Six- free-degree 3-3 orthogonal type parallel robot

A degree of freedom and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as high manufacturing maintenance costs, environmental pollution, and large dynamic response delays, and achieve pollution-free maintenance costs and good dynamic response characteristics. good isotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are described in detail below: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

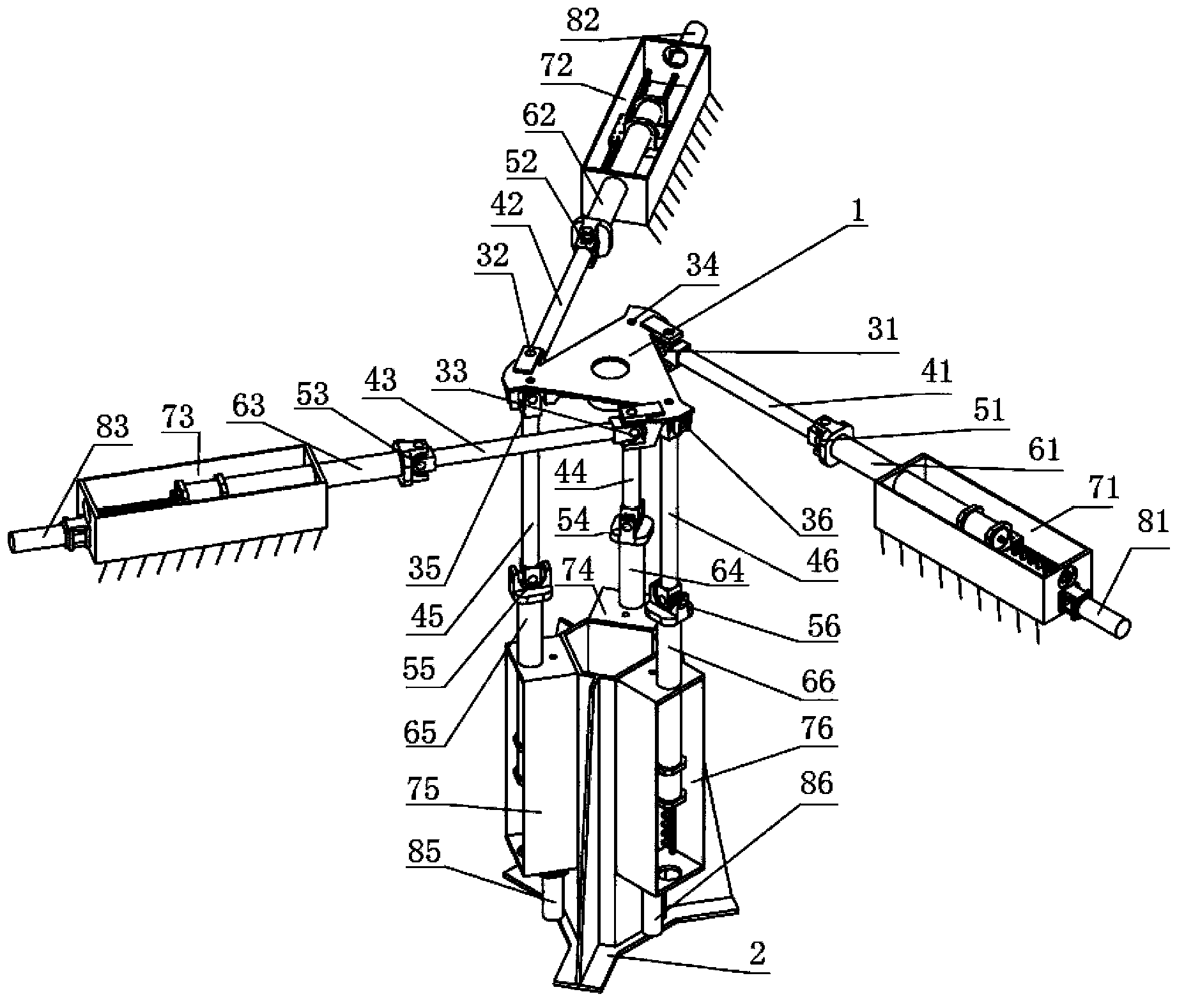

[0033] Such as figure 1 As shown, the present embodiment provides a six-degree-of-freedom 3-3 orthogonal type parallel robot, including a moving platform, a fixed frame, and a mechanical device that is arranged between the moving platform and the fixed frame and connects the moving platform and the fixed frame. A branch chain group, the mechanical branch chain group includes six mechanical branch chains in a 3-3 orthogonal arrangement.

[0034] Further, each of the mechanical branch chains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com