Asphalt shingle recycling system and method

a technology of asphalt shingle and recycling system, which is applied in the direction of working up pitch/asphalt/bitumen by melting, and applications, etc., can solve the problems of air pollution from existing recycling processes, high cost of liquid asphalt cement, and difficulty in regulating the consistency of asphalt pavement composition, etc., to achieve high degree of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

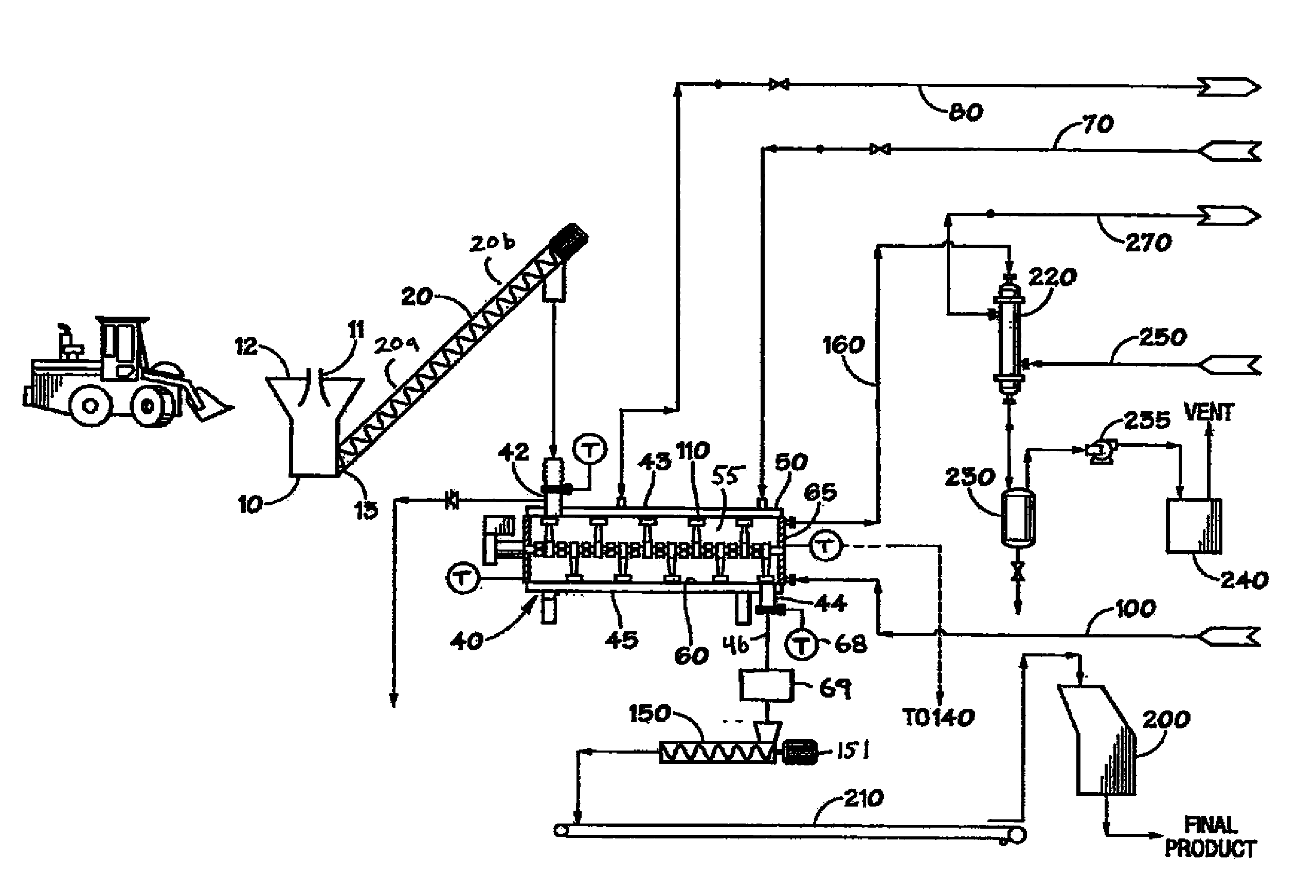

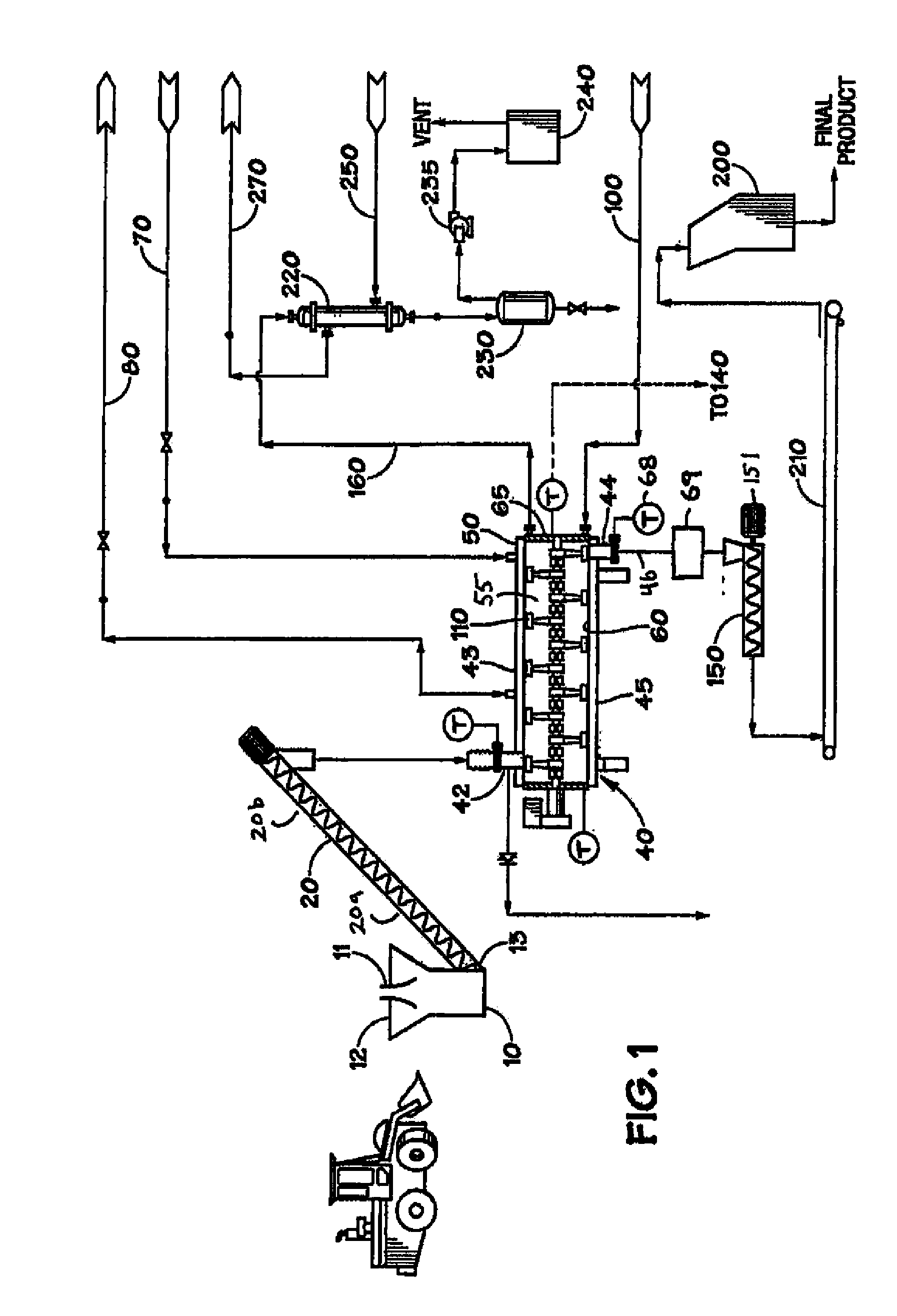

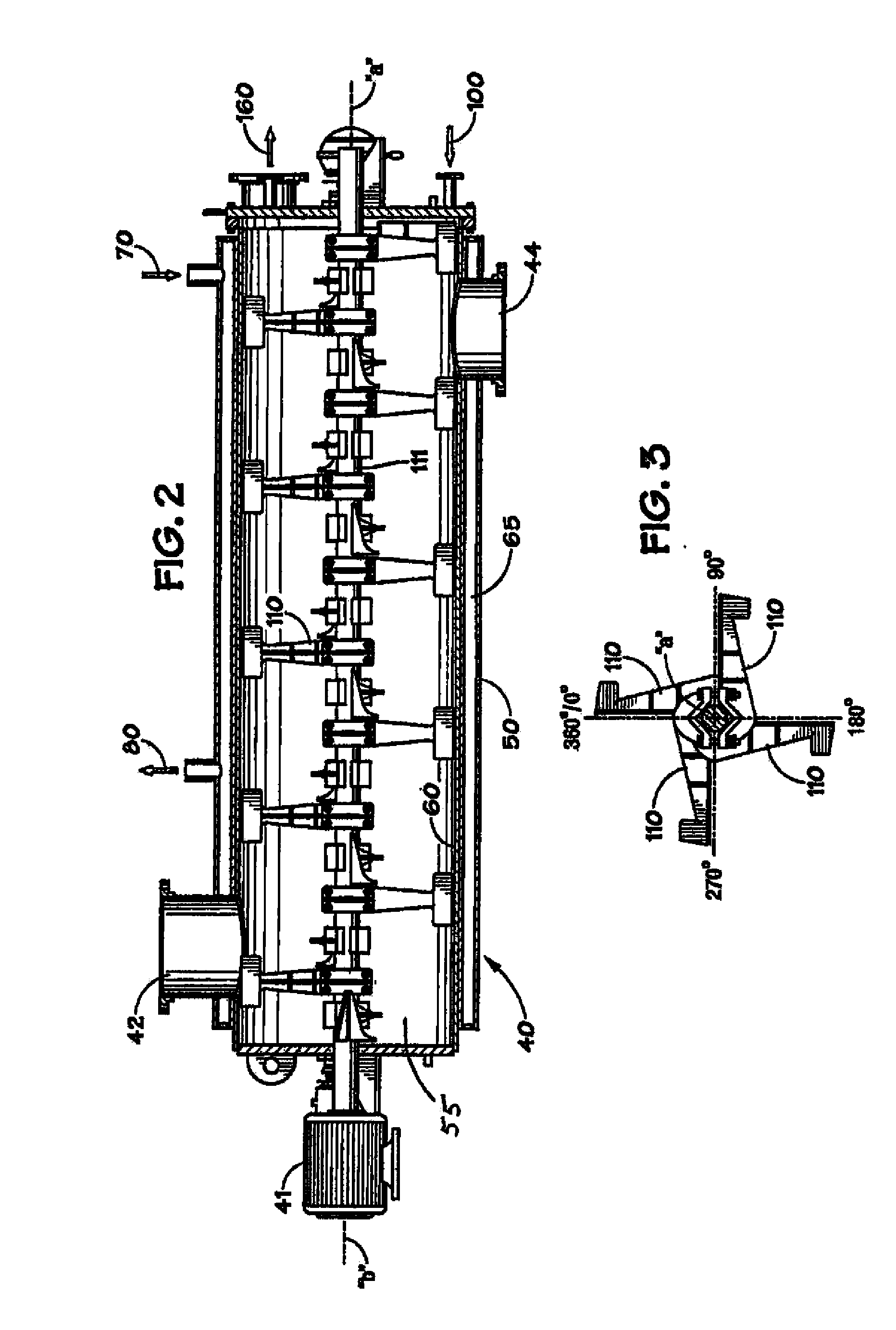

[0029]Referring now to FIGS. 1-5, an illustrative embodiment of an asphalt roofing shingle recycling system and method is provided. Scrap asphalt shingles (not shown) are collected and deposited in hopper 10. Hopper 10 is preferably of carbon steel construction and may have at least a three cubic yard storage capacity. In a specific embodiment, hopper 10 can have hinged doors 11 at or near its top end 12 through which scrap asphalt shingles may be loaded. Alternatively, scrap asphalt shingles may be loaded into hopper 10 by other means not requiring the use of hinged doors 11 as shown in the embodiment of FIG. 6, or by any feed, loader, or supply device capable of supplying scrap asphalt shingles into the shingle recycling system.

[0030]The contents of hopper 10 can empty onto a screw conveyer 20 by opening bottom doors 13. Screw conveyer 20 preferably has at least a ten ton-per-hour capacity and may be driven by any suitable motor, such as a variable frequency drive (“VFD”) motor, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com