Patents

Literature

124results about How to "Improve feeding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High density, energy component-added pelletized agricultural processing byproducts for animal feed

InactiveUS20070172540A1Improve feeding qualityHigh densityFood processingAnimal feeding stuffHigh densityGlycerol

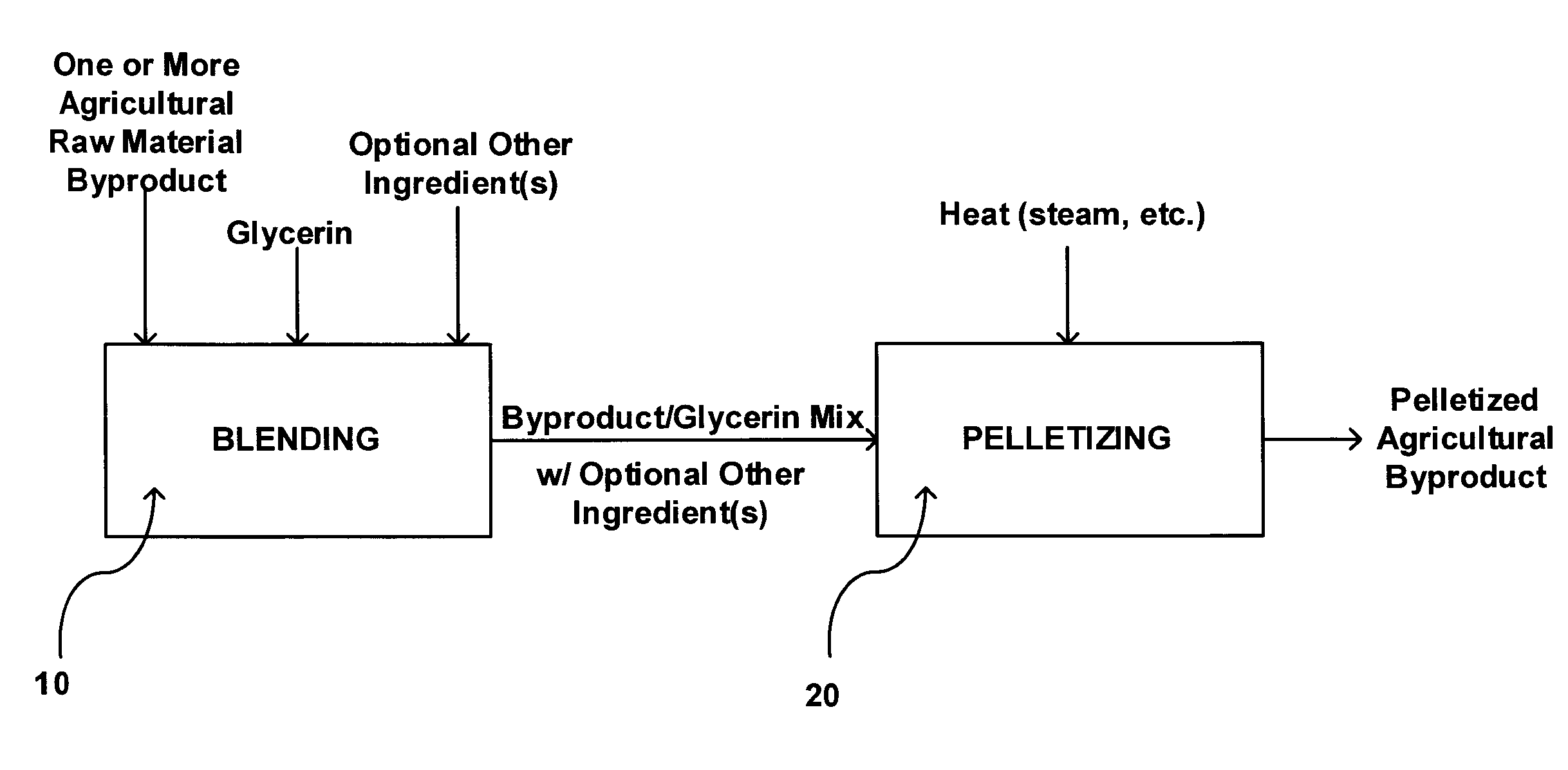

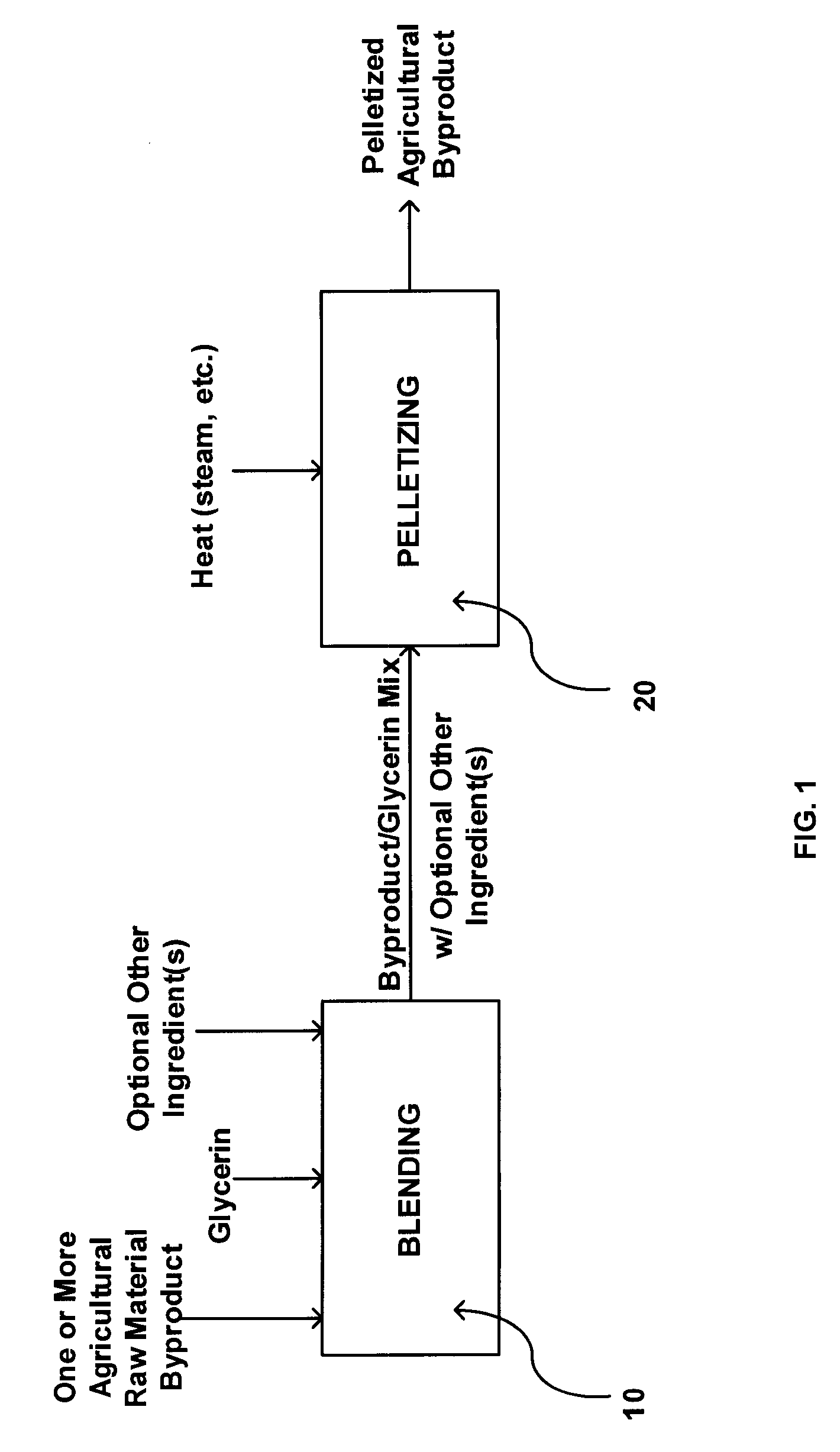

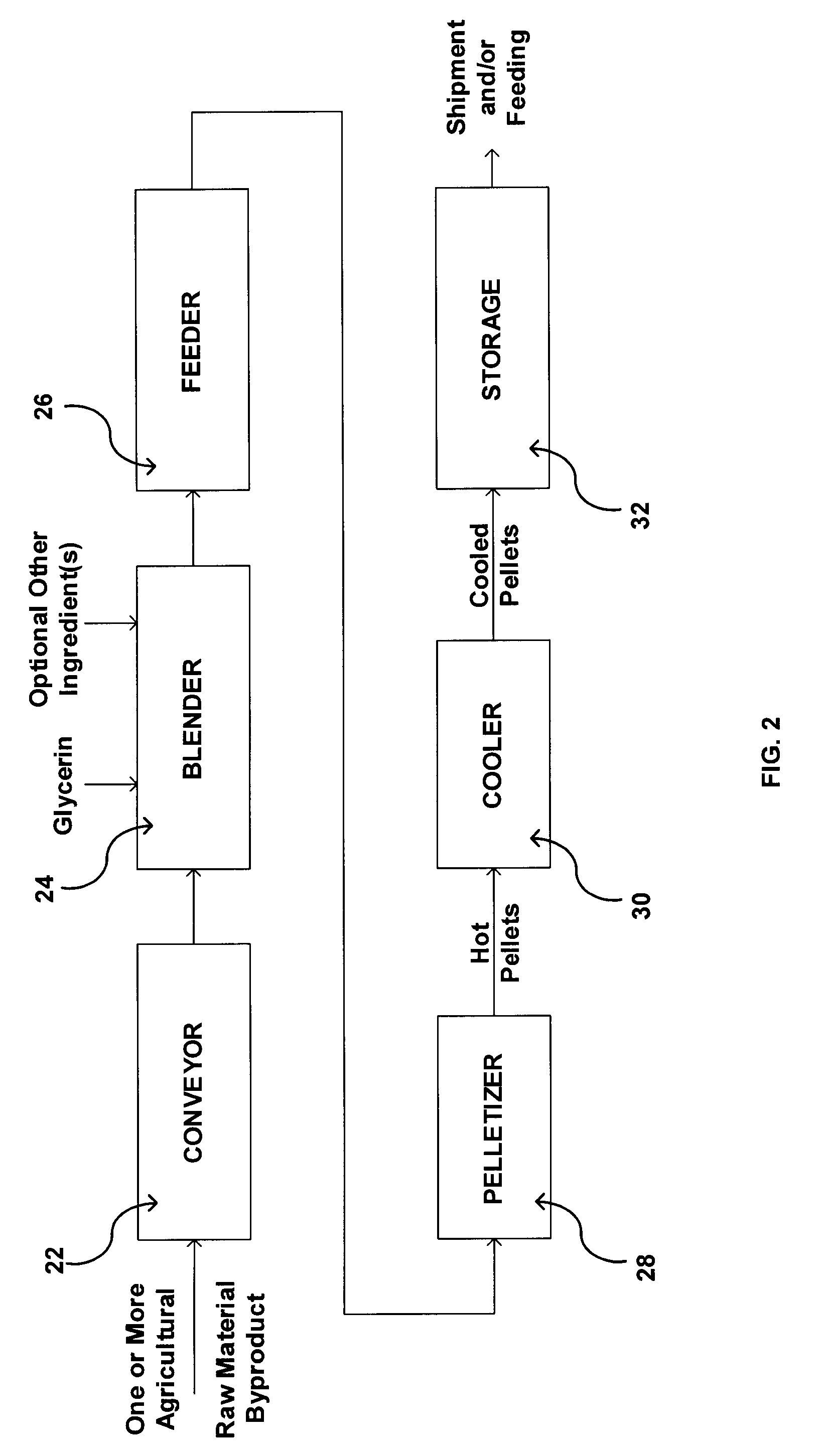

An animal feed in pellet form including one or more agricultural raw material byproduct and a glycerin binder. The animal feed may also include nutritional additives, vitamins, minerals, antibiotics, hormones and sweeteners in effective amounts. Further provided is a process for preparing an animal feed product, including providing one or more agricultural raw material byproduct; blending the one or more agricultural raw material byproduct with a quantity of glycerin; and pelletizing the blended agricultural raw material byproduct and glycerin into pellets. The glycerin may be present at a concentration effective to bind the blended one or more agricultural raw material byproduct and glycerin into a stable pellet, and may also be present at a concentration effective to improve the shelf life of the one or more byproduct.

Owner:FARMERS UNION IND

Biological fermented feed for crayfishes and preparation method thereof

PendingCN106306606AImprove animal immunityImprove feeding qualityFood processingClimate change adaptationGrowth factorBiotechnology

The invention discloses a biological fermented feed for crayfishes and a preparation method thereof. The biological fermented feed for crayfishes comprises fermentation raw materials and a microbial strain accounting for 0.1-0.5% of the mass of the fermentation raw materials; and the fermentation raw materials comprise the following materials in parts by mass: 40-50 parts of wheat, 30-40 parts of corns and 20-30 parts of soybeans. The biological fermented feed disclosed by the invention is prepared by fermenting the wheat, corns and soybeans, the pH value of the feed is relatively low, and the feed contains more lactic acid and acetic acid, and has characteristics of an acidifying agent and a microbial ecological agent and functions of similar antibiotic growth factors at the same time, so that the feed can significantly enhance animal immunity and improve breeding quality of aquatic animals, thereby promoting healthy development of the modern aquaculture industry.

Owner:湖北楚天艾科生物技术有限公司

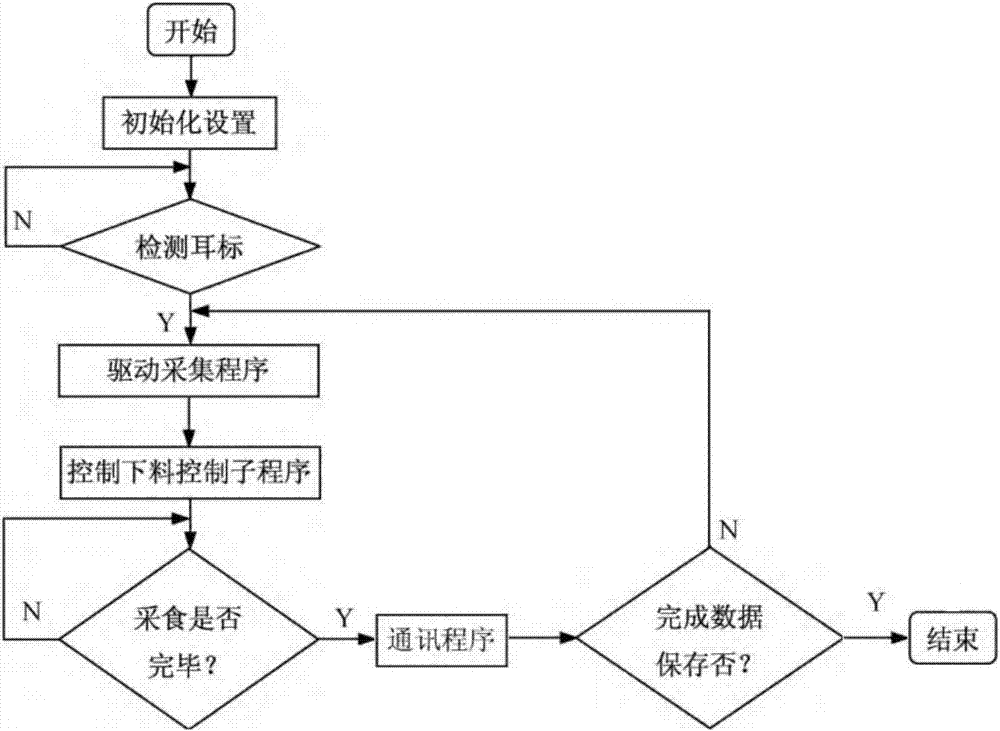

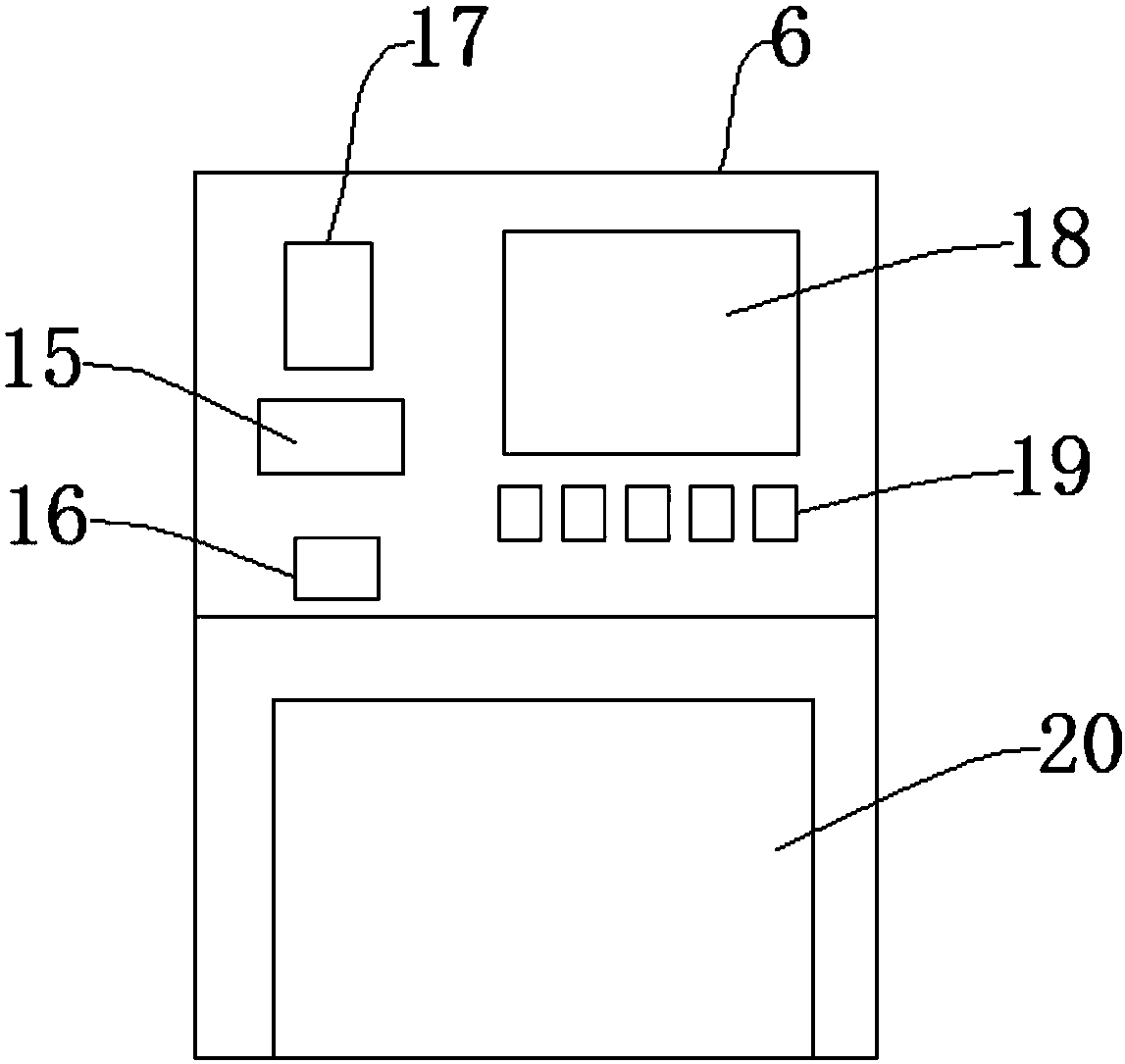

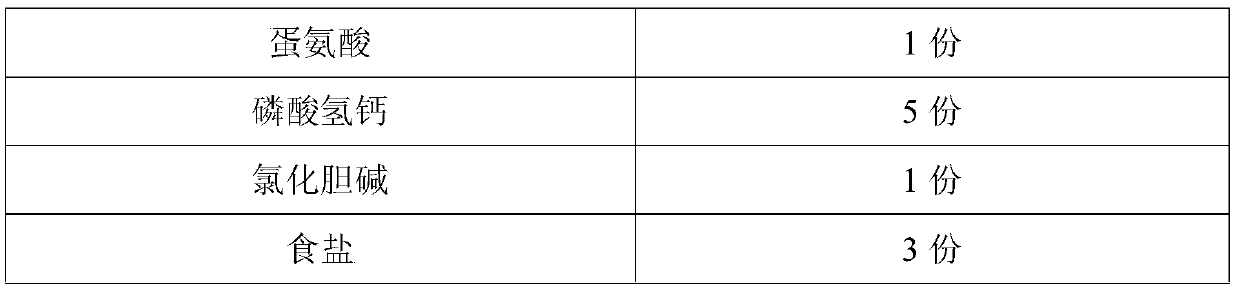

RFID-based automatic feeding control system and method for live pigs

PendingCN107114256AAchieving identifiabilityImplement trackingAnimal feeding devicesComputer hardwareAnimal science

The invention discloses an RFID-based automatic feeding control system and method for live pigs. The RFID-based automatic feeding control system comprises a remote server, a weighing feeding device and a PLC controller, wherein the weighing feeding device is arranged in a location bar and connected with the remote server through the PLC controller; and the weighing feeding device is provided with an RFID radio frequency identification system which is used for identifying identities of the live pigs and transmitting the identities to the remote server to achieve data management and remote control. By using an intelligent feeding control system formed by an RFID radio frequency identification system, the weighing feeding device and the PLC controller, ingredients can be accurately controlled and accurately measured; a theoretical basis can be provided for fine pig feeding; fast identification of individual information of the live pigs is achieved by adopting an RFID radio frequency identification technology; and non-contact live pig identification and tracking are achieved by using data transmission of a radio frequency identification system.

Owner:YULIN UNIV

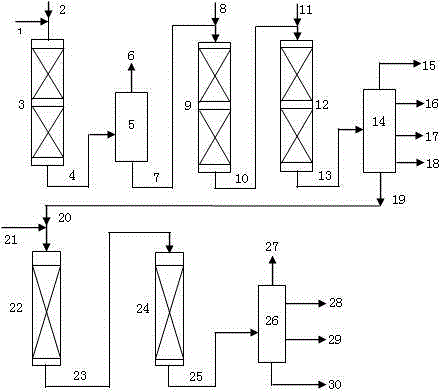

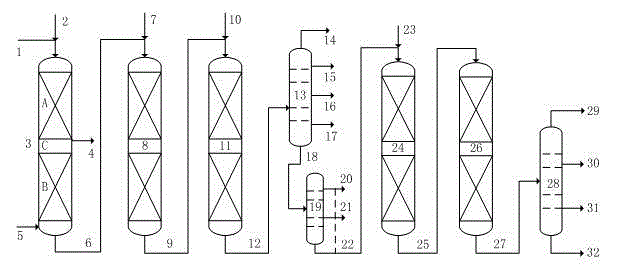

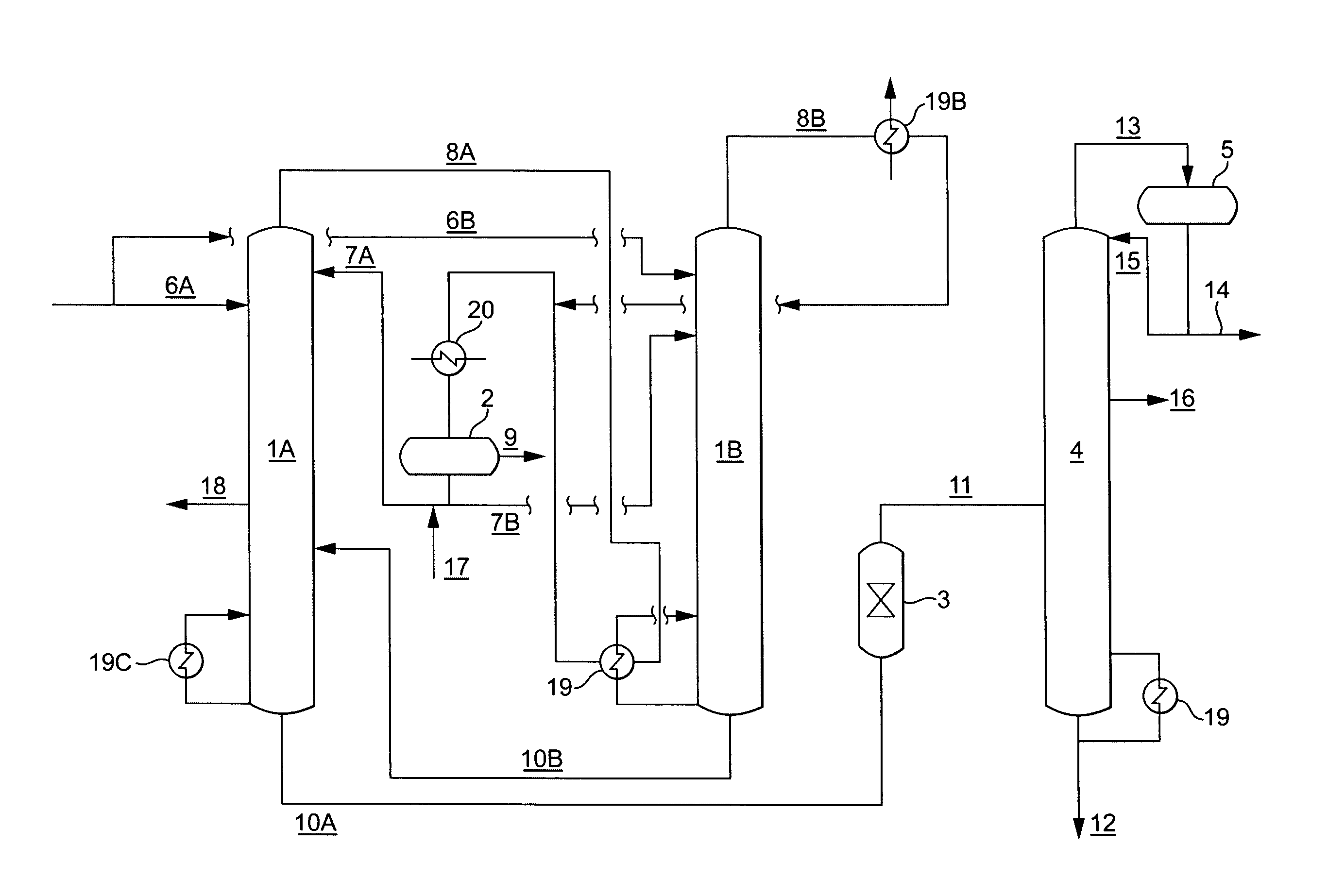

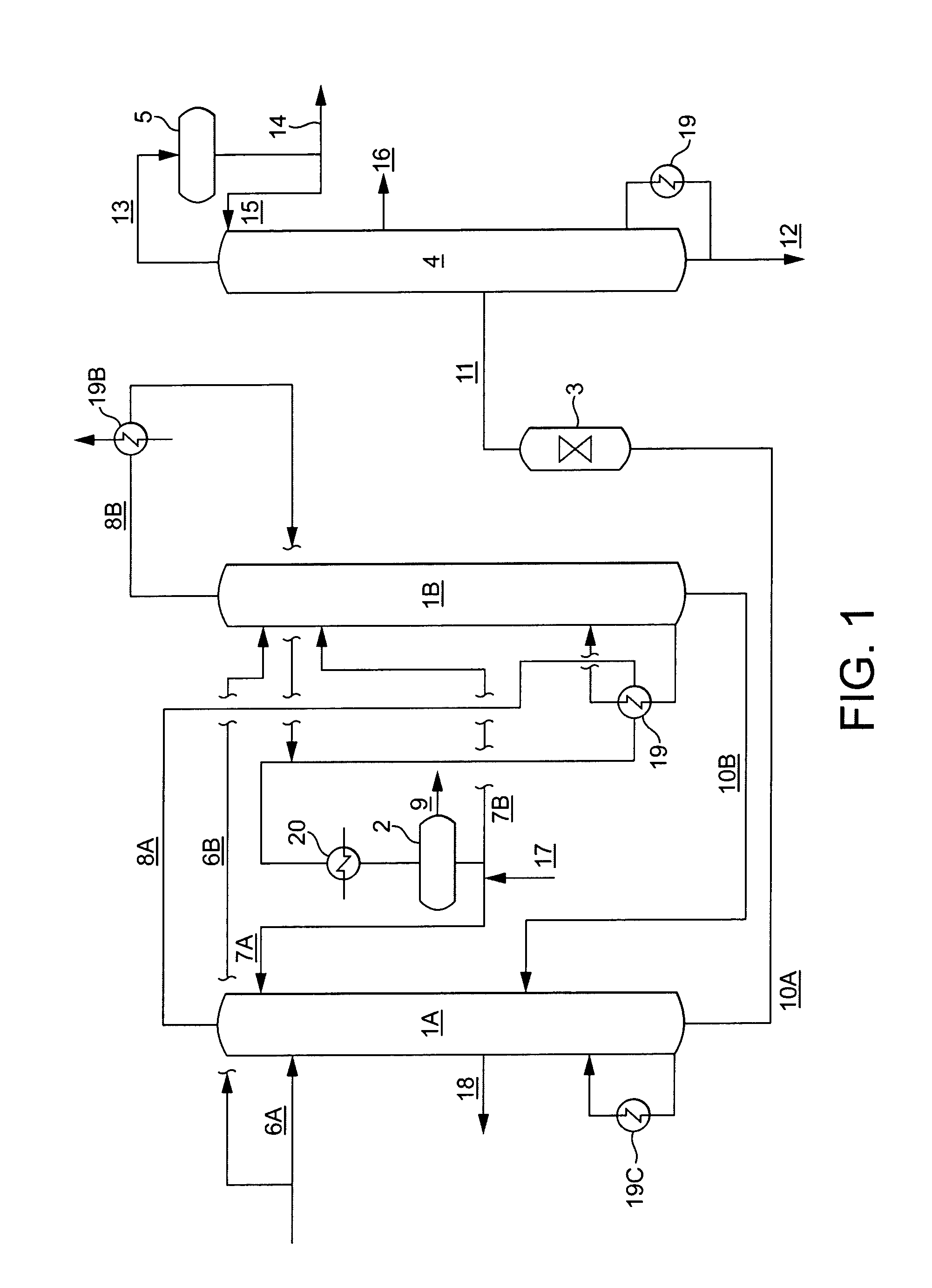

Hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil

ActiveCN104611037AEffectively play an active roleBroaden sources of raw materialsTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenNitrogen

The present invention discloses a hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil. According to the method, poor-quality heavy distillate oil and hydrogen gas enter a first-stage reaction zone to carry out a hydrorefining reaction, the reaction effluent is separated, the obtained liquid enters a second-stage reaction zone to carry out a hydrorefining reaction, the second-stage reaction effluent enters a third-stage reaction zone to carry out a hydrocracking reaction, the hydrocracking effluent is separated, and at least part of the tail oil and new hydrogen are mixed and then are subjected to an isomerizing dewaxing and finishing reaction to obtain various lubricating oil base oils. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the lubricating oil base oil raw material source is broadened; and the hydrorefining temperature is substantially reduced so as to increase the operation period of the device and process the poor-quality raw material, or increase the processing capacity of the device in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Feedstuff additive premix compound for breeding boars

InactiveCN101248842AIncrease semen collectionImprove feeding qualityAnimal feeding stuffAccessory food factorsChemistryCalcium

The invention provides a feed additive premix compound for breeding boars, and is characterized in that the premix compound comprises the following constituents by the weight percentages as follows: cupric sulphate 0.1%-1%, ferrous sulphate 0.1%-2%, zinc sulphate 0.1%-2%, manganese sulphate 0.01%-0.5%, sodium selenite 0.001%-0.1%, potassium iodide 0.001%-0.1%, chromium polynicotinate 0.001v-0.1%, lysine 1%-10%, methionine 0.1%-10%, threonine 1%-10%, choline chloride 0.1%-10%, common salt 1%-20%, calcium hydrophosphate 1%-50%, Sodium bicarbonate 0.1%-10%, calcium carbonate 1%-50% and the rest is pig feed carrier. The feed additive premix compound for the breeding boars effectively improves the quality of breeding boars, and avoids the loss of the breeding boars caused by high temperature and high humidity, thereby directly improving the economic benefit of pig-keeping production.

Owner:CHONGQING ACAD OF ANIMAL SCI

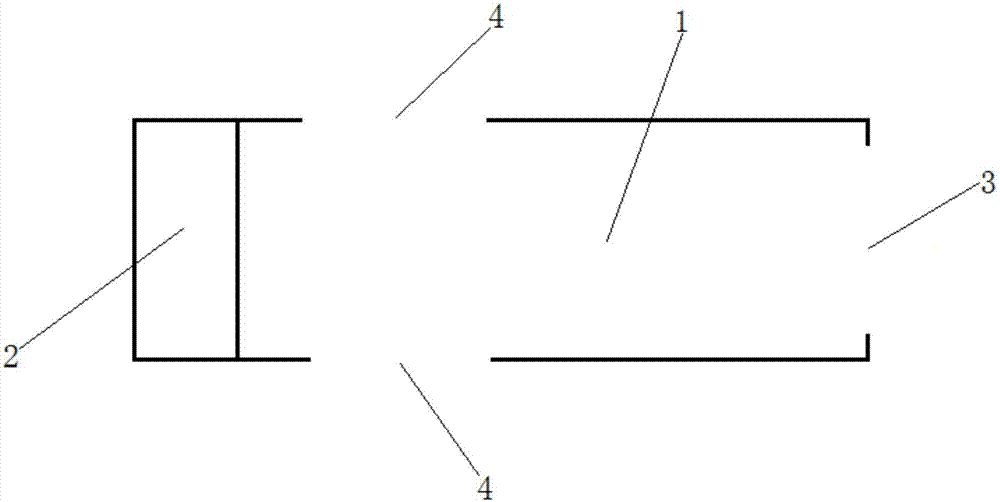

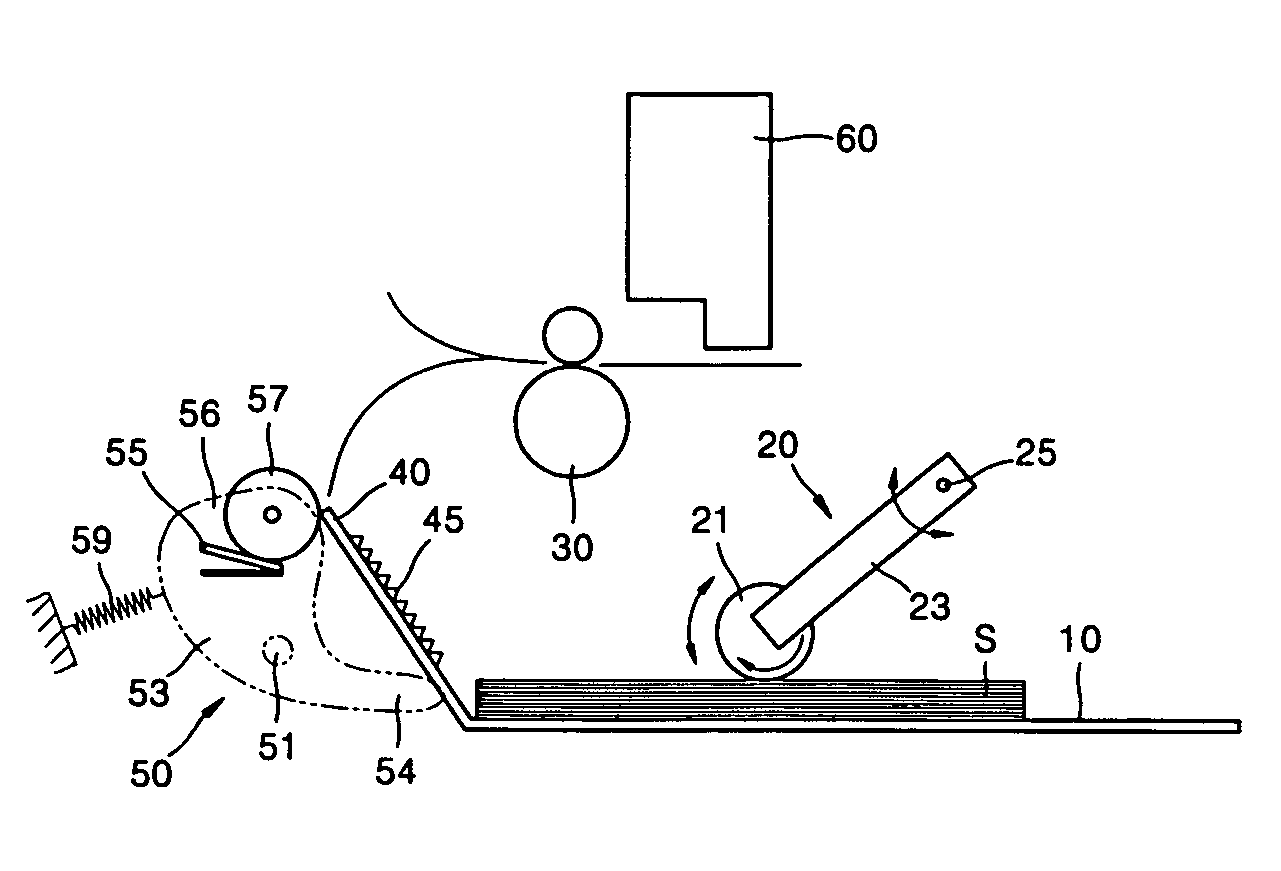

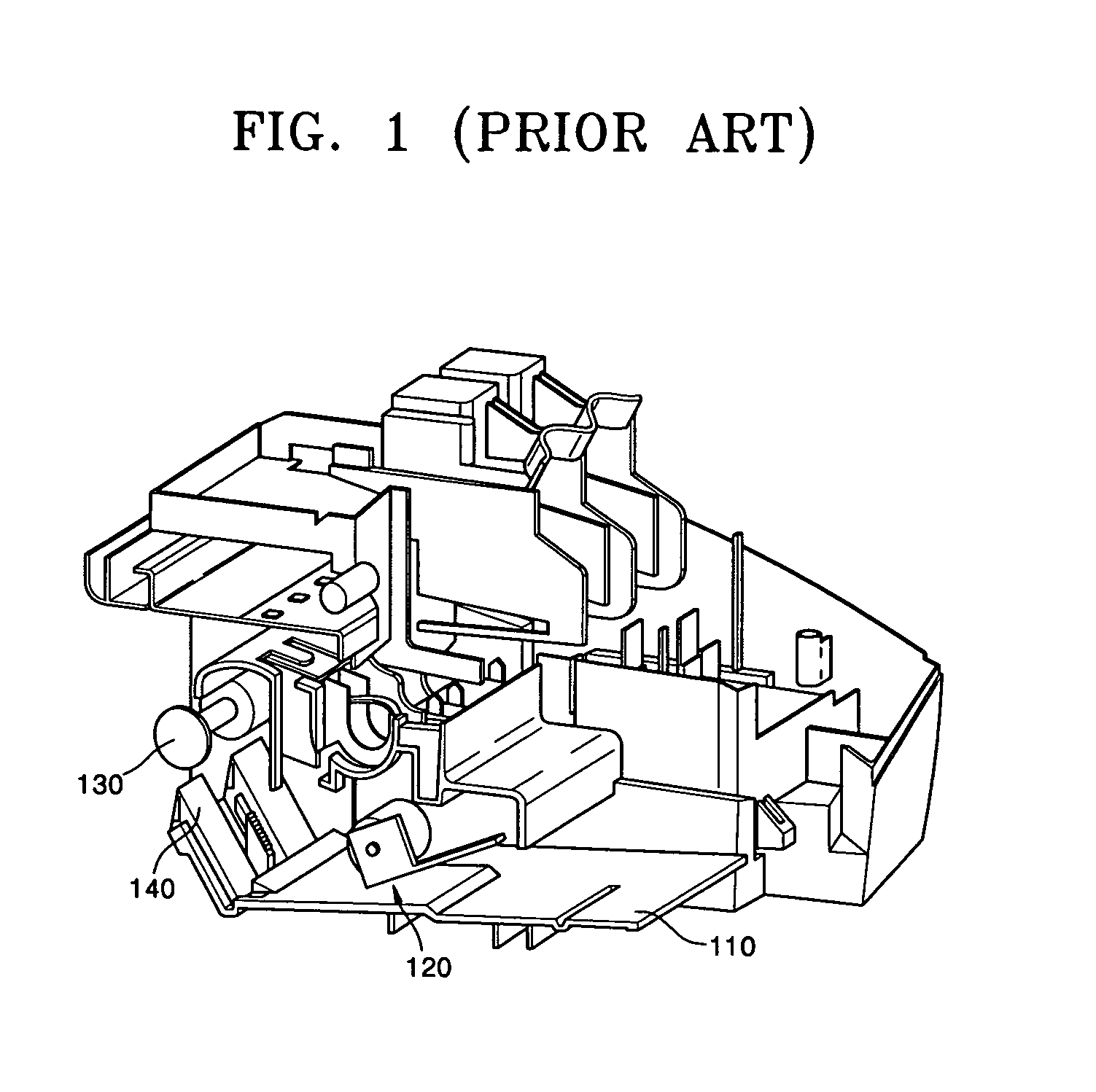

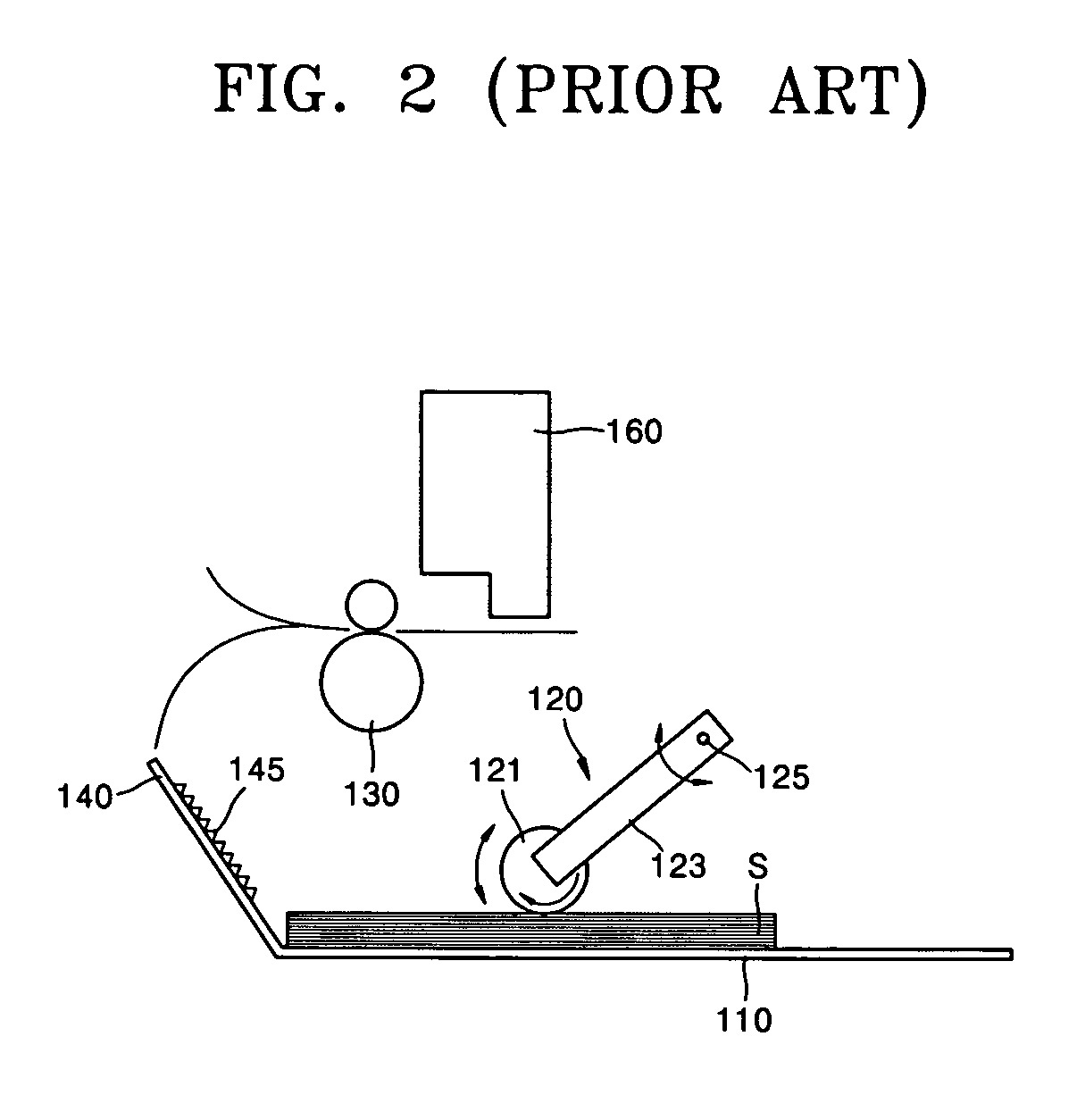

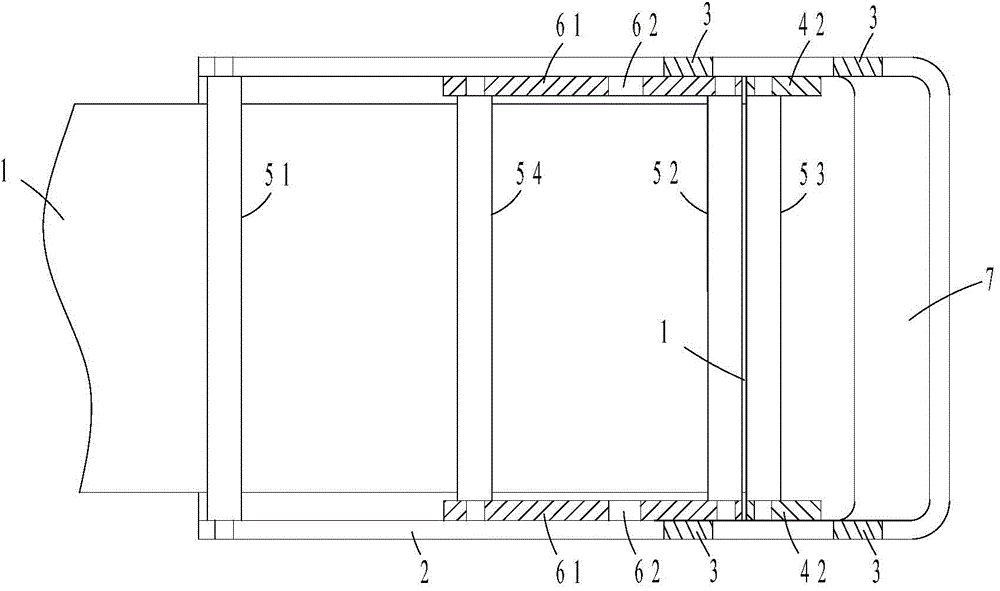

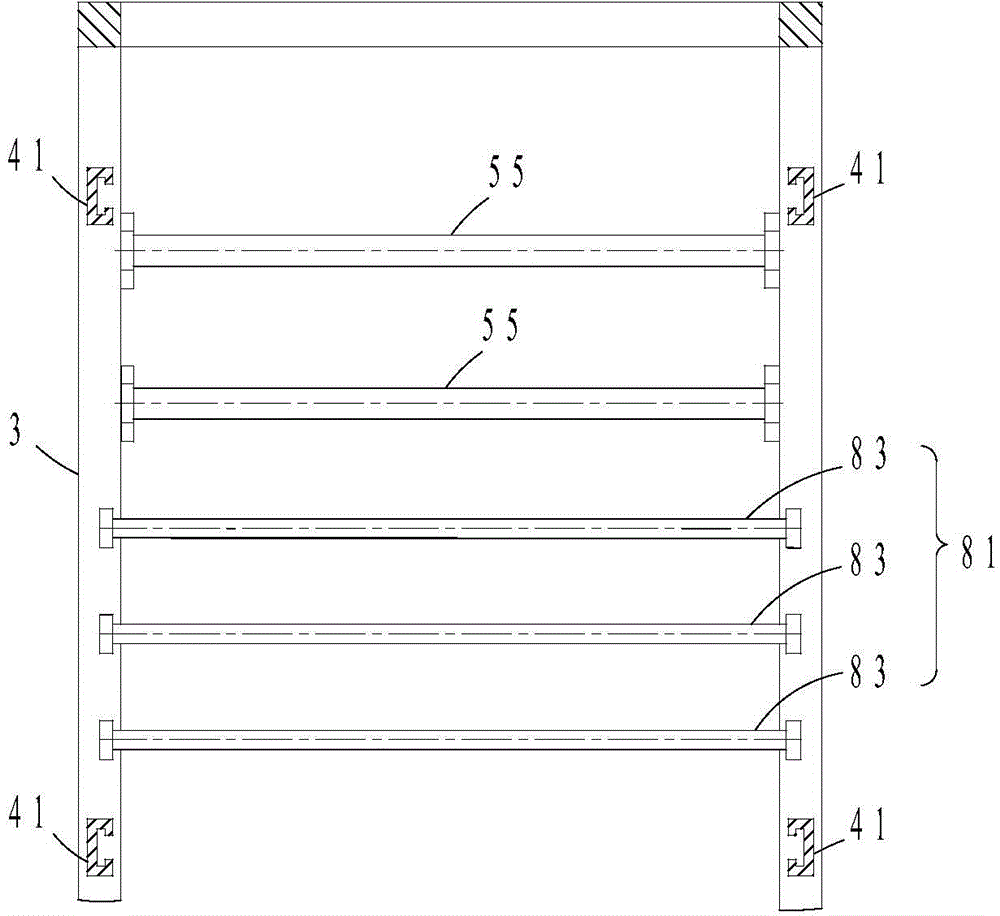

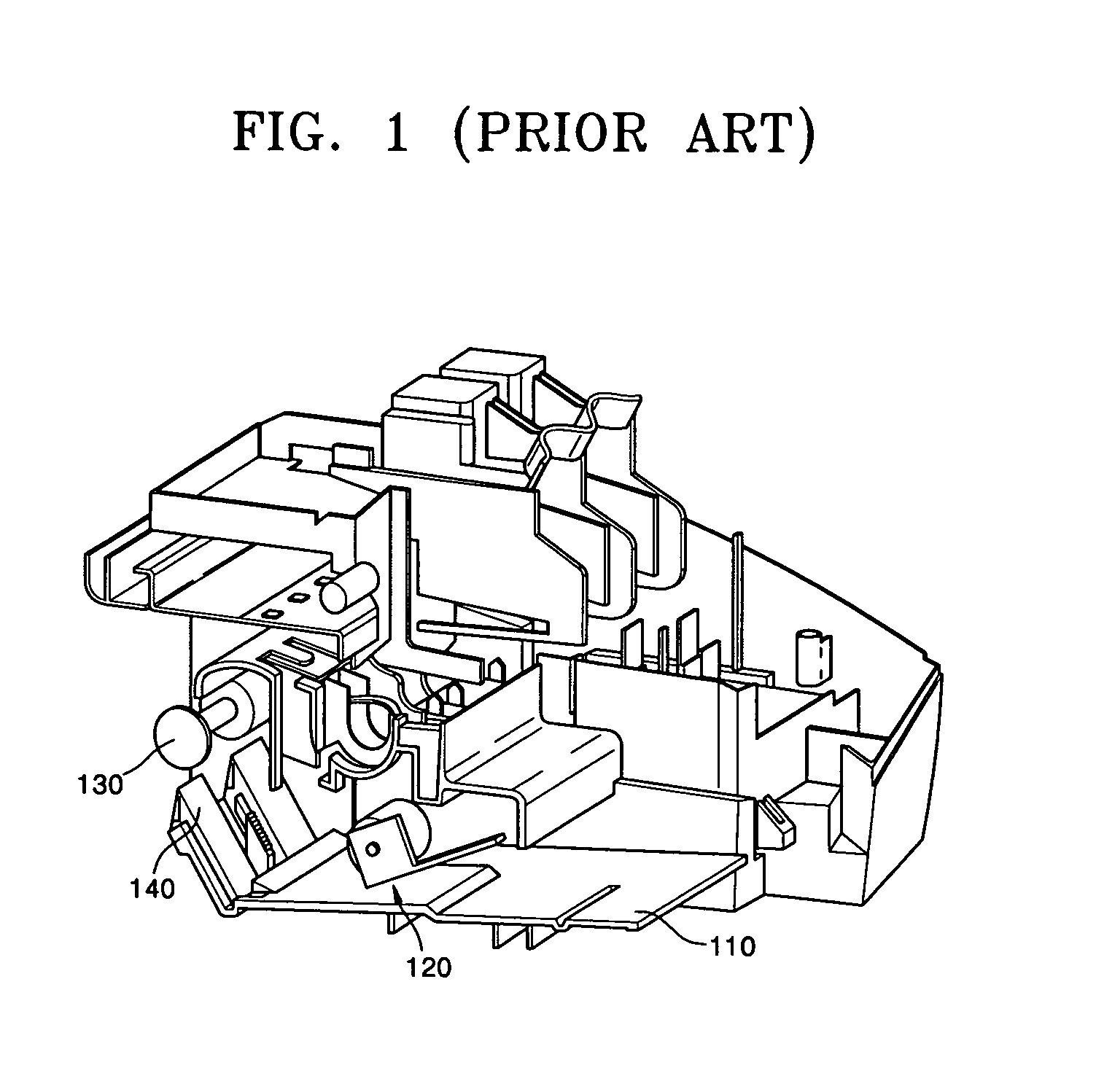

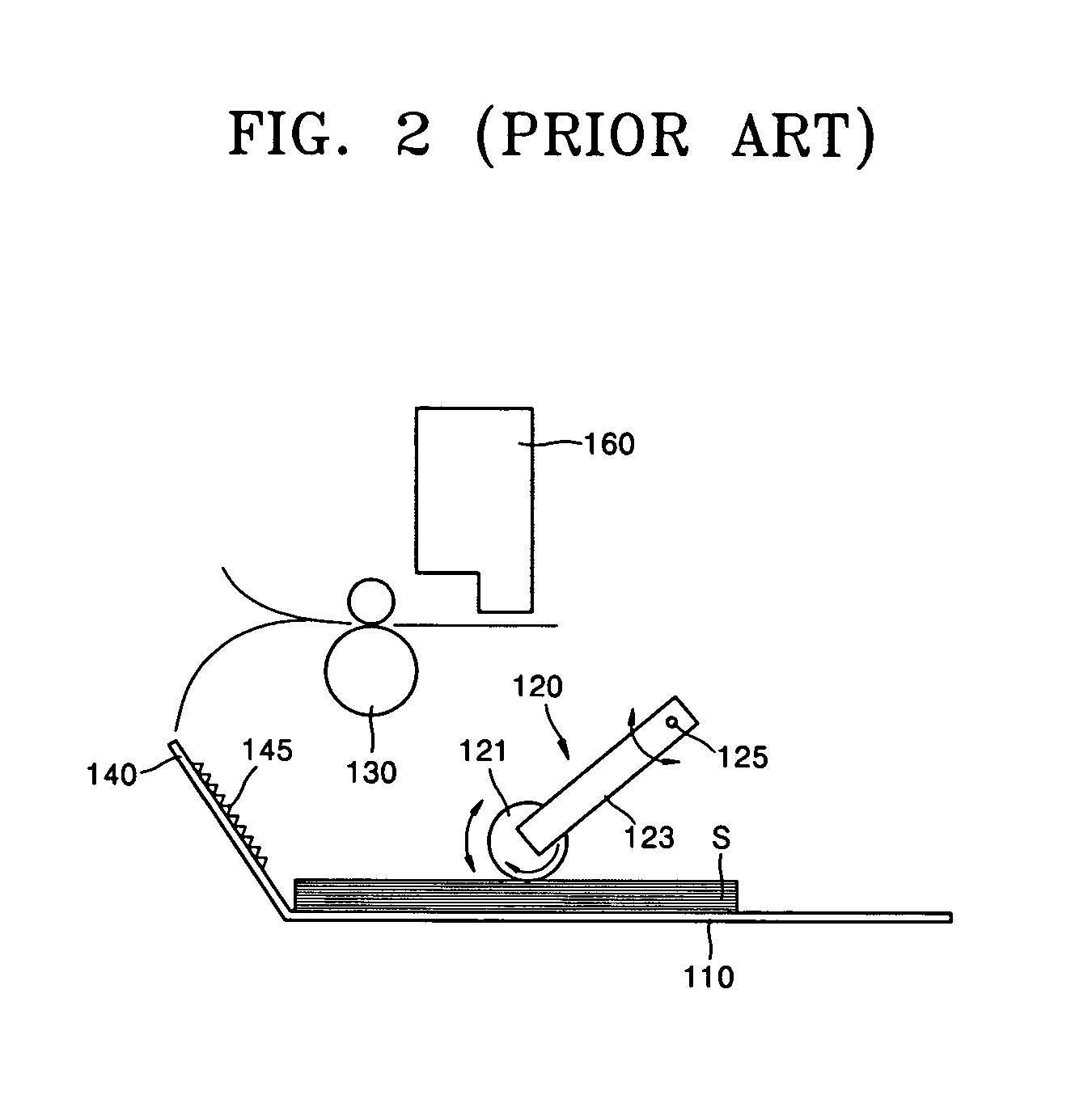

Two-way paper pickup system

InactiveUS7481419B2Improve feeding qualityEasy feedingSewerage structuresOther printing apparatusMechanical engineering

A two-way paper pickup system in which both a feed tray and a feed cassette can be used, and a printer adopting the same. The paper pickup system includes a feed tray on which paper or a feed cassette is placed, a first pickup assembly that moves the paper placed on the feed tray, a resistance plate that allows the moved paper to be separately transferred, and a second pickup assembly that is moved to a paper exit of the feed cassette so as to move paper included in the feed cassette when the feed cassette is placed on the feed tray. When the feed cassette is inserted into the printer, the first pickup assembly is moved on the feed cassette while being rotated.

Owner:HEWLETT PACKARD DEV CO LP

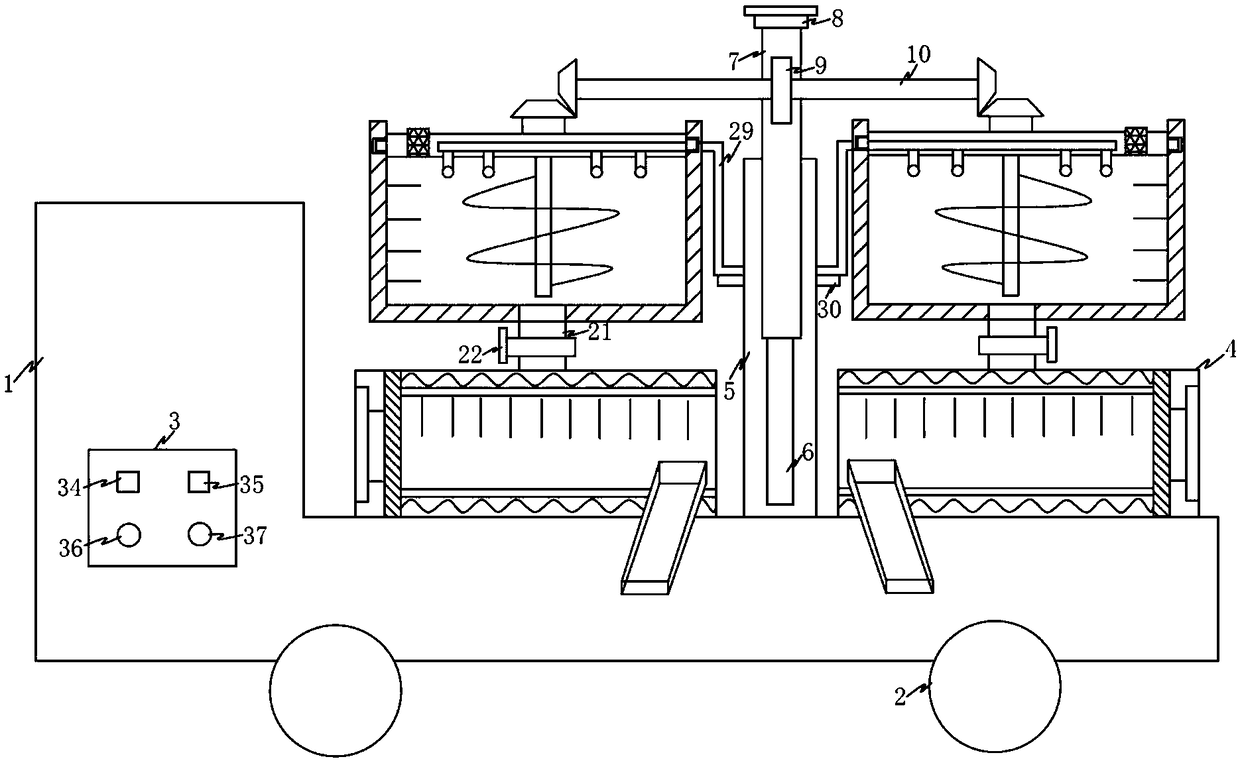

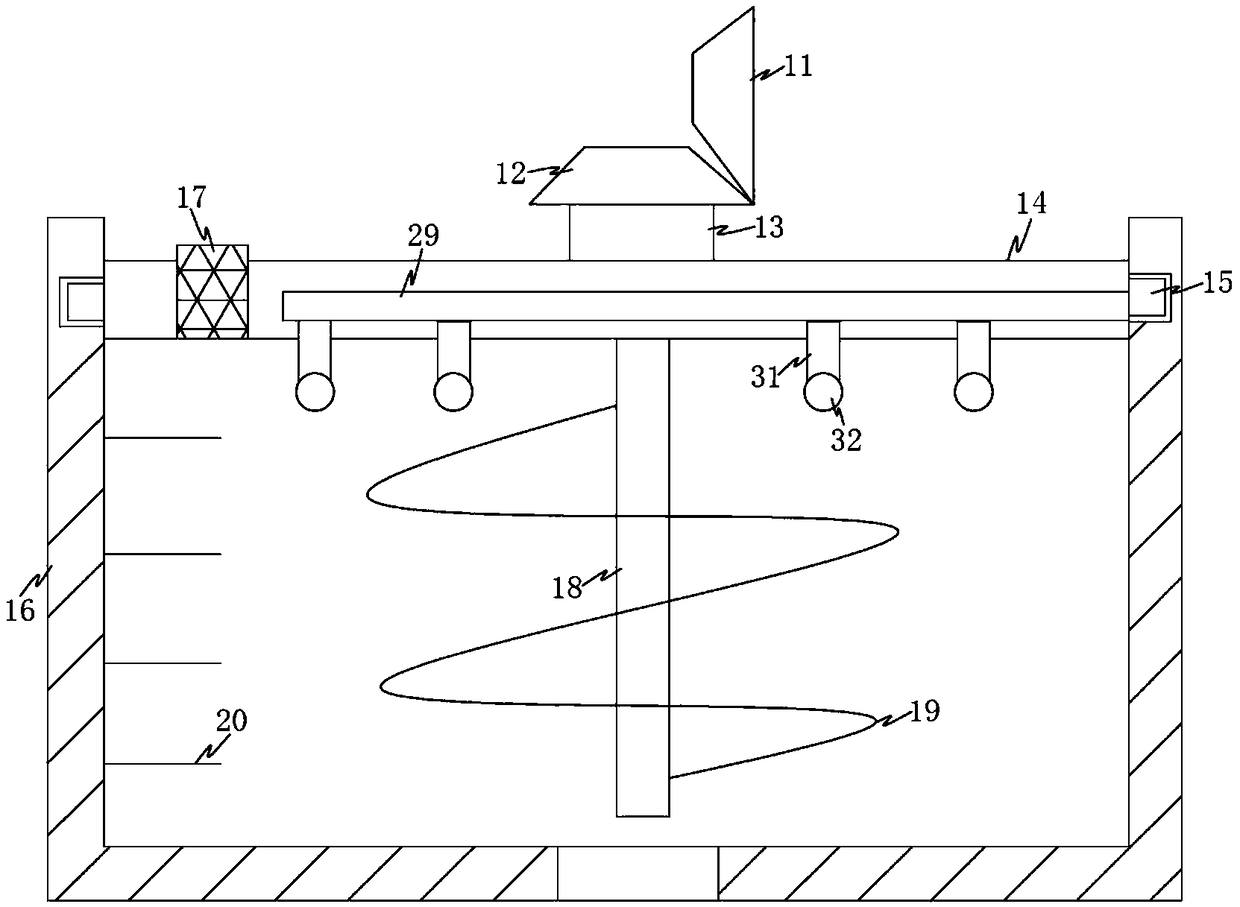

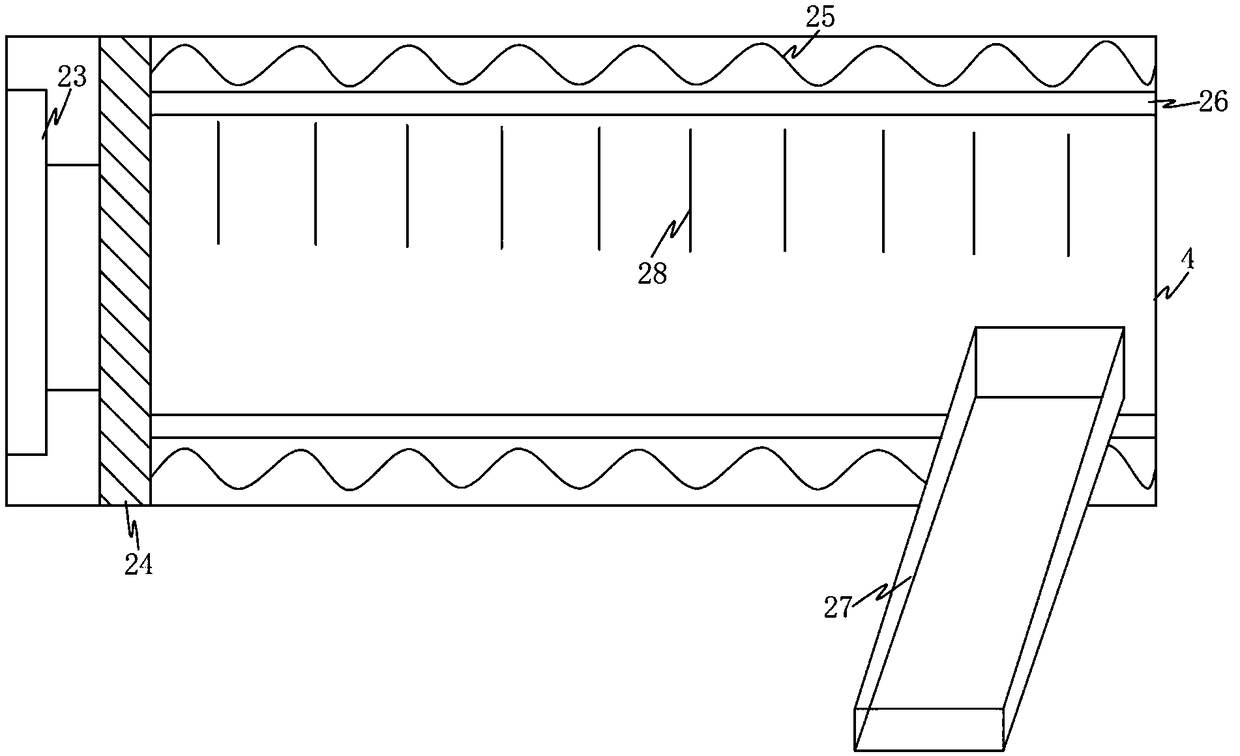

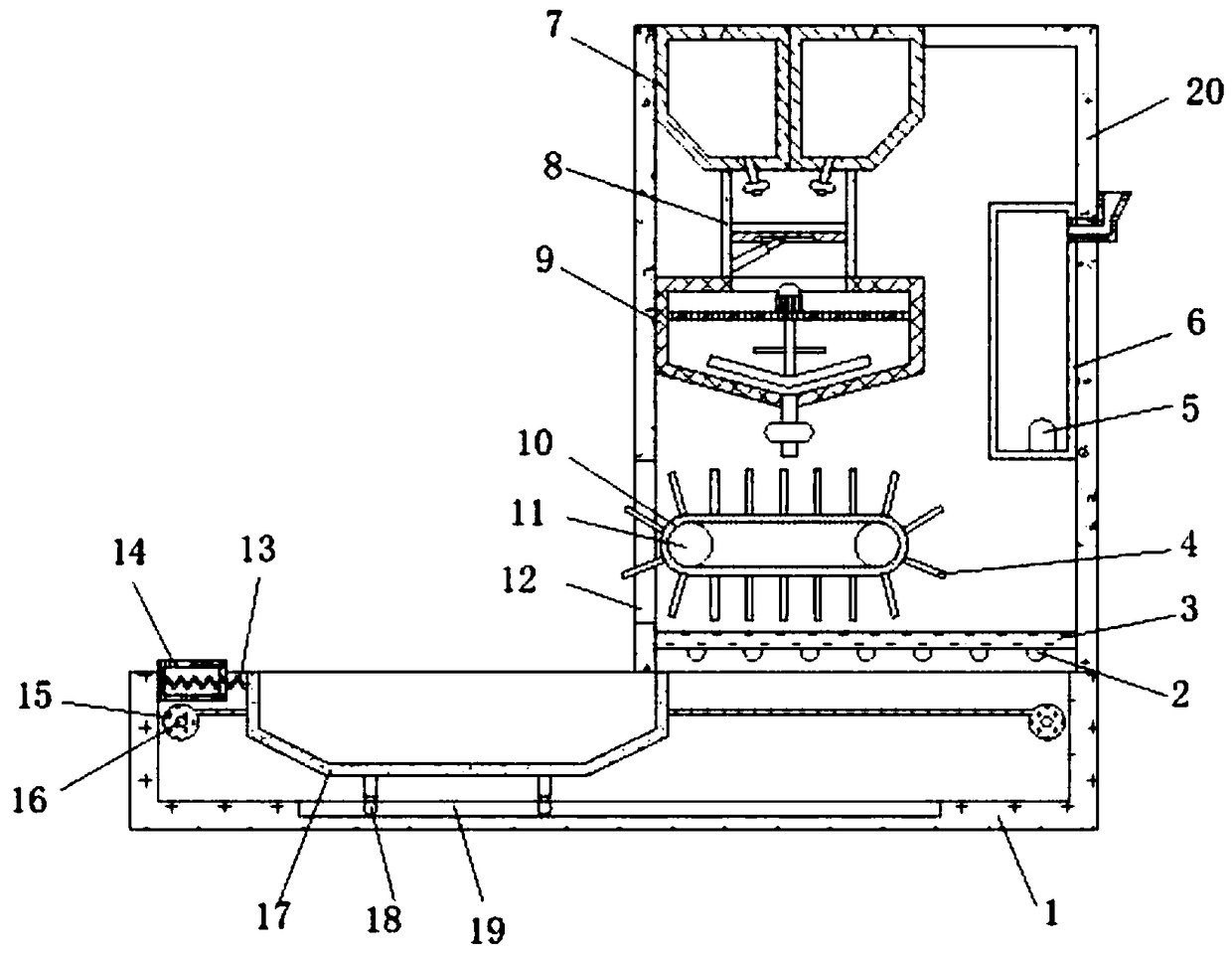

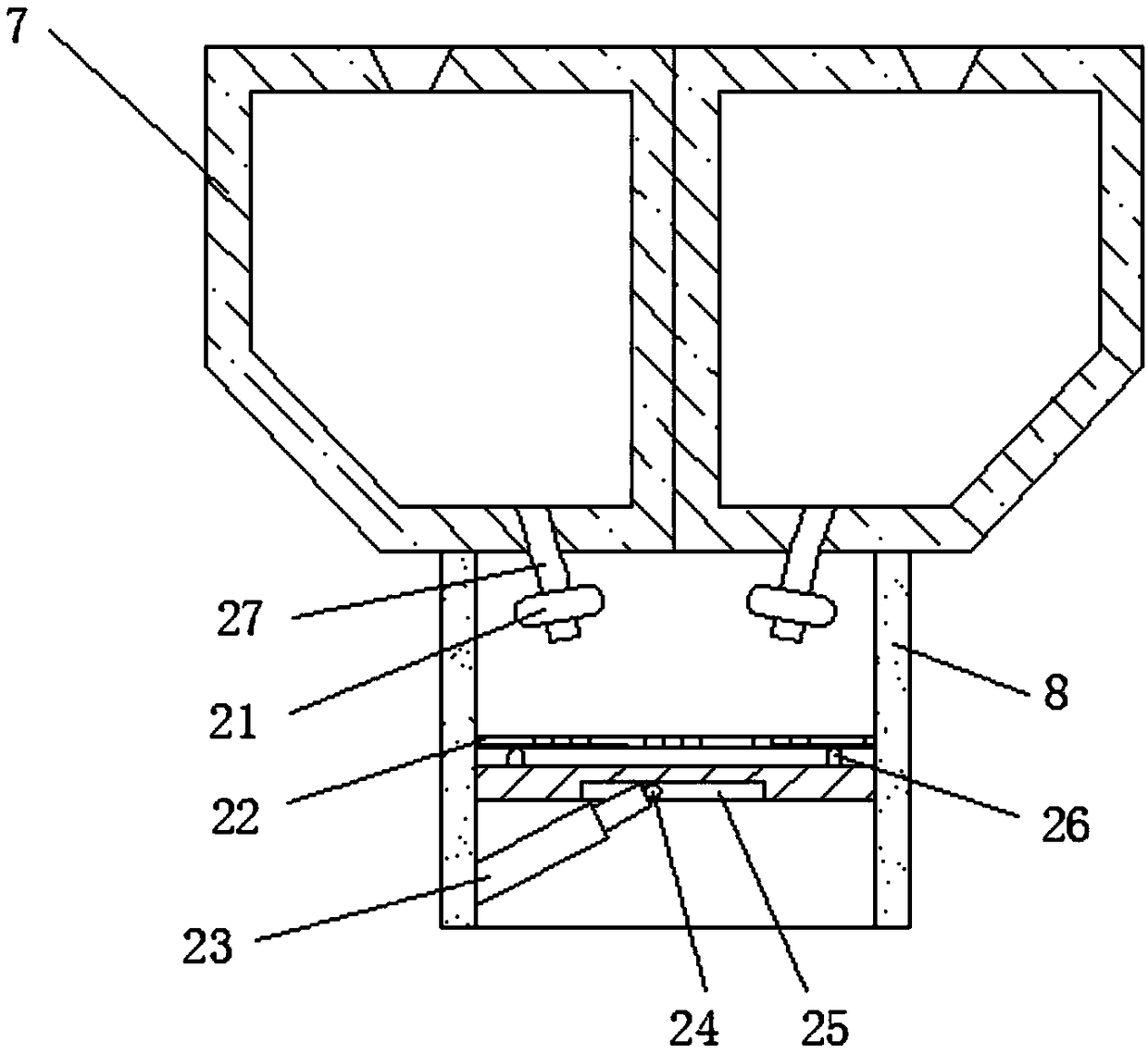

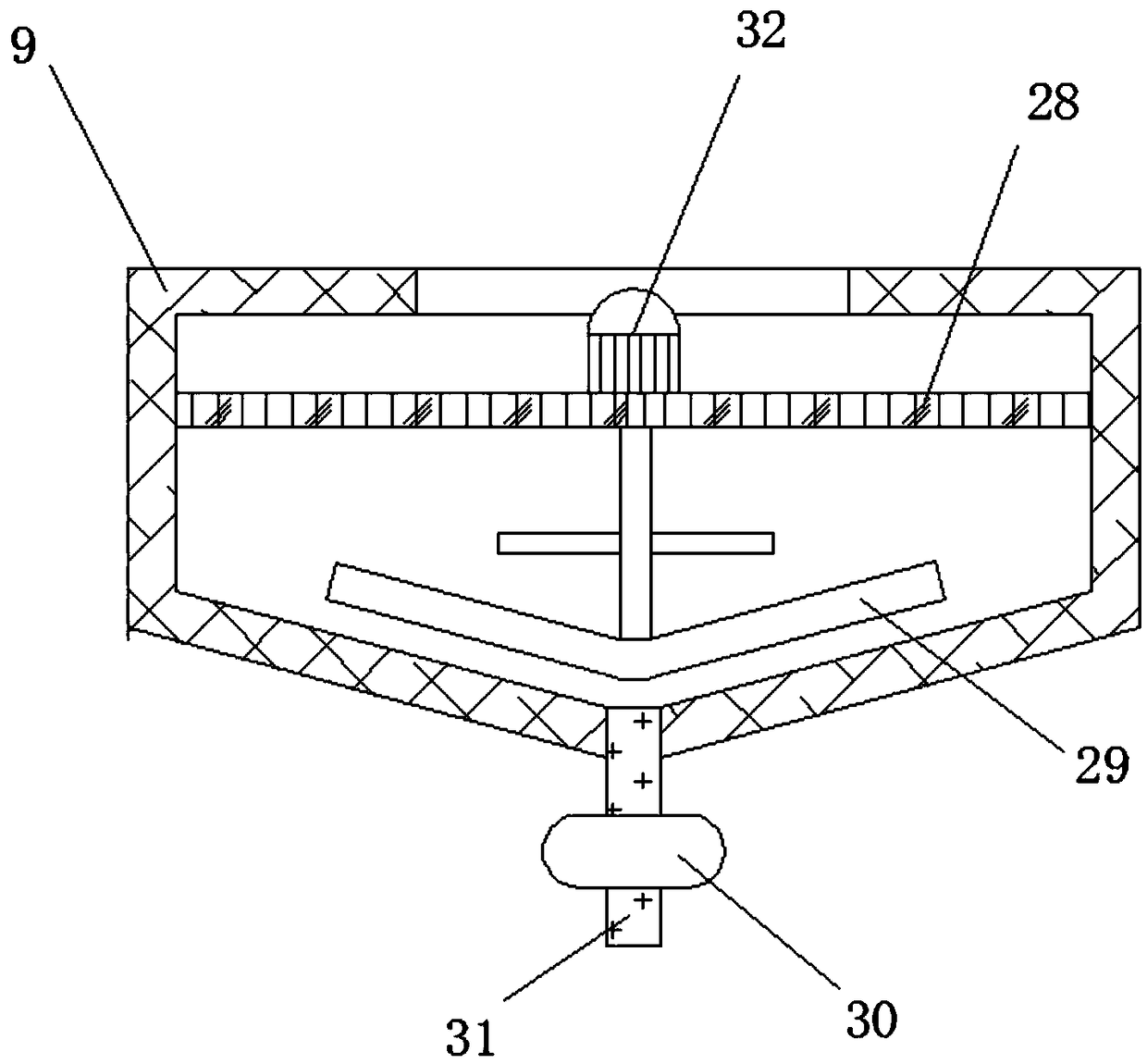

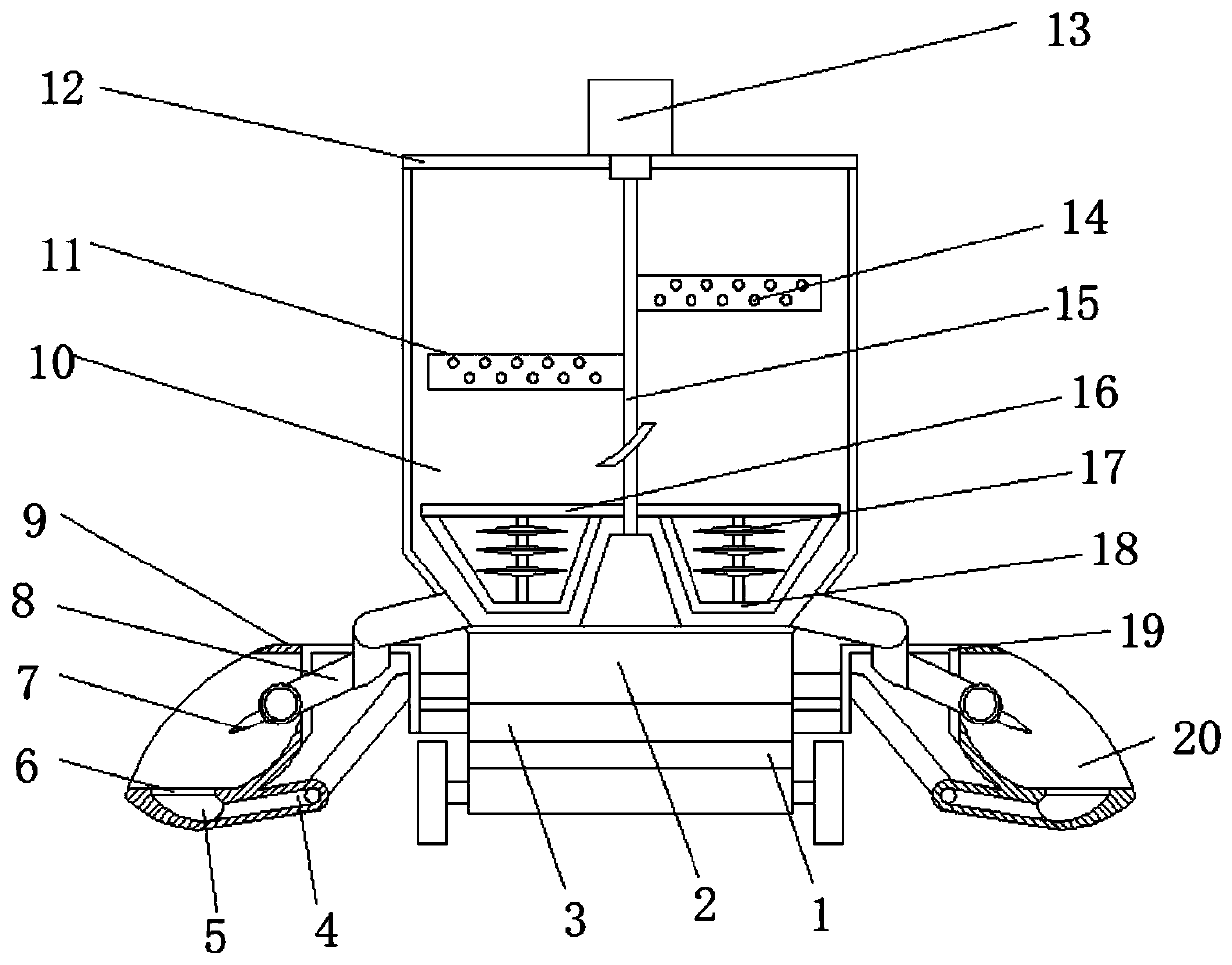

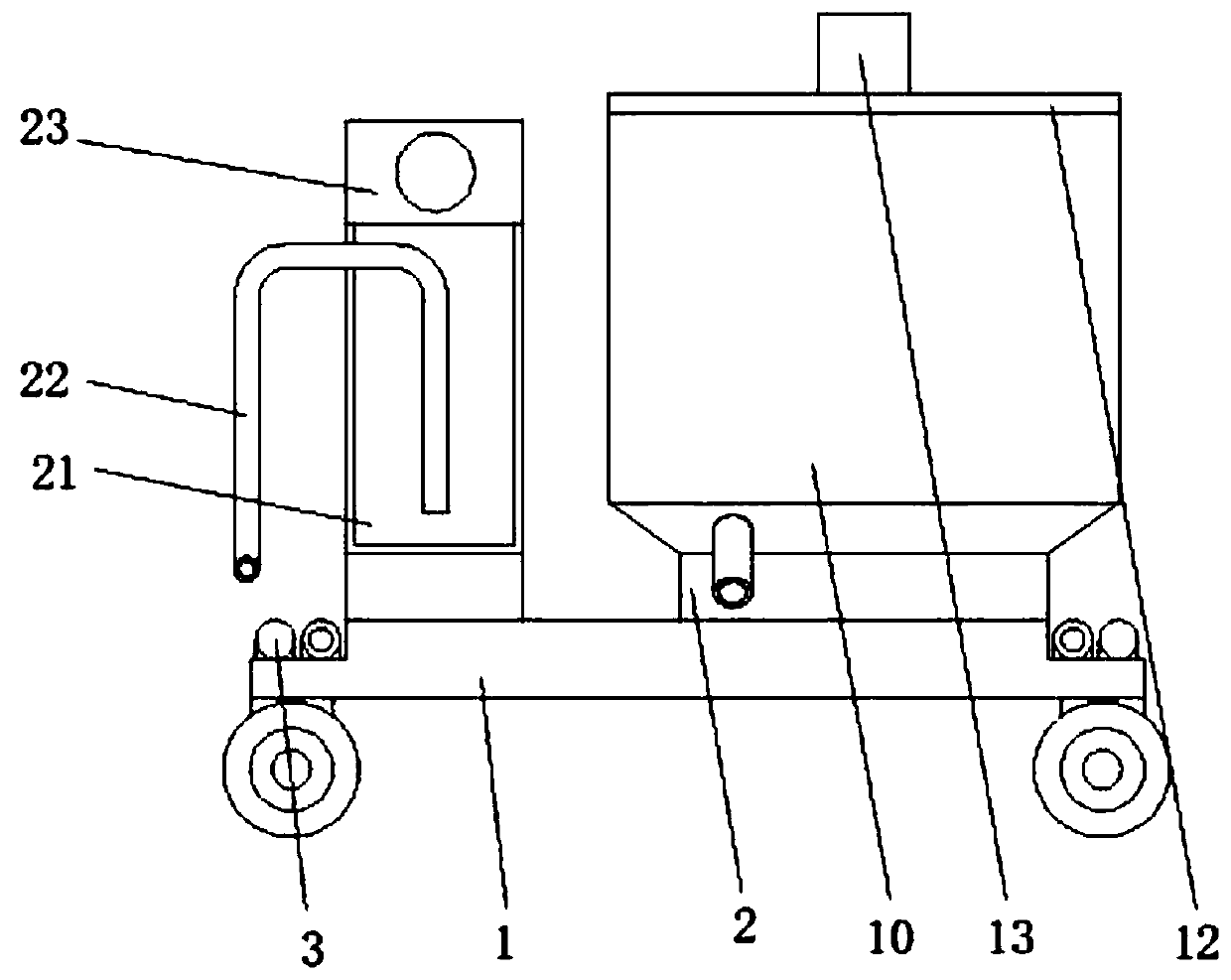

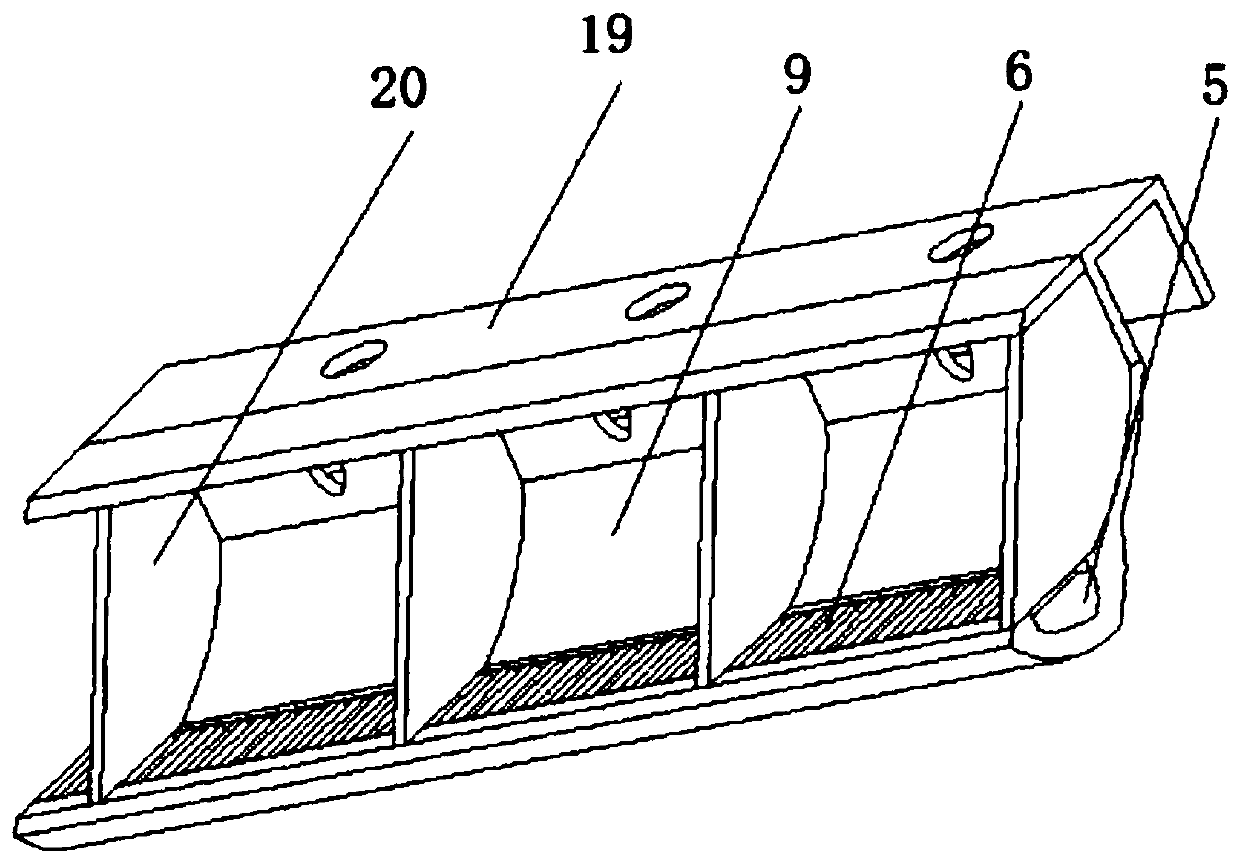

Intelligent mechanical feeding trolley

PendingCN108967237AReduce manual labor intensityStir evenlyAnimal feeding devicesAnimal ForagingEngineering

The invention discloses an intelligent mechanical feeding trolley. The trolley comprises a trolley body, on which a control box, forage stirring devices and quantitative feeding boxes are arranged. Arack is movably equipped with a gear. The center of the gear is fixedly equipped with a connecting rod in a penetrating manner. Two ends of the connecting rod are symmetrically equipped with driving bevel gears which are movably connected with driven bevel gears. The driven bevel gears are connected with cover boards through connecting blocks. The centers on one sides, away from the connecting blocks, of the cover boards are fixedly equipped with support columns. Spiral rods are fixedly arranged on the support columns. The side walls of the quantitative feeding boxes are fixedly equipped withsecond electric push rods fixedly connected with push boards. The intelligent mechanical feeding trolley is internally equipped with devices used for uniformly stirring forages. Therefore, human resources are saved. According to conditions of livestock, types of forages are flexibly selected and forage weight is adjusted. The trolley is simple in operation. Meanwhile, a built-in water tank is usedfor cleaning the trolley. The trolley has concentrated functions and is widely used.

Owner:ANHUI YOMO MACHINERY TECH

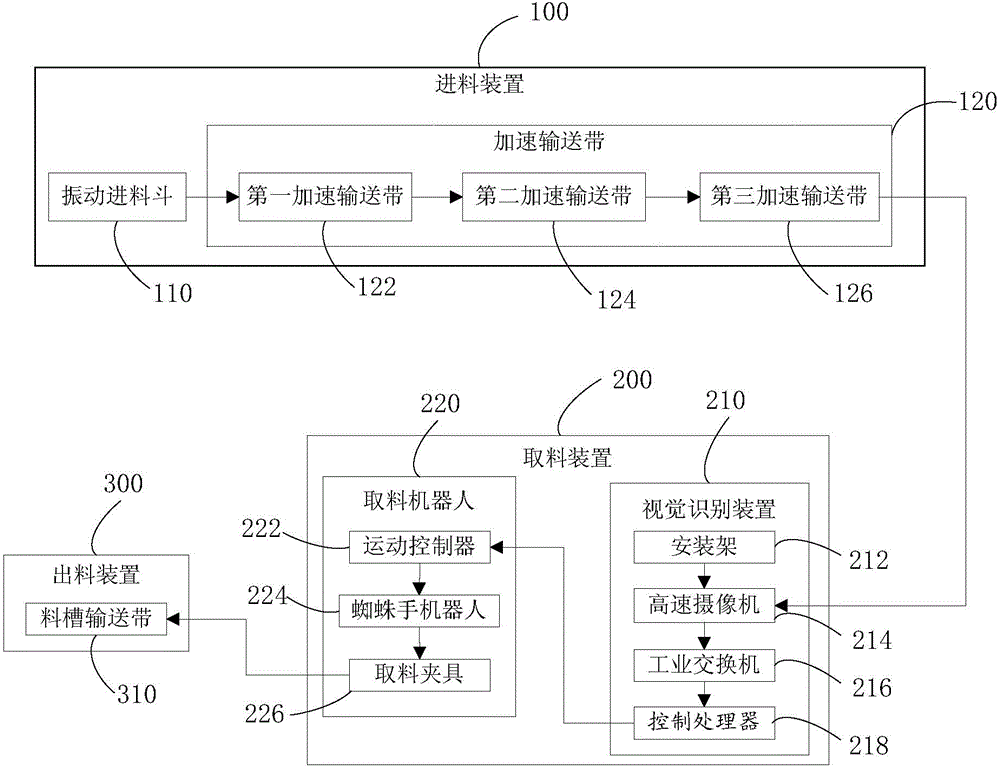

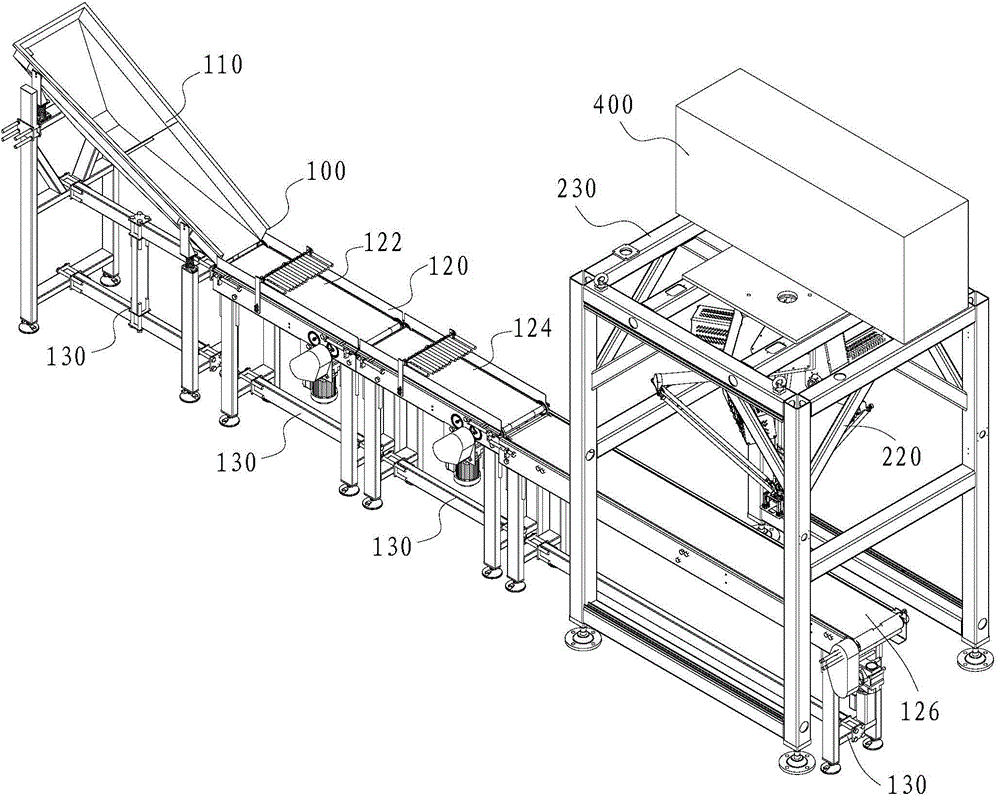

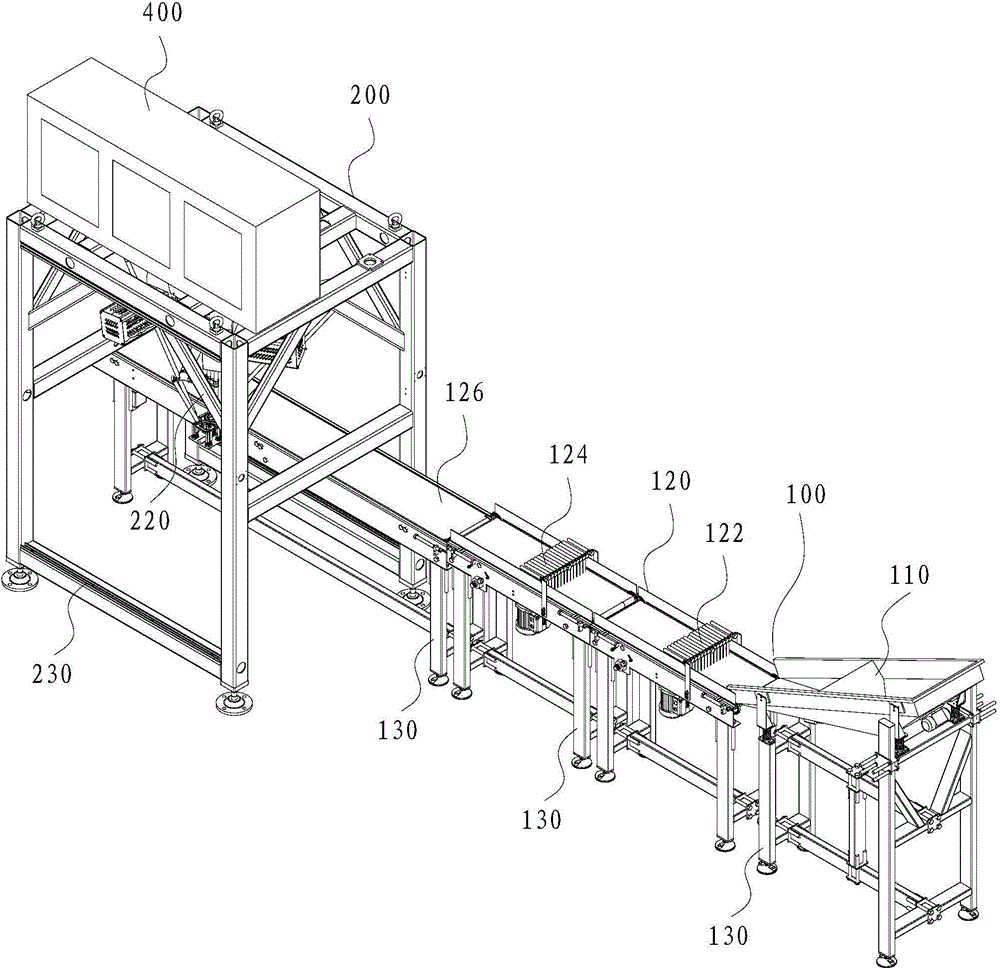

Feeding system and method for block-shaped food

ActiveCN104890936AEnsure food hygiene and safetyGuaranteed quantityPackaging automatic controlEngineeringRobot

The invention provides a feeding system and method for block-shaped food. The feeding system comprises a feeding device, a reclaiming device and a discharging device which are arranged in sequence. The feeding device comprises a vibration feed hopper and an acceleration conveying belt connected with the vibration feed hopper. The reclaiming device comprises a rack arranged at the end of the acceleration conveying belt in a covering mode, a visual identity device arranged above the rack and above the acceleration conveying belt and a reclaiming robot arranged inside the rack. The reclaiming robot is in communicating connection with the visual identity device. The discharging device comprises a trough conveying belt. The end of the trough belt is arranged inside the rack and is arranged below the reclaiming robot. According to the technical scheme provided by the feeding system and method for the block-shaped food, the problems that manually feeding cost for the block-shaped food is high, the efficiency is low, the quality is bad, and the sanitation is bad in the traditional technology in the traditional technology are solved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

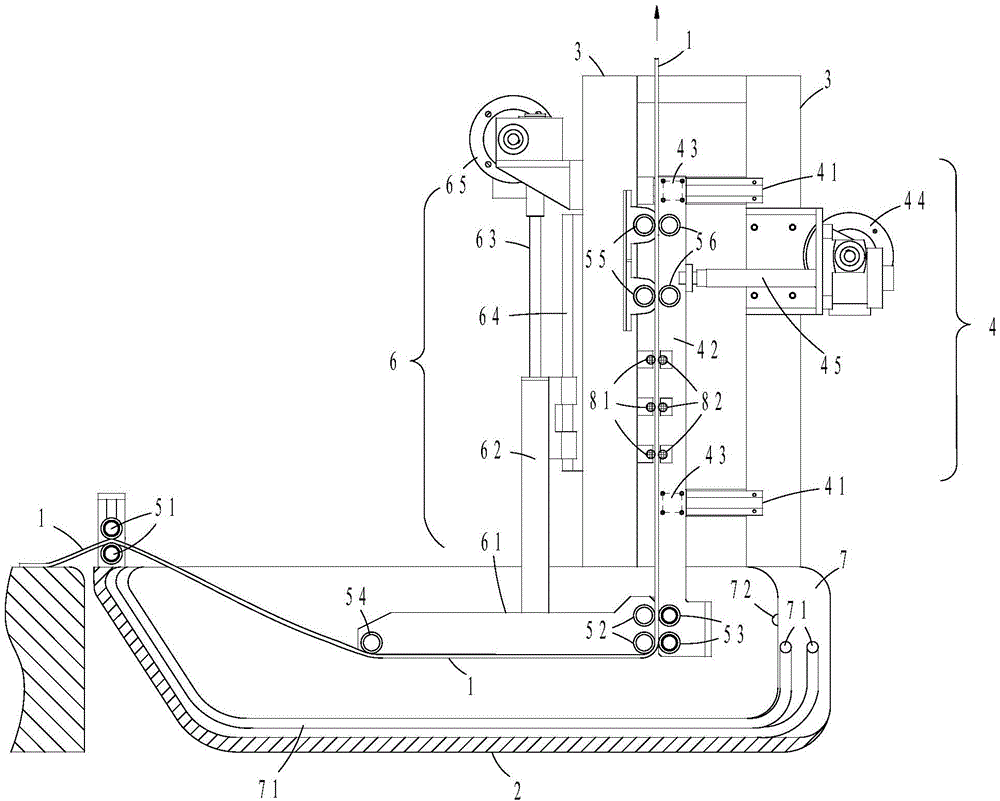

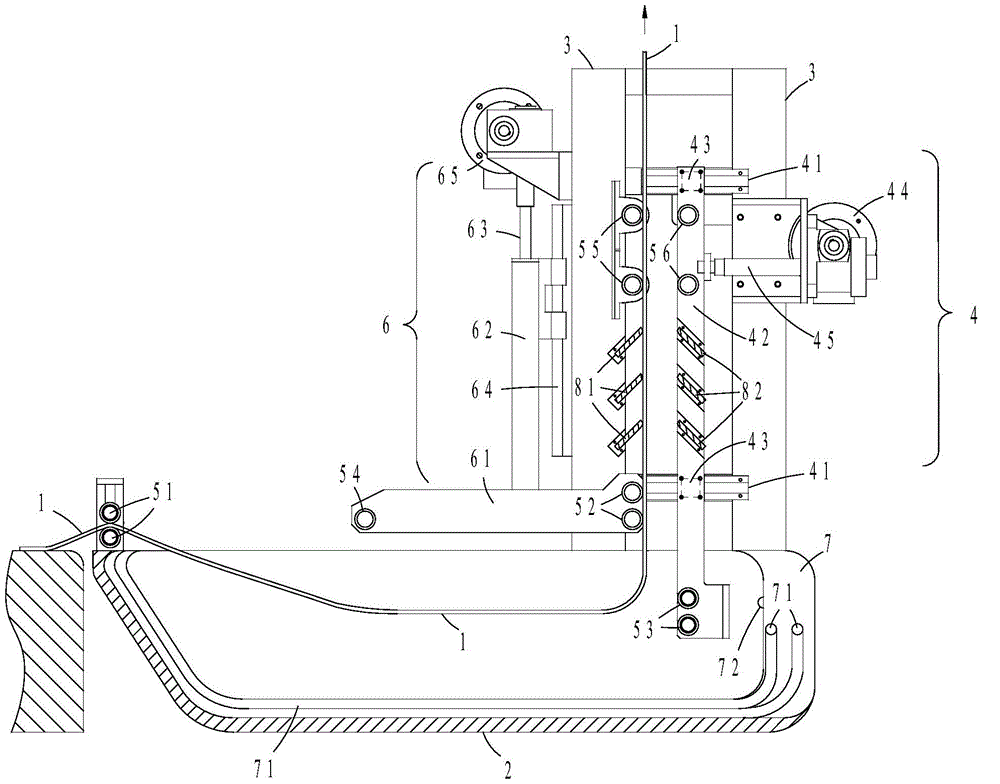

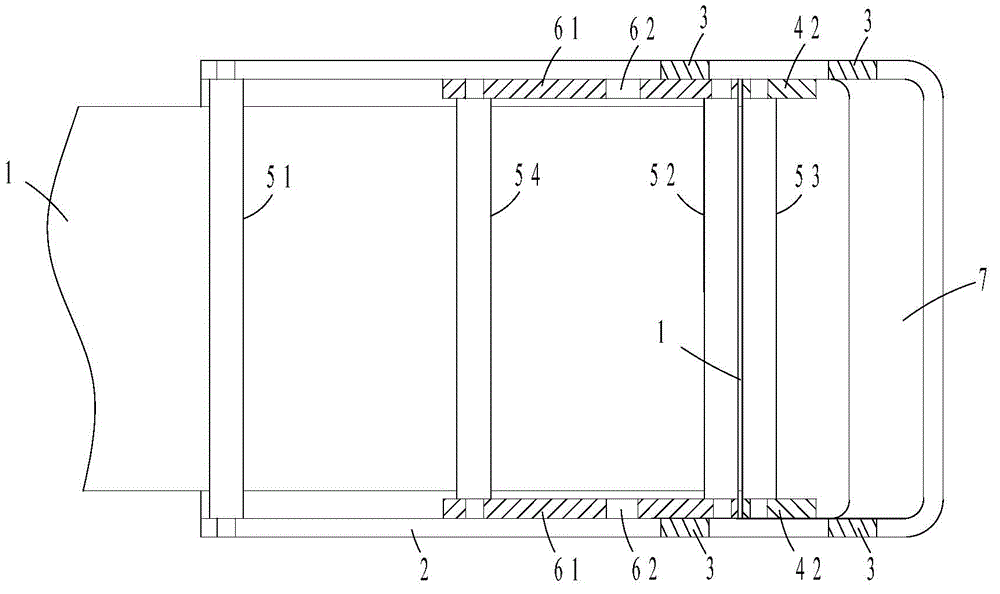

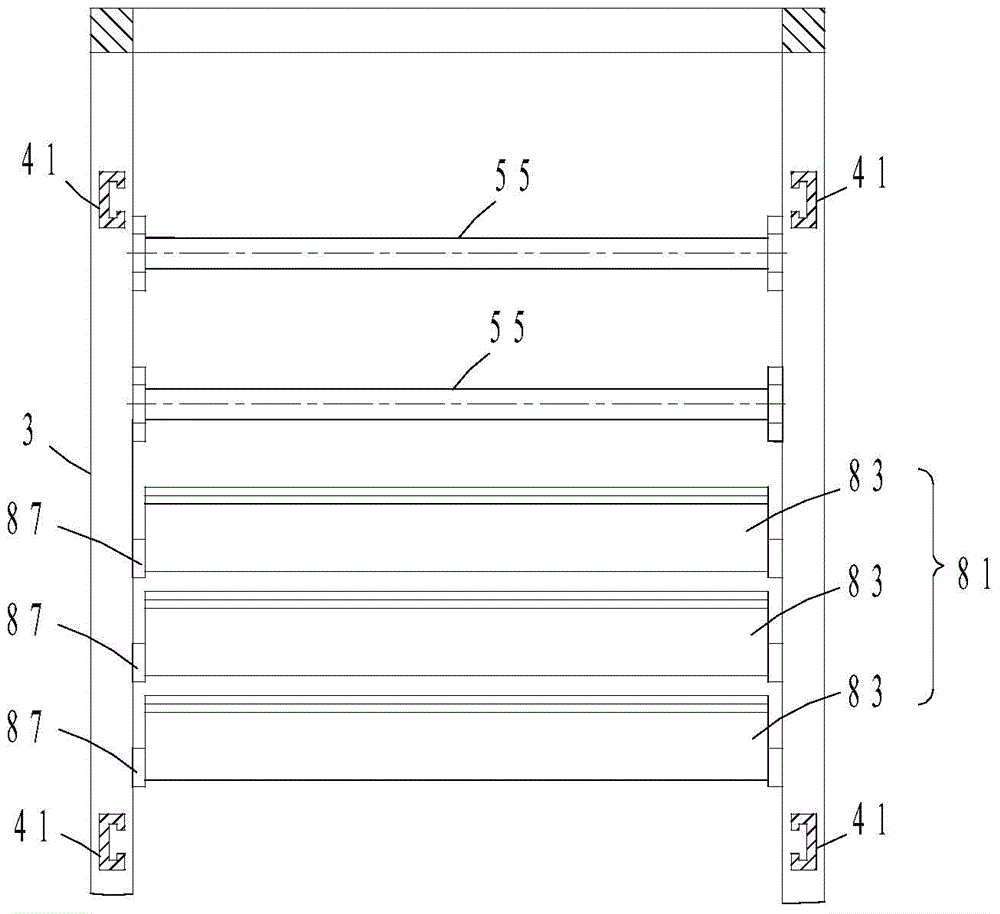

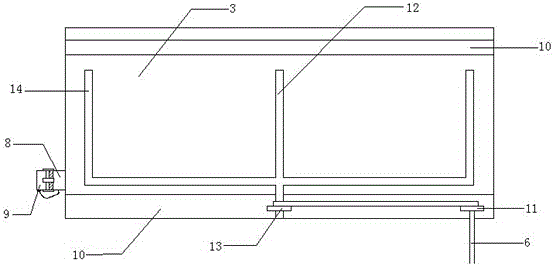

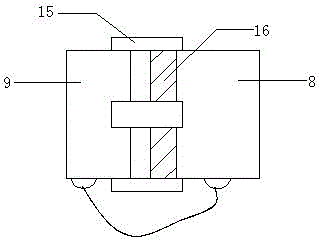

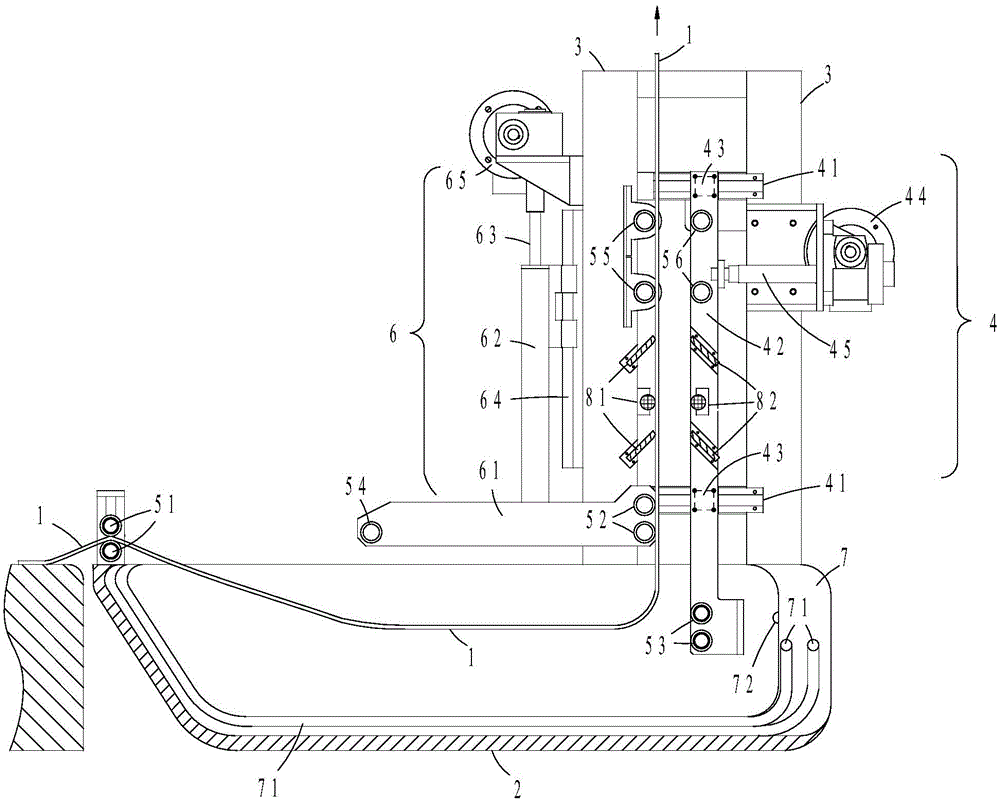

Feeding device for seamless ventilation ducting fabric production

ActiveCN104562718AEasy to pass throughEven scrapingTunnel/mines ventillationTextiles and paperBiochemical engineeringGroup ii

The invention relates to a feeding device for seamless ventilation ducting fabric production. The feeding device comprises a concave tank body, wherein a bracket is arranged on the tank body; a clamping roll group I and a scraper group I are arranged on the bracket; a slidable clamp device is further arranged on the bracket; a clamping roll group II and a scraper group II are arranged on the clamp device; base cloth can pass through a gap between the clamping roll group I and the clamping roll group II and a gap between the scraper group I and the scraper group II; each of the clamping roll group I and the clamping roll group II comprises at least one clamping roll; each of the scraper group I and the scraper group II comprises at least one scraper which adopts a steel wire; a soaking and lifting device capable of lifting relative to the tank body is arranged on the bracket; and a heat conduction box for heating size is arranged on the inner wall of the tank body. The feeding device can perform uniform feeding on seamless ventilation ducting fabric, the gap between the two clamping roll groups and the gap between the two scraper groups are adjustable, so that the requirement for different thicknesses of the size on the base cloth can be met, and the production efficiency is improved; and the scrapers adopt the steel wires, accordingly, the cost is lower, and the replacement is convenient.

Owner:成都众成新型复合材料有限公司

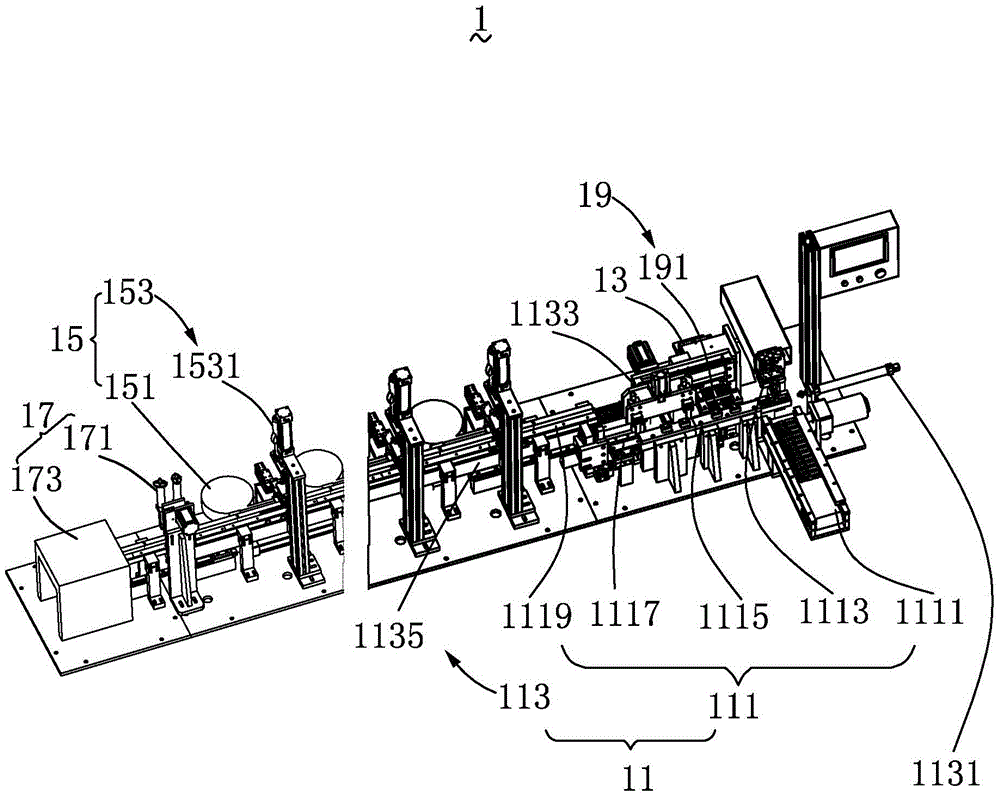

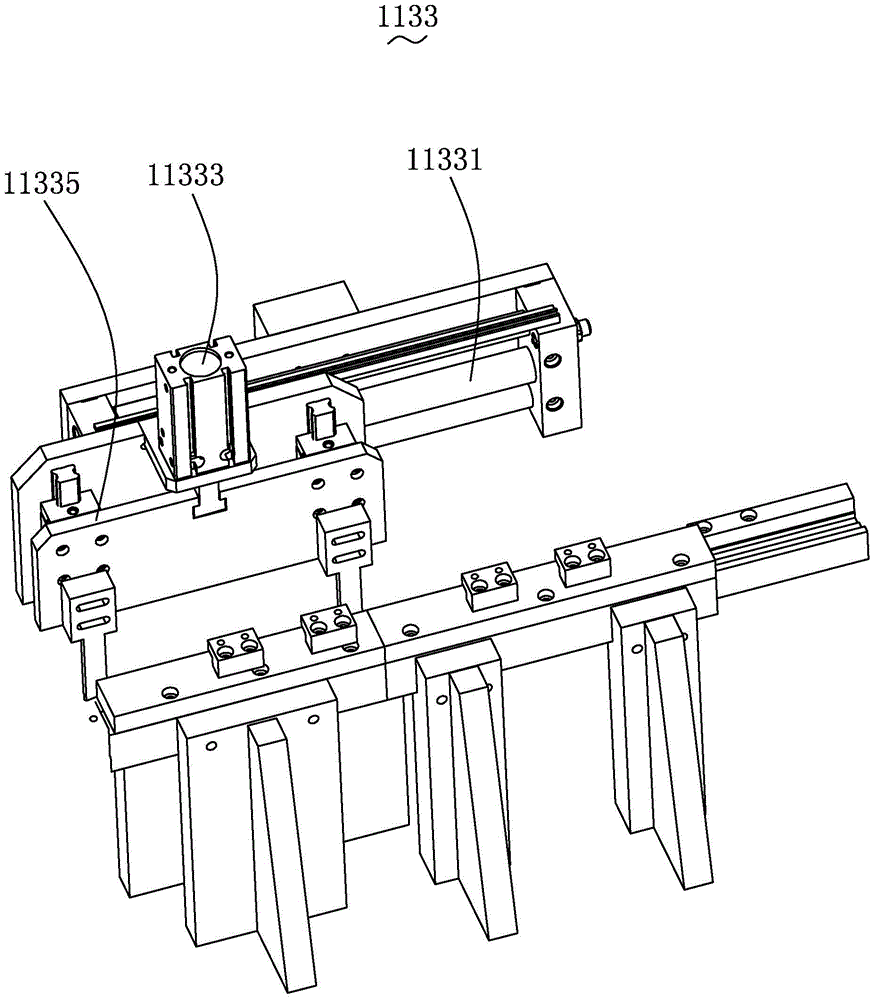

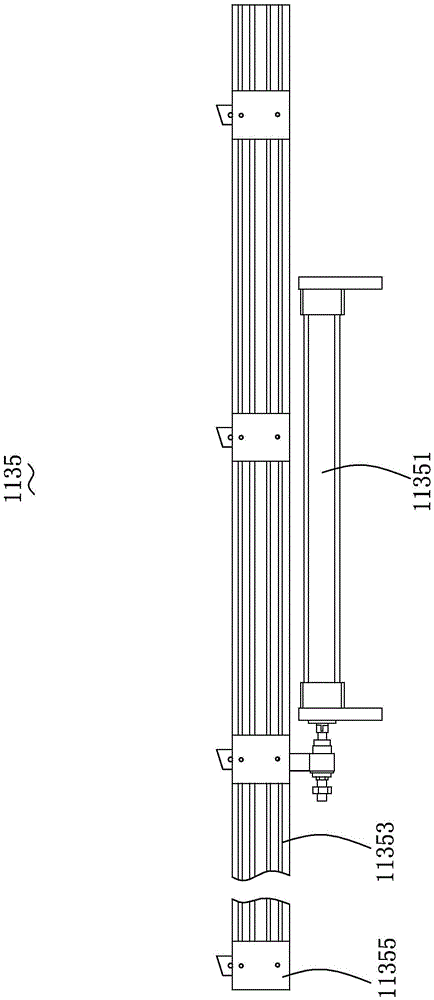

Wiring terminal machining equipment and control system therefor

InactiveCN105610032ACompact structureImprove reliabilityLine/current collector detailsControl systemMachining

The invention provides wiring terminal machining equipment. The equipment comprises a wiring terminal conveying module, a wiring body loading module, a wiring bent piece locking module, and a glue dispensing module. The wiring terminal conveying module comprises a conveying module and a material pulling module, which are arranged cooperatively. The wiring body loading module comprises a wiring body feeding module, a wiring body material pushing module, and a wiring body material receiving module, wherein the wiring body feeding module, the wiring body material pushing module and the wiring body material receiving module are arranged cooperatively. The wiring bent piece locking module comprises a wiring bent piece loading module and a screw locking module, which are arranged cooperatively. The glue dispensing module comprises an automatic dispensing machine and a dryer, which are arranged cooperatively. The invention also provides a control system for the equipment. The equipment and system are simple in structure, are high in reliability, save manpower, are higher in production efficiency, and reduces the production cost.

Owner:NINGBO HUYA AUTOMATION TECH

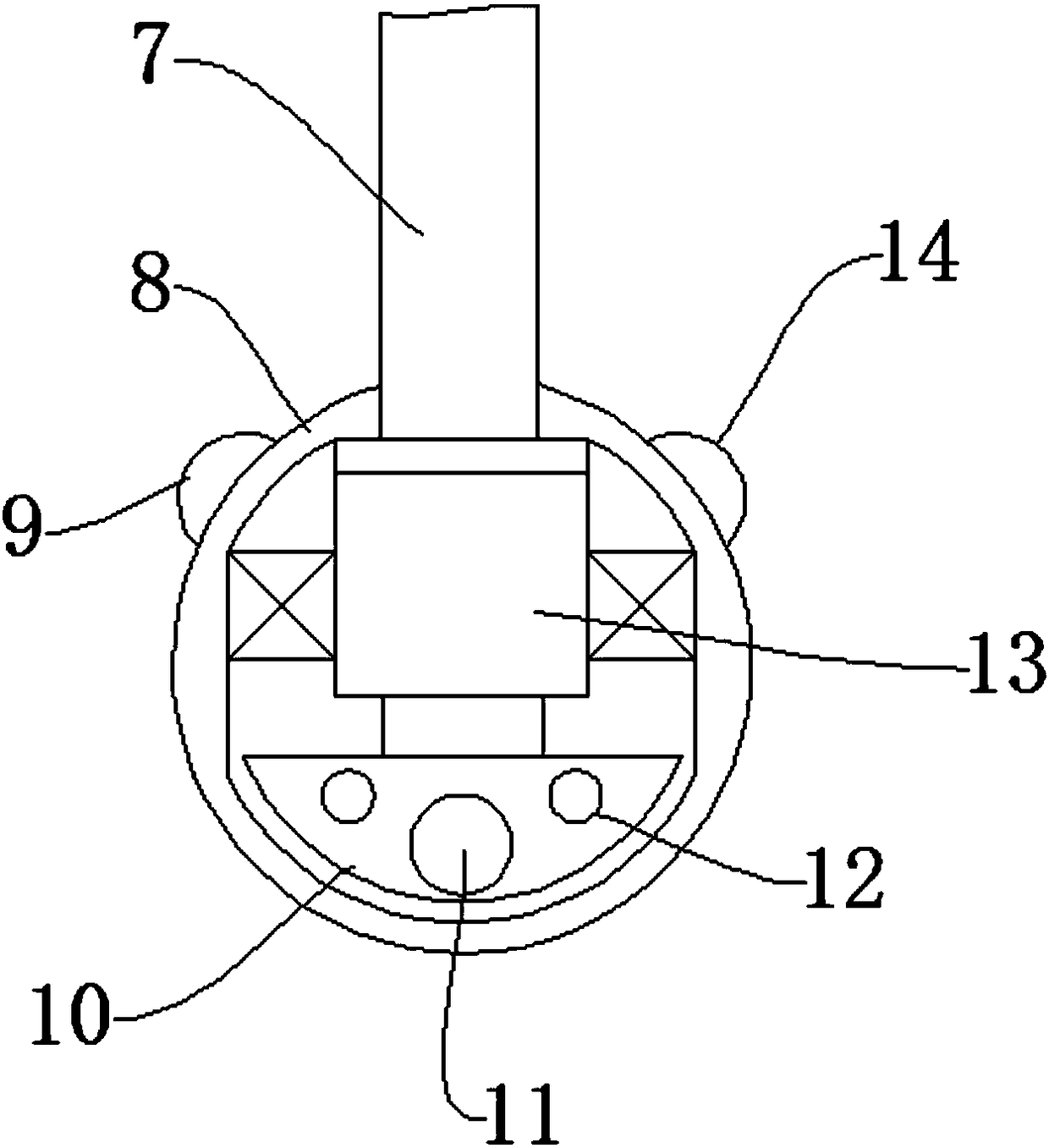

Underwater monitoring device for aquaculture

PendingCN108414024AImprove feeding qualityIncrease shooting areaTransmission systemsTesting waterShoalEngineering

The invention discloses an underwater monitoring device for aquaculture. The underwater monitoring device comprises a solar panel, a control box, a buoyancy plate, a motor and a dissolved oxygen sensor. The control box is mounted in the middle of a supporting frame which is arranged at the bottom of the solar panel, a view window is mounted in the front of the control box, a controller is mountedabove a wireless communication chip which is arranged in the control box, a GPS chip is arranged below the wireless communication chip, and keys are arranged below a display screen which is arranged on the lateral side of the wireless communication chip. The underwater monitoring device for aquaculture has advantages that by underwater temperature and oxygen content detection, fish feeding qualityis improved for fishermen; shoals of fish can be observed through a camera, a shooting area of the camera is expanded through a motor, and accordingly practicality of the device is improved.

Owner:王爱金

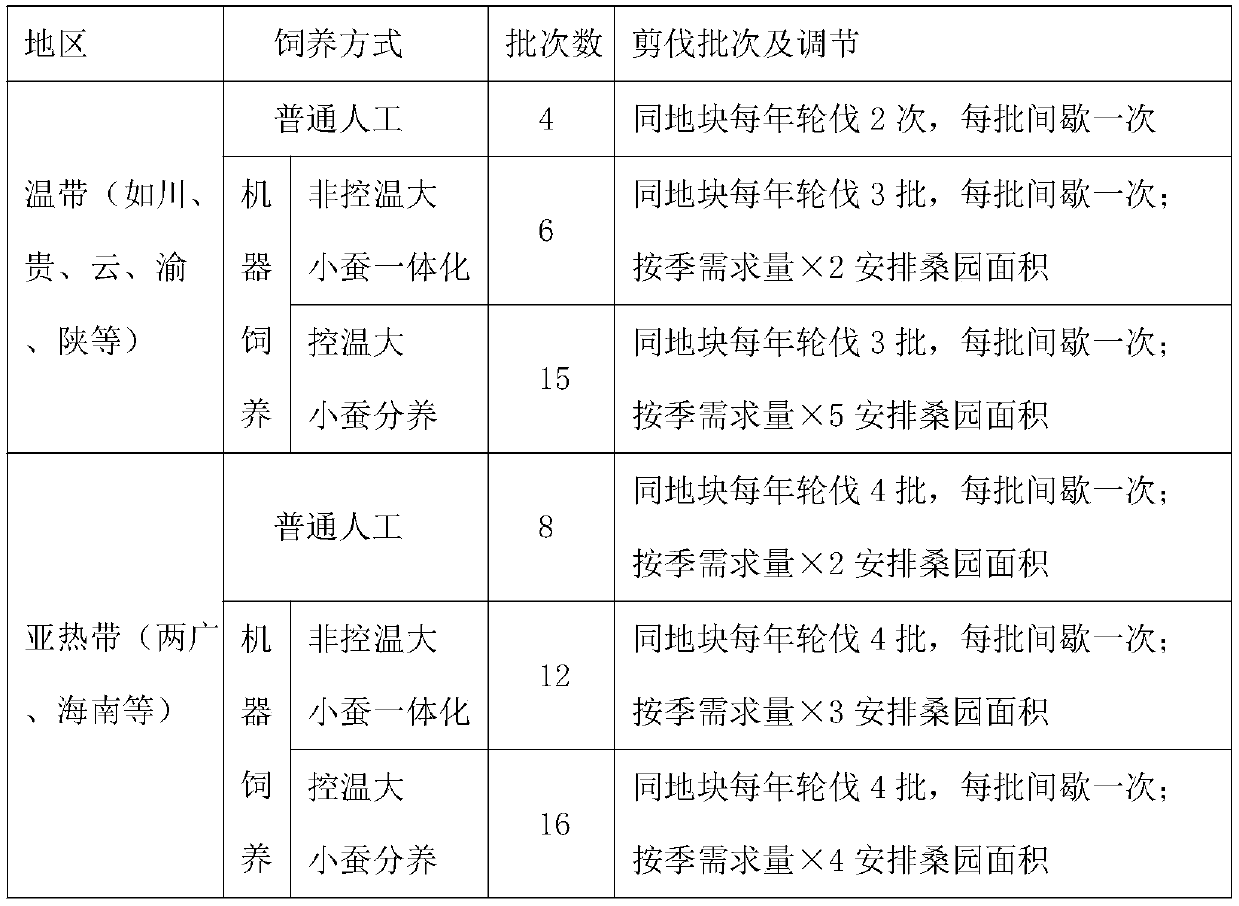

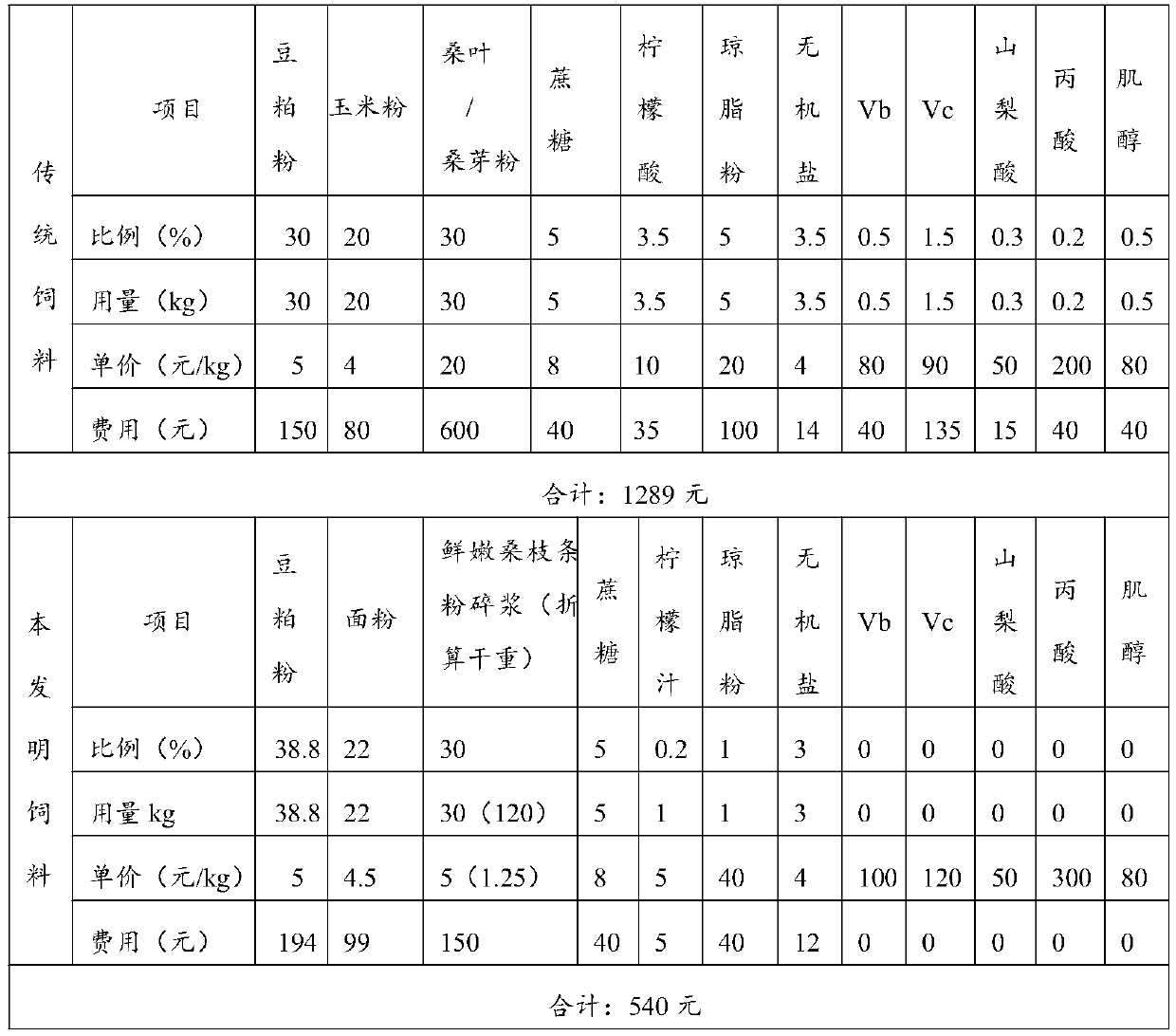

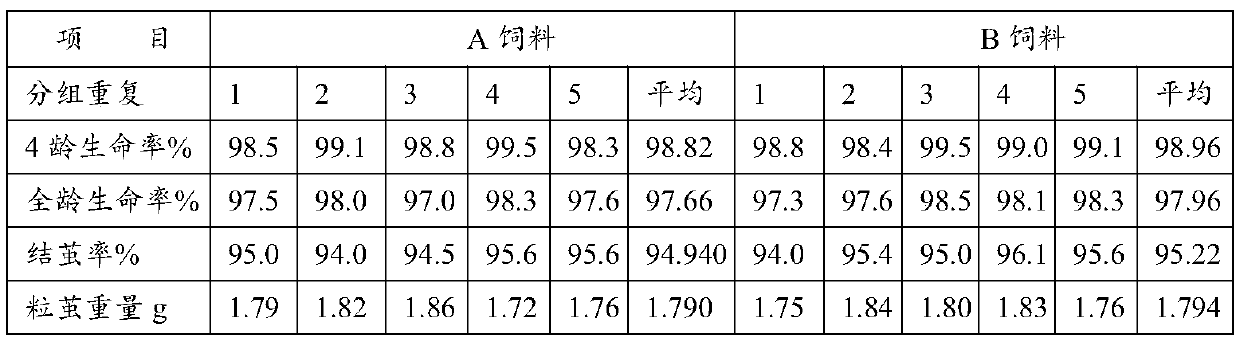

Ultra-low-cost artificial feed for silkworms and preparation method and use method thereof

The invention relates to the technical field of silkworm breeding, and discloses an ultra-low-cost artificial feed for silkworms and a preparation method and use method thereof. The preparation methodcomprises the following steps: kneading fresh and tender crushed mulberry twig pulp, freshly-squeezed lemon juice, soybean meal, flour, cane sugar, agar powder and inorganic salt into a dough-shapedmixture, extruding the mixture into strip-shaped artificial feed by an extruder, and laying the feed on a silkworm rearing bed for silkworm rearing. The fresh and tender crushed mulberry twig pulp isused for replacing mulberry leaf powder, the freshly-squeezed lemon juice is used for replacing a preservative, the soybean meal and other raw materials are added to prepare the artificial feed on site, heating and drying are not needed during preparation, the raw material and processing costs of the artificial feed are greatly reduced, and vitamins, food calling components and other nutrient substances in mulberry twigs and leaves cannot be damaged by high temperature; the tender mulberry twigs provide cellulose for the artificial feed, so that the feeding habit, main nutrients and physiological growth requirements of silkworms are met; and an atomization humidifier is used for humidifying silkworm breeding rooms, the problem that silkworms cannot eat due to the fact that artificial feedbecomes hard after moisture is evaporated is avoided, the input amount is reduced, and the cost is further reduced.

Owner:SICHUAN ACAD OF AGRI SCI SERICULTURE INST

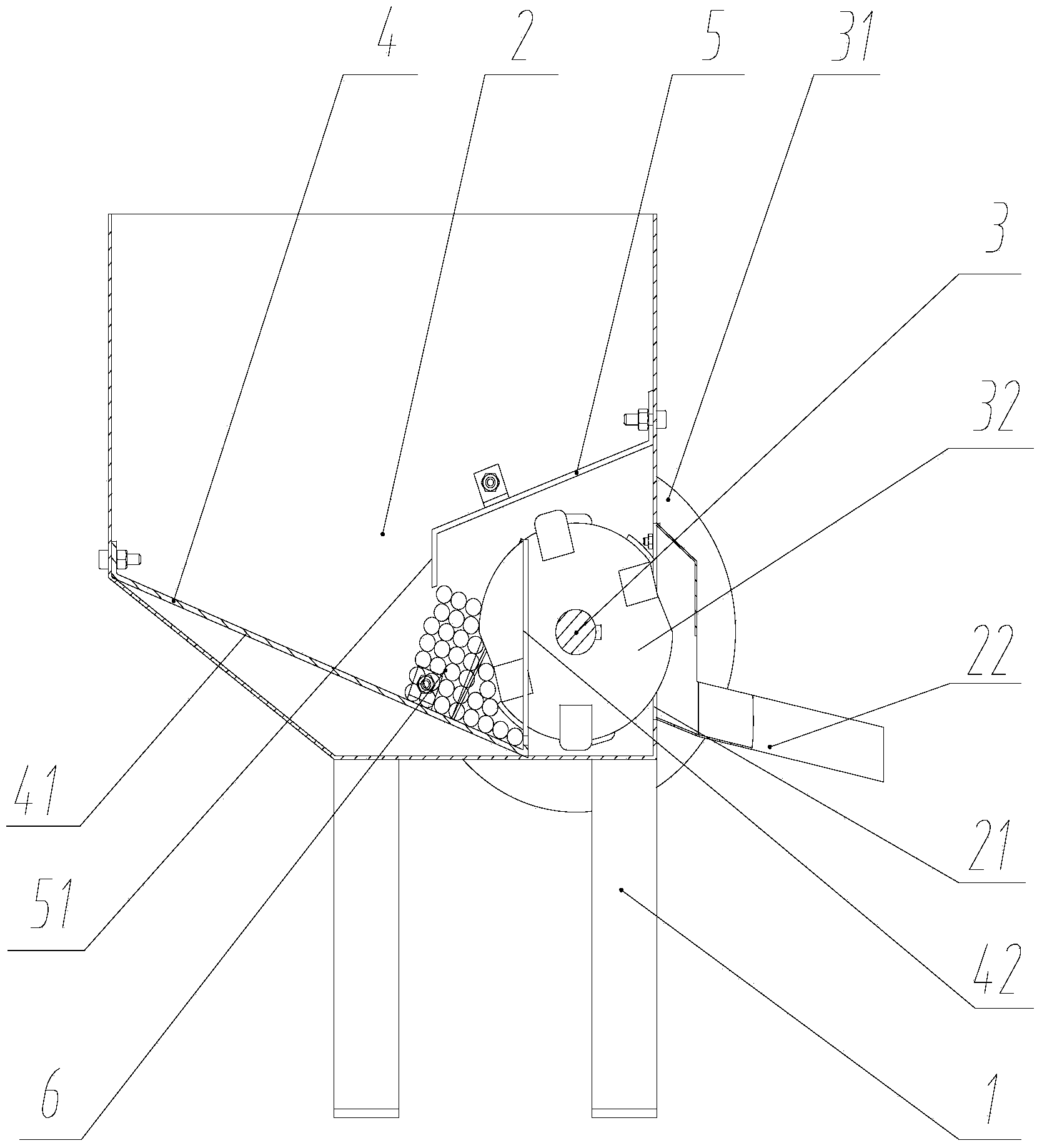

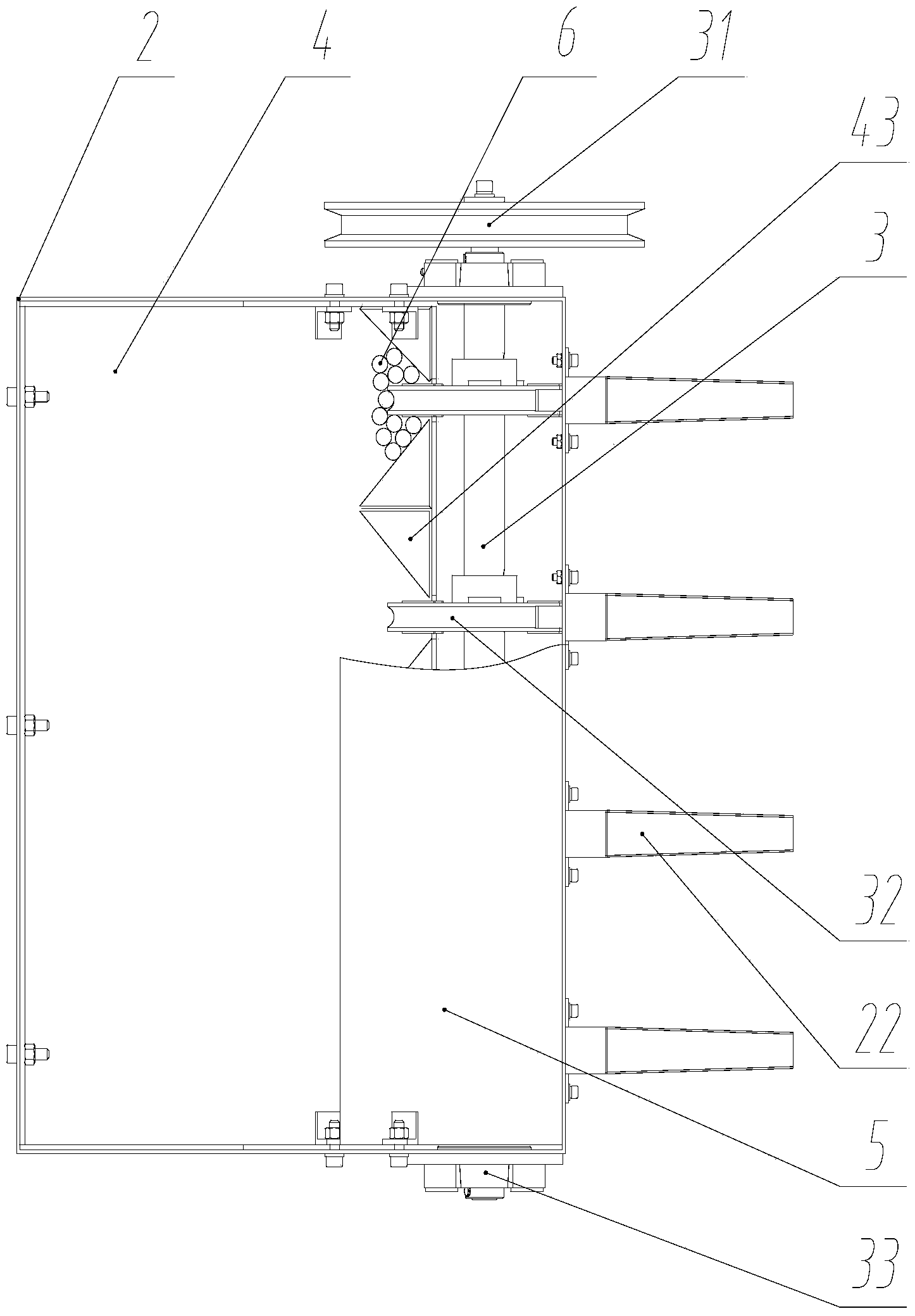

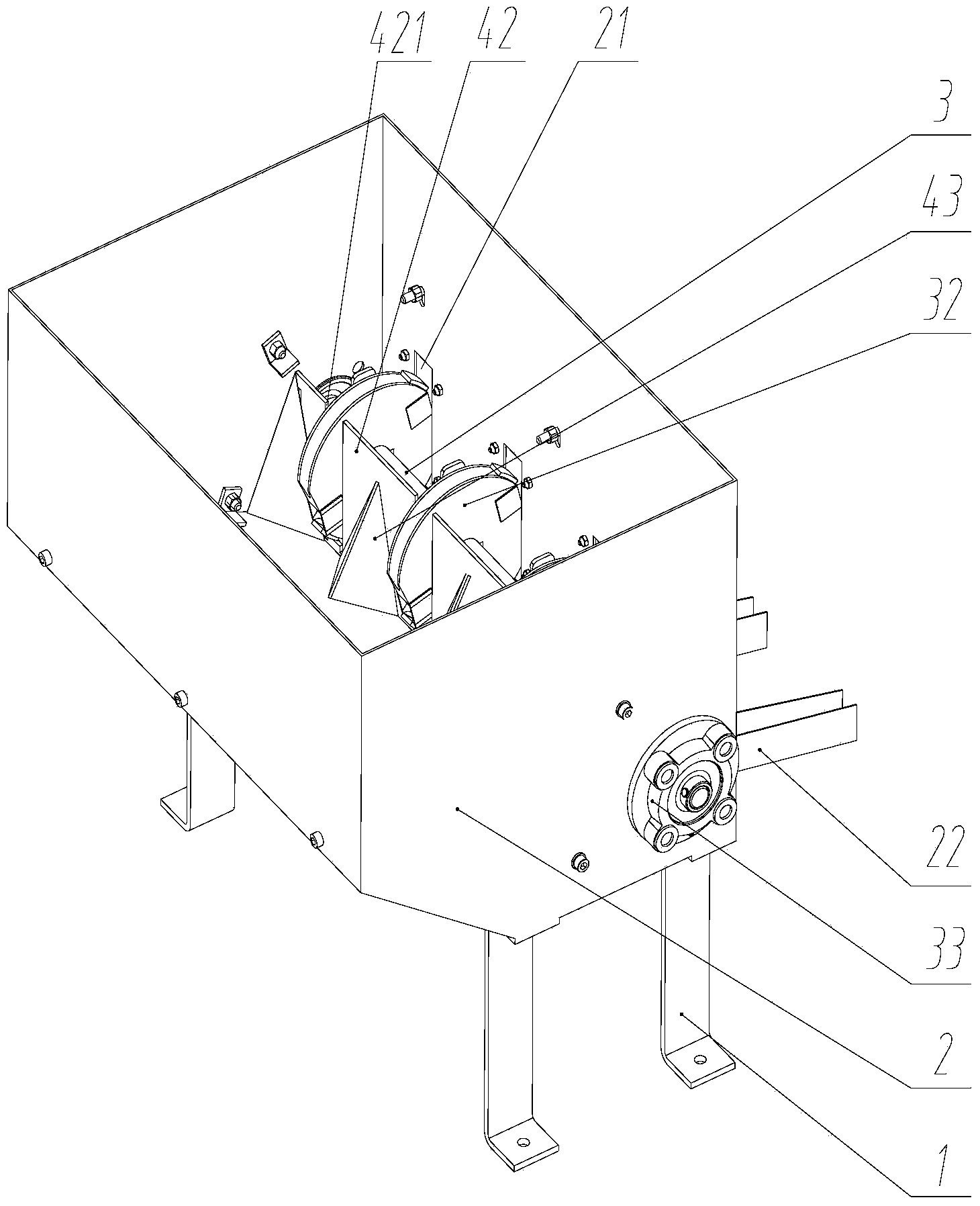

Quantitative feeding device for lotus seed processing equipment

The invention discloses a quantitative feeding device for lotus seed processing equipment. The quantitative feeding device for the lotus seed processing equipment comprises a feeding hopper and a rotation feeding mechanism. The rotation feeding mechanism is arranged on the bottom in the front of the feeding hopper and comprises a main shaft, the two ends of the main shaft are supported by bearing seats, a belt wheel is arranged at one end of the main shaft, at least one material grabbing disc is arranged on the main shaft in the feeding hopper, openings corresponding to the material grabbing disc are formed in a vertical plate of lining plates and the front side wall of the feeding hopper, the material grabbing disc penetrates through the two openings, a discharging chute is formed in the bottom of the outer side of the front side wall of the feeding hopper, and the opening in the front side wall of the feeding hopper is communicated with the discharging chute. At least one groove is formed in the contour of the material grabbing disc, side plates are arranged on the two sides of the groove, and an auxiliary feeding plate is arranged at the inlet end of the groove in the circumferential direction. Circular-arc grooves are formed in the circumferential face of the material grabbing disc. The quantitative feeding device for the lotus seed processing equipment can feed materials evenly and quantitatively to the lotus seed processing equipment, the phenomenon that multiple lotus seeds are fed at one time can be avoided effectively, and the feeding quality and the feeding efficiency of the quantitative feeding device for the lotus seed processing equipment and the quality of the processed lotus seeds are improved.

Owner:XIANGTAN UNIV

Process method for producing lubricating oil base oil through poor-quality raw material

ActiveCN104611047AFully activeExpand sourceTreatment with hydrotreatment processesLubricant compositionCounter flowHydrogenation reaction

The present invention discloses a process method for producing lubricating oil base oil through a poor-quality raw material. According to the process method of the present invention, a poor-quality raw material firstly enters a first-stage reaction zone to carry out a hydrorefining reaction, a co-current flow process and a counter flow process are concurrently adopted in the first stage, the generated oil obtained in the first stage enters a second-stage reaction zone to carry out a deep hydrogenation reaction, and the second-stage reaction effluent is subjected to hydrocracking; and the cracking tail oils are subjected to cutting pre-fractionation to obtain the suitable tail oil distillate, and the suitable tail oil distillate is subjected to an isomerizing dewaxing and finishing reaction to obtain the lubricating oil base oil distillate. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the lubricating oil base oil raw material source is broadened; and the operation period of the device can be increased and the poor-quality raw material can be processed, or the processing capacity of the device can be increased in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

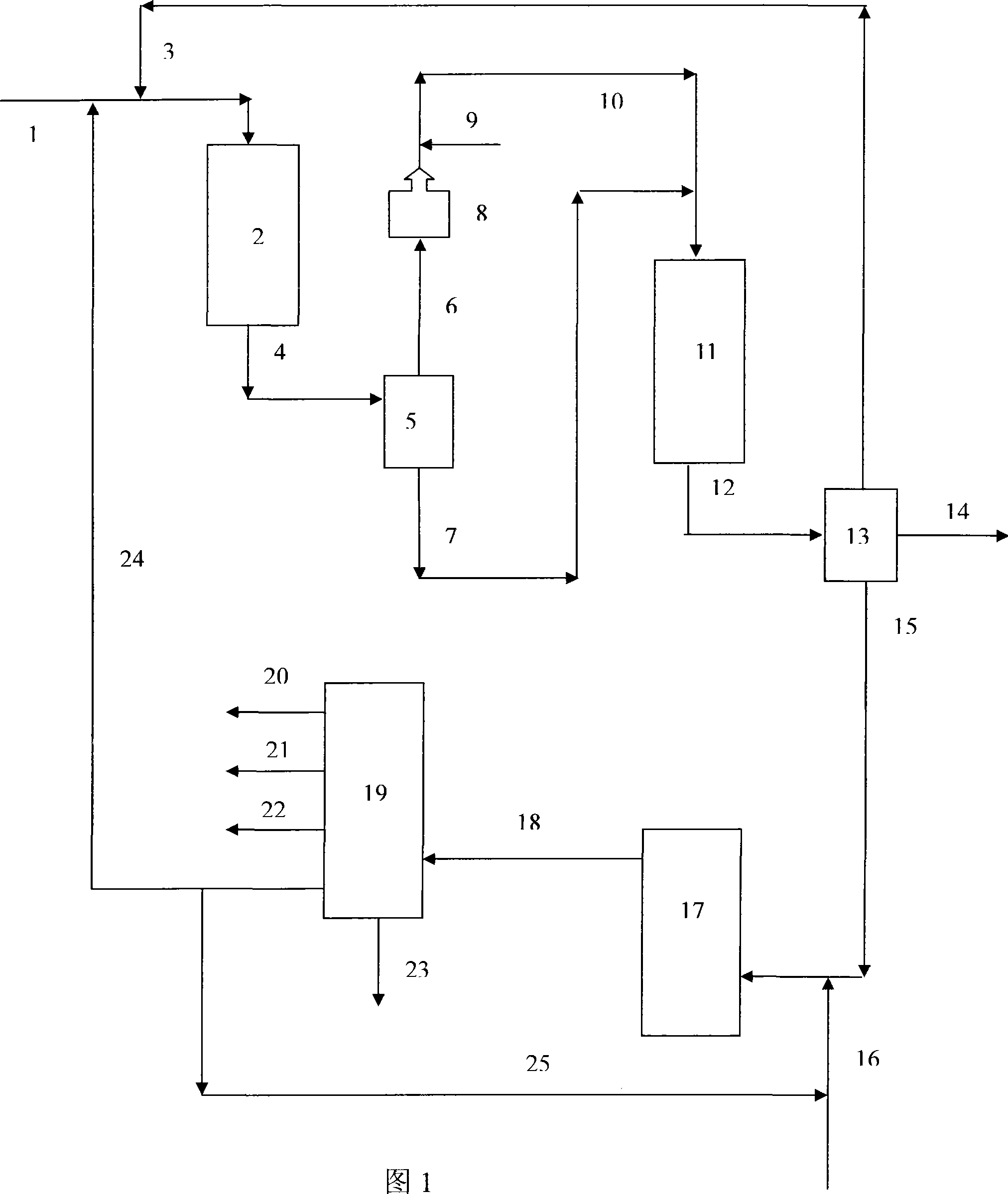

Heavy distillate hydrogenation and catalytic cracking combined method

ActiveCN101434866AIncrease throughputImprove product qualityTreatment with hydrotreatment processesHydrogenSulfur

The invention relates to a combination method of hydrogenation disposal and catalytic cracking used for heavy distillate oil. Under the hydrogenation disposal condition, the heavy distillate oil is used as raw material oil, and the raw material oil and hydrogen are mixed and pass by a first hydrogenation disposal reaction area, thus generating oil by hydrogenation disposal; the oil is separated to obtain the gas which is then desulfurized; the gained liquid is mixed with hydrogen desulfurized and pressurized by a circular hydrogen compressor and then passes by a second hydrogenation disposal reaction area, thus generating the oil by the hydrogenation disposal; the oil is separated to gain the gas which enters the first hydrogenation disposal reaction area directly; and the gained liquid is fractionated in a fractionating tower to gain the low-sulfur light oil product and heavy oil product. The heavy oil product can be independently catalytically cracked or mixed with other heavy raw material oils and then catalytically cracked, thus obtaining various light oil products and circular oil; and the circular oil can be circulated and returned to the catalytic cracking process and also can enter the hydrogenation disposal process. Compared with the prior art, the method effectively improves the hydrogenation disposal depth of the raw material oil, needs only one circular hydrogenation system for two hydrogenation disposal reaction areas, has low investment of equipment, low operation expense, and can directly produce clean gasoline and diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

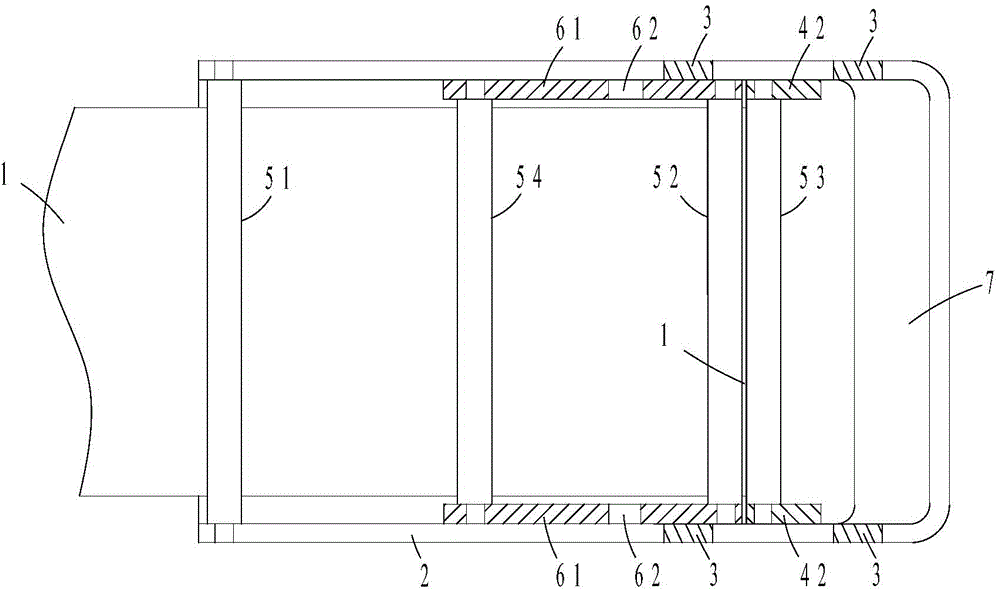

Feeding system for production of seamless air duct cloth

ActiveCN104562496AEasy to pass throughMeet the needs of different thicknessTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentMechanical engineeringPhysics

The invention relates to a feeding system for production of seamless air duct cloth. The feeding system comprises a tank body, wherein a bracket is arranged on the tank body; a clamping roller group I and a scraping blade group I are arranged on the bracket; a slidable clamp device is further arranged on the bracket; a clamping roller group II and a scraping blade group II are arranged on the clamp device; each of the clamping roller group I and the clamping roller group II comprises at least one clamping roller; each of the scraping blade group I and the scraping blade group II comprises at least one scraping blade; the end, in contact with base cloth, of each scraping blade is inclined in the moving direction of the base cloth; the included angle between each scraping blade and the base cloth is smaller than 90 degrees; a liftable prepreg lifting device is arranged on the bracket; a heat conduction box for heating a sizing agent is arranged on the inner wall of the tank body. The feeding system can uniformly feed the seamless air duct cloth, can adjust the interval between two clamping roller groups as well as between the two scraping blade groups, is reliable in scraping, can meet the requirement for different thicknesses of the sizing agent fed on the base cloth and improves the production efficiency; the scraping blades are connected with compression springs, so that damage to the base cloth can be reduced.

Owner:成都众成新型复合材料有限公司

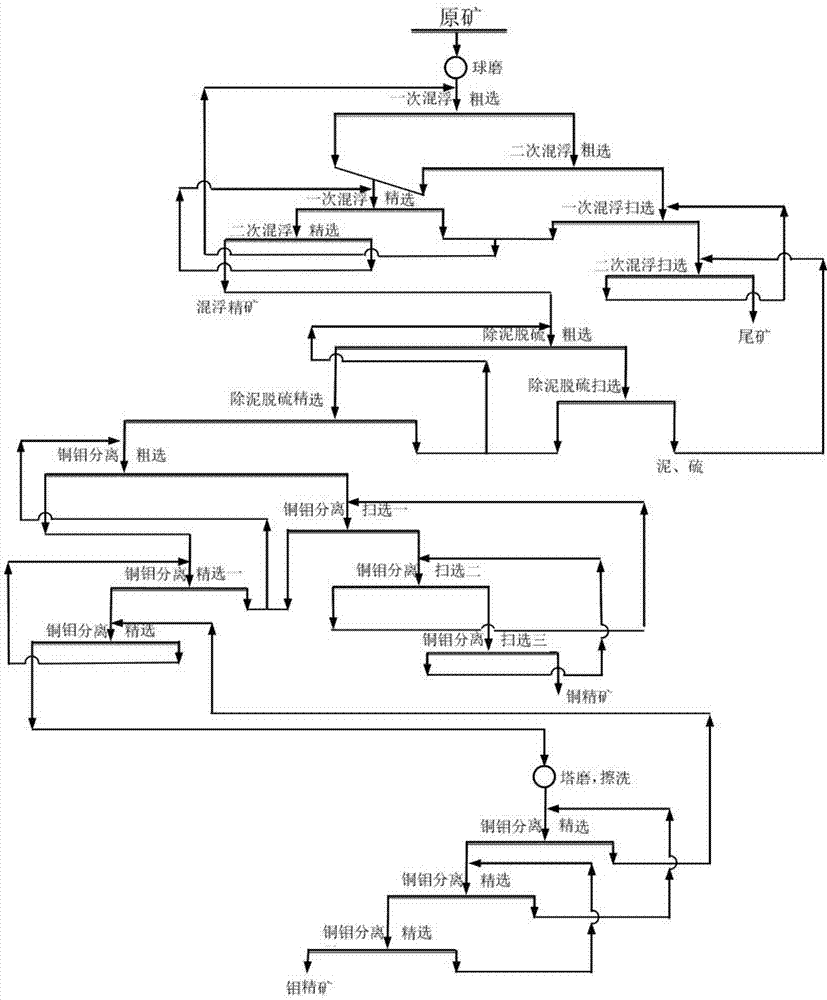

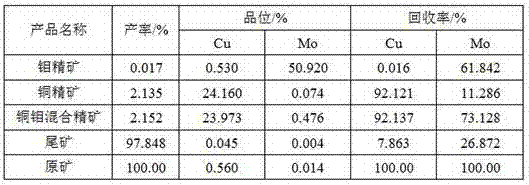

Method for separating copper and molybdenum from slime-containing sulfur-containing low-grade copper-molybdenum ore

ActiveCN107971124AFavorable mixed harvestAvoid a lot of floatingFlotationWet separationPyriteLower grade

The invention discloses a method for separating copper and molybdenum from slime-containing sulfur-containing low-grade copper-molybdenum ore. The process flow of the method sequentially comprises anore grinding process, a copper molybdenum mixed flotation process, a desliming and desulfurizing process and a copper molybdenum separation flotation process; the copper molybdenum mixed flotation process comprises a mixed floatation rough floatation procedure, a mixed floatation scavenging floatation procedure and a mixed flotation fine floatation procedure; and the desliming and desulfurizing process comprises at least one-time desliming and desulfuration rough floatation procedure, at least one-time desliming and desulfuration scavenging floatation process and at least one-time desliming and desulfurizing fine floatation process. According to the method, when the raw ores contain a lot of slime and pyrite, the technical means can be applied to achieve the effect of throwing and removingthe slime and the pyrite in the copper-molybdenum mixed concentrate so that the relatively pure copper-molybdenum mixed concentrate can be provided for subsequent operation of the copper-molybdenum separation, the aim of the subsequent operation of copper-molybdenum separation can be smoothly realized, the qualified copper concentrate and the qualified molybdenum concentrate can be obtained, andthe recovery of useful metals is not affected at the same time.

Owner:TIBET HUATAILONG MINING DEV

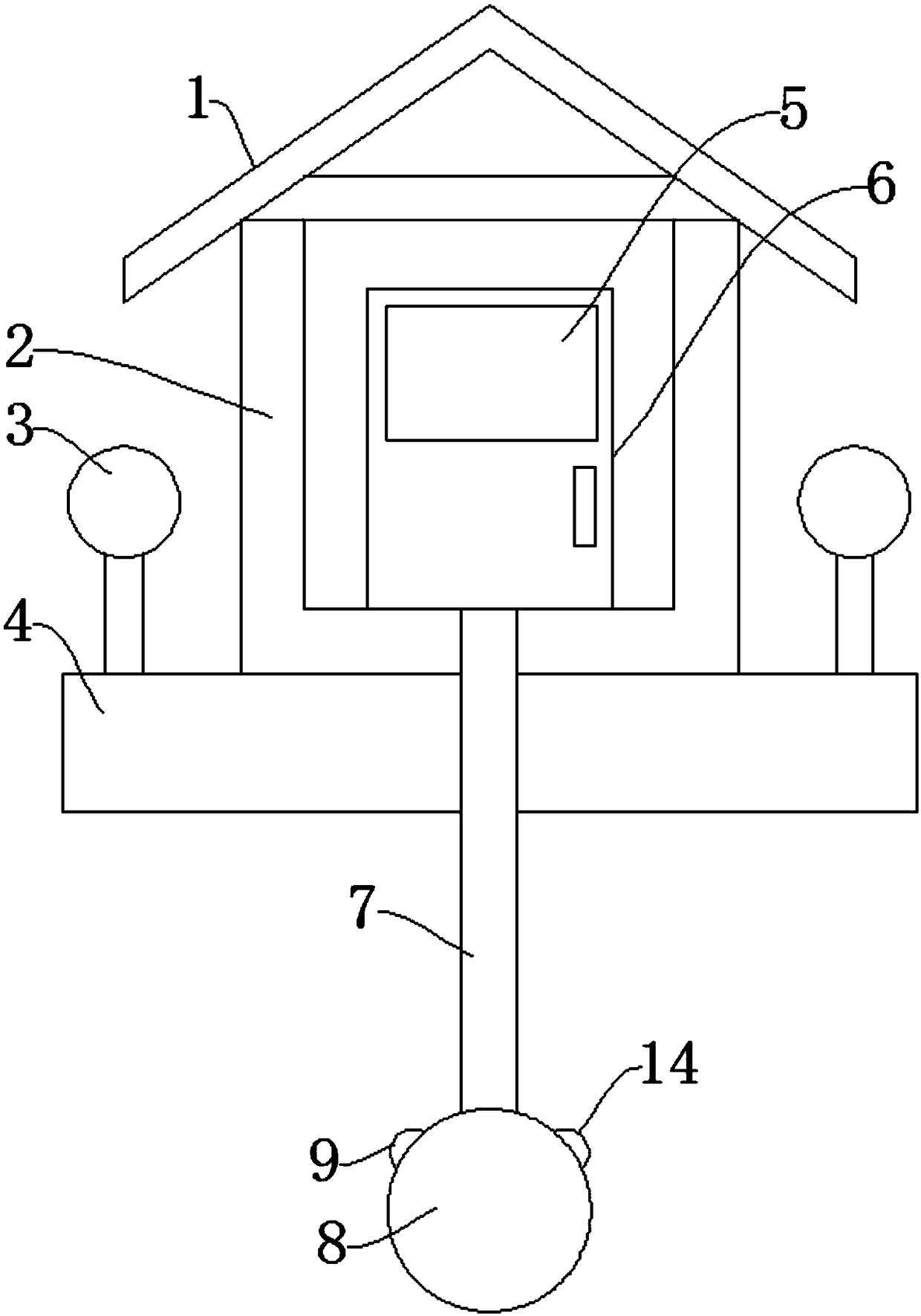

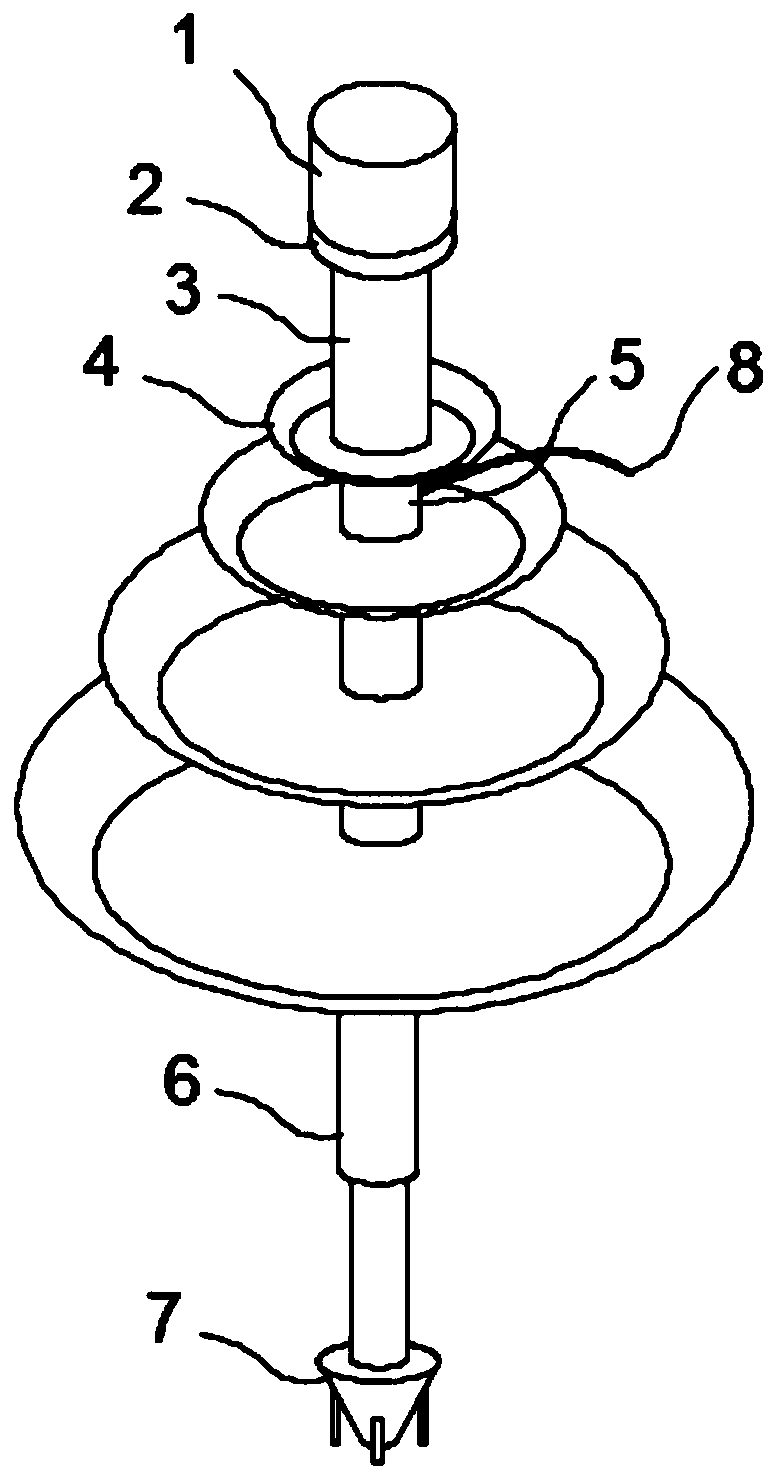

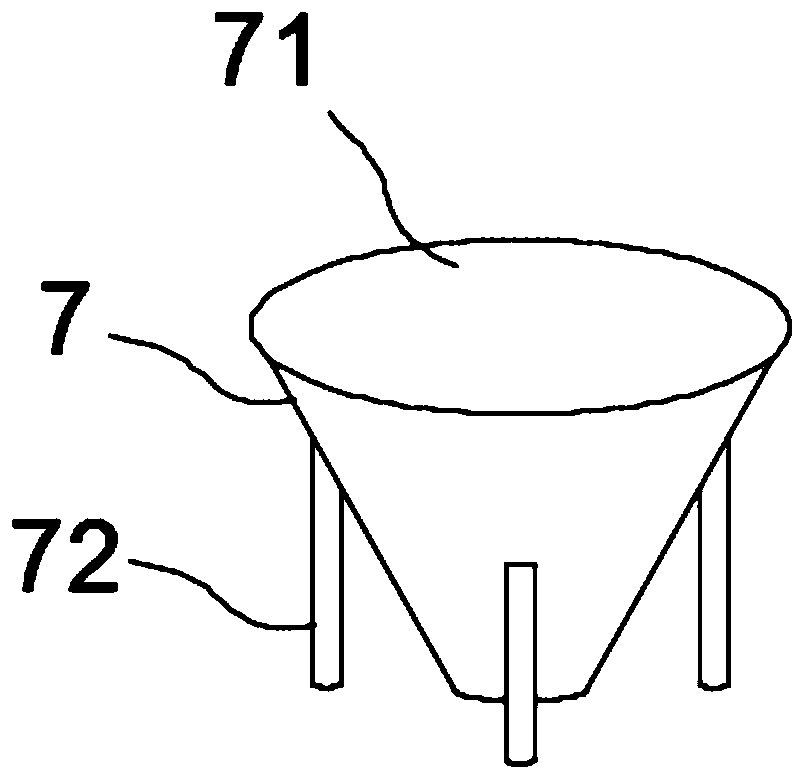

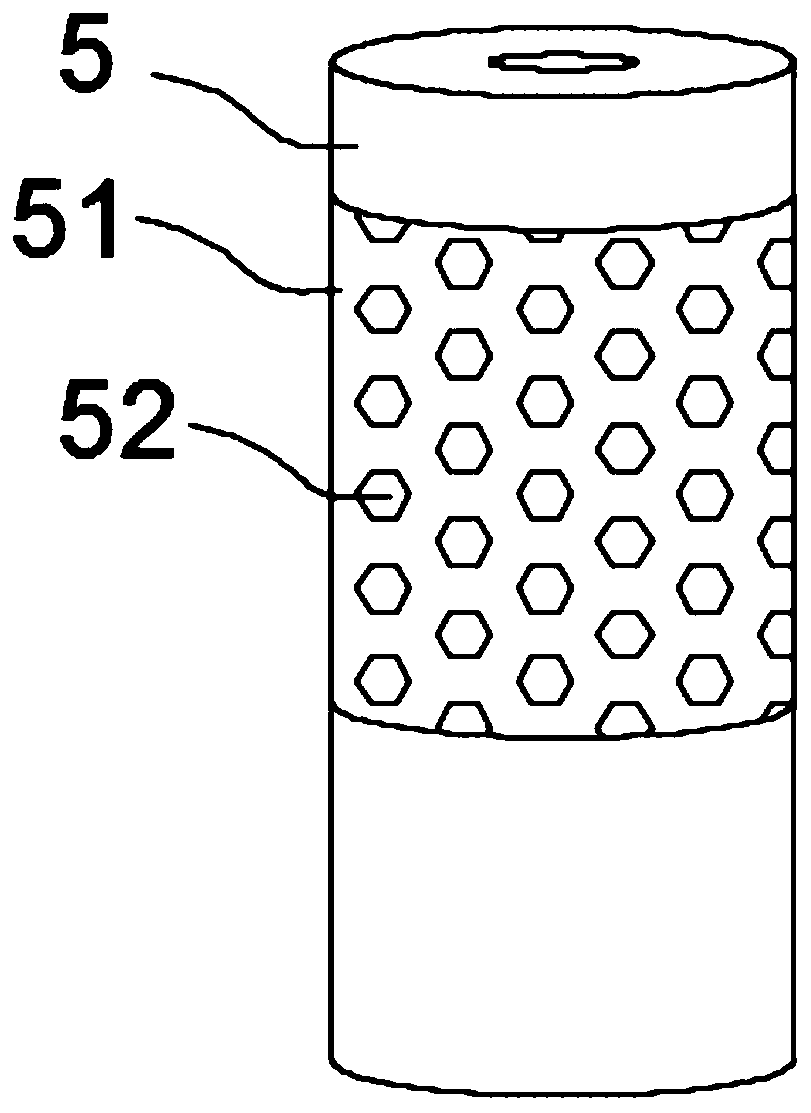

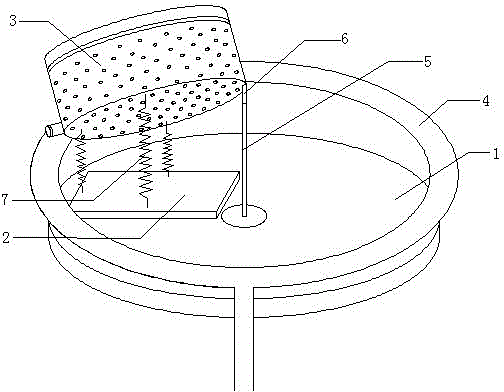

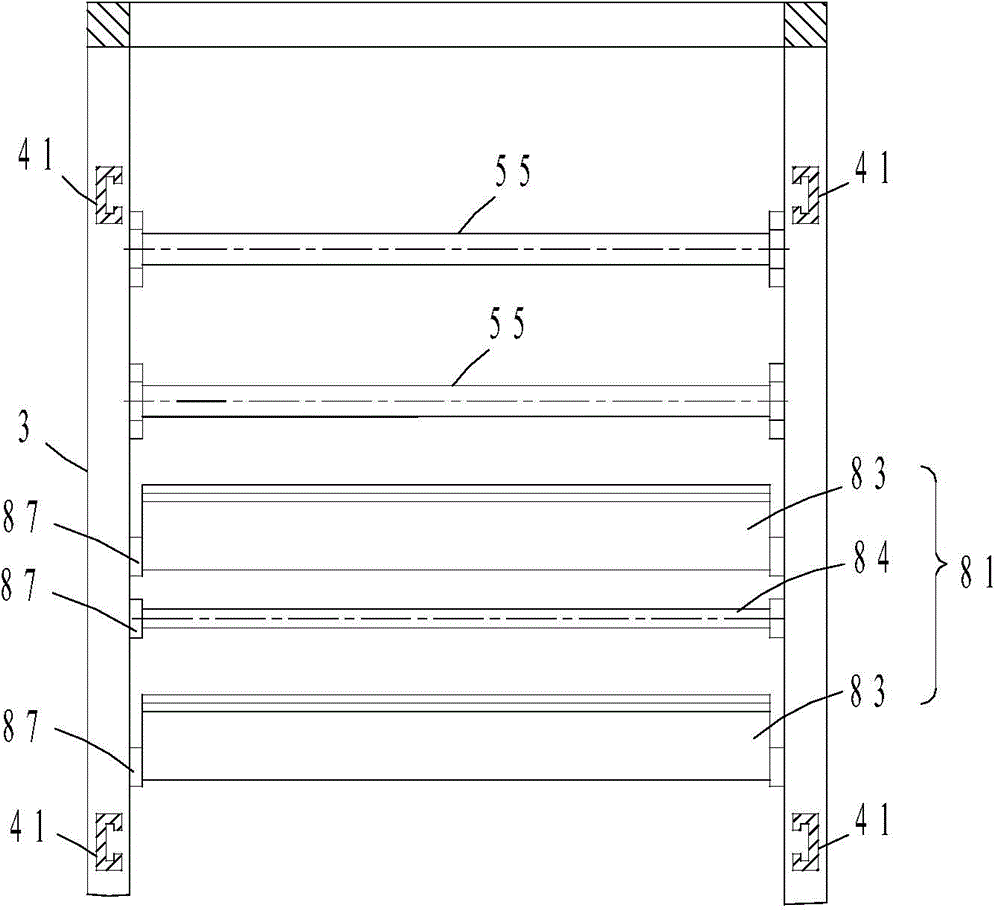

Breeding supply stand for fish breeding

InactiveCN110999842APrevent fallingImprove feeding qualityClimate change adaptationPisciculture and aquariaFisheryZoology

The invention particularly discloses a breeding supply stand for fish breeding and belongs to the technical field of breeding. The breeding supply stand comprises feeding discs, wherein the feeding discs are fixed through a fixing column; a support column is fixed at tops of the feeding discs; a feeding machine is mounted on the support column on one side far away from the feeding discs; a feed tank is mounted on the feeding machine; a plurality of the feeding discs are provided and are connected through connecting tubes; and diameter lengths of opening discs of the plurality of the feeding discs are sequentially increased from top to bottom. The plurality of the feeding discs are mounted at the bottom of a pond through the fixing column, fish feeds are fed into the feeding machine throughthe feed tank and are cast to water surfaces, fish feeds which are not eaten in time are dropped onto the plurality of the feeding discs that the diameter lengths of the opening discs are sequentially increased from top to bottom in layers, then the fish feeds can be prevented from falling to the bottom of the pond and can be eaten by fishes for a second time, the feeding quality is high, and thecost can be reduced.

Owner:郭娟

Treatment of Phenol

ActiveUS20100280285A1Easy to handleOutput maximizationPhysical/chemical process catalystsOrganic chemistryExtractive distillationHigh pressure

A process for the removal of by-products from a phenolic mixture, which process may include the following steps: subjecting a phenolic mixture to extractive distillation to produce an initial phenolic mixture, contacting the initial phenolic mixture containing phenol and one or more by products with a catalyst to produce a first purified phenol product mixture, and distilling the first purified phenol product mixture to produce a second purified phenol product mixture; wherein the extractive distillation is carried out in two columns, a higher pressure column and a lower pressure column.

Owner:BOREALIS TECH OY

Method for breeding experimental macaca mulatta

InactiveCN104521892AImprove feeding qualityHigh reproductive rateAnimal husbandryPregnancy rateMacaca majori

The invention provides a method for breeding experimental macaca mulatta. The mode of female money single-cage raising and regular mating is adopted in the mating period, the mode that infant monkeys and a female monkey are raised in a concentrated mode in the lactation period and an adult male monkey is isolated is adopted, the monkey group fighting problem is effectively solved, the infant monkeys are raised in a single-breeding monkey cage in the ablactation period, the breeding quality is further improved, and the health condition of the macaca mulatta can be discovered and managed in time. The breeding rate and the pregnancy rate of the macaca mulatta are further improved, the phenomenon that the female monkey of the right age is infertile in the breeding period is greatly reduced, the oestrus, mating and farrowing activities of personal macaca mulatta can be observed conveniently, and the health condition of the macaca mulatta can be discovered and managed in time. According to the method, overall comprehensive breeding management is combined with rich and reasonable breeding equipment, and thus the yield and the quality of the experimental macaca mulatta are greatly improved.

Owner:四川横竖生物科技股份有限公司

Water and food feeding device with quantitative feeding function for livestock breeding

InactiveCN108901886AWith the function of quantitative feedingFeeding scientific normsAnimal watering devicesAnimal feeding devicesAgricultural scienceAnimal husbandry

The invention belongs to the technical field of animal husbandry, and particularly relates to a water and food feeding device with a quantitative feeding function for livestock breeding, aiming at solving the problems of no quantitative feeding function, no sterilization and disinfection function and inconvenient use. The water and food feeding device comprises a hollow base, wherein two chutes are arranged at the middle of the inner wall of the bottom of the base, two pulleys are connected to the inside of each chute in a slidable manner, the tops of the four pulleys are connected to a feeding trough through fastening bolts, the tops of the inner walls of both sides of the base are connected to reeling shafts by bearings, and reeling ropes wind the circumferential middles of the two reeling shafts. The water and food feeding device has a quantitative feeding function, ensures scientific and standard feeding, improves feeding quality, ensures supply and sanitation of drinking water, prevents animals from stepping on a water tank, sterilizes and disinfects the inside of the feeding trough, facilitates the storage and removal of the feeding trough, and can effectively prevent animalsfrom stepping on the inside of the base.

Owner:兰州集智信息技术有限公司

Feeding machine

A feeding machine comprises a supporting rotary plate, a vibration block, a feeding plate and a feeding trough, wherein the supporting rotary plate is in a shape of a circular ring, the bottom of the supporting rotary plate is fixedly provided with a rotary motor, and a support bar is fixed on center of the upper surface of the supporting rotary plate; the vibration block is fixed on the upper surface of the supporting rotary plate; a vibration motor is arranged in the vibration block; screening holes are formed in the bottom and side face of the feeding plate; a feeding plate support bar and springs are arranged on the bottom of the feeding plate; the furthest end, away from the feeding plate support bar, of the feeding plate is provided with a feeding plate discharging hole, and is connected with a discharging cover; the feeding trough is in a shape of an oblique circular ring, and the connection line of the center of the feeding trough and the center of the supporting rotary plate is perpendicular to the upper surface of the supporting rotary plate; the feeding plate discharging hole is positioned above the feeding trough. The raw material selection and feeding functions are integrated, so the quality of feeding is significantly improved; raw materials are screened in a way of centrifugal rotation and vibration, so screening is more efficient and fast; large size raw materials are screened, isolated and stored effectively, and the cost of production is reduced.

Owner:JIANGSU BOILN PLASTICS CO LTD

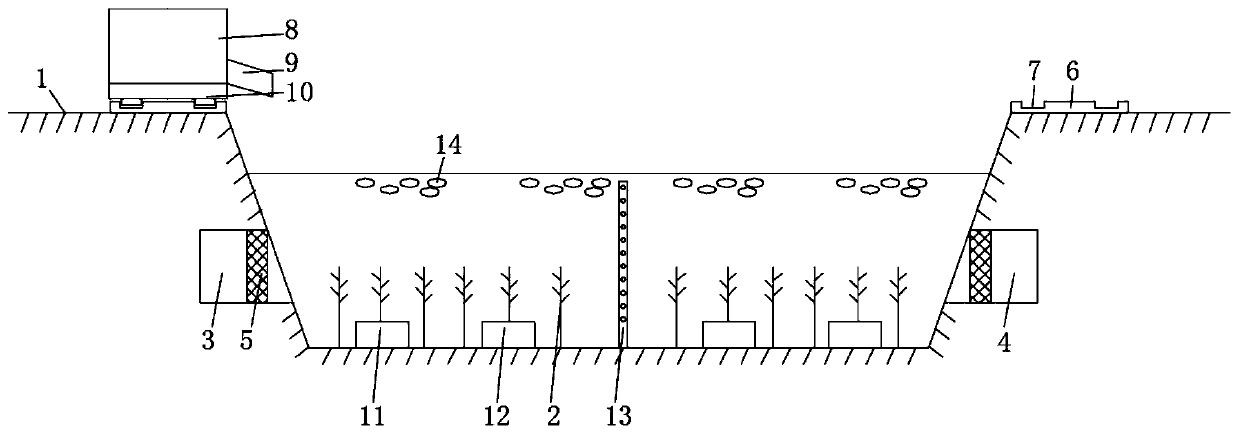

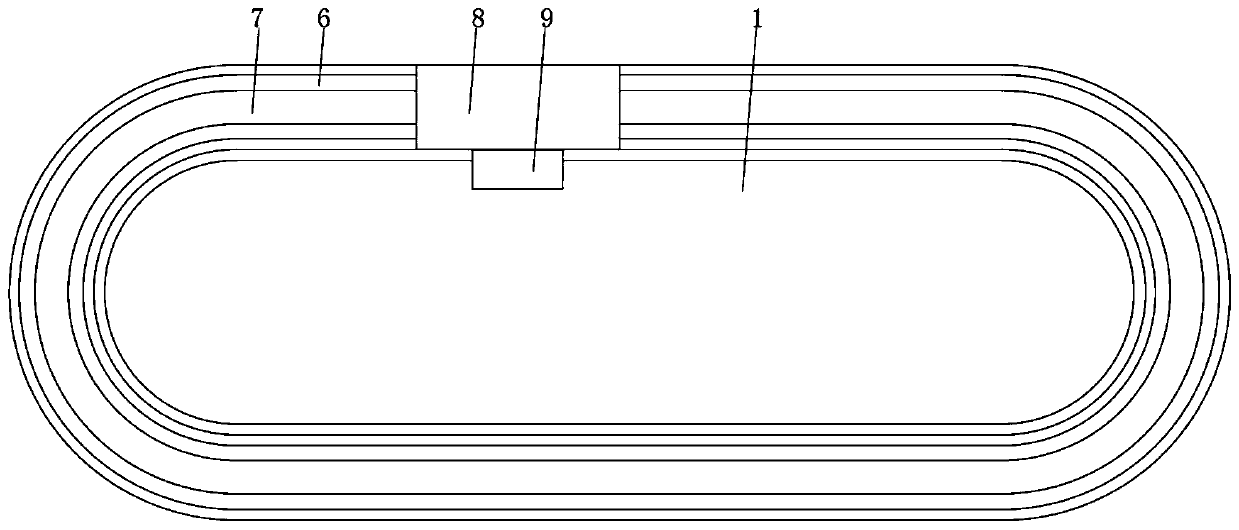

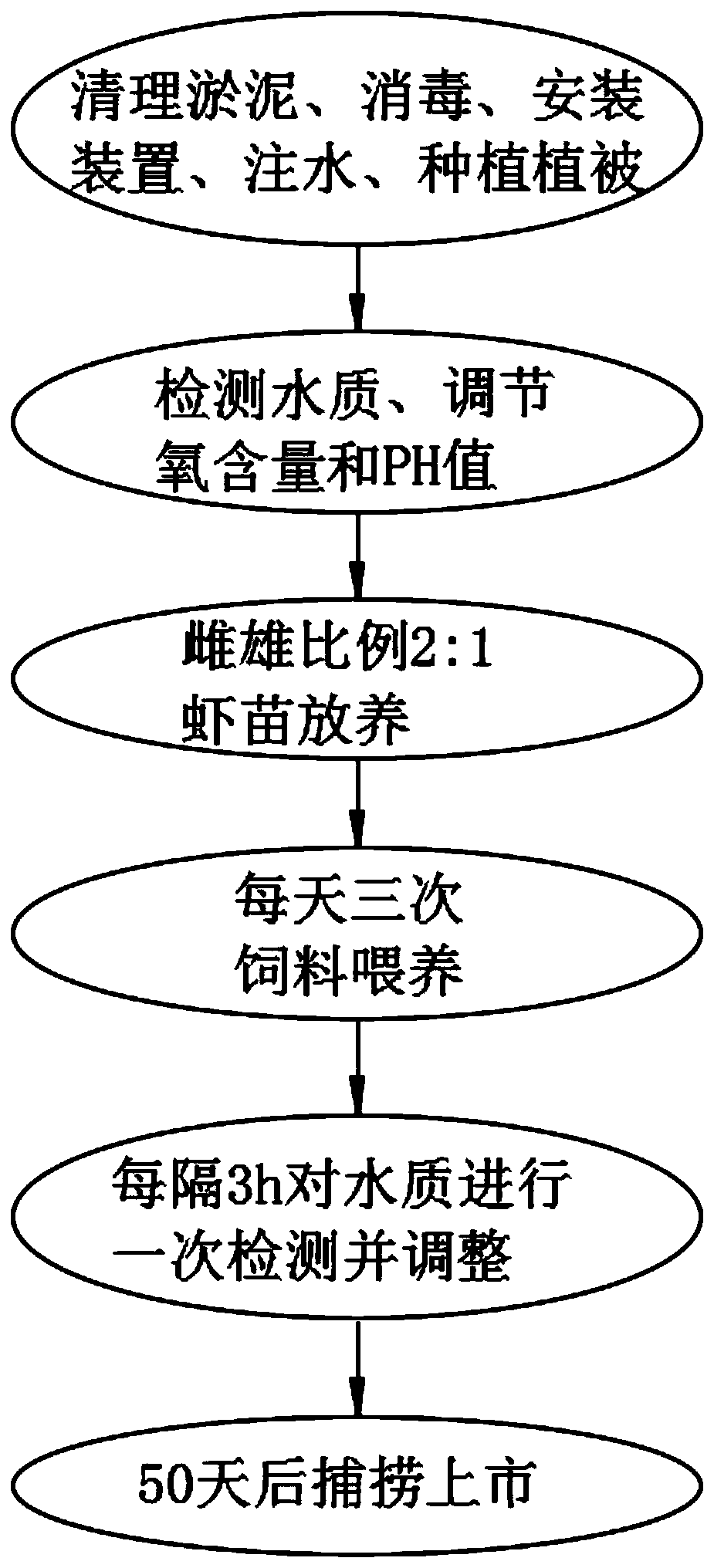

Special high-density Australia lobster breeding pond and method

InactiveCN110547236AReduce deliveryServe evenlyClimate change adaptationPisciculture and aquariaVegetationHigh density

The invention discloses a special high-density Australia lobster breeding pond, and relates to the technical field of related lobster breeding. The pond comprises a pond body, underwater vegetation isplanted at the bottom of the pond body, floating vegetation is planted on the water surface of the pond body, and one end of the pond body is fixedly connected with a water inlet pipe; the other endof the pond is fixedly connected with a water discharging pipe, the top edge of the pond body is fixedly connected with a rail, a pulley groove is formed in the top of the rail, a storage cart is arranged on the rail, and the bottom of the storage cart is fixedly connected with a driving system. The invention further discloses a high-density Australia lobster breeding method. The method comprisesthe following steps of A, pond preparation; B, water quality regulation; C, lobster seed releasing; D, feeding adopting feed; E, water quality detection; F, fishing and selling on the market. According to the breeding pond and method, the growth quality of lobsters is ensured, the growth and development speed of the lobsters is greatly increased, and the yield density of the lobsters is improved.

Owner:六安市叶集区金有祥水产养殖专业合作社

Native chicken raising method

ActiveCN106614306APromote growthShorten the time to marketAnimal feeding stuffAccessory food factorsAnimal scienceAnimal Foraging

The invention discloses a native chicken raising method. The native chicken raising method comprises the steps that (a) newly born native chickens are put in a chicken breeding room to be bred for 4 weeks, the indoor temperature of the chicken breeding room is kept to be 36 DEG C in the breeding process, the relative humidity is 60%, and the native chickens are exposed to light with the light intensity of 380 Lux for 3 hours starting from two o'clock in the afternoon and are fed with a feeding A; (b) after the native chickens are 4 weeks old, the native chickens are put in a wooded mountain in the daytime for free foraging and are driven into a chicken house at night, a feed b is fed on 11:00-12:00 in the noon every day and on 4:00-5:00 at nightfall respectively till slaughtering and sell. The feeds prepared for the native chicken raising method are reasonably matched, the native chicken feeding quality can be effectively improved, native chicken growth can be promoted, and the native chicken slaughtering time is shortened by about 10%.

Owner:阜阳金满地生态农业科技股份有限公司

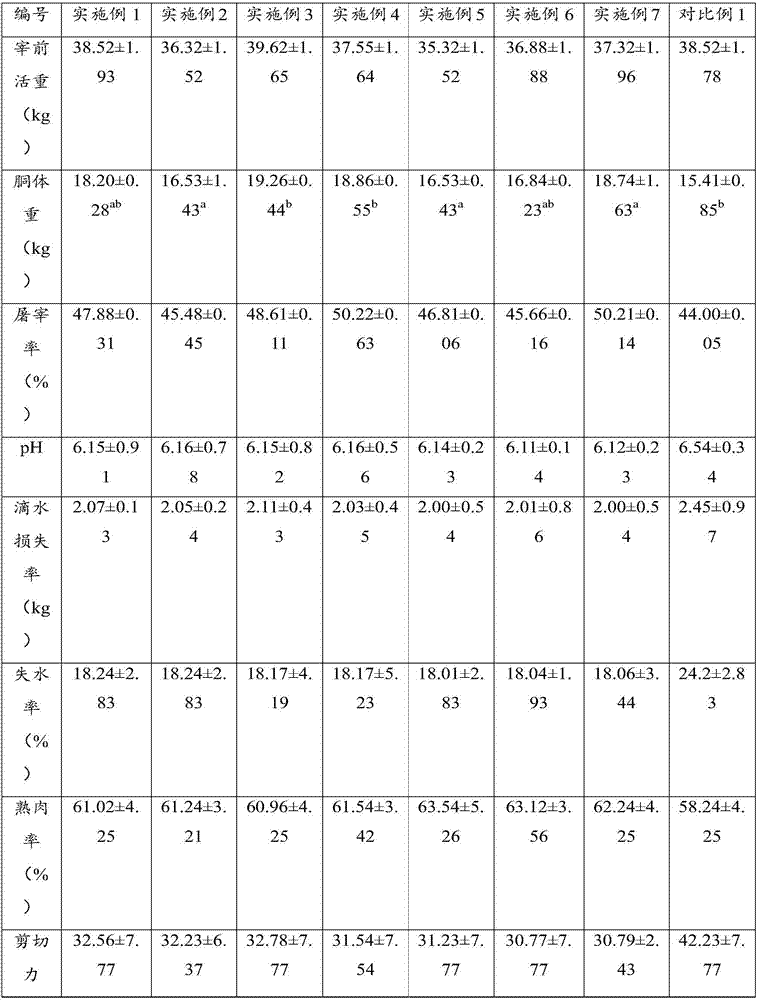

Sheep feed additives and preparation method thereof

InactiveCN107410720AImprove meat qualityImprove immunityAnimal feeding stuffAccessory food factorsAnimal scienceLycopene

The invention provides sheep feed additives and a preparation method thereof and relates to the technical field of sheep feeding. The sheep feed additives is mainly prepared by mixing a first component, a second component and a third component, wherein the first component comprises 0.1-0.2 part of ginseng stem leaf, 0.01-0.02 part of ginseng root, 3-8 parts of radix astragali, 1-2 parts of rapeseed, 1-6 parts of radix glycyrrhizae, 7-8 parts of radix codonopsis and 1-4 parts of angelica sinensis; the second component comprises 10-12 parts of lycopene, 30-36 parts of Atriplex patens shrub, 11-16 parts of flaxseed and 3-8 parts of thyme; the third component comprises 1-2 parts of Fujian medicated leaven, 3-6 parts of Hierochloe odorata, 2-4 parts of stevia rebaudiana and 1-2 parts of Meconopsis Vig.. The feed additives are safe, reliable, low in cost, capable of increasing the meat quality, productivity, immune level and carcass quality of mutton sheep in a short time and capable of increasing the economic benefits of enterprises.

Owner:新余市梦羚畜牧发展有限公司

Feed for growing of meat-breeding chickens and manufacture method thereof

InactiveCN106173468AImprove feeding qualityNo side effectsFood processingAnimal feeding stuffBiotechnologyFeed conversion ratio

The present invention discloses a feed for growing of meat-breeding chickens and a manufacture method thereof. The feed consists of the following raw materials in parts by weight: 12-18 parts of watermelon rinds, 30-40 parts of soybean cakes, 5-10 parts of selenium-rich corn flour, 5-7 parts of bombyx batryticatus powder, 8-10 parts of calcium hydrogen phosphate, 10-15 parts of camellia seeds, 6-10 parts of soybean oil, 5-10 parts of lotus root starch powder, 4-5 parts of soda, 6-8 parts of collagen, 2-4 parts of cuttlebone powder, 5-7 parts of vitamin D, 8-10 parts of edible salt, 2-4 parts of trace elements, 3-4 parts of bone meal and 5-7 parts of peptone. Compared with the prior art, the feed for the growing of the meat-breeding chickens has comprehensive nutrition in a recipe and is reasonable in ingredient proportions. Each raw material component of the feed is free of any toxic or side effects. Besides, through a reasonable matching, the feed effectively improves the feeding quality of the chickens, at the same time has the functions of killing bacteria and strengthening stomach, improving the immunity and enhancing metabolism, and can remarkably improve the disease-resistant ability of the meat chickens and significantly reduce the feed conversion ratio and the prevalence rate of the meat chickens.

Owner:赵浩

Cub feeding device for industrial breeding in animal husbandry

InactiveCN111480591AAvoid snatchingImprove protectionTransportation and packagingAnimal feeding devicesAnimal scienceElectric machinery

The invention belongs to the technical field of animal husbandry, particularly relates to a cub feeding device for industrial breeding in the animal husbandry, and aims to solve the problem that an existing cub feeding device is prone to cause food snatching in a feeding process. According to the scheme, the cub feeding device comprises a saddle; two supporting frames are fixedly mounted at the top of the saddle; a milk tank and a residual liquid tank are fixedly mounted at the top ends of the two supporting frames correspondingly; a sealing cover is mounted at the top end of the milk tank through a hasp lock and a hinge; and a driving motor is fixedly mounted at the top end of the sealing cover. When cubs are fed, feeding troughs are pushed out into a breeding fence through electric pushrods installed on the side surfaces, so that the cubs can be attached into the feeding trough for eating; the feeding troughs are separated through separation plates, so that the cubs are prevented from snatching for food, and the feeding quality is improved; and meanwhile, the flexible feeding troughs and the separation plates can prevent skin scratches of the cubs during eating and moving, so that the protection effect on the cubs is improved.

Owner:胡锦强

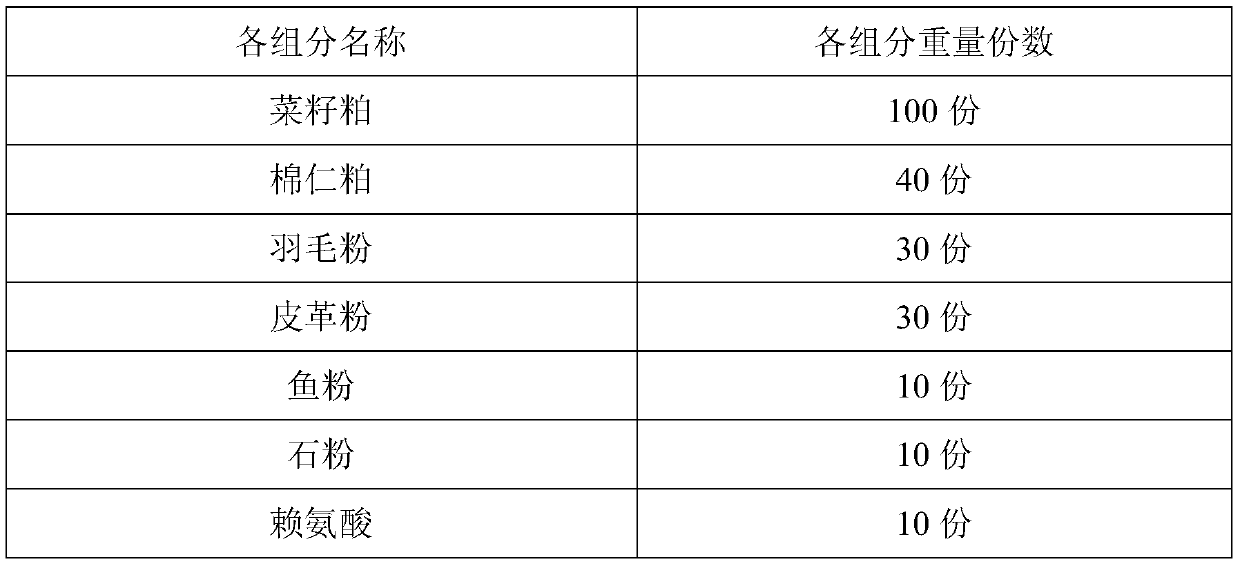

Growing-finishing pig concentrated feed

InactiveCN105494985AIntensive Adaptive TransformationImprove feeding qualityFood processingAnimal feeding stuffAnimal scienceFinishing pig

The invention discloses growing-finishing pig concentrated feed. The growing-finishing pig concentrated feed is prepared from the following feed components in parts by weight: 50 to 100 parts of rapeseed meal, 20 to 40 parts of cottonseed meal, 10 to 30 parts of feather meal, 10 to 30 parts of leather meal, 5 to 10 parts of fish meal, 3 to 10 parts of rock flour, 3 to 10 parts of lysine, 0.5 to 1 part of methionine, 2 to 5 parts of calcium hydrogen phosphate, 0.5 to 1 part of choline chloride and 1 to 3 parts of edible salt. The growing-finishing pig concentrated feed disclosed by the invention is suitable for pigs of which the weight is 20 to 50 kg, the pigs in the stage just come into a finishing period from piglets, and the change of adaptation of the pigs on feed in the stage is especially strengthened aiming at the growing characteristics and the nutritional requirements of the pigs in the stage, so that the feeding quality is increased, the nutrition is balanced, and the cultivation cost is reduced because the used raw materials are cheap and easy to obtain.

Owner:TIANJIN MODERN TIANJIAO AGRI TECH CO LTD

Feeding device for seamless air duct cloth production

ActiveCN104562497AEasy to pass throughEasy to installTextile treatment machine arrangementsTextile treatment carriersBiochemical engineeringHeat conducting

The invention relates to a feeding device for seamless air duct cloth production. The feeding device comprises a tank body, wherein a bracket is arranged on the tank body; a first clamping roller group and a first material scraping group are arranged on the bracket; a slideable clamp device is further arranged on the bracket; a second clamping roller group and a second material scraping group are arranged on the clamp device; each of the first clamping roller group and the second clamping roller group comprises at least one clamping roller; each of the first material scraping group and the second material scraping group comprises at least one scraping piece and at least one scraping rope; the end, in contact with base cloth, of the scraping piece is arranged in an inclined manner in the movement direction of the base cloth; the included angle between the scraping piece and the base cloth is smaller than 90 degrees; a liftable immersed material lifting device is arranged on the bracket; a heat conducting box used for heating slurry is arranged on the inner wall of the tank body. According to the feeding device, the uniform feeding of the seamless air duct base cloth can be realized; the distances between the two clamping roller groups and the two material scraping groups are adjustable, so that the requirement on different thicknesses of the slurry on the base cloth can be met; each material scraping group comprises the scraping piece and the scraping rope, so that the material is scraped more uniformly; the scraping piece and the scraping rope are connected with compression springs, so that the damage to the base cloth can be reduced.

Owner:成都众成新型复合材料有限公司

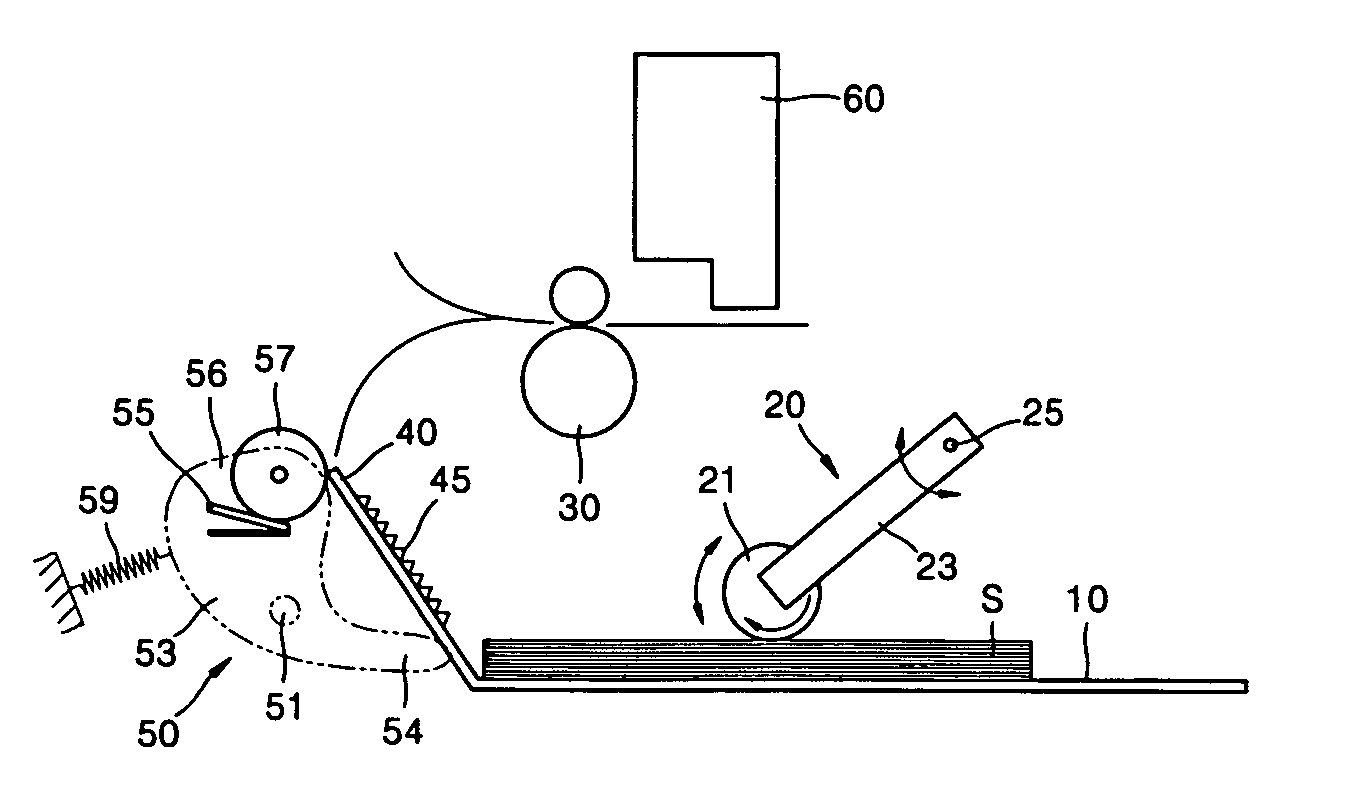

Two-way paper pickup system

InactiveUS20050189695A1Improve feeding qualityEasy feedingSewerage structuresOther printing apparatusPaper sheet

A two-way paper pickup system in which both a feed tray and a feed cassette can be used, and a printer adopting the same. The paper pickup system includes a feed tray on which paper or a feed cassette is placed, a first pickup assembly that moves the paper placed on the feed tray, a resistance plate that allows the moved paper to be separately transferred, and a second pickup assembly that is moved to a paper exit of the feed cassette so as to move paper included in the feed cassette when the feed cassette is placed on the feed tray. When the feed cassette is inserted into the printer, the first pickup assembly is moved on the feed cassette while being rotated.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com