Novel inorganic thermal protection structure and manufacturing method thereof

A thermal protection structure and manufacturing method technology, applied in the direction of chemical instruments and methods, fuselage insulation, lamination, etc., can solve the problems affecting the normal operation of the equipment in the cabin that affect the structural strength of the projectile, and achieve a simple and fast molding method with average density Low, strengthen the effect of heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

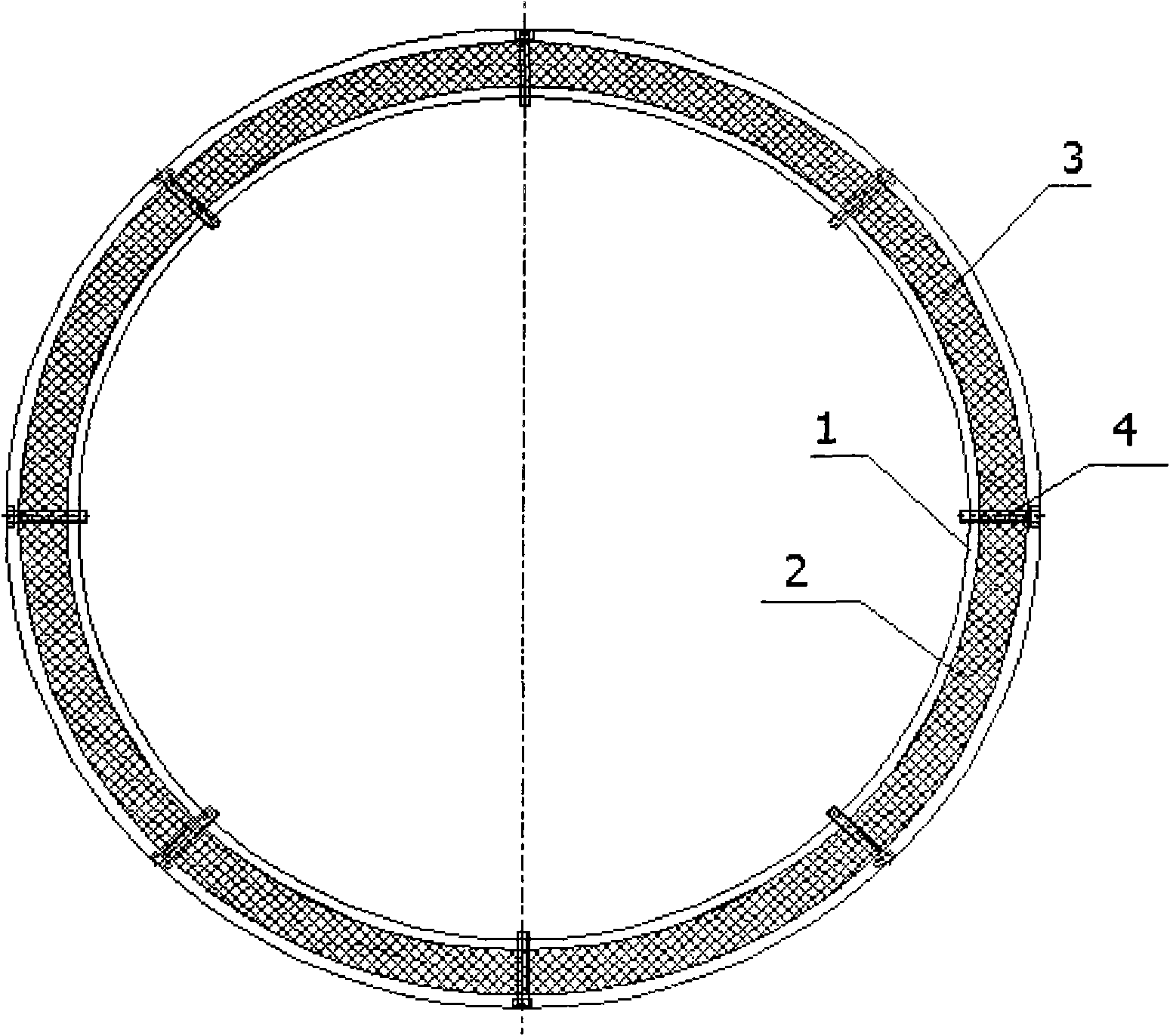

[0038] Embodiment 1: A new inorganic thermal protection structure cabin heat protection test piece, the steps are:

[0039] 1. Production of heat-proof layer:

[0040] a) Prepare silicon nitride powder.

[0041] b) Compression: The powder is compressed and formed with a mold.

[0042] c) Isostatic pressing: performing isostatic pressing on the billet, performing isostatic pressing on the billet, and controlling the pressure to 150MPa±10MPa.

[0043] d) Sintering: Carry out sintering molding according to the sintering temperature of 1800°C±30°C.

[0044] e) Grinding: Grinding to size, the thickness of the silicon nitride heat-resistant layer is 4mm.

[0045] 2. Production of insulation layer:

[0046] a) Aluminum alloy substrate treatment: cleaning with acetone, roughening by sandblasting.

[0047] b) Glue coating: coat a thin layer of silicone rubber adhesive on the surface of the treated aluminum alloy.

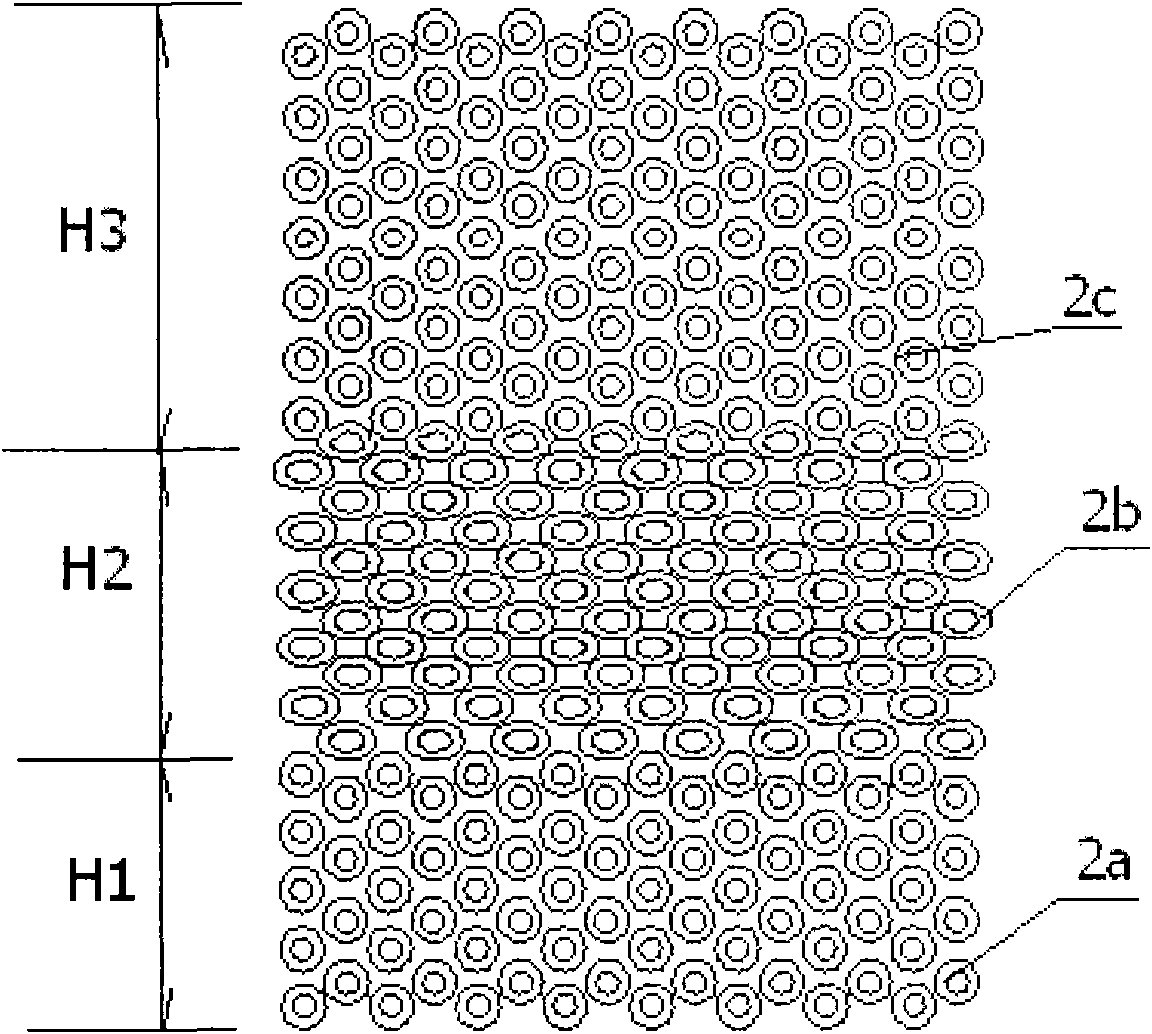

[0048] c) winding forming:

[0049] According to Al 2 o 3 , SiO ...

Embodiment 2

[0061] Example 2 The cabin heat protection test piece 2, the thickness of the heat protection layer is 2 mm, and the thickness of the heat insulation layer is 42 mm. The steps are:

[0062] 1. Production of heat-proof layer

[0063] a) Prepare silicon nitride powder.

[0064] b) Compression: The powder is compressed and formed with a mold.

[0065] c) Isostatic pressing. The blank is subjected to isostatic pressing, and the pressure is controlled at 150MPa±10MPa.

[0066] d) Sintering: Carry out sintering molding according to the sintering temperature of 1800°C±30°C.

[0067] e) Grinding: According to the size of the aluminum alloy substrate, the grinding process is carried out to the required size.

[0068] 2. Production of heat insulation layer

[0069] a) Surface treatment of aluminum alloy compartment: cleaning with acetone, roughening by sandblasting.

[0070] b) Glue application: coat a thin layer of silicone rubber adhesive on the surface of the treated aluminum a...

Embodiment 3

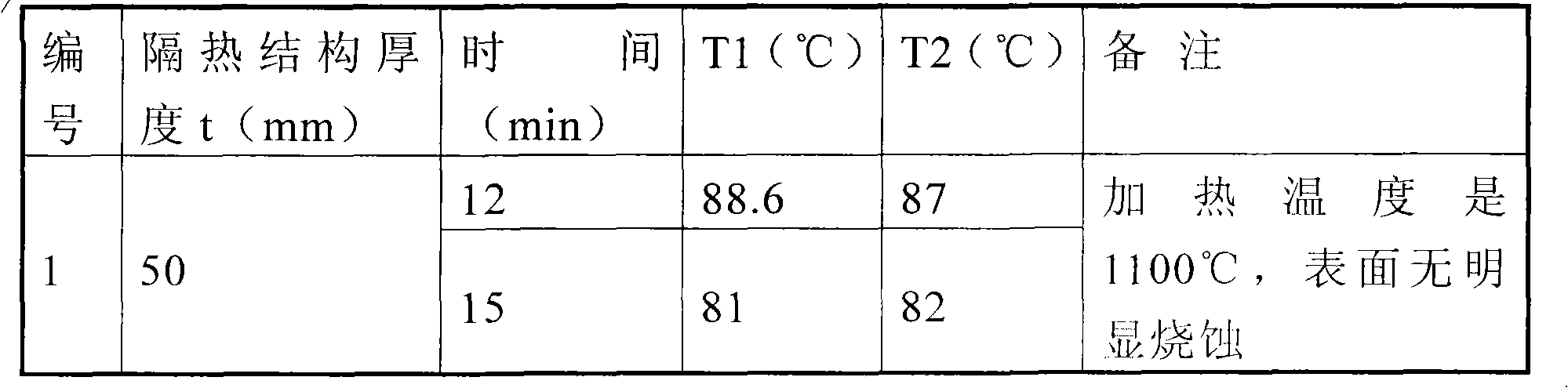

[0083] Example 3: Experiments were carried out with different thicknesses, different spacings and different winding parameters. The thickness of the inner circumferential winding layer was 1-4mm; the thickness of the middle spiral winding layer was 20-35mm; the thickness of the outer circumferential winding layer was 5-20mm; the middle spiral winding The layer helix angle is about 70°~85°, and the casing spacing is 1~4mm. details as following:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com