Method for machining mirror surface of aluminum alloy

A technology of mirror surface processing and aluminum alloy, which is applied in the field of aluminum alloy processing, can solve problems such as uneven thickness of the grinding and polishing surface, failure to achieve ultra-precision mirror processing, and easy scratches on the grinding and polishing surface, so as to achieve stable product quality and easy operation Convenience, the effect of achieving the ideal mirror effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

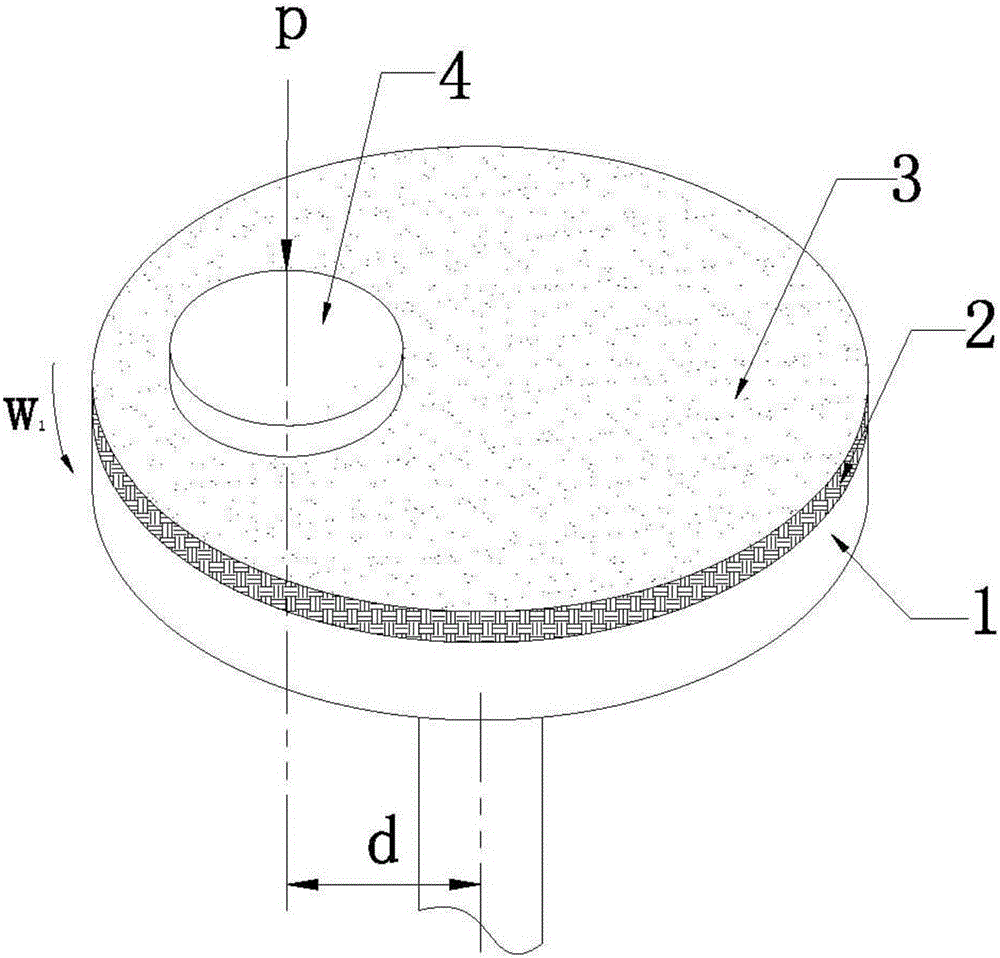

[0029] Such as figure 1 Shown, a kind of aluminum alloy mirror finishing method comprises the following steps:

[0030] a Rough grinding: place the aluminum alloy workpiece 4 to be ground on the grinding and polishing disc 1, use white corundum (F240#) for rough grinding, the rough grinding time is 1.5min, and the speed is 300r / min; after rough grinding, the surface roughness Reach Ra0.2;

[0031] b Rough polishing: place the roughly ground aluminum alloy workpiece 4 on the grinding and polishing disc 1, use the first abrasive paste for rough polishing, the grinding time is 10min, and the rotation speed is 600r / min; after rough polishing, the surface roughness reaches Ra0 .12;

[0032] c The first fine polishing: the aluminum alloy workpiece 4 that has been roughly polished is placed on the grinding and polishing disc 1, and the second abrasive paste is used for the first fine polishing, the grinding time is 8min, and the rotating speed is 600r / min; After fine polishing, th...

Embodiment 2

[0044] A method for processing an aluminum alloy mirror, comprising the following steps:

[0045] a Coarse grinding: Place the aluminum alloy workpiece 4 to be ground on the grinding and polishing disc 1, and use white corundum for rough grinding, the rough grinding time is 1min, and the speed is 350r / min; after rough grinding, the surface roughness reaches Ra0.24;

[0046] b Rough polishing: Place the roughly ground aluminum alloy workpiece 4 on the grinding and polishing disc 1, use the first abrasive paste for rough polishing, the grinding time is 8min, and the rotation speed is 500r / min; after rough polishing, the surface roughness reaches Ra0 .13;

[0047] c The first fine polishing: put the aluminum alloy workpiece 4 that has been roughly polished on the grinding and polishing disc 1, and use the second abrasive paste to perform the first fine polishing, the grinding time is 7min, and the rotating speed is 500r / min; After fine polishing, the surface roughness reaches Ra...

Embodiment 3

[0058] A method for processing an aluminum alloy mirror, comprising the following steps:

[0059] a Rough grinding: Place the aluminum alloy workpiece 4 to be ground on the grinding and polishing disc 1, and use white corundum for rough grinding, the rough grinding time is 2min, and the speed is 250r / min; after rough grinding, the surface roughness reaches Ra0.18;

[0060] b Rough polishing: Place the roughly ground aluminum alloy workpiece 4 on the grinding and polishing disc 1, use the first abrasive paste for rough polishing, the grinding time is 12min, and the rotation speed is 400r / min; after rough polishing, the surface roughness reaches Ra0 .11;

[0061] c The first fine polishing: the aluminum alloy workpiece 4 that has been roughly polished is placed on the grinding and polishing disc 1, and the second abrasive paste is used for the first fine polishing, the grinding time is 9min, and the rotating speed is 400r / min; After fine polishing, the surface roughness reaches...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com