High-pore controllable three-dimensional through hole foam molybdenum and preparation method thereof

A high-porosity, three-dimensional technology, applied in the field of porous metal materials, can solve the problems of foaming agent segregation, affecting the uniformity and connectivity of pores, and affecting material properties, etc., to achieve high porosity, good isotropy, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

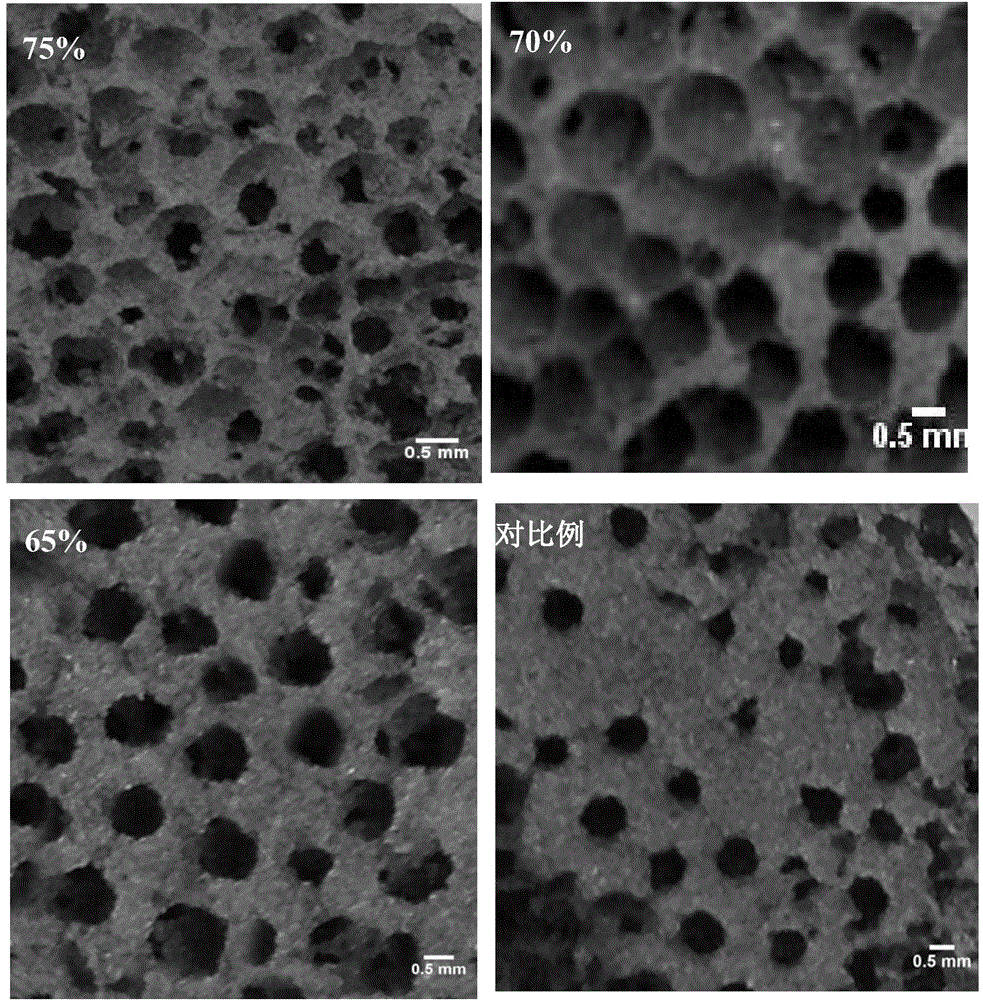

[0032] Preparation of molybdenum with a porosity of 75%

[0033] Step 1) Weighing. According to the required porosity and each layer of molybdenum powder and urea mass relationship formula, the required mass of each layer of molybdenum powder is 0.392g, and the required mass of urea is 0.154g. Divide 74μm molybdenum powder into 0.392g each, and urea into 0.154g each.

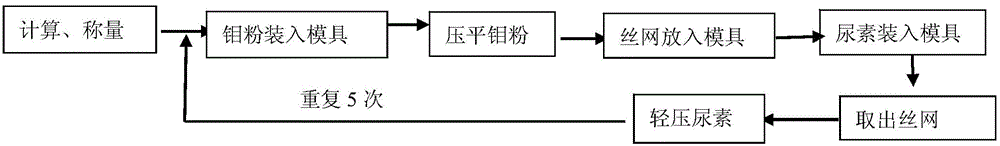

[0034] Step 2) charging. Put 1 part of molybdenum powder weighed in step 1 into the mold, flatten the molybdenum powder with a pressure rod, put it into the wire mesh, then introduce 1 part of urea into the mold, then put the wire mesh into the mold, pour the weighed urea, pull out the metal mesh and lightly press the urea with a pressure rod, so that the urea particles are rearranged and evenly embedded between the molybdenum powders (see figure 1 ). Repeat the above charging process 5 times.

[0035] Step 3) Compression. The mold that has been charged in step 2 is pressed into a billet at 300 MPa on a hy...

Embodiment 2

[0039] Preparation: Prepare molybdenum with a porosity of 70%

[0040] According to the required porosity and each layer of molybdenum powder and urea mass relationship formula, the required mass of each layer of molybdenum powder is 0.471g, and the required mass of urea is 0.143g. The molybdenum powder of 74μm is divided into 0.471g each, and the urea is divided into 0.143g each. All the other steps are the same as in Example 1.

Embodiment 3

[0042] Preparation: Preparation of molybdenum with a porosity of 65%

[0043] According to the required porosity and each layer of molybdenum powder and urea mass relationship formula, the required mass of each layer of molybdenum powder is 0.55g, and the required mass of urea is 0.133g. Divide 74μm molybdenum powder into 0.55g each, and urea into 0.133g each. All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com