Small solid rocket engine

A solid rocket and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as threats, and achieve the effect of ensuring airtightness, ensuring performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

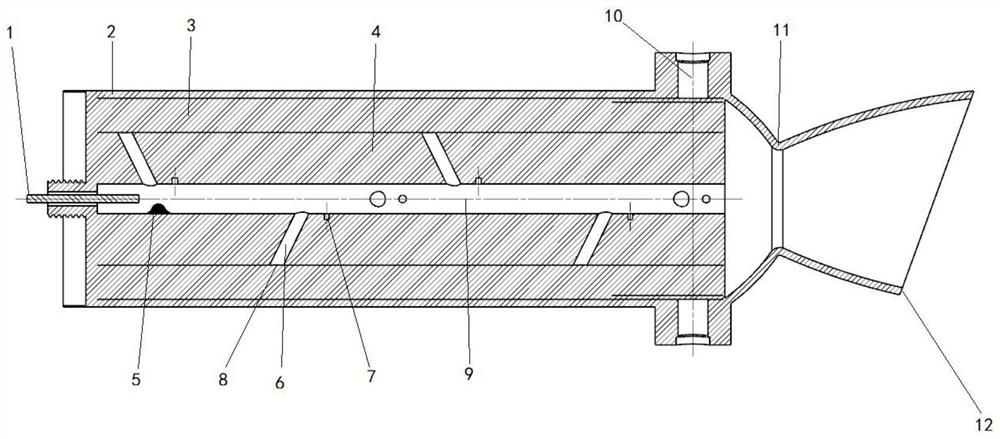

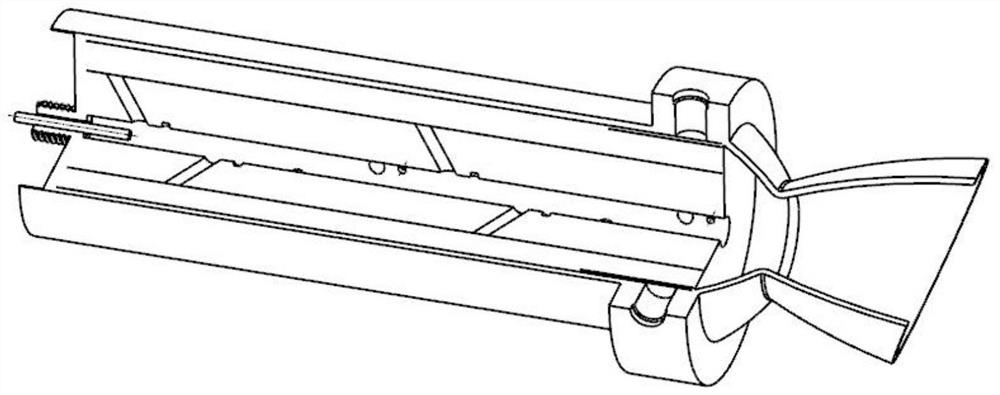

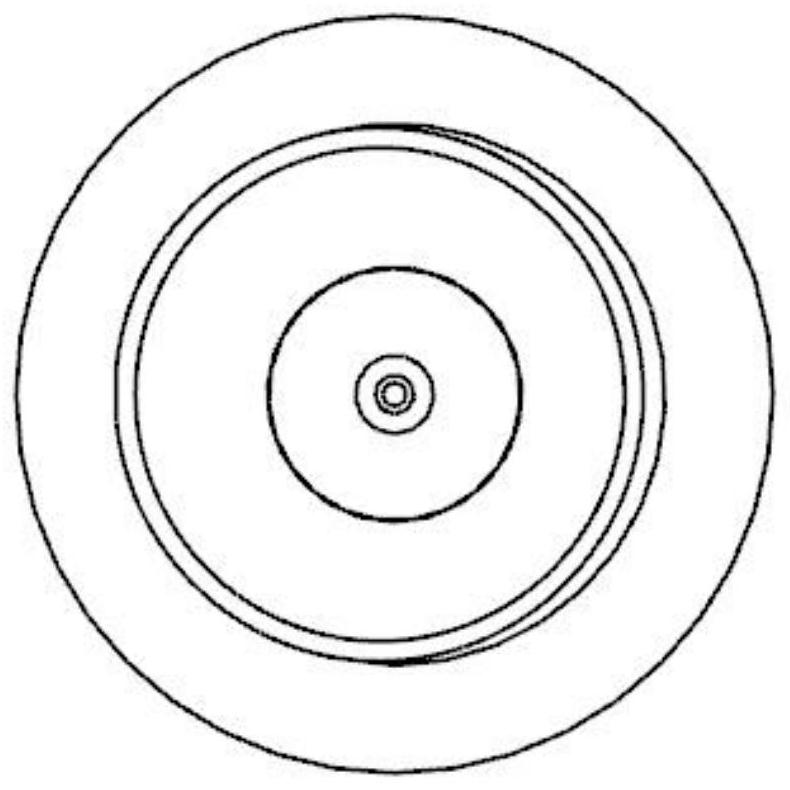

[0020]The present invention will now be further described in conjunction with the drawings:

[0021]Combinefigure 1 ,figure 2 ,image 3 ,Figure 4, The present invention is a small solid rocket motor.figure 1 Is a half-sectional view of a small solid rocket motor,figure 2 It is a 3 / 4 sectional view of a small solid rocket motor,image 3 Is a schematic diagram of the head section of a small solid rocket motor,Figure 4It is a schematic diagram of the overall structure of a small solid rocket motor.

[0022]The igniter 1 is fixed at the front entrance of the gas channel 9. The igniter 1 first starts to ignite and ignites the pre-ignition fuel 5. The high-temperature gas from the fuel passes into the oxidizer hole 6 and the gunpowder hole 7, and the oxidizer layer 3 and the gunpowder layer 4 are heated and volatilized , And then inject the gas passage 9 through the oxidizer hole 6 and the gunpowder hole 7. The oxidizer hole 6 and the gunpowder hole 7 are arranged obliquely and oppositely, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com