Polyurethane long-distance rapid fixed-point hole sealing device and method for underground drilling of coal mine

A sealing device, polyurethane technology, applied in the direction of safety devices, mining equipment, earthwork drilling and mining, etc., can solve the problems of unable to achieve long-distance fixed-point sealing, reduce the quality of sealing holes, and short operating time, so as to achieve long-distance rapid Fixed-point sealing, the effect of improving the quality of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

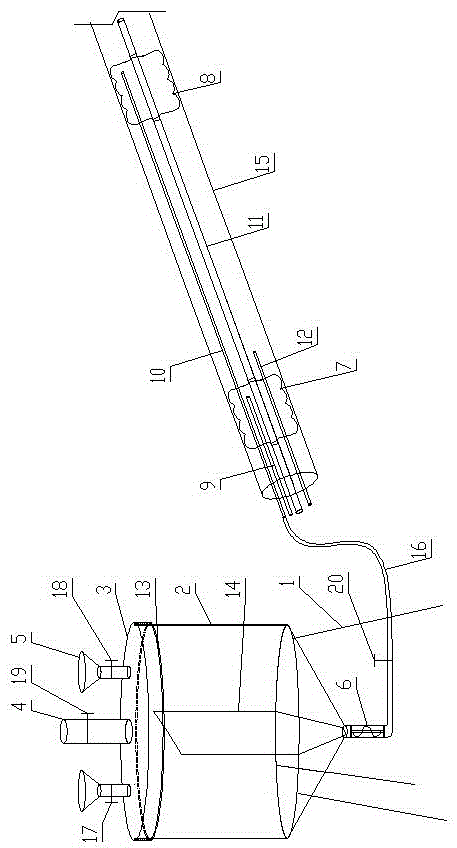

[0029] Such as figure 1 As shown, the polyurethane long-distance fixed-point fast-point sealing device for underground coal mine drilling of the present invention includes a support leg 1, an injection barrel 2, a barrel cover 3, a compressed air connecting pipe 4, a feeding funnel 5, and a non-powered pipeline mixer 6. The first polyurethane foam bag 7, the second polyurethane foam bag 8, the pressure measurement or extraction pipe 11, the first injection pipe 9, the second injection pipe 10 and the grouting pipe 12; On the outrigger 1, the bottom of the filling barrel 2 has a conical structure with a thick top and a thin bottom. The barrel cover 3 is horizontally arranged on the top of the filling barrel 2. Ring 13, the filling barrel 2 is vertically provided with a partition 14 that divides the interior of the charging barrel 2 into a material storage room and b material storage room, and there is a gap between the upper edge of the partition 14 and the lower surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com