Sheep feed additives and preparation method thereof

A feed additive and additive technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of meat and mutton quality, carcass quality and immune level indicators cannot be effectively improved, and the effect has not been recognized by the public. The effect of enhancing immunity, improving meat quality and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

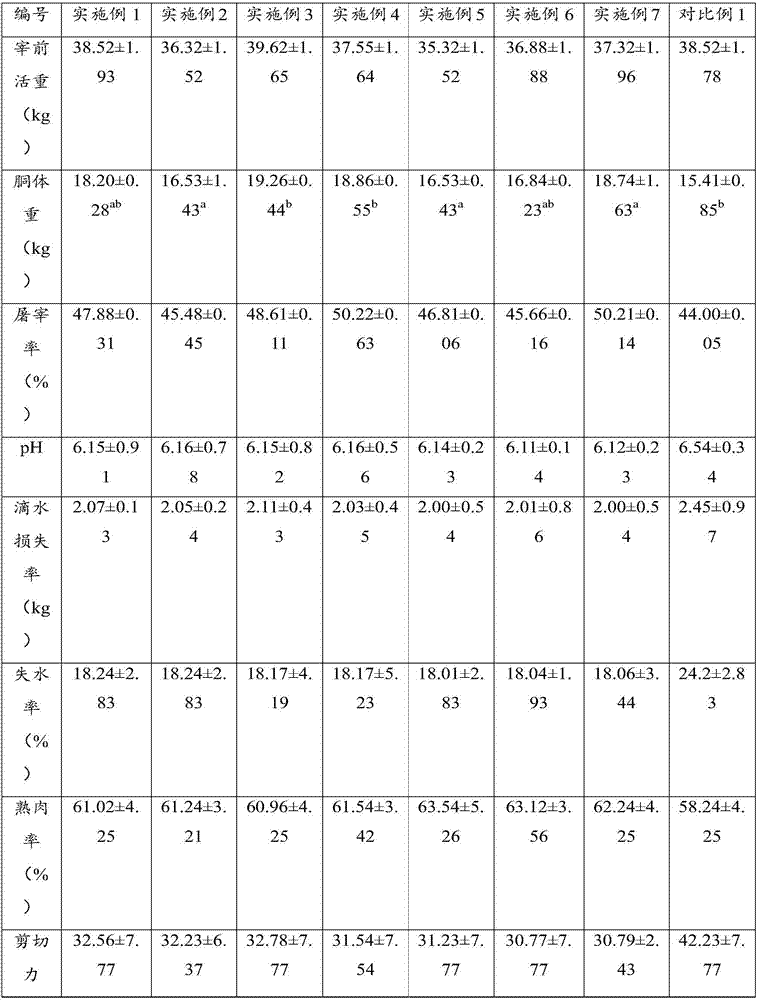

Examples

preparation example Construction

[0055] Embodiments of the present invention also provide a method for preparing a feed additive for sheep, comprising:

[0056] The first component, the second component and the third component are respectively subjected to sand removal operations;

[0057] Mix the first component, the second component and the third component after removing sand and gravel, and then dry, wash, pulverize and sterilize in sequence; where:

[0058] The first component is mainly made of the following raw materials in parts by weight: 0.1-0.2 parts of ginseng stems and leaves, 0.01-0.02 parts of ginseng roots, 3-8 parts of astragalus, 1-2 parts of rapeseed, 1-2 parts of 6 parts of licorice, 7-8 parts of Codonopsis and 1-4 parts of angelica;

[0059] The second component is mainly made of the following raw materials in parts by weight: 10-12 parts of lycopene, 30-36 parts of atribus shrub, 11-16 parts of flax seeds and 3-8 parts of thyme;

[0060] The third component is mainly made of the followin...

Embodiment 1

[0063] This embodiment provides a feed additive for sheep, prepared by the following preparation method:

[0064] A method for preparing a feed additive for sheep, comprising:

[0065] The first component, the second component and the third component are respectively subjected to sand removal operations;

[0066] Mix the first component, the second component and the third component after removing sand and gravel, and then dry, wash, pulverize and sterilize in sequence; where:

[0067] The first component is mainly made of the following raw materials in parts by weight: 0.1 part of ginseng stem and leaf, 0.01 part of ginseng root, 3 parts of astragalus, 1 part of rapeseed, 1 part of licorice, 7 parts of Codonopsis and 1 serving of angelica;

[0068] The second component is mainly made of the following raw materials in parts by weight: 10 parts of lycopene, 30 parts of agarwood bushes, 11 parts of flax seeds and 3 parts of thyme;

[0069] The third component is mainly made of...

Embodiment 2

[0071] This embodiment provides a feed additive for sheep, the difference between its preparation method and the preparation method provided in Example 1 is:

[0072] A method for preparing a feed additive for sheep, comprising:

[0073] The first component, the second component and the third component are respectively subjected to sand removal operations;

[0074]The first component, the second component, the third component and 0.1 part of cysteine, 0.1 part of rumen-passed lysine, 0.1 part of conjugated linoleic acid, 0.1 part of N-carbamoylglutamic acid and 0.2 parts of β-hydroxy-β-methylbutyrate compound are mixed and then dried, washed, pulverized and sterilized in sequence; wherein:

[0075] The first component is mainly made of the following raw materials in parts by weight: 0.15 parts of ginseng stems and leaves, 0.015 parts of ginseng roots, 4 parts of astragalus, 1.5 parts of rapeseed, 4 parts of licorice, 7.5 parts of Codonopsis and 2 servings of angelica;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com