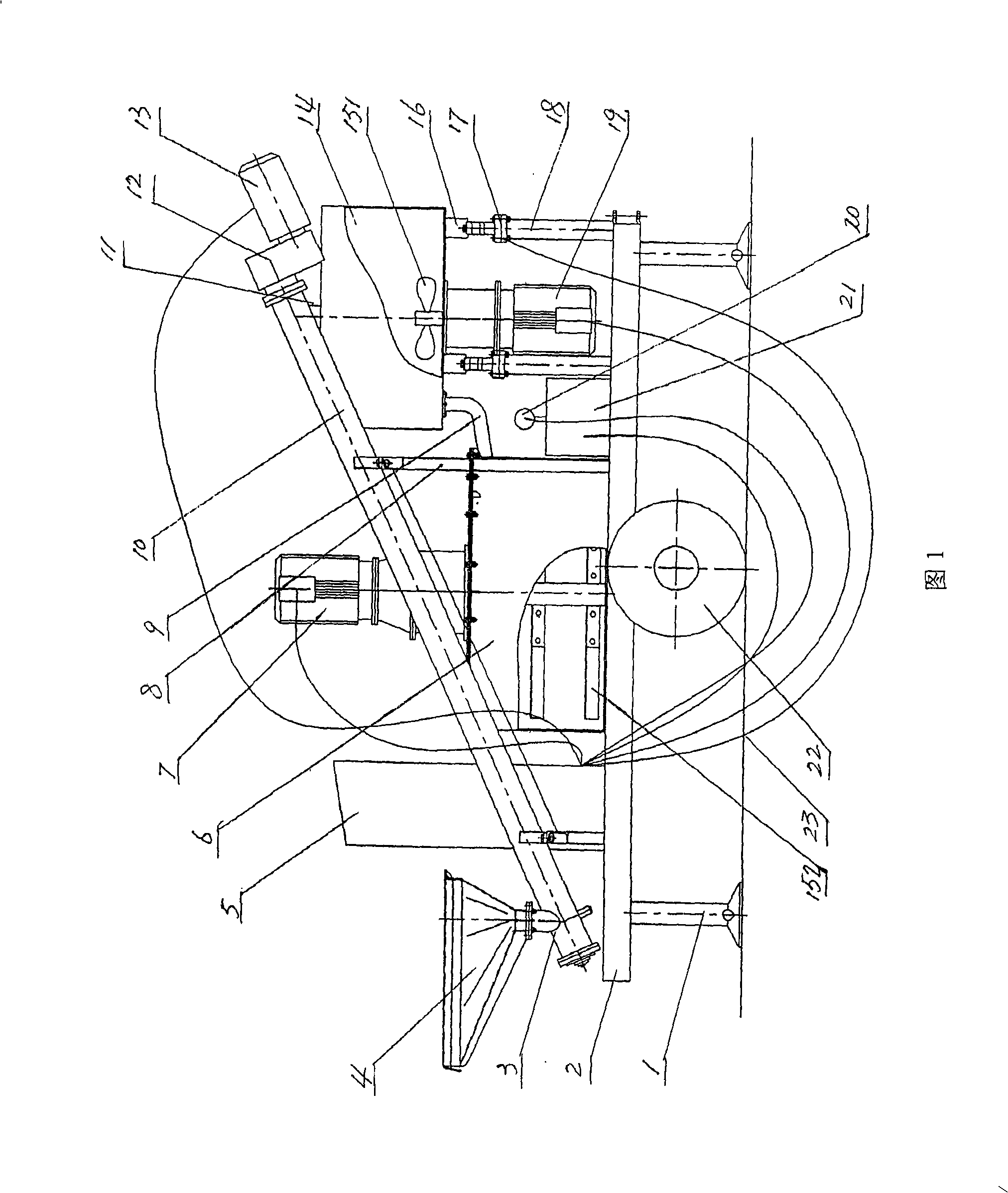

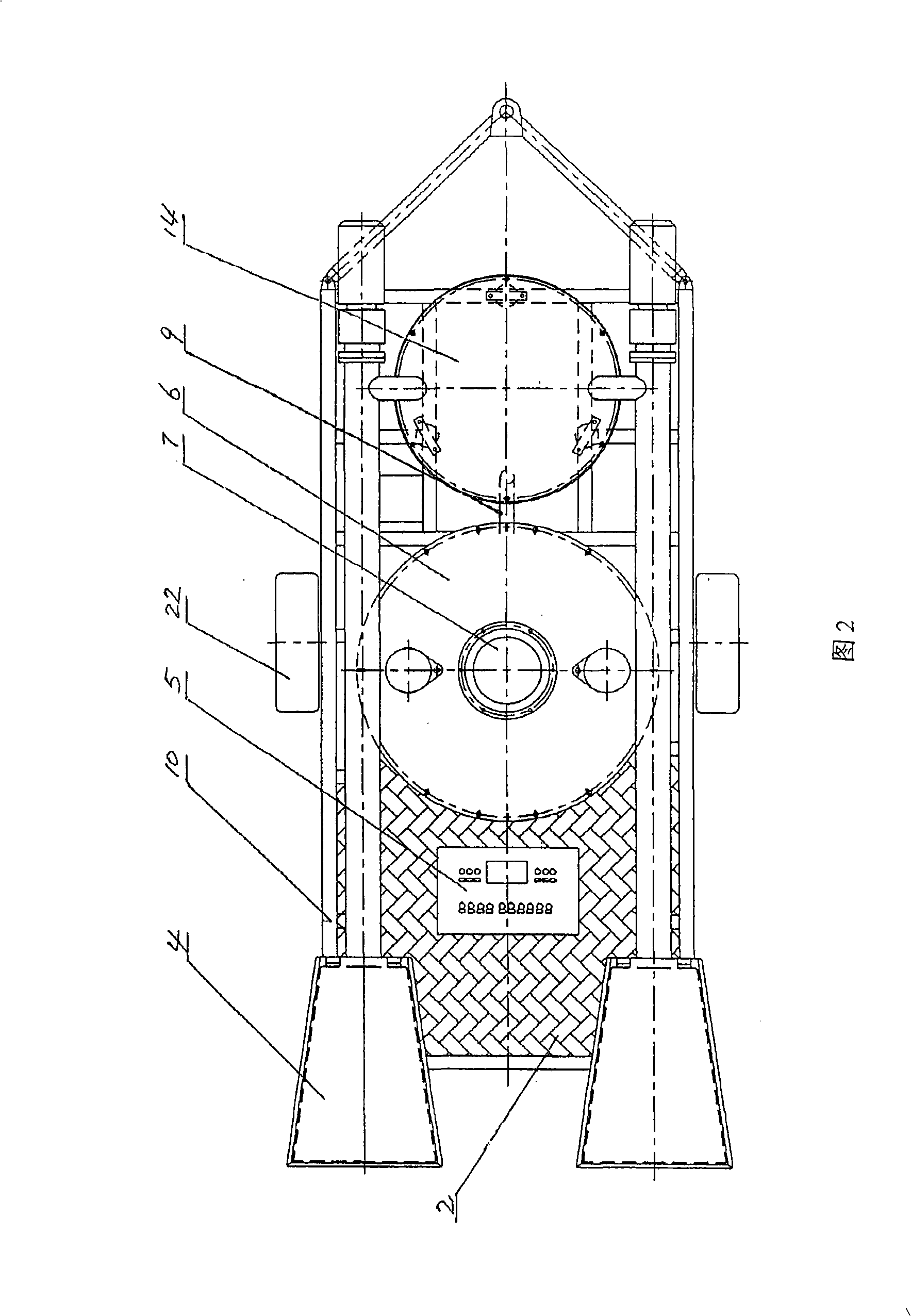

[0018] As shown in FIGS. 1 and 2 , the high-speed stirring and grouting trolley of the present invention includes a vehicle frame, which is composed of a vehicle plate 2 and two wheels 22 . Vehicle plate 2 wherein is rectangular, and two wheels 22 are respectively installed in the middle of its two long sides. The vehicle plate 2 is provided with a screw conveying mechanism, a high-speed stirring mechanism, a grouting pump 21 and a controller 5 . Wherein, the high-speed stirring mechanism is on one end of the car plate 2, and it is made up of a high-speed stirring drum 14, a pillar 18 and a high-speed stirring motor 19. There are three pillars 18, and the lower ends of the three pillars 18 are fixed on the vehicle board 2. Three short columns 16 are arranged on the bottom surface of the high-speed mixing drum 14, and the three short columns correspond to the three pillars 18. Three load cells 17 are arranged between the two, and the three short columns 16 pass through the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com