Bitumen flue gas purifying method and device

A bitumen flue gas and purification device technology, which is applied to chemical instruments and methods, separation methods, melting and processing of tar pitch/petroleum pitch/natural pitch, etc., can solve the problems of high operating costs, achieve reliable operation, low operating costs, and high-tech principle reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

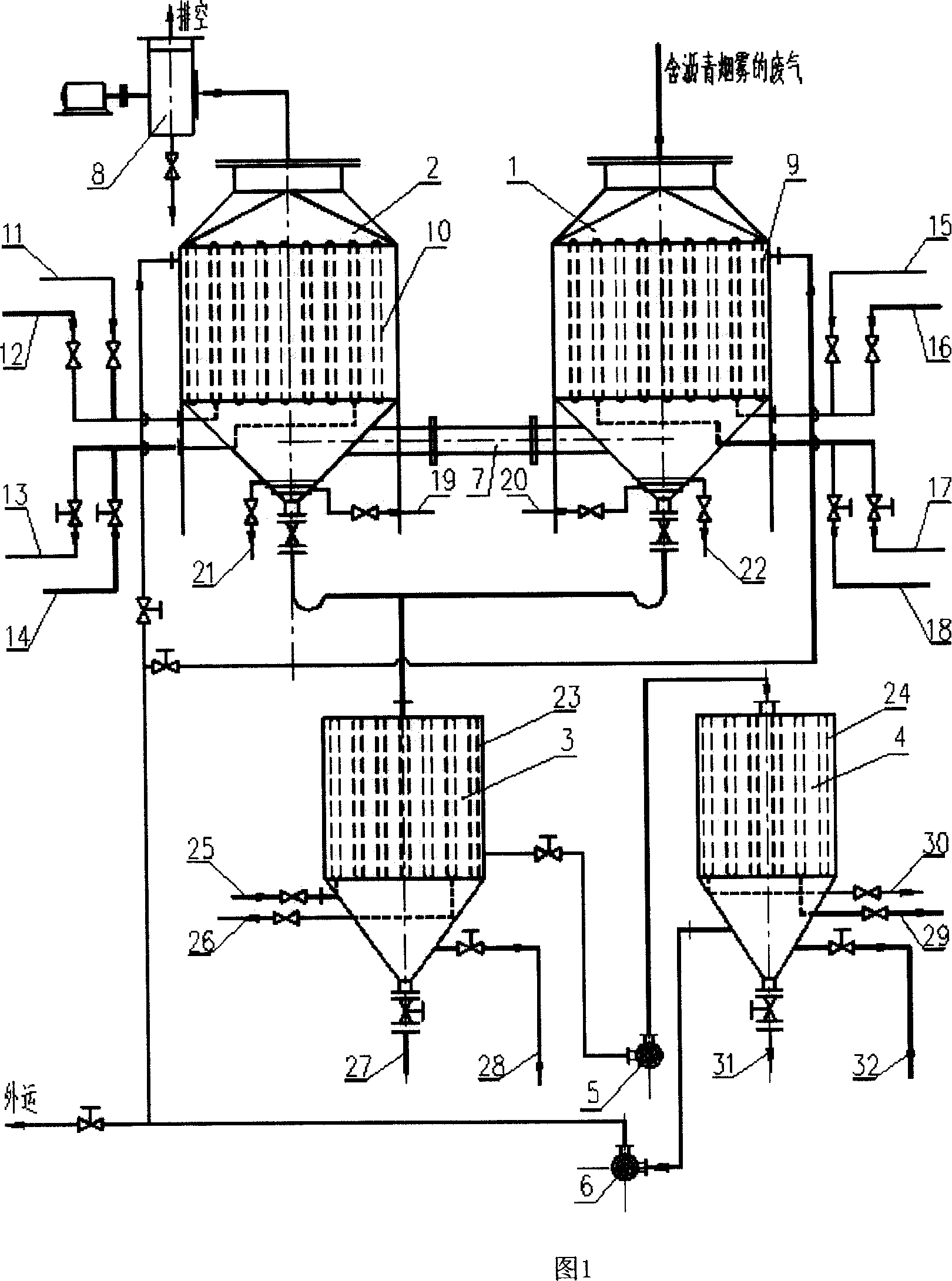

[0019] Embodiment of the present invention: the condenser 1 and the condenser 2 are respectively provided with a serpentine tube 9 and a serpentine tube 10 . Serpentine pipe 9 is connected with water outlet 11, steam outlet 12, drain outlet 13, and steam outlet 14; serpentine pipe 10 is connected with water outlet 15, steam outlet 16, drain outlet 17, and steam outlet 18; water outlet 11. Cooling water is passed through the water outlet 15, and the temperature is 25°C to 30°C and 15°C to 20°C respectively. The lower part of the lower cone of the condenser 1 is provided with a steam outlet 20 and a steam outlet 22; the lower part of the lower cone of the condenser 2 is provided with a steam outlet 19 and a steam outlet 21; the steam outlet 20, the steam outlet 19, heat preservation (steam pressure p=0.2~0.3Mpa) through steam.

[0020] The oil-water separator 3 and the tar storage tank 4 are also provided with a serpentine pipe 23 and a serpentine pipe 24 respectively. The serp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com