Beneficiation method for improving comprehensive recovery indexes of complex low-grade molybdenum polymetallic ores

A technology of polymetallic minerals and mineral processing methods, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problem of low level of resource utilization, difficulty in obtaining separation indicators, and comprehensive recovery of copper minerals and sulfur minerals and other problems, to achieve the effect of excellent comprehensive recovery index, ideal selectivity, and avoiding the decline of floatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

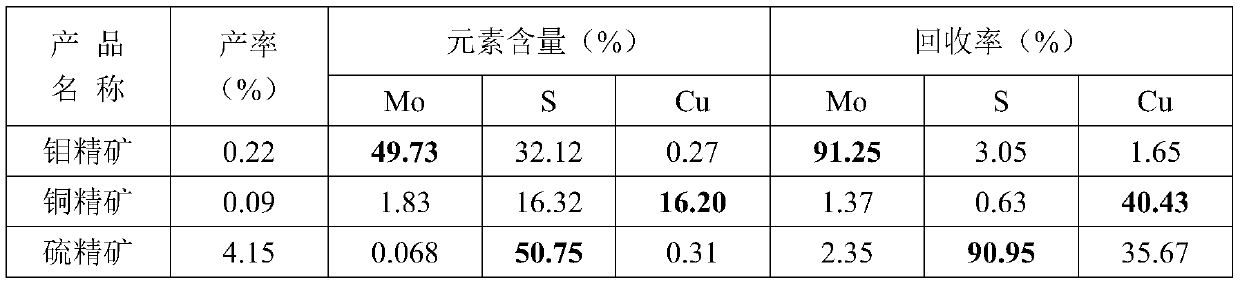

Embodiment 1

[0055] 1. Ore characteristics

[0056] In a fine-crystalline low-grade molybdenum ore in Henan, the molybdenum grade is 0.12%, the copper grade is 0.037%, and the sulfur grade is 2.31%, all of which are low in content. The molybdenite in the ore is mainly in the form of sparse disseminated structure or star point structure. The embedded type of molybdenite is mainly in the form of thin slabs, needles and columns wrapped by quartz, with small particle size; chalcopyrite mainly It is inhomogeneous and small stars embedded in the gangue grains and holes, with a particle size of 0.02~0.05mm; the pyrite is mainly in the form of euhedral-semi-auto-shaped monomers embedded in the gangue particles The particle size is between 0.1mm and 0.7mm in the gaps and cracks. The pyrite often contains chalcopyrite or fine-grained pyrrhotite. The above ore characteristics make it difficult to separate and recover the sulfide minerals in the low-grade molybdenum ore.

[0057] 2. Beneficiation method ...

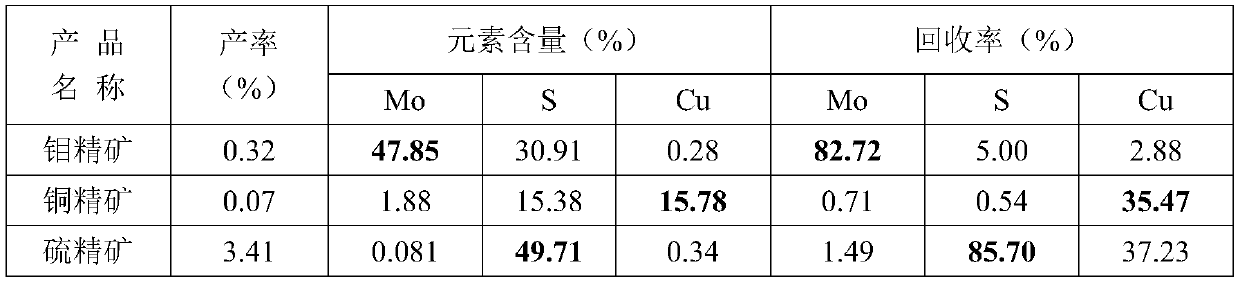

Embodiment 2

[0075] 1. Ore characteristics

[0076] In a fine-crystalline molybdenum ore in Xinjiang, the molybdenum grade is 0.18%, the copper grade is 0.031%, and the sulfur grade is 1.98%. The sulfide content is relatively low, and the molybdenum has a certain degree of oxidation, with an oxidation rate of about 3%. The molybdenite in the ore is covered by quartz in the form of thin plates and needles, with fine particle size; the chalcopyrite has a fine grain size and is closely related to the gangue minerals; pyrite often contains emulsion chalcopyrite or The comprehensive recovery of fine-grained pyrrhotite is difficult.

[0077] 2. Beneficiation method

[0078] (1) Preparation of floating material and one-stage grinding: Grind the molybdenum polymetallic ore finely, and the particle size of the floating material obtained is -74μm, accounting for 72% of the total weight of the floating mineral;

[0079] (2) Molybdenum roughing / sweeping: adding 70 g / ton of molybdenum combined collector and 2...

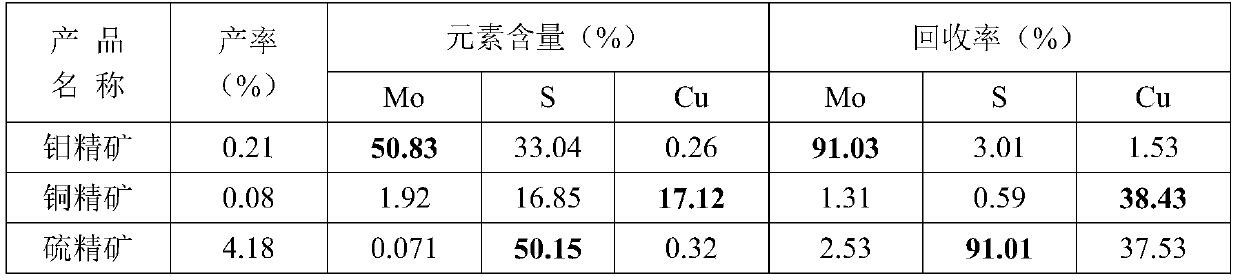

Embodiment 3

[0095] The ore characteristics and beneficiation steps of this example are the same as those of Example 1. The difference lies in the different dosages of reagents in the molybdenum roughing / sweeping, molybdenum beneficiation, copper beneficiation, sulfur roughing / sweeping, and sulfur beneficiation steps. ; The drug content of each step is:

[0096] Molybdenum roughing / sweeping: Molybdenum combined collector dosage for rough molybdenum selection is 50 g / ton raw ore, and the amount of foaming agent 2-hexanol is 15 g / ton raw ore. The dosage is 10 g / ton of raw ore, and the amount of foaming agent 2-hexanol is 35 g / ton of raw ore;

[0097] Molybdenum selection: The dosage of each molybdenum selection and copper combination inhibitor is 450 g / ton of ore, the amount of collector kerosene is 4 g / ton of ore, and the dosage of 2-hexanol is 2 g / ton of ore;

[0098] Copper beneficiation: The amount of copper sulfate used for each copper beneficiation is 60 g / ton of raw ore, and the amount of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com