Coarsening laser processing system and method for surface of roller with circumferential irregular coarsening dots

A laser processing and textured point technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of irregular distribution of textured points that cannot be processed on the surface of rollers, and achieve good appearance quality and good orientation. same-sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

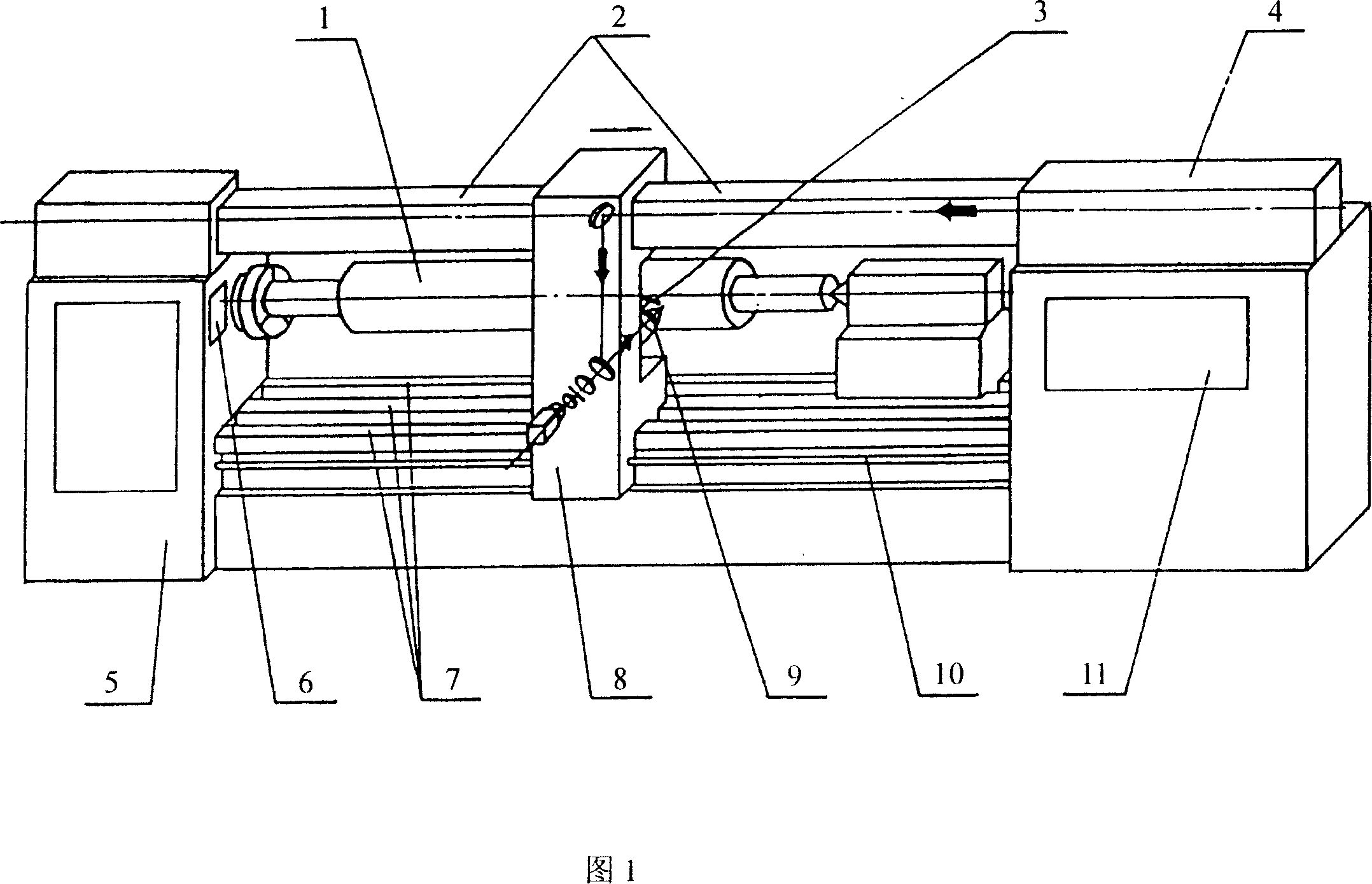

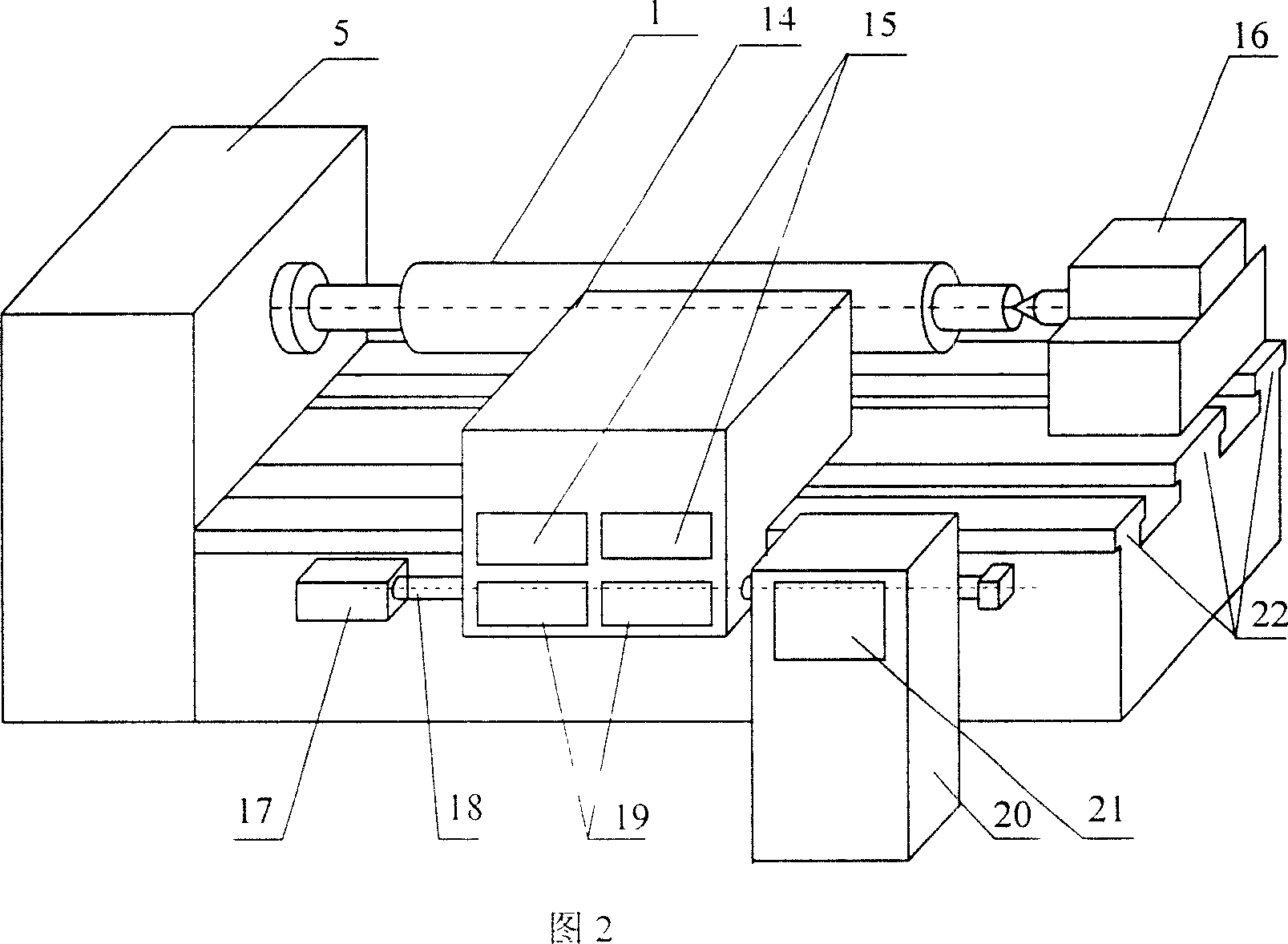

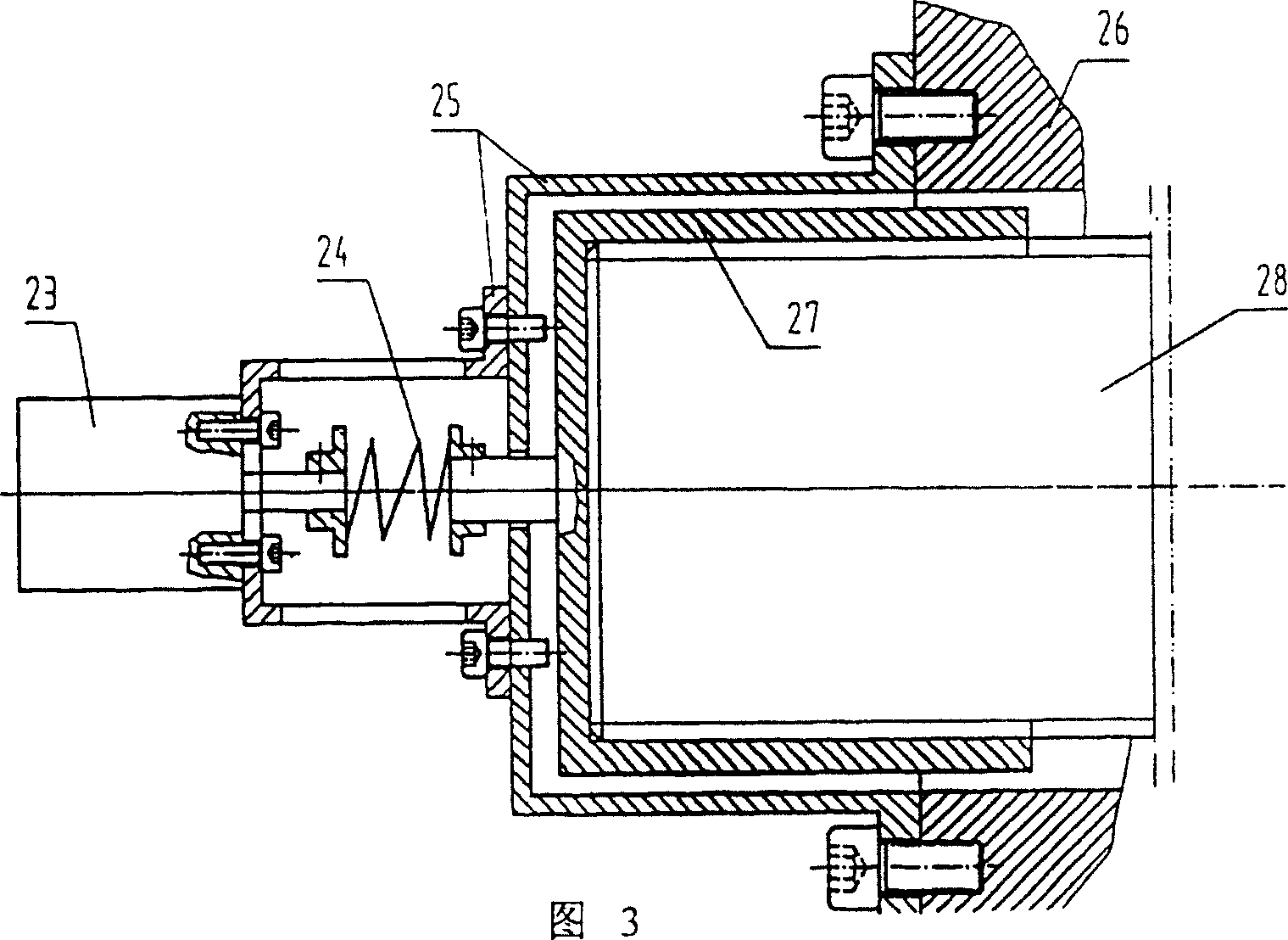

[0030] In order to realize the random distribution of laser texturing, the scheme proposed in this embodiment is shown in Fig. 2, Fig. 3, Fig. 7 and Fig. 11 . The texture processing of the irregular texture points on the surface of the roller is realized by a pseudo-random delay device and a pseudo-random deflection device. That is to say, in the controllable distribution laser texturing equipment, a device whose control amount changes according to a pseudo-random signal is added to make the texturing points randomly distributed. Therefore, this equipment is also called a roller surface texturing laser processing system with controllable random distribution of texturing points.

[0031] The overall structural schematic diagram of this embodiment is the same as that shown in Figure 2. The equipment consists of three parts: the head of the machine tool, the bed of the machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com