Method for separating copper and molybdenum from slime-containing sulfur-containing low-grade copper-molybdenum ore

A separation method and technology for copper-molybdenum ore, which are applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of reducing the recovery rate of copper-molybdenum mixed separation, unfavorable production efficiency, and difficulty in separation of copper and molybdenum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

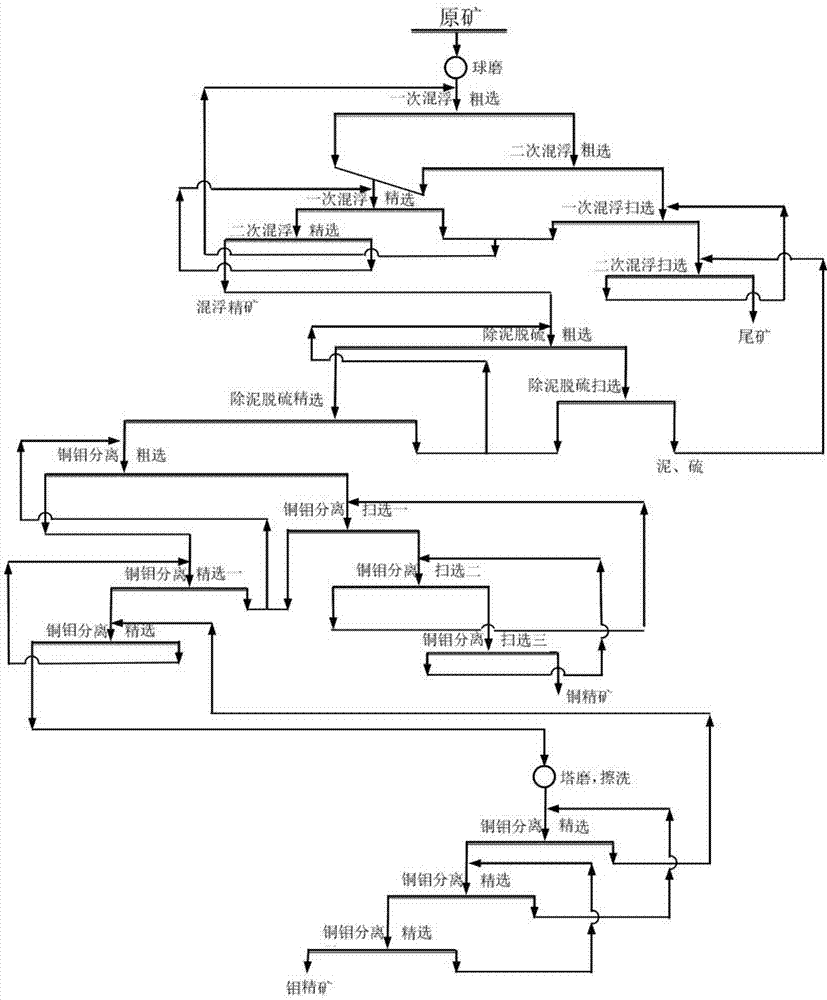

[0038] A copper-molybdenum separation method for low-grade copper-molybdenum ore containing sludge and sulfur. The process flow of the method is: grinding-copper-molybdenum mixed flotation process-desilting and desulfurization process-copper-molybdenum separation flotation process, wherein each process The specific process is as follows:

[0039] The copper-molybdenum mixed flotation process includes a mixed flotation roughing process, a mixed flotation sweeping process and a mixed flotation beneficiation process. The tailings after the mixed flotation roughing process enter the mixed flotation sweeping process. The mixed-float coarse concentrate enters the mixed-flotation concentration process, and the mixed-float concentrate after the mixed-flotation concentration process enters the desilting and desulfurization process.

[0040] Preferably, the copper-molybdenum mixed flotation process includes two mixed flotation roughing processes, two mixed flotation sweeping processes, and t...

Embodiment 2

[0052] A copper-molybdenum separation method for low-grade copper-molybdenum ore containing sludge and sulfur. The process flow of the method is: grinding-copper-molybdenum mixed flotation process-desilting and desulfurization process-copper-molybdenum separation flotation process, wherein each process The specific process is as follows:

[0053] The copper-molybdenum mixed flotation process includes a mixed flotation roughing process, a mixed flotation sweeping process and a mixed flotation beneficiation process. The tailings after the mixed flotation roughing process enter the mixed flotation sweeping process. The mixed-float coarse concentrate enters the mixed-flotation concentration process, and the mixed-float concentrate after the mixed-flotation concentration process enters the desilting and desulfurization process.

[0054] Preferably, the copper-molybdenum mixed flotation process includes two mixed flotation roughing processes, two mixed flotation sweeping processes, and t...

Embodiment 3

[0066] A copper-molybdenum separation method for low-grade copper-molybdenum ore containing sludge and sulfur. The process flow of the method is: grinding-copper-molybdenum mixed flotation process-desilting and desulfurization process-copper-molybdenum separation flotation process, wherein each process The specific process is as follows:

[0067] The copper-molybdenum mixed flotation process includes a mixed flotation roughing process, a mixed flotation sweeping process and a mixed flotation beneficiation process. The tailings after the mixed flotation roughing process enter the mixed flotation sweeping process. The mixed-float coarse concentrate enters the mixed-flotation concentration process, and the mixed-float concentrate after the mixed-flotation concentration process enters the desilting and desulfurization process.

[0068] Preferably, the copper-molybdenum mixed flotation process includes two mixed flotation roughing processes, two mixed flotation sweeping processes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com