Patents

Literature

200results about How to "Improve isotropic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isotropic graphite product and preparation method thereof

The invention relates to an isotropic graphite product and a preparation method thereof. The materials consist of caking agent and skeletal material. The mass ratio of the caking agent and the skeletal material is (0.30-0.70) to 1, wherein the weight of the rarefied natural crystallite graphite is 30 to 100% of that of the skeletal material, and the other materials are one or more than two of thegraphite returning charge, the pitch coke, the refinery coke, the secondary coke and the intermediate carbon sphere. The preparation method comprises the steps of uniformly mixing the caking agent andthe skeletal material, molding, baking, dipping, secondarily baking, and graphitizing. With rich materials, low cost, small limitation for molding, high capability of prepared isotropic graphite product, the invention can be widely applied in the field of preparing graphite product.

Owner:TSINGHUA UNIV +1

Carbon composite high-thermal-conductivity plastic material and preparation method thereof

The invention discloses a carbon composite high-performance thermal-conductive plastic and a preparation method thereof; the thermal-conductive insulating plastic is prepared from a resin basic material, a carbon composite material, a thermal-conductive agent, a coupling agent, an antioxidant and other processing agents; by means of the special crystalline structure of the carbon composite material added in the formula of the thermal-conductive insulating plastic disclosed by the invention, the inter-particle bridging effect is realized; a thermal-conductive passage composed of the thermal-conductive agent is more and more perfect; therefore, the thermal conductivity of the composite material can be rapidly increased; a filling material gathering and thermal-conductive passage is more and more perfect; simultaneously, with the help of the processes, such as a pre-mixing process, an extrusion process, a cooling process, an air drying process and a granulating process, the problems of being degraded in high filling property and low in thermal-conductive property of the plastic are solved; the thermal-conductive composite material having excellent mechanical property and good thermal-conductive effect and insulating property can be prepared; and the thermal-conductive composite material can be widely applied in the fields, such as electrons, automobiles and LED (Light Emitting Diode) lamps.

Owner:HUIZHOU KINGBALI TECH

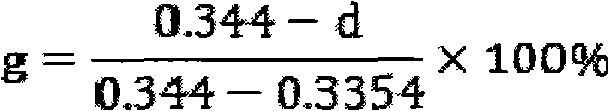

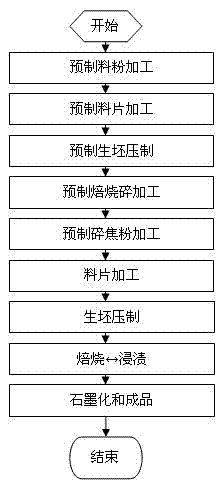

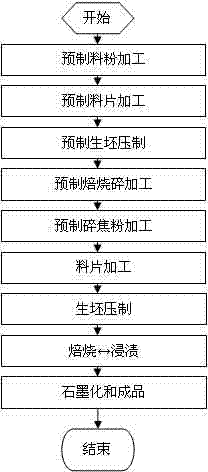

Production process of large isotropic and isostatic high purity graphite with fine particles

The invention discloses a production process of large isotropic and isostatic high purity graphite with fine particles, which comprises the following steps: processing prefabricated powder; processing prefabricated tablets; pressing prefabricated green bodies; processing prefabricated roasting scraps; processing prefabricated smashed coke powder; processing tablets; pressing green bodies; roasting and soaking; and graphitizing and finishing. A graphite product produced by the production process provided by the invention has a large size and has the diameter being more than phi 900; the strength, the density and the elasticity of the product are improved, and the mechanical behavior physical and chemical indicators of a final product is improved; and simultaneously, the produced graphite product has the characteristics of favorable isotropic performance, uniform and delicate structure, high volume density and the like.

Owner:雅安恒圣高纯石墨科技有限责任公司

Modified bamboo fiber/polymer composite high-toughness concrete and preparation method thereof

The invention discloses a modified bamboo fiber / polymer composite high-toughness concrete and a preparation method thereof. In the method, bamboo fibers are modified successively through a coupling agent and a maleic anhydride grafted terpolymer and are added to an epoxy resin toughening emulsion. With water, the epoxy resin toughening emulsion containing the modified bamboo fibers, a polyurethane toughening emulsion, cement, coal ash, slag powder, a fine aggregate, crushed stone and a water reducing agent are employed as raw materials, the modified bamboo fiber / polymer composite high-toughness concrete are prepared through a stirring and mixing process. A test proves that the high-toughness concrete has a significant strain hardening characteristic or a significant deformation hardening characteristic under an effect of a direct stretch load of a direct bending load. The high-toughness concrete has a bending strength being 17-26 MPa, a compressive strength being 75-92 MPa and a tensile strength being 6-15 MPa. The high-toughness concrete can be applied in fields such as a bridge floor of a long-span cross-sea or cross-river bridge, the bridge floor of a viaduct of a high-speed railway, and various tunnel arch walls, in a subway and the like, and the like.

Owner:FUJIAN JUAN CONSTR ENG CO LTD

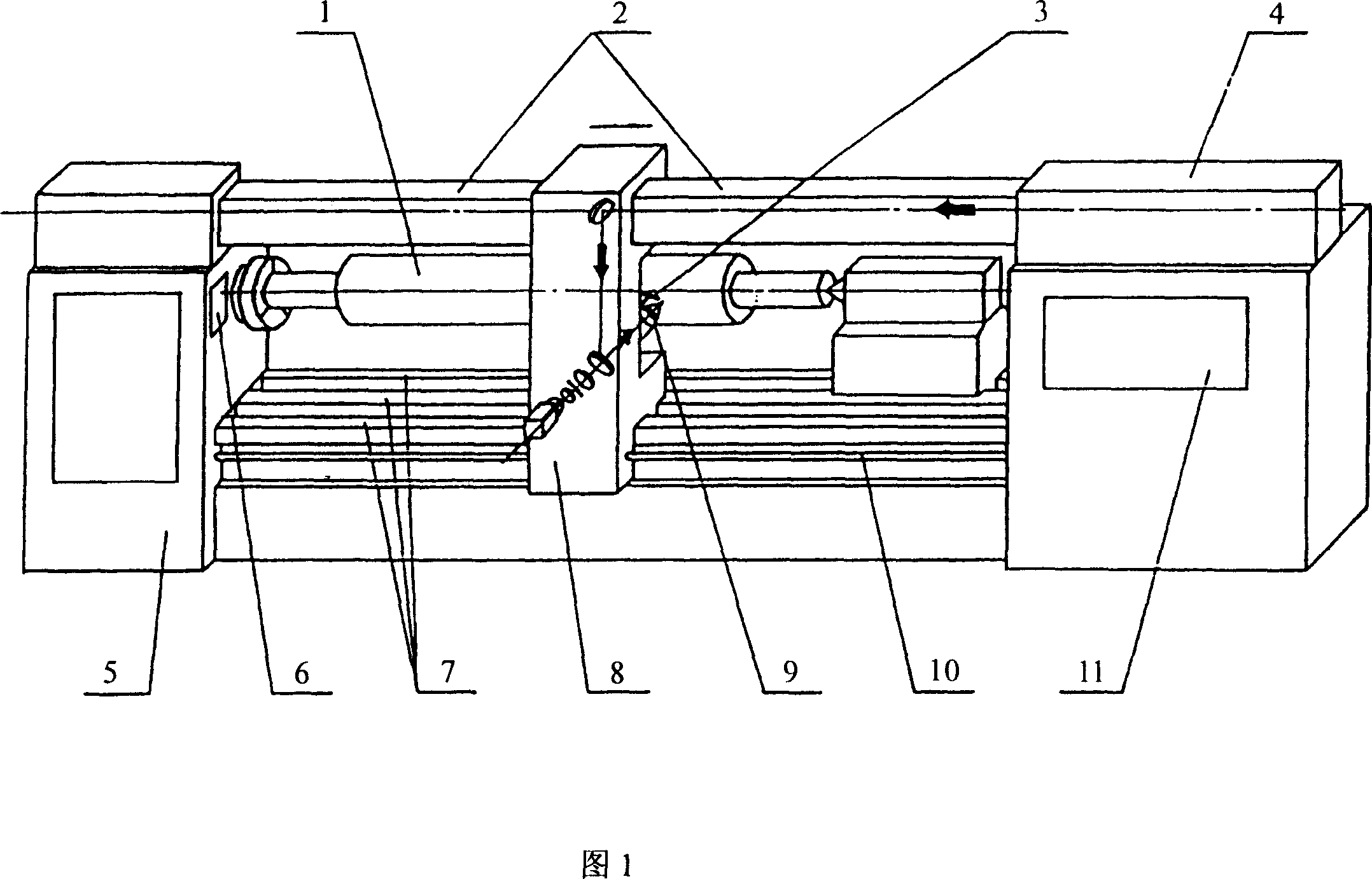

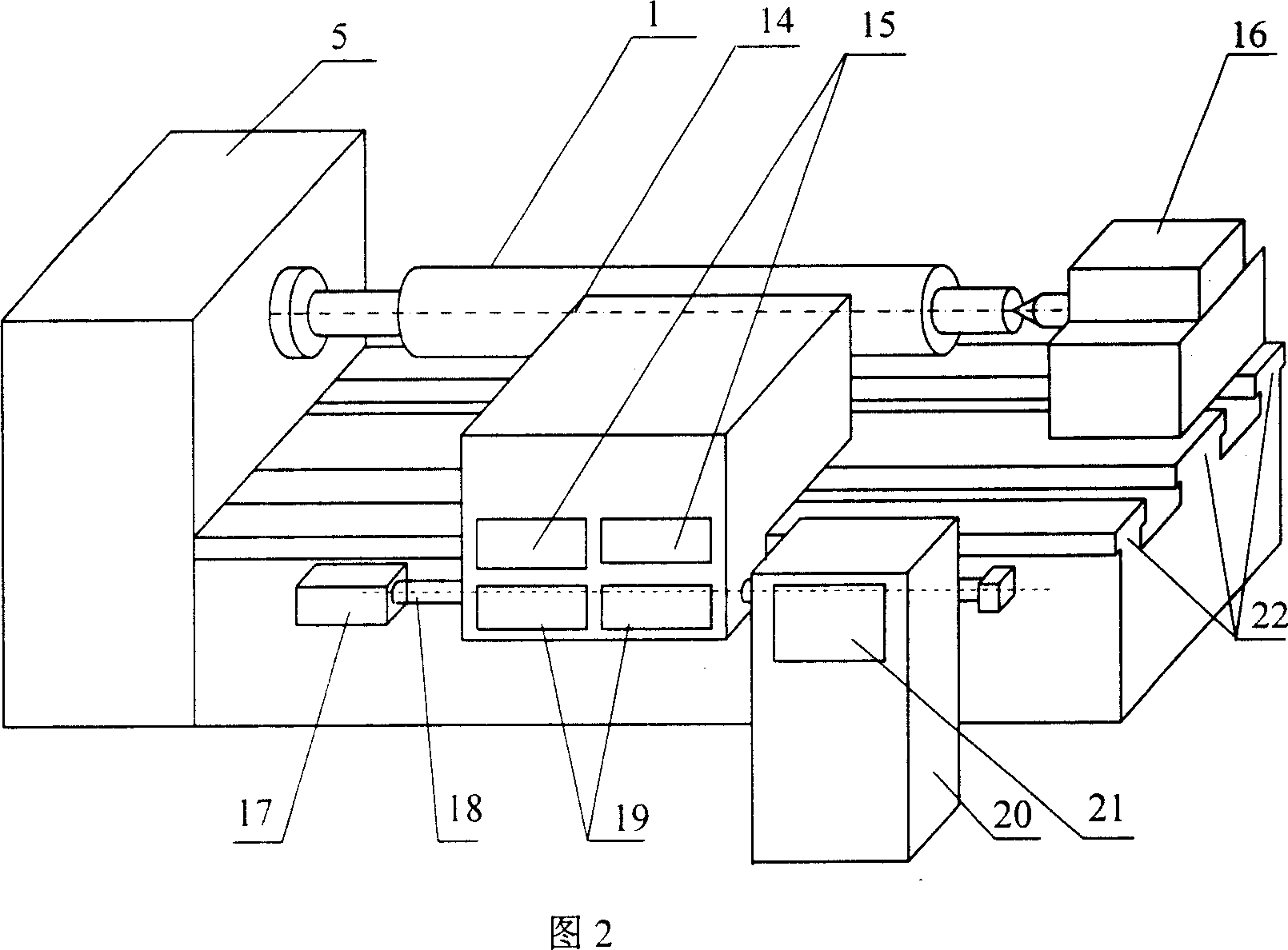

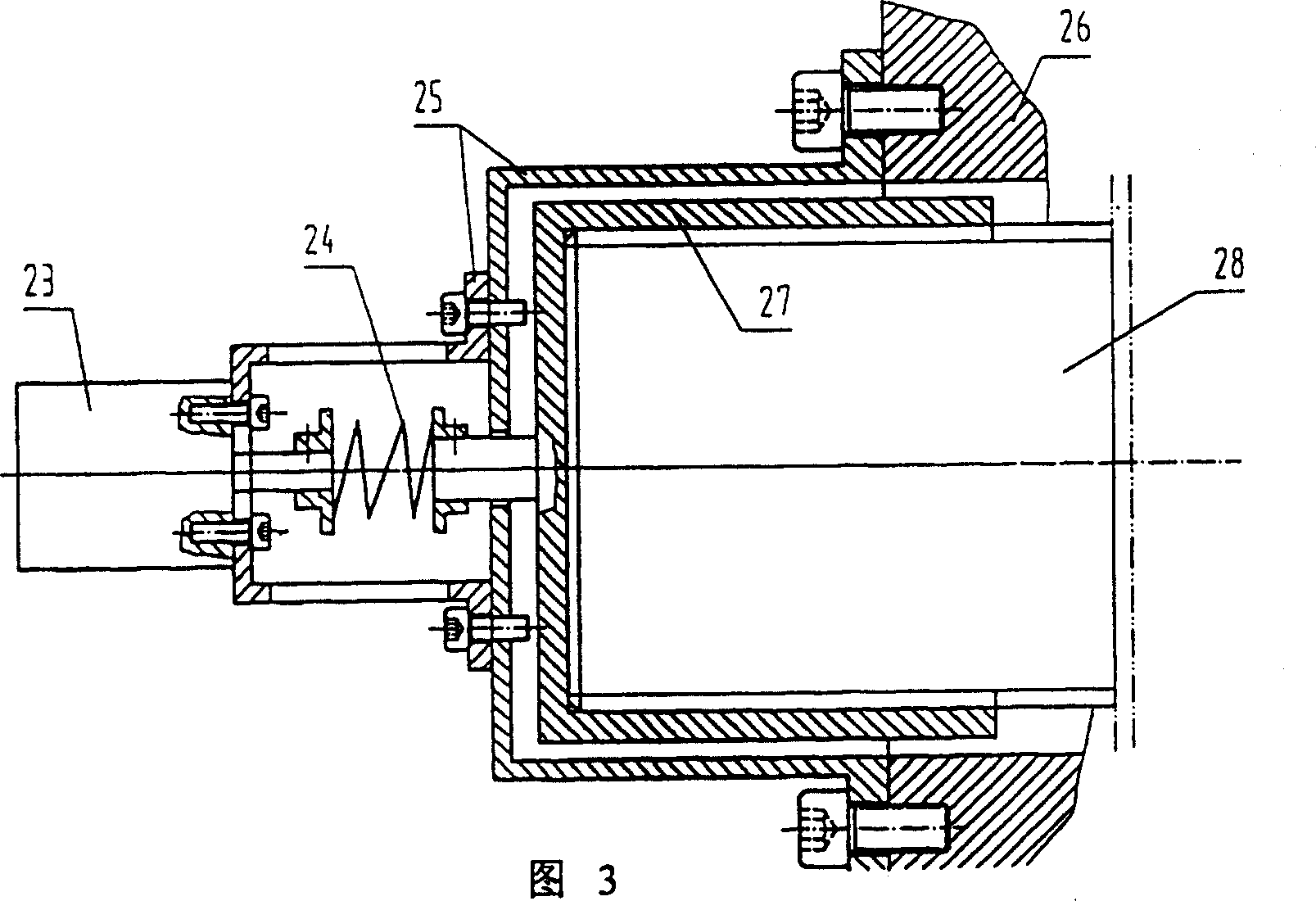

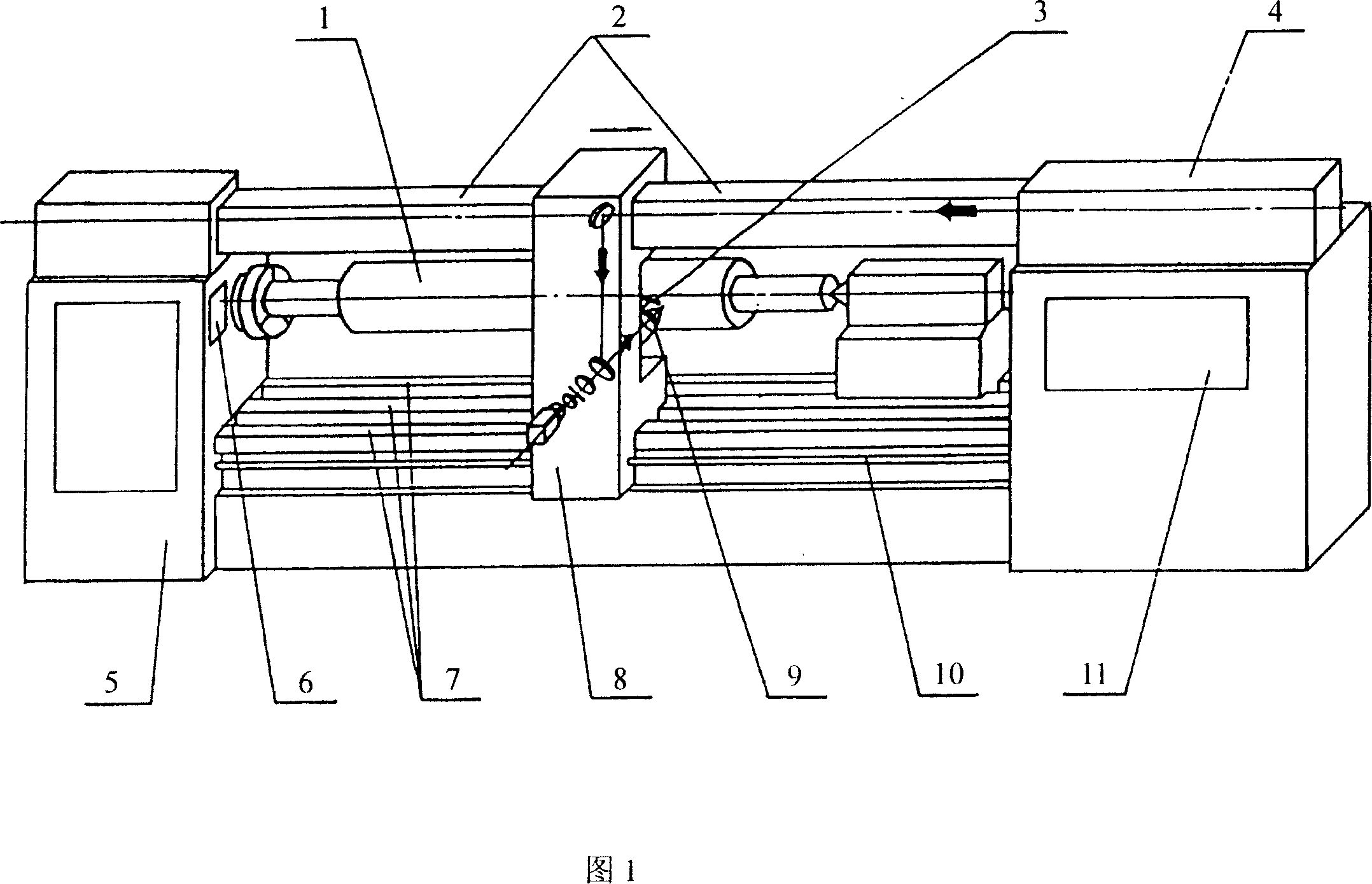

Laser processing system and method for roller surface burr without regular deflection burr

InactiveCN1954955AImprove isotropic performanceImprove appearance qualityLaser beam welding apparatusLaser processingLight beam

A laser machining system for roughening the surface of roller in such manner that the roughened dots are irregularly deflected is composed of a machine-tool for driving the roller to be machined to rotate, a laser machining unit moving axially along said roller, and a pseudo-random deflecting mechanism consisting of pseudo-random signal generator, the driver of the motor for making lens to vibrate, and the lens vibrating assemblage comprising lens vibrating motor and reflector. Its method is also disclosed.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Composite material toughened ceramisite concrete and preparation method thereof

ActiveCN105541212AImprove toughnessImprove isotropic performanceSolid waste managementFiberAggregate (composite)

The invention belongs to the field of preparation of concrete, and in particular relates to composite material toughened ceramisite concrete and a preparation method thereof. The composite material toughened ceramisite concrete comprises the following components in parts by weight: 320-360 parts of cement, 40-80 parts of lithium slagpowder, 20-40 parts of silica fume, 700-900 parts of recycled coarse aggregates, 500-800 parts of ceramisites, 3-4 parts of a water reducing agent, 100-200 parts of water, 10-20 parts of polyacrylate, 20-30 parts of a toughening composite material, 0.05-0.1 part of sodium gluconate, and 10-15 parts of triethanolamine, wherein the toughening composite material is prepared from the following raw materials in parts by weight: 1.2-1.8 parts of modified silicon dioxide nanotubes, 22-28 parts of a styrene-butadiene-styrene block copolymer, 46-50 parts of activated wood powder fibers, 3.5-5 parts of a silane coupling agent, 3.0-3.5 parts of a solubilizing agent, 4-6 parts of a filler and 180-220 parts of water. The concrete has good toughness, isotropy, fatigue resistance, compactness, crack resistance, shock resistance and permeability resistance, and is a high-performance concrete toughening material, and the 28-day compression strength of the prepared concrete can reach 30-60MPa, so that the concrete is suitable for building bearing structures.

Owner:福建省东霖建设工程有限公司

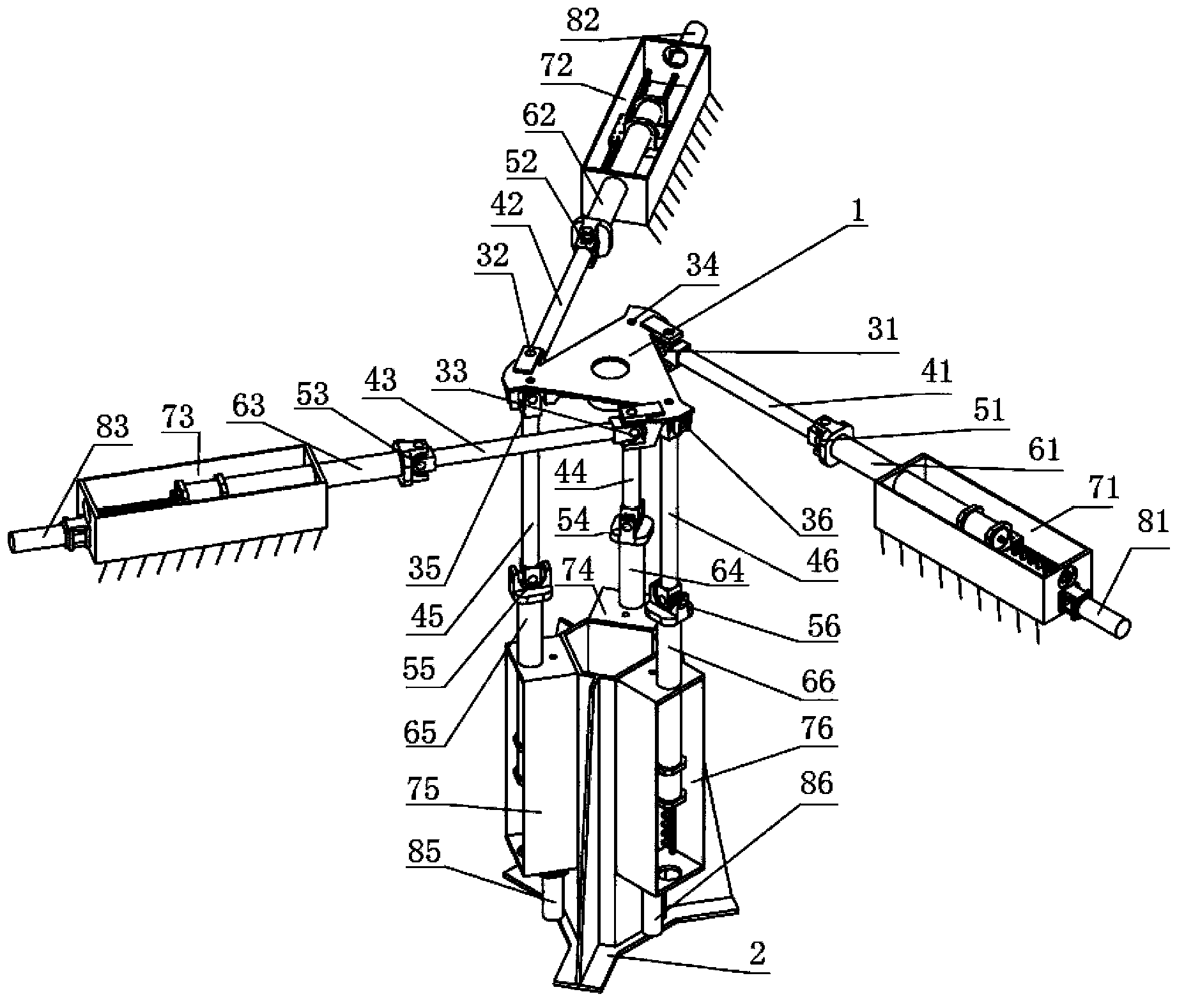

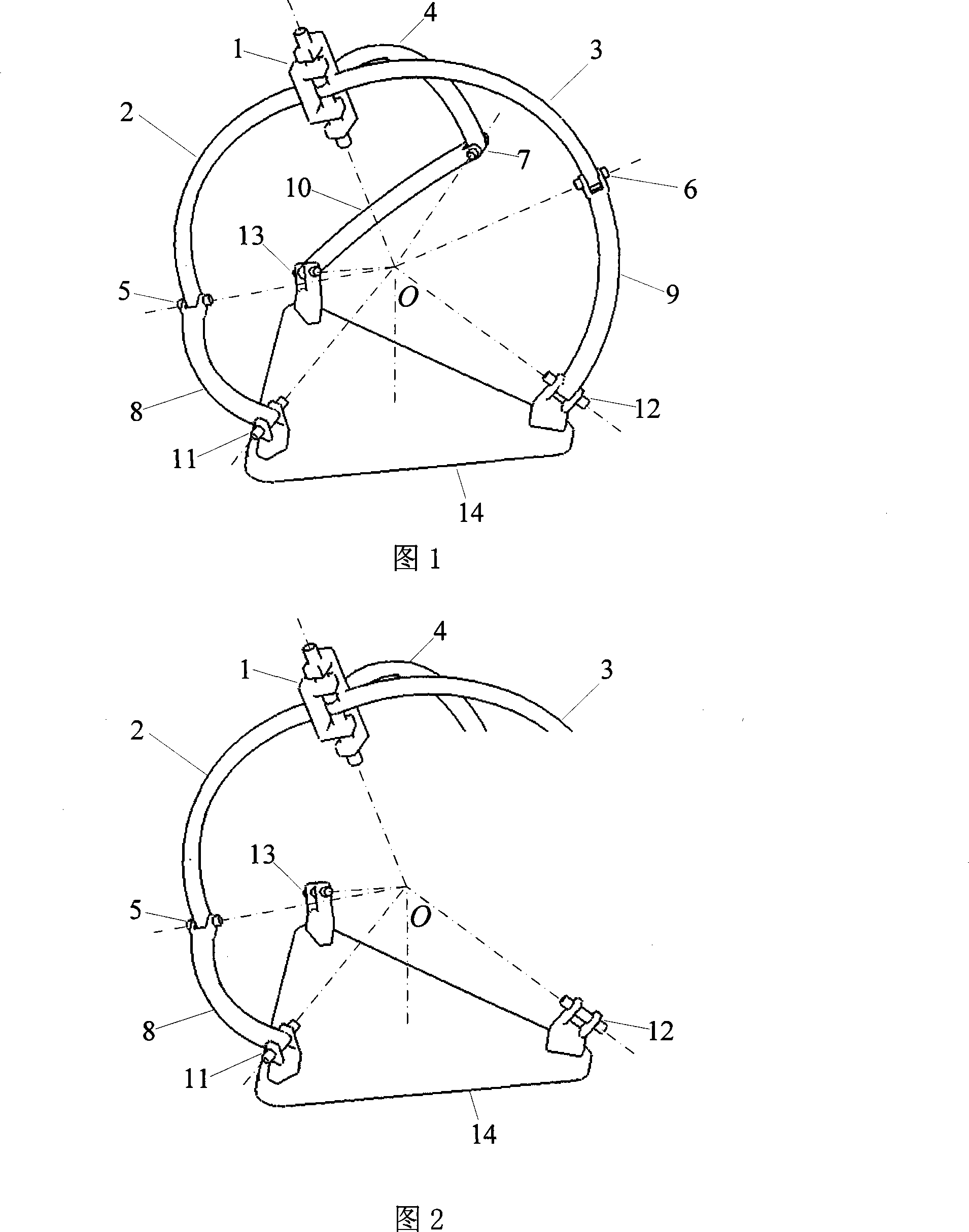

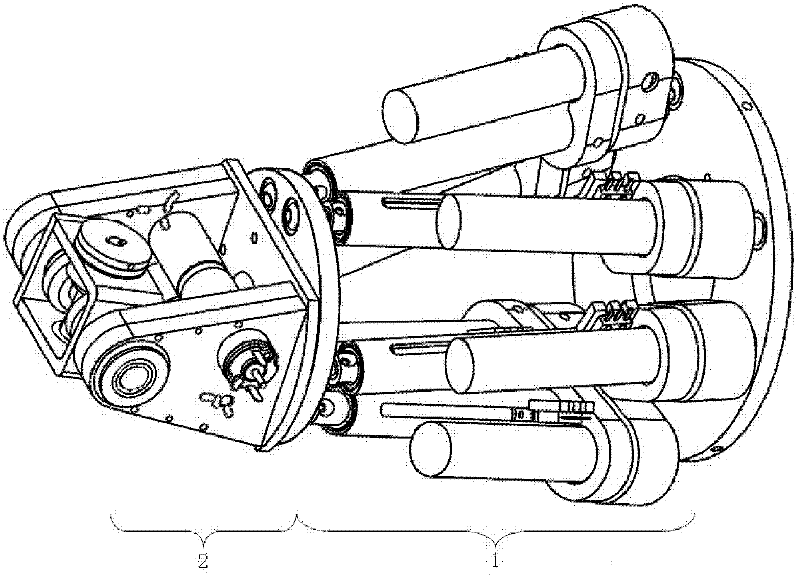

Six- free-degree 3-3 orthogonal type parallel robot

ActiveCN103381601AImprove rigidityHigh precisionProgramme-controlled manipulatorEngineeringMechanical property

The invention discloses a six-free-degree 3-3 orthogonal type parallel robot which comprises a motion platform, a fixed framework and a mechanical branch chain set, wherein the mechanical branch chain set is arranged between the motion platform and the fixed framework and connected with the motion platform and the fixed framework, the mechanical branch chain set comprises six mechanical branch chains in 3-3 orthogonal arrangement. The 3-3 orthogonal arrangement refers to that the six mechanical branch chains are divided into two sets, and each set comprises three mechanical branch chains. The axes in the three driver directions of the three mechanical branch chains in the first set are positioned in the same plane surface, and each two axes form a 120-degree angle but do not cross at one point; the axes in the three driver directions of the three mechanical branch chains in the other set are parallel to one another, but do not in the same surface, and the axes are in pairwise orthogonal with the axes in the direction of the three mechanical branch chains in the first set. The six-free-degree 3-3 orthogonal type parallel robot provided by the invention has the advantages of high system rigidity, high positioning accuracy, excellent dynamic response property, excellent isotropy of mechanical properties such as rigidity, bearing and the like, small occupied space, low energy consumption, long service life, low manufacturing cost, less maintenance cost, zero contamination and the like.

Owner:SHANGHAI JIAO TONG UNIV

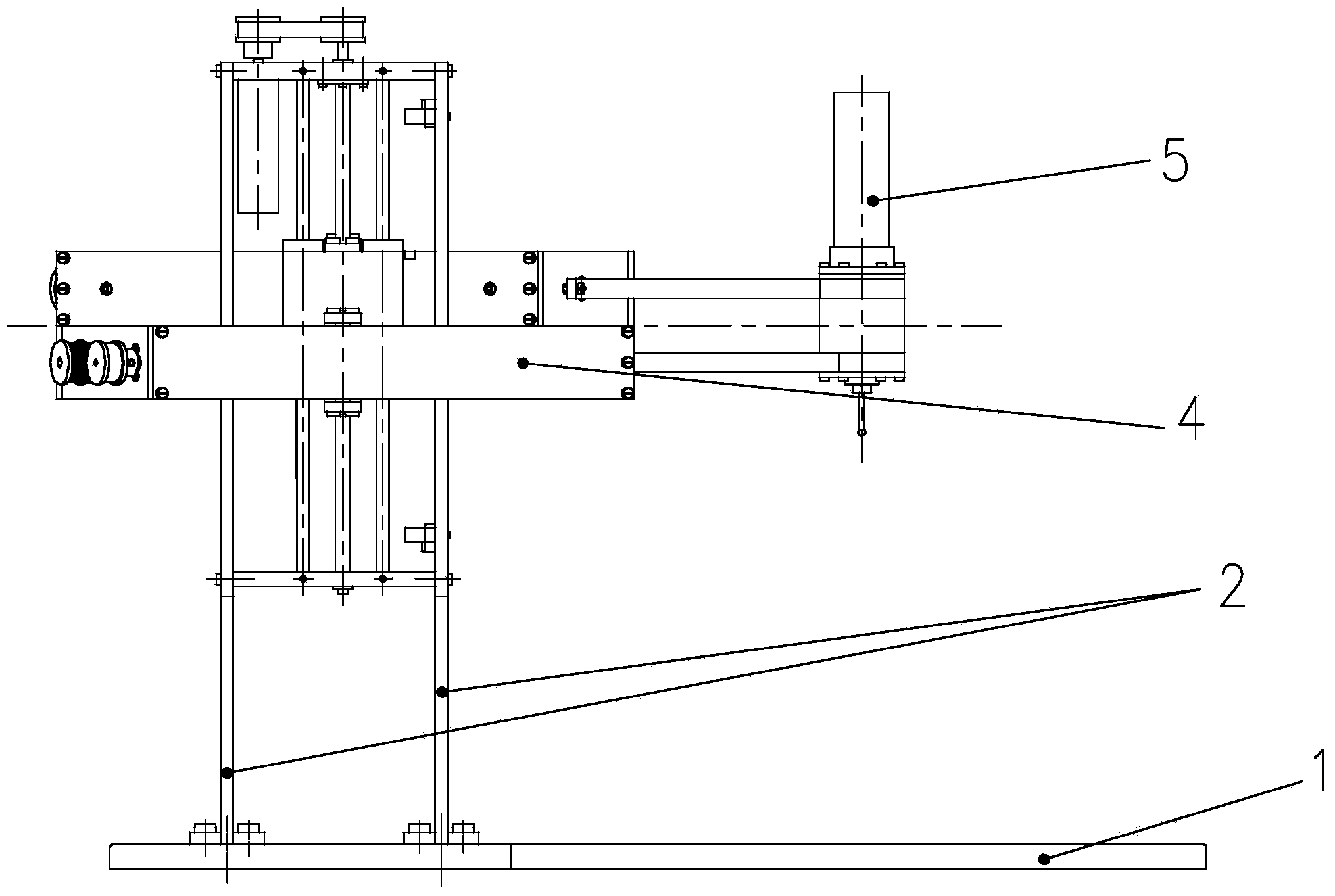

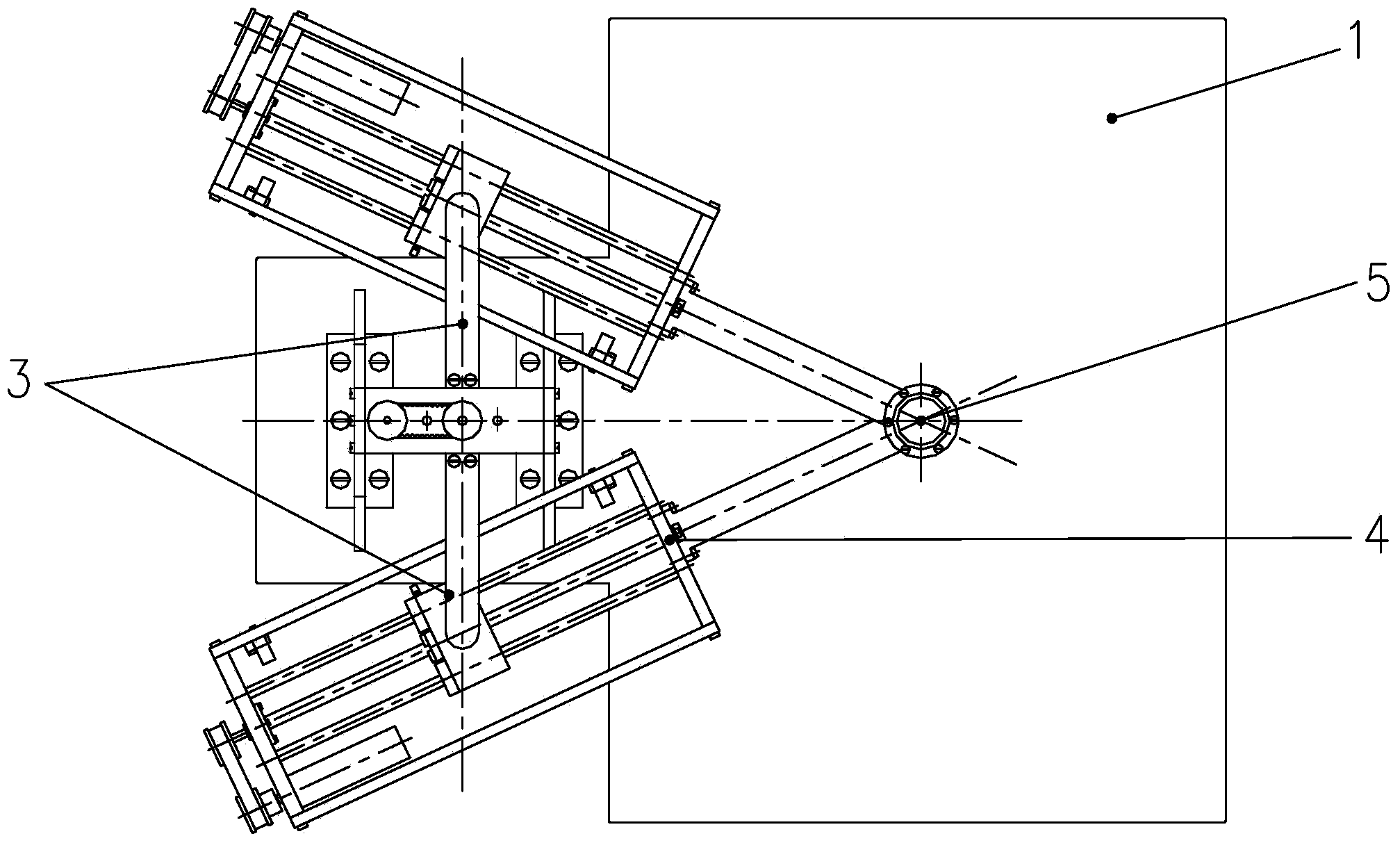

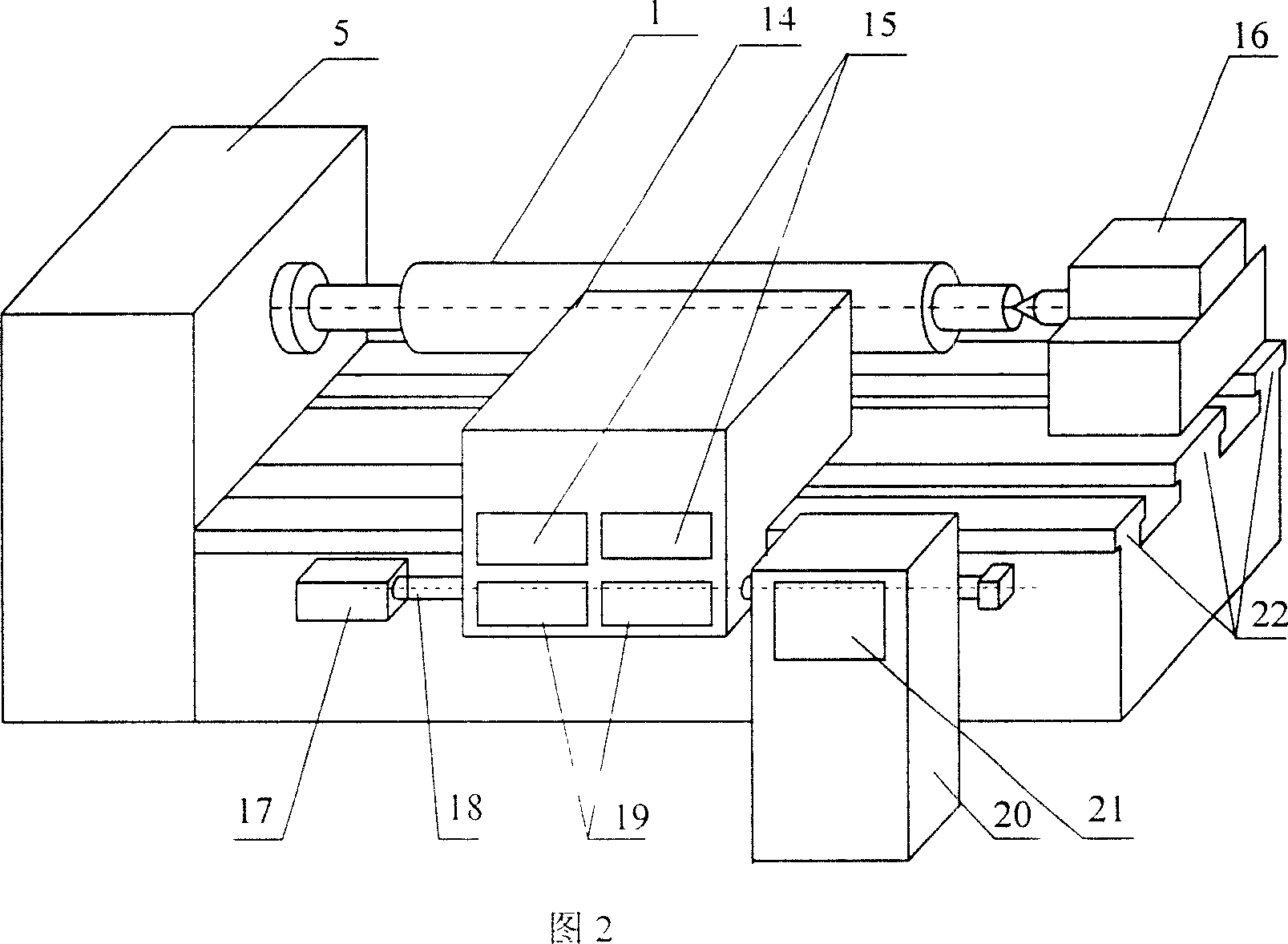

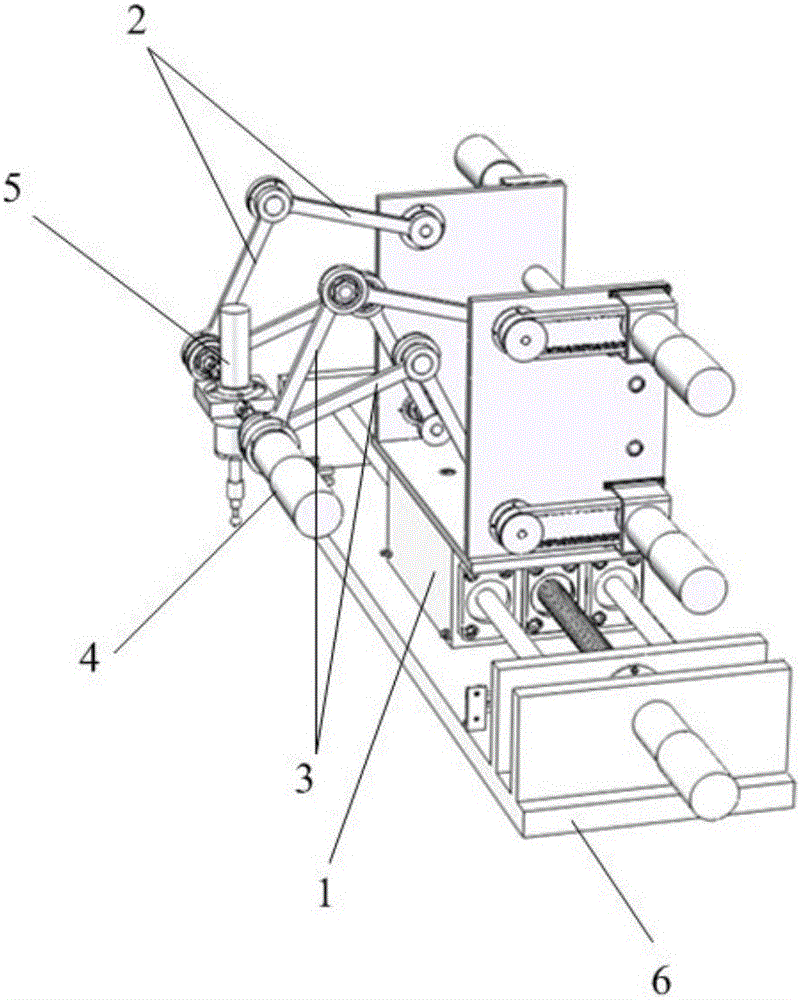

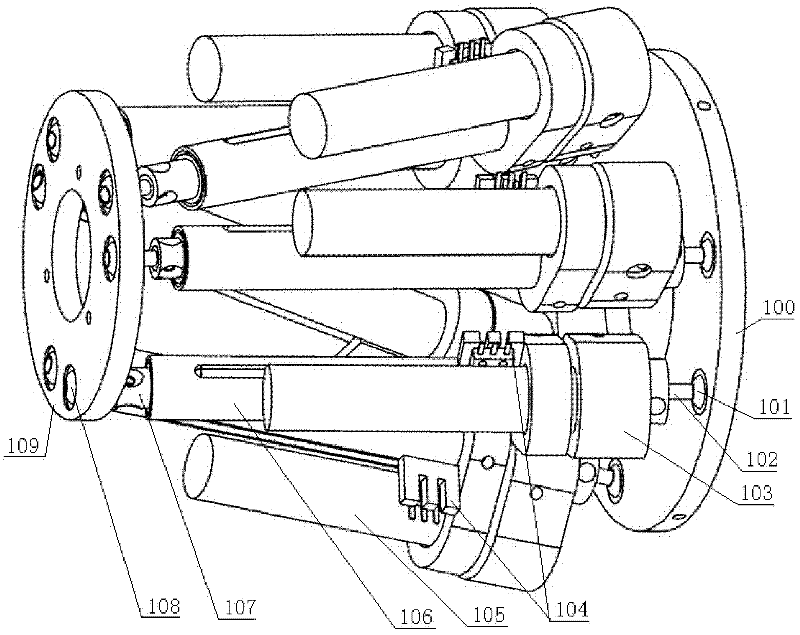

Three-degree-of-freedom parallel serial joint plastic operation robot

ActiveCN104323861ACompact structureImprove isotropic performanceDiagnosticsSurgeryThree degrees of freedomThree-dimensional space

The invention provides a three-degree-of-freedom parallel serial joint plastic operation robot. The problems of uneven operation level of doctors and low overall precision in the present prosthesis joint replacement are solved. The three-degree-of-freedom parallel serial joint plastic operation robot comprises a workbench, wherein a vertical mechanism and horizontal mechanisms are arranged on the workbench; an abrasive drilling mechanism is arranged on each of the horizontal mechanisms; the quantity of the horizontal mechanisms is two; the horizontal mechanisms are respectively arranged on the two sides of the vertical mechanism; the vertical mechanism comprises a vertical sliding table and a vertical driving component; each of the horizontal mechanisms comprises a horizontal sliding table and a horizontal driving component; connecting arms are fixedly connected with the two sides of the vertical sliding table; an outer end of each connecting arm is hinged to the horizontal sliding table on the corresponding side; a claw arm forward extends from each of the horizontal mechanisms; a sleeve ring is arranged at the front end of each claw arm; the sleeve rings forward extending from the horizontal mechanisms on the two sides are vertically overlapped and formed into a communicated sleeve hole; the abrasive drilling mechanism is penetrated through the sleeve hole; an inner wall of the sleeve hole is in sliding contact with an outer wall of the abrasive drilling mechanism. According to the invention, a triangular structure is adopted by the robot, so that the accurate route of a three-dimensional space track is realized and the face cutting precision of a bone joint is increased.

Owner:SHANDONG UNIV OF SCI & TECH

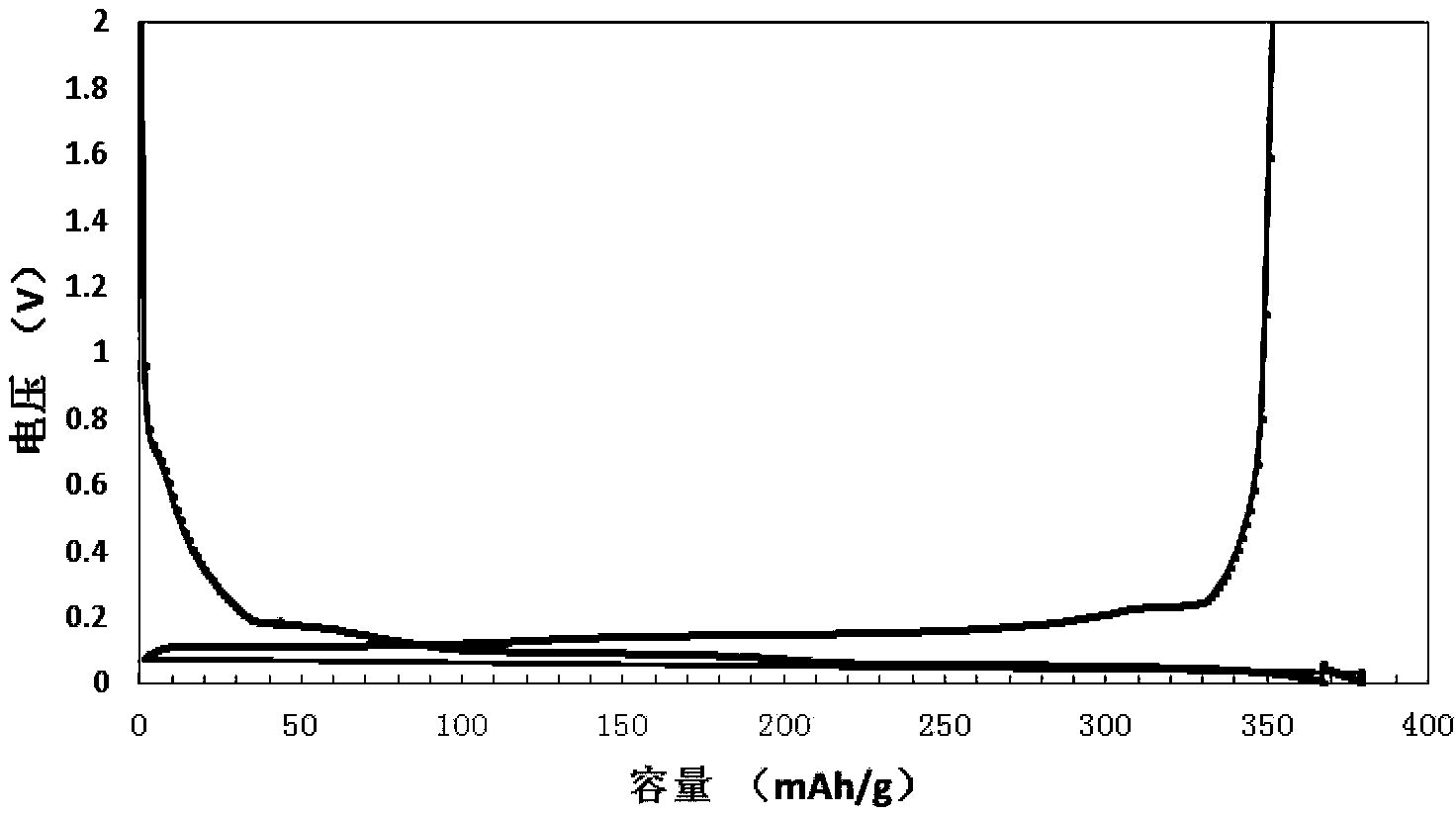

Lithium battery negative electrode material and preparation method thereof

InactiveCN103855369AIncrease energy densityHigh liquid absorptionNegative electrodesLi-accumulatorsNanotechnologyElectrode material

The invention discloses a lithium battery negative electrode material and a preparation method thereof. The preparation method of the lithium battery negative electrode material comprises the following steps of heating and stirring a mixture of carbon powder, a binder and a catalyst, pressing and molding, carbonizing, and graphitizing the mixture. The prepared lithium battery negative electrode material is high in graphitization degree, good in isotropic property, high in energy density, good in cycling property and low in preparation cost; the preparation process combining the molding graphitization and catalytic graphitization is also applicable to the graphitization process of other powder materials.

Owner:SHANGHAI SHANSHAN TECH CO LTD

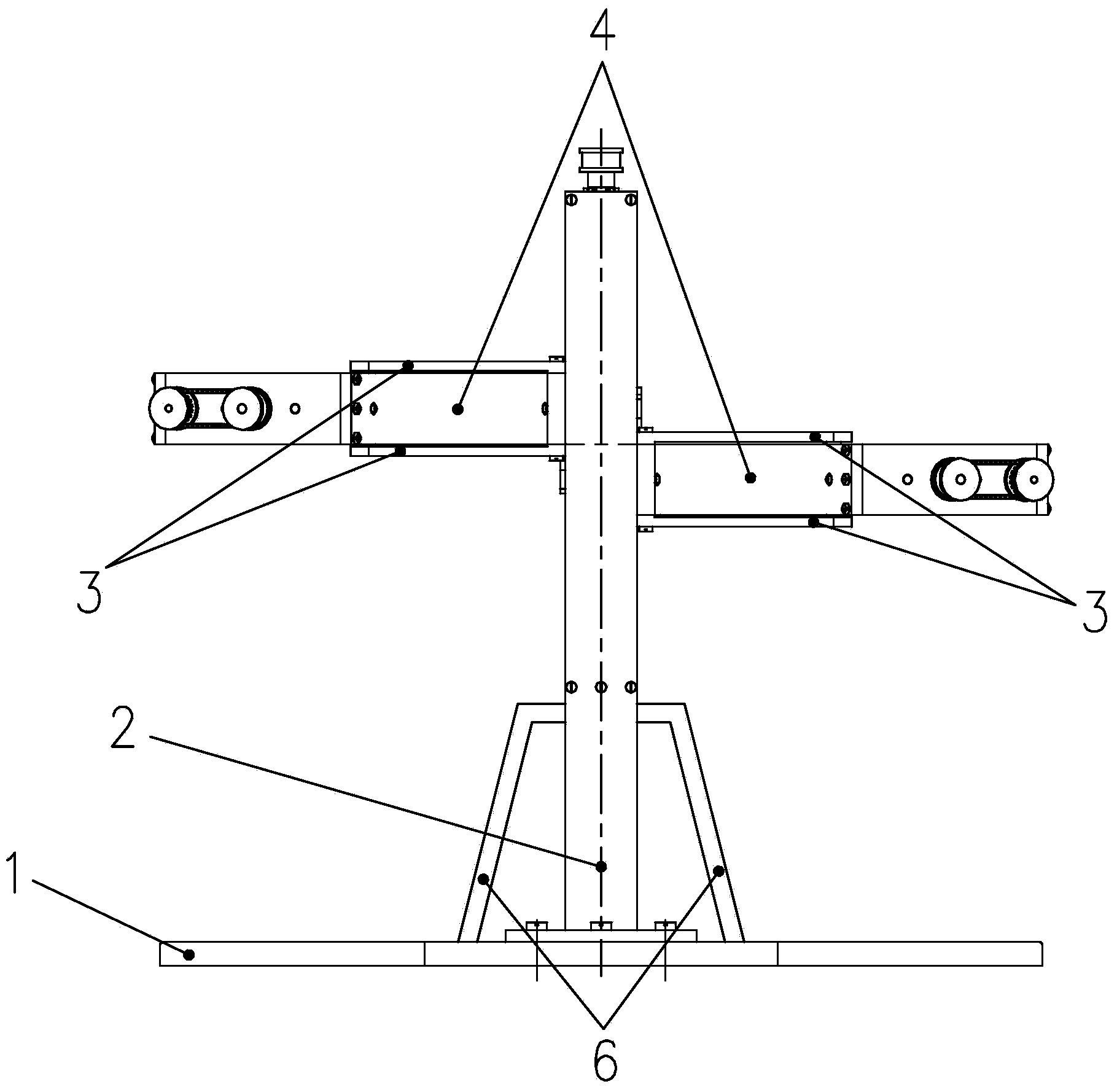

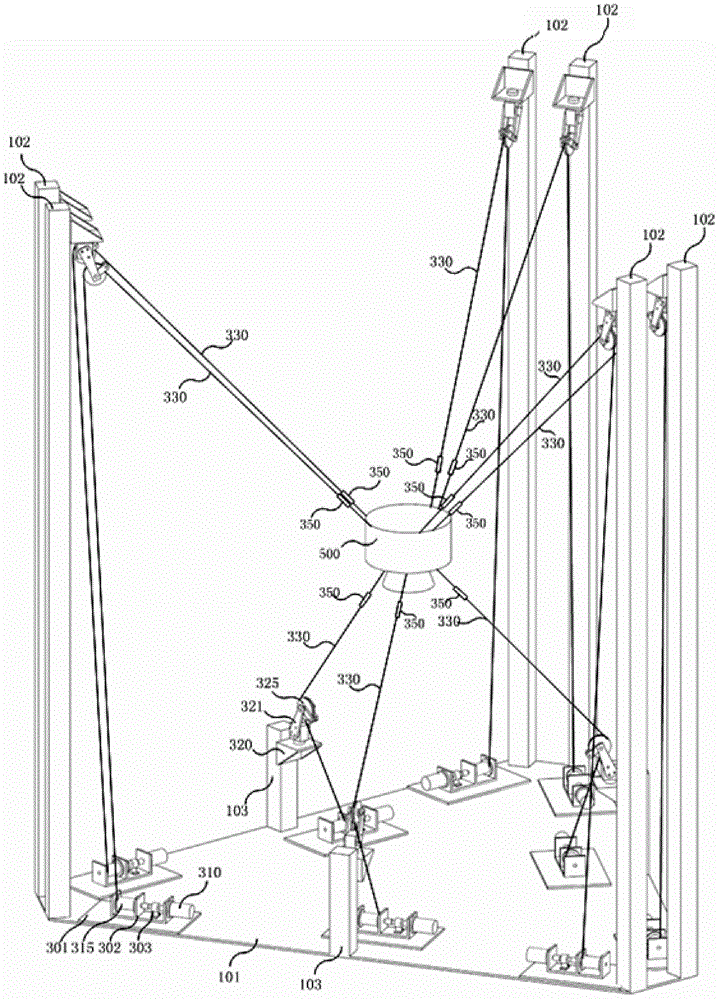

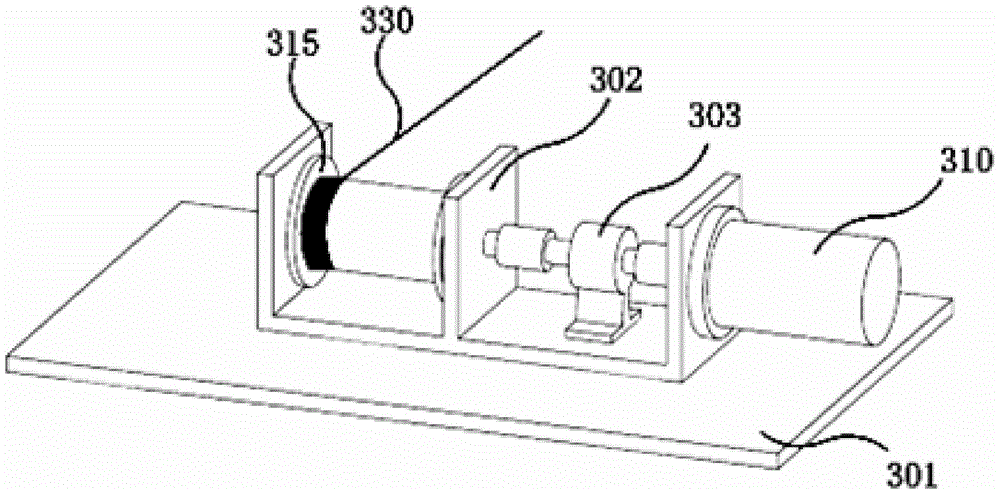

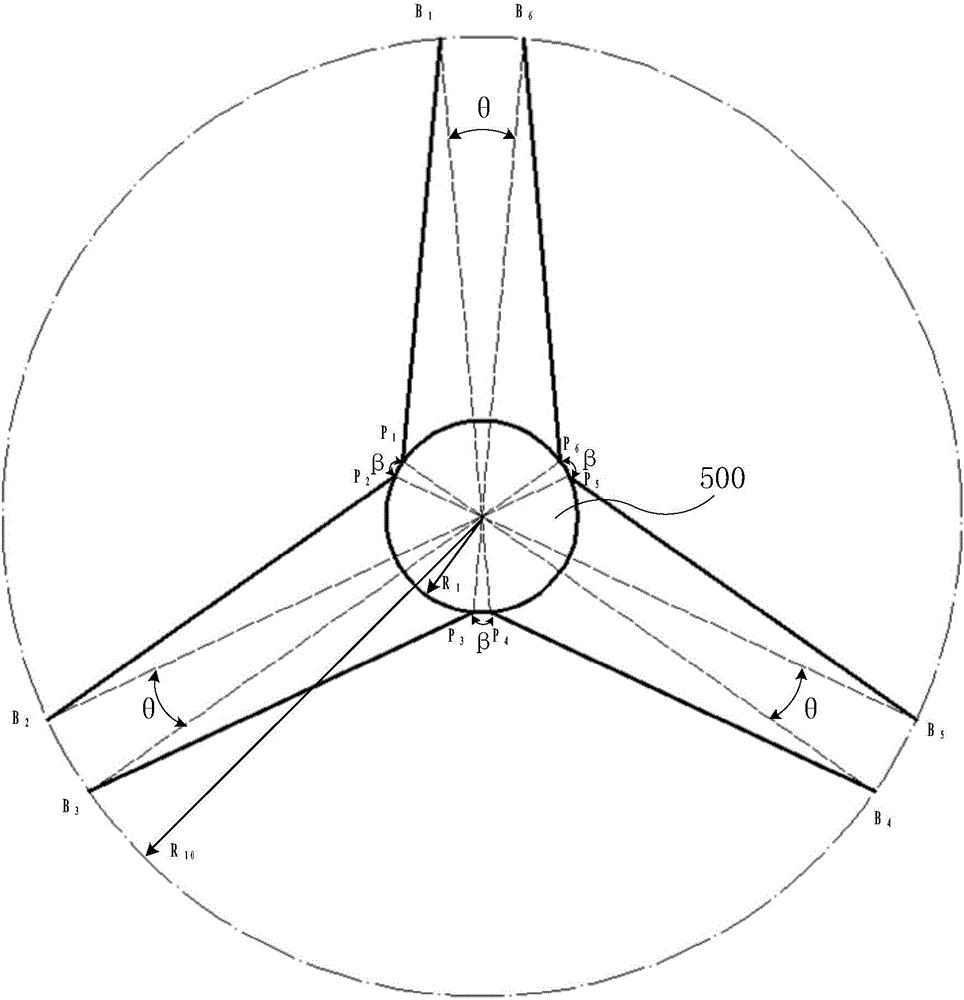

Nine-rope driving robot device for simulating zero gravity and low gravity

ActiveCN104477420ALarge working spaceImprove dynamic characteristicsCosmonautic condition simulationsControl systemClosed loop

A nine-rope driving robot device for simulating zero gravity and low gravity comprises a foundation framework, ropes, a rope driving unit, a rope guiding device, a simulation load platform, a sensor and a control system. According to the nine-rope driving robot device for simulating the zero gravity and the low gravity, a nine-rope redundant driving scheme is adopted, the nine ropes are distributed in a mode with six ropes being arranged at the top and three ropes being arranged at the bottom; extension and shortening of the ropes are achieved through a driving unit which is driven by a motor according to a command of the control system; the control system achieve closed-loop or semi-closed-loop control on the length and force of every rope according to the force and pose position data from the sensor; meanwhile the upper six ropes can be adopted to control and simulate the pose position and movement of a load platform, the lower three ropes perform force tensioning or compensation control, and accordingly the nine-rope driving robot device for simulating the zero gravity and the low gravity has the capability of stimulating six degrees of freedom under the zero gravity or low gravity environment in large working space and meanwhile can apply the distributing force in a superposition mode through the lower three ropes or mote ropes. The nine-rope driving robot device for simulating the zero gravity and the low gravity is good in isotropy performance and has an application potential in other fields such as rehabilitation equipment.

Owner:TSINGHUA UNIV

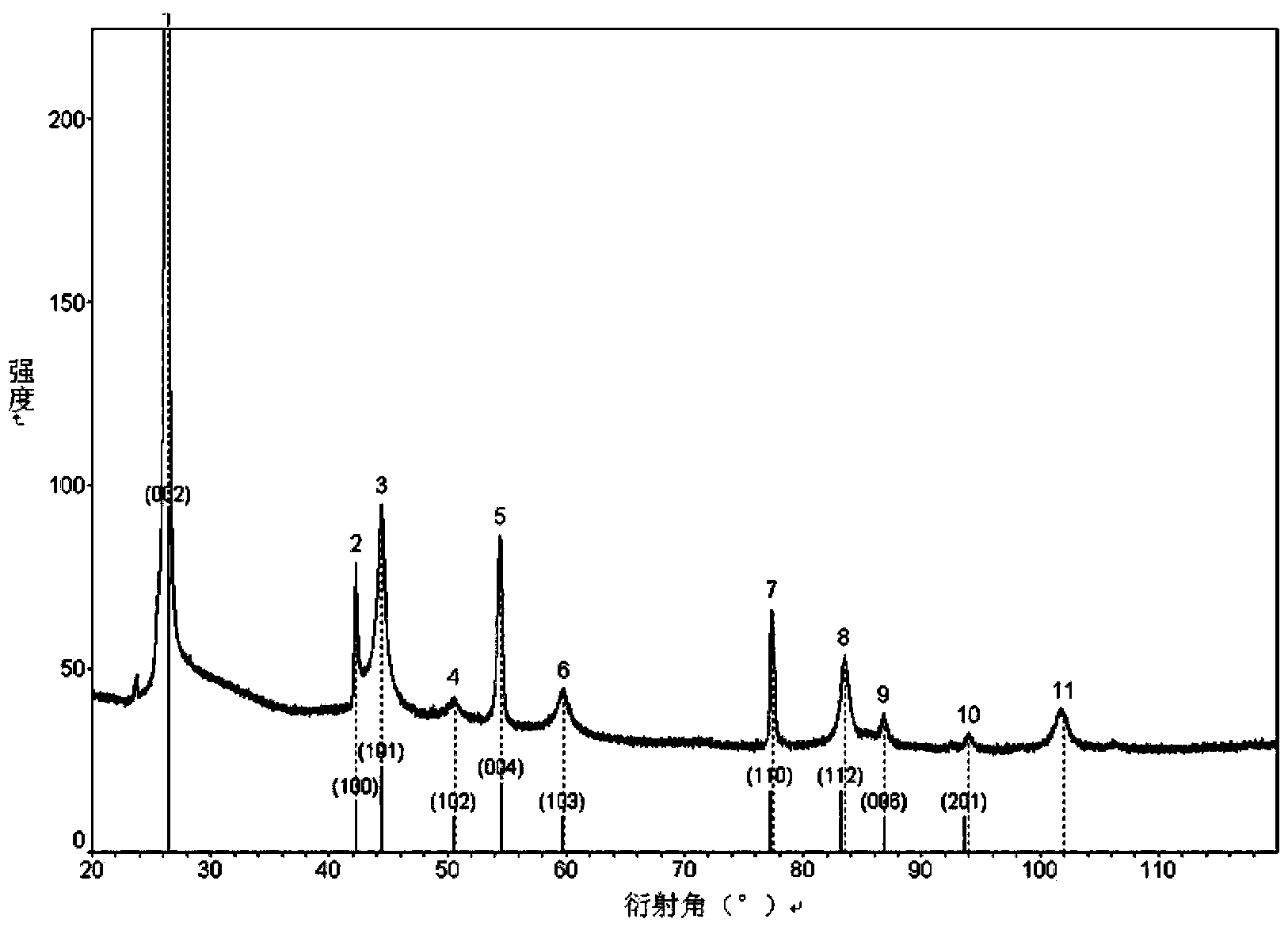

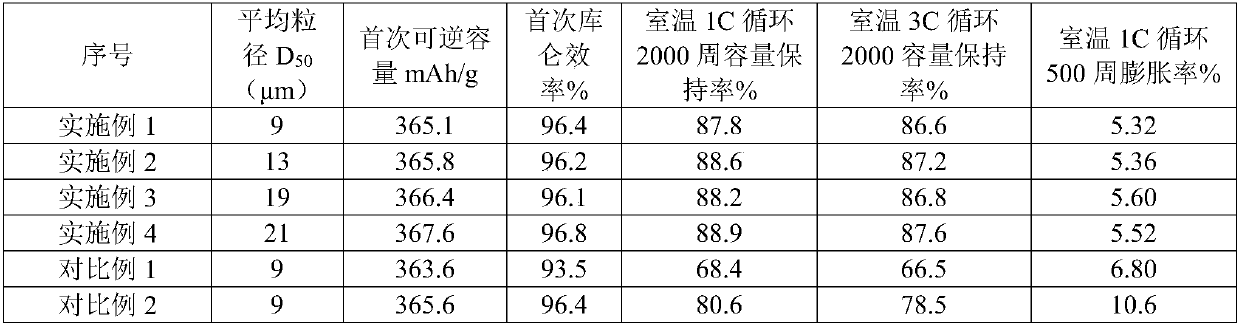

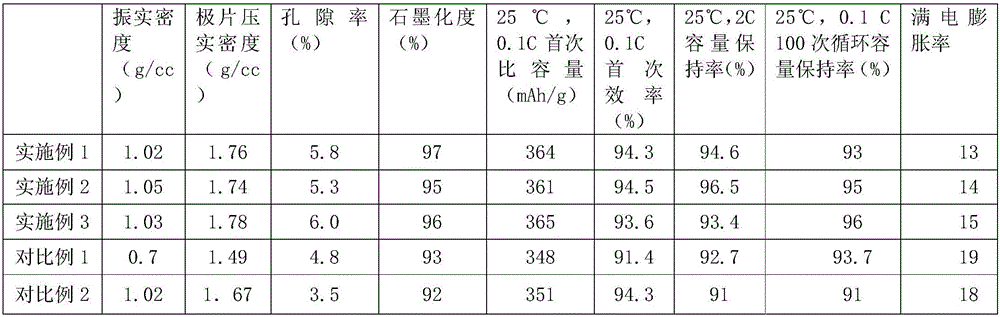

Modified microcrystal graphite cathode material of lithium ion battery as well as preparation method and application thereof

ActiveCN107814383APreserve structural propertiesHigh sphericityGraphiteCell electrodesSodium-ion batteryLithium-ion battery

The invention relates to the technical field of lithium ion battery carbon cathode materials and in particular to a modified microcrystal graphite cathode material of a lithium ion battery as well asa preparation method and application thereof. The material has the advantages that (1) a modified core-shell structured natural graphite cathode material with artificial graphite embedded into and onthe surface of natural graphite in situ is prepared, the overall structural properties of natural microcrystal graphite are maintained, pores of the natural microcrystal graphite is filled with the artificial graphite, and the outer surface of the natural microcrystal graphite is wrapped by the artificial graphite; (2) compared with a conventional cathode material, the cathode material prepared byusing the method provided by the invention is good in isotropy, is capable of inhibiting and absorbing expansion of electrodes in the charge and discharge process, is high in primary coulombic efficiency, long in service life and good in high-magnification charge and discharge performance and is capable of replacing artificial graphite to manufacture cathode materials of power batteries, so as tolower the cost greatly; and (3) the method is simple in preparation process, low in cost and relatively high in practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

High-toughness inorganic material/polymer composite concrete and preparation method thereof

The invention discloses high-toughness inorganic material / polymer composite concrete and a preparation method thereof. The preparation method of the high-toughness inorganic material / polymer composite concrete comprises the following steps: modifying carbon nanometer tubes through a chemical reaction to obtain modified carbon nanometer tubes of which the surface is chemically grafted with high-substituted hydroxyproxyl cellulose, adding the modified carbon nanometer tubes in polyacrylate emulsion and stirring and mixing with water, a polyacrylate toughening emulsion, concrete, gravel, a fine aggregate, slag powder, fly ash and a water reducer as raw materials, thus obtaining the high-toughness inorganic material / polymer composite concrete. Through detection, the high-toughness concrete provided by the invention can show the significant strain hardening or deformation hardening characteristics under the action of a direct tensile load or a bending load, the bending strength can reach 19-29MPa, the tensile strength can reach 8-16MPa and the compressive strength can reach 78-95MPa. The high-toughness inorganic material / polymer composite concrete can be applied to fields such as bridge floor of large-span cross-sea / cross-river bridges, high-speed rail overhead viaducts and arch walls of various tunnels such as subway.

Owner:FUJIAN JUAN CONSTR ENG CO LTD

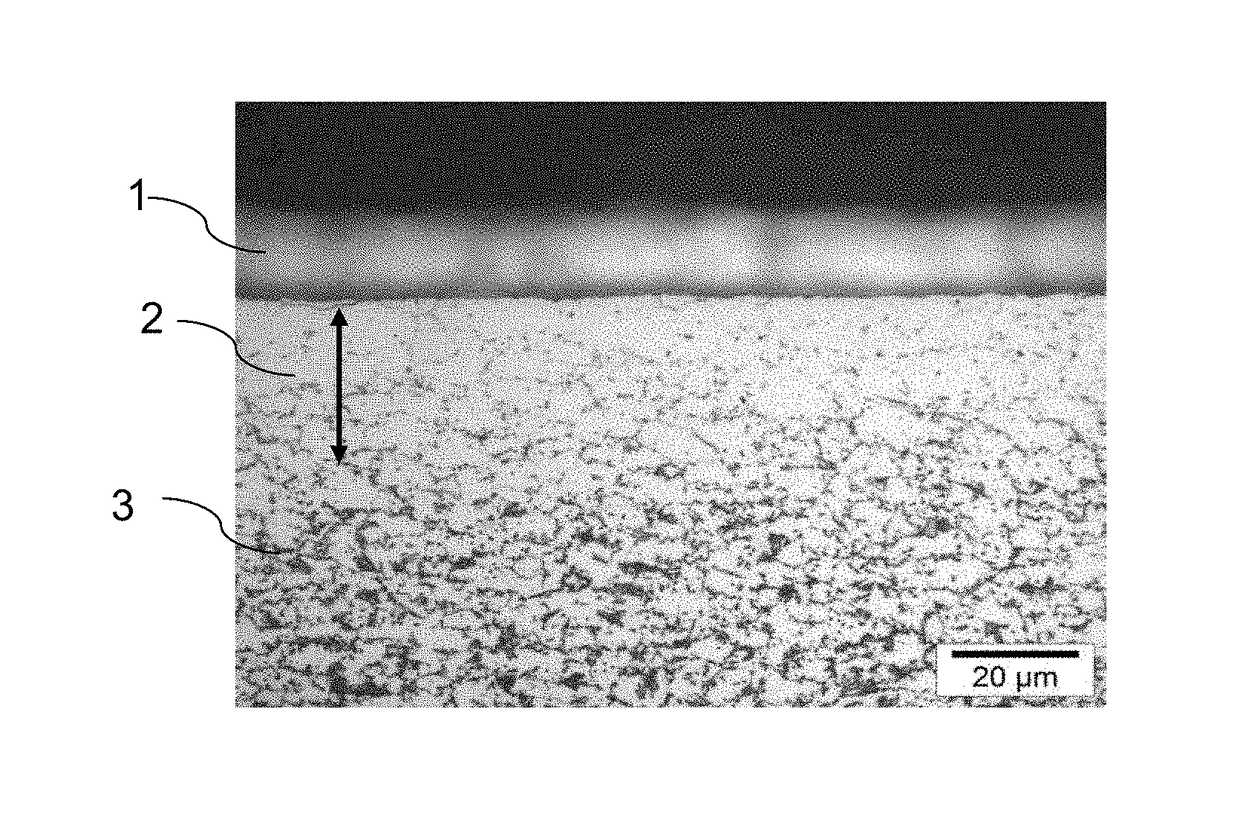

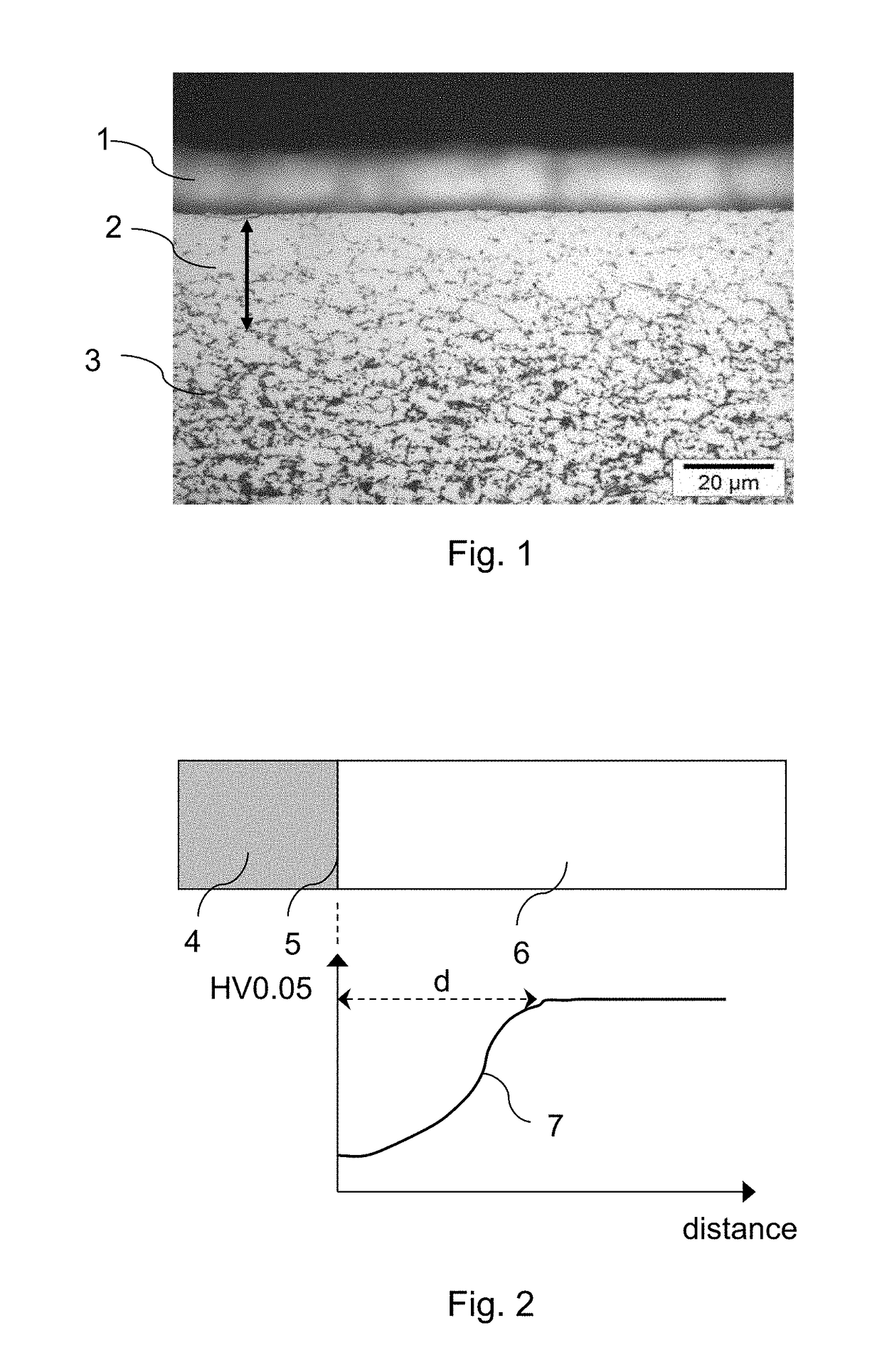

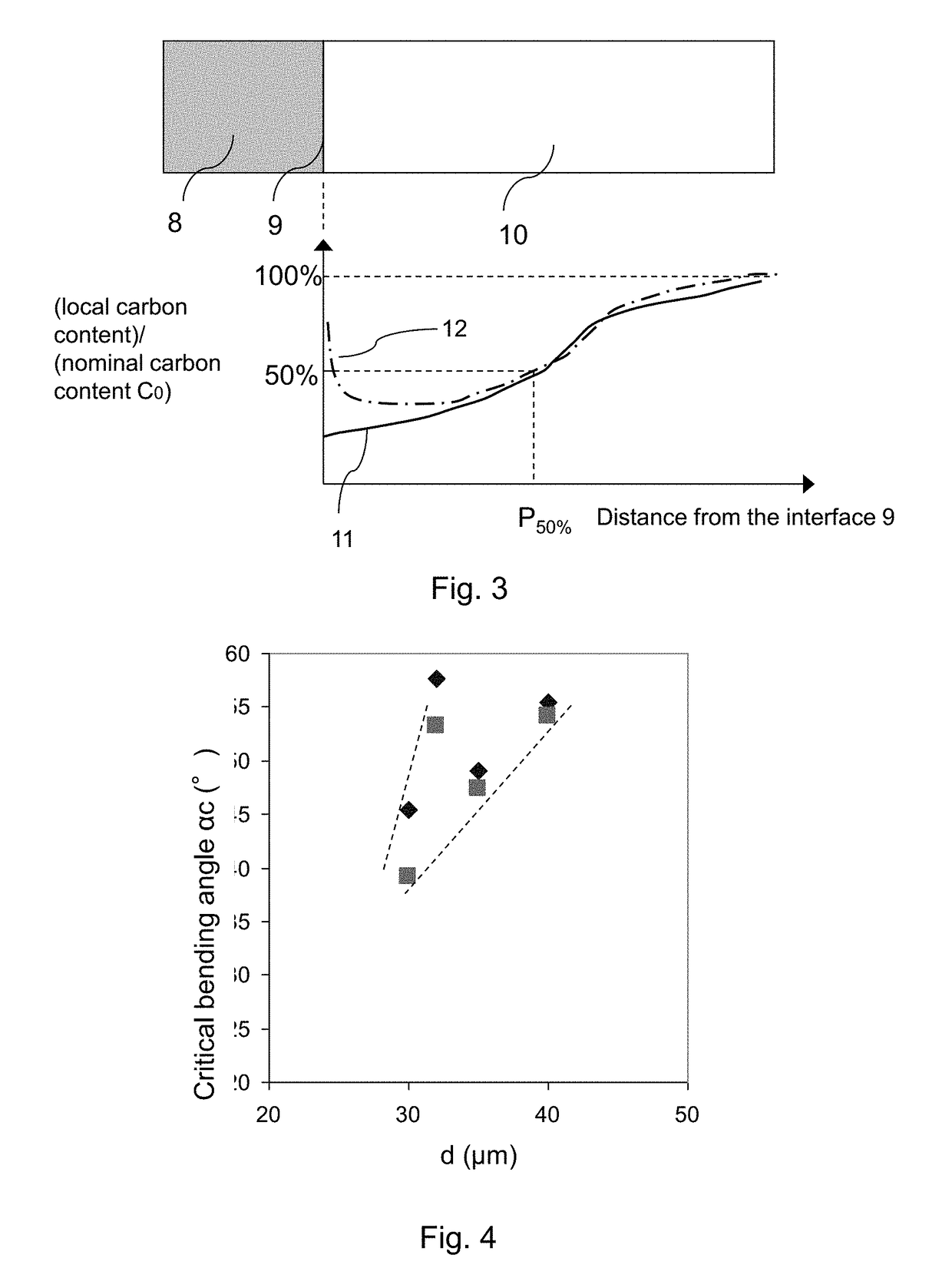

Precoated sheets for manufacturing press-hardened coated steel parts

ActiveUS20170260599A1Improve bending performanceImprove isotropic performanceHot-dipping/immersion processesMetal layered productsBrown iron oxideSheet material

A cold-rolled sheet is provided. The cold-rolled sheet includes a steel substrate with a carbon content C0 between 0.07% and 0.5%, expressed by weight, and a metal pre-coating on at least the two principal faces of the steel substrate. The substrate has a decarburized area on the surface of each of the two principal faces. The depth p50% of the decarburized area is between 6 and 30 micrometers, and p50% is the depth at which the carbon content is equal to 50% of the content C0. The sheet does not contain a layer of iron oxide between the substrate and the metal pre-coating.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Production method of heavy-gauge large-single-weight low-alloy high-strength structural steel plates

InactiveCN102732674AReduce the process of forging billet openingReduce processProcess efficiency improvementElectric furnaceElectro-slag remeltingHeat treated

The invention provides a production method of heavy-gauge large-single-weight low-alloy high-strength structural steel plates. The method comprises the steps of smelting, casting, electroslag remelting, electroslag ingot cleaning, heating, rolling, water cooling, hydrogen diffusion treatment, supersonic wave flaw detection, normalization, examination and warehousing. The largest thickness of the steel plates produced through the method of the invention can reach 410mm. The method allows the isotropy, the impact toughness and the Z-directional performances of the heavy-gauge steel plates to be realized through adopting large slab electroslag remelting treatment and a reasonable controlled rolling and heat treatment technology, the production cost to be reduced, the time of delivery to be substantially shortened and the specification range to be wide, and is used for satisfying continuously increased market application amount demands; and the steel plates can completely substitute import products to satisfy various requirements of heavy-gauge large-single-weight steel plates applied to water power, wind power and large building structures.

Owner:WUYANG IRON & STEEL +1

Spherical surface two-freedom symmetrical parallel connection robot mechanism with redundancy drive

InactiveCN101214647AOptimize layoutStructural symmetryProgramme-controlled manipulatorKinematic pairEngineering

The present invention discloses a spherical 2-degree-of-freedom symmetric parallel robot mechanism with redundant actuation. A composite turning pair, which is composed of three turning pairs hinged with the same axial line, is connected with a fixed platform via three branches with the same structure, the two connecting bars of each branch, between which one turning pair is connected, are respectively connected with the composite turning pair and the fixed platform via two turning pairs, all the kinematic pairs of the three branches are the turning pairs, and the axial lines of all the turning pairs are converged at a rotating spherical center. When three base turning pairs are selected as the input of the robot mechanism and the composite turning pair as the output of the mechanism, the composite turning pair has two degrees of freedom while moving along a spherical surface. The present invention has the advantages of symmetric distribution of the structure and driving, no singular configuration, high rigidity and bearing capacity, easy production and assembly, etc.

Owner:YANSHAN UNIV

Coarsening laser processing system and method for surface of roller with circumferential irregular coarsening dots

A laser system for generating the roughened dots with irregular circumference on the surface of a roller is composed of a machine-tool system, a laser processing system and a pseudo-random delay unit for randomly delaying the laser output signals. Its method features that the laser output signals emitted to the surface of roller are randomly delayed in a defined time range.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

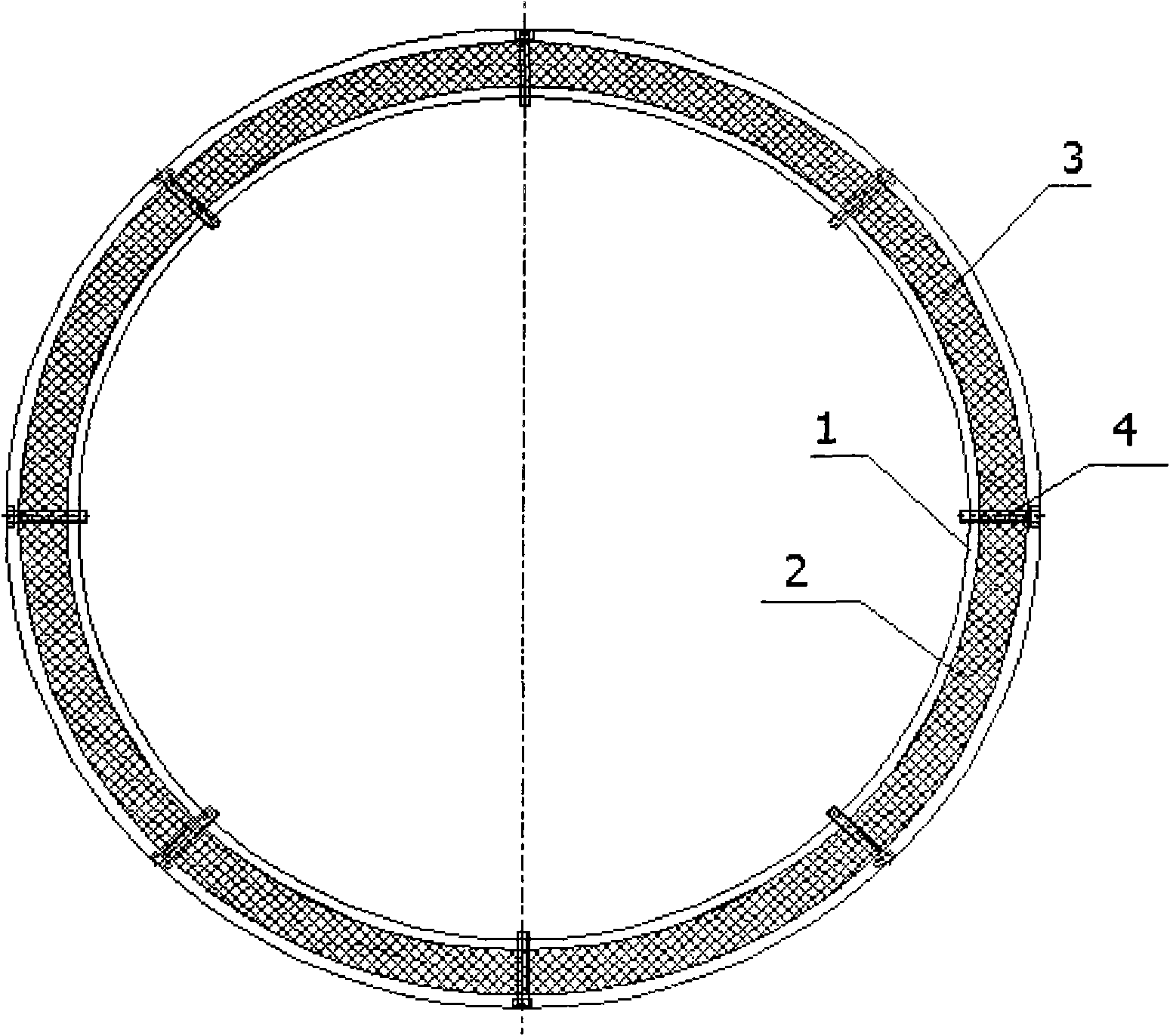

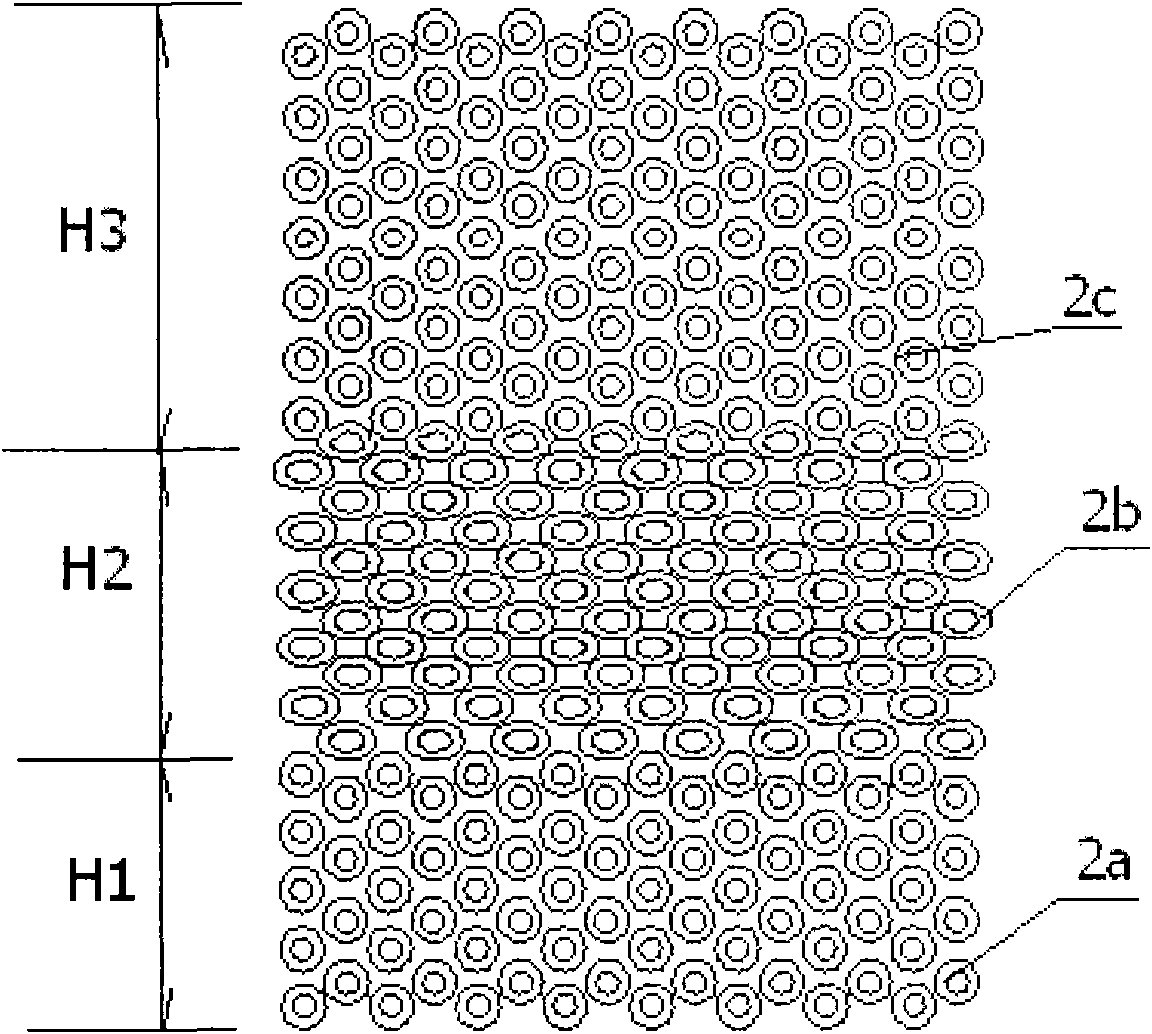

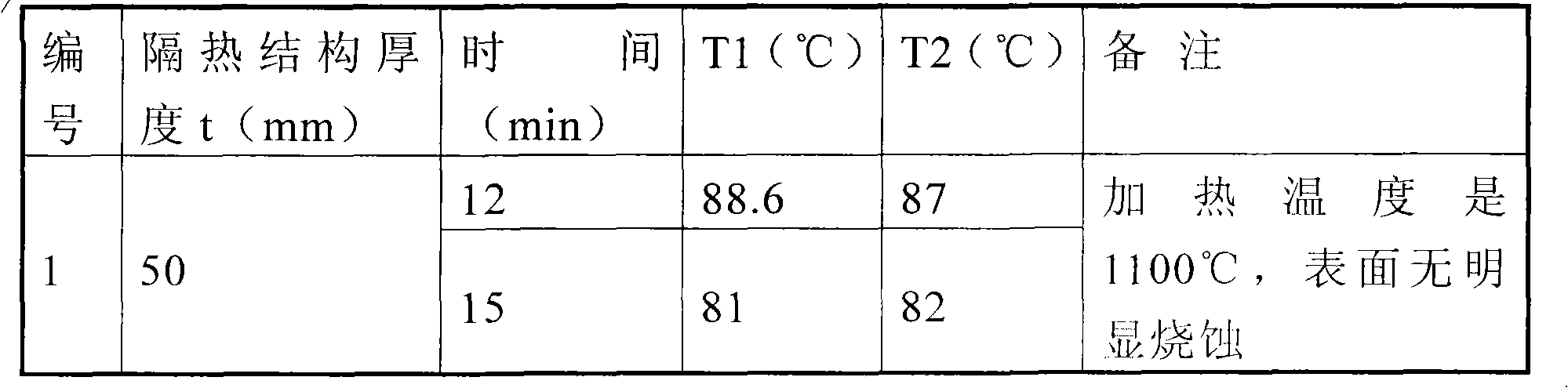

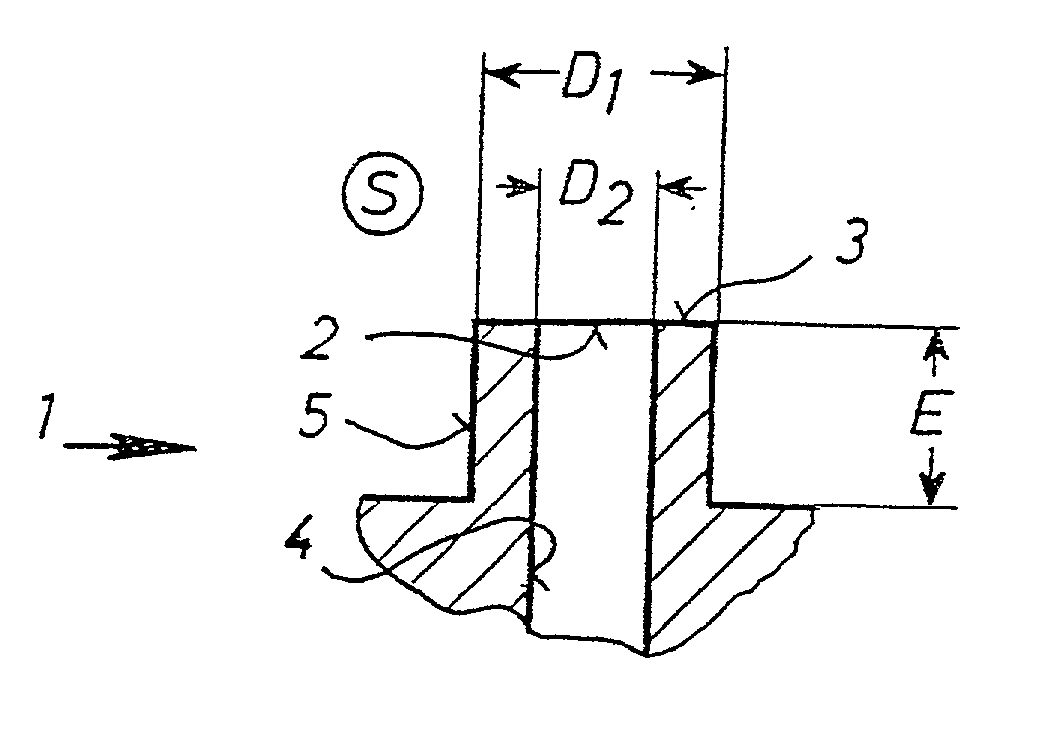

Novel inorganic thermal protection structure and manufacturing method thereof

InactiveCN101648598ALow densityLow ablation resistanceLaminationLamination apparatusFlagellar basal bodyFiber

The invention discloses a novel inorganic thermal protection structure and a manufacturing method thereof. The novel inorganic thermal protection structure comprises an aluminum alloy basal body, a heat insulation layer and a heat-protection layer, wherein the heat insulation layer is a space reticular structure with a plurality of staggered hole gaps, the staggered hole gaps comprise a hollow sleeve pipe braided by a plurality of layers of quartz fibre wound on the aluminum alloy basal body, and the heat-protection layer is a model body which is formed by pressing a silicon nitride powder body and is matched with the heat insulation layer. The internal diameter of the quartz fibre sleeve pipe is 0.5-1.0 mm. The quartz fibre sleeve pipe is wound by a wet method, and the distance of the sleeve pipe is 1-4 mm; the quartz fibre sleeve pipe comprises the following parameters from the inside to the outside: the internal ring direction winding layer thickness H 1 is 1-4 mm, the spiral winding layer thickness H2 is 20-35 mm, and the external ring direction winding layer thickness H3 is 5-20 mm; the winding parameter of the spiral winding layer thickness is 75-85 degrees, and the winding direction between layers is formed by opposite superposition. The thickness of the silicon nitride heat-protection layer is 2-4 mm.

Owner:国营江北机械厂

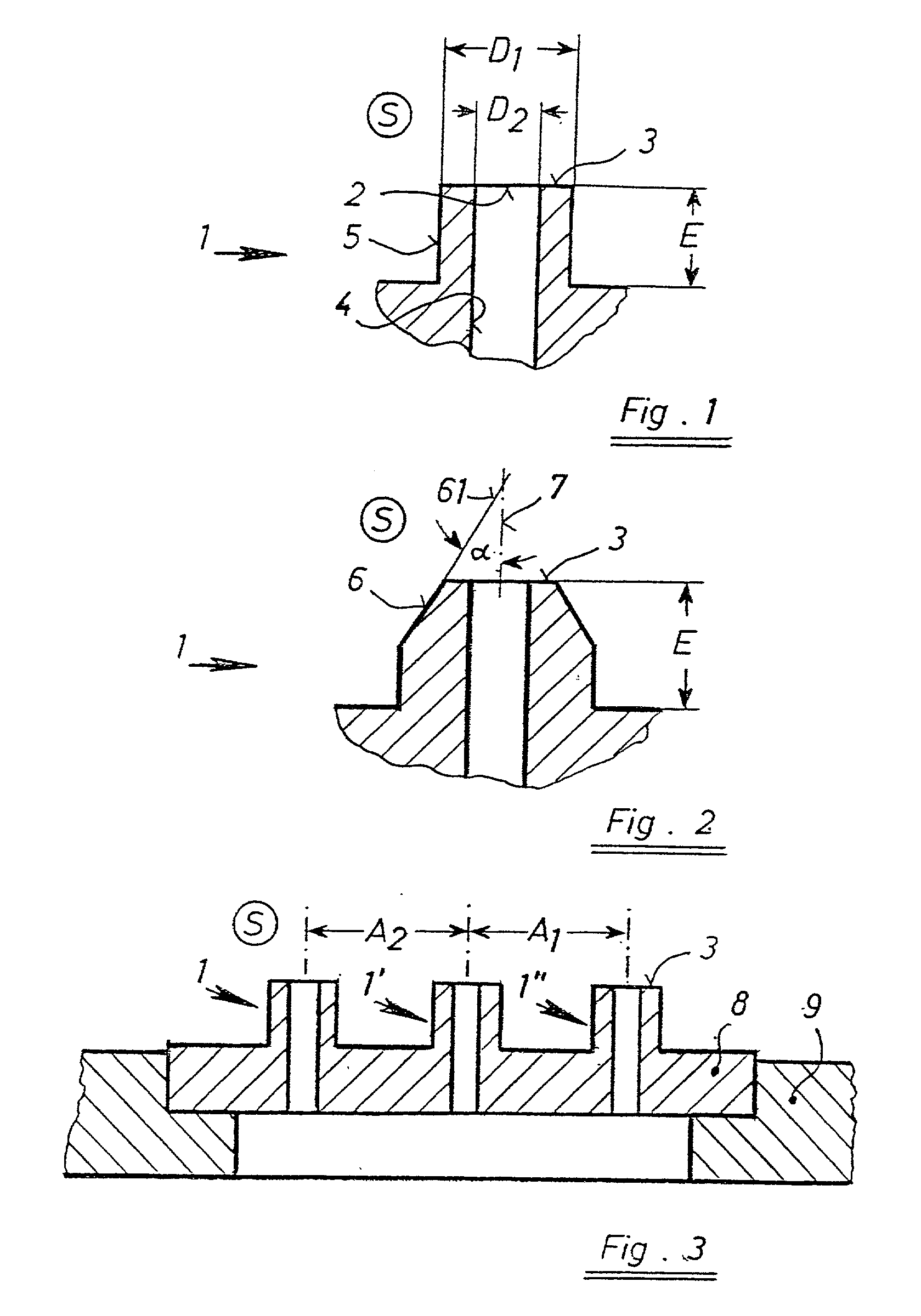

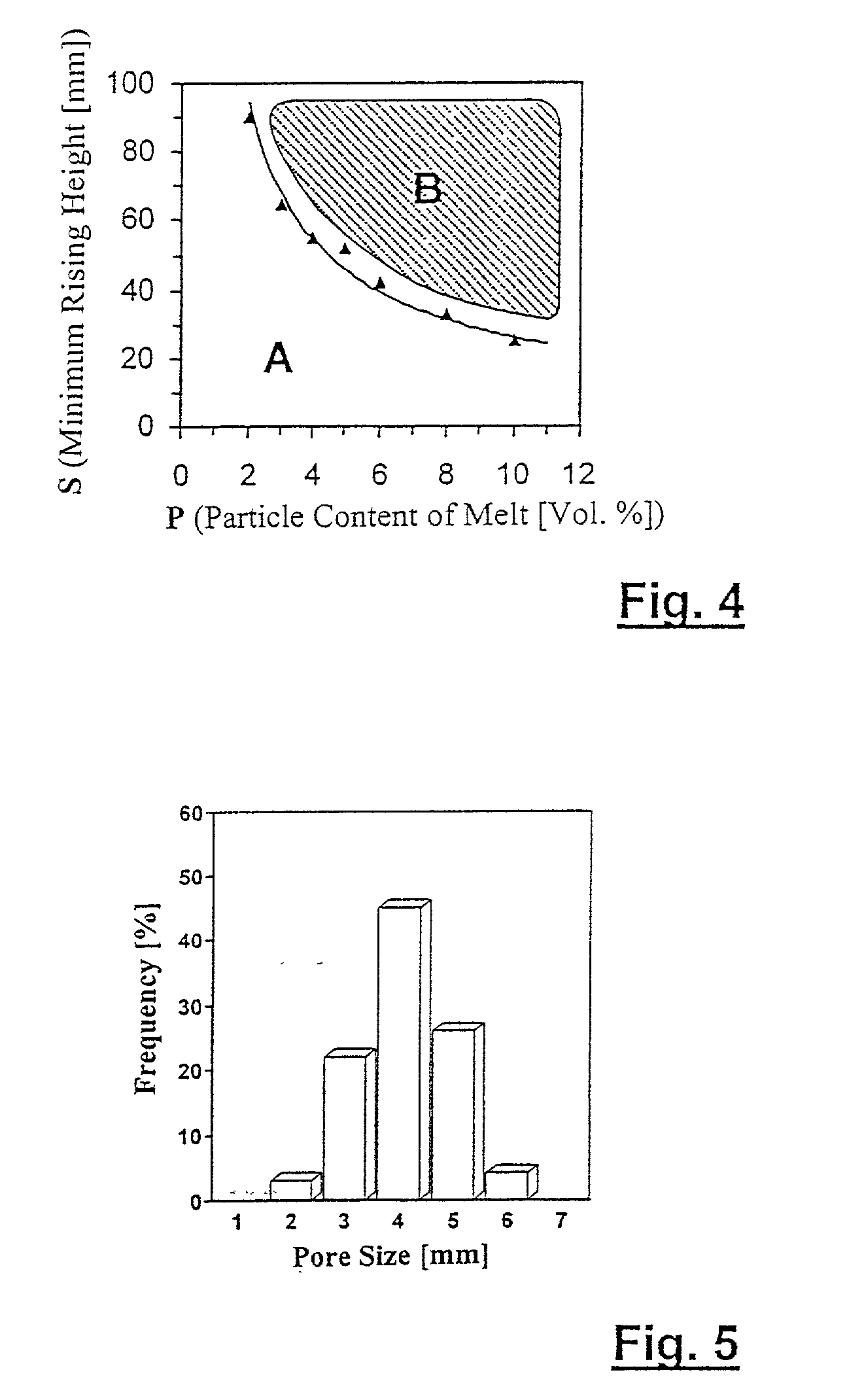

Device and process for producing metal foam

InactiveUS20030047036A1Effective stable separation criterionIncrease load capacityManufacturing convertersPolymer scienceLiquid metal

A device for feeding gas in a melt of foamable metal by means of at least one pipe for producing metal foam. The gas insertion pipe projects inwardly into the melt and at the projecting end has a gas outlet having a cross section of 0.006 to 0.2 mm2 and a pipe face area of less than 4.0 mm2. A flowable metal foam has gas bubbles defined by walls of a liquid metal matrix with solid reinforcing particles, and the diameter of the largest gas bubbles divided by that of the smallest gas bubbles is less than 2.5.

Owner:HUTTE KLEIN REICHENBACH

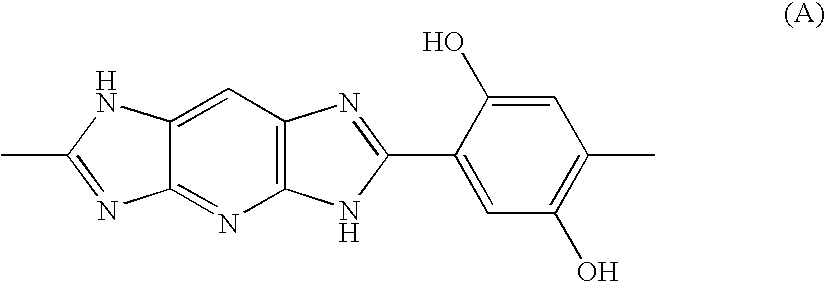

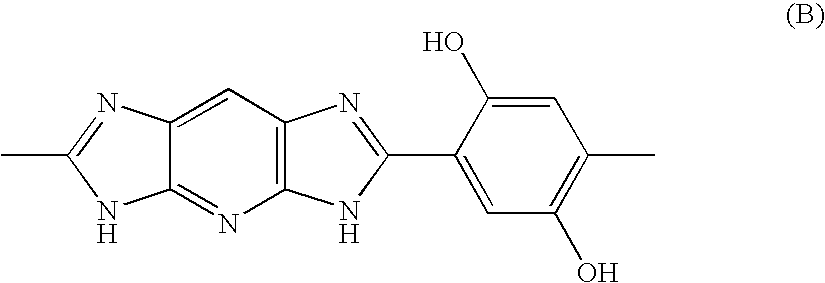

Electrolytic membrane

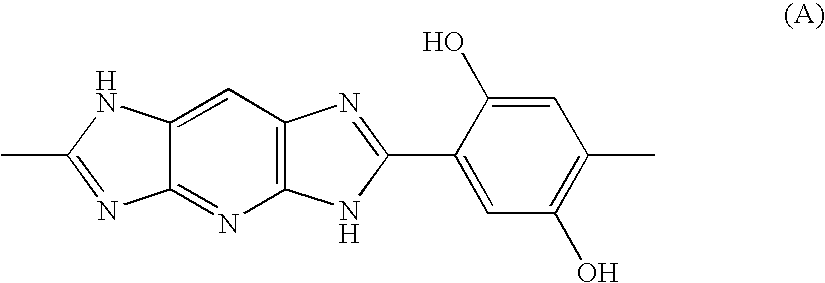

InactiveUS7833644B2Excellent in ion conductivity and oxidation resistanceImprove isotropic performanceNon-metal conductorsElectrolyte holding meansMethanesulfinic acidElectrolyte

An object of this invention is to provide an electrolytic membrane excellent in ion conductivity and oxidation resistance, and this invention is directed to an electrolytic membrane formed of a polymer comprising at least one recurring unit selected from the group consisting of a recurring unit of the following formula (A),and a recurring unit of the following formula (B),and having a reduced viscosity, measured in a methanesulfonic acid solution having a concentration of 0.5 g / 100 ml at 25° C., of 0.05 to 200 dl / g, and a process for the production thereof.

Owner:TEIJIN LTD

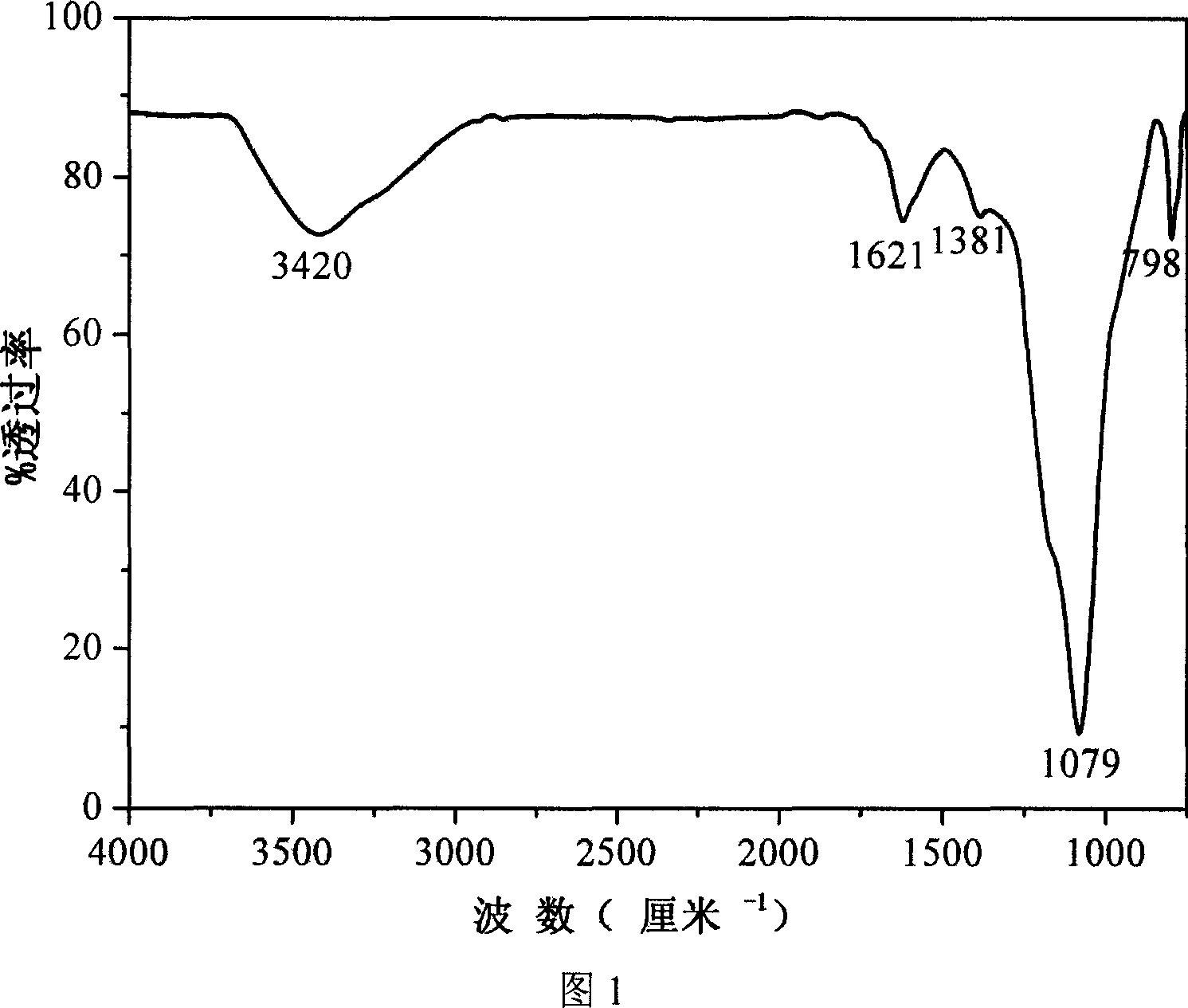

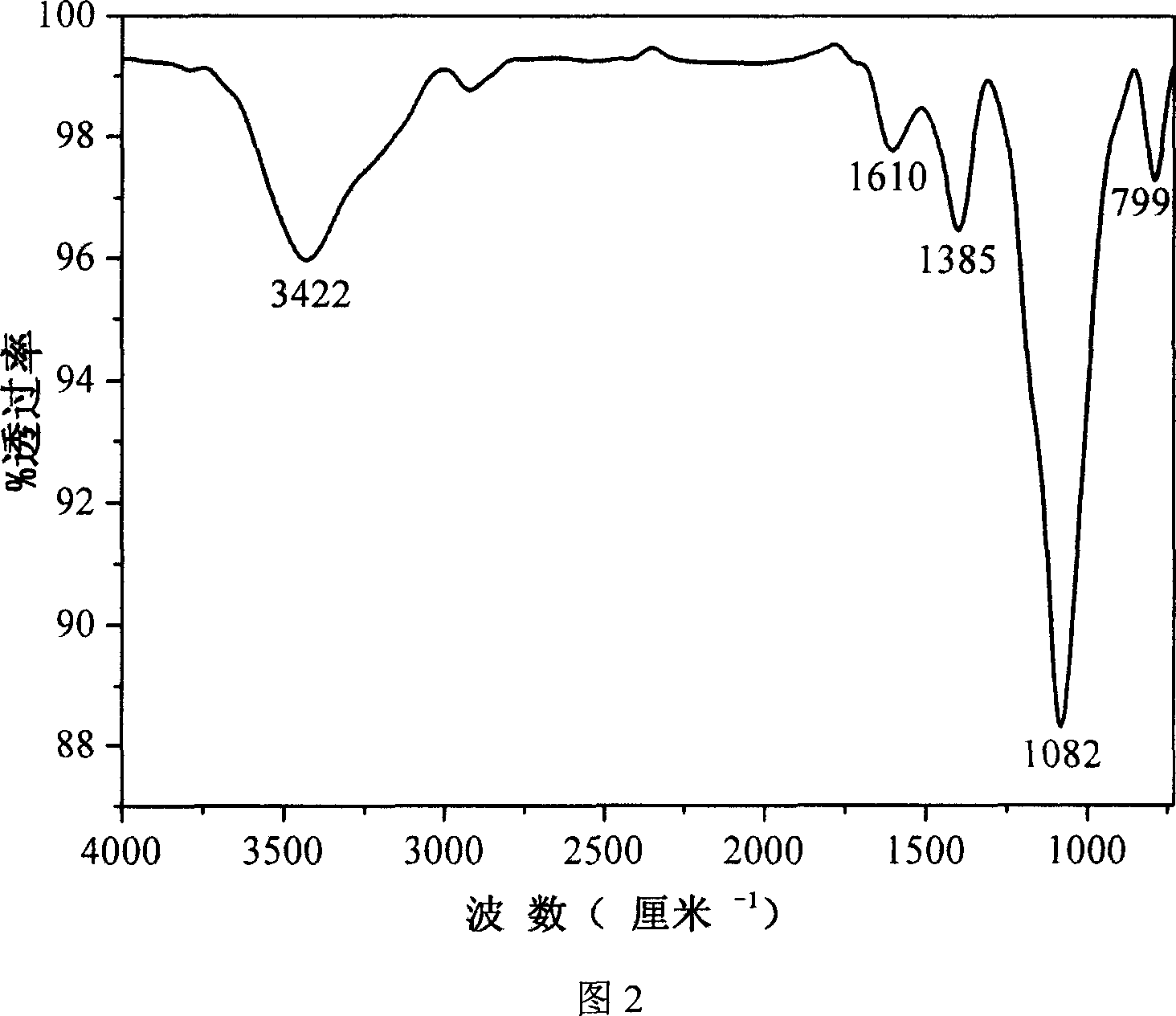

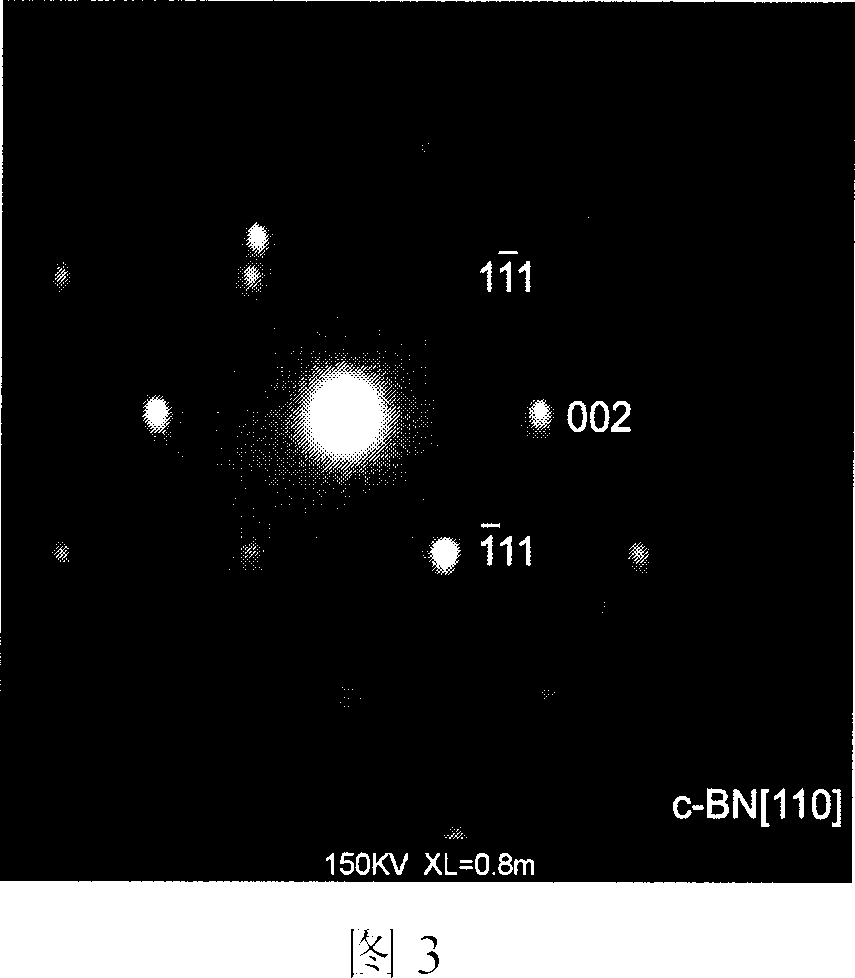

Dissolvent hot liquid state phase-change method for synthesizing superhard micro nano material

InactiveCN1919441AImprove crystal qualityImprove uniformityPolycrystalline material growthNitrogen compoundsMicro nanoHexagonal boron nitride

The invention discloses a solvent hot-liquid phase transforming method to synthesize superhard micro-nanometer material in the chemical and new material domain, which comprises the following steps: dispersing hexagonal boron nitride, graphite mold carbon nitride or graphite powder solid particle in the liquid dielectric organic solvent, proceeding ultrasonic dispersing disposal for suspension liquid, adding fitful addictive to reduce phase-transforming needed temperature and pressure, changing boundary energy condition between solid particle and liquid dielectric, accelerating the solid particle to change to needed material.

Owner:SHANDONG UNIV

Preparation method of large-size and fine-grain molybdenum tantalum alloy sputtering target material

ActiveCN105714253AEvenly distributedAvoid defectsVacuum evaporation coatingSputtering coatingSputteringLarge size

A preparation method of a large-size and fine-grain molybdenum tantalum alloy sputtering target material comprises steps of cold isostatic pressing molding through combination of a steel mold with a rubber plate, sintering, levelling and reshaping, hot isostatic pressing treatment, rolling and machining. The grain size of the produced target material is smaller than 50 microns, the change of the grain size is maintained within 20%, and grains are evenly distributed in the plane direction and the thickness direction of the target material; the relative density of the target material is higher than 97%; besides, the large-size sputtering target material with the length being about 2 m and the width being about 1.3 m can be produced.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

Production method of high-density long-life tungsten-molybdenum alloy crucible

ActiveCN105728708AGood flatnessWear reductionTransportation and packagingMetal-working apparatusDislocationCrystallite

The invention relates to a production method of a high-density long-life tungsten-molybdenum alloy crucible. The production method comprises the steps of preparing tungsten-molybdenum mixed powder, preparing powder blanks, lathing and machining the powder blanks, sintering, performing surface treatment, and then performing hot isostatic pressing. According to the production method, cold isostatic pressing, sintering treatment and the hot isostatic pressing are combined to treat the tungsten-molybdenum powder, so that the dislocation density in a product is high, and dislocations mutually intersect so as to form jogs, so that the intensity of the product is increased. Additionally, fibrous tissues of the blanks formed by the cold isostatic pressing are disconnected again and recrystallized by hot isostatic pressing molding, so that the conditions of tissue delamination, uneven grain distribution and uneven grain size are avoided, the obtained tissues are uniform, small and dense, and the service life is prolonged.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

Preparation method of high-performance graphite negative electrode material for lithium ion battery

InactiveCN105789627AEasy to processImprove cycle performanceCell electrodesSecondary cellsHigh rateMass ratio

The invention discloses a preparation method of a high-performance graphite negative electrode material for a lithium ion battery. The method comprises the following steps of 1) collecting petroleum coke micropowder in a shaper and a grinder in normal graphite production, and mixing the petroleum coke micropowder, ground expanded graphite powder, raw mesocarbon microbeads and an adhesive in a mixer for 0.5-3 hours according to a mass ratio of 1 to (0.01-0.3) to (0.7-1.5) to (0.1-0.2) to form a solid-phase coated mixture, wherein the frequency of the mixer is 30-50HZ; and 2) graphitizing the solid-phase coated mixture obtained in the step 1) to obtain the high-performance graphite negative electrode material for the lithium ion battery. The method is simple and feasible; micropowder wastes in a dust collector are recycled, so that the cost is reduced; the method is easy for large-scale industrial production; and the obtained graphite negative electrode material has the characteristics of high energy density, good liquid absorption and retention performance, good cycle performance, good isotropic performance, good high-rate charge / discharge performance and low expansion rate in a charge / discharge process.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

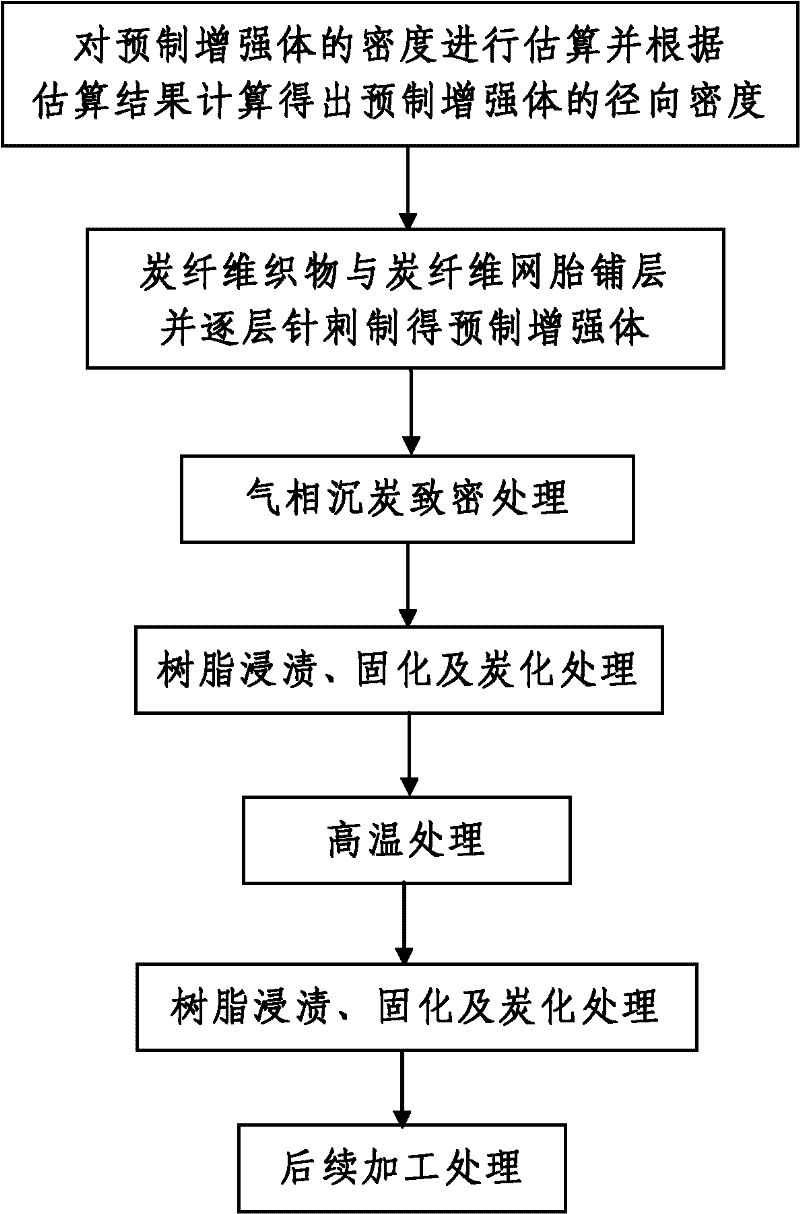

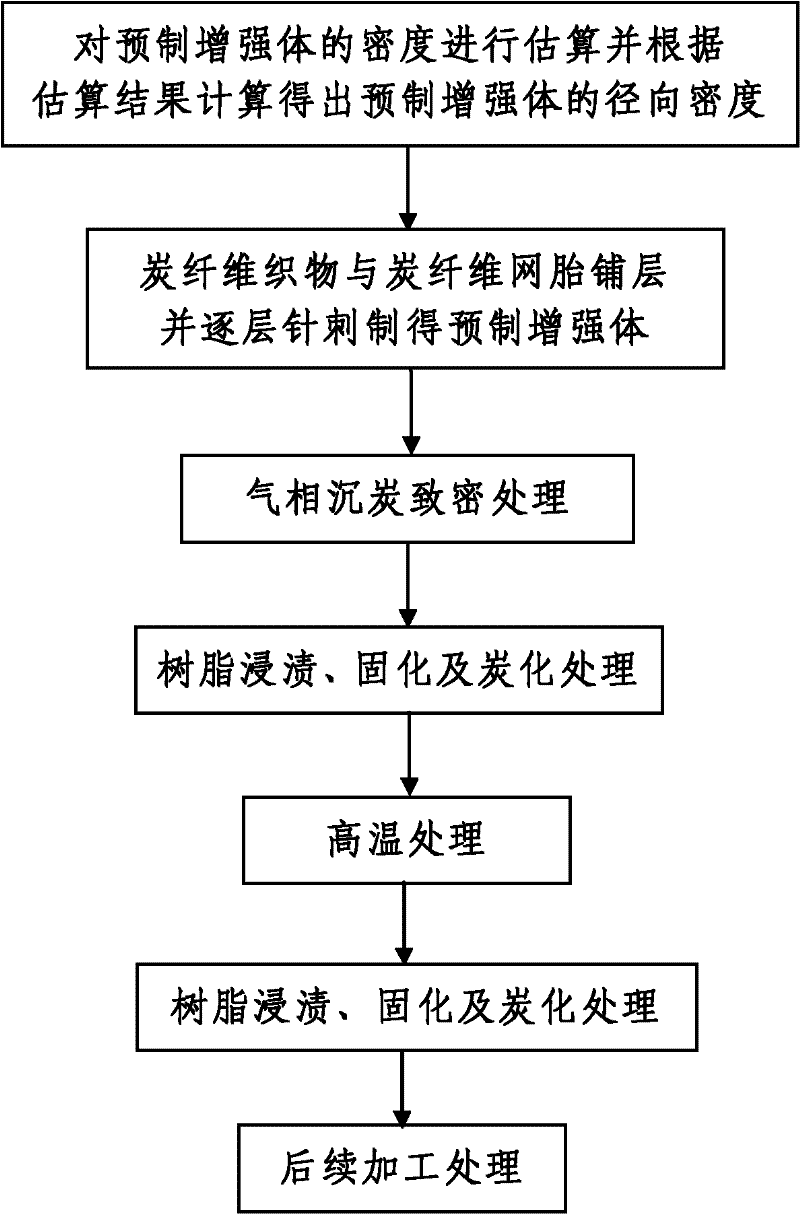

Preparation method of C/C composite tube of optical telescope

The invention discloses a preparation method of a C / C composite tube of an optical telescope. The method comprises the following steps: 1) carbon fiber fabrics and carbon fiber felts are spread layer by layer, needle-punching is performed on each layer to prepare a preformed reinforcement body, the density of the preformed reinforcement body is estimated before layer spreading and the radial density of the preformed reinforcement body is calculated according to the estimation result; 2) composite densifying is performed; 3) high temperature treatment is performed; and 4) the subsequent treatment is performed. The densifying process comprises the following steps: 201) performing gas-phase carbon-settling densifying treatment, namely using a gas-phase carbon-settling device to perform gas-phase carbon-settling treatment; and 202) performing resin impregnation, curing and carbonization treatment, namely performing further densifying treatment on the preformed reinforcement body after thegas-phase carbon-settling densifying treatment. The method has reasonable design, simple processing steps, low input cost, simpleness in operation and convenience in quality control; and the processed C / C composite tube has good performance, higher overall strength and stability and an ultralow thermal expansion coefficient.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Method for producing large-thickness lamination-crack-resistant tempered high-strength steel plate

The invention discloses a method for producing a large-thickness lamination-crack-resistant tempered high-strength steel plate. The method is characterized by comprising the steps: smelting, performing continuous casting, performing electroslag remelting, heating, rolling, annealing and performing heat treatment. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.18 percent of C, 0.20-0.50 percent of Si, 0.95-1.25 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.80-1.15 percent of Ni, 0.40-0.60 percent of Cr, 0.40-0.60 percent of Mo, 0.020-0.050 percent of Nb, 0.010-0.030 percent of Ti, 0.020-0.045 percent of TAl, and the balance of Fe and inevitable impurities. According to the method, electroslag remelting treatment is adopted, good overall performance of the large-thickness steel plate with the diameter of 30mm can be met due to the reasonable controlled rolling and heat treatment process, and the production cost is reduced; and the specification range is wide. The method adopts the steps of electric furnace smelting, continuous casting and electroslag remelting smelting, the contents of P and S in the obtained tempered high-strength steel plate are low, and the steel is pure; and moreover, a large-slab electroslag remelting technology is adopted, the round ingot hammer cogging process during electroslag remelting is reduced, the production period is shortened, and the cost is obviously reduced.

Owner:WUYANG IRON & STEEL

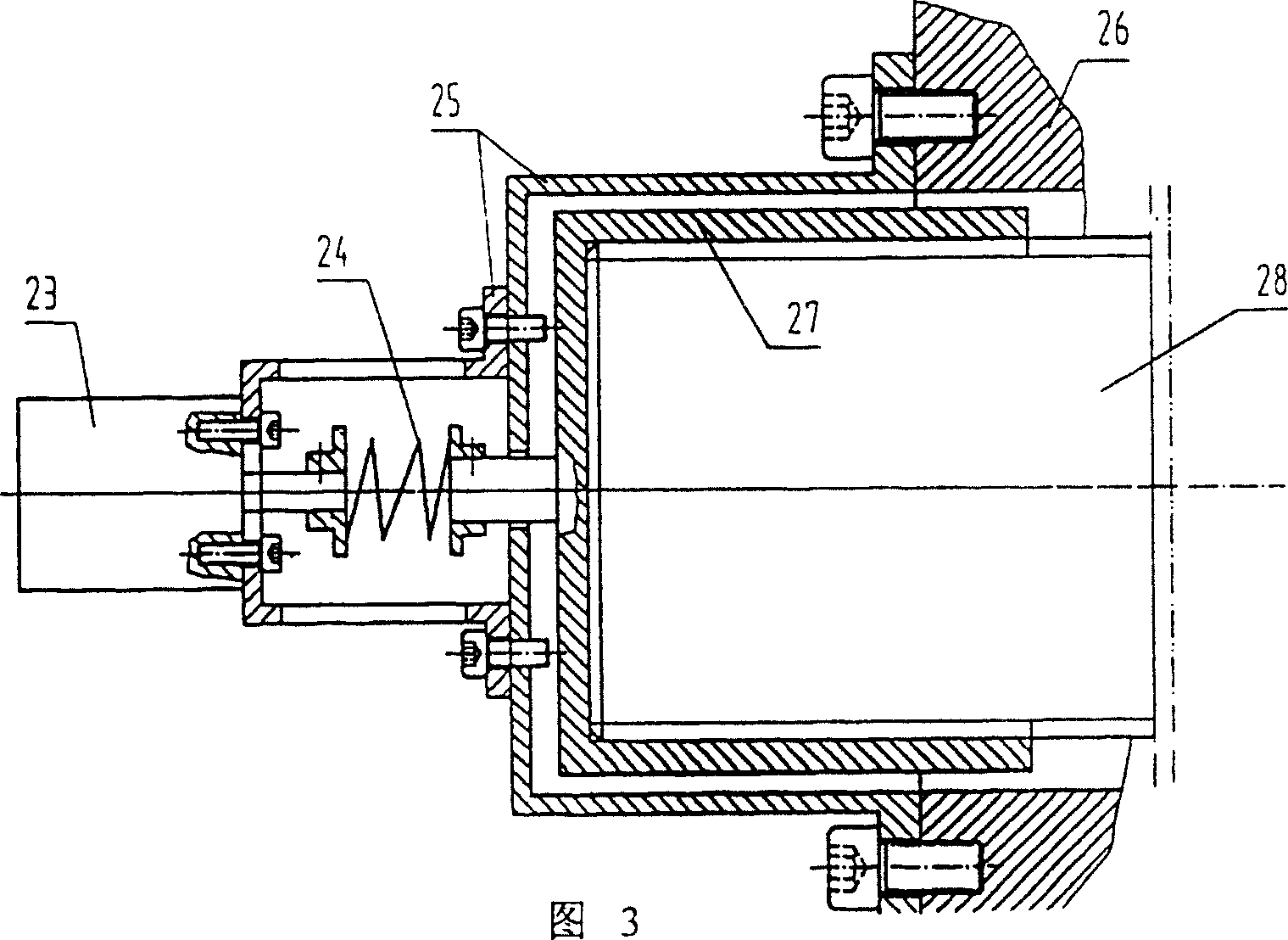

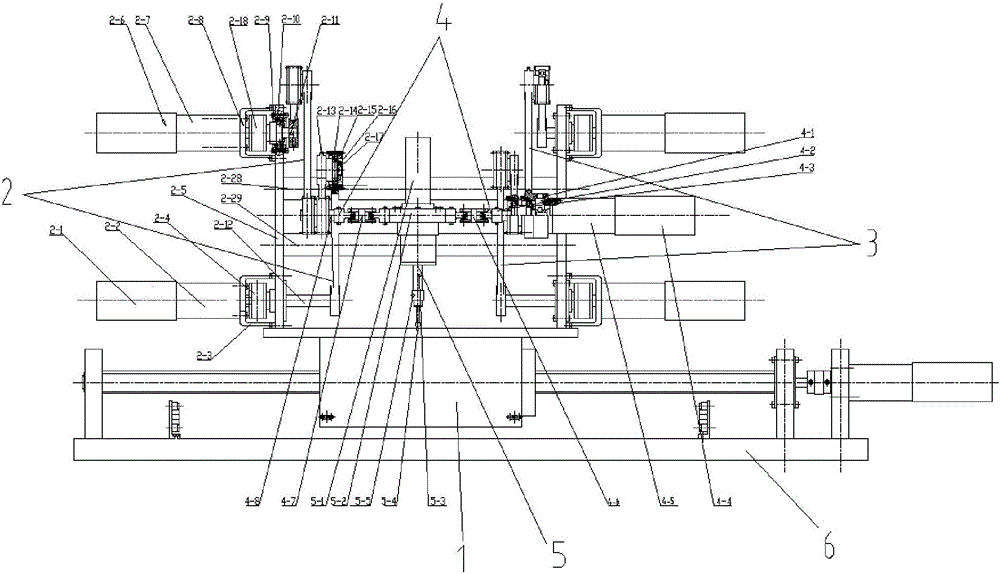

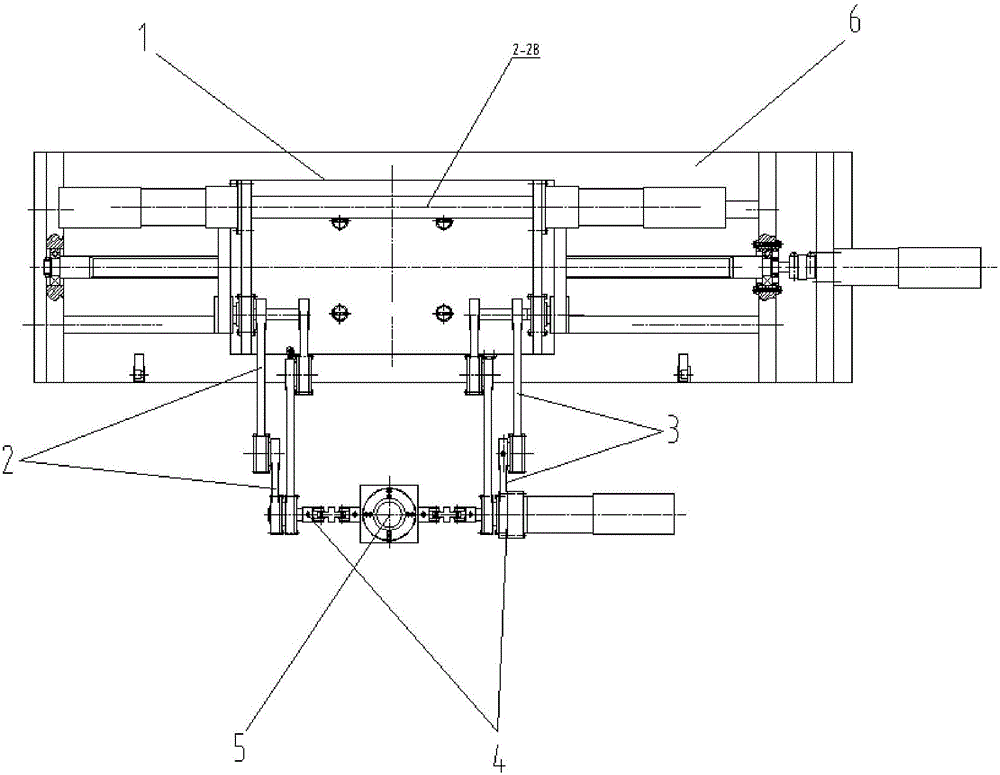

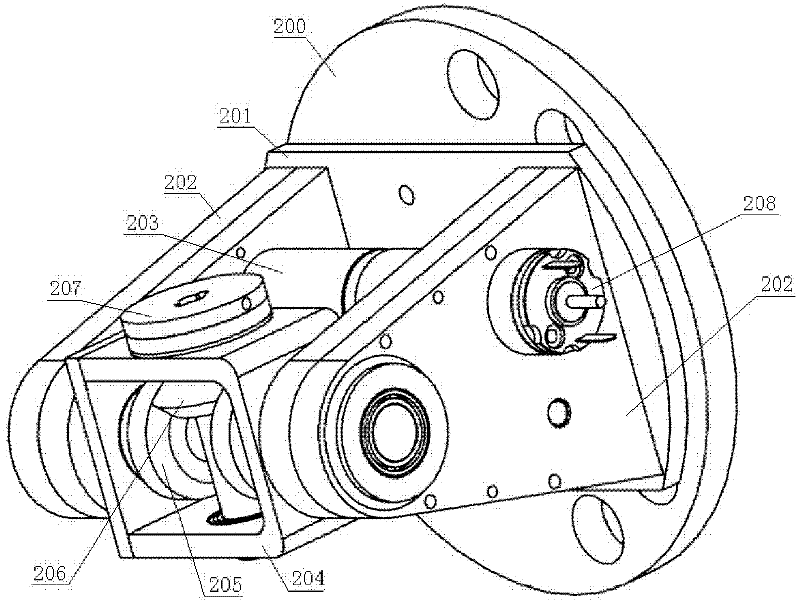

Orthopaedics operation robot

ActiveCN105662587ACompact structureGood dynamic responseSurgical robotsSurgical operationUniversal joint

The invention discloses an orthopaedics operation robot which structurally comprises six parts including a pedestal, a moving platform, two symmetrical five-linkage mechanisms, a polishing and drilling attitude adjustment mechanism and a polishing and drilling part, wherein the pedestal drives the moving platform to do rectilinear motion in the horizontal direction by virtue of a main component, that is, a screw sliding table; the two five-linkage mechanisms are connected in parallel with the polishing and drilling attitude adjustment mechanism; the polishing and drilling attitude adjustment mechanism and the polishing and drilling part are mounted on universal joints by virtue of a polishing and drilling fixed seat, are connected with the five-linkage mechanisms via shafts, and are driven by an independent EC motor, so that the polishing and drilling part has a front-and-back swing degree of freedom to meet the requirement of high-precision accurate execution of various complex actions. The orthopaedics operation robot is high in precision, flexible to operate, and high in isotropy, has no accumulative errors, and is especially suitable for drilling and polishing in a bone surgical operation.

Owner:SHANDONG UNIV OF SCI & TECH

Eight-degree-of-freedom series-parallel combined automatic welding robot

InactiveCN102357879AImprove carrying capacityHigh control precisionProgramme-controlled manipulatorDrive motorSix degrees of freedom

The invention discloses an eight-degree-of-freedom series-parallel combined automatic welding robot, which consists of two parts of a six-degree-of-freedom parallel robot and a double-degree-of-freedom direction regulation mechanism which are connected in series through a movable platform to form the eight-degree-of-freedom series-parallel combined robot, wherein the six-degree-of-freedom parallel robot comprises a base, the movable platform and a mechanical leg which is arranged between the base and the movable platform, and the two ends of the mechanical leg are respectively hinged with the base and the movable platform; the double-degree-of-freedom direction regulation mechanism is installed on a mechanism static platform, the mechanism static platform is designed in consistence with the movable platform and is connected with the movable platform in series, the double-degree-of-freedom direction regulation mechanism is driven with a linear drive mode, a connection plate is arranged on the mechanism static platform, two direction drive motors are installed on a box body of the mechanism static platform on the connection plate, and are connected with a connection part of a welding output mechanism in a linear drive transmission way. The eight-degree-of-freedom series-parallel combined automatic welding robot has higher bearing capacity and control precision, the movement space of the parallel robot is prevented from being limited, and the welding performance with higher quality is further improved.

Owner:北京华巍中兴电气有限公司

Anti-impact flexible protective composite material based on shear thickening adhesive and preparation method thereof

InactiveCN110091562AImprove isotropic performanceImprove mechanical propertiesNon-macromolecular adhesive additivesProtective equipmentAdhesiveDiluent

The invention discloses an anti-impact flexible protective composite material based on a shear thickening adhesive, and a preparation method of the composite material comprises the following steps of:(1) preparing the shear thickening adhesive; (2) preparing a shear thickening adhesive diluent and a fixed shape shear thickening adhesive; (3) preparing a shear thickening adhesive composite flexible protective fabric; and (4) placing the fixed shape shear thickening adhesive obtained in the step (2) into an interlayer of two layers of the shear thickening adhesive composite flexible protectivefabric obtained in the step (3) or interlayers of multiple layers of the shear thickening adhesive composite flexible protective fabric obtained in the step (3), and sewing and fixing the periphery ofthe interlayers to obtain the flexible protective composite material. The anti-impact flexible protective composite material not only maintains good flexibility but also has excellent antistatic property and impact resistance.

Owner:JIANGNAN UNIV

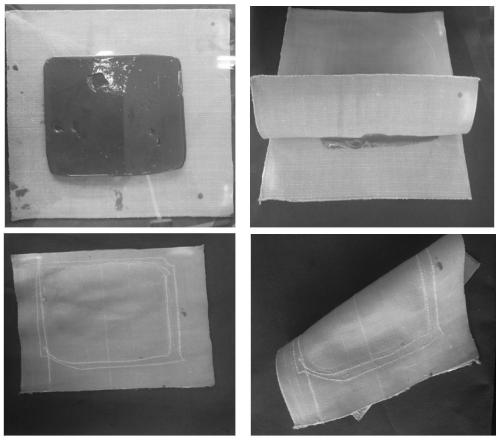

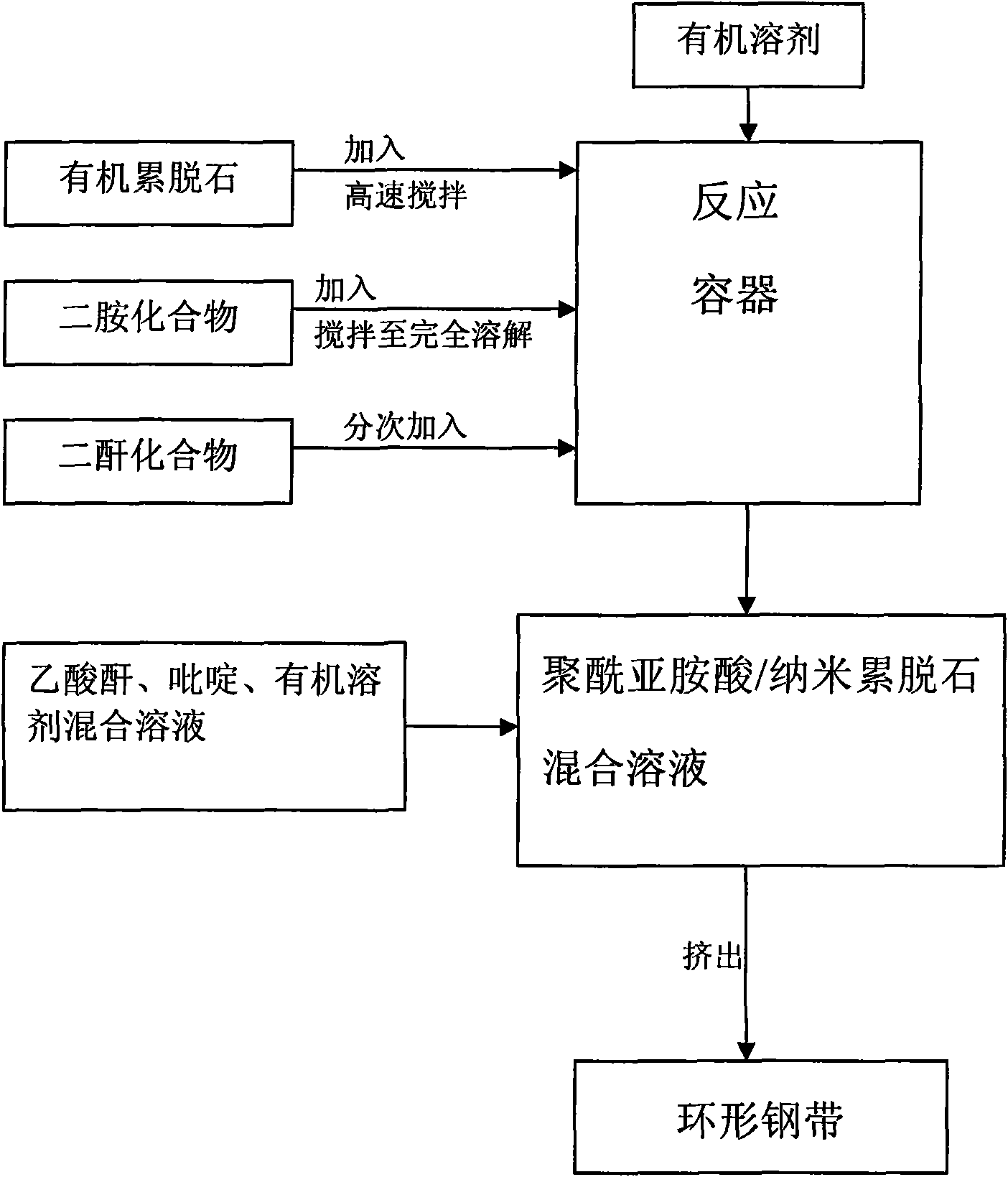

Chemical imidization preparation method of nano rectorite/polyimide film

The invention relates to a chemical imidization preparation method of nano rectorite / polyimide film. A binary surface modifying agent is adopted for organic modifying on rectorite, and the prepared organic rectorite has wider interlamination region and better dissociation effect and is easier to form polyimide / nano rectorite intercalation compound; in-situ polymerization is adopted for adding the organic rectorite, so as to cause the organic rectorite to be more evenly dispersed in polyimide acid; and chemical imidization is used for preparing polyimide nano composite material, so that film forming performance thereof is better. The nano rectorite / polyimide compound film prepared by the invention is improved in thermal stability and size stability with low thermal expansion coefficient.

Owner:西安航天三沃化学有限公司

High-tenacity crack-resistant grouting cement mortar and preparing method thereof

ActiveCN105621990AImproves microscopic stress-strain performanceGood mechanical propertiesEpoxyCrack resistance

The invention belongs to the field of cement mortar preparing, and particularly relates to high-tenacity crack-resistant grouting cement mortar and a preparing method thereof. The mortar comprises 80-100 parts of cement, 120-180 parts of 50-200-mesh silver sand, 20-50 parts of water, 5-10 parts of polyurethane solutions, 5-10 parts of epoxy resin emulsion, 10-15 parts of toughening composite materials, 1.5-6 parts of early strength agent, 2-9 parts of methacrylic acid, 2-6 parts of calcium formate, 2-8 parts of neopentyl glycol, 0.2-0.8 part of sodium dodecyl benzene sulfonate and 0.9-2.4 parts of water reducing agent. As toughening composite materials are added into the cement mortar, whole concrete has good tenacity, good isotropy and good fatigue resistance, the crack resistance of the grouting mortar is better facilitated, tenacity is improved, and the later-period maintenance cost of engineering is reduced.

Owner:福建省东霖建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com