Laser cladding nozzle convenient for cooling and manufacturing method thereof

A technology of laser cladding and manufacturing method, applied in manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems of limited cooling area, water leakage, complicated process, etc., to achieve good powder feeding effect and improve the effect of powder feeding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

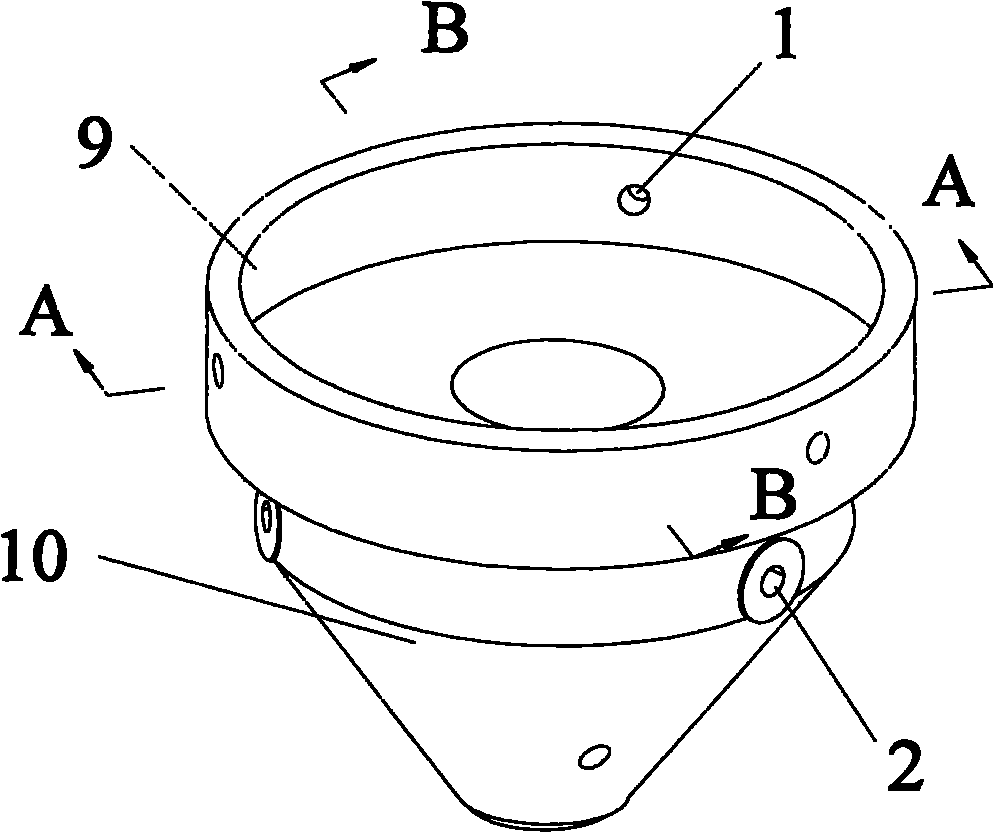

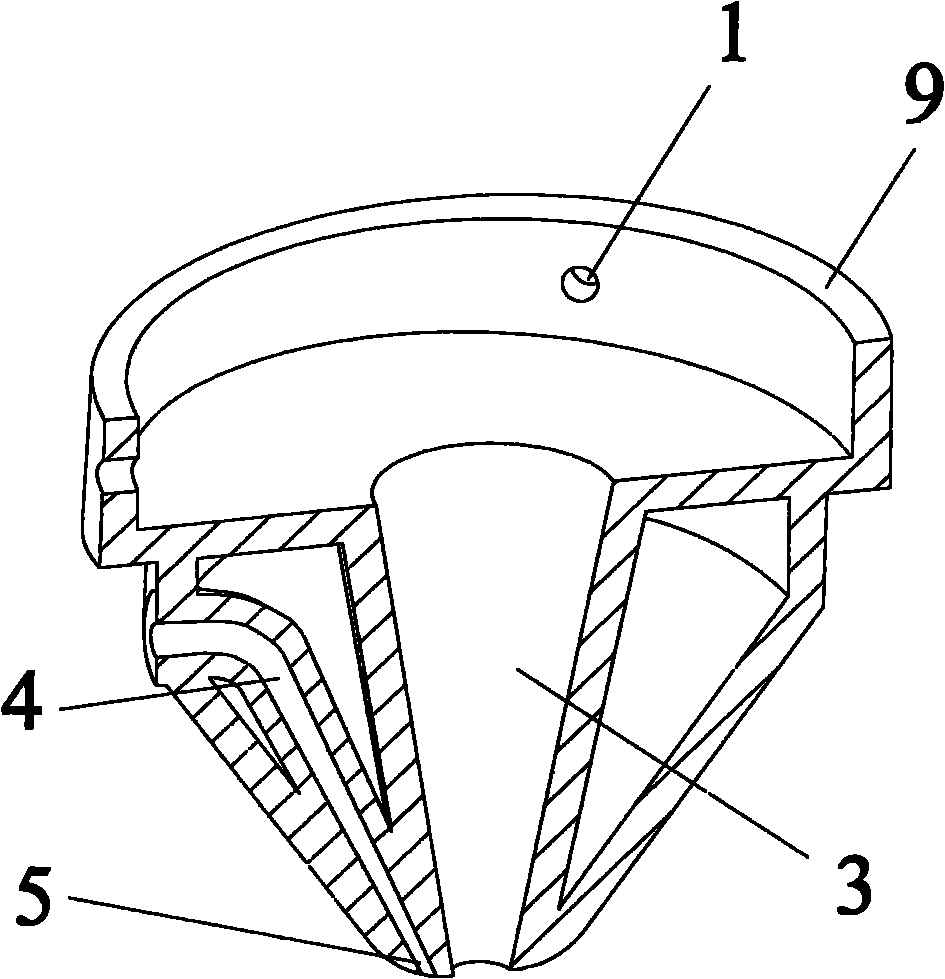

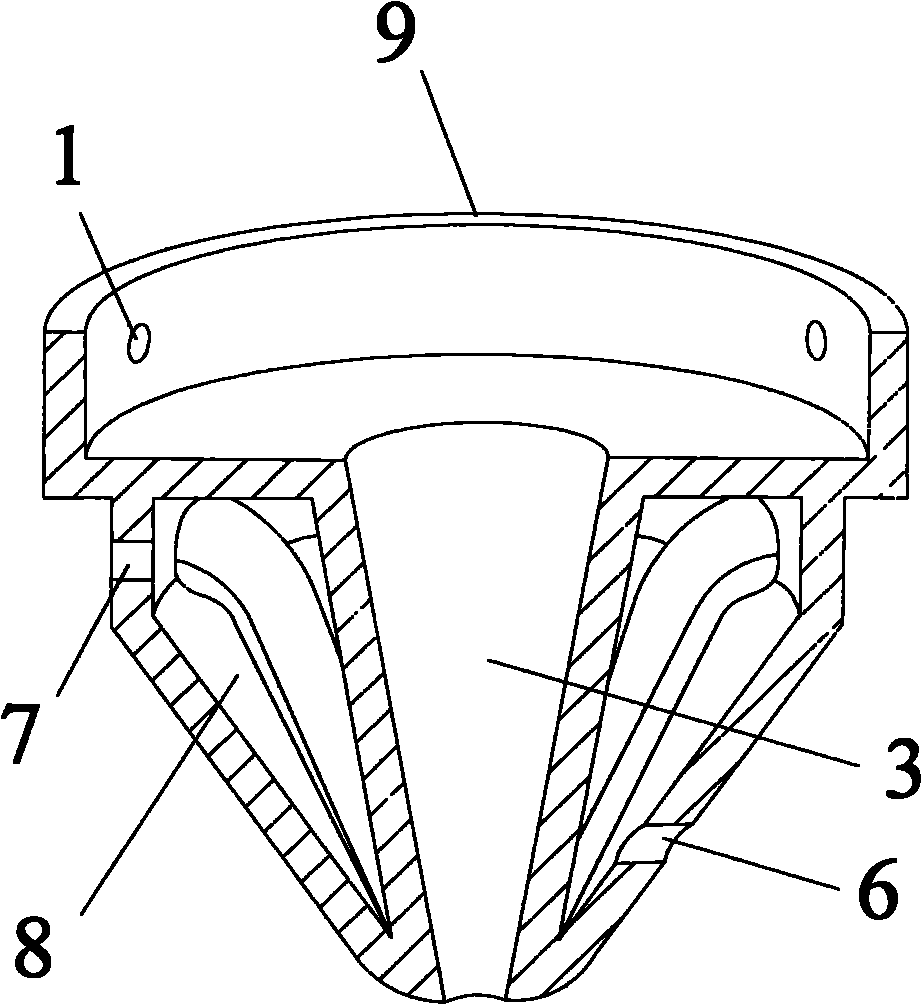

[0038] Such as figure 1 As shown, the laser cladding nozzle that is convenient for cooling includes a nozzle core 10 and a connecting head 9 connected above it for an external laser system. The nozzle core 10 is provided with a beam channel 3, a cooling cavity 8 and three The powder feeding channel 4, the cooling cavity 8 is the cavity formed between the outer circumference of the beam channel 3, the outer circumference of each powder feeding channel 4, and the inner wall of the nozzle core 10 (that is, in the nozzle core 10, the beam channel 3 and the powder feeding channel are removed. The remaining cavity part behind the passage 4 all constitutes the cooling cavity 8); as figure 2 and image 3As shown, the outer wall of the upper end of the nozzle core 10 is provided with a powder inlet 2 communicating with the powder feeding channel 4 and a water outlet 7 communicating with the cooling cavity 8, and the lower end of the nozzle core 10 is opened with a powder feeding chan...

Embodiment 2

[0053] Present embodiment except following feature other structures are with embodiment 1: as Figure 4 As shown, the beam channel 3 is a through hole opened at the center of the nozzle core, and the through hole is a cylindrical hole.

[0054] In the step (3), the raw material powder is copper.

Embodiment 3

[0056] Present embodiment except following feature other structures are with embodiment 1: as Figure 5 As shown, the connecting head is a cylinder provided with an external thread 11, and a through hole 12 communicated with the beam passage is opened at the center thereof.

[0057] The number of powder feeding channels 4 is six; the number of powder inlets 2 and powder outlets 5 is the same as the number of powder feeding channels 4, which are six respectively, and six powder inlets 2 and six powder outlets 5 They are respectively connected with six powder feeding channels 4, and the powder inlet 2, powder outlet 5 and powder feeding channel 4 correspond one by one; the outer wall thickness of the nozzle core is 5 mm; the wall thickness of the beam channel is 5 mm; the powder feeding channel 4 The wall thickness is 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com