Geosynthetic material contact surface friction strength test method

A geosynthetic material, strength testing technology, applied in analytical materials, measuring devices, instruments, etc., can solve problems such as the inability to meet stress environment requirements, and achieve the effect of simple manufacturing and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

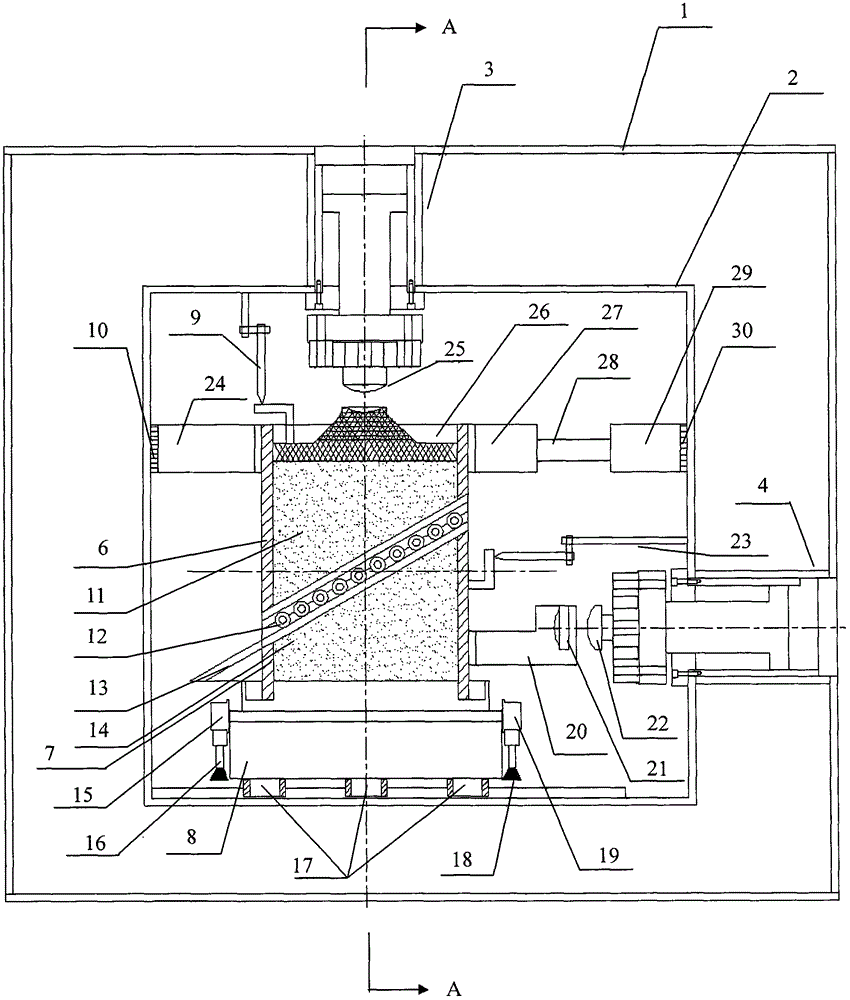

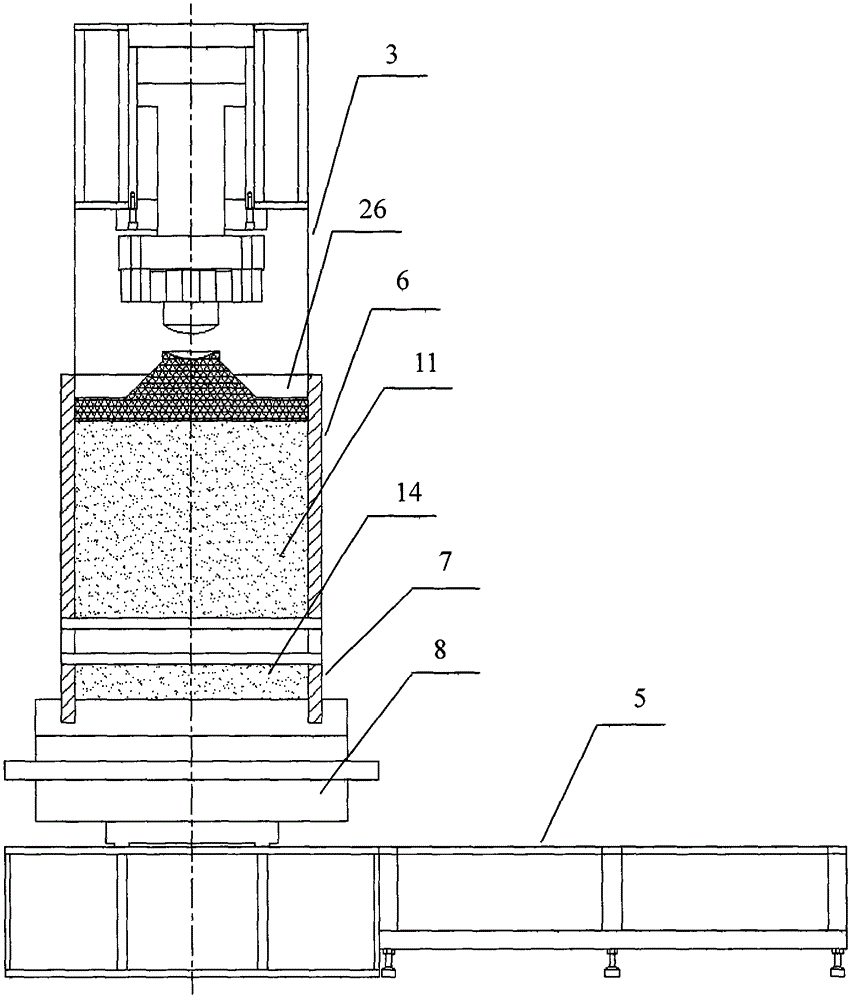

[0027] Embodiment: The test method for the friction strength of the contact surface of geosynthetics is as follows,

[0028] ①According to water content 15%, stone content 20% and density 1.9g / cm 3 Requirements, weigh the soil body, gravel and water of corresponding quality, mix the soil body, gravel and water evenly to become a mixture, and divide it into three uniform parts for later use;

[0029] ②Move the rail car 8 to the sample loading platform 5, align the upper shear box 6 with the lower shear box 7 via the ball shaft row 12, put the first mixture into the lower shear box 7, and place the pressure plate 26 is placed on the mixture, the rail car 8 is moved to just below the vertical loading shaft 25, the first jack 15 and the second jack 19 are started, and the first supporting base 16 and the second supporting base 18 are respectively connected to the loading Frame 2 is contacted, rail car 8 is suspended in the air, first servo motor 3 is started, vertical loading sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com