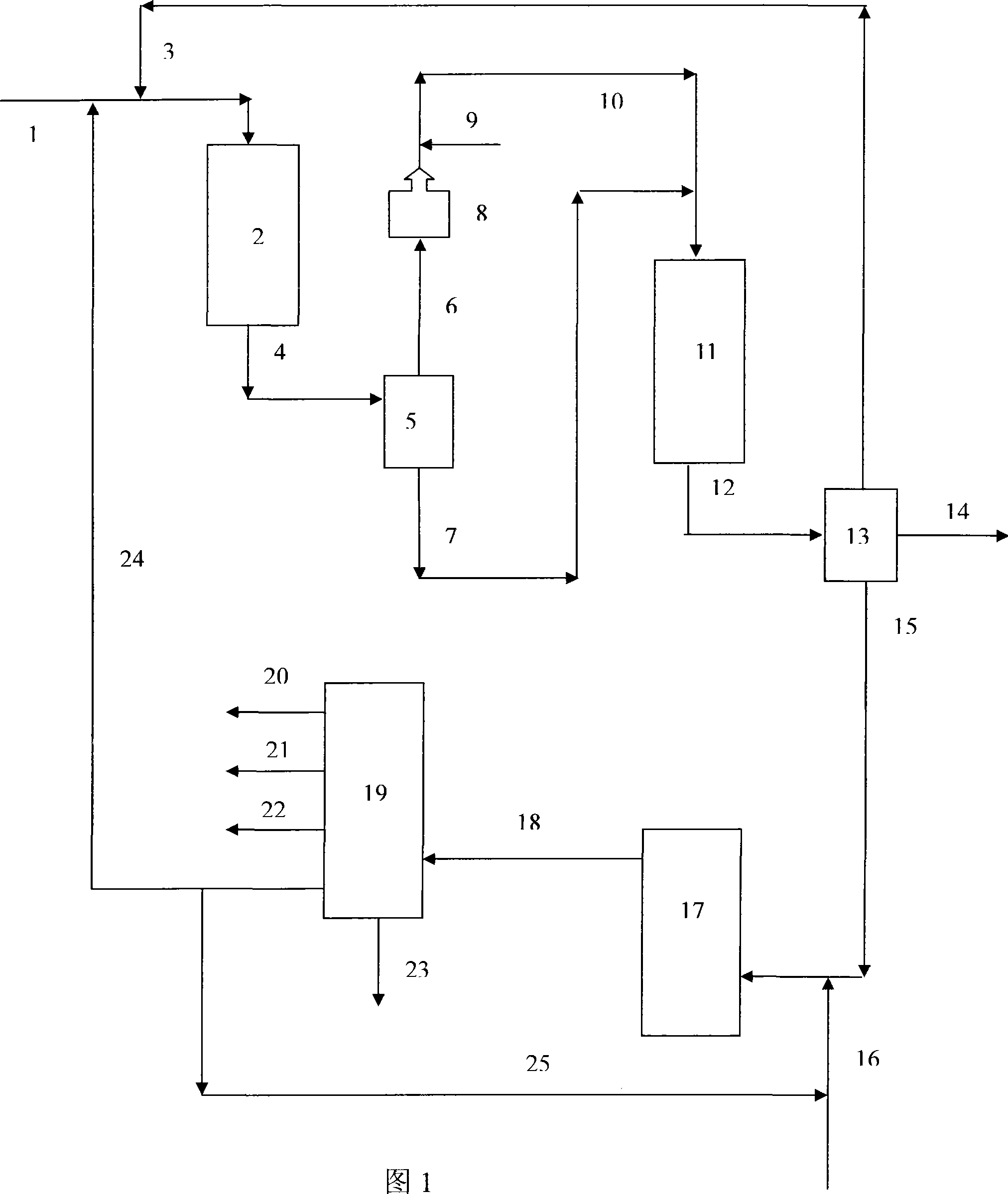

Heavy distillate hydrogenation and catalytic cracking combined method

A heavy distillate oil, hydrotreating technology, applied in the field of combination, can solve the problems of harsh operation, failure to meet environmental protection requirements, poor quality of gasoline products, etc., to increase processing capacity, reduce equipment investment and operating costs, and improve feedstock quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0026] Table 1 Properties of raw oil

[0027] Raw oil name Raw oil 1 * Raw oil-2 ** Density(20℃) / g·cm -3 0.931 0.902 Distillation range / ℃ 360~600 360~560 Sulfur content, wt% 3.10 1.60 Aromatic content, wt% 58 43

[0028] * Raw oil-1 is mixed oil (where VGO:CGO:DAO=50:25:25 weight ratio)

[0029] ** Raw oil-2 is mixed oil (wherein VGO:CGO=60:40 weight ratio)

[0030] The catalysts used for hydroprocessing are 3936 and FF-14, both produced by Fushun Petrochemical Research Institute.

[0031] Table 2 Main composition and properties of hydrotreating catalysts

[0032] catalyst 3936 FF-14 Catalyst composition MoO 3 , wt% 24.5 24.0 NiO, wt% 3.8 2.0 CoO, wt% 1.6 Carrier, wt% margin margin The main properties of the catalyst Specific surface / m 2 g -1 >160 >160 Pore volume / ml·g -1 0.33 >0.30

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com