Hurricane panel

a technology of hurricanes and panels, applied in the direction of shutters/movable grilles, human health protection, coupling device connections, etc., can solve the problems of high structural damage, cumbersome and heavy, and inconvenient storage of plywood, etc., and achieve the effect of convenient storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

First Attempt

[0032]In our first attempt to devise a flexible window covering we tried a reinforced polypropylene membrane from CARLISLE™. The membrane was prepared by doubling the edges and heat welding. Grommets were spaced at approximately 1 ft apart. The initial material was taken to an independent laboratory and tested by firing a 2″×4″ board at 50 ft / sec at the panel. The material failed the test by tearing at the grommets. It was decided that the grommet spacing was too wide, and that the tensile strength and puncture resistance of the fabric were not strong enough. A stronger material was needed.

example 2

[0033]In our second attempt, we searched for a much stronger commercially available material. We chose a geocomposite with nonwoven batting on both sides for added strength, but having a core of EVA geomembrane in the center. We believed that batting would add considerable strength where it was needed, on the outside of the panel, and the interior core rendered the entire panel completely water- and wind-proof.

[0034]Suitable materials were available in three different weights (CANAL3 8208™, CANAL3 165016™, and CANAL3 123012™ available from HUESKER INC.™). These materials are used for environmental applications, including canal liners, landfill cover liners, and wastewater lagoon liners, but have never been applied to house construction or as hurricane protection of buildings.

[0035]The three geocomposites were purchased, fabricated into panels and tested by an independent laboratory, as above. Two of the three geocomposite panels failed the test tearing the material...

example 3

Testing

[0037]An independent laboratory performed testing on four (4) Weathervest panels. The following tests were performed:

[0038]1) ASTM E 1886-02: Standard Test Method for Performance of Exterior Windows, Curtain Walls, Doors and Storm Shutters Impacted by Missile(s) and Exposed to Cyclic Pressure Differentials.

[0039]2) ASTM E 1996-02: Standard Specification for Performance of Exterior Windows, Glazed Curtain Walls, Doors and Storm Shutters Impacted by Wind Borne Debris in Hurricanes.

[0040]3) TAS 202-94: Criteria for Testing Impact and Non Impact Resistant Building Envelope Components Using Uniform Static Air Pressure Loading.

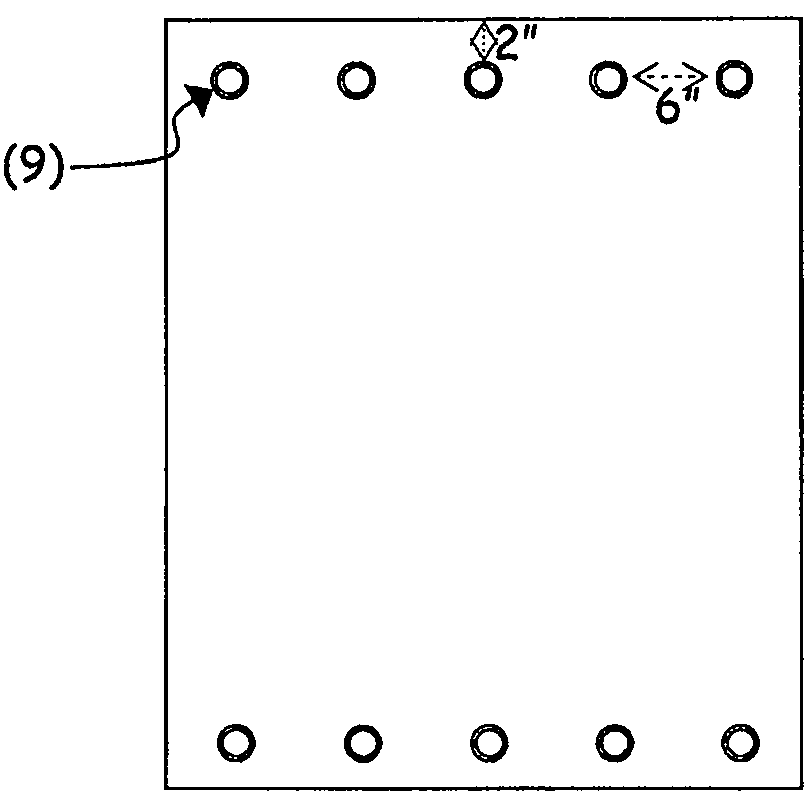

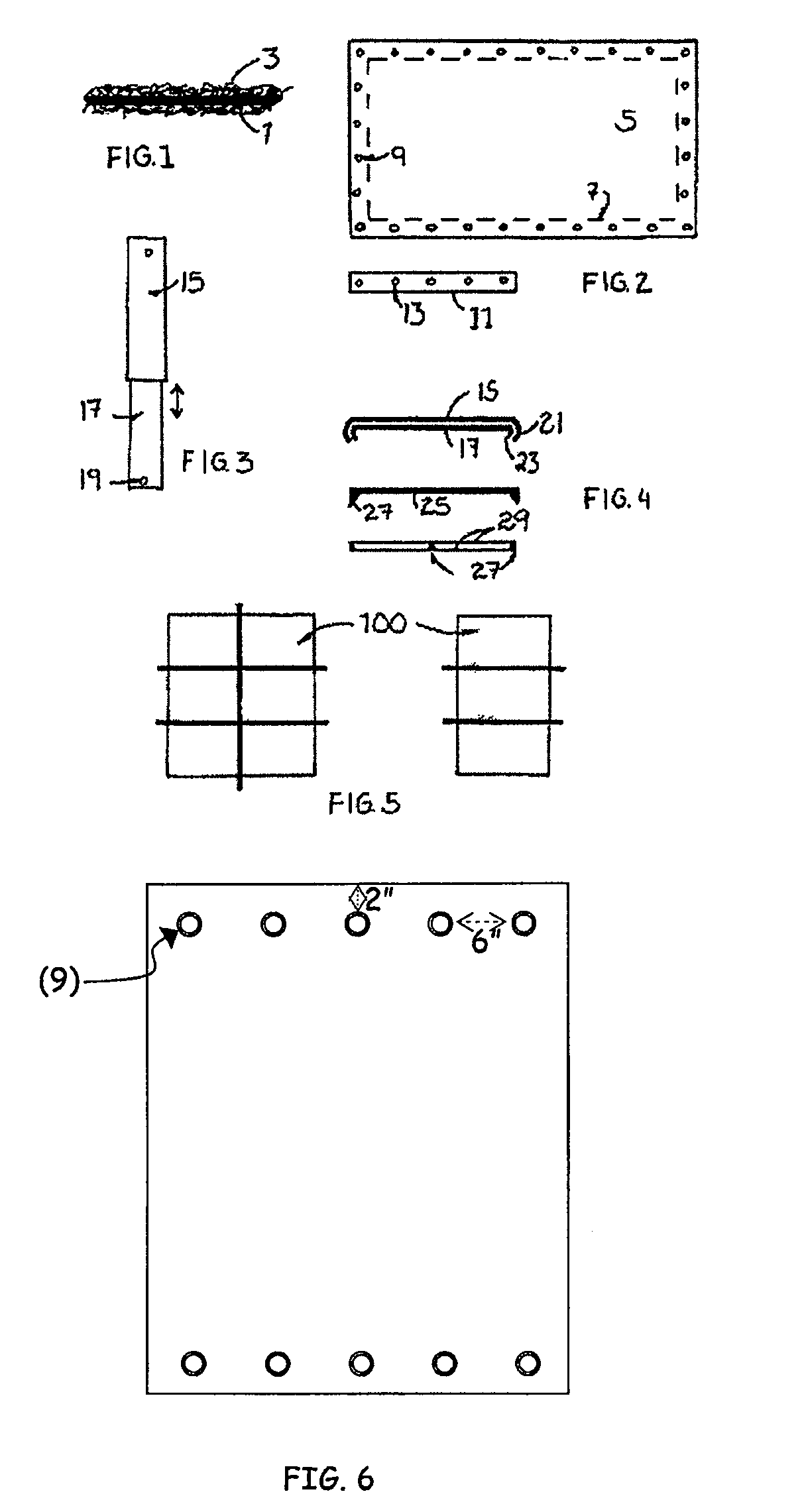

[0041]The test specimens were 6′3″ wide by 9′0″ Weathervest™ fabricated from CANAL3 123012. The edges were pierced with #4 grommets placed every 6 inches. The grommets were 2 inches away from the edge of the panel. With a 2 inch border and grommets at 6 inch intervals, it was not necessary to further reinforce the edge of the panels. The prototypes were insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com