Cub feeding device for industrial breeding in animal husbandry

A technology of animal husbandry and cubs, applied in the field of animal husbandry, can solve problems such as easy to grab food, achieve the effect of improving protection, facilitating absorption, and improving feeding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

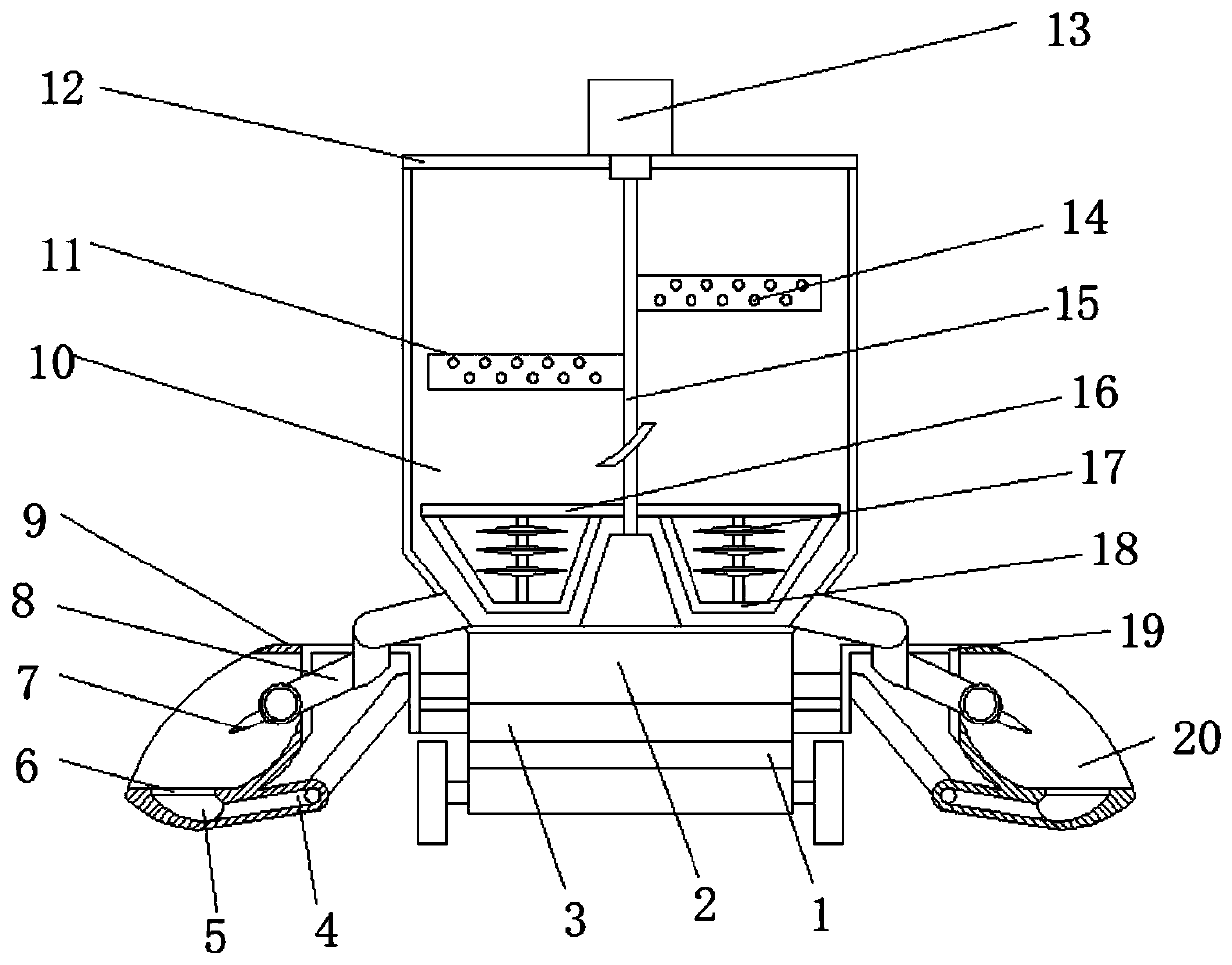

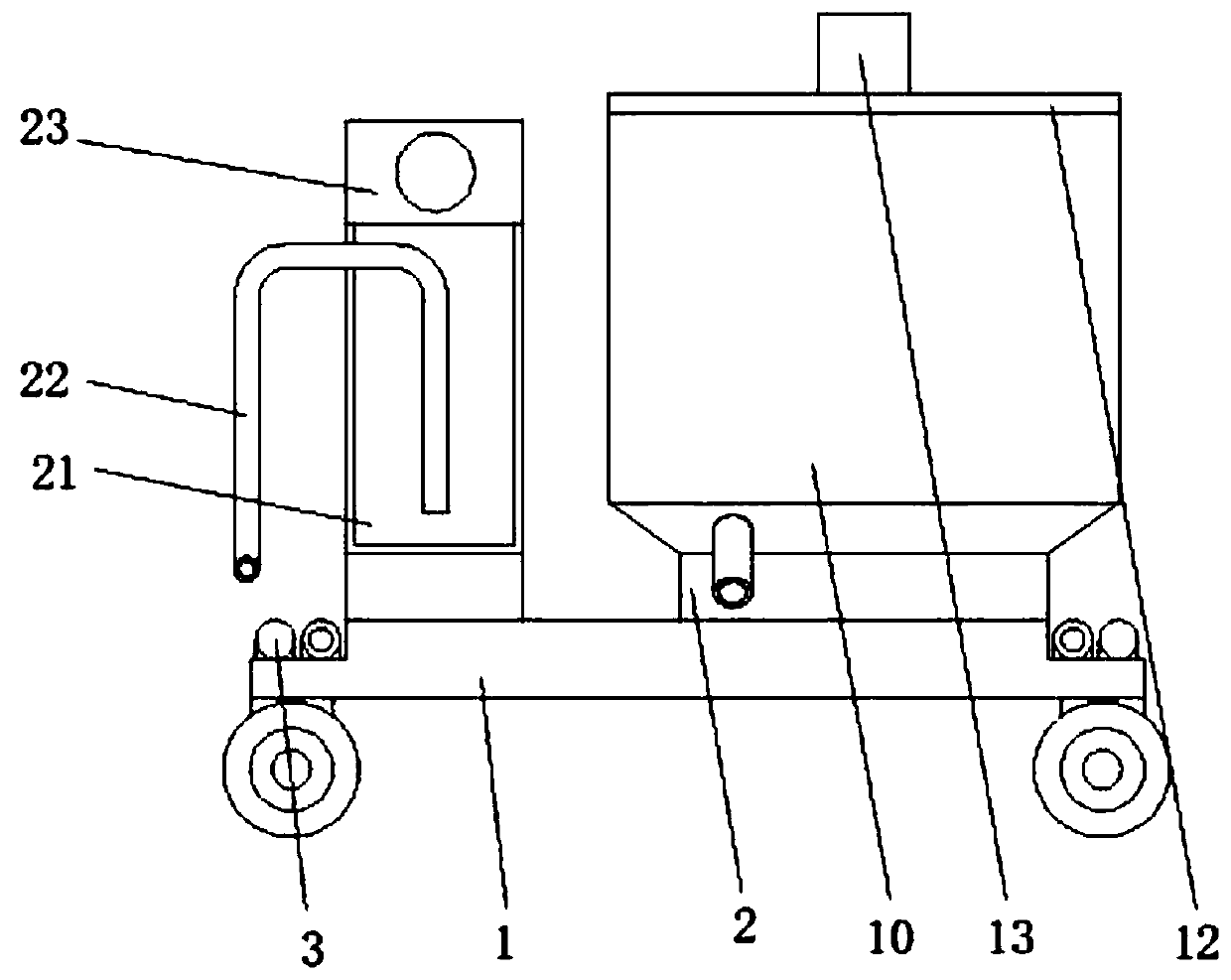

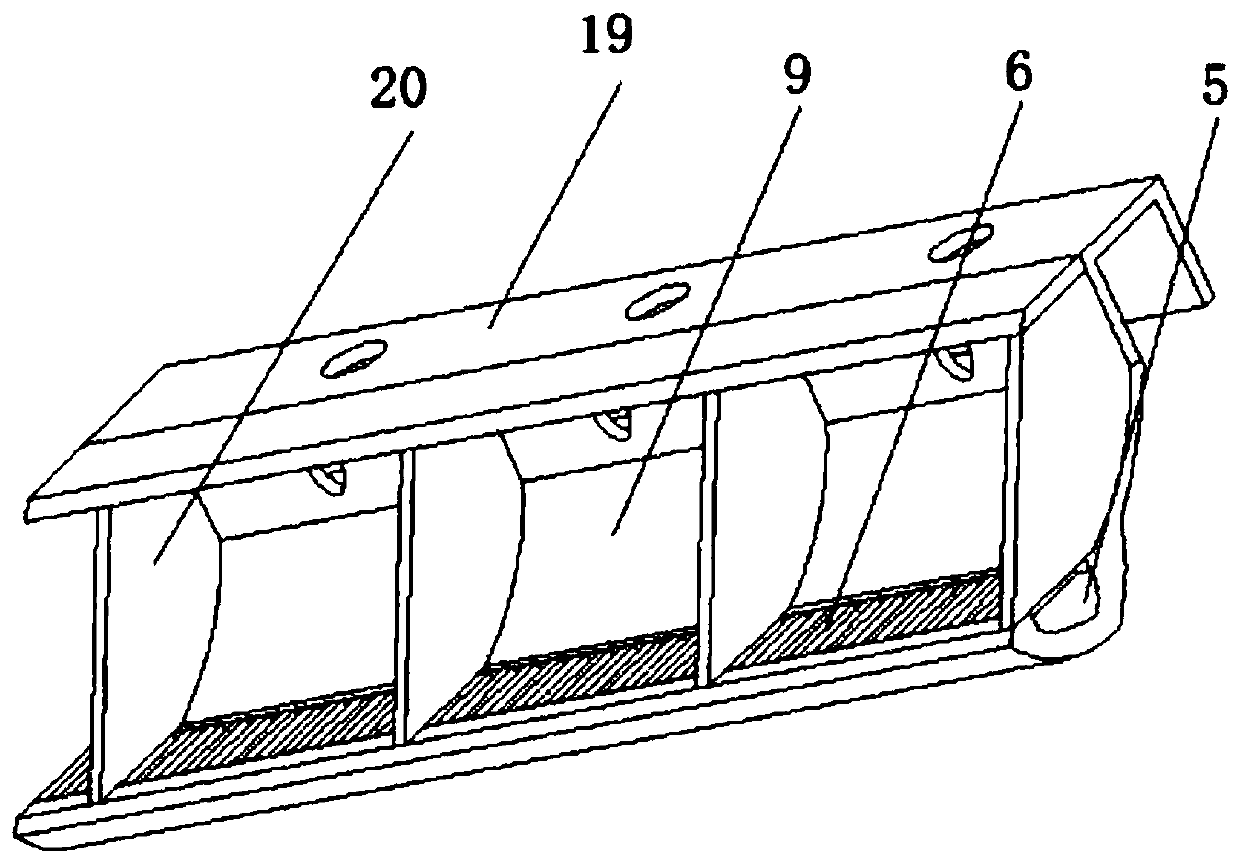

[0027] refer to Figure 1-4 , a cub feeding device for industrialized breeding of animal husbandry, comprising a vehicle seat 1, two support frames 2 are fixedly installed on the top of the vehicle seat 1, and a milk tank 10 and a residual liquid are fixedly installed on the top of the two support frames 2 respectively Tank 21, the top of the milk tank 10 is equipped with a cover 12 through a hasp lock and hinge, and the top of the cover 12 is fixedly installed with a driving motor 13, and both sides of the top of the car seat 1 are fixedly installed with two staggered electric motors. A push rod 3, and a connecting frame 19 is fixedly installed between the ends of two electric push rods 3 on the same side, a feeding trough 9 is fixedly installed on the outside of the connecting frame 19, and a plurality of isolation plates are arranged in the middle of the feeding trough 9 20. A feeding tube 8 with an L-shaped structure is fixedly installed between the side of the feeding tan...

Embodiment 2

[0035] refer to Figure 1-5 , a cub feeding device for animal husbandry industrialized breeding. Compared with Embodiment 1, the bottom of the stirring rod 16 is fixedly equipped with an extension rod 18 of U-shaped structure, and the extension rod 18 and the stirring rod 16 are fixed A shearing mechanism 17 is installed;

[0036] The shearing mechanism 17 includes a rod body and a plurality of shearing discs sleeved on the outside of the rod body, and the outer side of the shearing discs is provided with a ring-shaped cutting edge.

[0037] In this embodiment: when the drive motor 13 rotates in the device, the extension rod 18 and the shearing mechanism 17 at the bottom can stir and mix the milk at the bottom, and the multiple shearing blades on the shearing mechanism 17 can The undissolved milk powder mass in the milk is sheared and broken to improve the dissolution quality of the milk, which is more conducive to the absorption of the cubs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com