Patents

Literature

165results about How to "Fast recovery time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

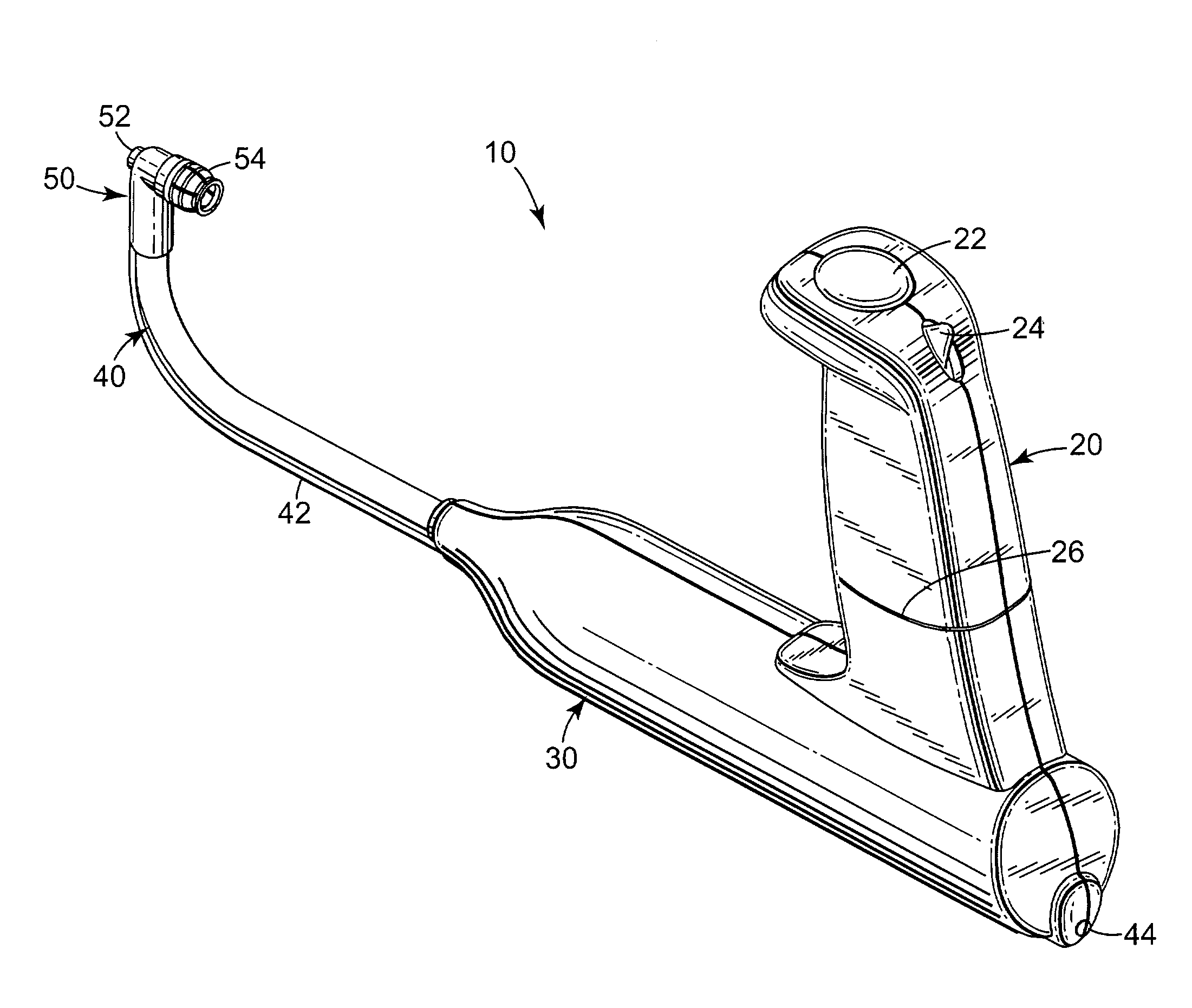

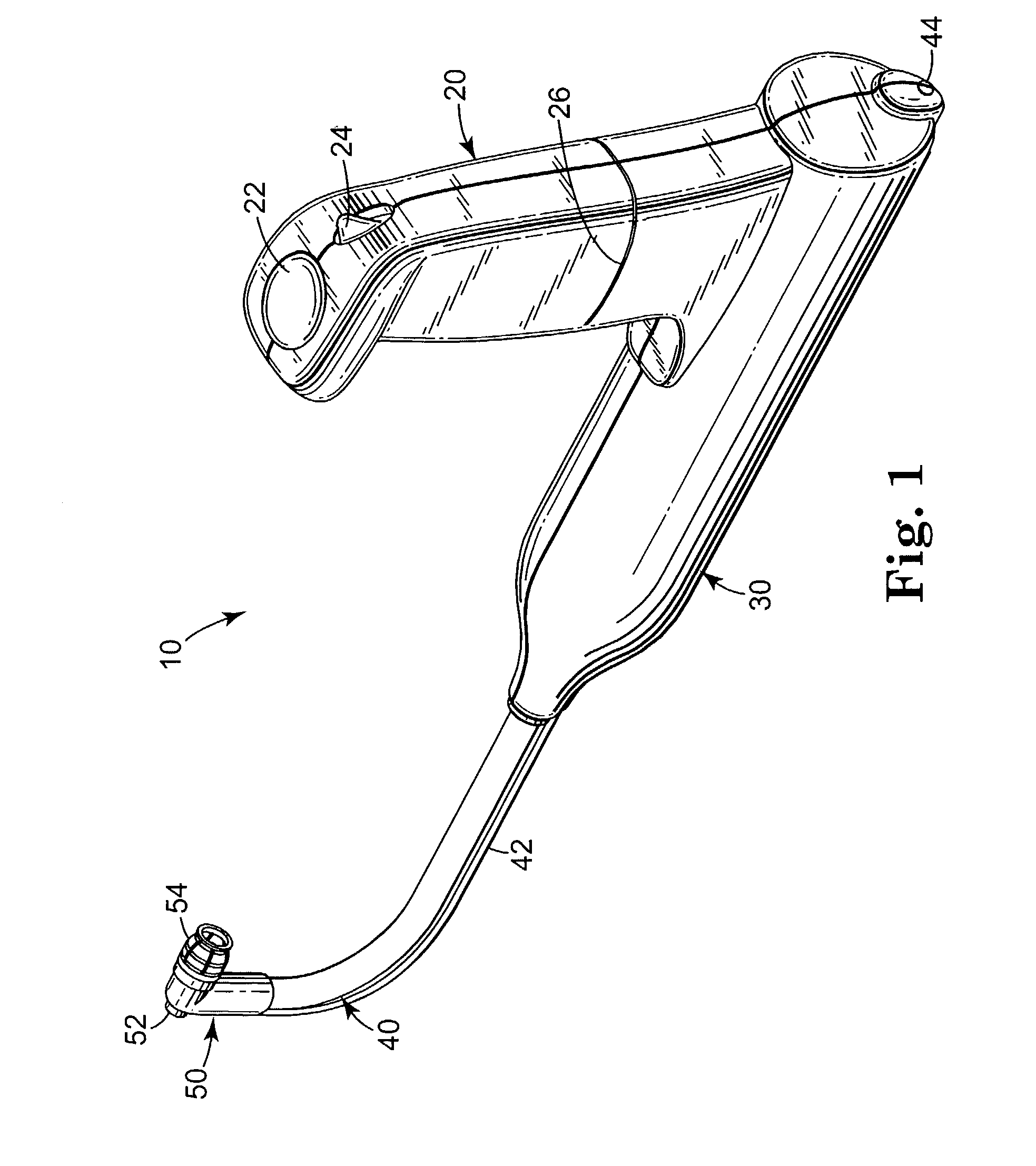

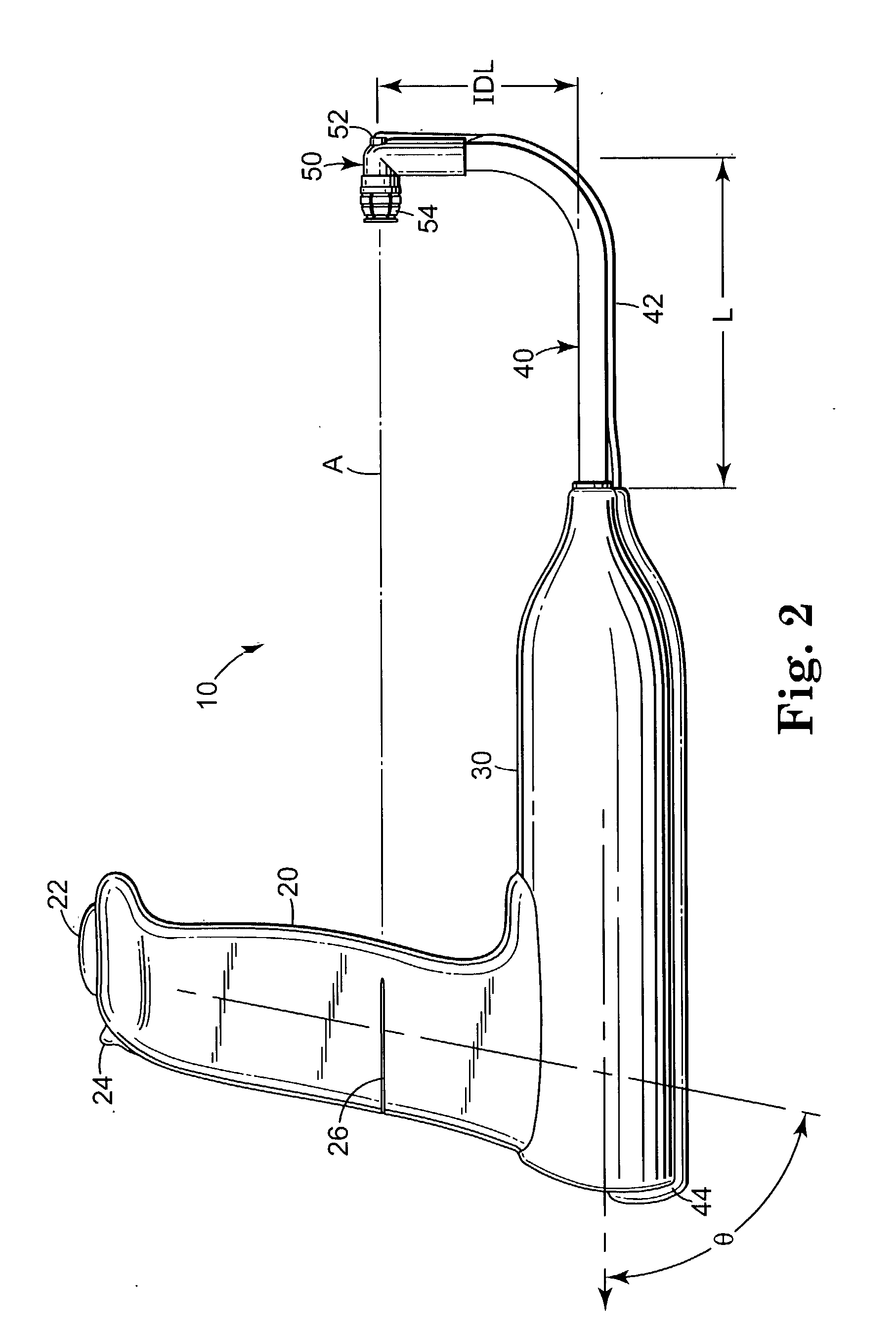

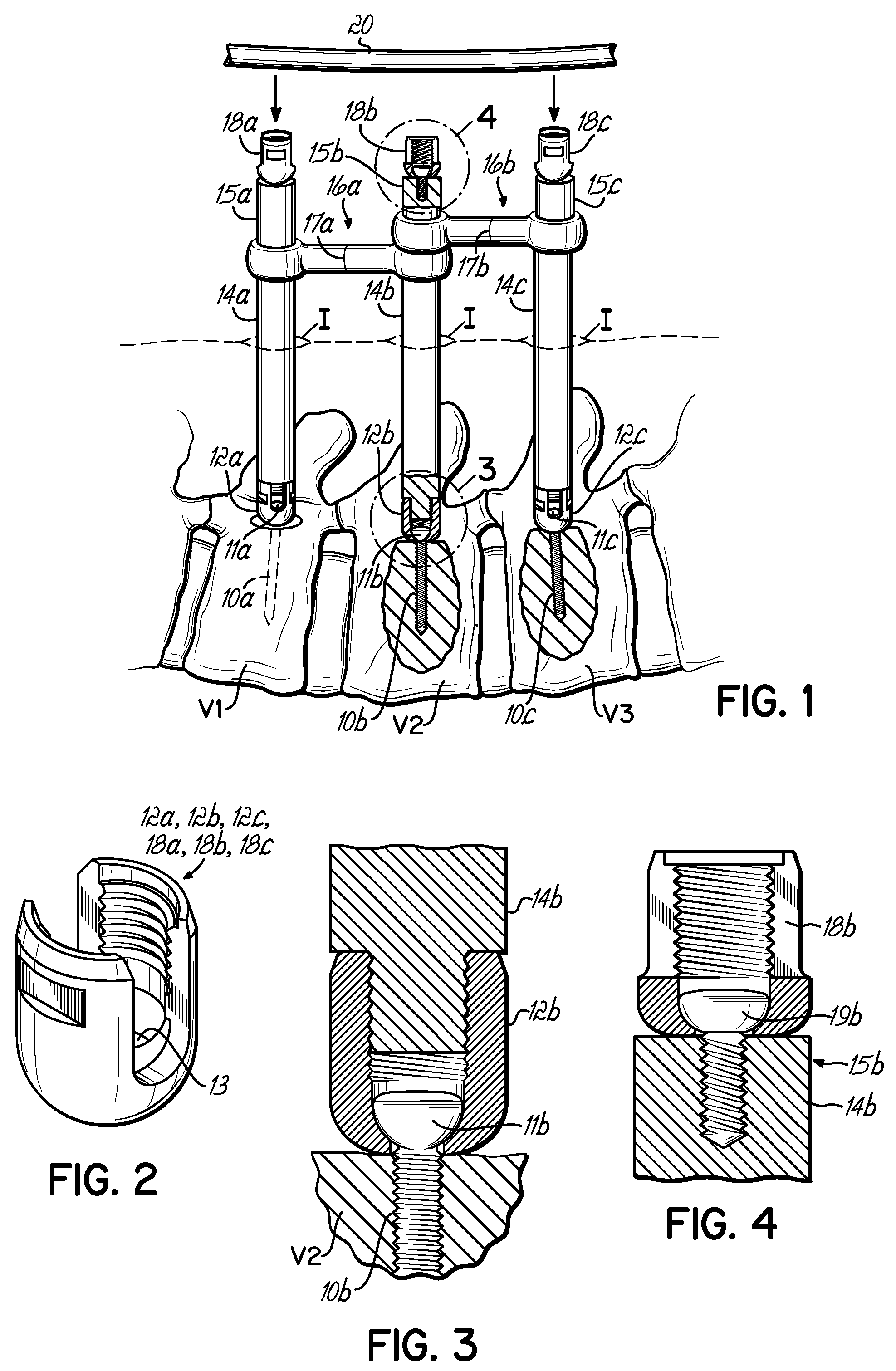

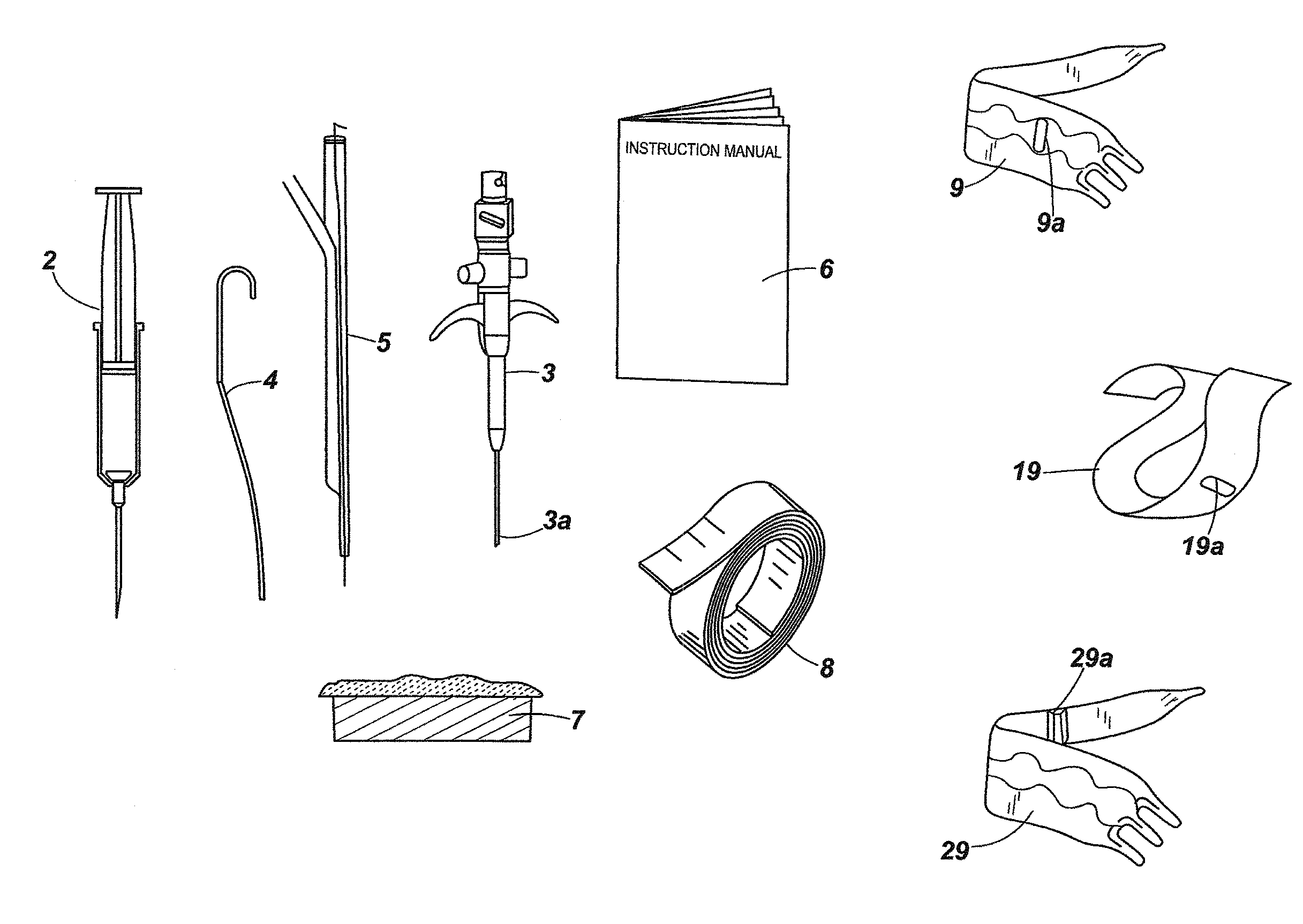

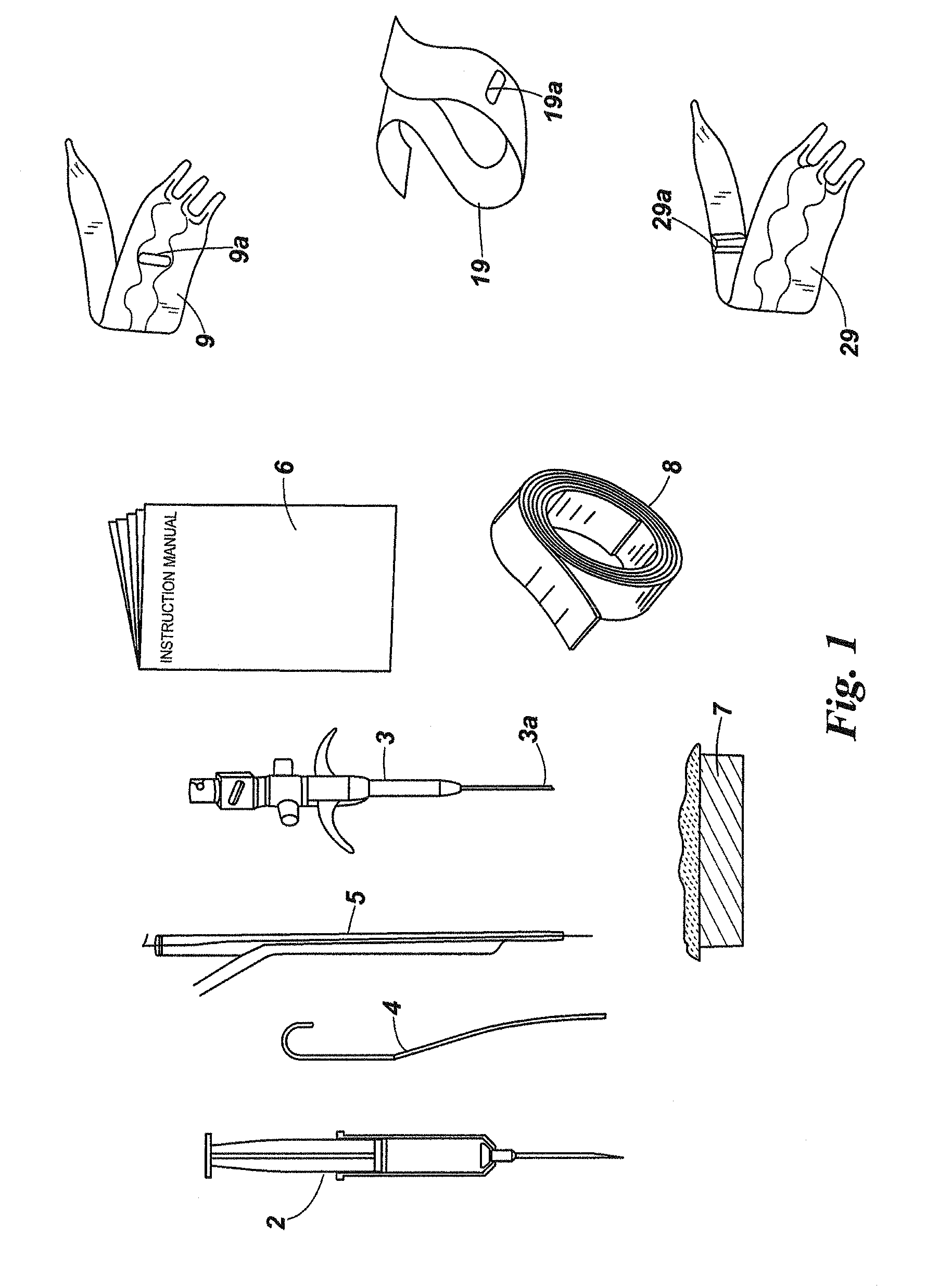

Bone anchor inserters and methods

InactiveUS20020183762A1Small sizeAvoid damageSuture equipmentsSpannersBiomedical engineeringBone Anchors

Bone anchor inserters are described. The inserters may be used in novel methods. Kits that include the novel inserters are also described.

Owner:AMS RES CORP

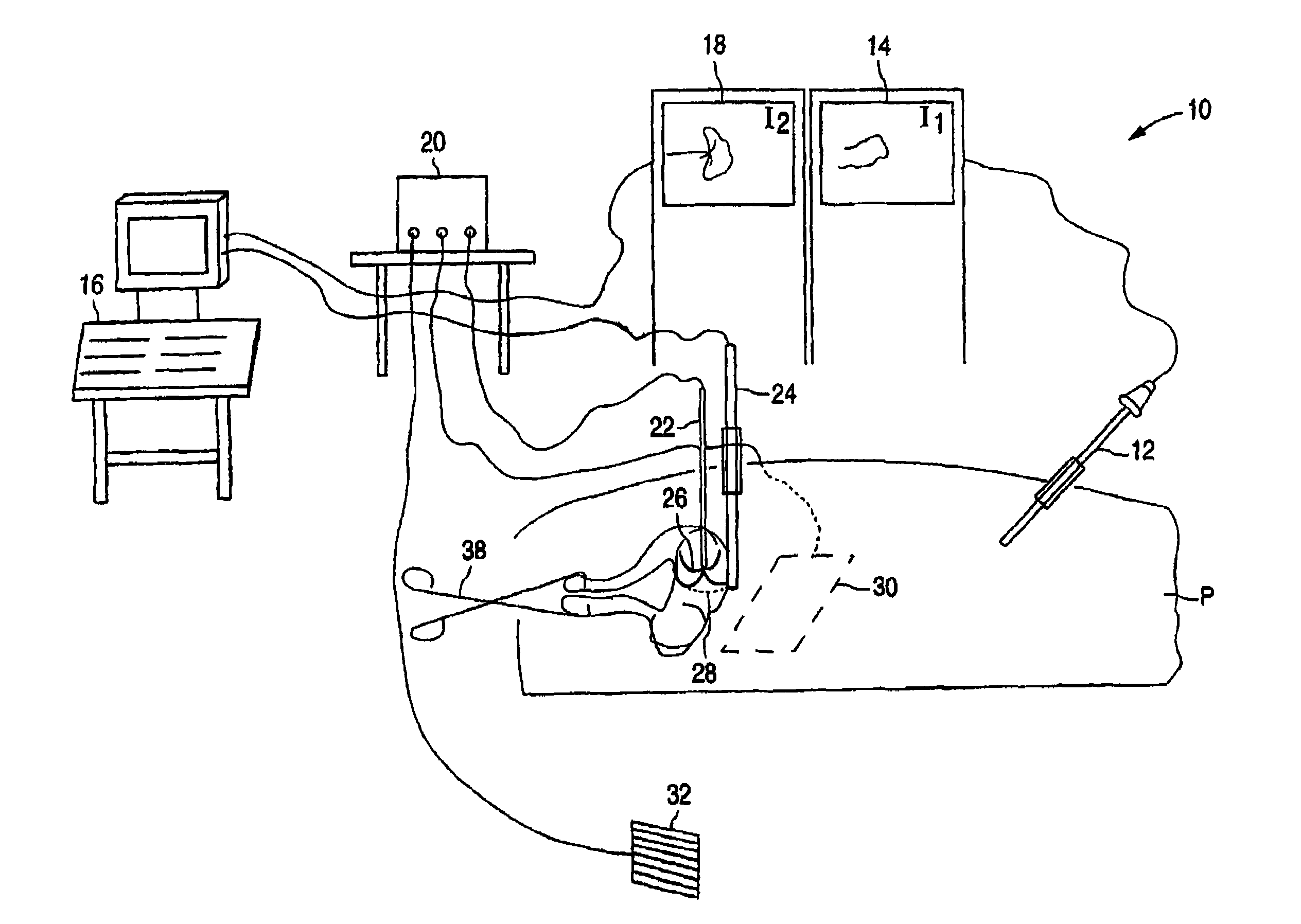

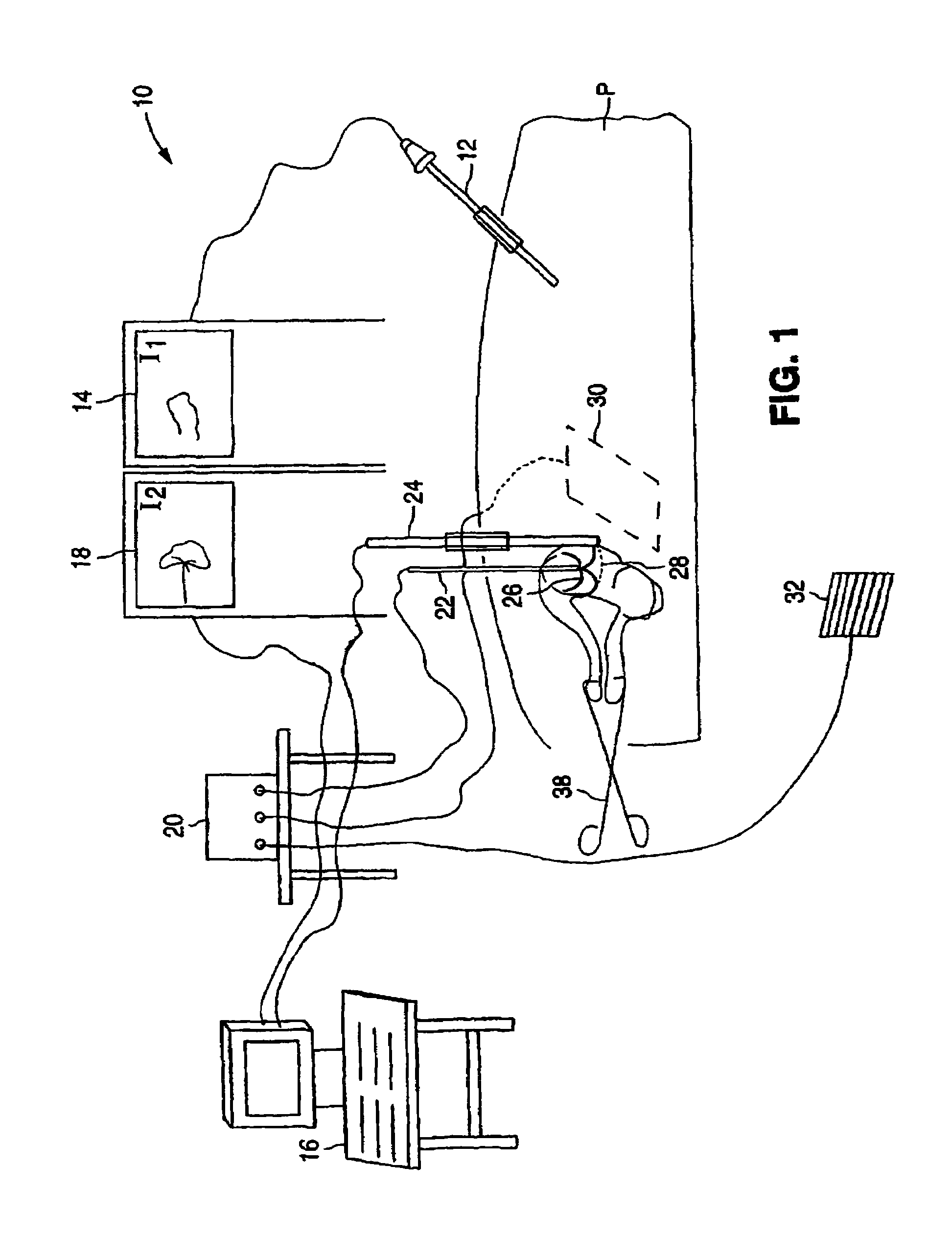

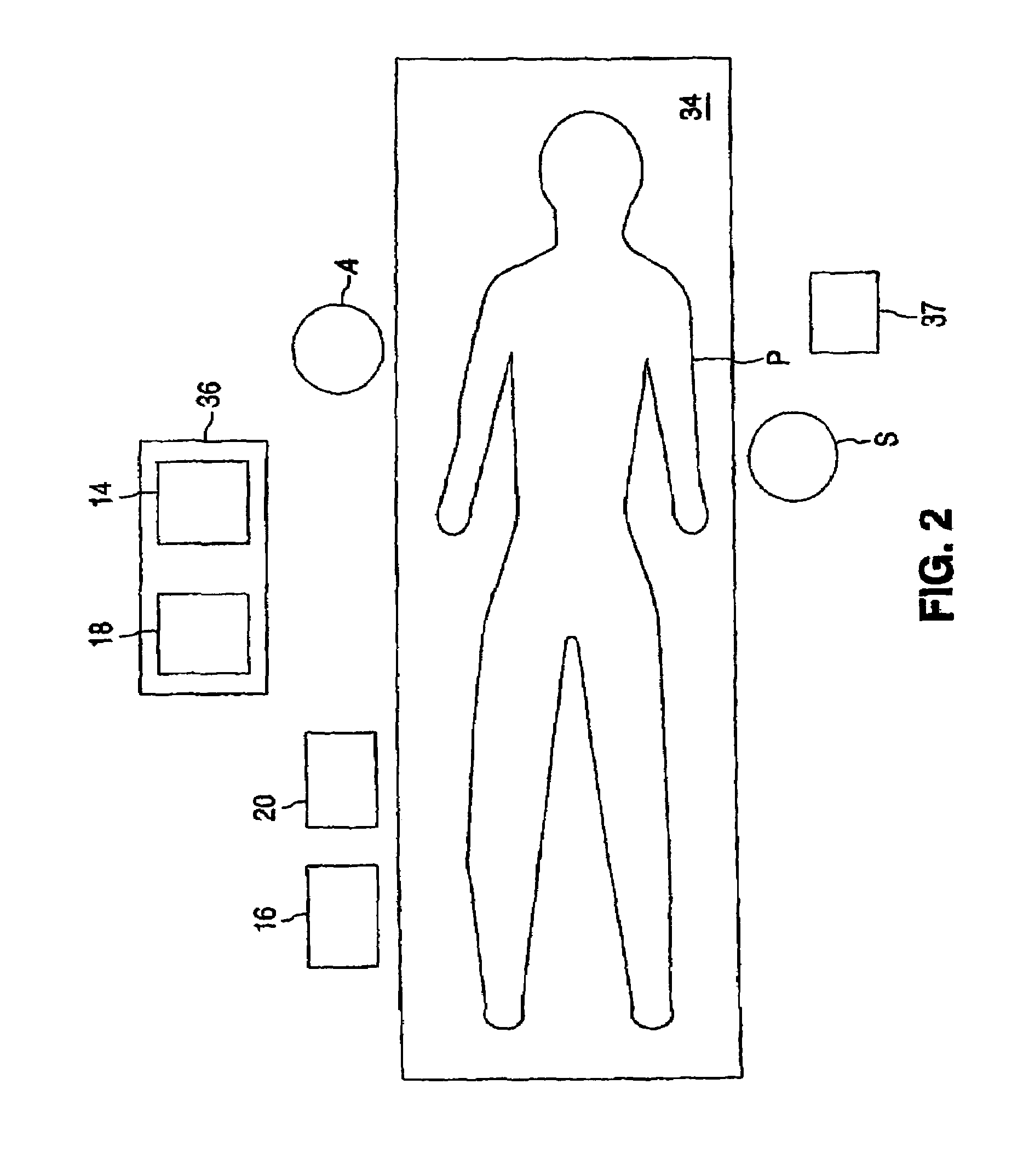

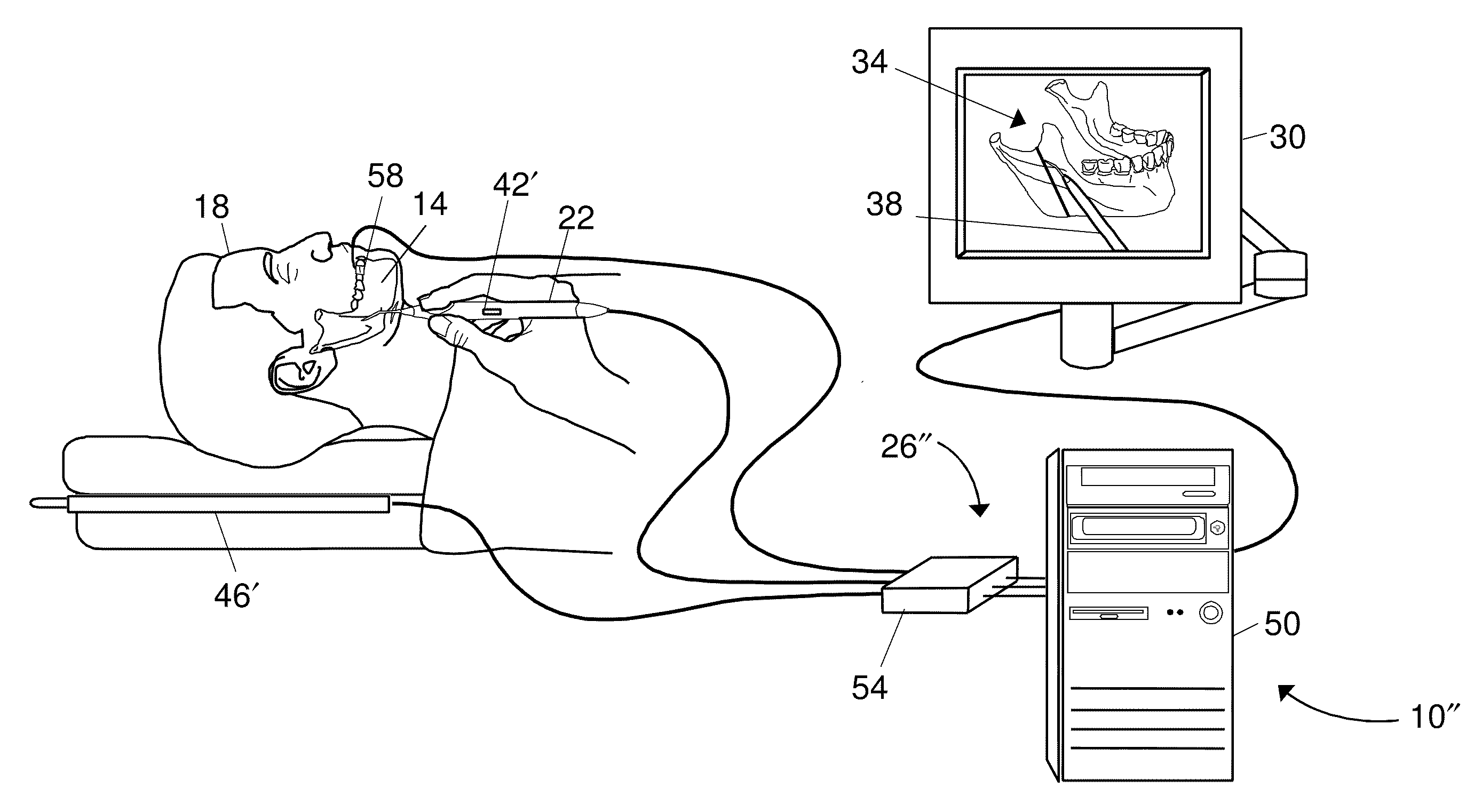

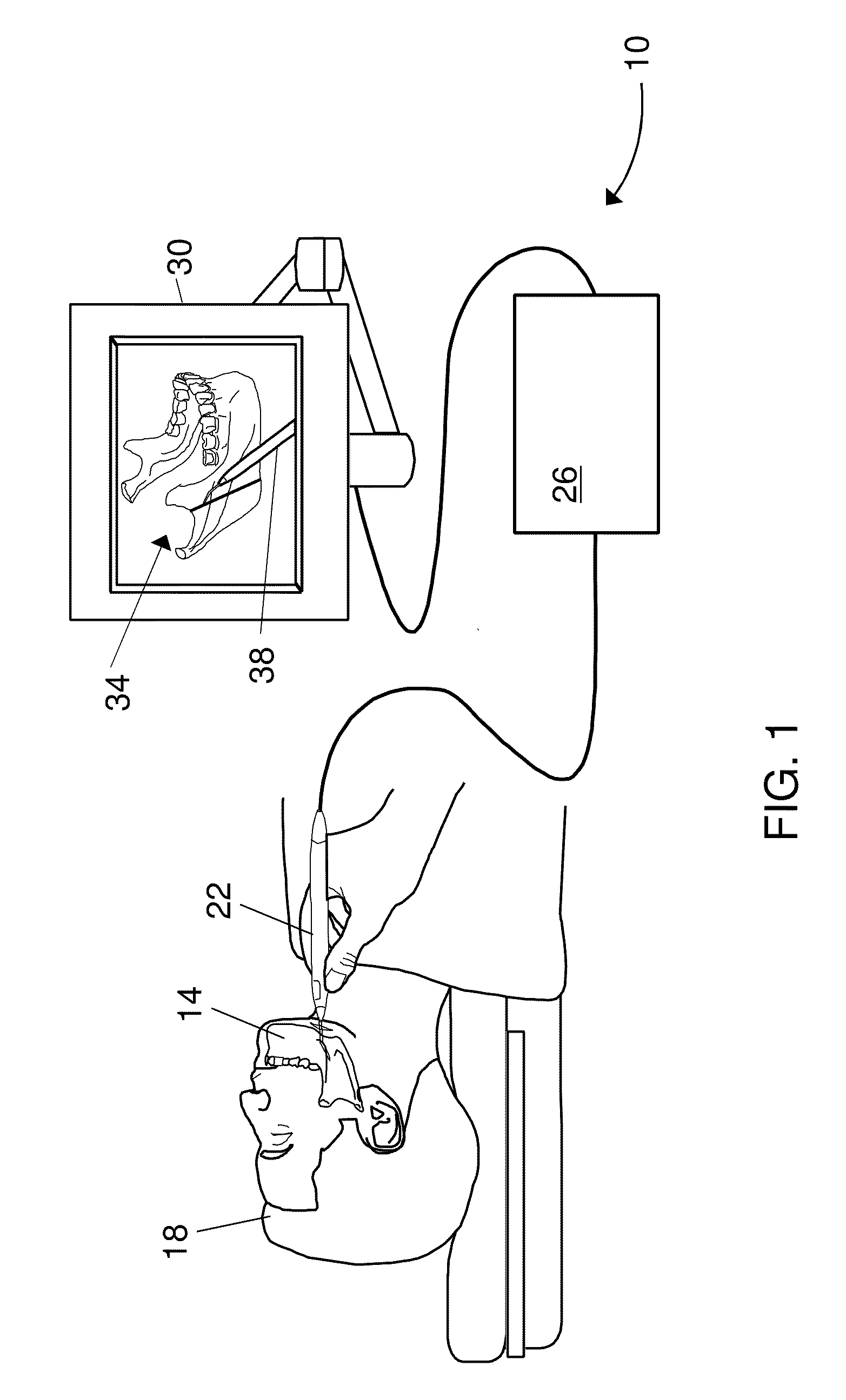

Gynecological ablation procedure and system

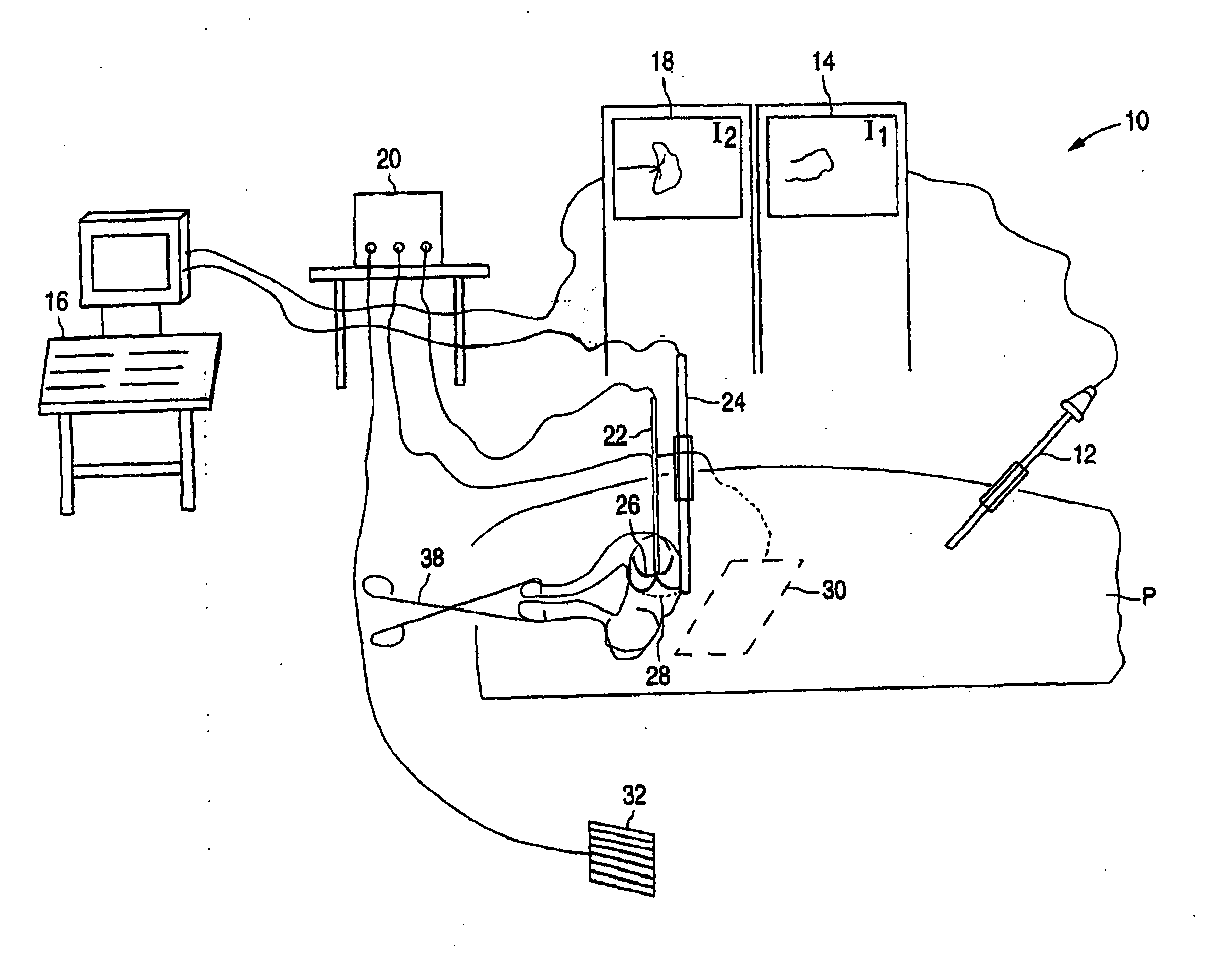

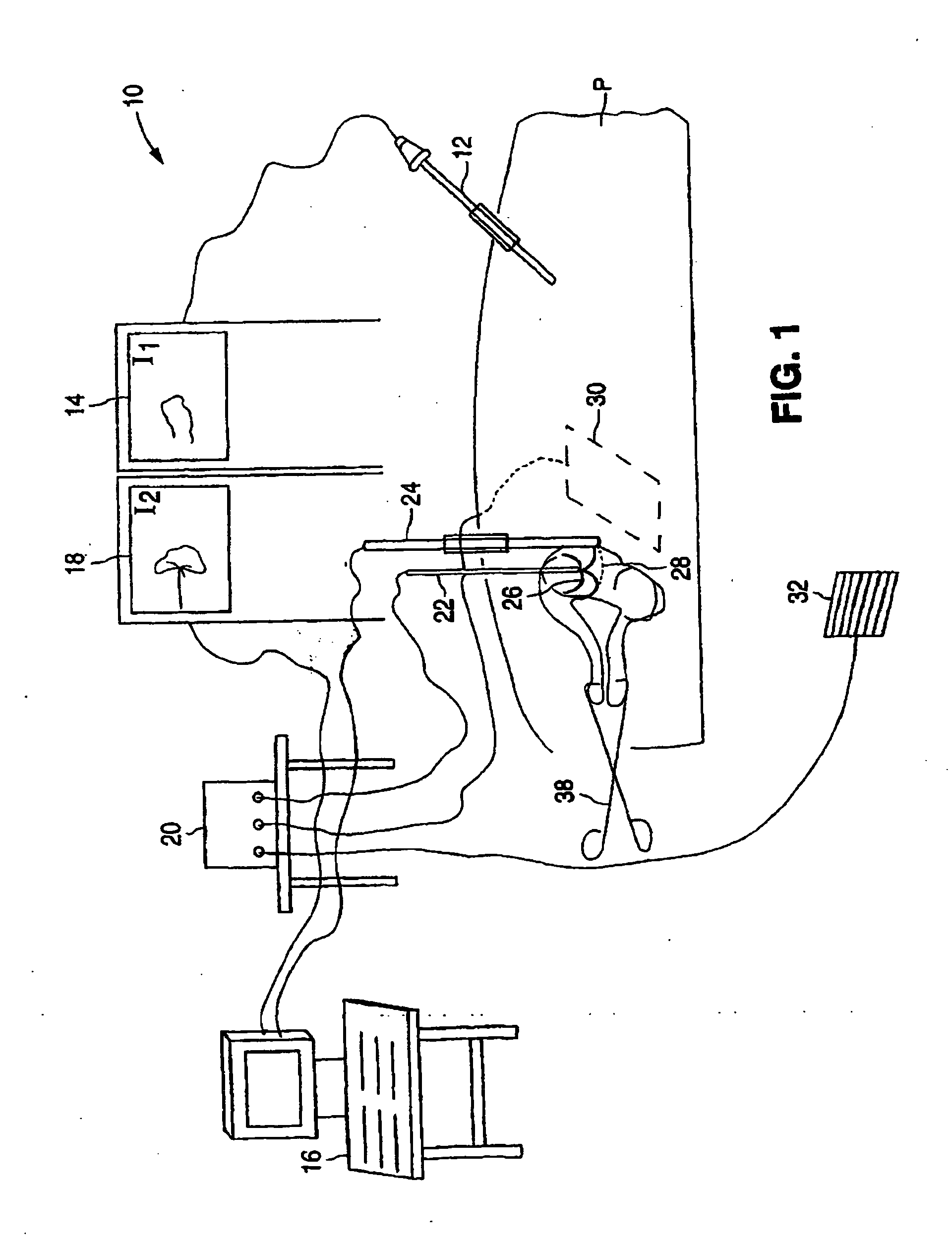

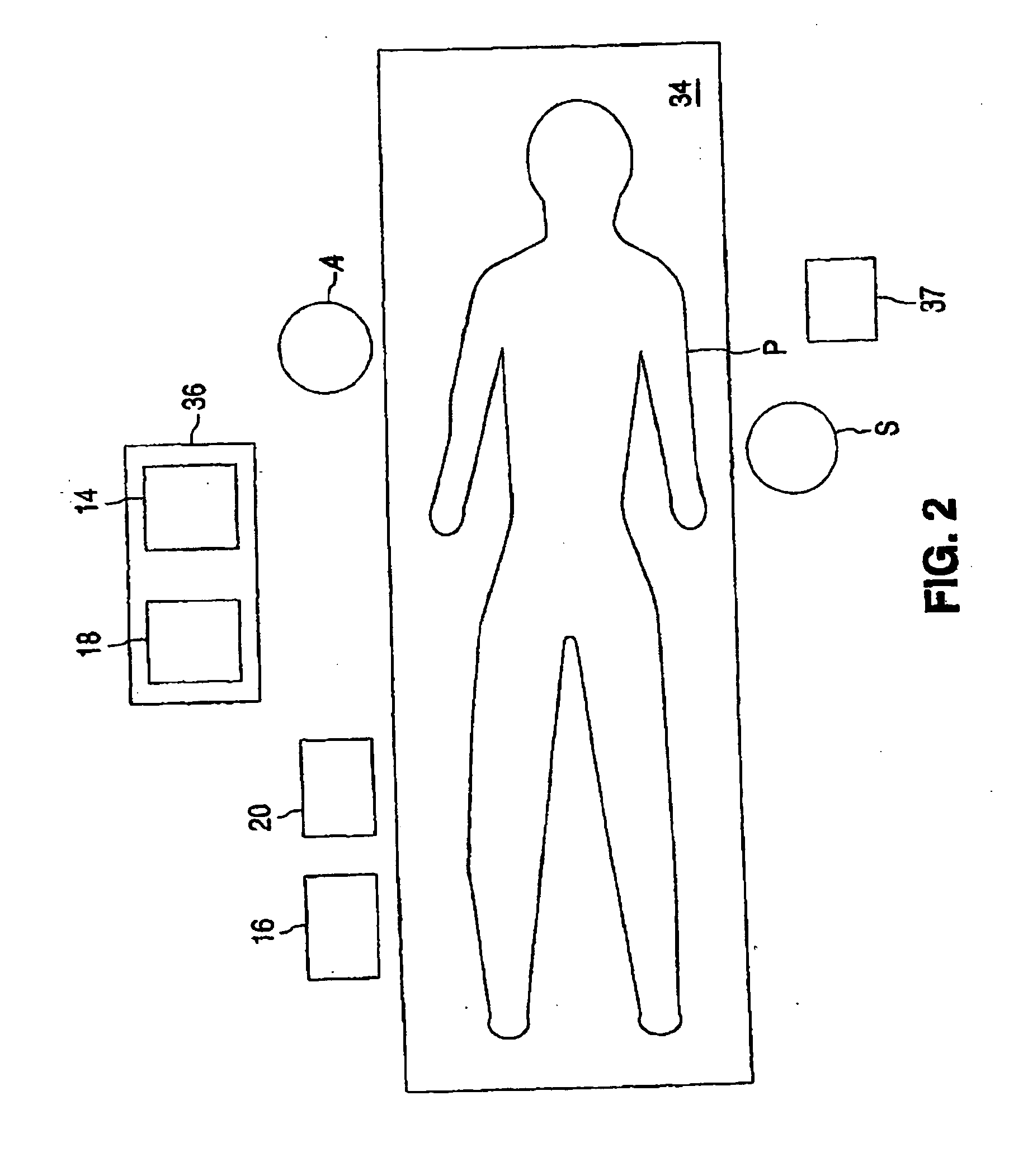

ActiveUS7678106B2Efficient ablationFast recovery timeDiagnosticsSurgical navigation systemsPelvic regionPERITONEOSCOPE

A method for treating tumors, such as uterine leiomyomata, includes inserting an ablation apparatus into a pelvic region and positioning the ablation apparatus into a pelvic tumor. The method further includes using a laparoscope and an imaging device, such as an ultrasound machine, to confirm the location of the pelvic tumor and placement of the ablation apparatus. The method further includes delivering electromagnetic energy or other energy through the ablation apparatus to the pelvic tumor to directly ablate the tumor. A surgical system for ablating pelvic tumors is also provided.

Owner:ACESSA HEALTH INC +1

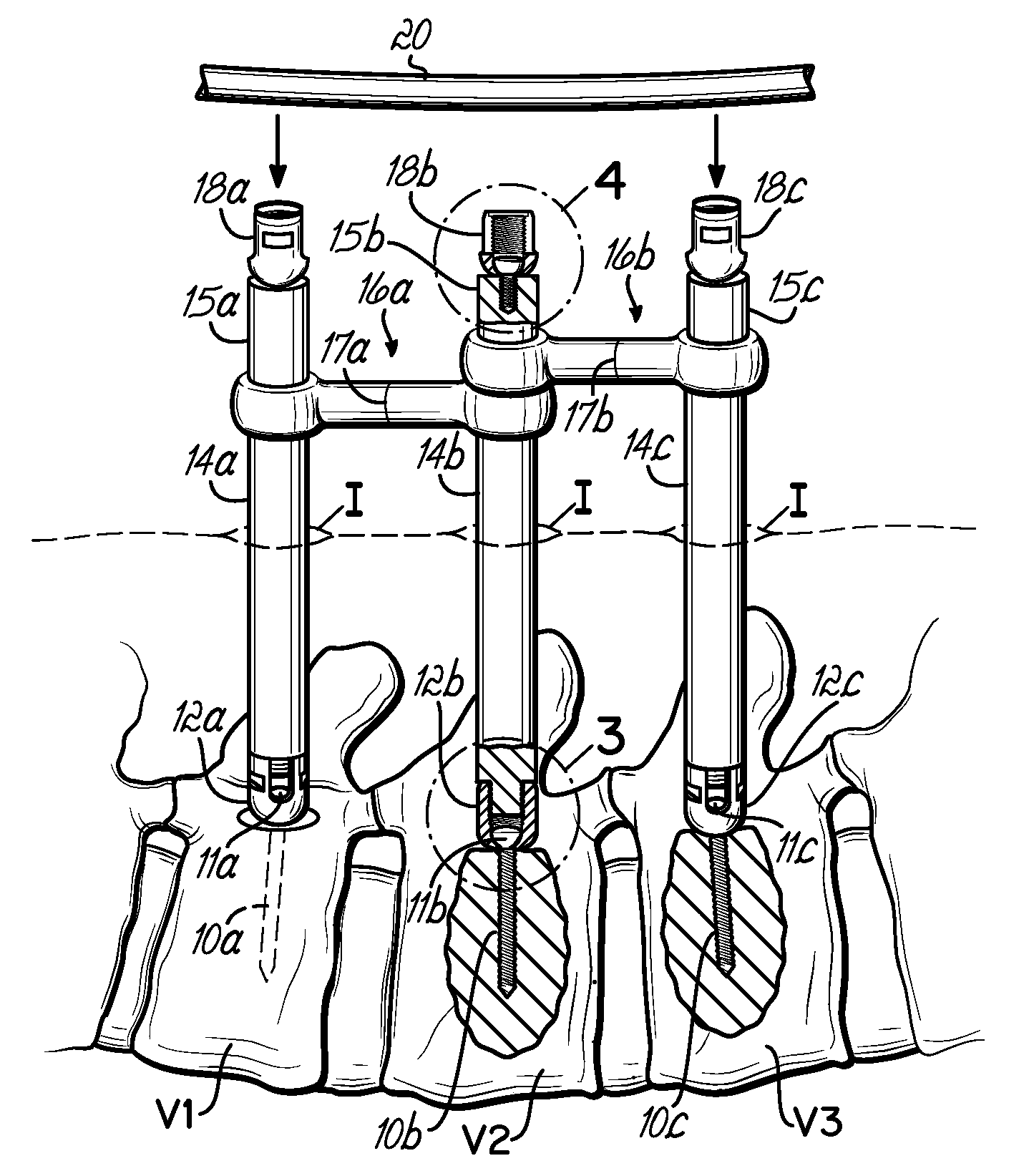

Pedicle fixation rod alignment system

InactiveUS20070093824A1Shorten the timeImprove visualizationInternal osteosythesisJoint implantsTranspedicular fixationEngineering

A method and associated system of implanting a vertebral anchor such as a pedicle screw assembly includes the steps of implanting a number of pedicle screws into a series of vertebrae; attaching a number of provisional posts to respective pedicle screws, each provisional post including a provisional saddle; bending a rod to conform to a desired alignment of the provisional saddles; removing the provisional posts from the pedicle screw heads; and connecting the bent rod to the pedicle screw heads. Advantageously, the method allows external fitting and sizing of a fixation rod before it is implanted and secured to the vertebral anchors via a minimally invasive manner.

Owner:ZIMMER SPINE INC

Gynecological ablation procedure and system

ActiveUS20050149013A1Efficient ablationFast recovery timeDiagnosticsSurgical navigation systemsAbnormal tissue growthPelvic region

A method for treating tumors, such as uterine leiomyomata, includes inserting an ablation apparatus into a pelvic region and positioning the ablation apparatus into a pelvic tumor. The method further includes using a laparoscope and an imaging device, such as an ultrasound machine, to confirm the location of the pelvic tumor and placement of the ablation apparatus. The method further includes delivering electromagnetic energy or other energy through the ablation apparatus to the pelvic tumor to directly ablate the tumor. A surgical system for ablating pelvic tumors is also provided.

Owner:ACESSA HEALTH INC +1

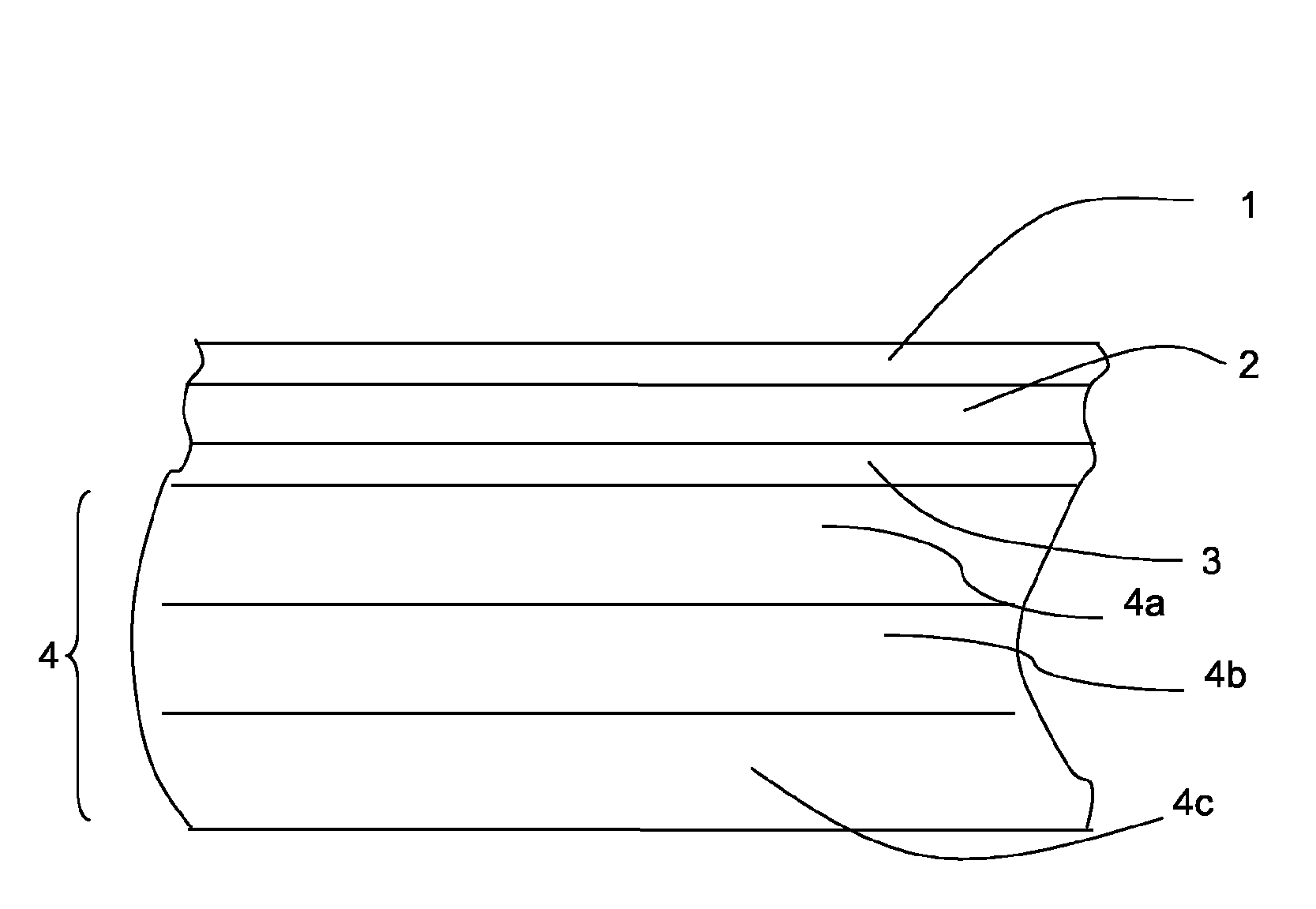

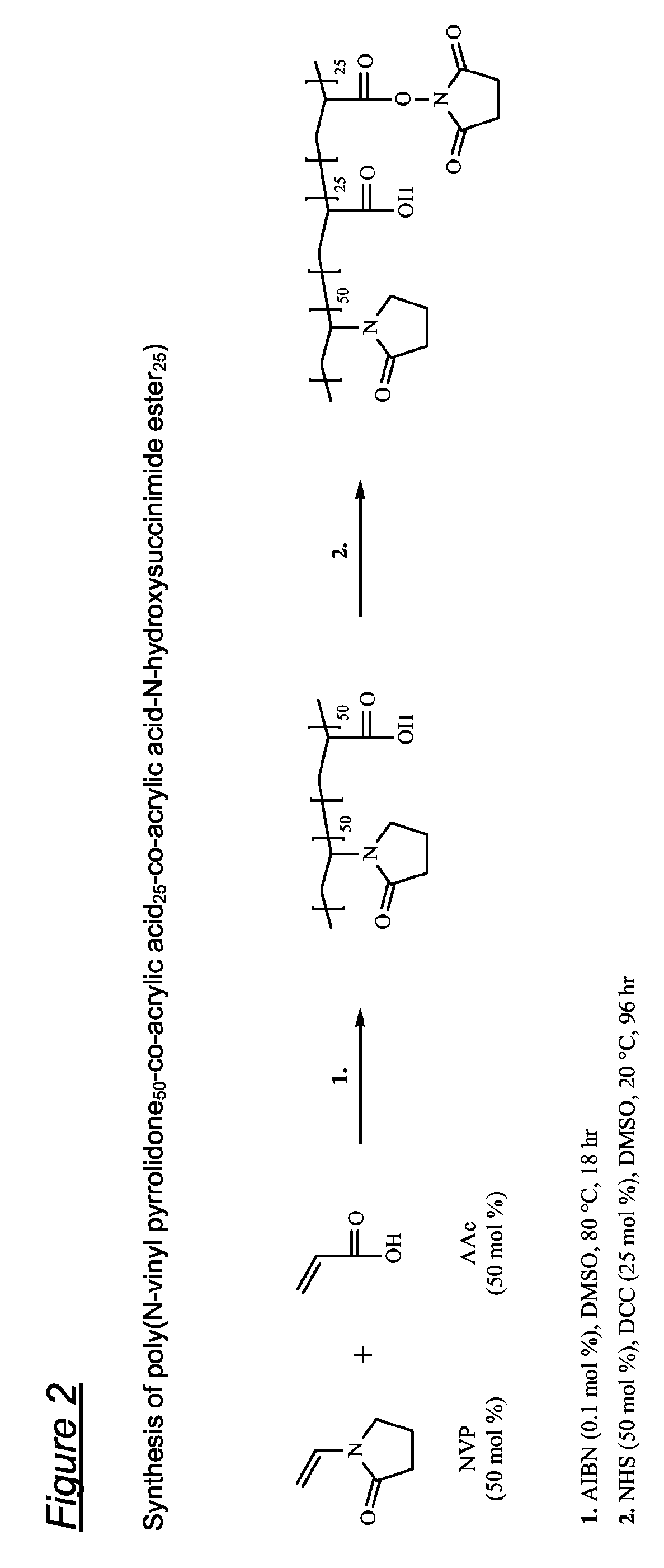

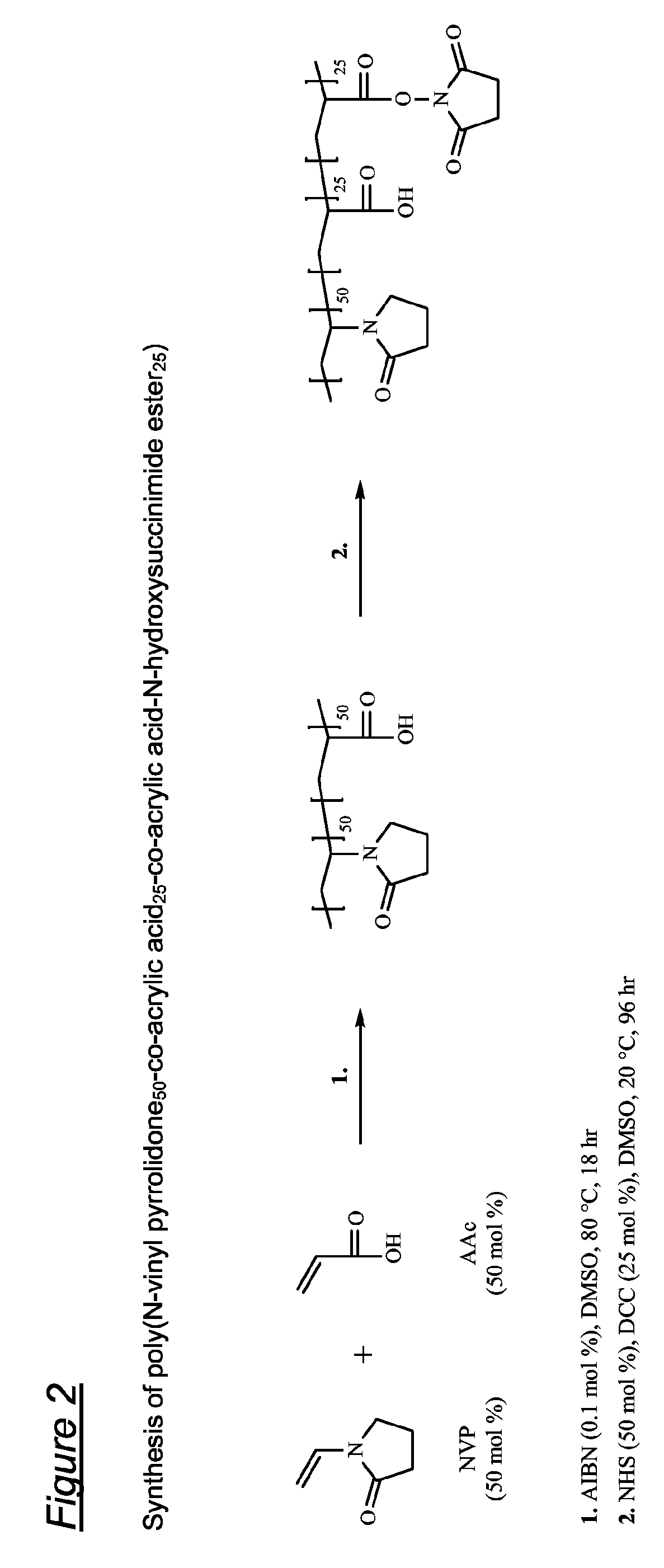

Tissue-adhesive materials

A multi-lamellar tissue-adhesive sheet comprises a structural layer or laminate conjoined to a tissue-contacting layer. The structural layer or laminate comprises one or more synthetic polymers having film-forming properties, and the tissue-contacting layer of material contains tissue-reactive groups. The synthetic polymers having film-forming properties are preferably biodegradable polyesters, and the tissue-reactive groups are most preferably NHS-ester groups.

Owner:TISSUEMED LTD

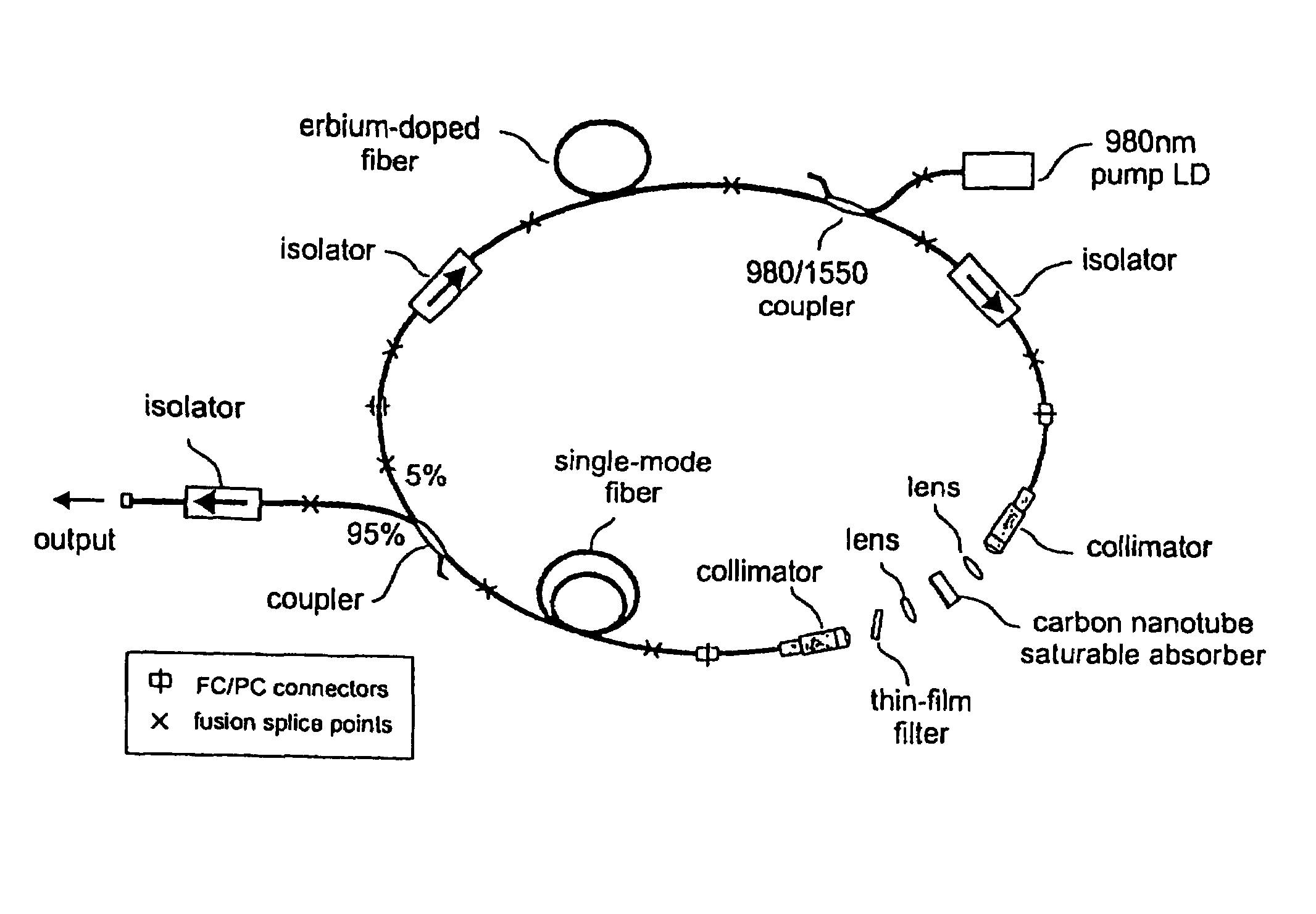

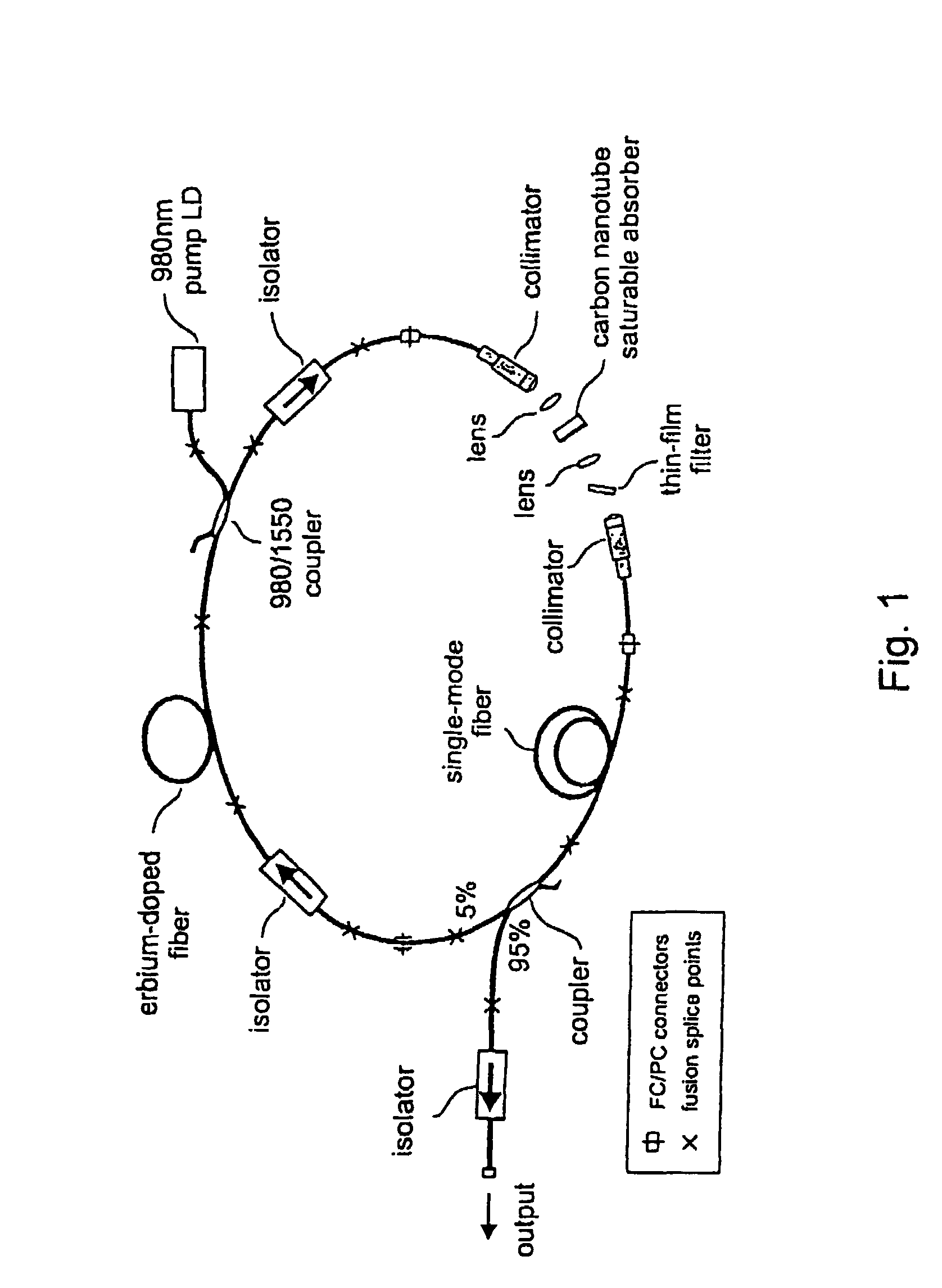

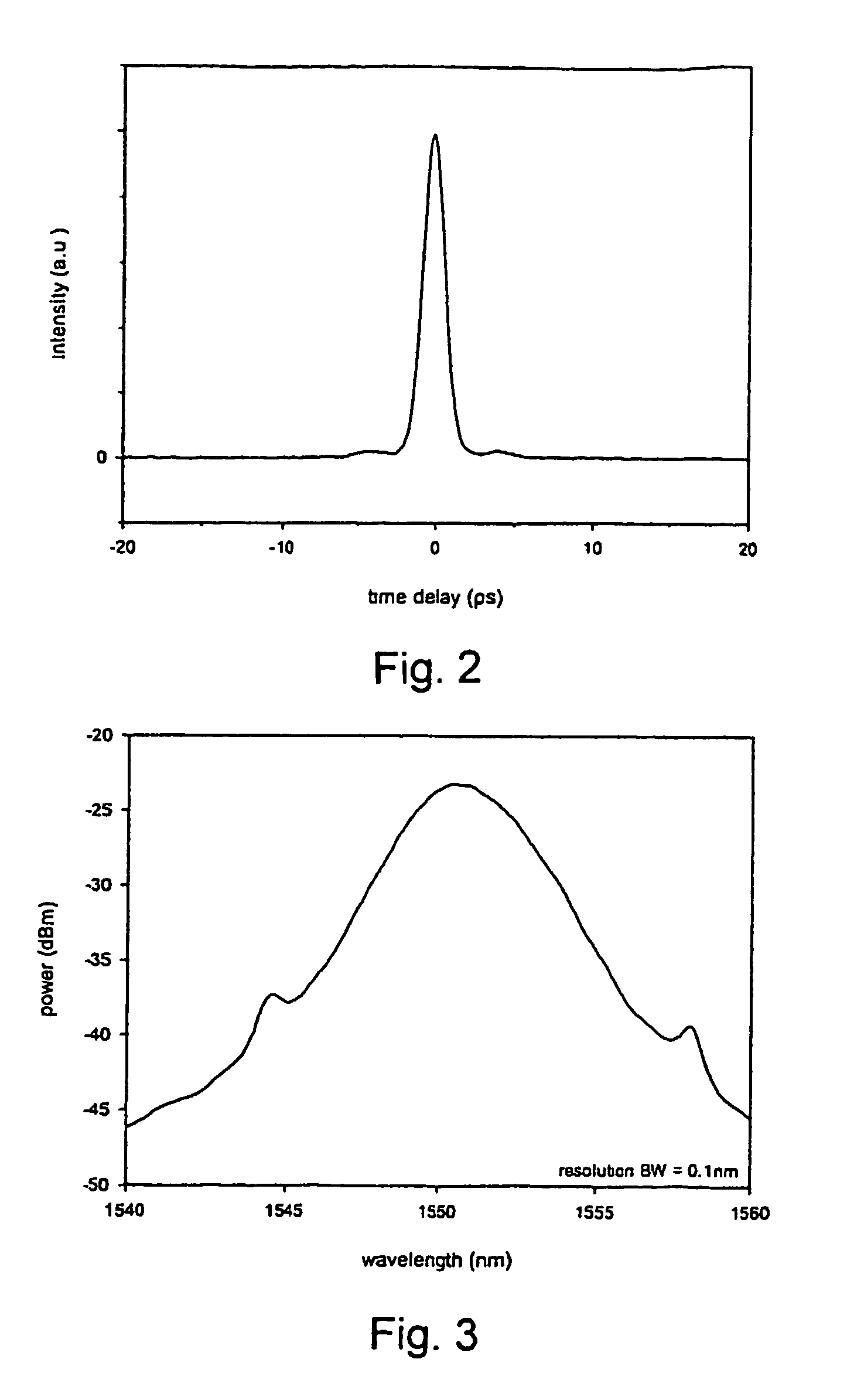

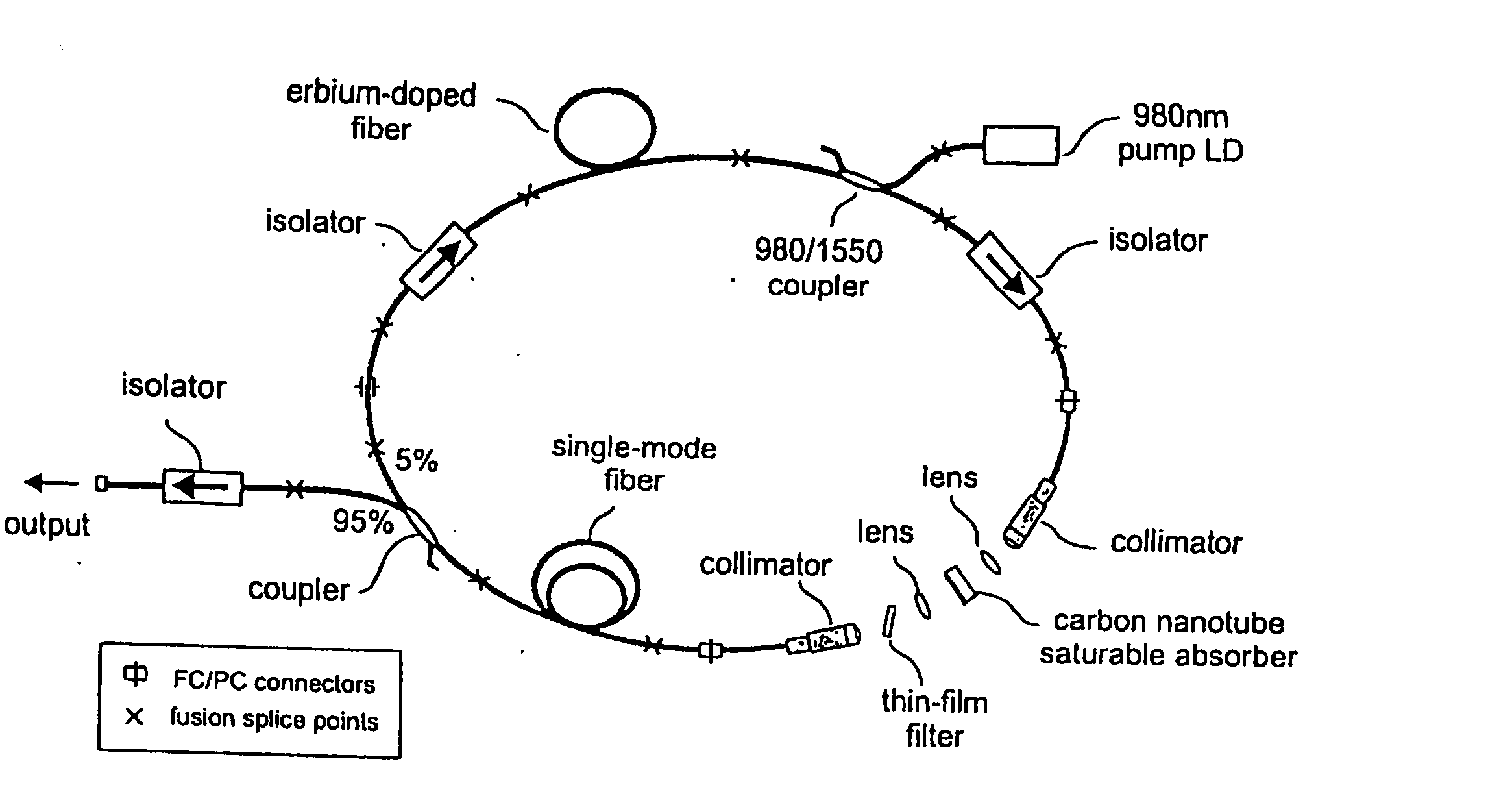

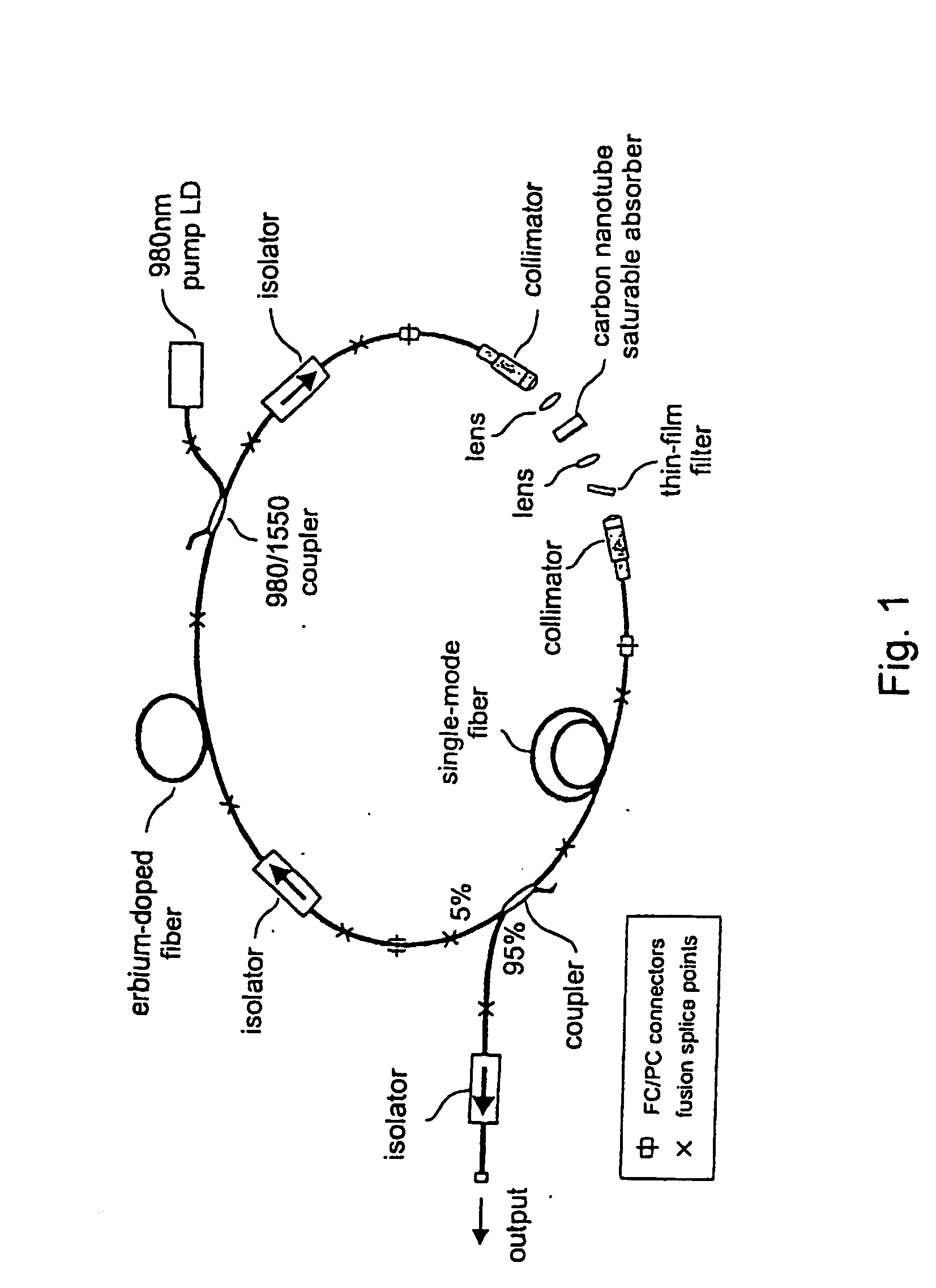

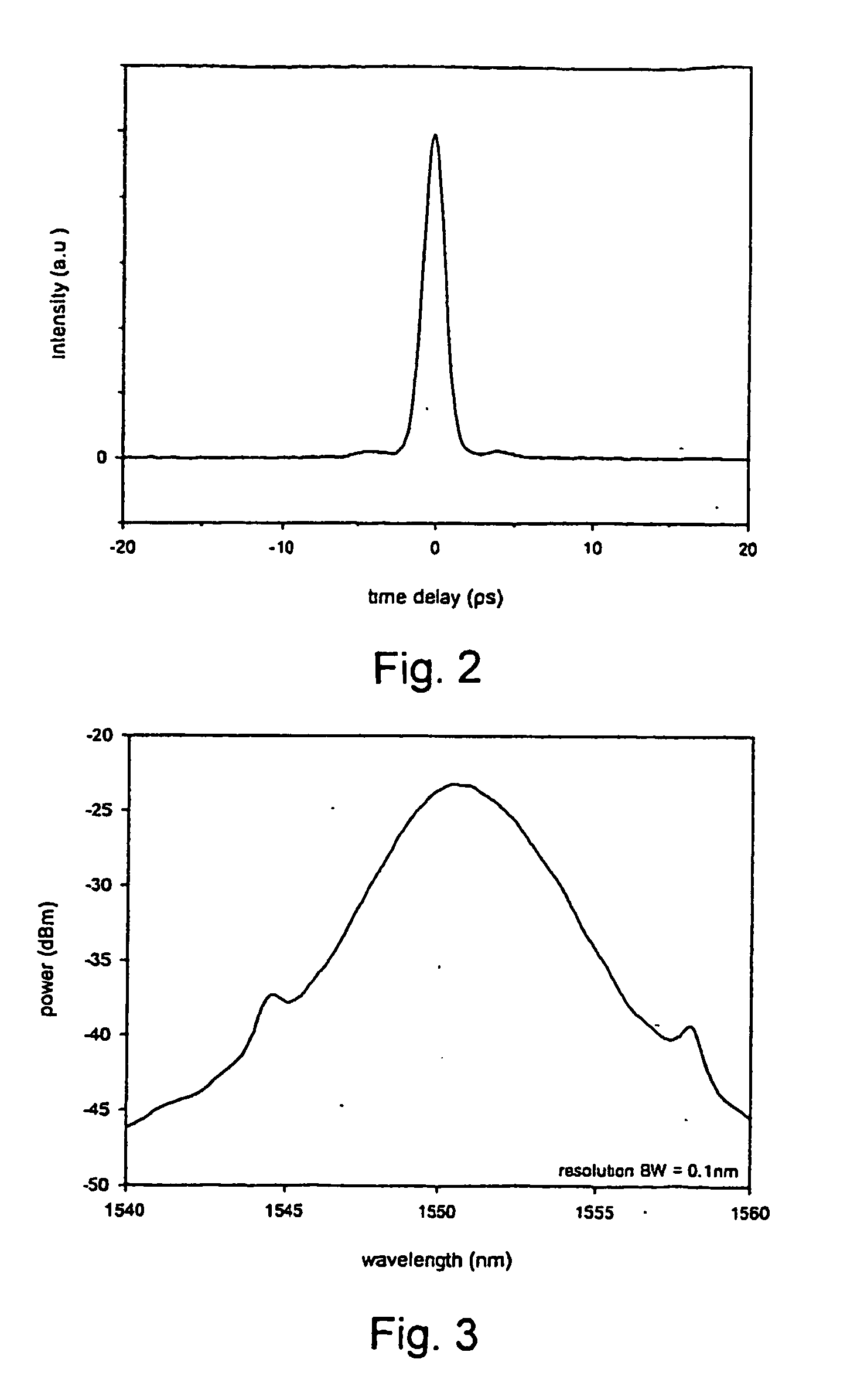

Optical pulse lasers

InactiveUS7372880B2Fast recovery timeHigh optical damage thresholdMirrorsNanoinformaticsCarbon nanotubeMode-locking

The present invention provides pulsed lasers which employ carbon nanotubes, particularly layers of carbon nanotubes, as saturable absorbers, mode lockers or for Q-switching elements. The present invention also provides methods and materials for mode-locking and Q-switching of lasers in which carbon nanotubes are employed as non-linear optical materials and / or saturable absorbers which facilitate mode-locking and / or Q-switching. The invention further provides mode locker and Q-switching elements or devices which comprise one or more layers containing carbon nanotubes which layer or layers function for mode locking and / or Q-switching.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Nutritional conjunctive support therapy for recovery in animals following stress or illness

ActiveUS20070009502A1Good treatment effectRapid preventionBiocideBacteria material medical ingredientsHeifer calfFluid replacement

A composition of probiotics, vitamins and minerals, electrolytes with glutamine and glucose along with medium chain triglycerides are provided as a supplement to animals. This is administered to cattle, calves, sheep, pigs, horses, dogs, and cats that are experiencing stress and or are undergoing medical drug therapy to treat conditions of diseases along with pre and post operative surgical conditions. The composition helps correct imbalances in beneficial bacteria, provides energy and helps in rehydration to reduce recovery time from stress or in disease treatment in these animals.

Owner:VETAB PLUS

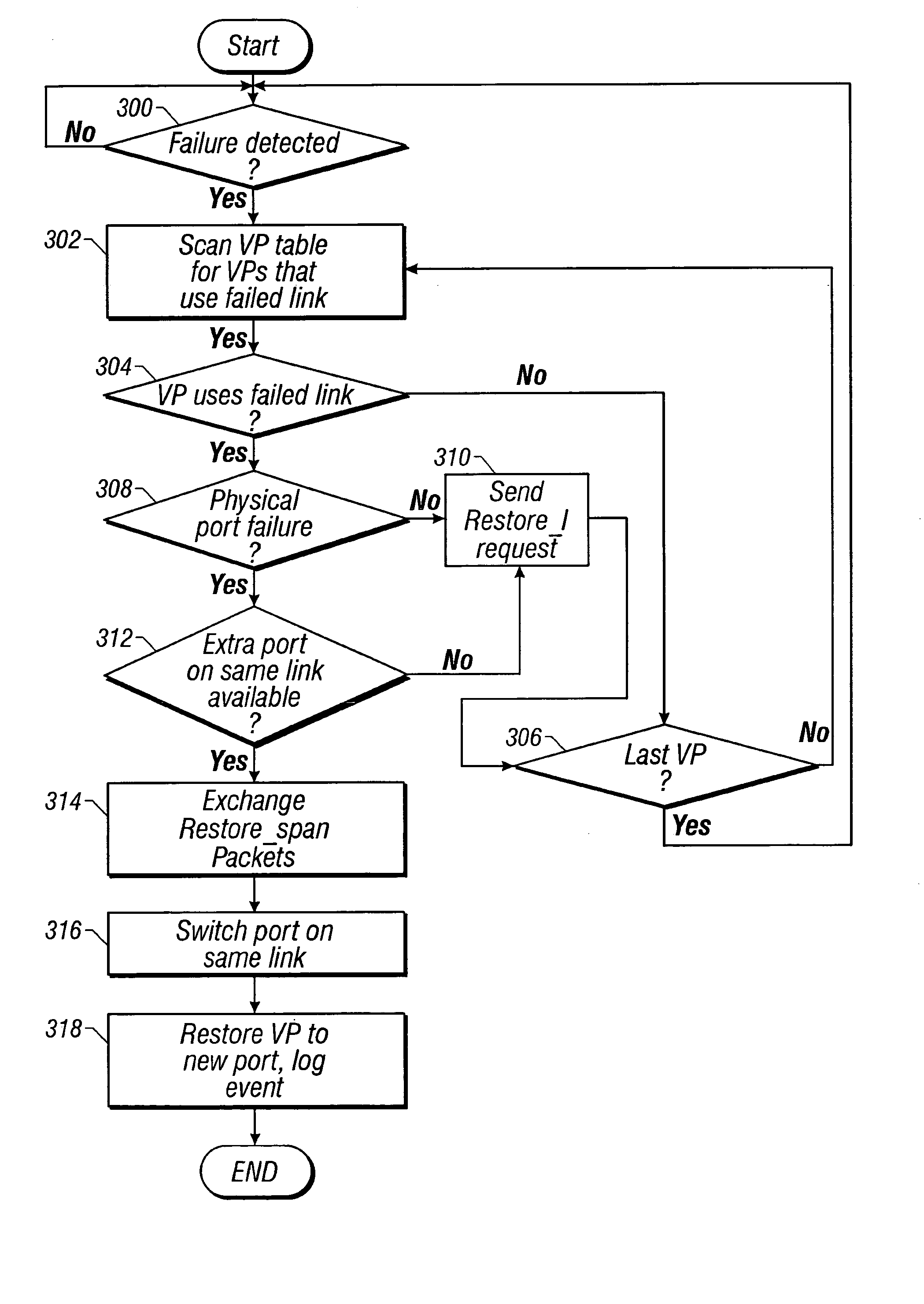

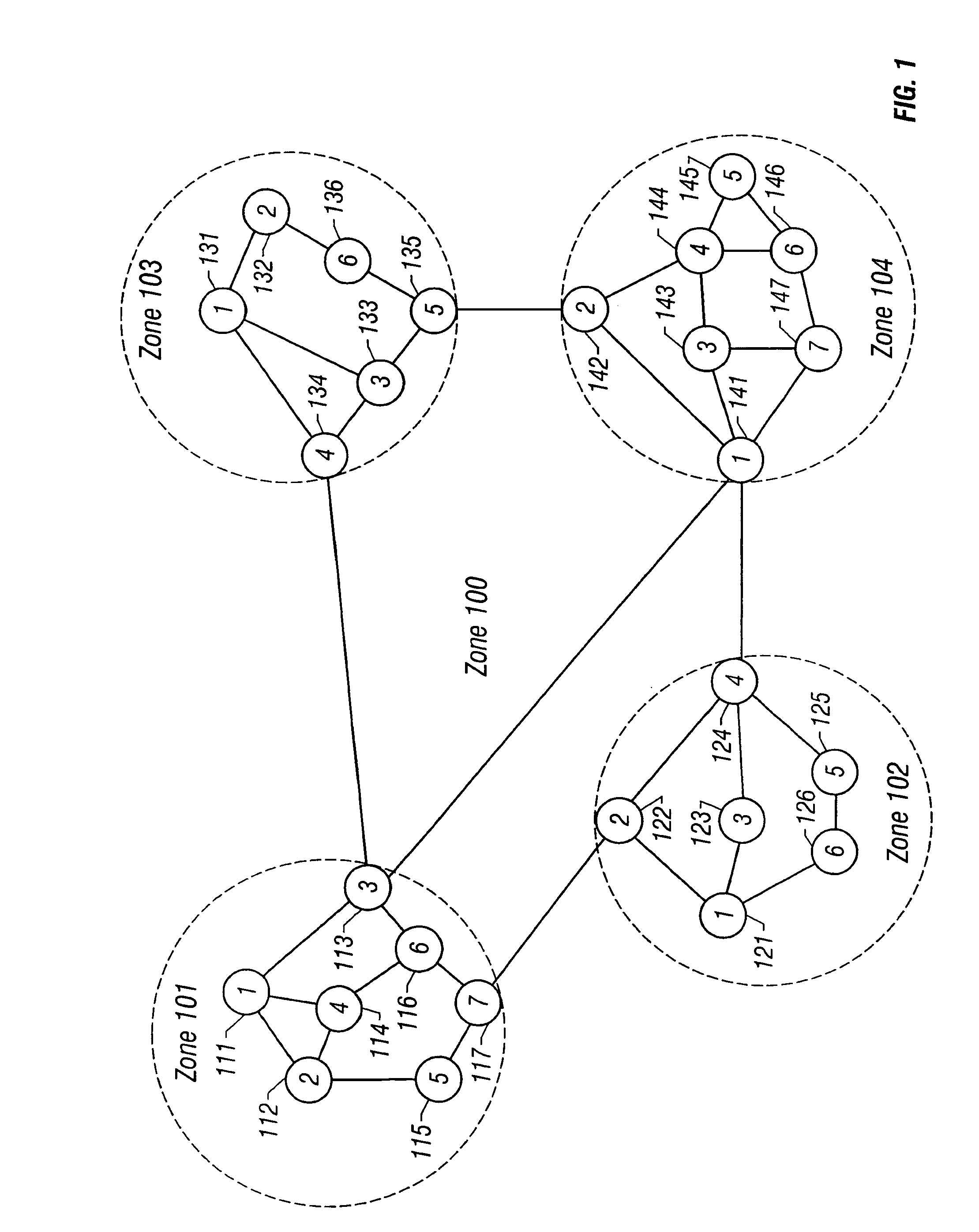

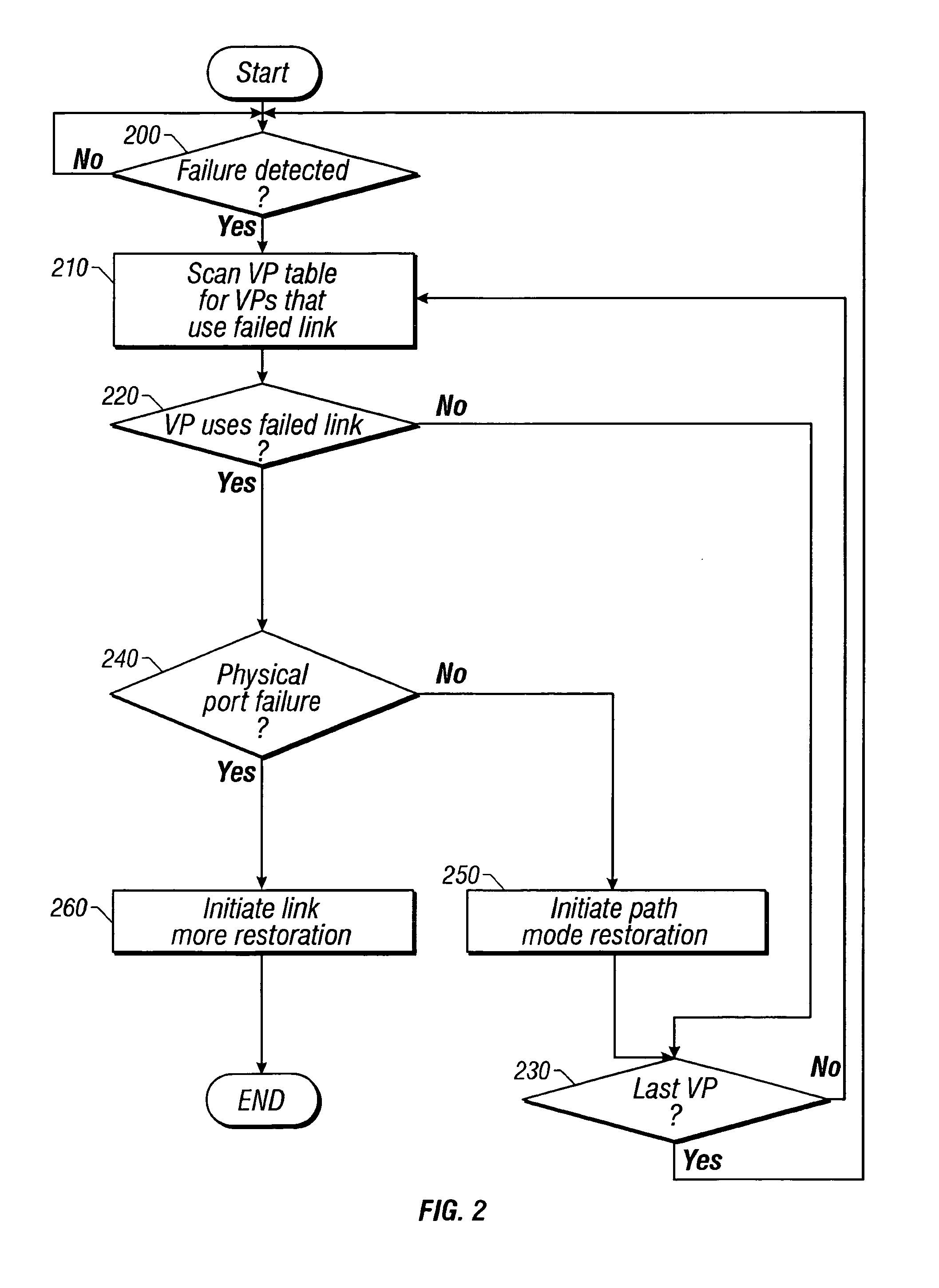

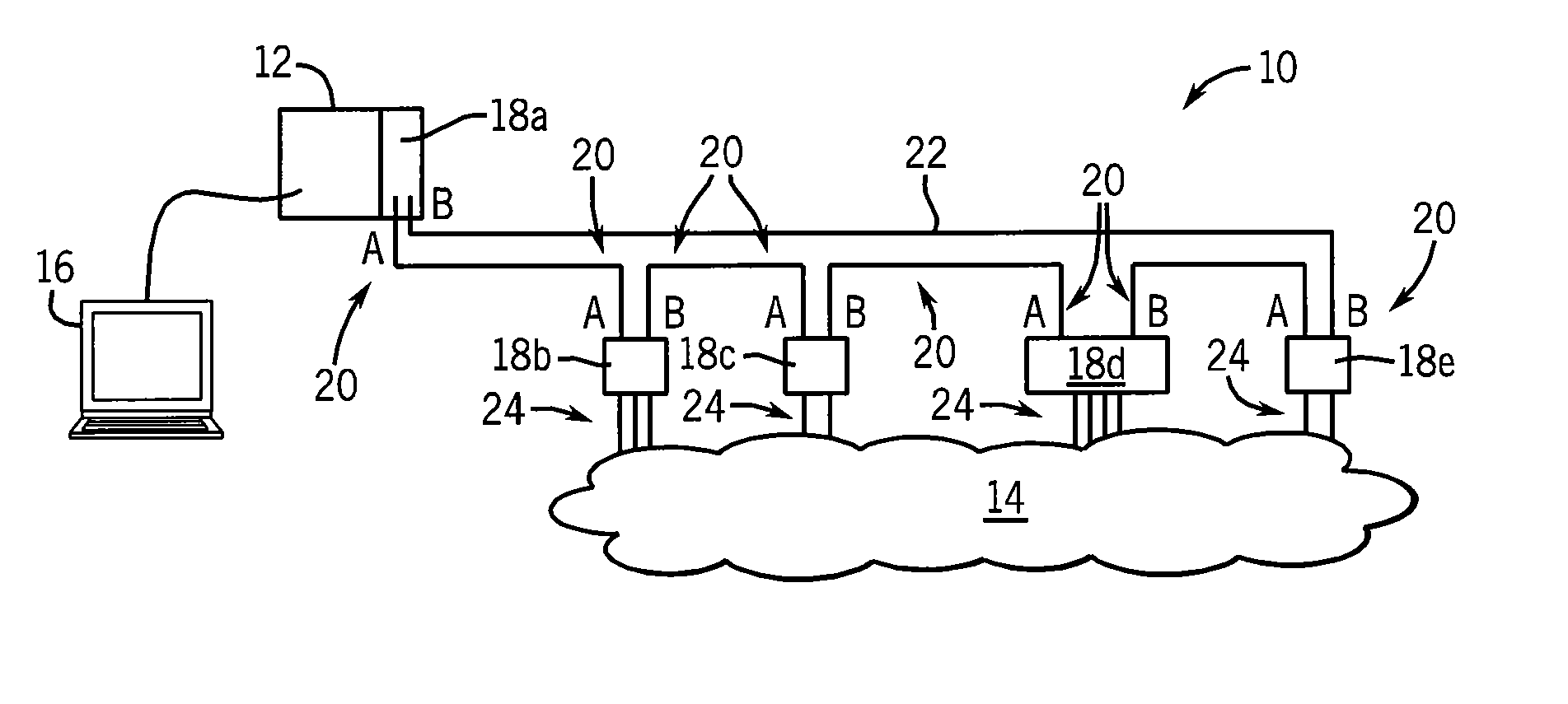

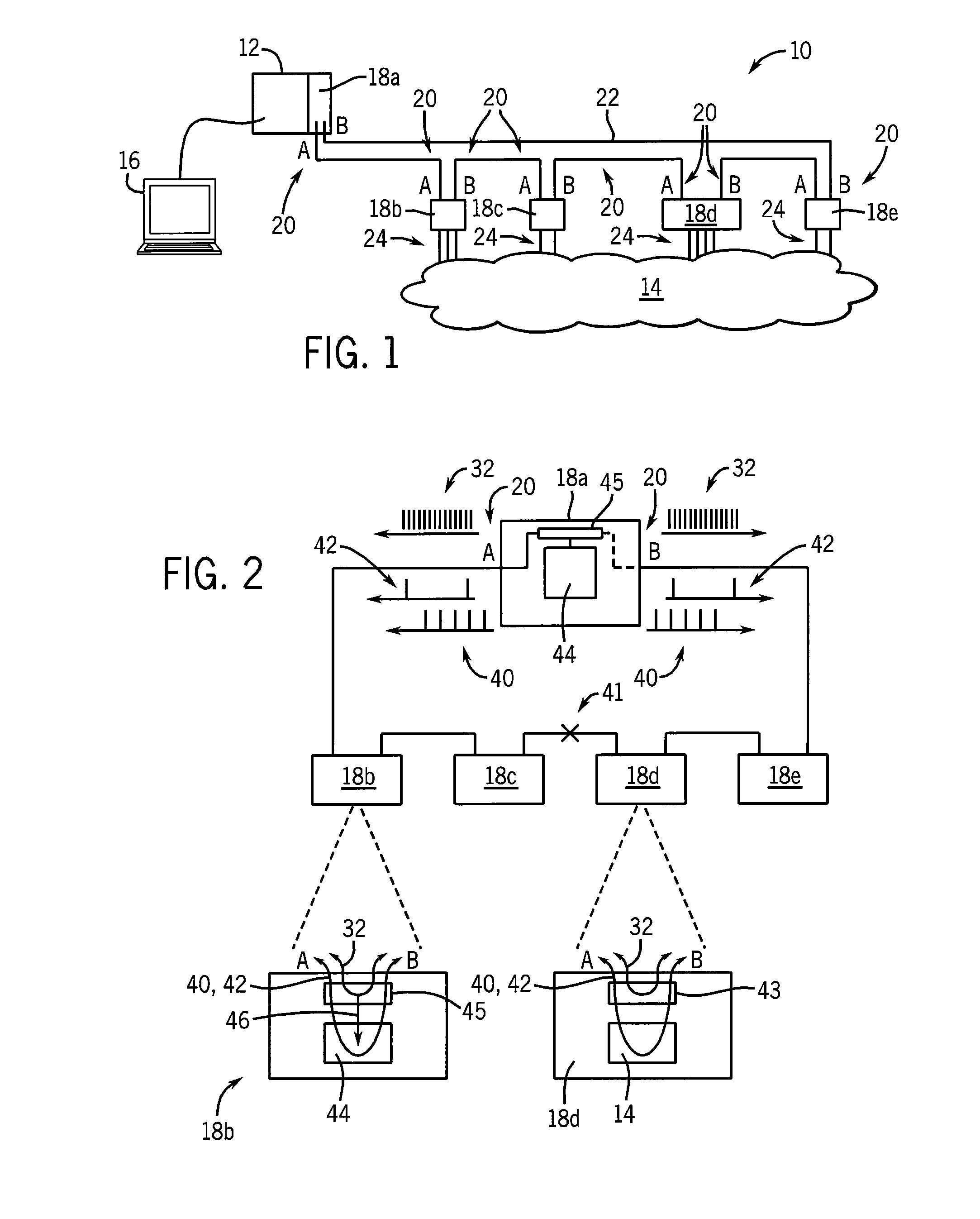

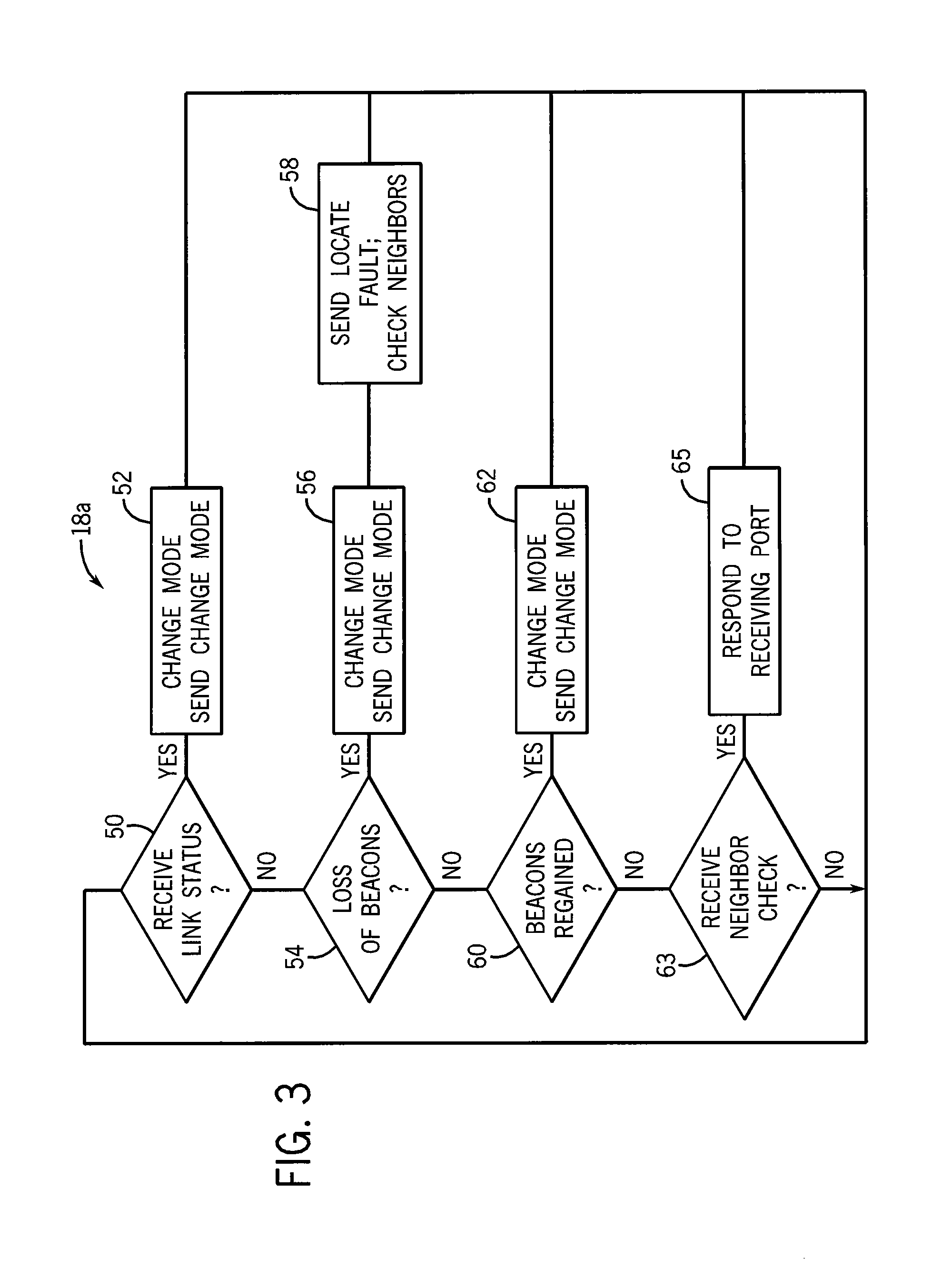

Virtual path restoration scheme using fast dynamic mesh restoration in an optical network

InactiveUS6990068B1Reduces time and resource requireFast restoration timeError preventionTransmission systemsTelenetDistributed computing

A method for restoring a virtual path, provisioned between a source and a target node, in a mesh zoned optical network is described. The method, in one embodiment, broadcasts or floods restore path requests in the network to expedite the identification of an alternate route and minimize the service disruption for failed virtual path. The flooding of requests is controlled to ensure efficient performance of the network yet guaranteeing minimum restoration time to allow critical telecommunication related traffic to flow through the network with virtually no interruption. The constant update of nodal topology by each node allows a fast identification of alternate physical path for failed virtual path.

Owner:CISCO TECH INC

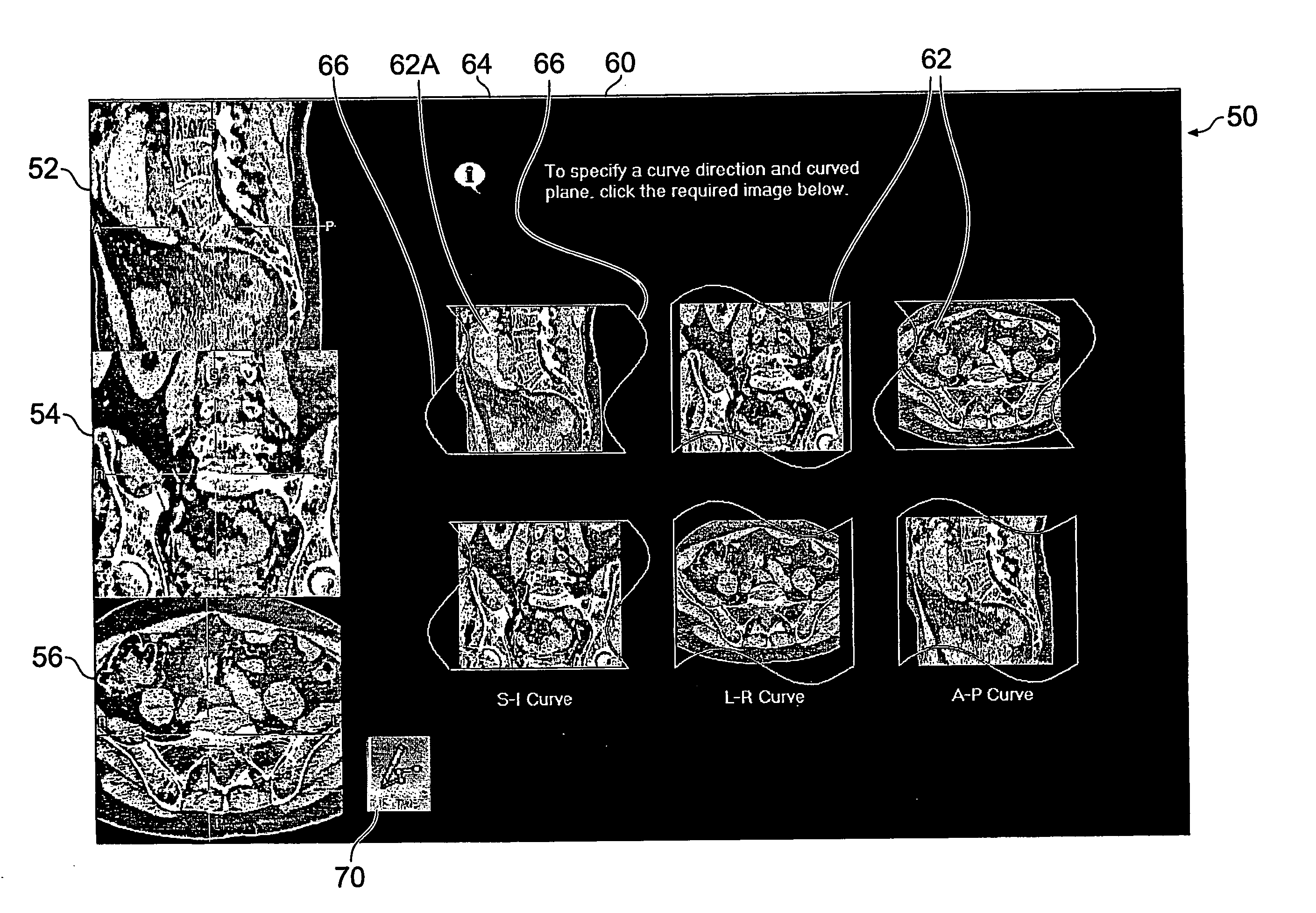

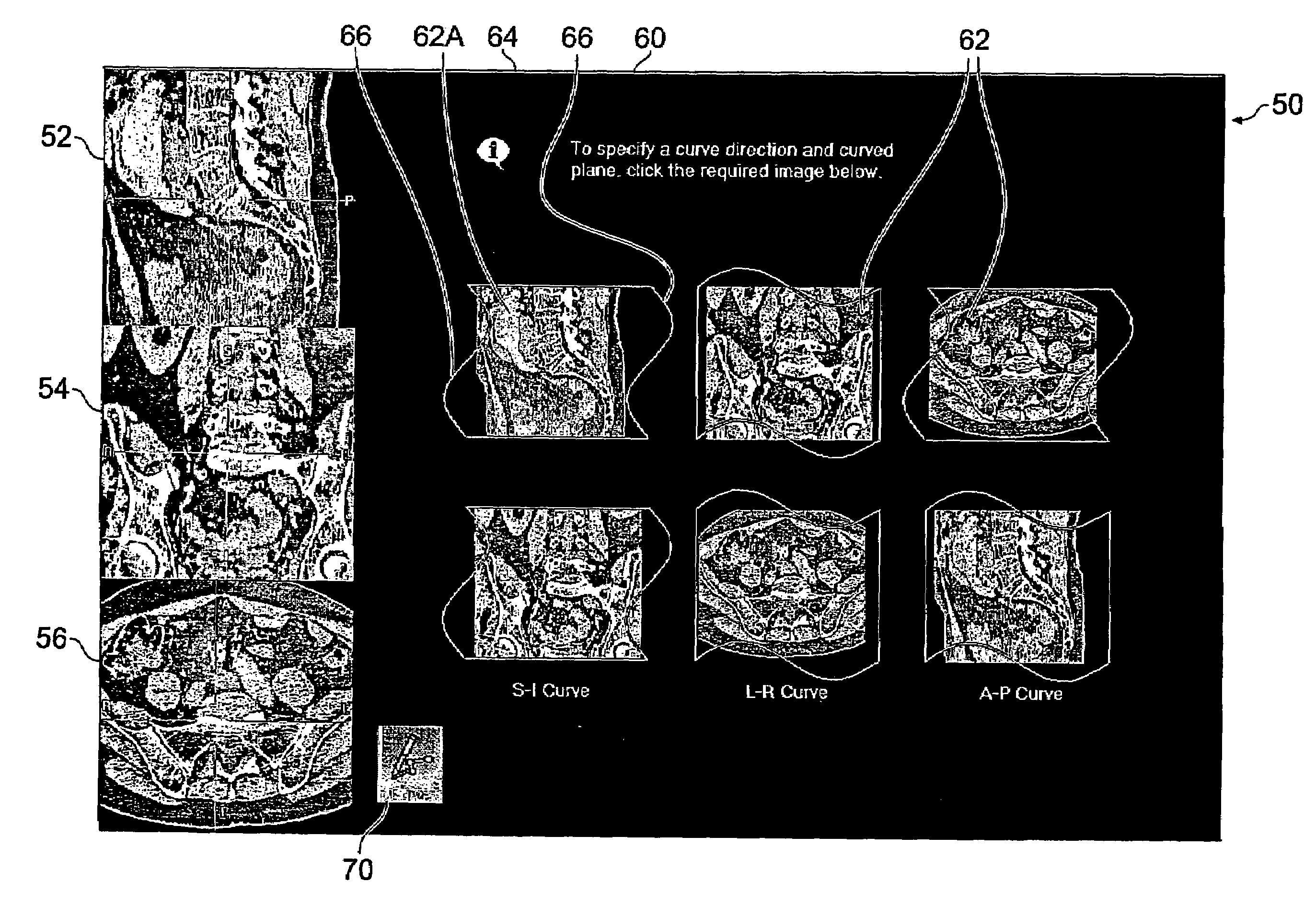

User-interface and method for curved multi-planar reformatting of three-dimensional volume data sets

ActiveUS20050122343A1Simple accessSimplify interfaceGeometric image transformationCathode-ray tube indicatorsVolumetric dataComputer graphics (images)

Owner:TOSHIBA MEDICAL VISUALIZATION SYST EURO

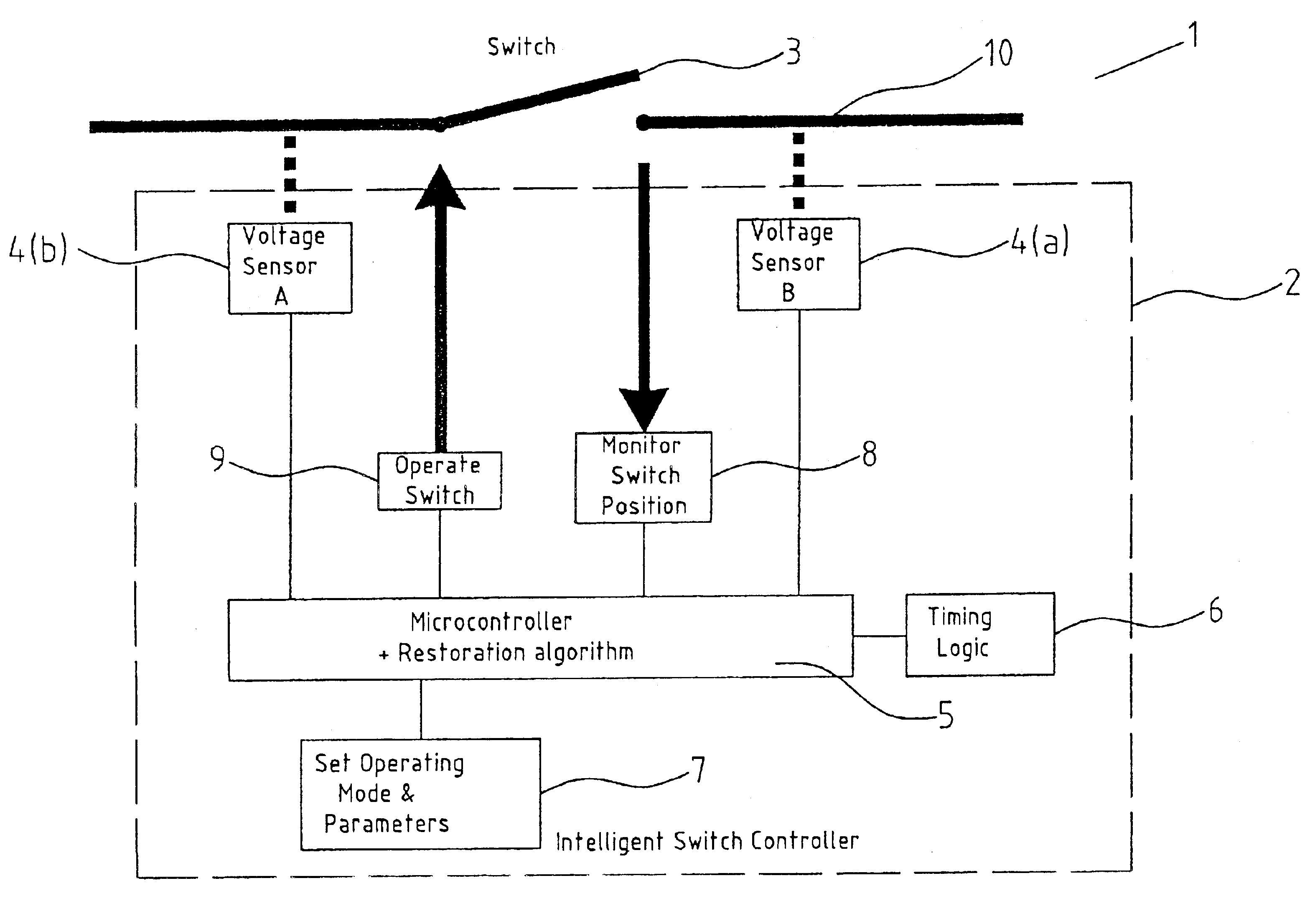

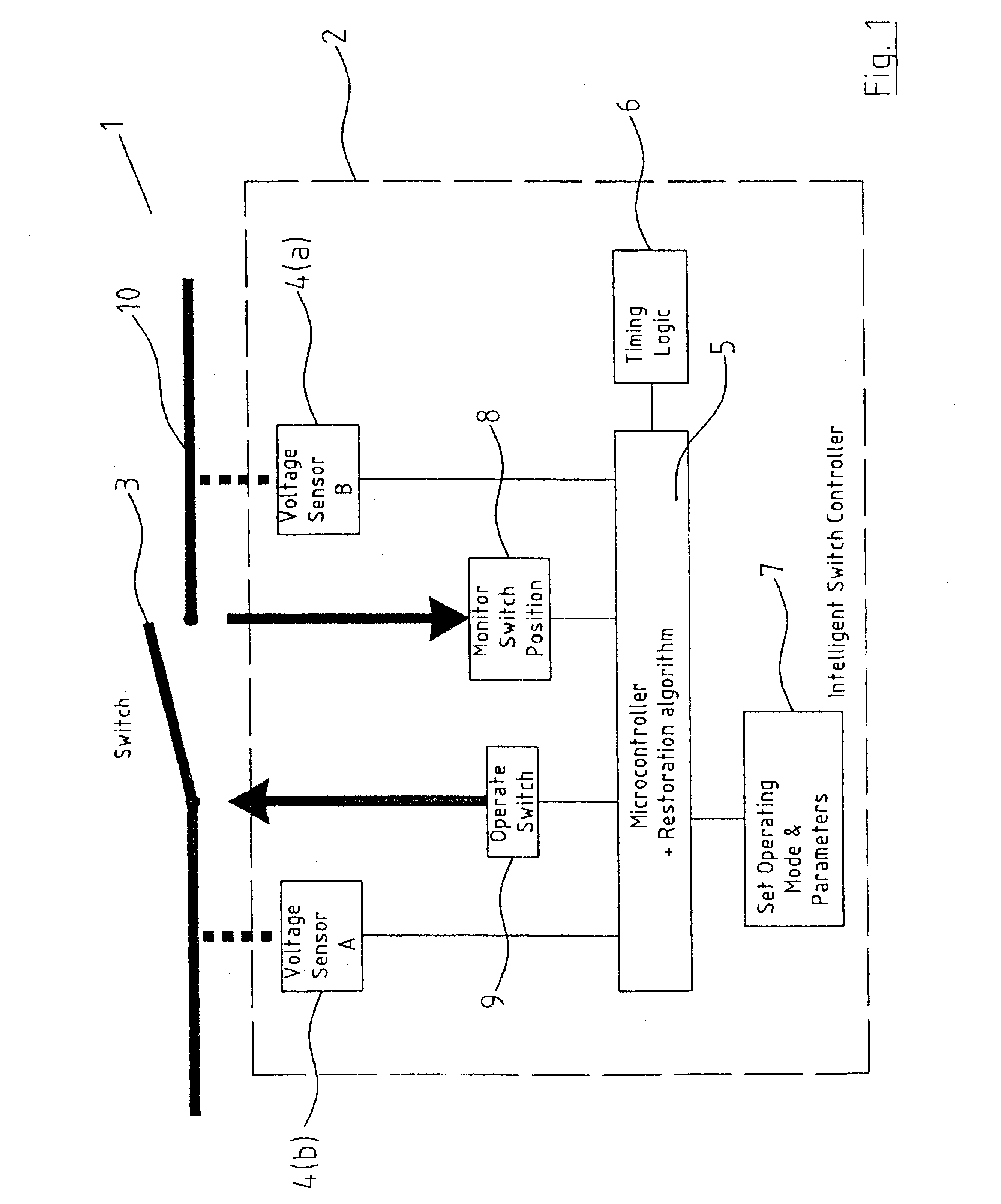

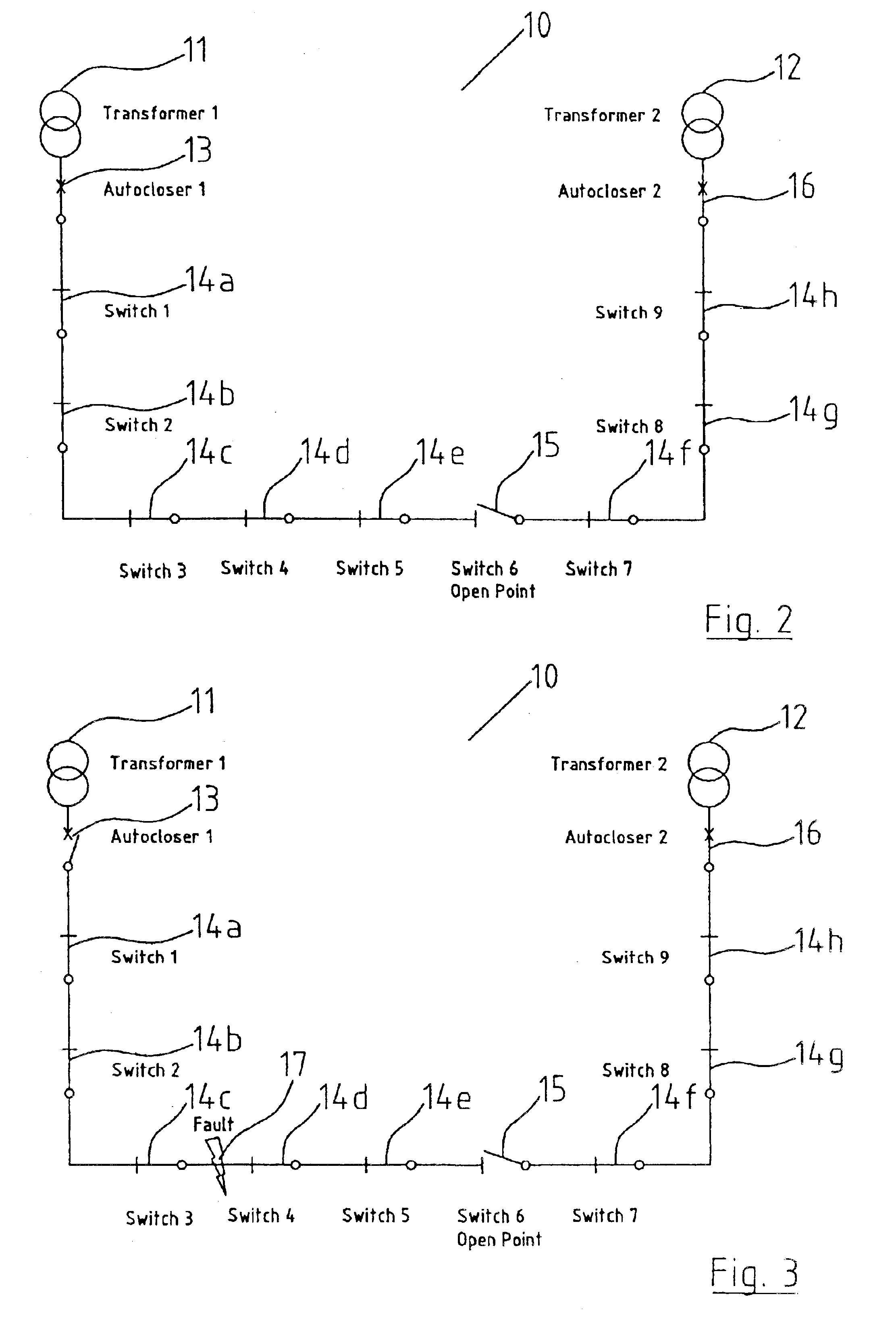

Fault control and restoration in a multi-feed power network

InactiveUS6907321B2Fast recovery timeReduce downtimeMechanical power/torque controlLevel controlCommunications systemControl system

The present invention relates to a control system for automatically reconnecting power to customers in a distribution automation multi-feed power network on a fault disconnecting customers in the network. This invention provides the simple switching architecture with local control means that are implemented in the event of a fault. Each switch in the system has an intelligent switch controller which results in a faster restoration time which reduces customer down time in the event of a fault in the network. The system operates without the need for complex communication systems or central controllers. Each intelligent switch controller has the ability to cause its respective switch to open or close in the event of a fault. The network may be restored in a sequential manner subsequent to the detection of a fault in the network thereby allowing for the simple detection of the location of a fault.

Owner:ANGLO IRISH BANK CORP PLC +1

Optical pulse lasers

InactiveUS20060198399A1Easy to operateFast recovery timeMirrorsNanoinformaticsMode-lockingCarbon nanotube

The present invention provides pulsed lasers which employ carbon nanotubes, particularly layers of carbon nanotubes, as saturable absorbers, mode lockers or for Q-switching elements. The present invention also provides methods and materials for mode-locking and Q-switching of lasers in which carbon nanotubes are employed as non-linear optical materials and / or saturable absorbers which facilitate mode-locking and / or Q-switching. The invention further provides mode locker and Q-switching elements or devices which comprise one or more layers containing carbon nanotubes which layer or layers function for mode locking and / or Q-switching.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

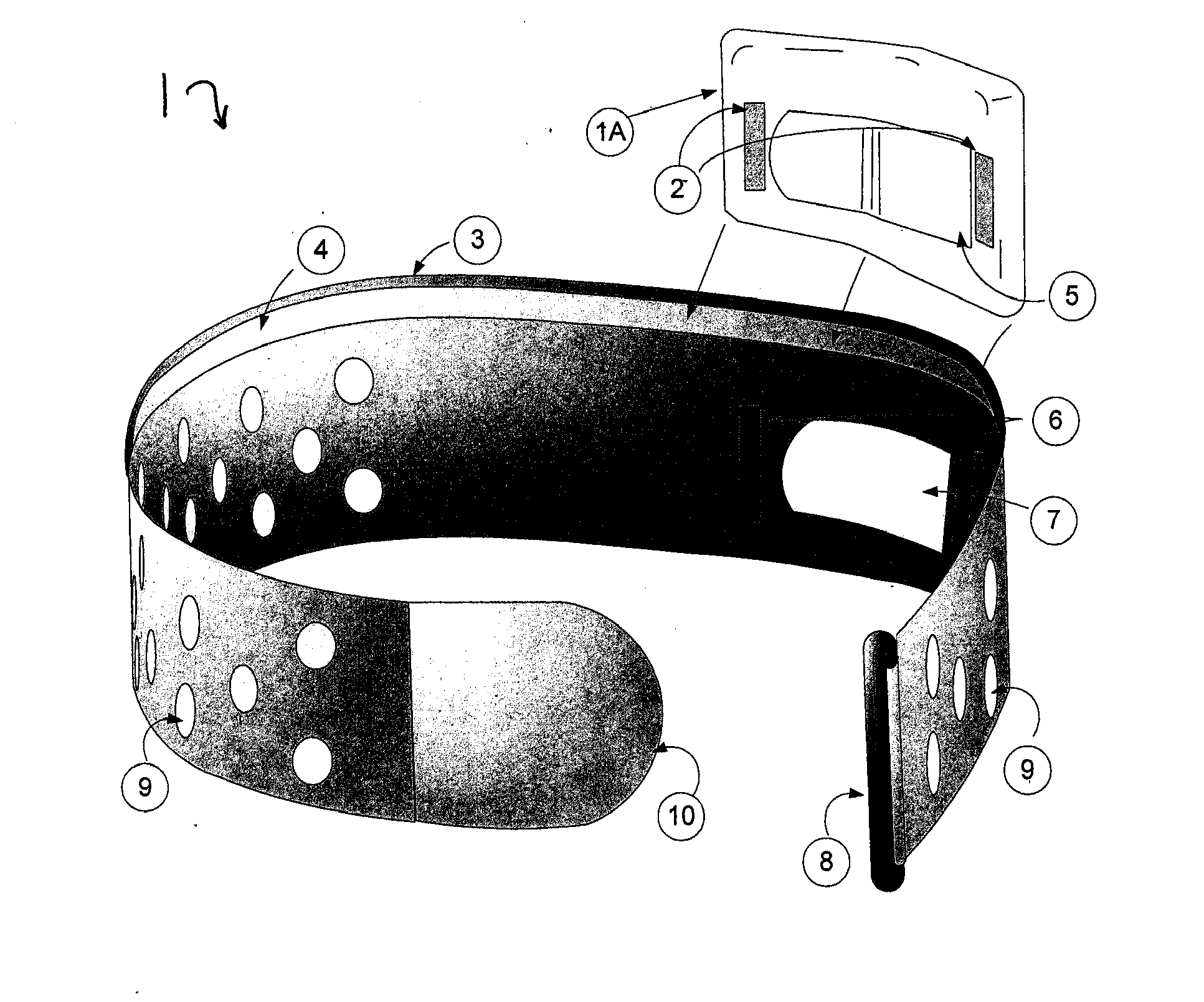

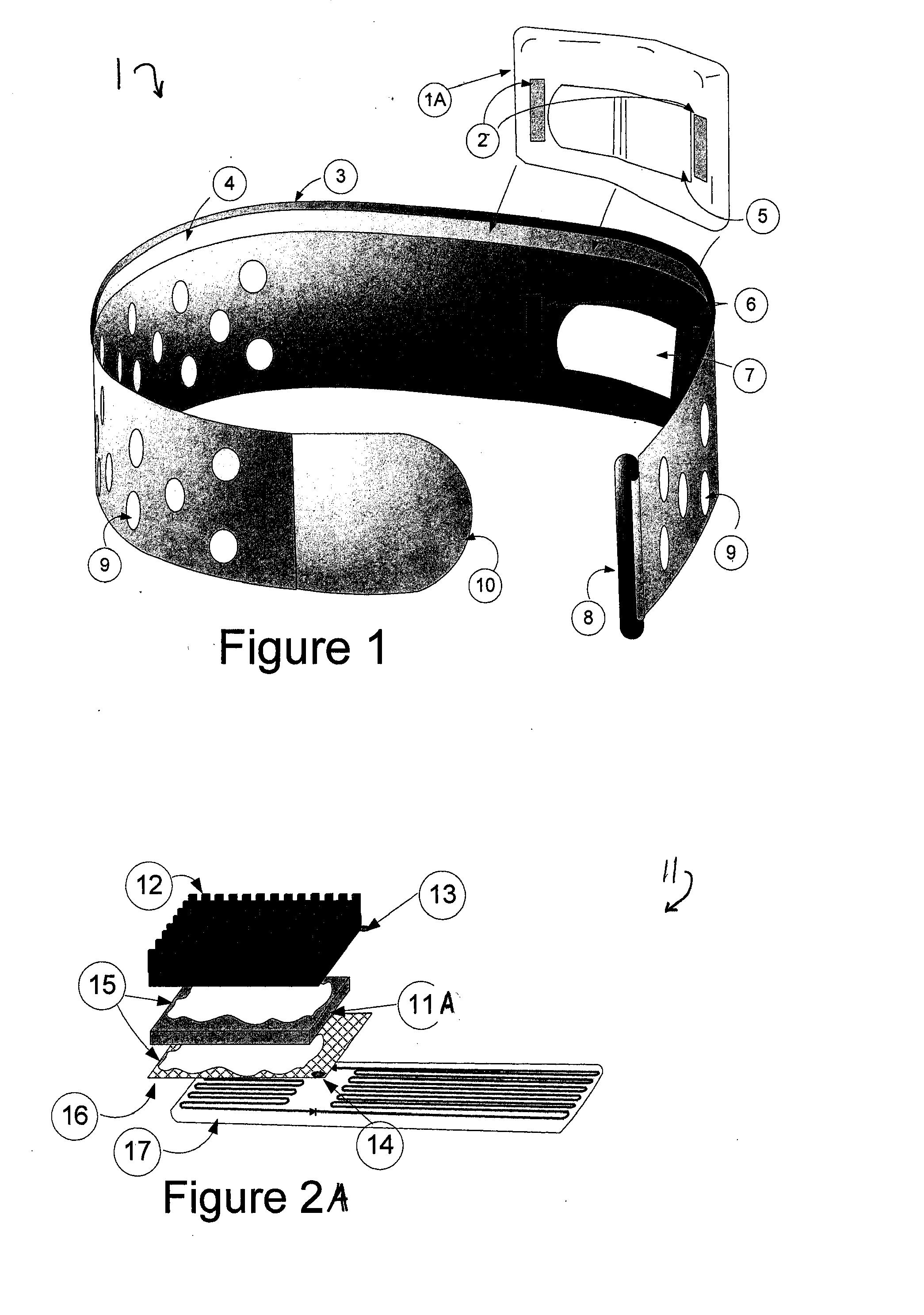

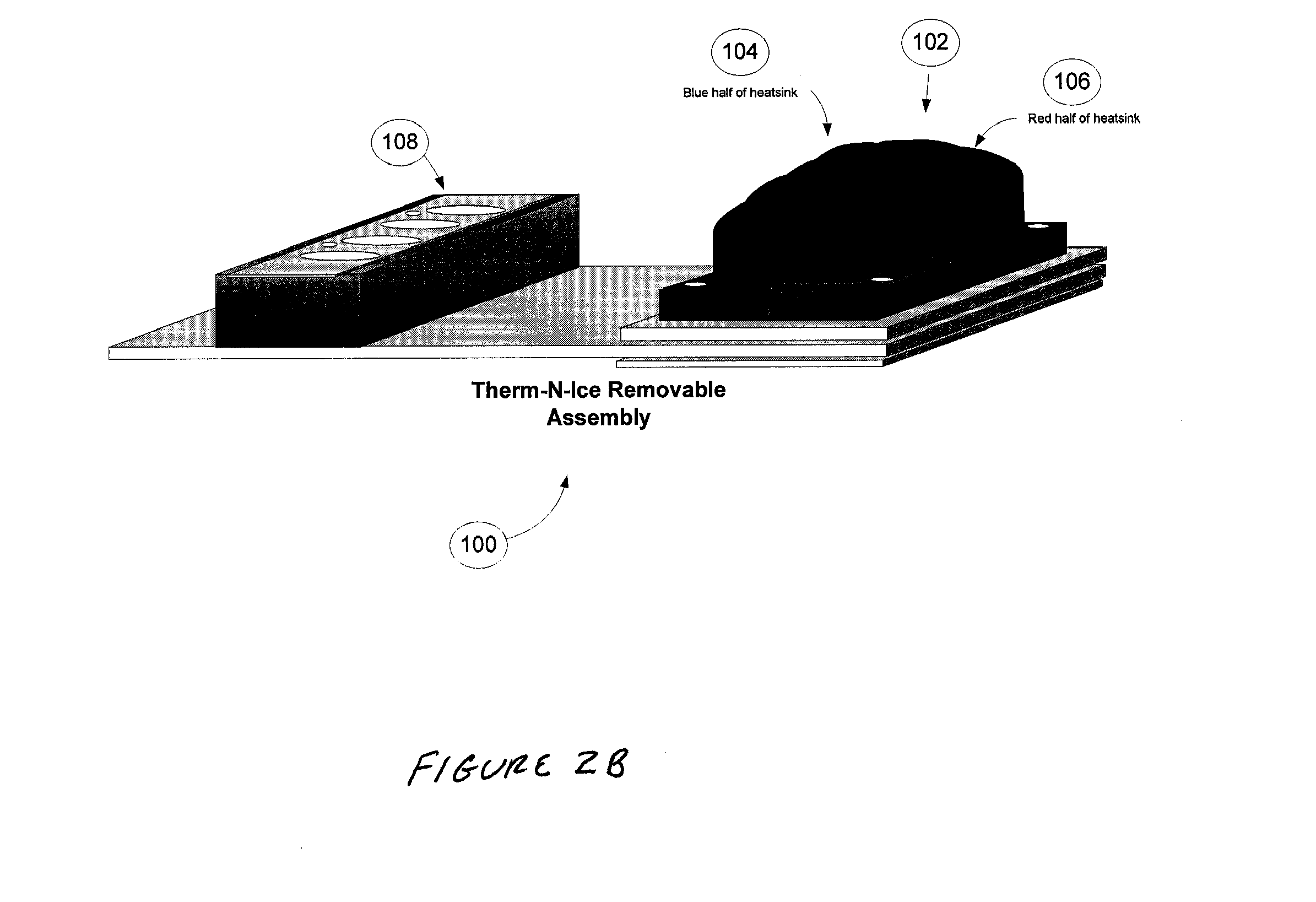

Apparatus for therapeutic cooling and warming of a body portion of a human or mammal

ActiveUS20130085552A1Relieve itchingReduce sweatingTherapeutic coolingTherapeutic heatingTime delaysTherapeutic Area

At least one thermoelectric assembly controlled by a microprocessor and disposed on a thermal conduction pad configured to conduct energy to and from the thermoelectric assembly and adjacent the treatment area positioned with removable electronics and a breathable liner. The hot intensity, cold intensity and time delay between sequences can also be selected as well as alternating temperature sequences with both vibration and tension monitoring to promote blood flow and speed up healing.

Owner:OASIS MEDICAL SOLUTIONS

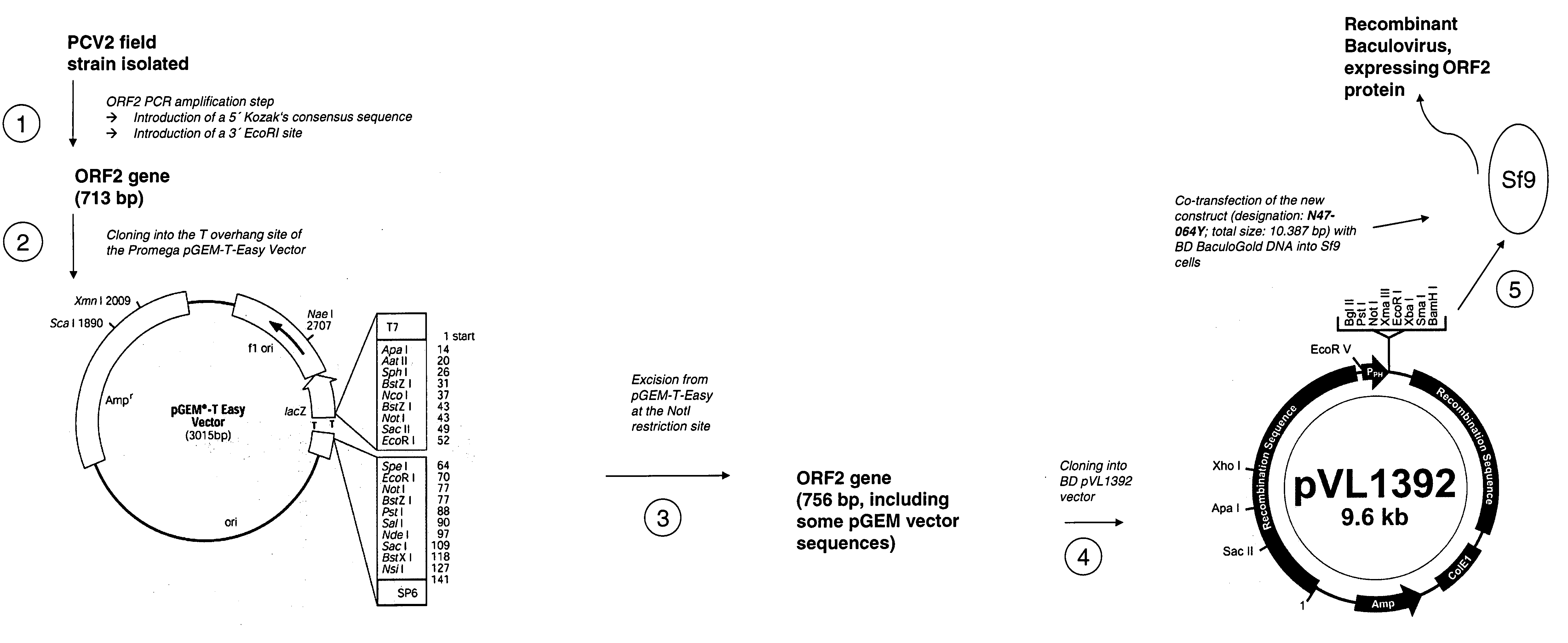

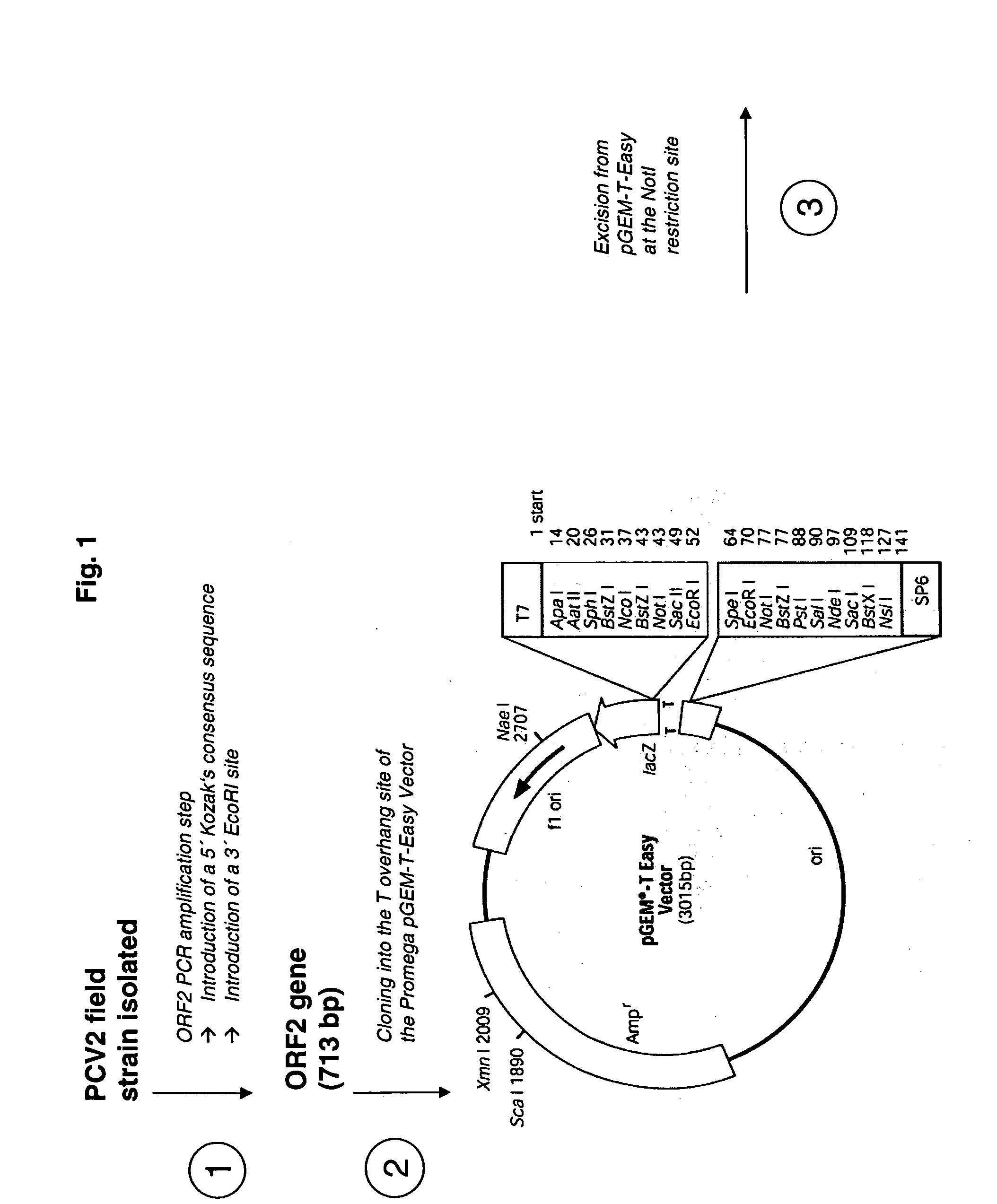

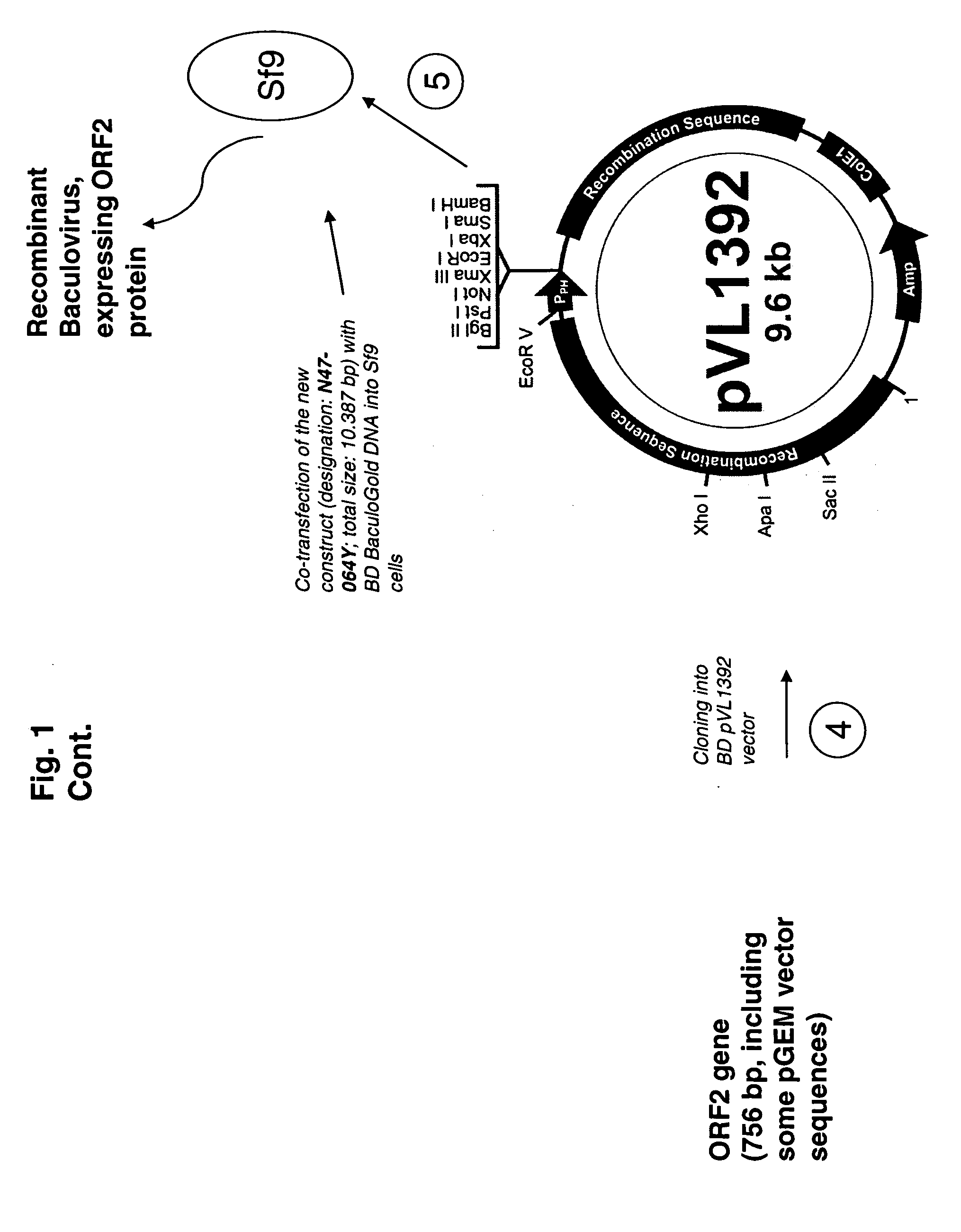

Multivalent pcv2 immunogenic compositions and methods of producing such compositions

InactiveUS20080226669A1Lowered viral titerImprove the immunityAntibacterial agentsCompounds screening/testingDiseaseOpen reading frame

An improved method for recovering the protein expressed by open reading frame 2 from porcine circovirus type 2 is provided. Also provided is recombinant PCV2 ORF2 protein, and immunogenic compositions comprising PCV2 ORF2 protein. Moreover, multivalent combination vaccines are provided which include an immunological agent effective for reducing the incidence of or lessening the severity of PCV2 infection, preferably PCV2 ORF2 protein, or an immunogenic composition comprising PCV2 ORF2 protein, and at least one immunogenic active component of another disease-causing organism in swine,

Owner:BOEHRINGER LNGELHEIM VETMEDICA GMBH

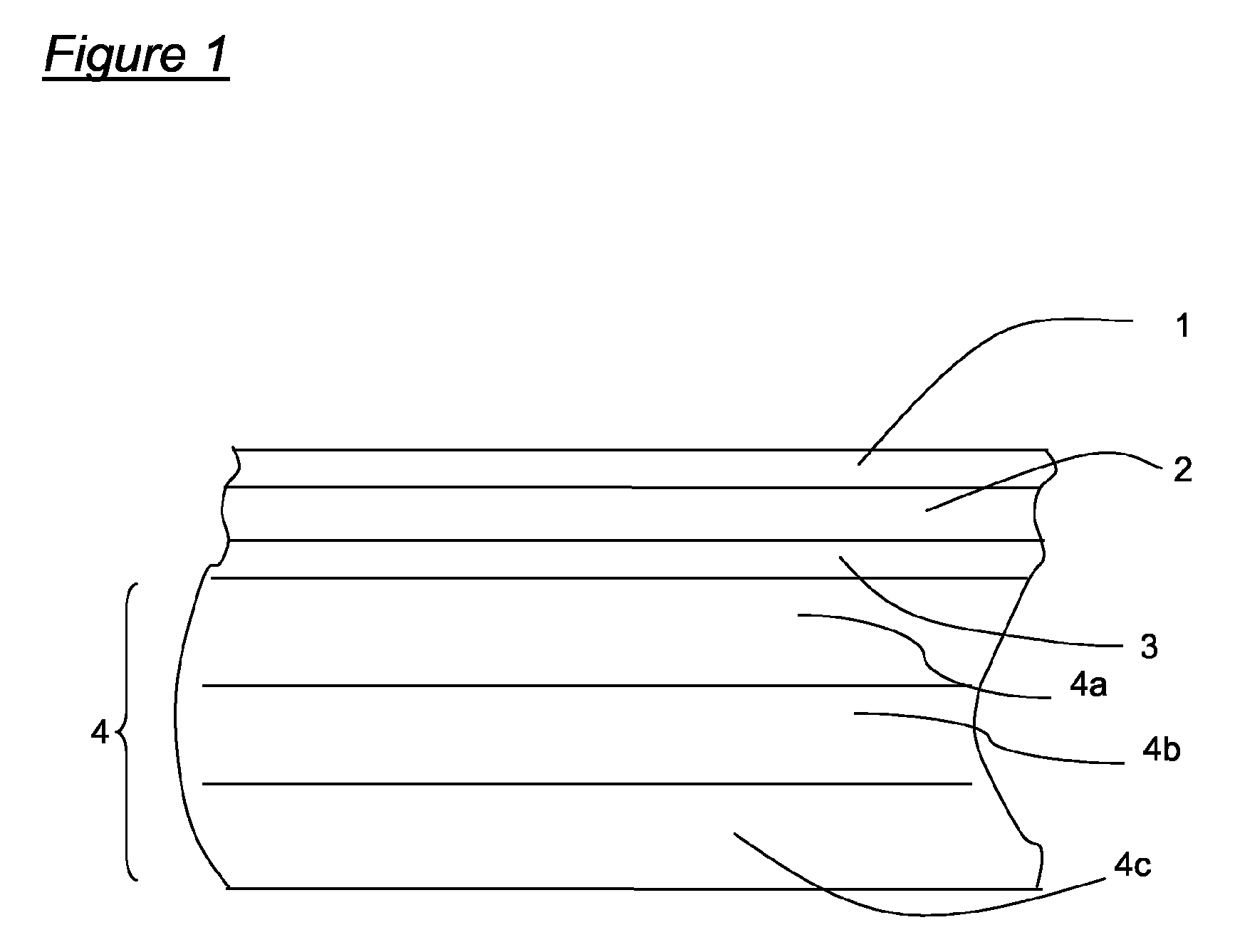

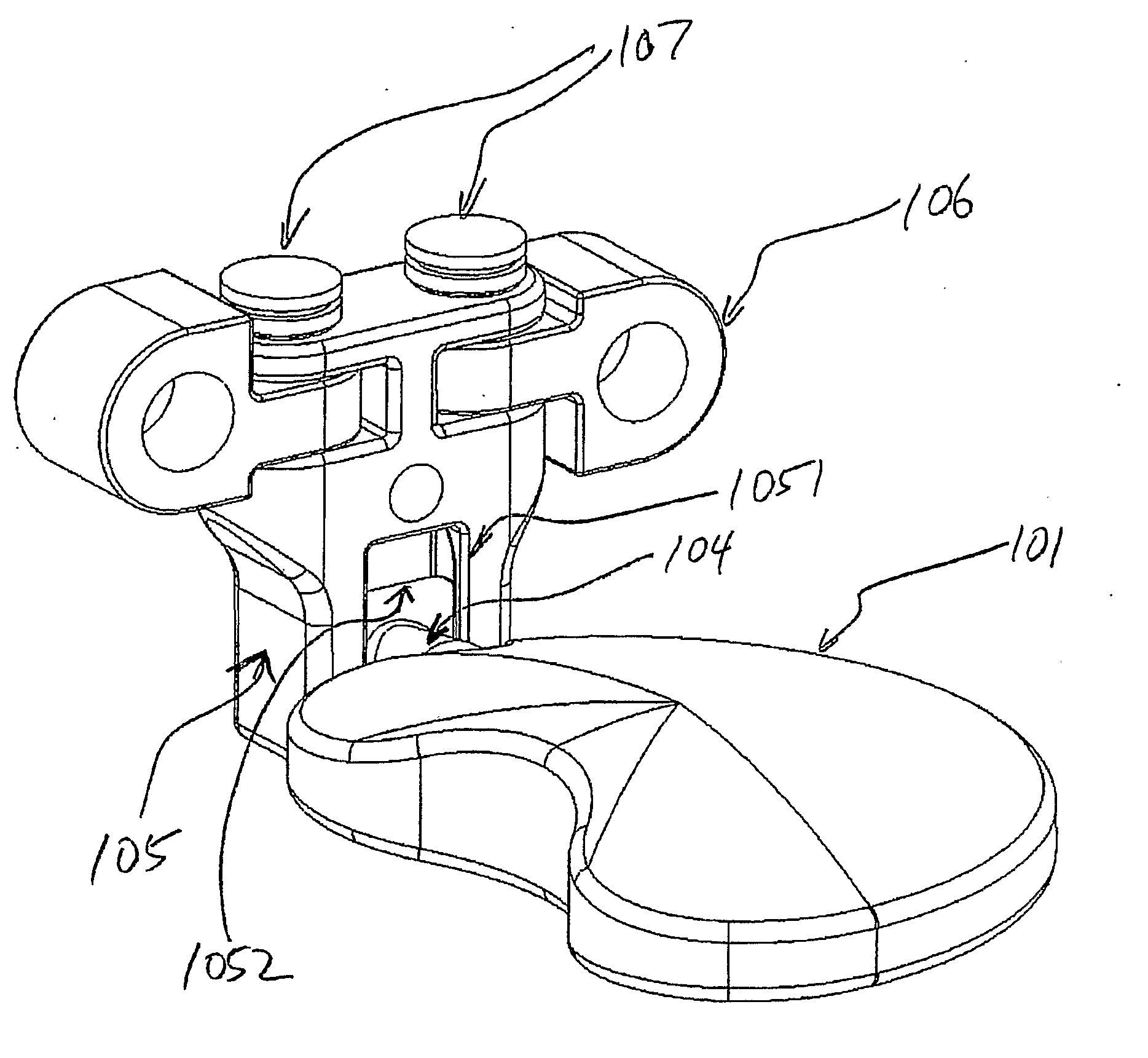

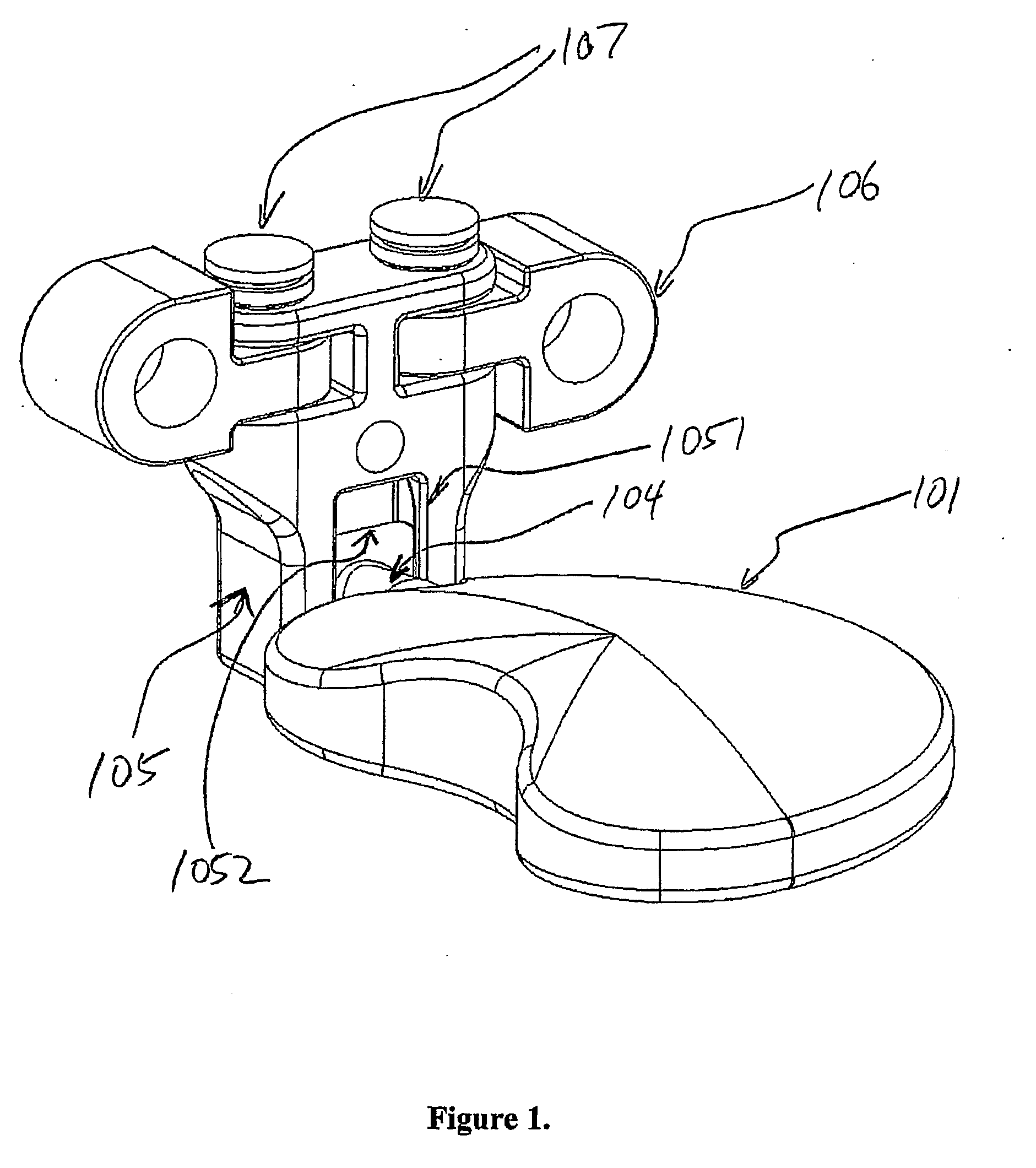

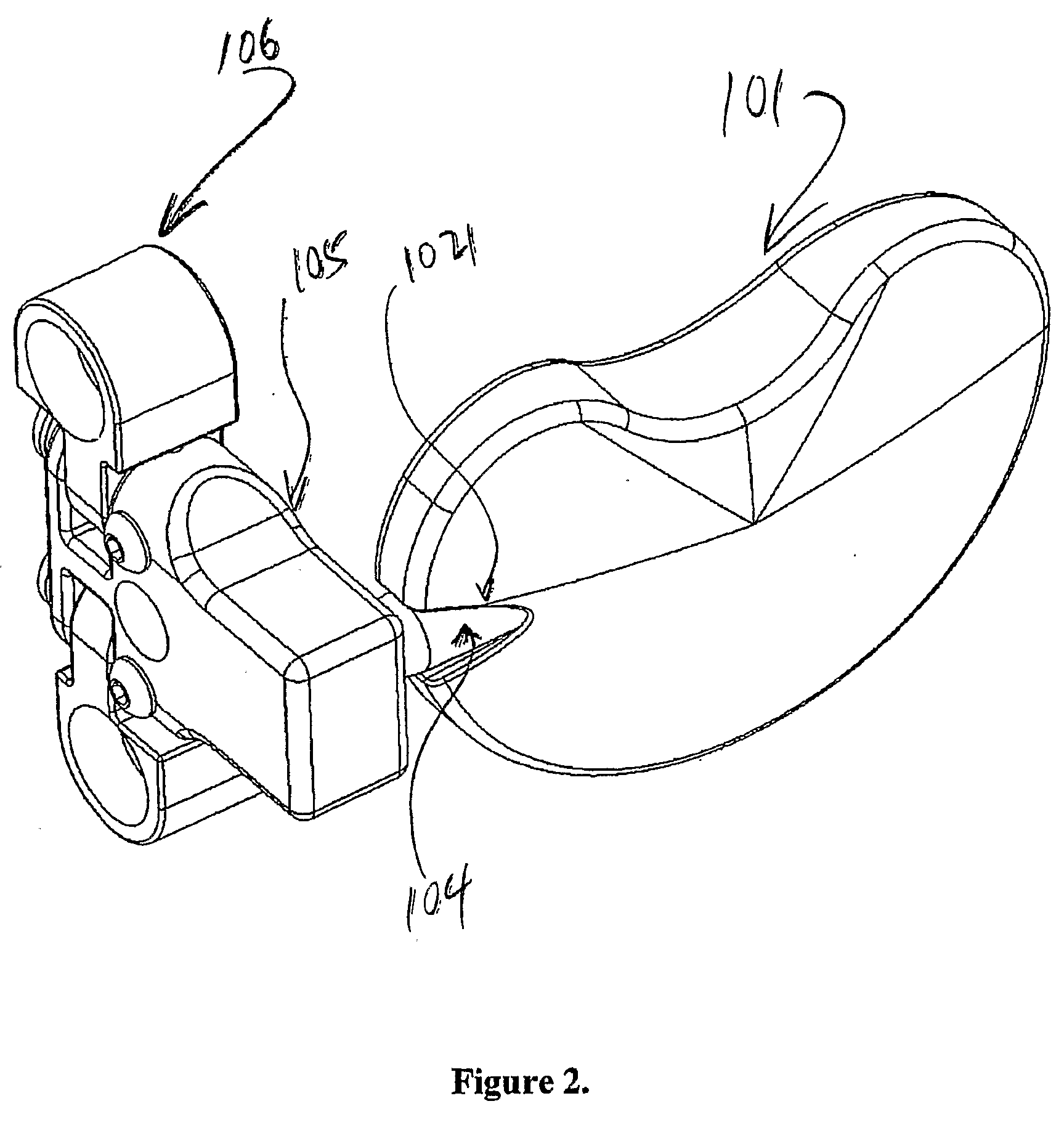

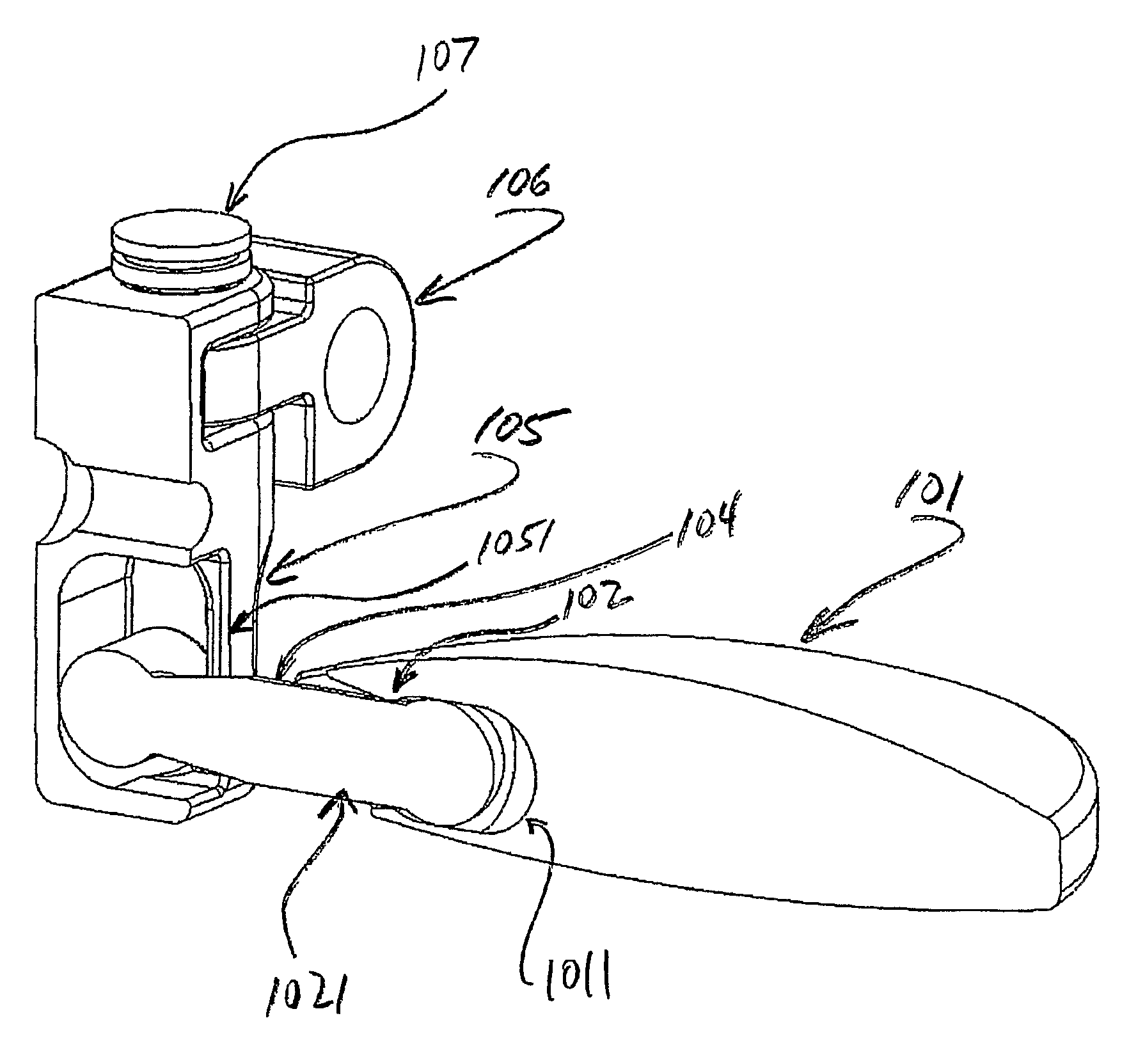

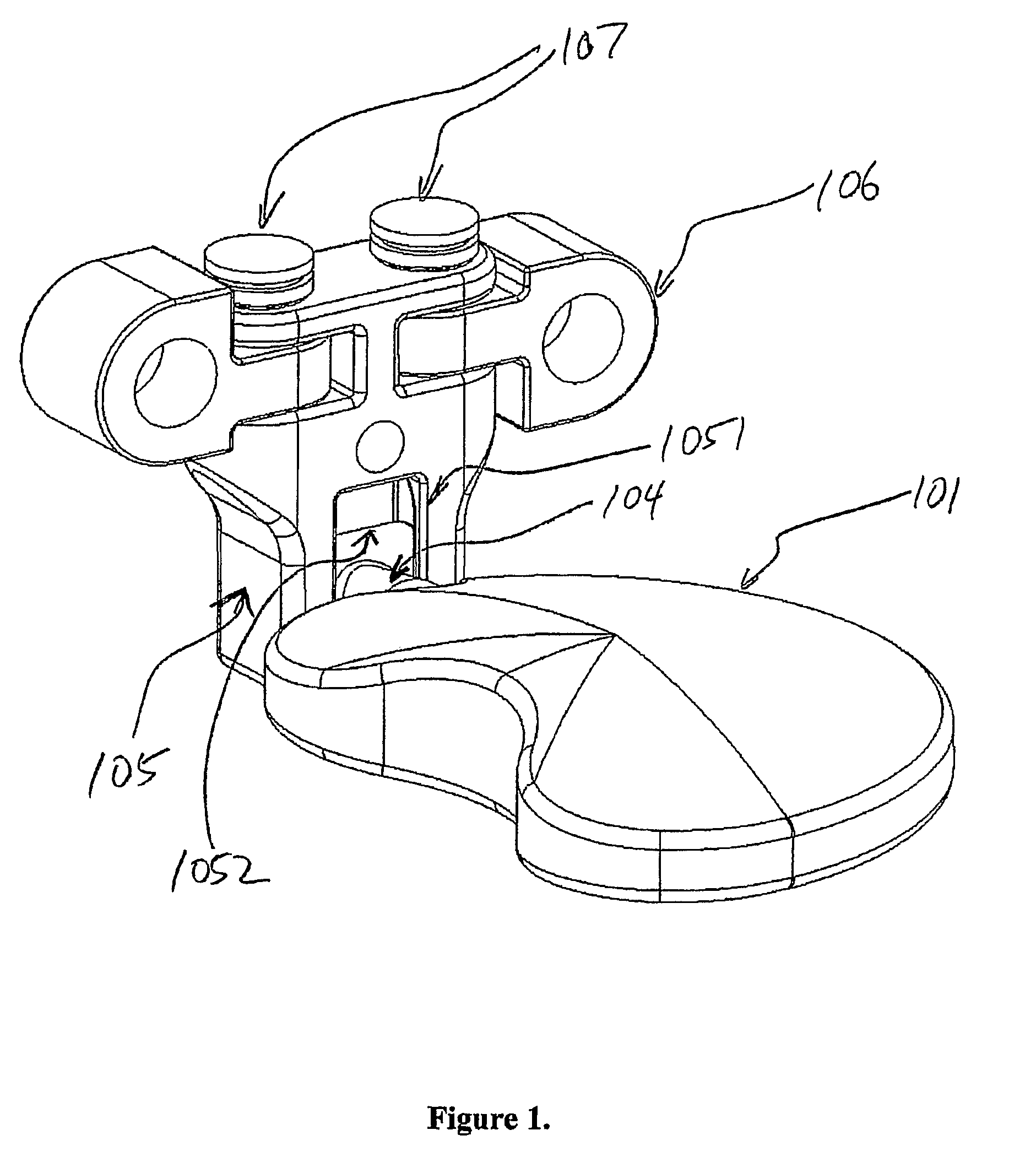

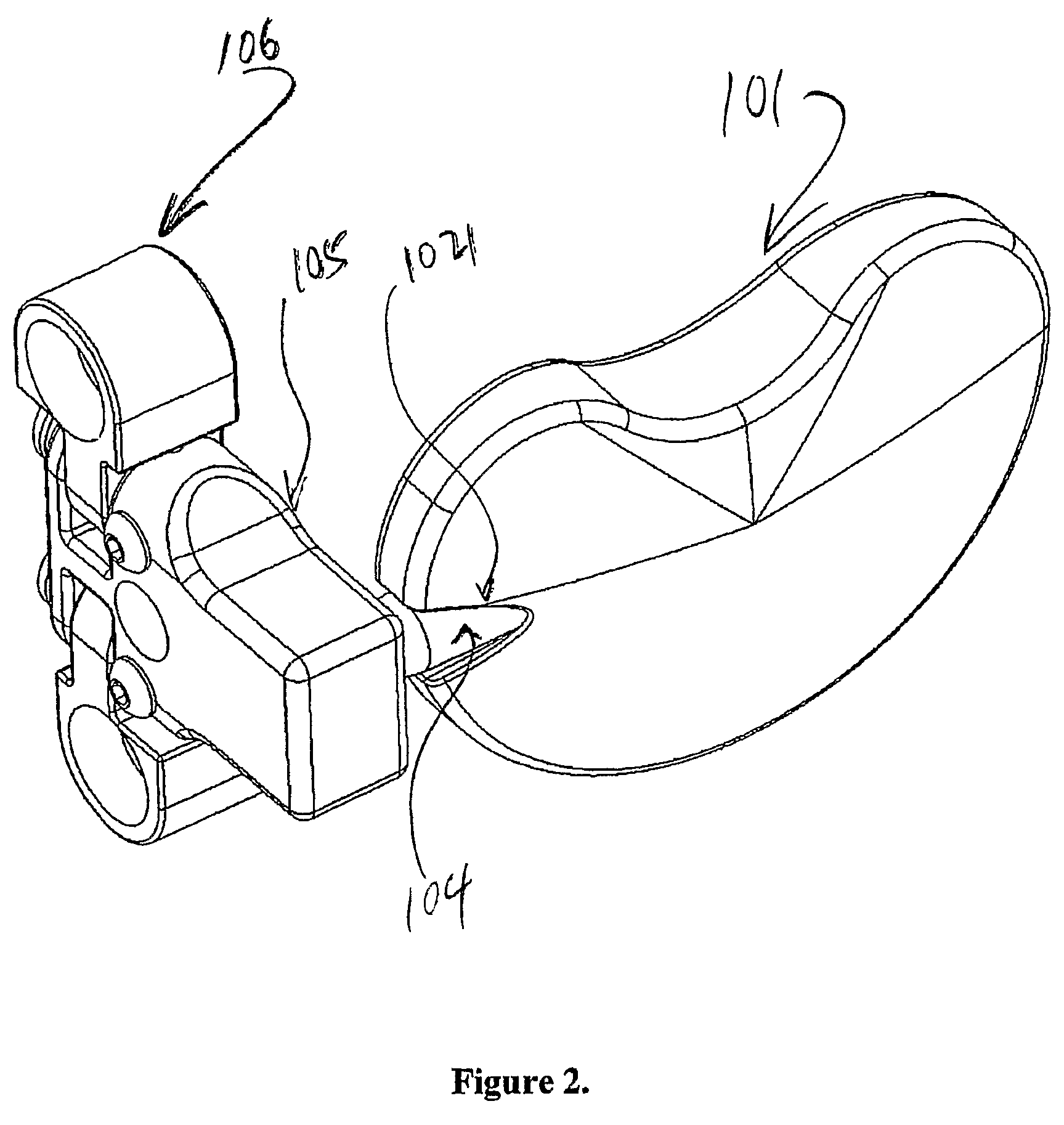

Hinged Artificial Spinal Disk Drive

An artificial spinal disk prosthesis comprised of an artificial disk (101), mounting bracket (105) assembly that secures the disk to at least one vertebrae and a sliding rod (104) that connects the two whereby the shape of the components determines the range of motion of the disk, thus allowing desirable motions of the disk consistent with normal body motions and preventing undesirable motions of the artificial disk. In the preferred embodiment, the angular motion of the disk is controlled by a hinge that is on the side of the artificial disk. In the preferred embodiment, the artificial disc is connected to the spine via one vertebra.

Owner:ADL ALI

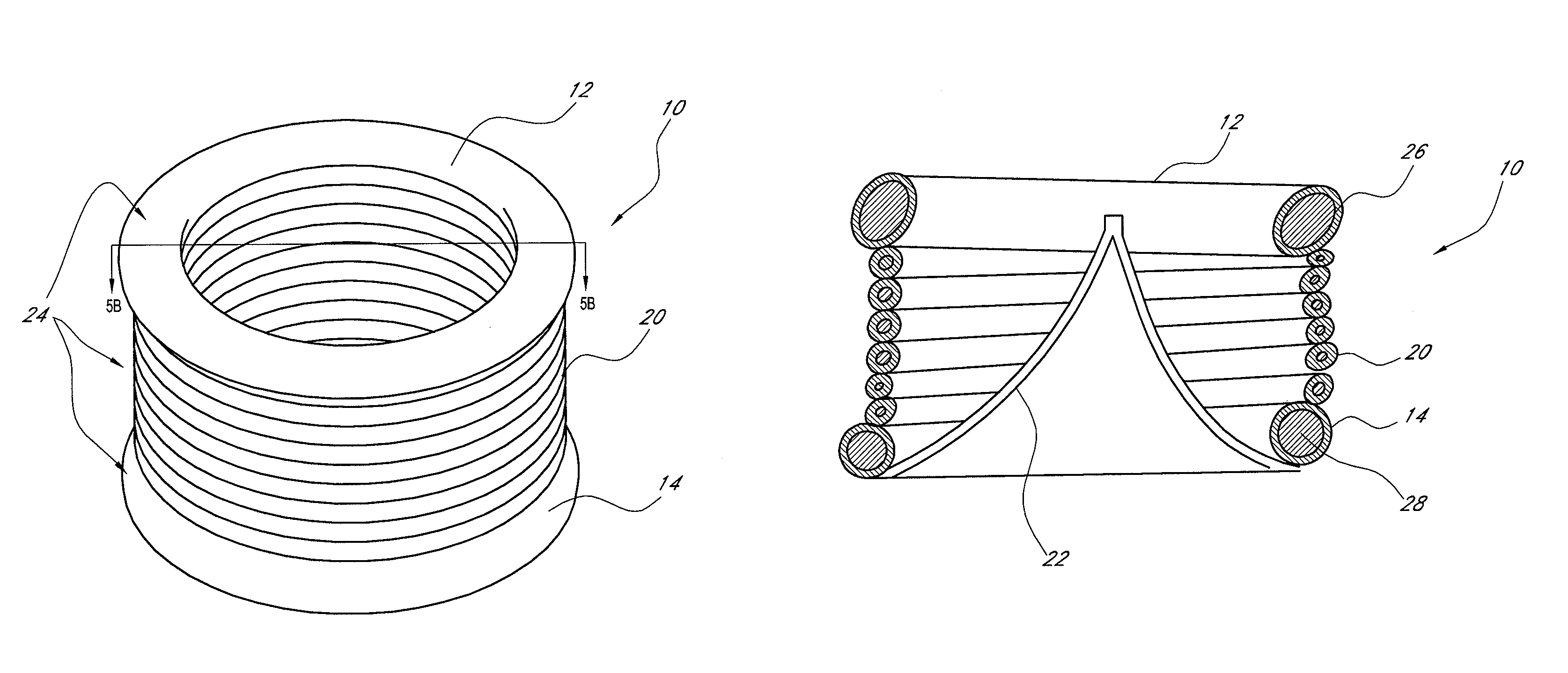

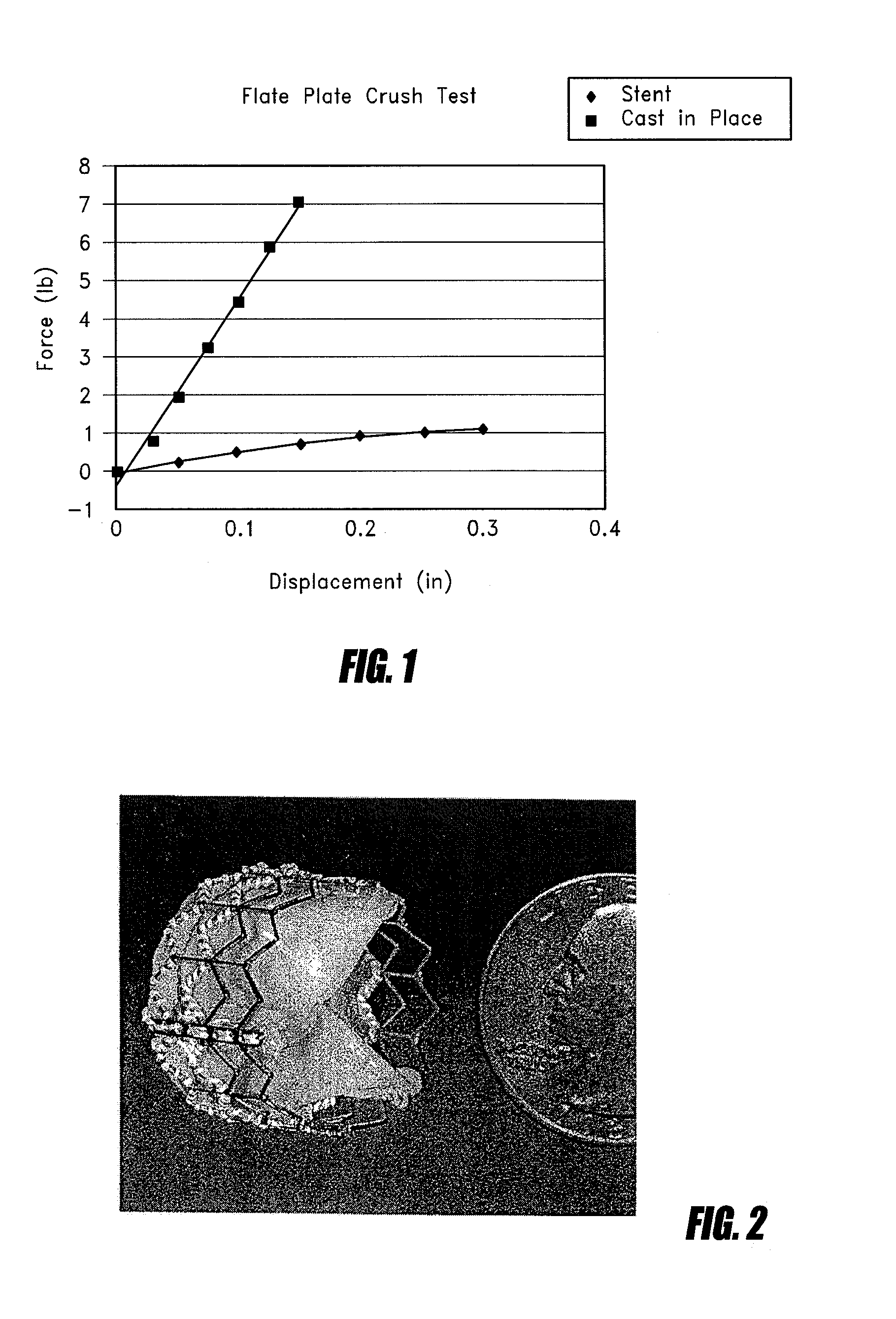

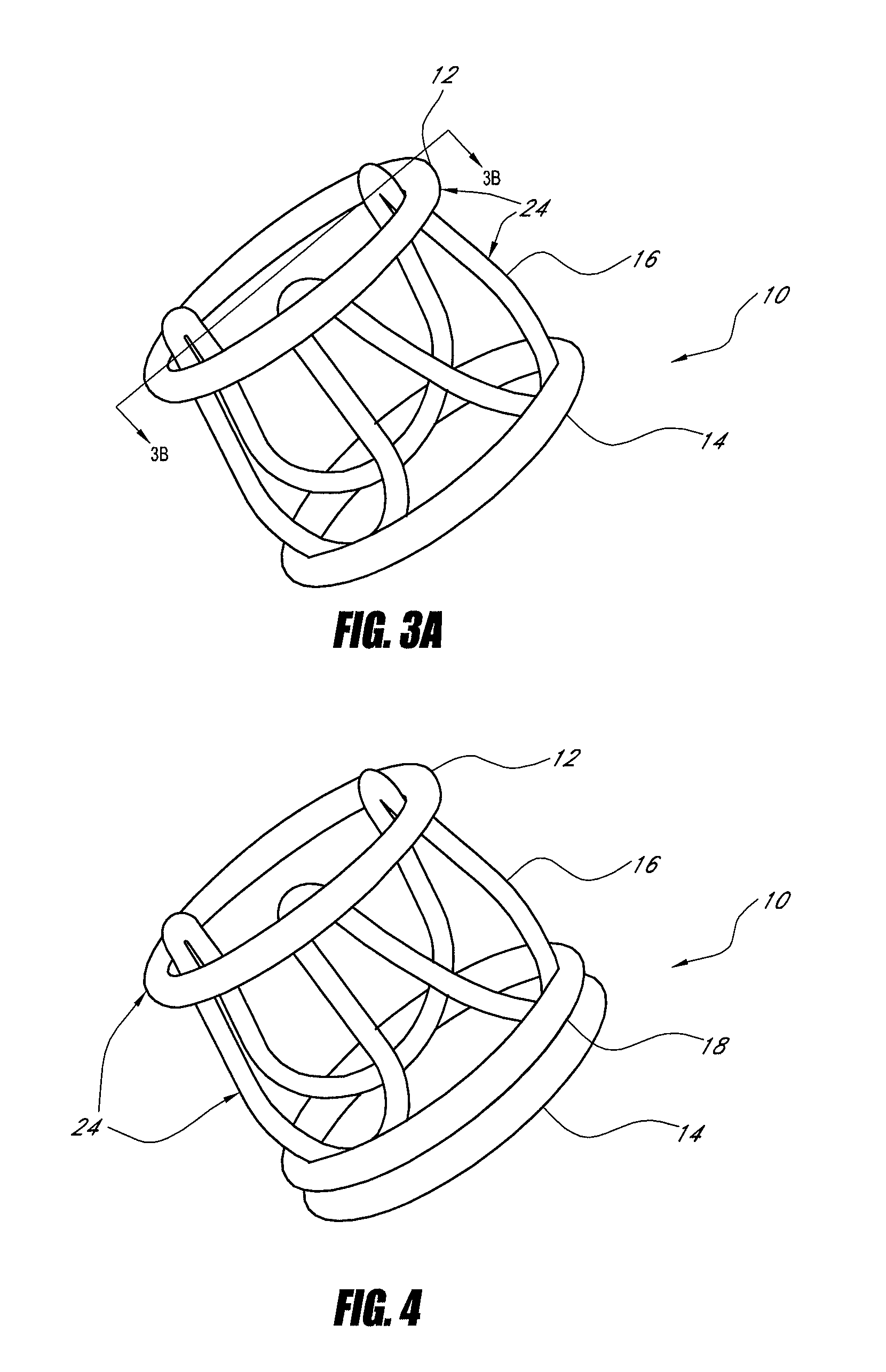

Stentless aortic valve replacement with high radial strength

InactiveUS8568477B2Improve radial strengthMinimally invasiveHeart valvesInsertion stentUltimate tensile strength

Disclosed is a stentless transluminally implantable heart valve, having a formed in place support. The formed in place support exhibits superior crush resistance when compared to conventional balloon expandable or self expandable stent based valves.

Owner:SPEYSIDE MEDICAL LLC

Hinged artificial spinal disk device

An artificial spinal disk prosthesis comprised of an artificial disk (101), mounting bracket (105) assembly that secures the disk to at least one vertebrae and a sliding rod (104) that connects the two whereby the shape of the components determines the range of motion of the disk, thus allowing desirable motions of the disk consistent with normal body motions and preventing undesirable motions of the artificial disk. In the preferred embodiment, the angular motion of the disk is controlled by a hinge that is on the side of the artificial disk. In the preferred embodiment, the artificial disc is connected to the spine via one vertebra.

Owner:ADL ALI

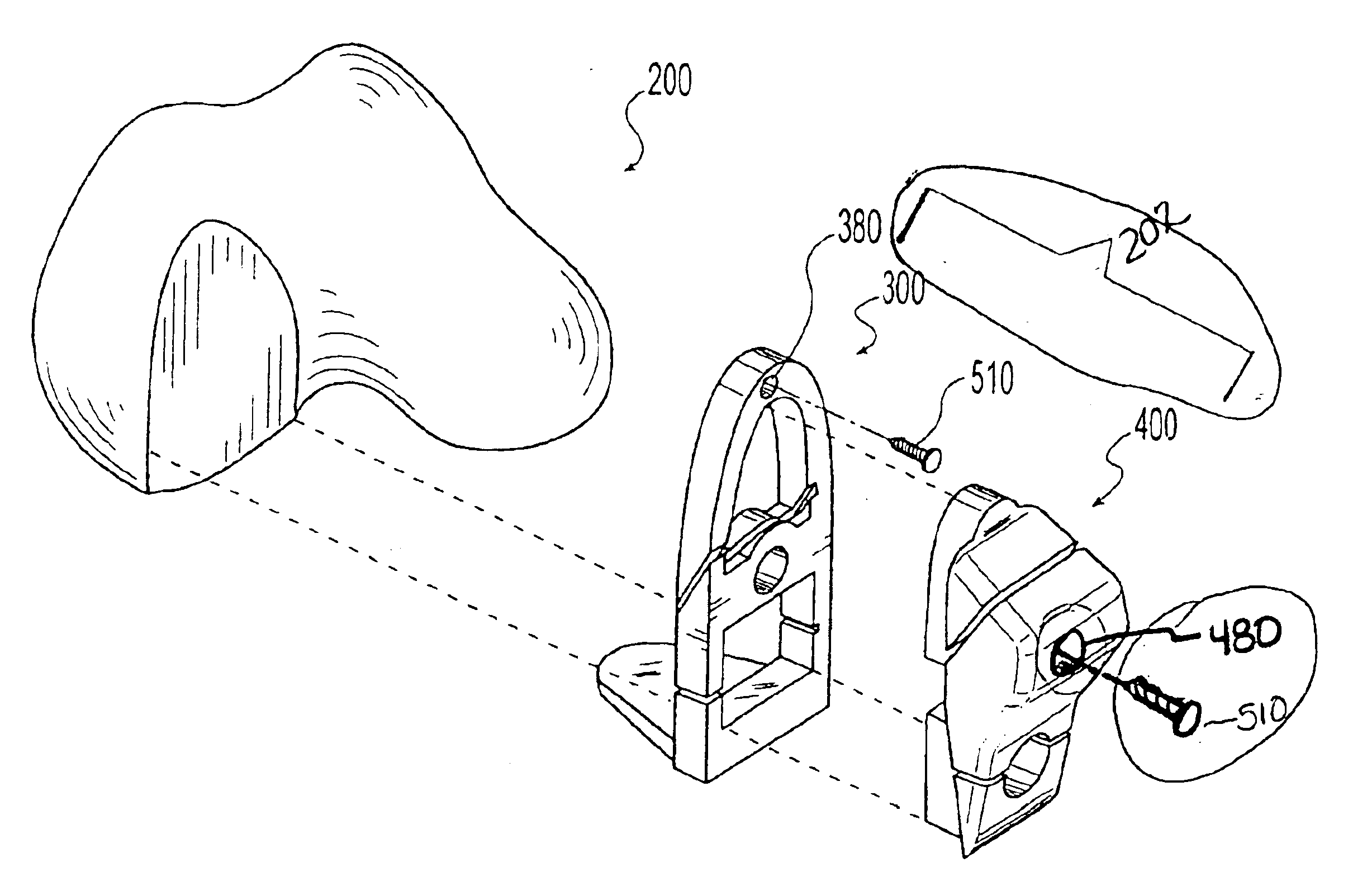

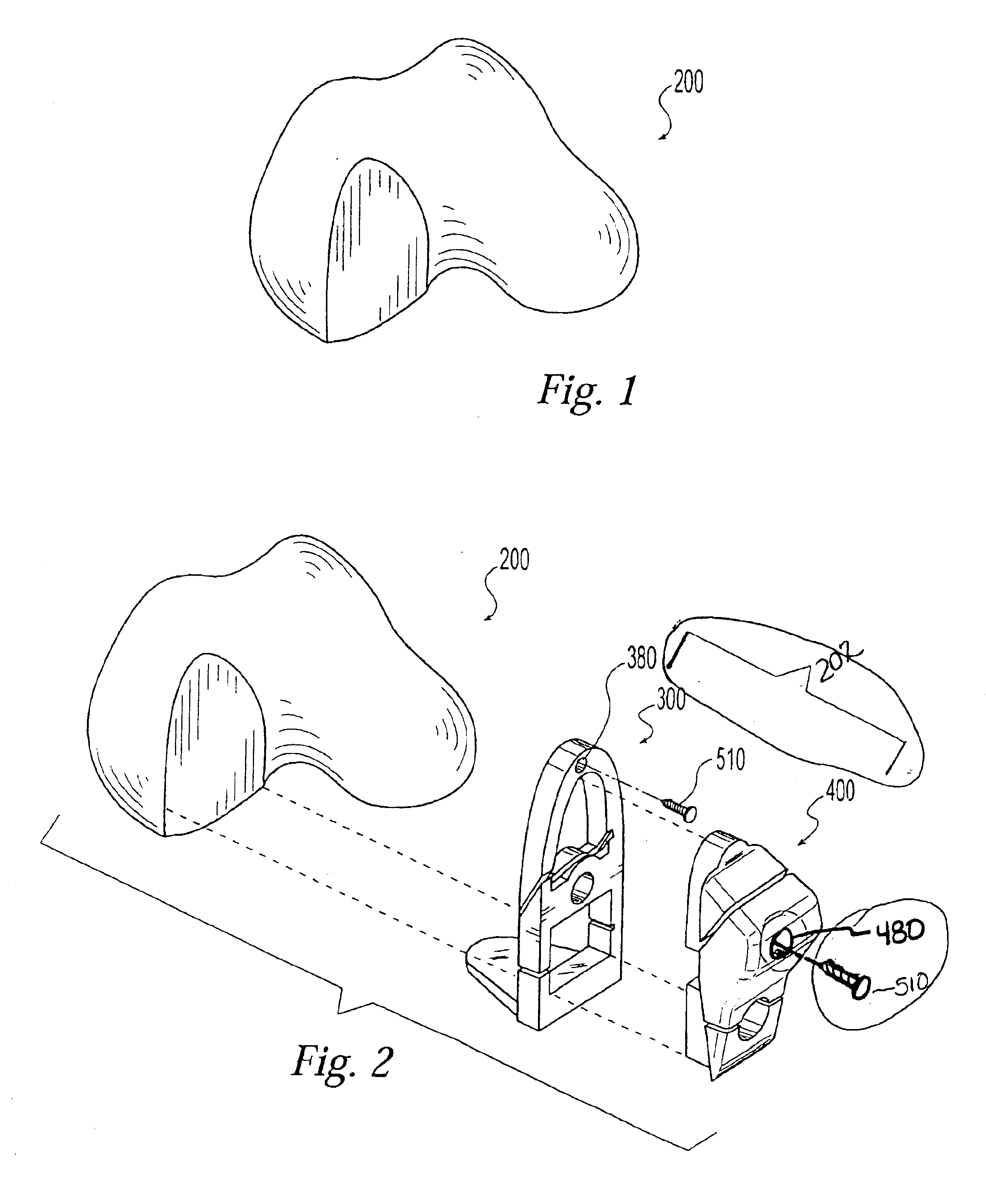

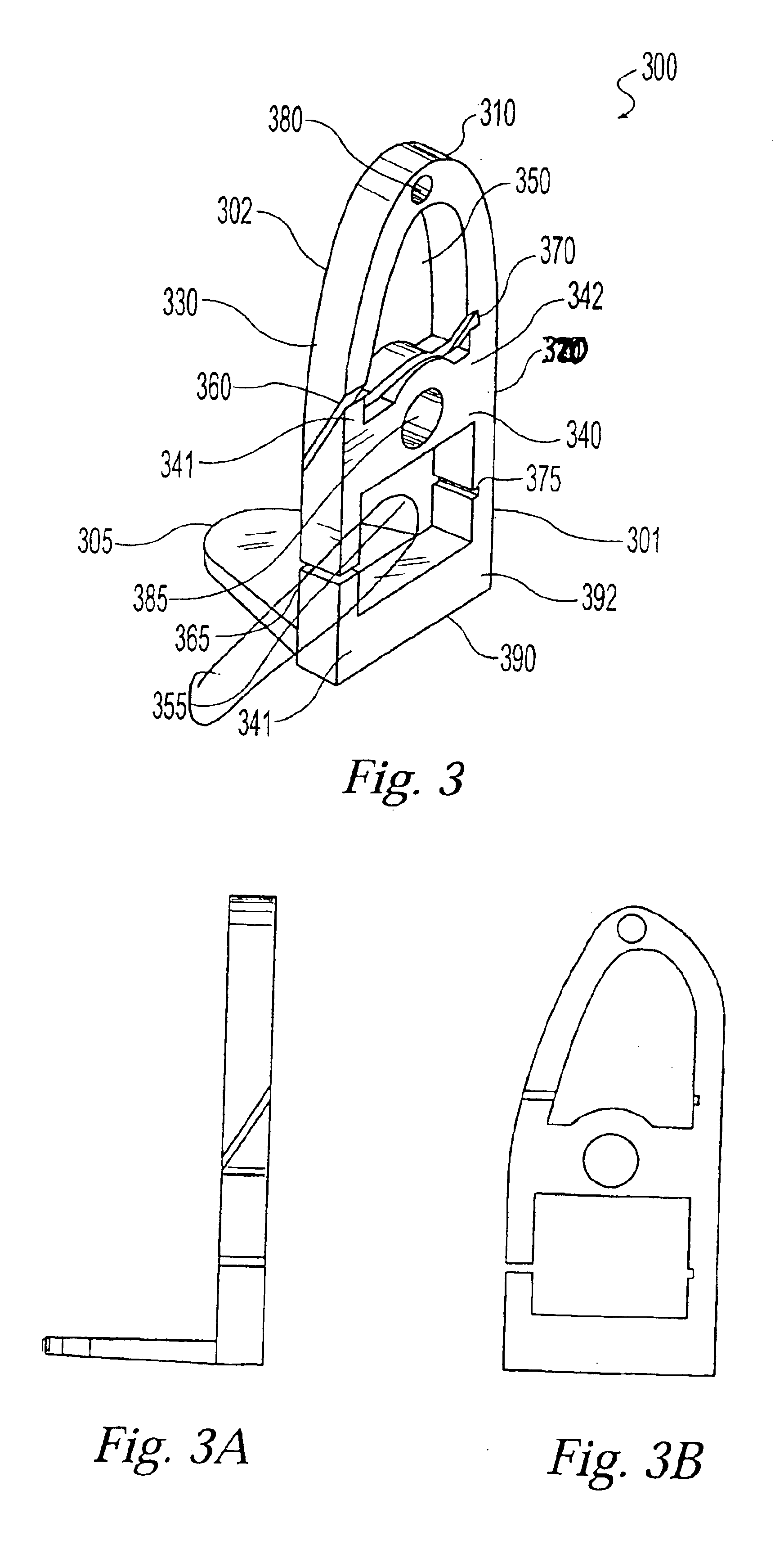

Two-piece cut block for minimally invasive surgical procedure

InactiveUS6962593B2Less initial traumaFast recovery timeJoint implantsNon-surgical orthopedic devicesTotal hip arthroplastyLess invasive surgery

A two-piece cut block for performing a minimally invasive partial or total knee arthroplasty. The present invention comprises a cut block that can be inserted into an incision in two parts then assembled in vivo. The two-piece design allows the relatively large surgical instrument to fit into a small, minimally invasive, surgical incision

Owner:ZIMMER INC

Bone Marking System and Method

InactiveUS20100305435A1Less difficultyMore procedureSurgical navigation systemsDiagnostic markersDisplay deviceAnatomical feature

An apparatus for marking bone of a patient includes a marker, a tracking system and a display. The marker includes pigment and is configured to impart the pigment on the bone. The tracking system is in communication with the marker. The tracking system is configured to determine a location of the marker relative to the bone and to match at least one anatomical feature of the bone of the patient to an image of the bone. The display is in communication with the tracking system and adapted to show an image of the location of the marker relative to the image of the bone while the marker imparts the pigment on the bone.

Owner:PHYSICAL SCI

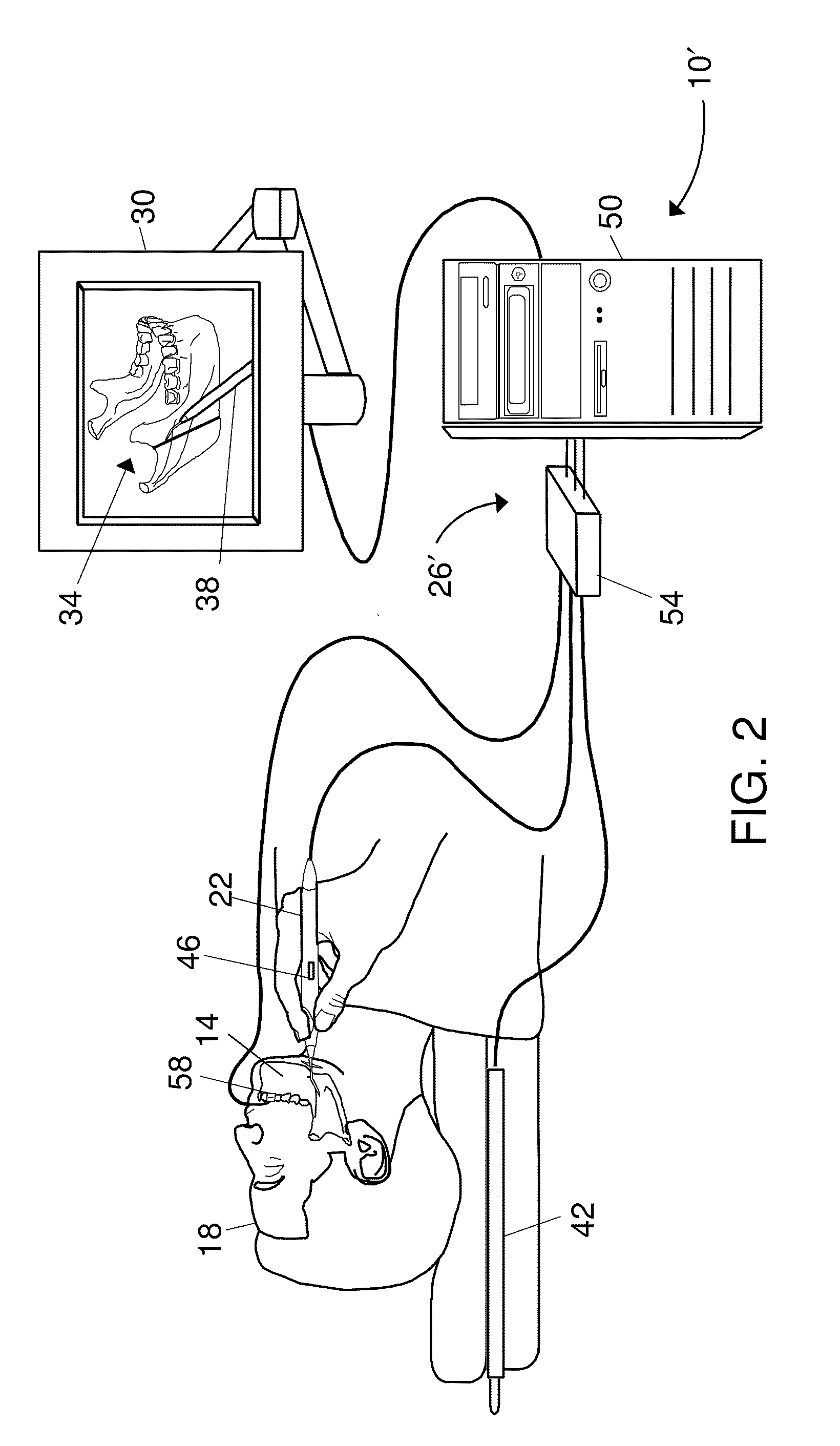

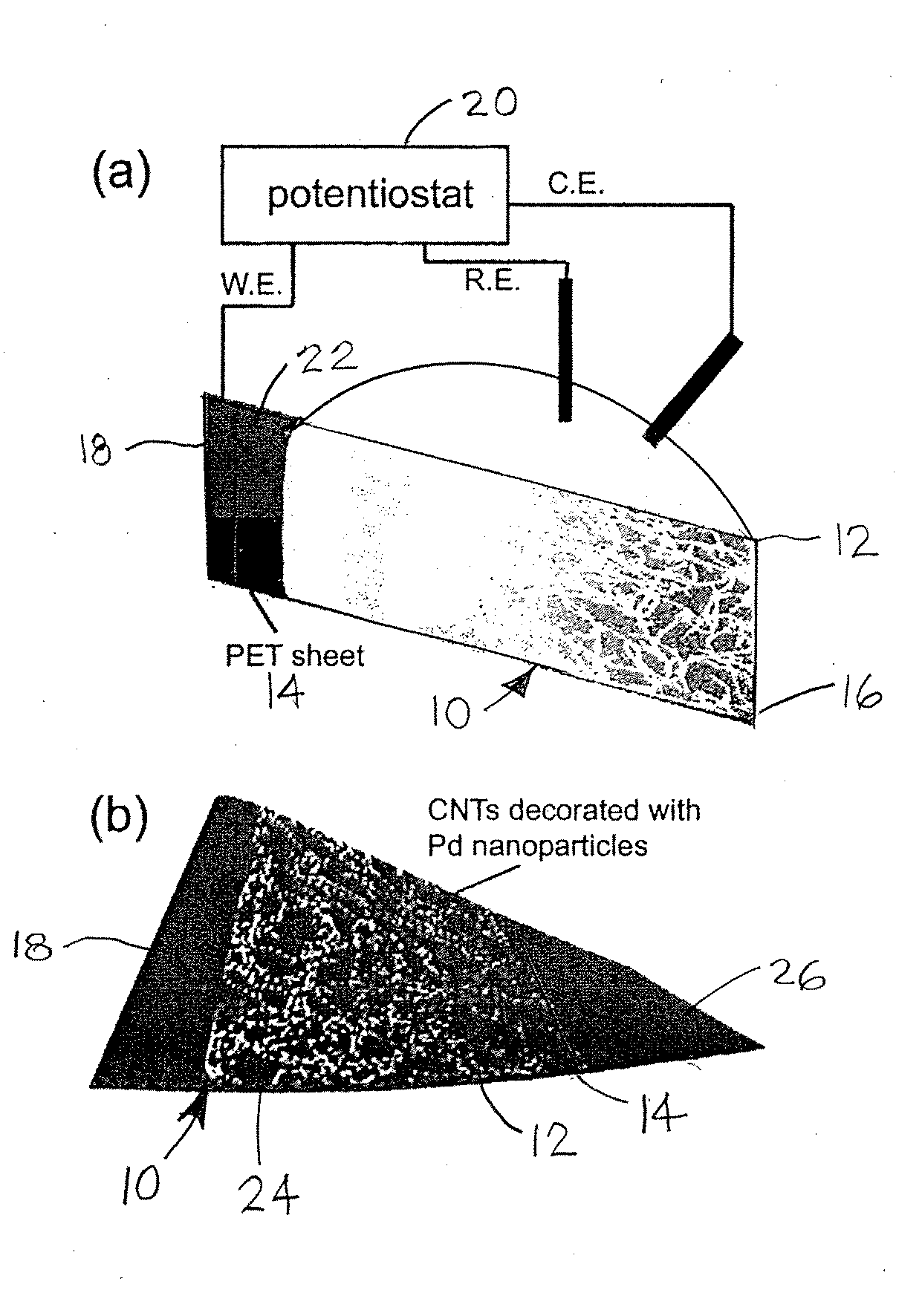

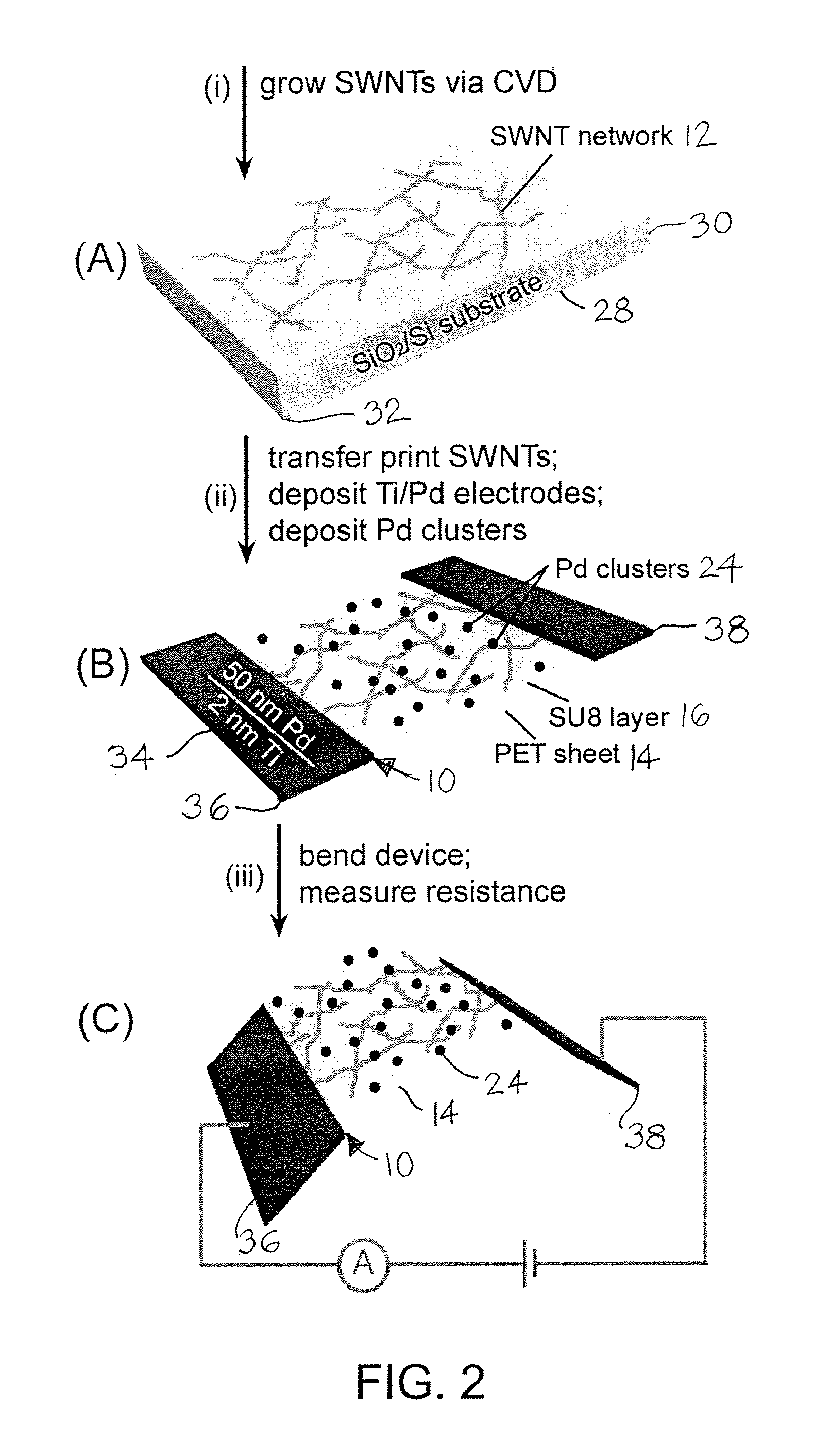

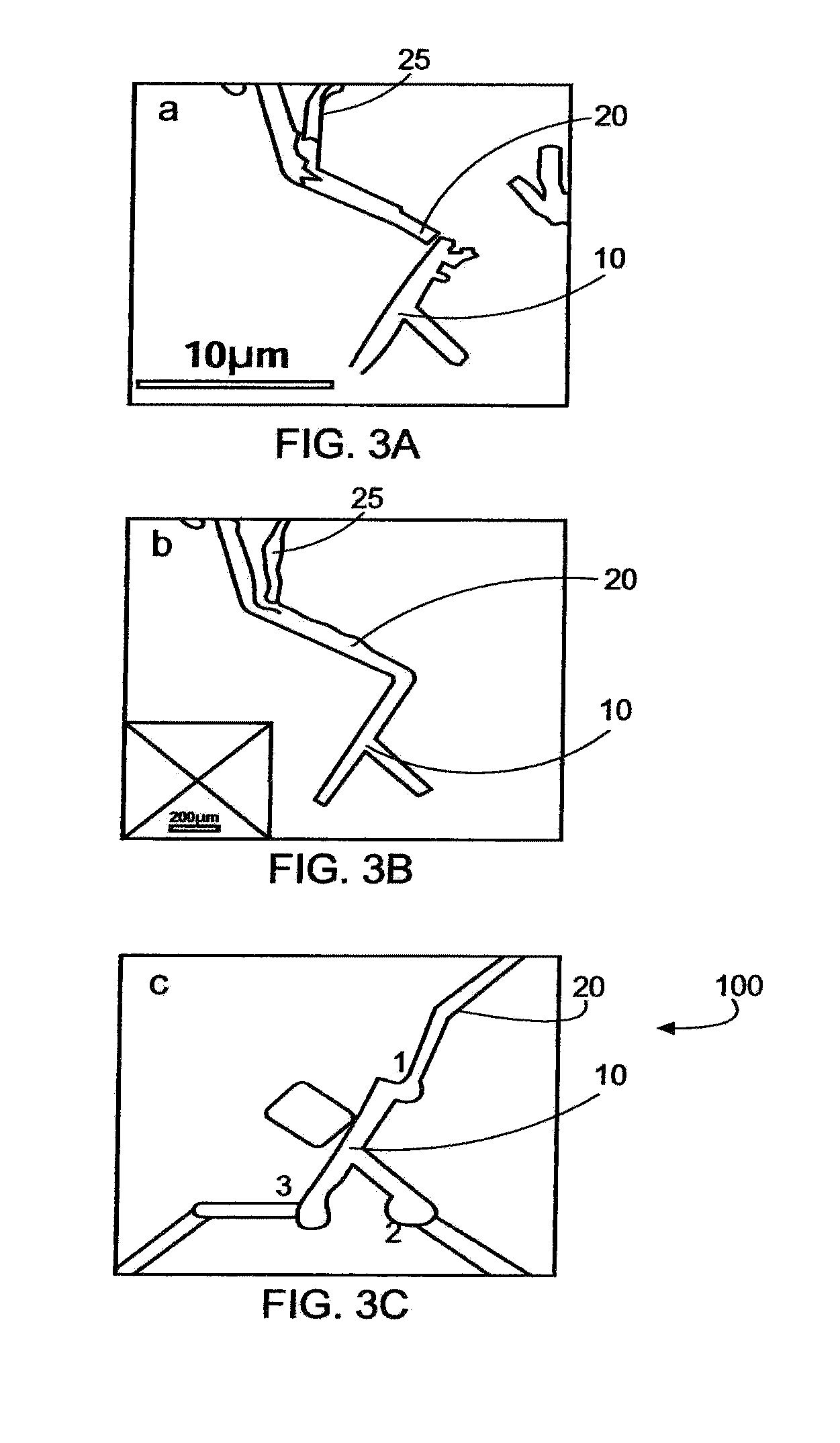

High-Performance Flexible Hydrogen Sensors

InactiveUS20090084159A1Easy to conformFast recovery timeAnalysing fluids using sonic/ultrasonic/infrasonic wavesNanotechCarbon nanotubeEvaporation

Single-walled carbon nanotubes (SWNTs) are decorated with metal nanoparticles to form high-performance flexible hydrogen sensors. The special process to form the high-performance flexible hydrogen sensors can combine a dry transfer printing technique and modification of SWNTs with palladium (Pd) nanoparticles to provide high-performance hydrogen sensors with excellent mechanical flexibility on plastic substrates. Two approaches can be used to decorate the SWNTs. One is physical deposition, such as electron beam evaporation (EBE) and the other is electrochemical deposition which can selectively grow palladium nanoparticles on the surface of the SWNTs, resulting in significantly decreasing the use of palladium. Preferably, the Pd nanoparticles are deposed on the SWNTs in a discontinuous arrangement so that the Pd nanoparticles are spaced away from each other to form individual discontinuous Pd nanoparticles rather a continuous Pd film. Advantageously, the SWNTs are arranged with substantial semiconducting pathways. Desirably, the high-performance flexible hydrogen sensors have an excellent response and recovery time, provide superior sensitivity for detecting hydrogen, and are bendable to conform to the contours of other structures.

Owner:UCHICAGO ARGONNE LLC

Industrial controller employing the network ring topology

A network for an industrial control system employs a ring topology that is normally opened by a ring supervisor at the ring supervisor. Upon failure of the network, the ring supervisor reconnects the ring to provide an alternative transmission path around the failure point. High speed operation is reconciled with the ability to use commercial switching integrated circuits through a dual communication channel of communicating a network state as either closed or open using both high-speed hardware handled beacon frames and low-speed software processed announce frames.

Owner:ROCKWELL AUTOMATION TECH

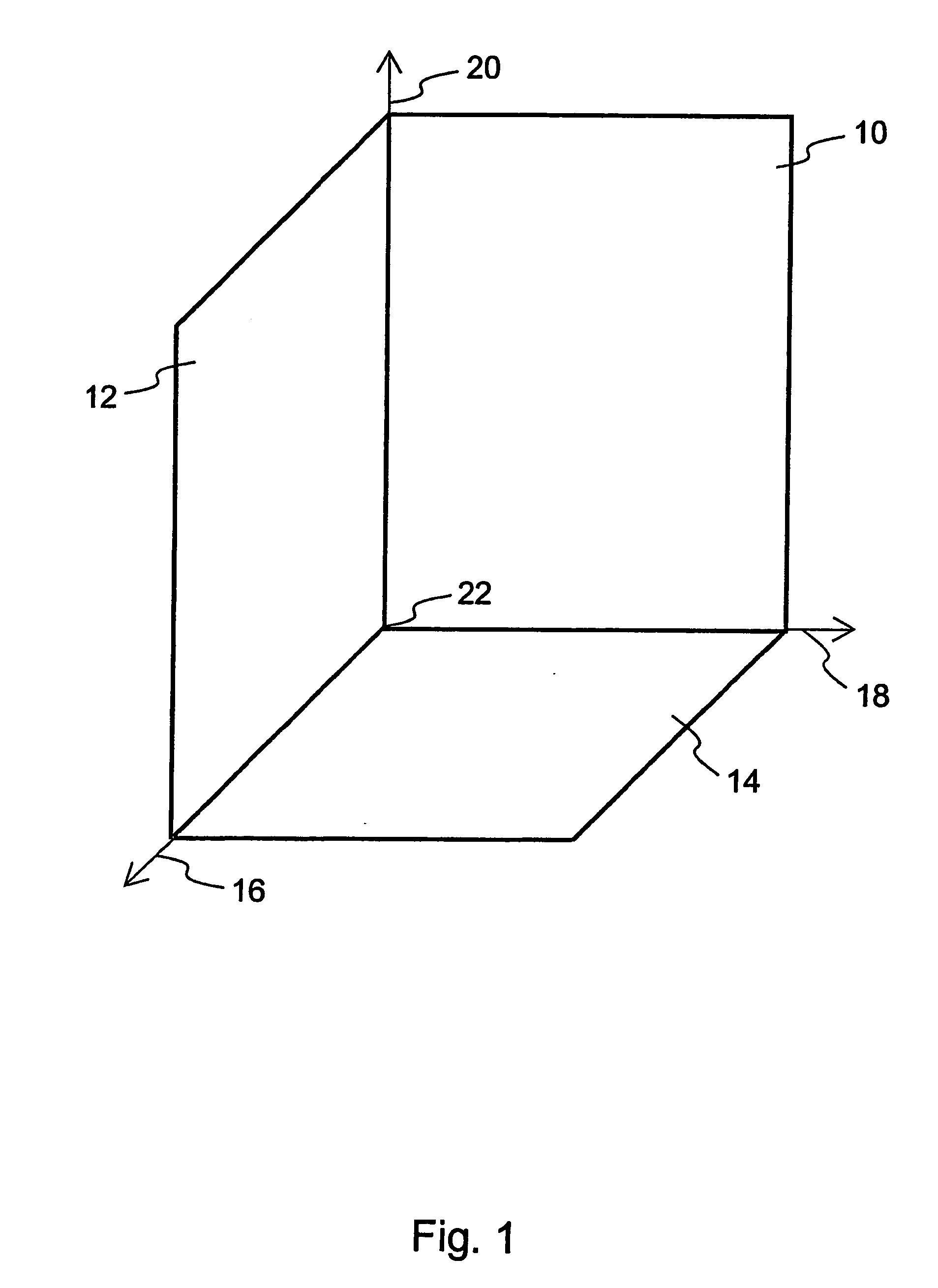

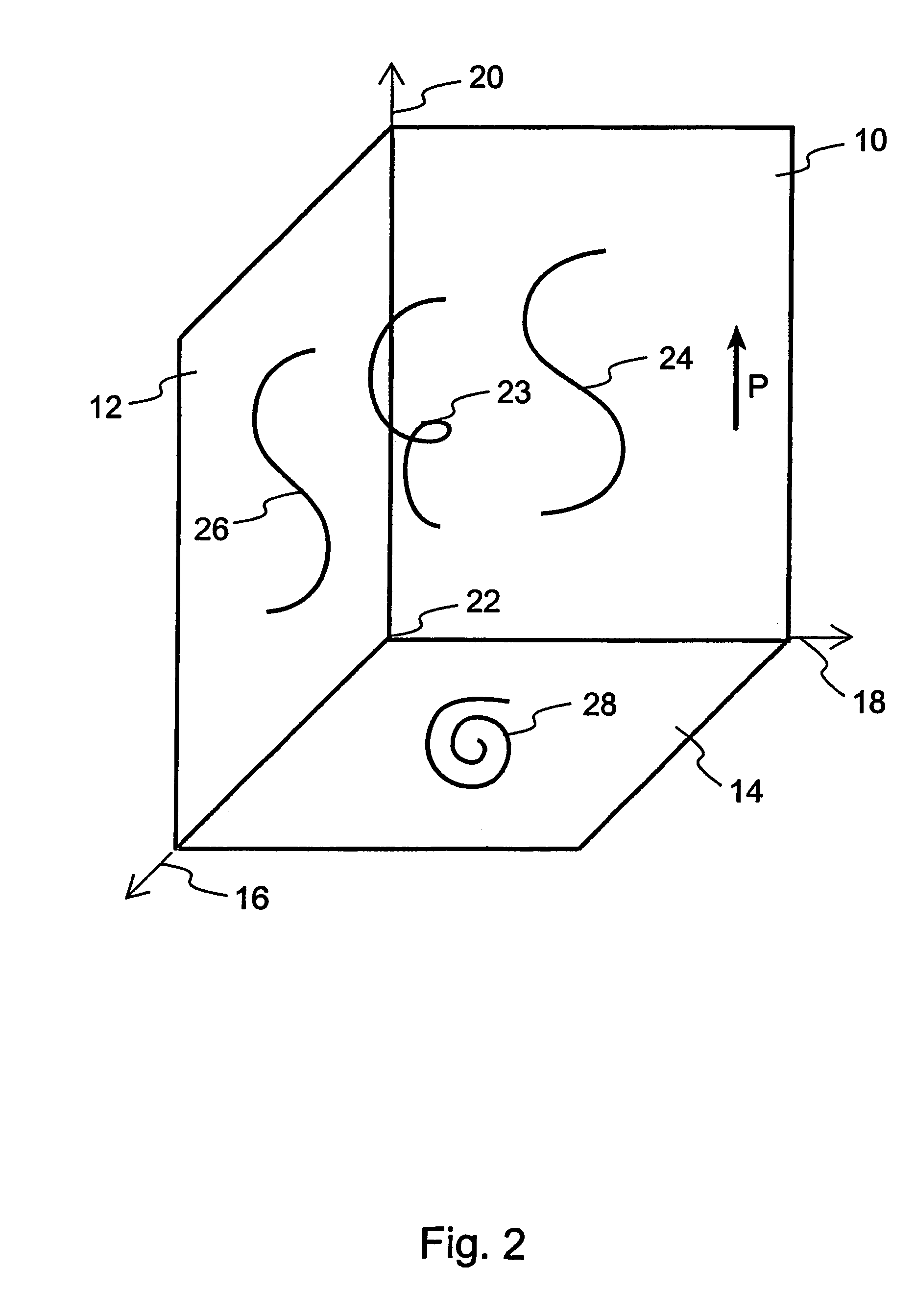

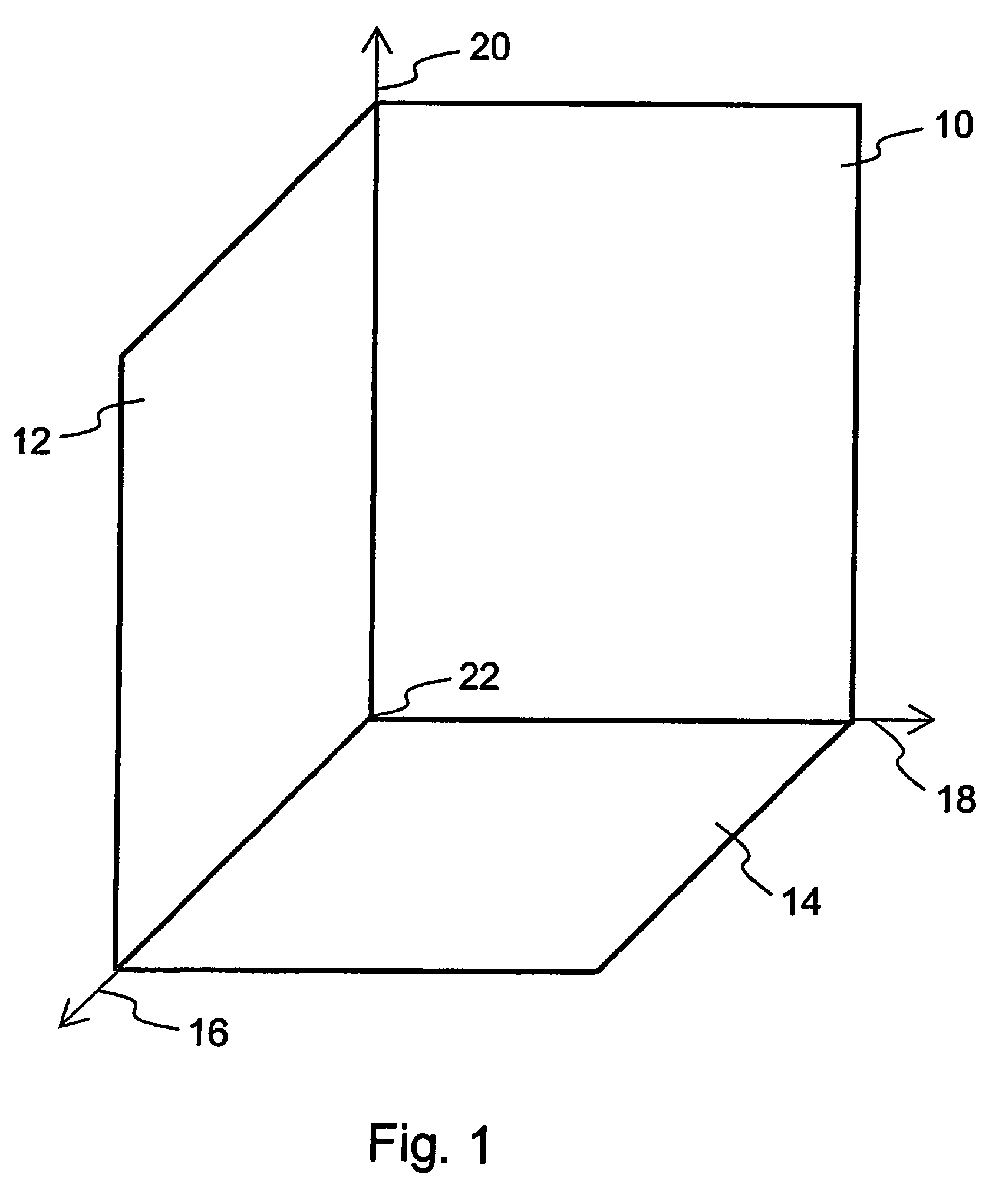

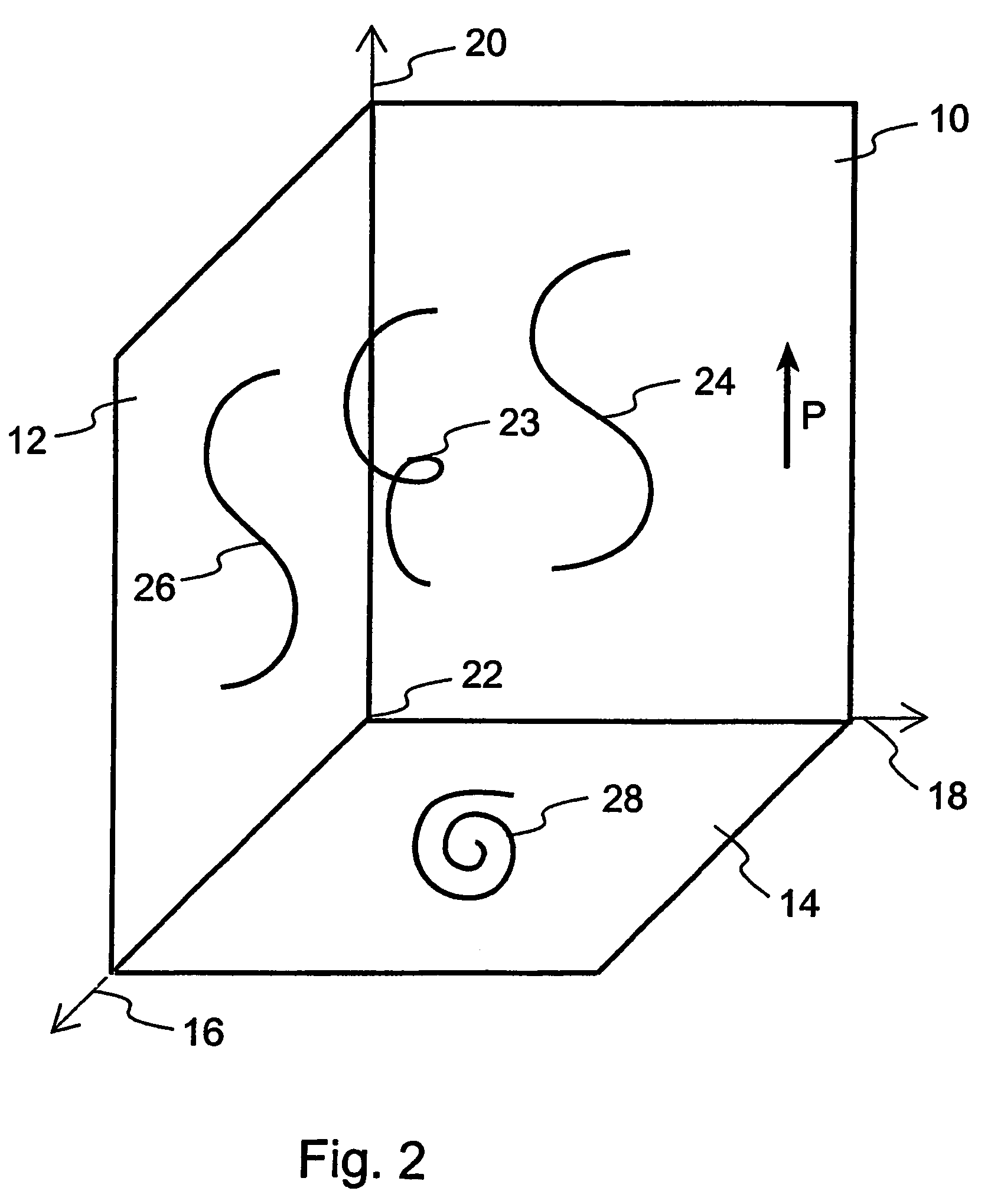

User-interface and method for curved multi-planar reformatting of three-dimensional volume data sets

InactiveUS7061484B2Efficient and straightforward user interfaceEfficient accessGeometric image transformationCathode-ray tube indicatorsMulti-planar ReformattingData set

A user interface for a computer-implemented Multi-Planar Reformatting (MPR) system comprises three display areas in which are displayed three orthogonal MPR images of the volume data set; a curve drawing tool to allow a user to define a curve through the volume data set; six selectable icons each representing one of six possible combinations of a plane parallel to one of the orthogonal MPR images and a direction substantially normal to a plane parallel to one of the other two MPR images, using which the user selects an approximate direction for the curve; and a fourth display area displaying a curve-related MPR image related to one or more points along the curve. The icons may be individually selectable to allow user input of adequate orientational information for a curved MPR image, or selectable in pairs for input of directional information for a cross-curve MPR image. Alternatively, three icons may be provided for a cross-curve MPR system. A tool to allow rotation of a curved MPR image about the curve can be provided, as can visual indicators of the depth of the curve within the volume, and of the orientation of the cross-curve image.

Owner:TOSHIBA MEDICAL VISUALIZATION SYST EURO

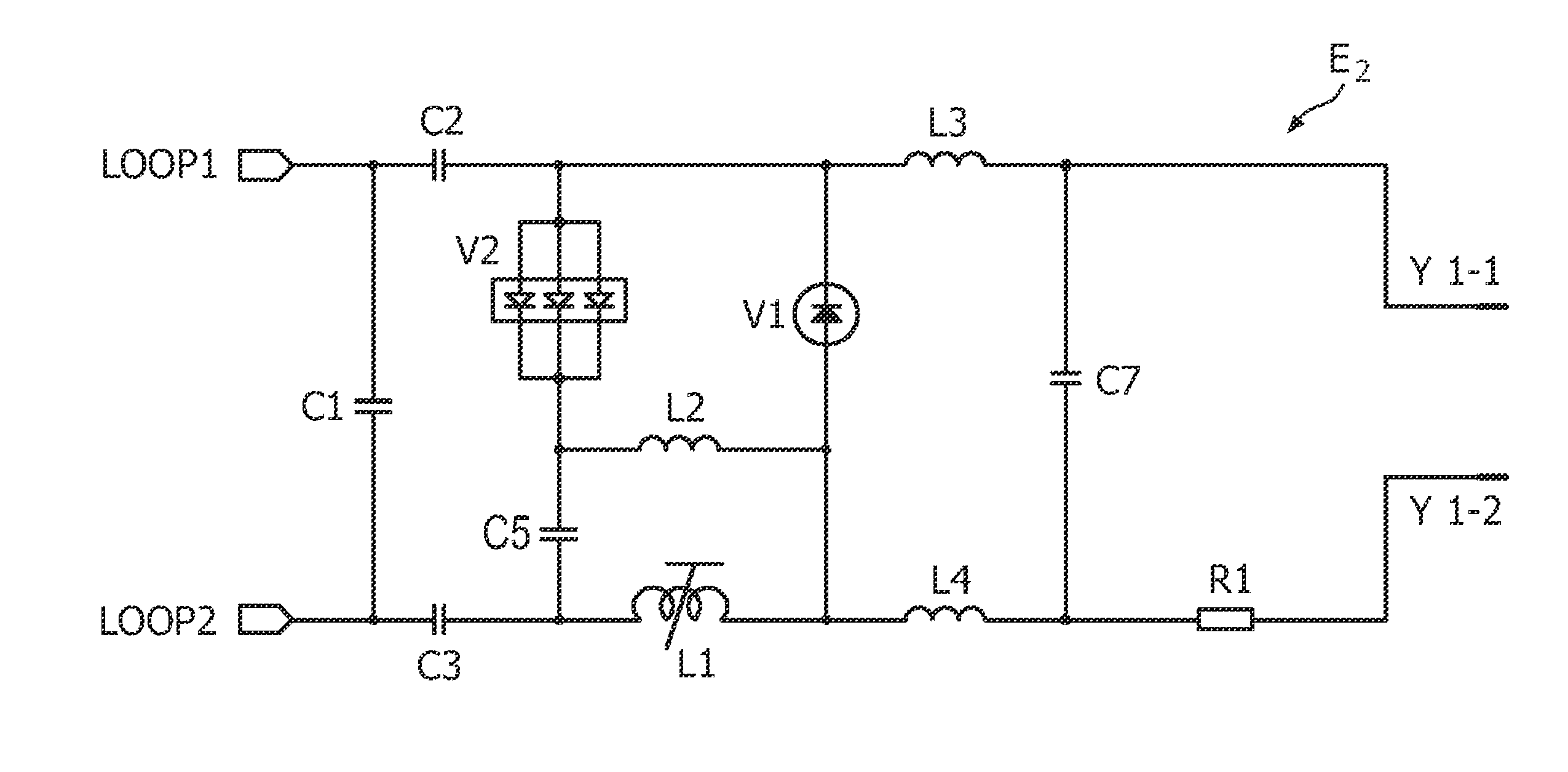

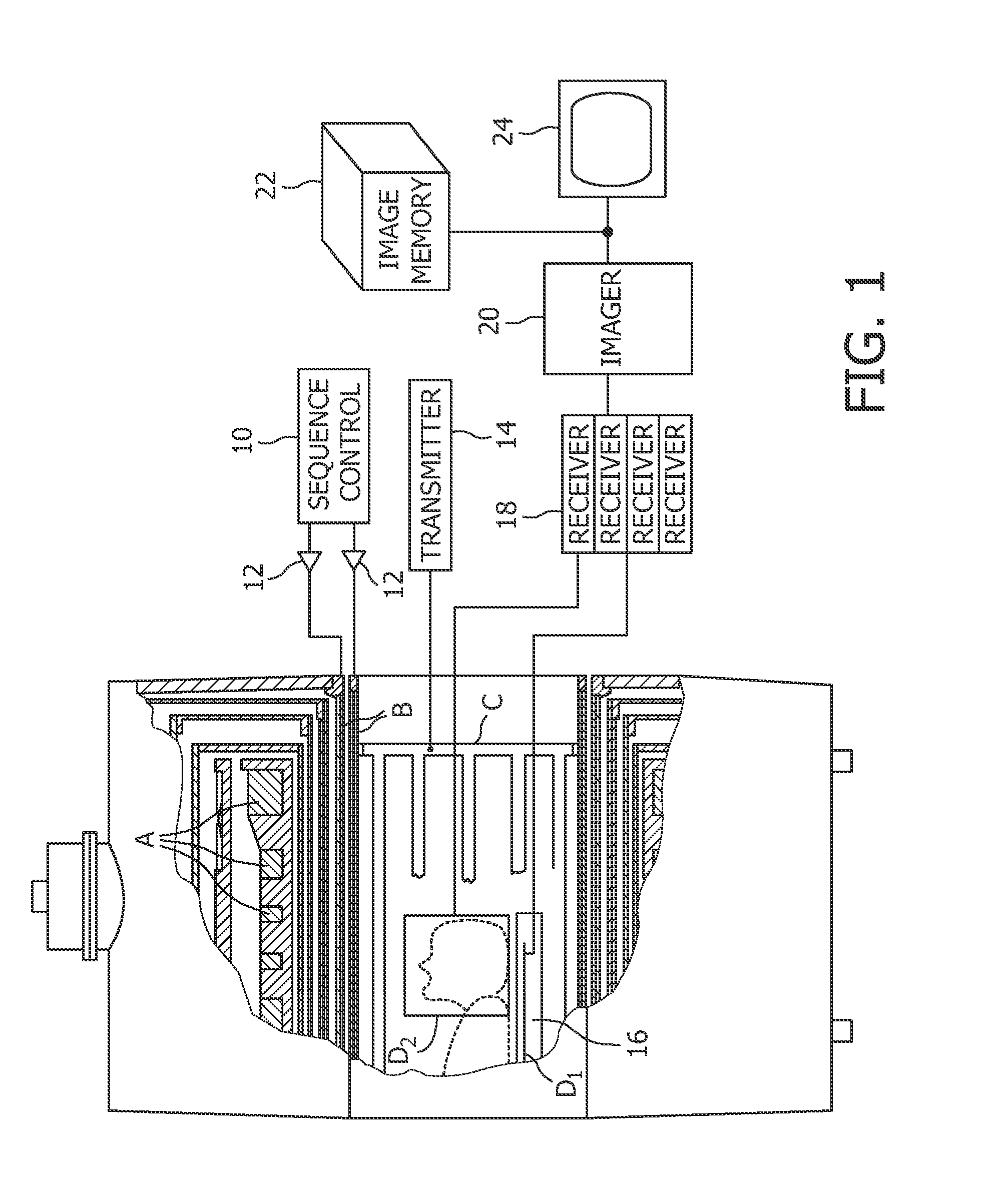

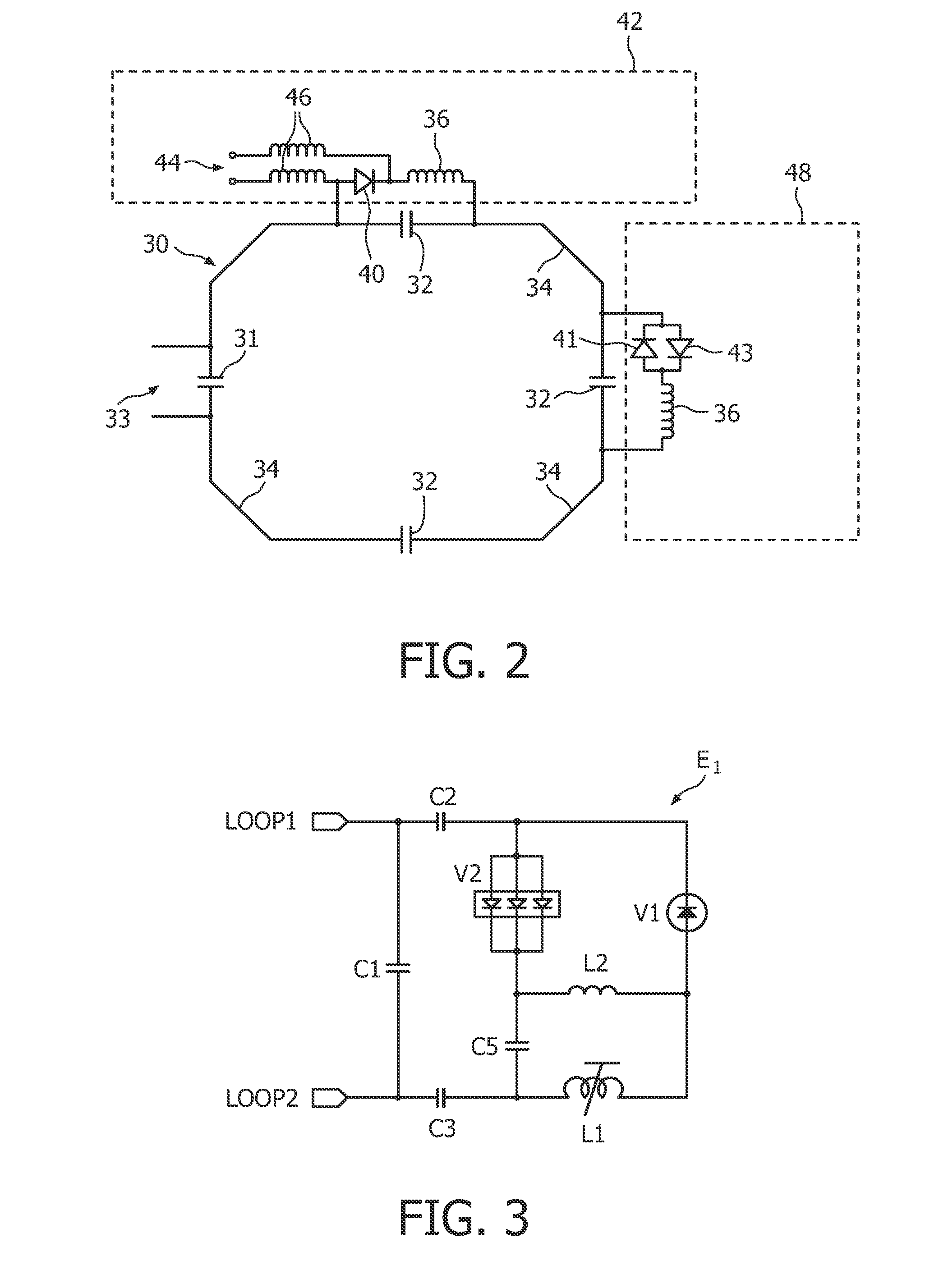

Detuning circuit and detuning method for an MRI system

InactiveUS8013609B2Sufficient deliveryRobustMagnetic measurementsElectric/magnetic detectionDc currentHigh field mri

The present invention relates to a magnetic resonance imaging system and a corresponding method having a transmit phase and a receive phase. Further, the present invention relates to a detuning circuit and a corresponding detuning method for detuning an RF receive coil during the transmit phase in such a magnetic resonance imaging system. In high-field MRI systems the transmit mode operating frequency is higher than normal high breakdown voltage rectifiers can handle when they are used to forward bias a passive detuning circuit PIN diode switch. The proposed circuit uses a current-limiting capacitor (C5) in series with a fast (e.g. schottky) rectifier diode (V2) with a reverse breakdown voltage of e.g. 20 volts and a fast reverse recovery time to generate a DC current. The rectifying circuit is isolated from the PIN diode (V1) with a relatively high-value inductor (L2), which ensures that no harmful transient current spikes can flow from the PIN diode anode to the rectifying circuit. The inductor (L2) still passes and maintains the DC current generated by the rectifying circuit through the PIN diode, thus enabling the robust forward-biasing of the PIN-diode during transmit mode. The use of a fast (and thus low-power) rectifier results in less dissipation on the detuning circuit, and helps in fulfilling the surface temperature limits posed on receiver coils.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

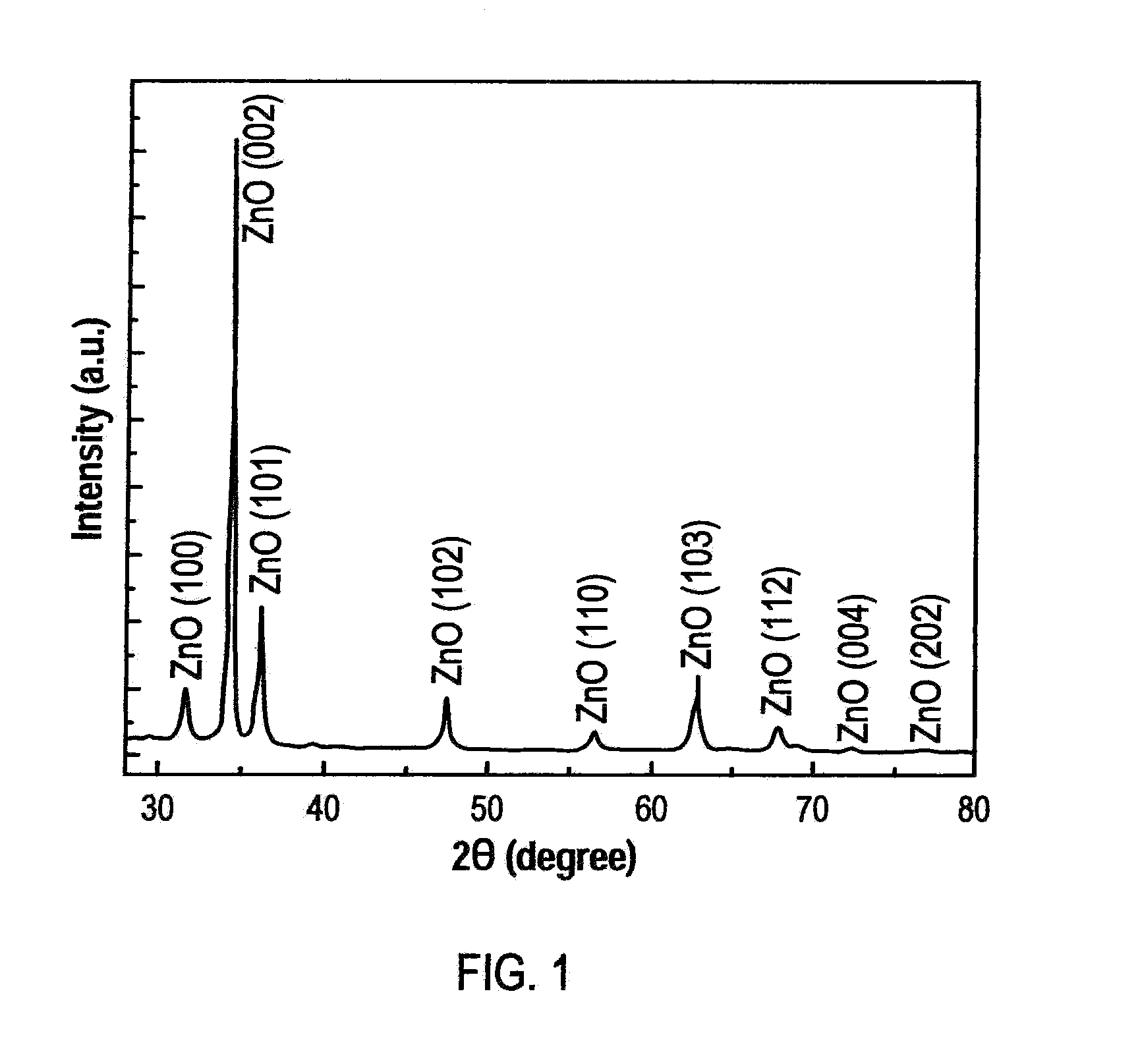

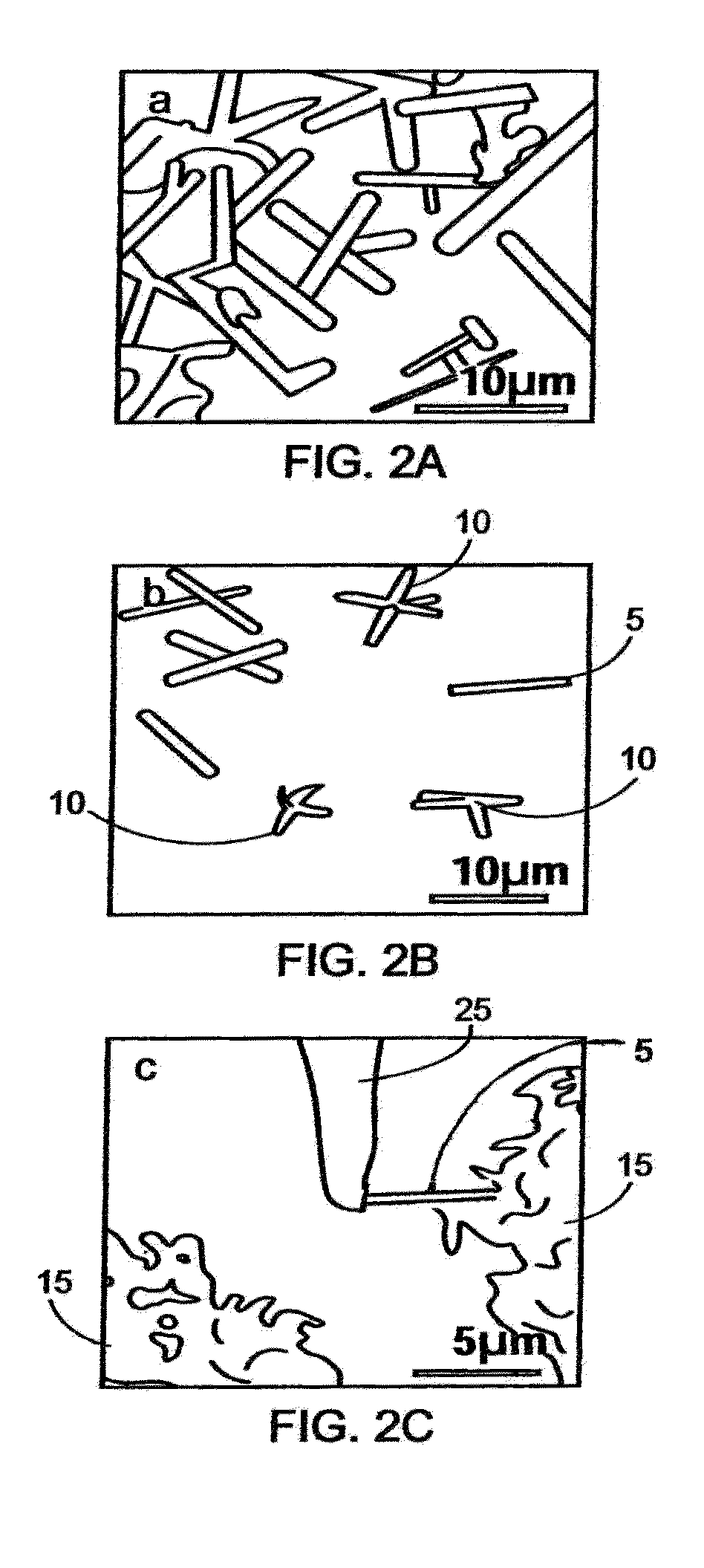

Fabrication of ZnO nanorod-based hydrogen gas nanosensor

InactiveUS8263002B1High sensitivityEasy transferMaterial analysis by optical meansMaterial resistanceEnergy dispersionElectron

The nanofabrication of a hydrogen gas nanosensor device from single straight and branched, tripod shaped ZnO nanorods using in-situ lift-out technique, performed in the chamber of a focused ion beam (FIB) system is disclosed. Self-assembled ZnO branched nanorods have been grown by a cost-effective and fast synthesis route using an aqueous solution deposition method and rapid thermal processing. The properties of the ZnO nanorod structures were analyzed by X-ray diffraction, scanning electron microscopy, energy dispersion X-ray spectroscopy, transmission electron microscopy and micro-Raman spectroscopy. High quality ZnO nanorods were obtained with a 90% success rate for building nanodevices. The fabricated nanosensor can gauge 150 ppm hydrogen gas in the air at room temperature. The nanosensor has selectivity for other gases such as oxygen, methane, carbon monoxide and liquid propane gas. The ZnO nanorod sensors of the present invention also operate at low power of less than 5 microwatts.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

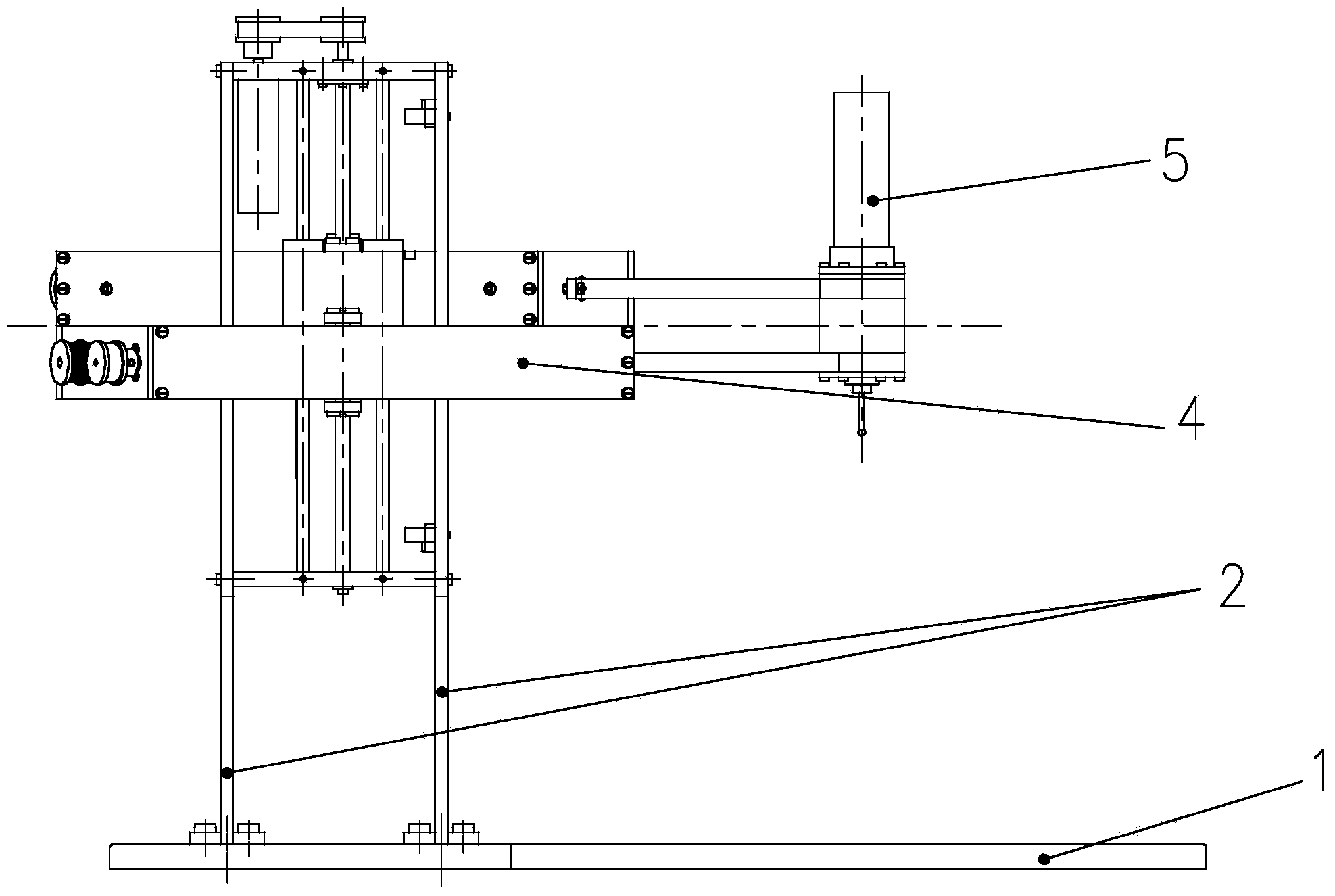

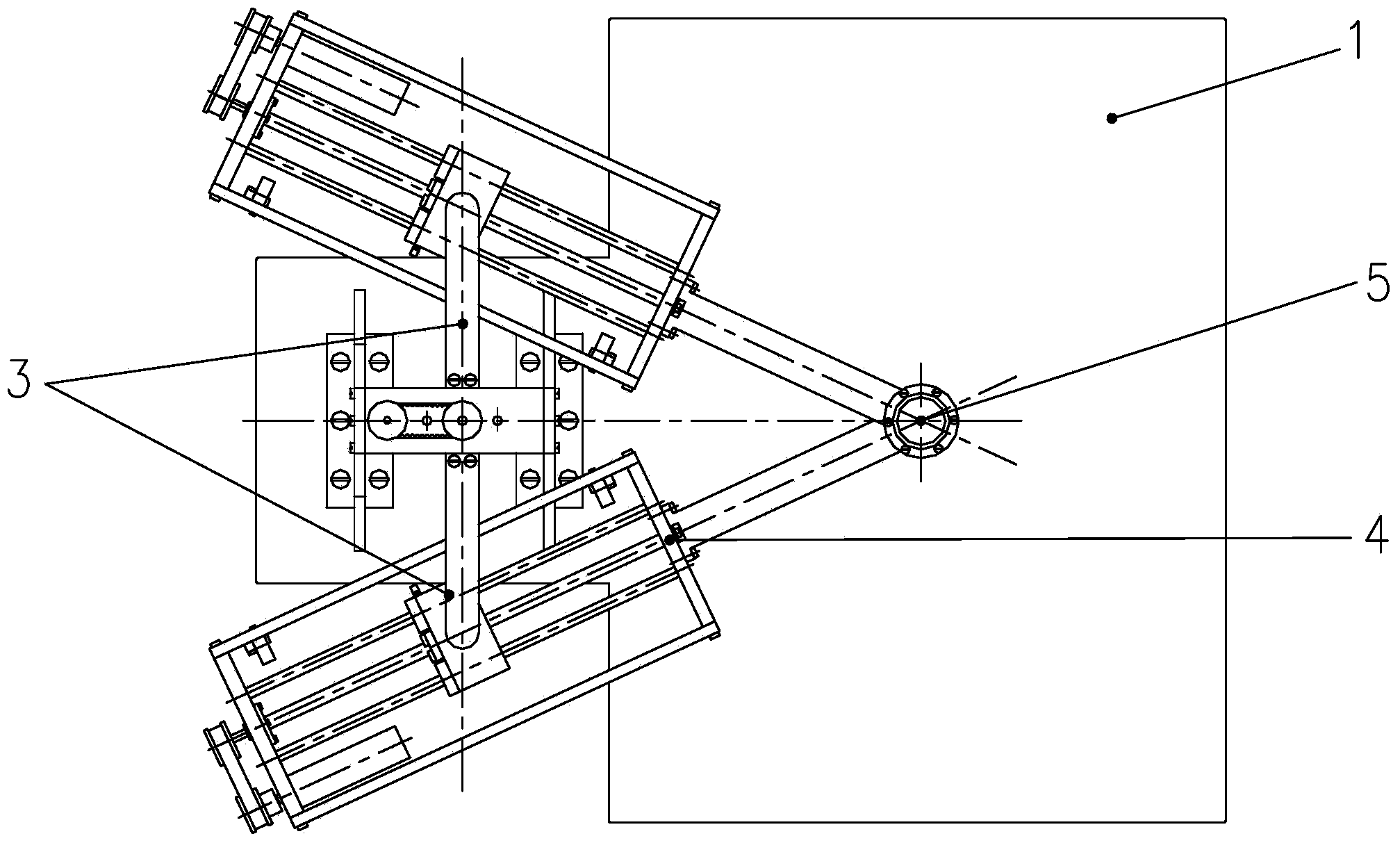

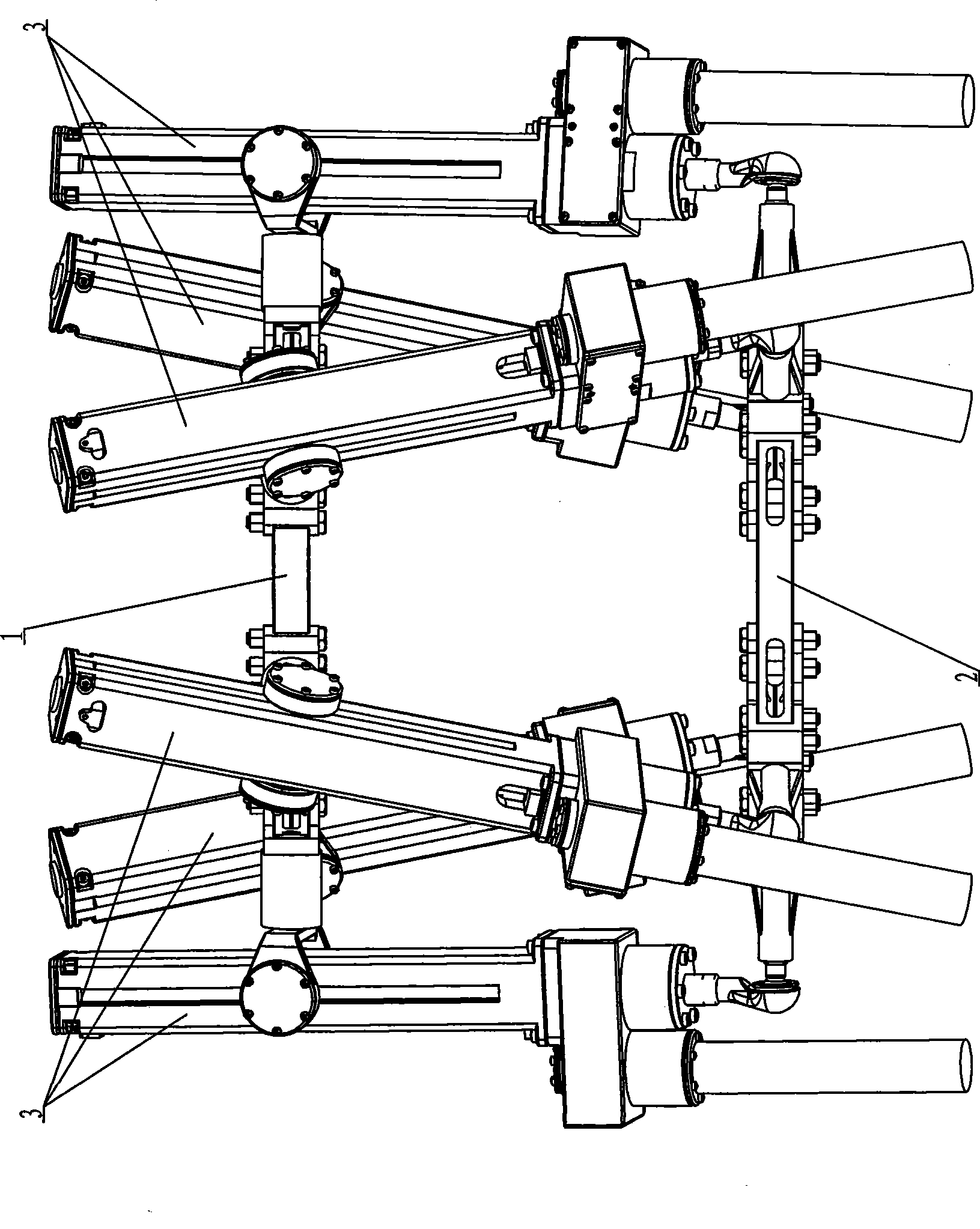

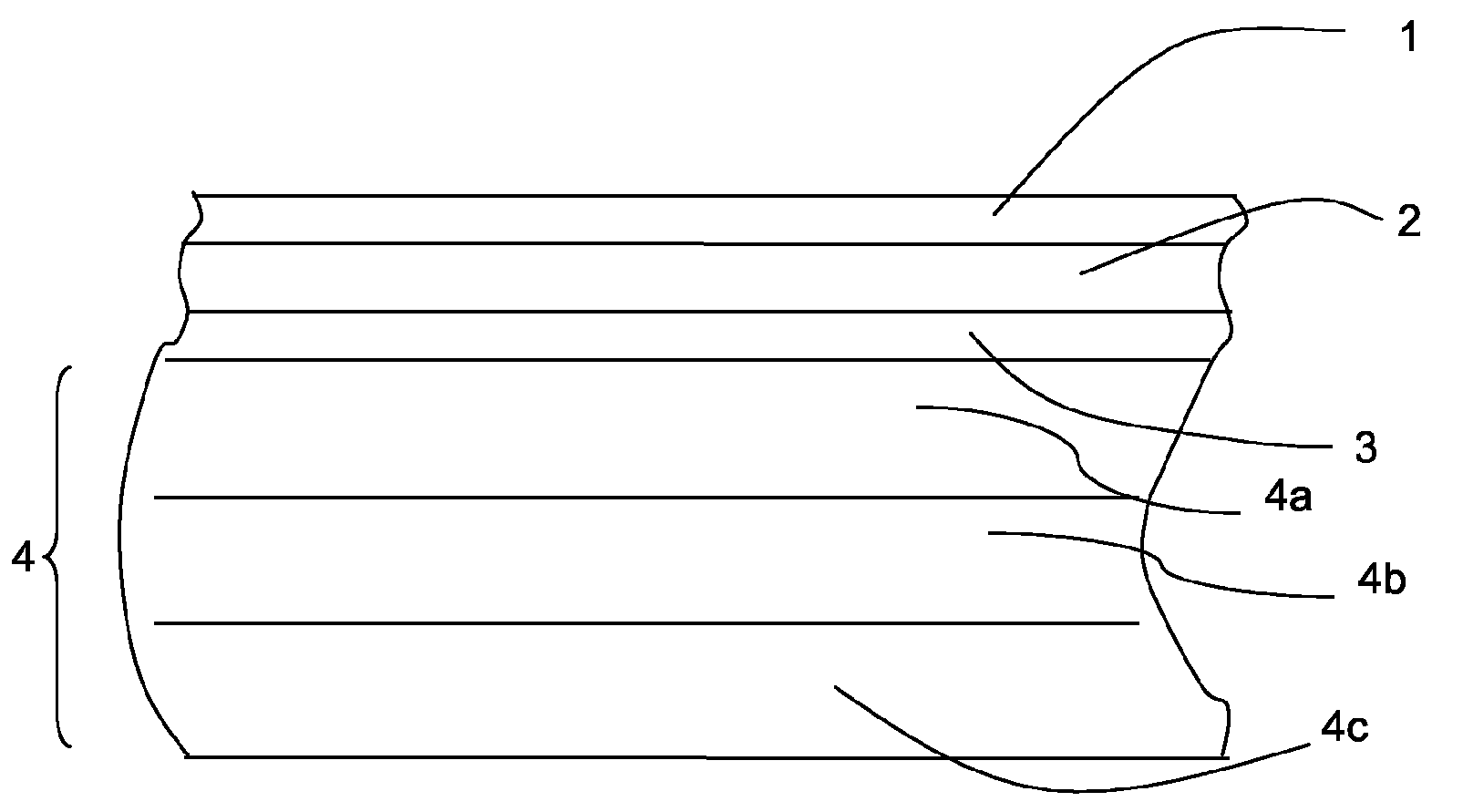

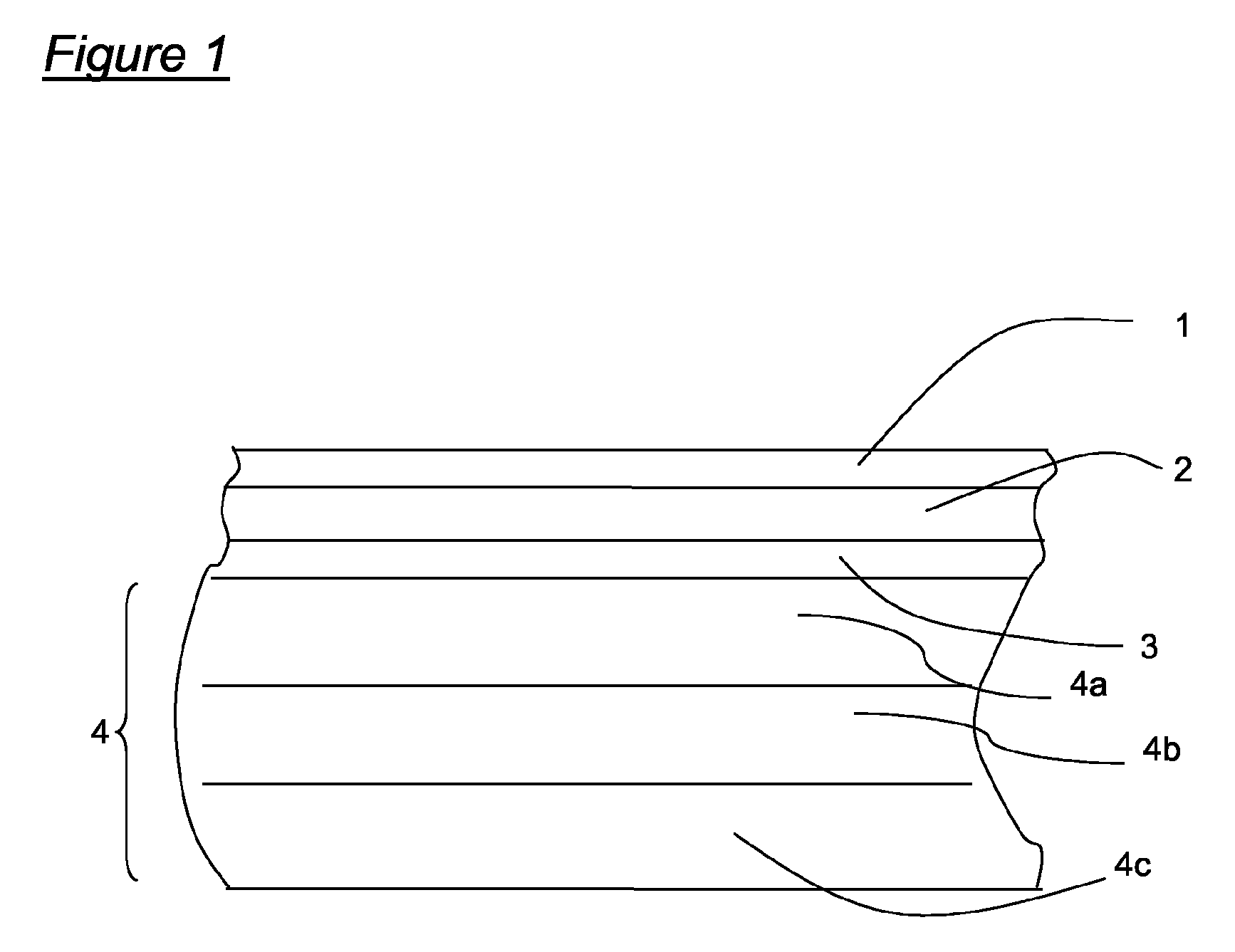

Three-degree-of-freedom parallel serial joint plastic operation robot

ActiveCN104323861ACompact structureImprove isotropic performanceDiagnosticsSurgeryThree degrees of freedomThree-dimensional space

The invention provides a three-degree-of-freedom parallel serial joint plastic operation robot. The problems of uneven operation level of doctors and low overall precision in the present prosthesis joint replacement are solved. The three-degree-of-freedom parallel serial joint plastic operation robot comprises a workbench, wherein a vertical mechanism and horizontal mechanisms are arranged on the workbench; an abrasive drilling mechanism is arranged on each of the horizontal mechanisms; the quantity of the horizontal mechanisms is two; the horizontal mechanisms are respectively arranged on the two sides of the vertical mechanism; the vertical mechanism comprises a vertical sliding table and a vertical driving component; each of the horizontal mechanisms comprises a horizontal sliding table and a horizontal driving component; connecting arms are fixedly connected with the two sides of the vertical sliding table; an outer end of each connecting arm is hinged to the horizontal sliding table on the corresponding side; a claw arm forward extends from each of the horizontal mechanisms; a sleeve ring is arranged at the front end of each claw arm; the sleeve rings forward extending from the horizontal mechanisms on the two sides are vertically overlapped and formed into a communicated sleeve hole; the abrasive drilling mechanism is penetrated through the sleeve hole; an inner wall of the sleeve hole is in sliding contact with an outer wall of the abrasive drilling mechanism. According to the invention, a triangular structure is adopted by the robot, so that the accurate route of a three-dimensional space track is realized and the face cutting precision of a bone joint is increased.

Owner:SHANDONG UNIV OF SCI & TECH

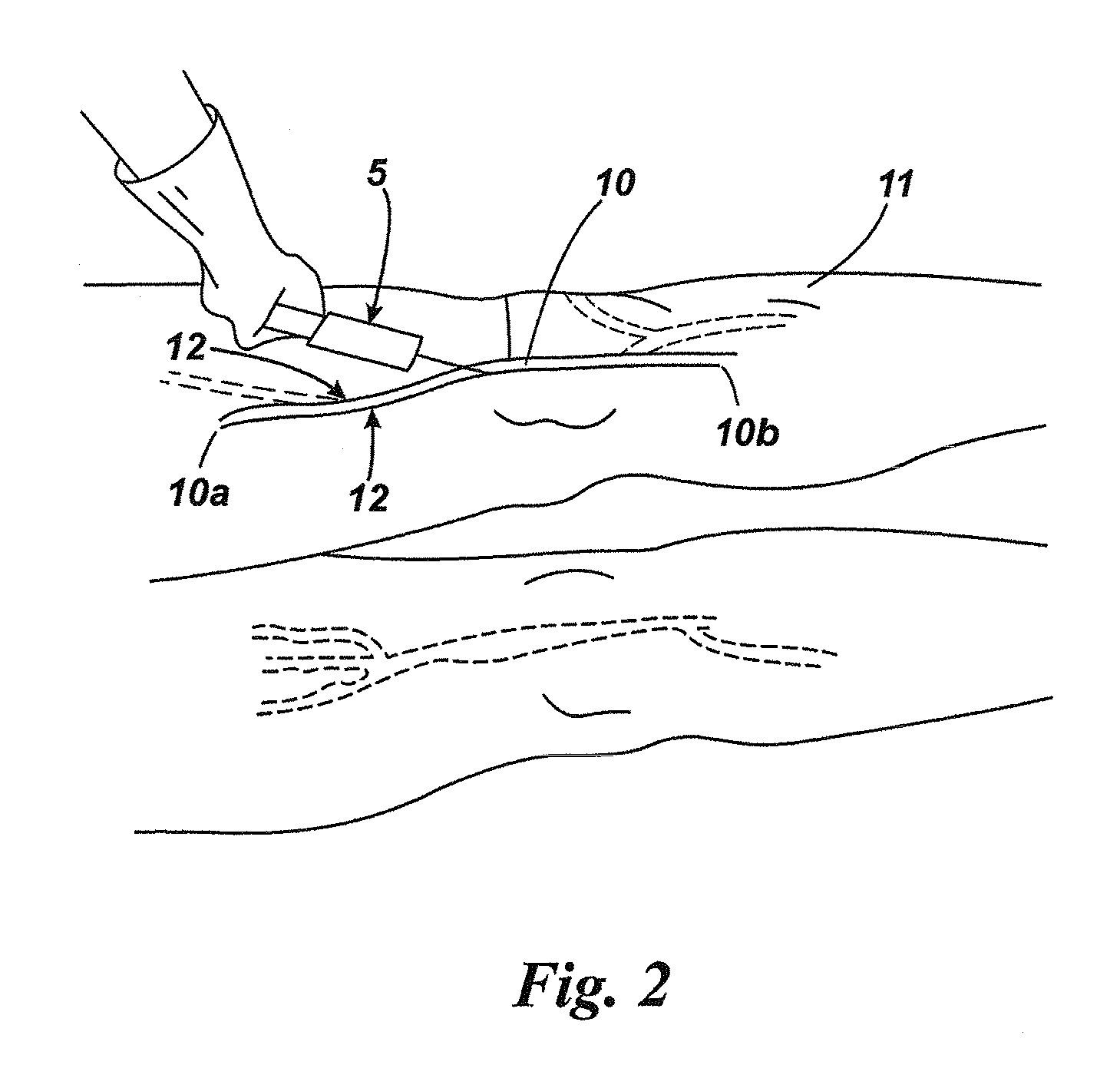

Varicose vein treatment

ActiveUS20110060277A1Fast recovery timePromote resultsSurgical furnitureDiagnosticsAdhesiveGuide wires

Methods for treating an undesired varicose or spider vein in a venous system of a patient generally includes substantially emptying the vein of blood between its proximal end and distal end; introducing a medically acceptable adhesive into the substantially emptied vein; and applying pressure to the vein to cause the opposing side walls of the vein to be adhered together in a collapsed configuration by the adhesive. Also disclosed are kits for the treatment of undesired varicose or spider vein in a venous system of a patient. The kits include a medically acceptable adhesive; a cannula; a guide wire; and a catheter.

Owner:JEAN PIERRE LILLEY

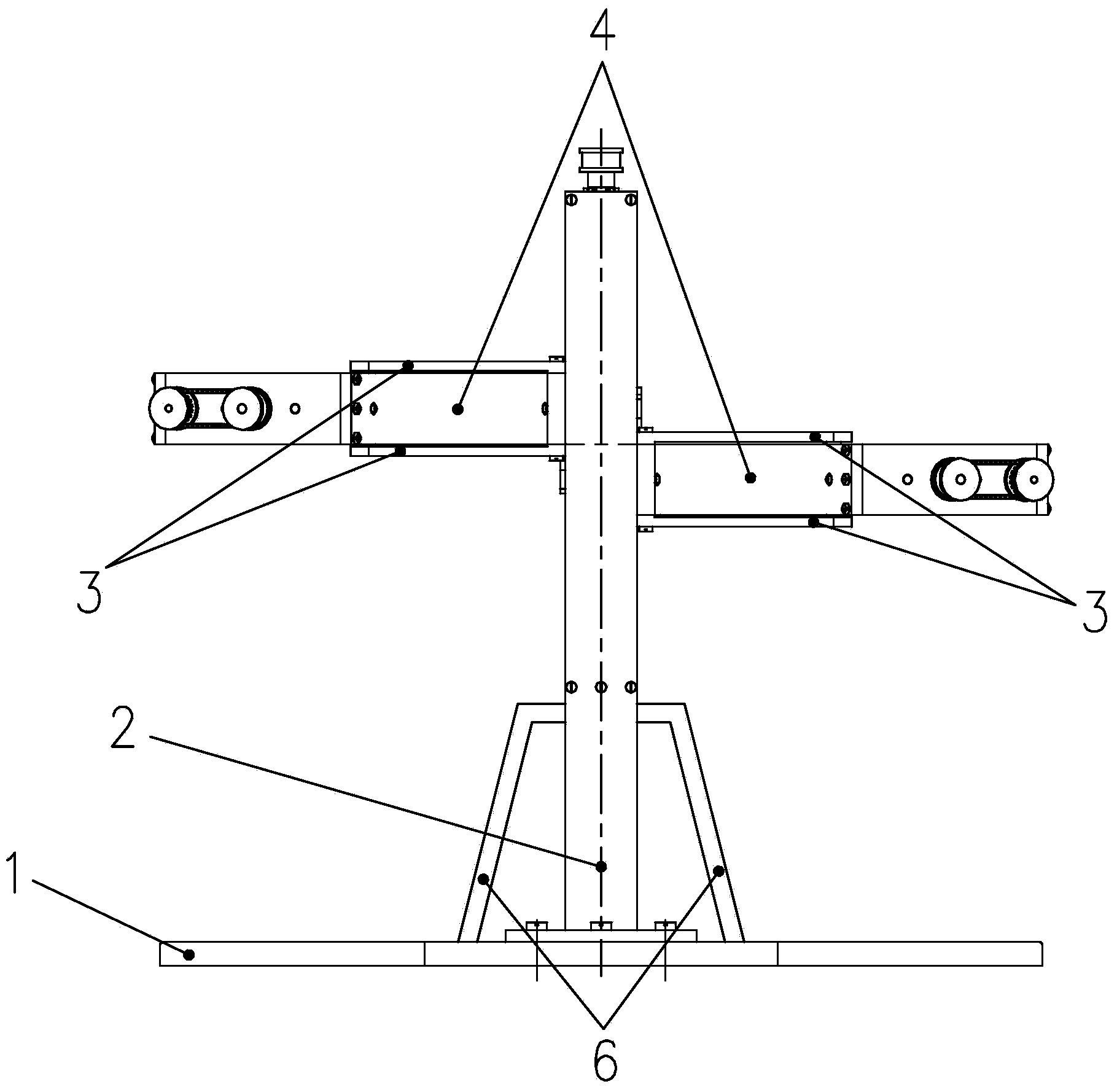

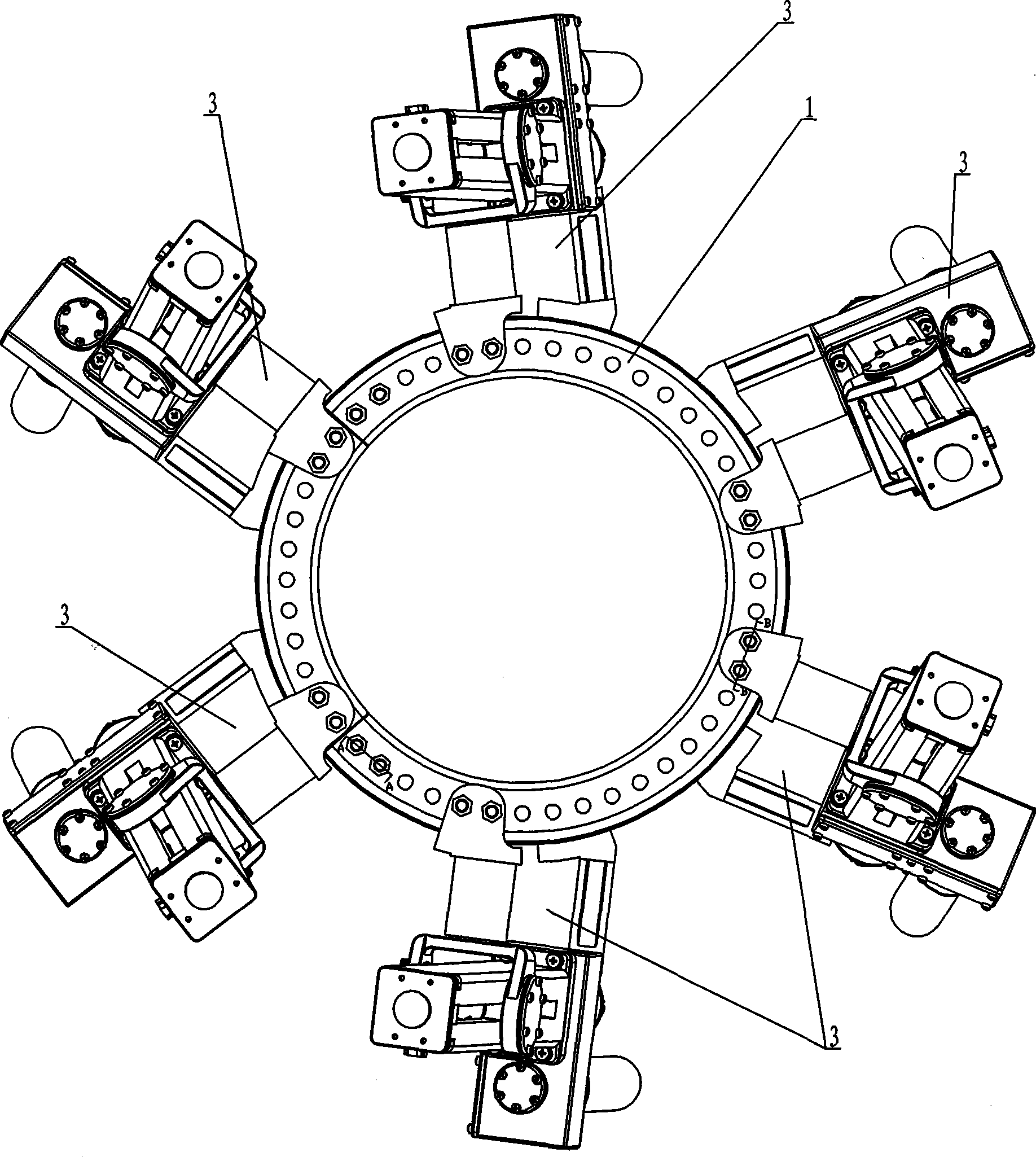

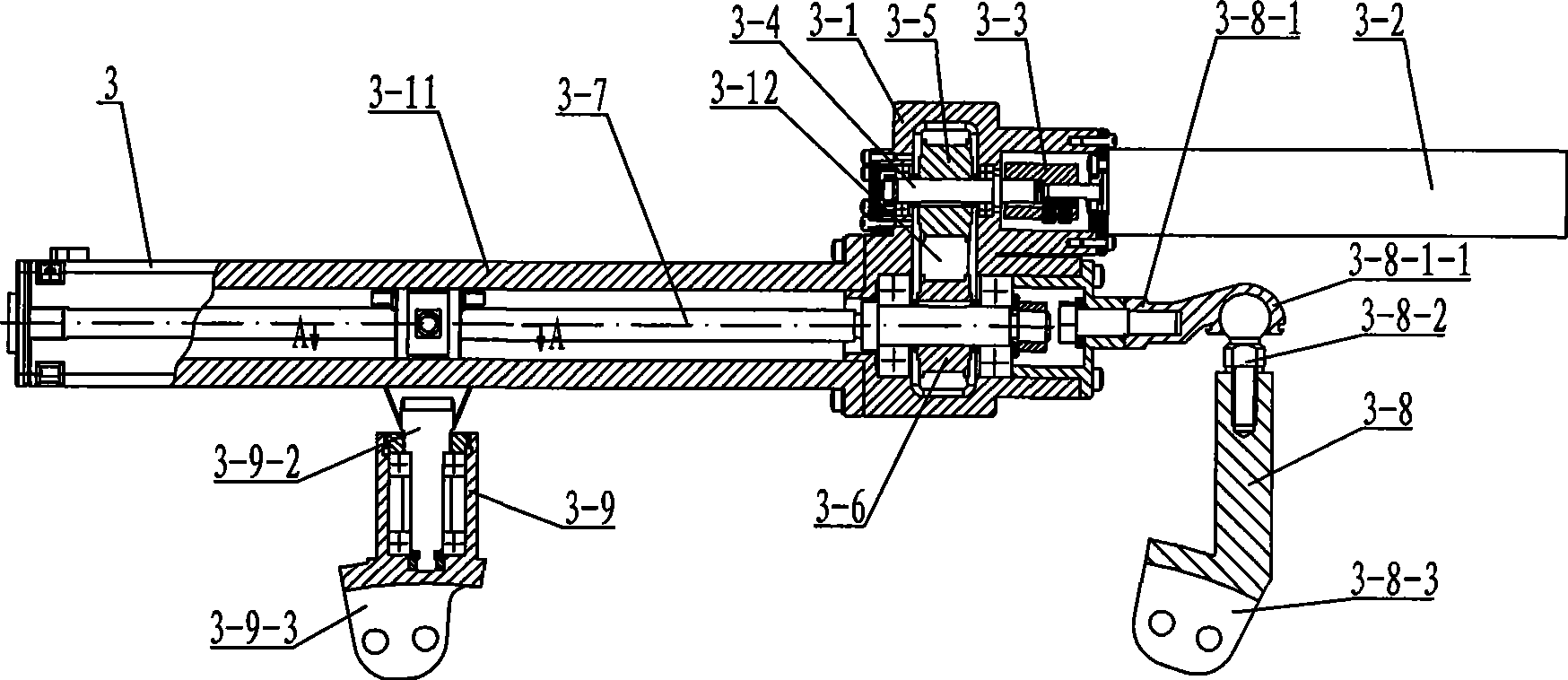

Six-freedom degree wearing type auxiliary bone-knitting parallel-connected robot

InactiveCN101474090AImprove work efficiencyDecrease productivitySurgeryManipulatorReduction driveSurgical site

A six degree of freedom wearable auxiliary bone-knitting parallel connection robot relates to a robot device used in medical treatment. The invention solves the problem that an existing skeletal external fixation can only be used for fixation after reduction of the fracture and can not give attention to the problems of the shaping replacement carried out on simultaneously with the fixation. A connecting shaft is articulated in a shell of a reducer. The input end of the connecting shaft is connected with the output shaft of a motor. An initiative belt wheel is sheathed on the connecting shaft and is connected with a passive belt wheel by a leather belt. The driven belt wheel is sheathed on a guide screw which is articulated in the shell of the reducer and arranged in the shell of the guide screw. The shell of the guide screw is fixedly arranged on the shell of the reducer. A nut is sheathed on a guide screw. One end of a hook joint is connected with the nut and the other end of the hook joint is fixedly arranged on a primary ring. One end of a spherical hinge mechanism is fixedly arranged on the shell of the reducer and the other end is fixed on the primary ring. Combined with the external bone fixation technology, the parallel connection robot can assist doctors to finish the exact position of the surgery place and realizes that the shaping replacement and the fixation of fracture are carried out simultaneously.

Owner:HARBIN INST OF TECH

Tissue-adhesive materials

ActiveUS20090044895A1Improve flexibilityGood adhesivenessSurgical adhesivesCoatingsSynthetic polymerTissue adhesives

A multi-lamellar tissue-adhesive sheet comprises a structural layer or laminate conjoined to a tissue-contacting layer. The structural layer or laminate comprises one or more synthetic polymers having film-forming properties, and the tissue-contacting layer of material contains tissue-reactive groups. The synthetic polymers having film-forming properties are preferably biodegradable polyesters, and the tissue-reactive groups are most preferably NHS-ester groups.

Owner:TISSUEMED LTD

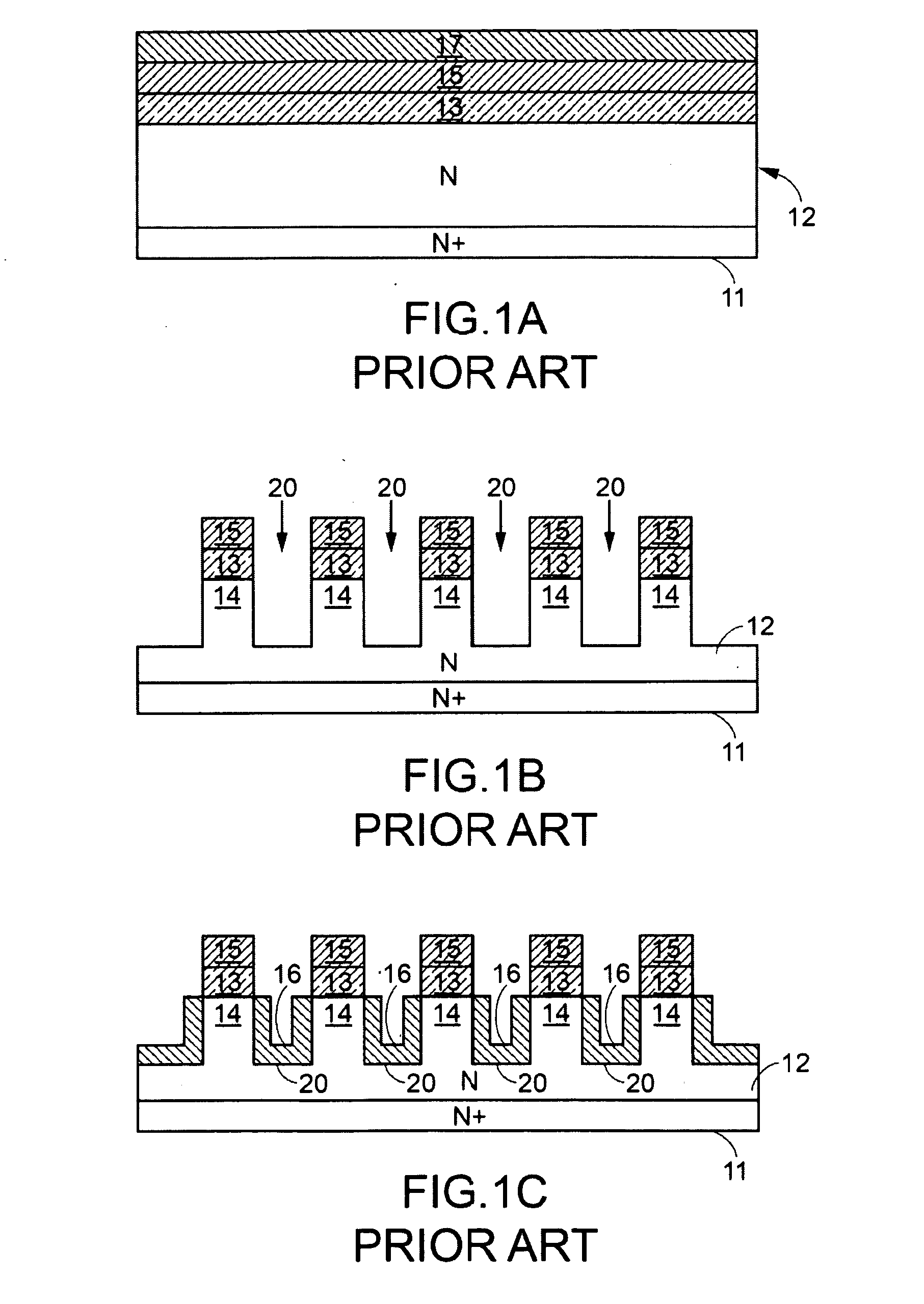

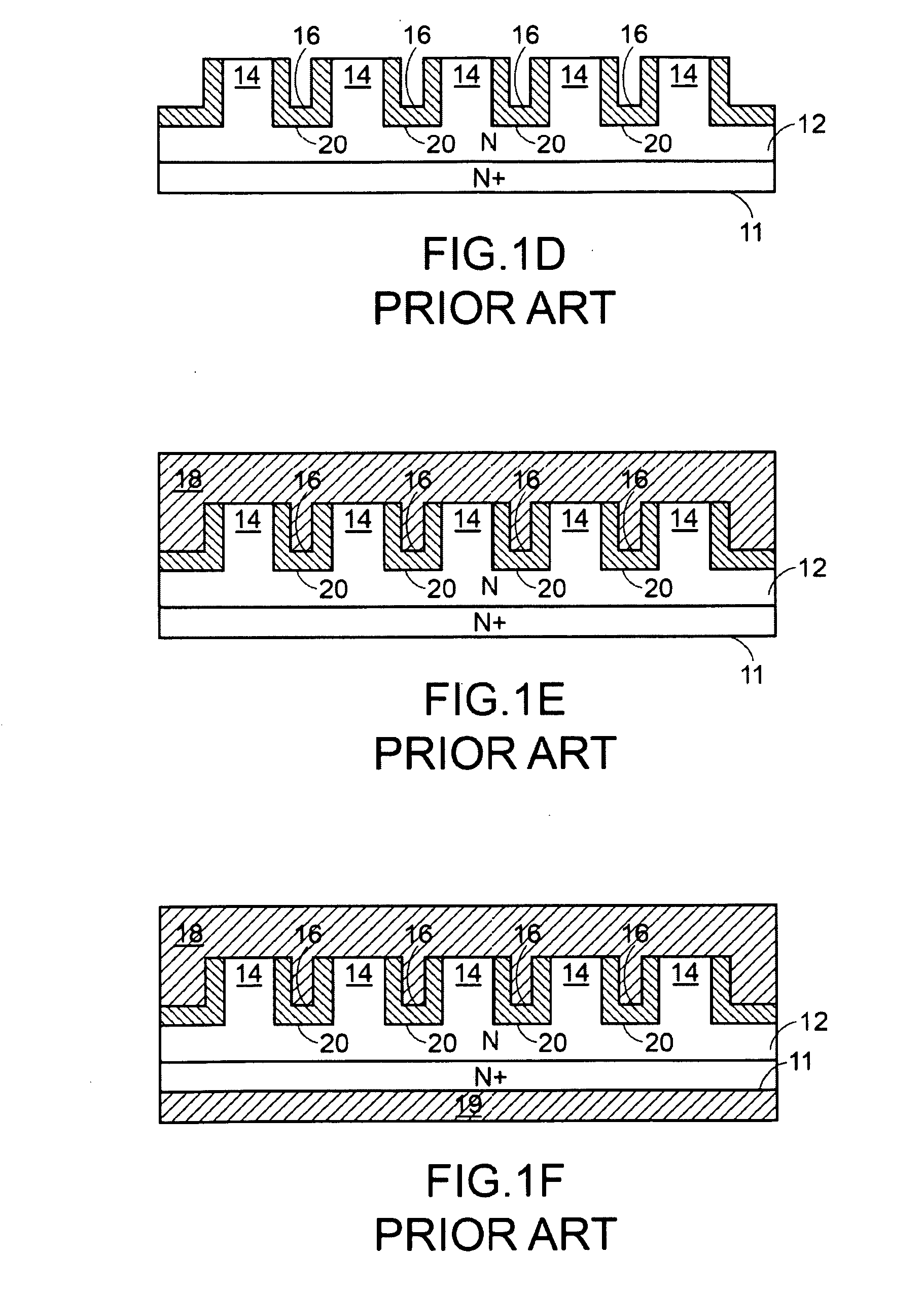

Mos p-n junction schottky diode device and method for manufacturing the same

ActiveUS20090261428A1Improve performanceReduce leakage currentSemiconductor/solid-state device manufacturingDiodeOhmic contactReverse recovery

A MOS P-N junction Schottky diode device includes a substrate having a first conductivity type, a field oxide structure defining a trench structure, a gate structure formed in the trench structure and a doped region having a second conductivity type adjacent to the gate structure in the substrate. An ohmic contact and a Schottky contact are formed at different sides of the gate structure. The method for manufacturing such diode device includes several ion-implanting steps to form several doped sub-regions with different implantation depths to constitute the doped regions. The formed MOS P-N junction Schottky diode device has low forward voltage drop, low reverse leakage current, fast reverse recovery time and high reverse voltage tolerance.

Owner:PFC DEVICE HLDG

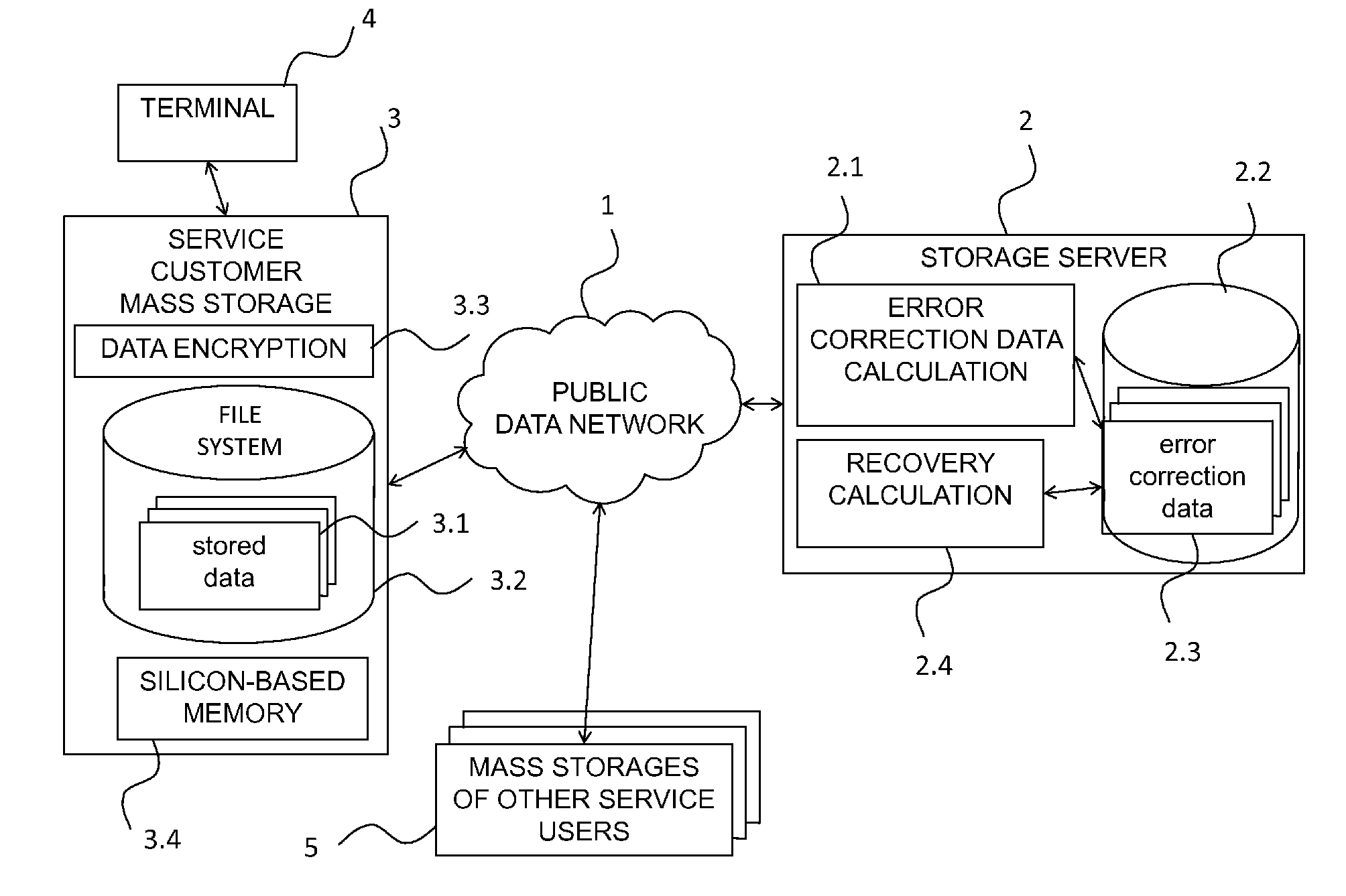

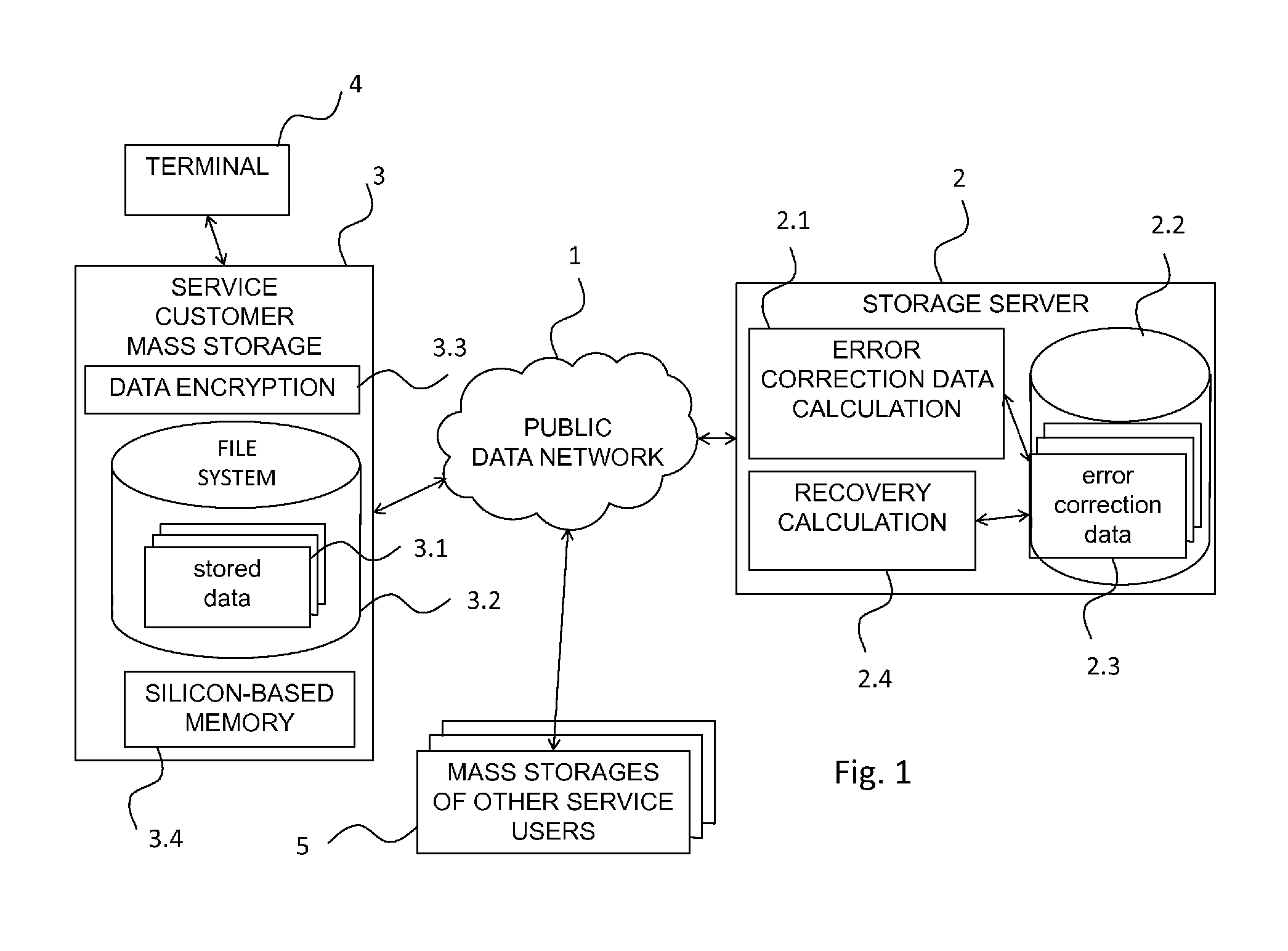

Method and a storage server for data redundancy

ActiveUS20120173925A1Ensure data integrityReduce riskTransmissionRedundant data error correctionMass storageFile system

A method and a storage server for backing up data involves mass storage devices of users of the service that connect to the storage server of the service provider over a public data network. The customers store the data with their terminals. The data is stored to the file system of the mass storage device which encrypts the stored data and transfers the data in encrypted form over the public data network to the storage server. The storage server calculates error correction data from the encrypted data. The error correction data is stored in the mass memory of the storage server. When recovering the stored data of the users, the storage server requests the stored data of all the users whose data was used for the error correction data calculation over the public data network to be used for the recovery calculation.

Owner:VARAANI WORKS

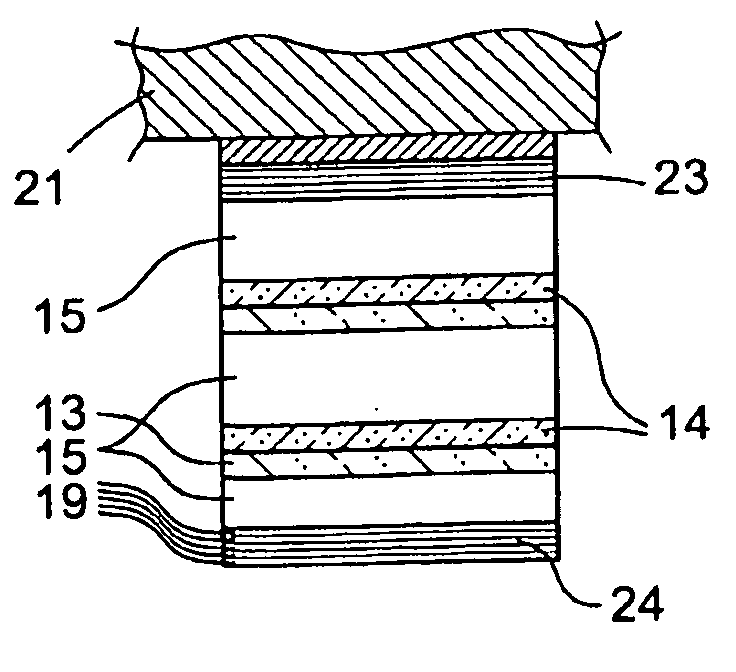

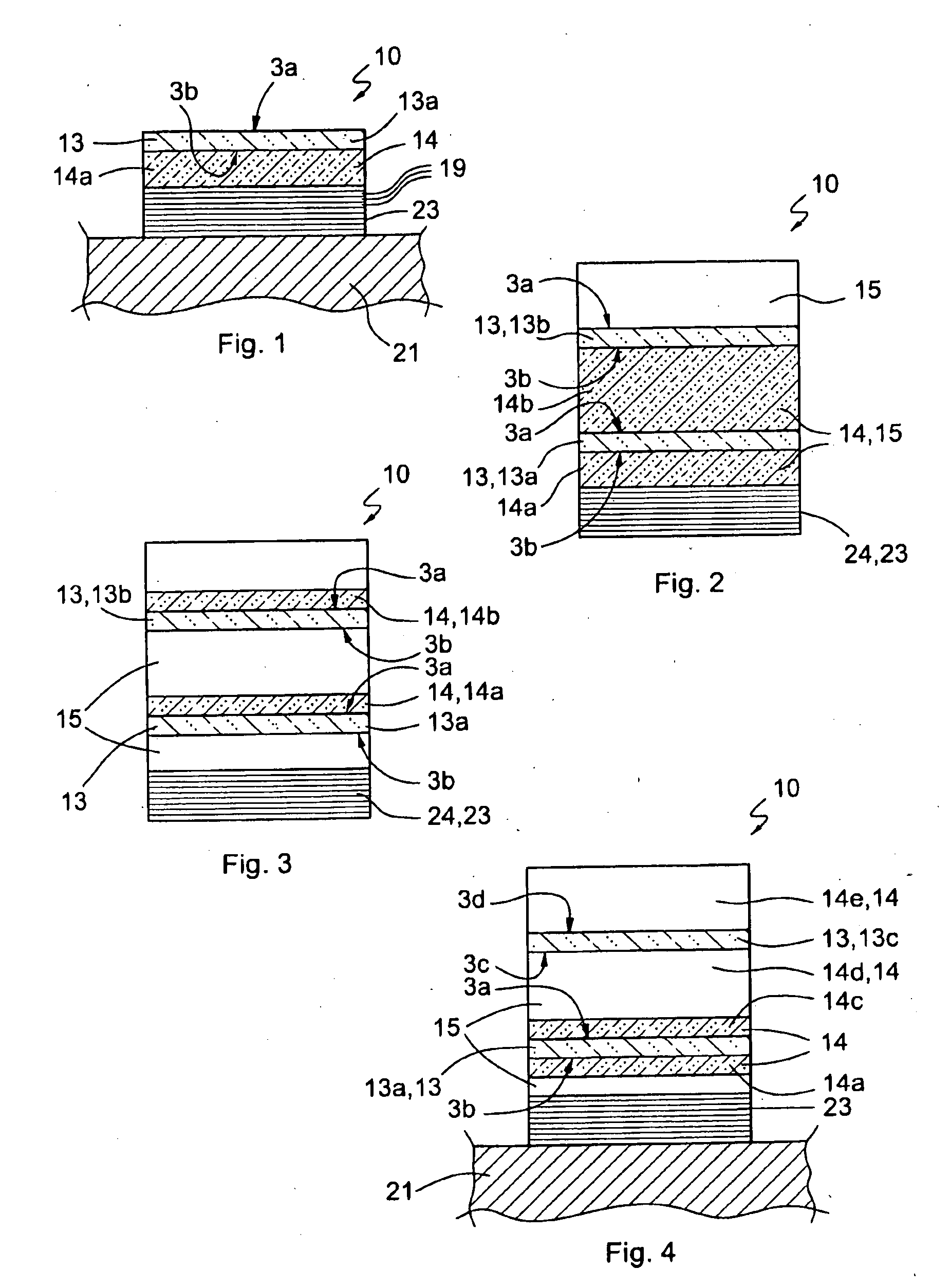

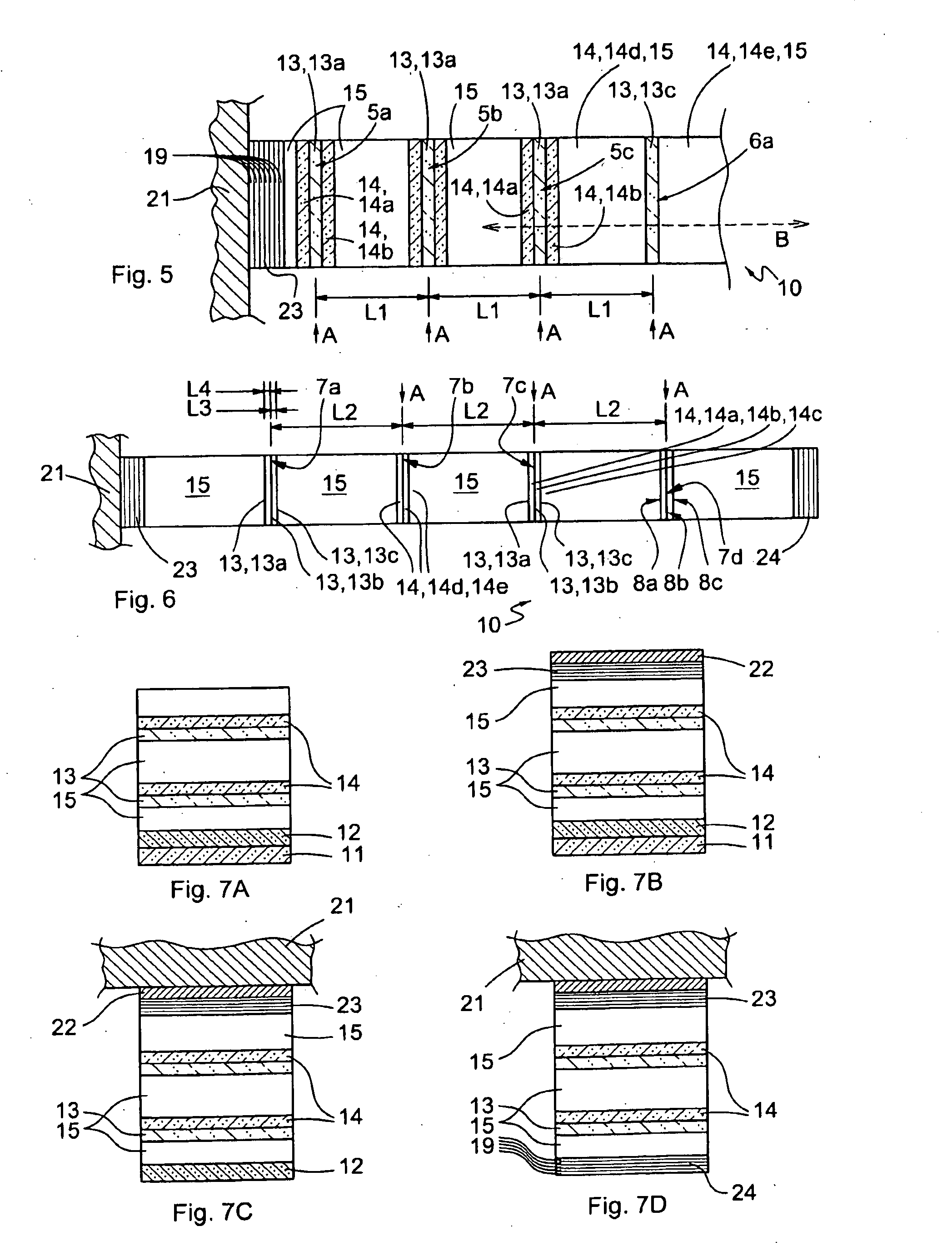

Saturable absorber structure

InactiveUS20090052479A1Big contrastImproves Structural IntegrityLaser detailsSemiconductor/solid-state device manufacturingHeterojunctionSemiconductor materials

The invention relates to a saturable absorber structure (10) with multiple-layer epitaxial heterostructure absorbers. Typically the structure comprises first absorber layers of a quantum well semiconductor QW-material, which has a nonlinearly on radiation intensity dependent optical absorption; first contacting layers of a first optically transparent semiconductor material against a surface or surfaces of said first absorber layers; and a first Bragg-reflector (23). The first contacting layers have lattice fit or pseudomorphism with said first absorber layers. The absorber layer (13, 13a, 13b) of the QW-material has a thickness (S) of at maximum 60 nm. Further, said first optically transparent semiconductor material of the contacting layer (14, 14a, 14b, 14c) is a reactive R-material, which semiconductor material contains two or more main components, at least one dopant (M2), and at least one metallic alloying element (M1) substituting one of said main components and enhancing the incorporation of said dopant(s). The metallic alloying element has a concentration of at least 50 atomic-% of that main component it substitutes. This way the charge carriers originating in said QW-material of the first absorber layer has a first recombination time at maximum 100 picoseconds determined by recombination of the charge carriers at sites of said dopant(s), thus forming a fast saturable absorber.

Owner:CORELASE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com