Constant-tension wire moving mechanism with automatic wire feeding function

A technology of automatic threading and constant tension, applied in manufacturing tools, electric processing equipment, metal processing equipment, etc., can solve problems such as the inability to guarantee the constant tension of the metal wire, affecting the threading efficiency and quality, and affecting the processing accuracy of parts, etc. The effect of threading efficiency and production efficiency, improving threading quality and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

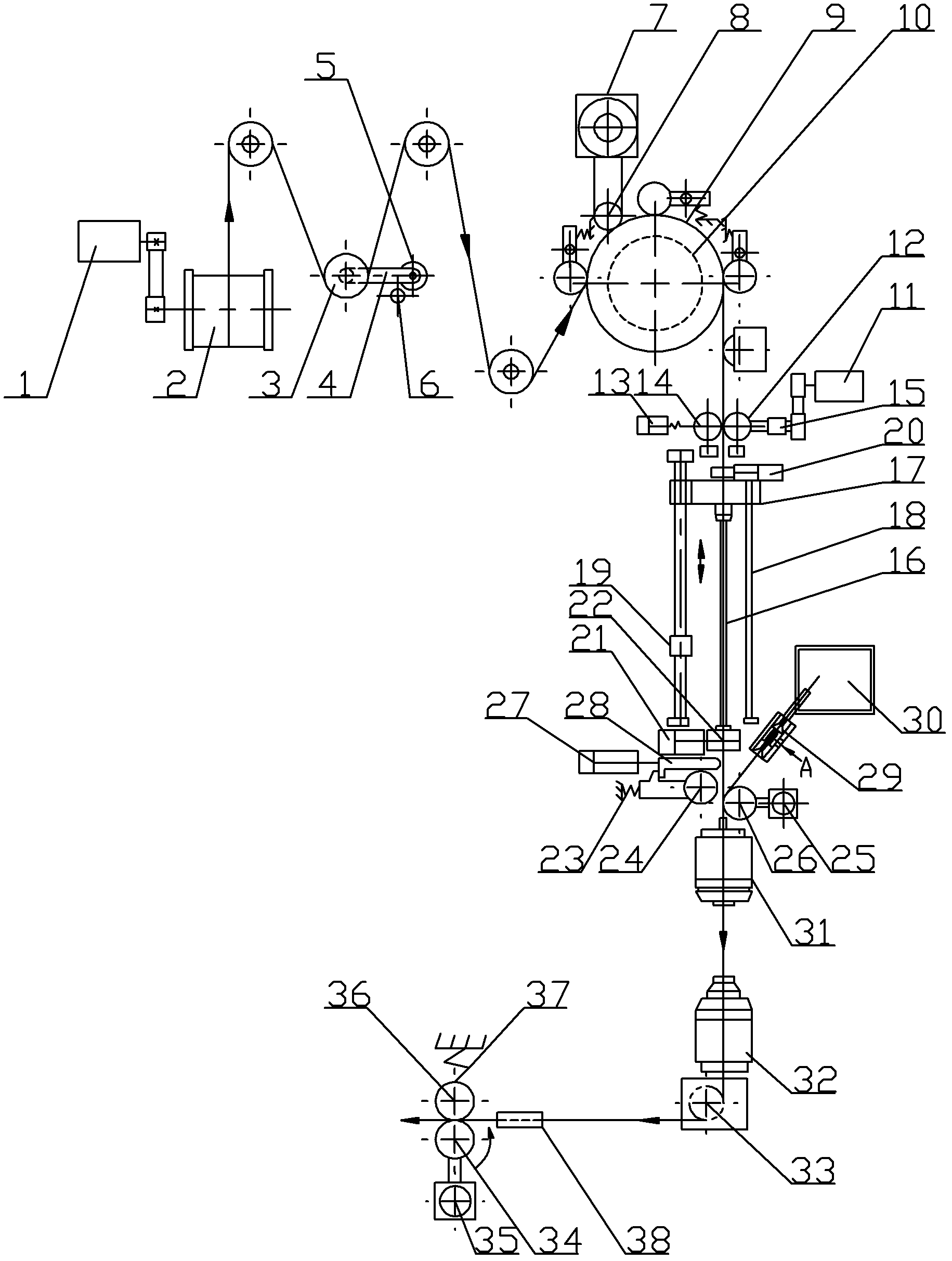

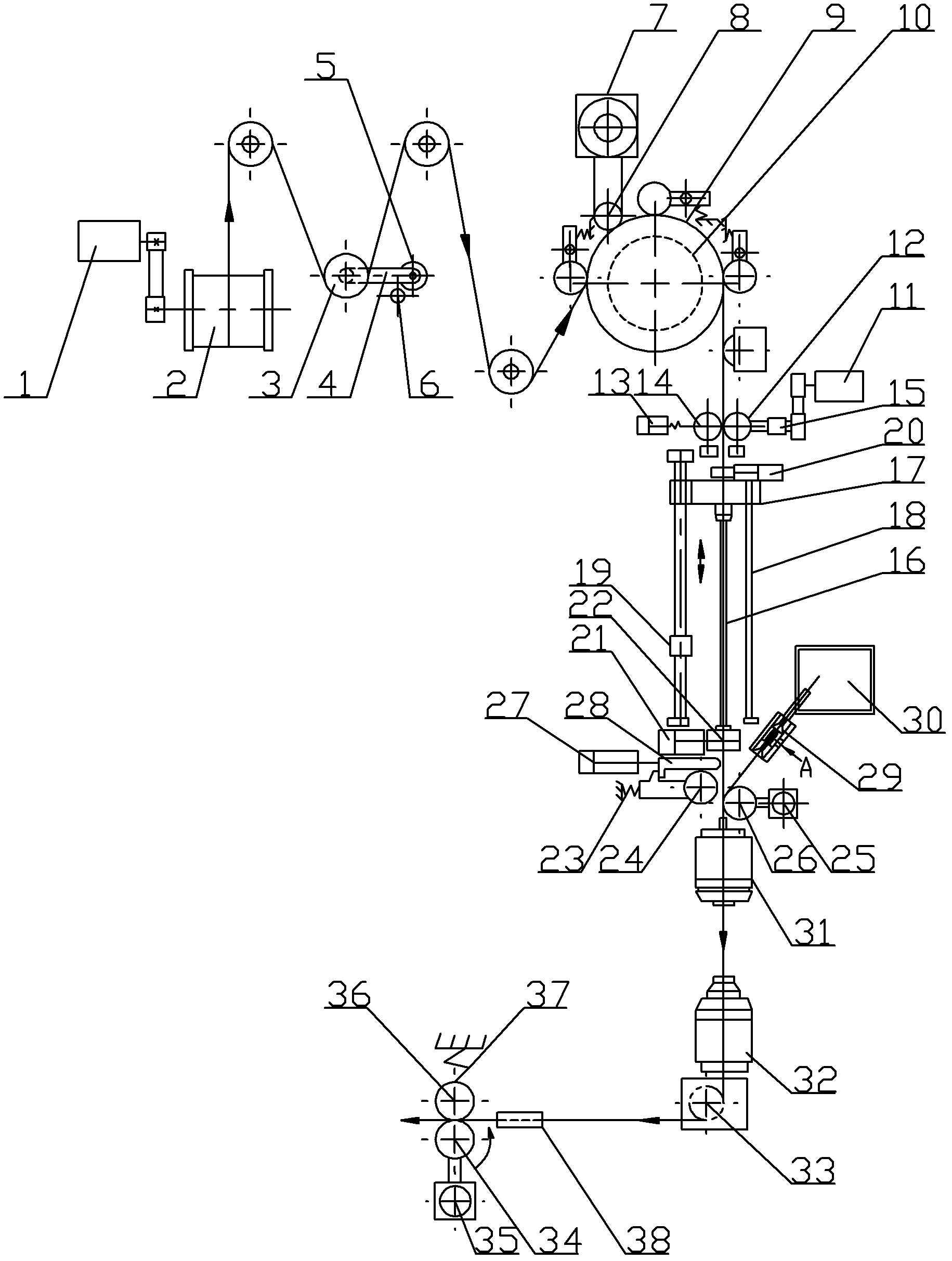

[0015] Such as figure 1 As shown, in this embodiment, the constant tension wire feeding mechanism with automatic wire threading function includes a wire release and collection device, a tension adjustment device and an automatic wire threading device, and the wire release and collection device is up to the automatic wire threading device. A first-stage tension adjustment device and a second-stage tension adjustment device are arranged between the devices; the first-stage tension adjustment device includes a balance wheel 3 and a swing rod 4, and the balance wheel 3 is connected to the sensor 5 through the swing rod 4, And on the counterclockwise rotation path of the balance wheel 3 along the swing rod 4, a reverse sensor 6 is provided; the second stage tension adjustment device includes a motor a 7, a gear 8 and a tension wheel 9, and the motor a 7 and the tension wheel 9 are driven by a gear 8, and a precision magnetic powder clutch 10 is installed inside the tension wheel 9;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com