Patents

Literature

86results about How to "Improve thermophysical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

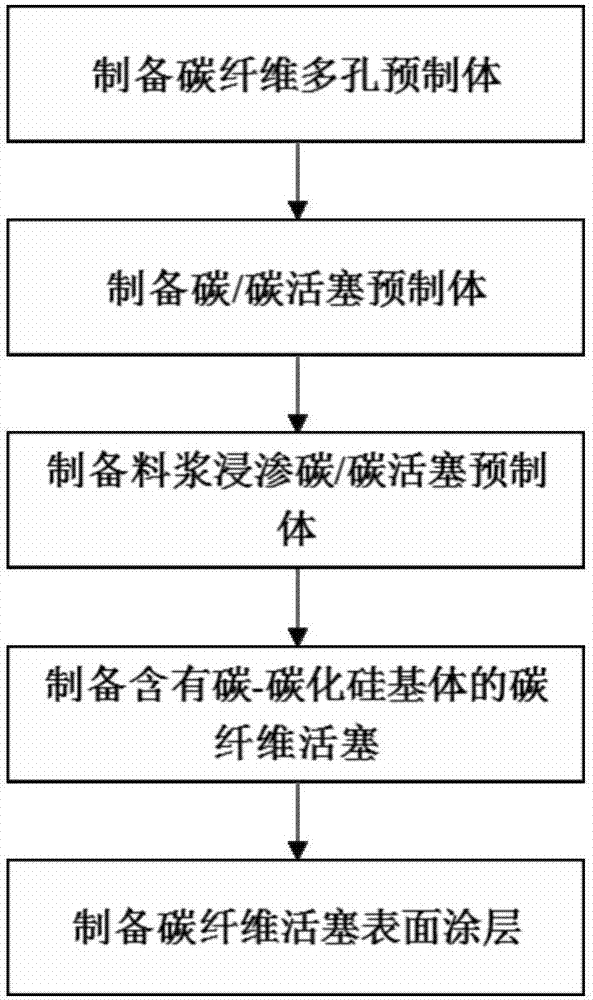

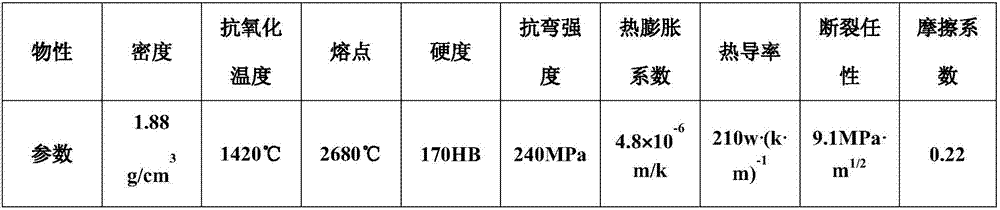

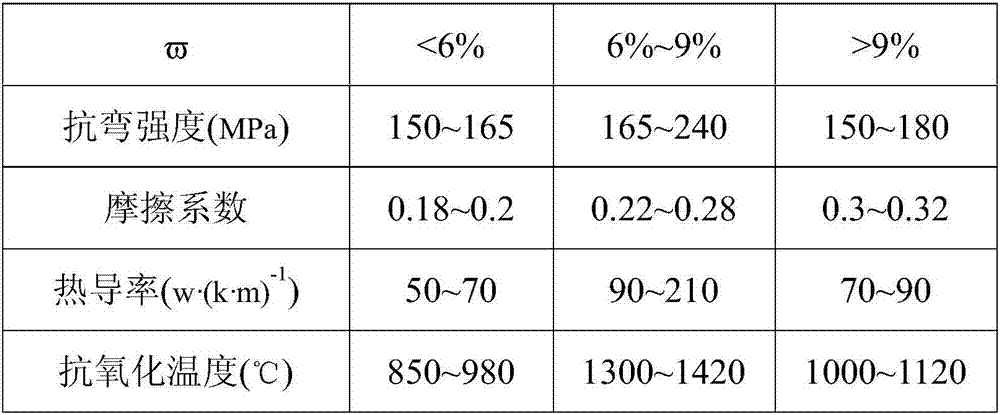

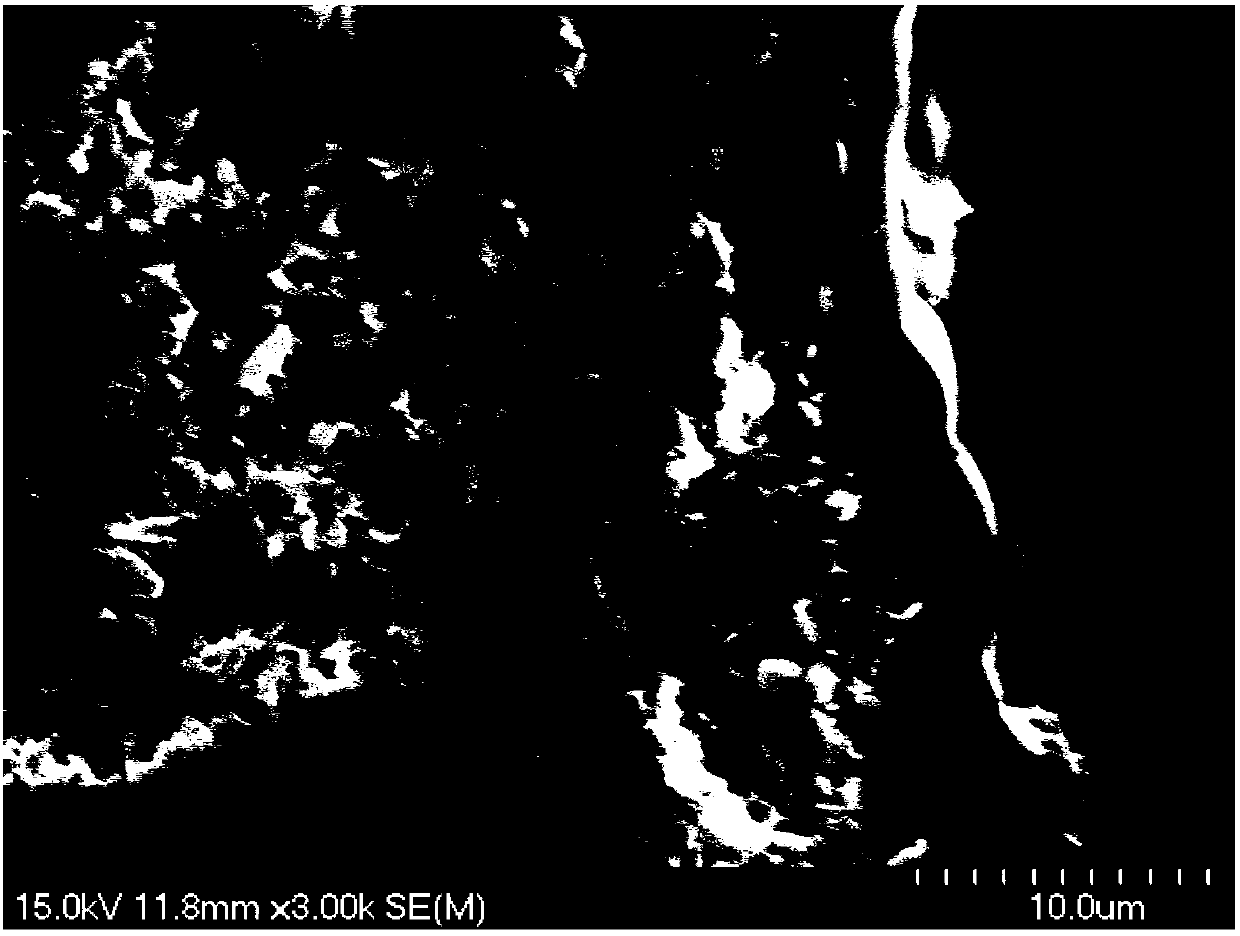

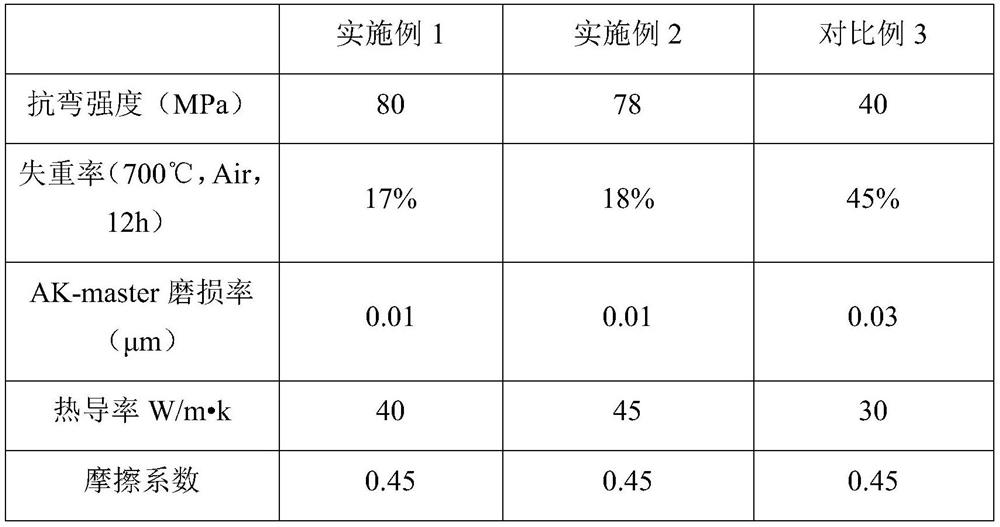

Cf/C-SiC composite material as well as preparation method and application thereof

The invention designs a composite material. The composite material comprises carbon-fiber perform, matrix carbon, filler and diamond-like carbon, wherein the matrix carbon is uniformly adhered on the carbon fiber of the perform to form the carbon-fiber perform with the matrix carbon; the filler fills the inside of the carbon-fiber perform with the matrix carbon and coats the outside of the carbon-fiber perform with the matrix carbon to form a semifinished product; the diamond-like carbon comprises a diamond-like carbon layer coated on the semifinished product; and the filler contains a Ti element, a Si element, a C element and a Mo element. The composite material has the advantages that a method of combining four processes of CVI, SI, RMI and PECVD to prepare a finished product with the advantages of high compactness, low thermal expansion coefficient and friction coefficient, high self-lubricating property, high thermal conductivity, oxidation resistance, thermal shock resistance, ablation resistance, wear resistance, high strength and toughness and the like; and simultaneously, the process is simple, the preparation period is short, the equipment requirement is low, the cost is low, net shaping can be realized and convenience is brought for large-scale industrial application.

Owner:XIANGTAN UNIV

High-temperature-resistant high-strength tough silicon nitride based wave-transparent composite material and preparation method thereof

ActiveCN107698271AEasy to processHigh forming precisionRadiating element housingsCeramicwareGas phaseBoron nitride

The invention relates to a high-temperature-resistant high-strength tough silicon nitride based wave-transparent composite material and a preparation method thereof. The preparation method comprises the following steps: preparing a porous Si3N4 whisker biscuit through gel casting, and performing drying and rubber discharging to obtain a porous Si3N4 preform; and preparing a boron nitride (BN) interface in the whisker preform through a chemical vapor infiltration (CVI) process, and preparing a multilayer alternate BN / Si3N4 matrix through the CVI process. In accordance with the design requirements for the structure and performance of a high-temperature wave-transparent antenna housing, the microstructure of each layer, the number of layers and the layer thickness of the multilayer alternateBN / Si3N4 matrix are regulated and controlled through CVI regulation and control to realize the regulation, control and optimization of the structure and performance of the composite material, therebyobtaining the high-temperature-resistant high-strength high-toughness Si3N4 based wave-transparent composite material which realizes broadband wave transmission and has excellent thermophysical properties.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

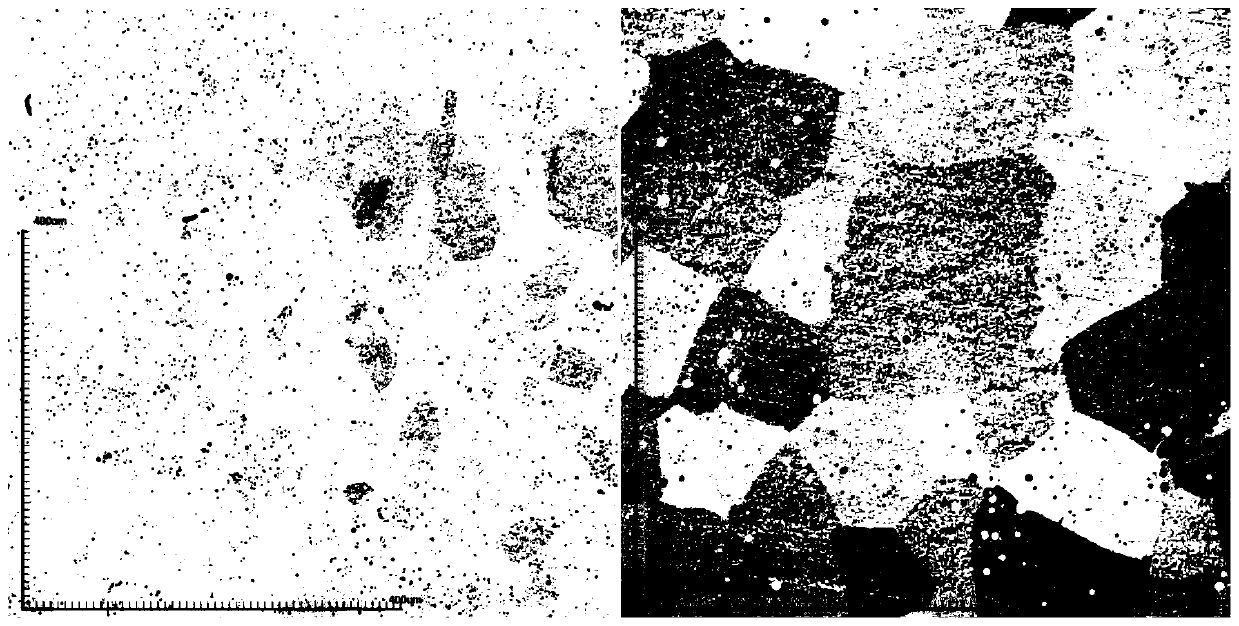

Preparation technology of UO2-graphene composite fuel

ActiveCN107342110AEvenly dispersedEvenly distributedNuclear energy generationReactors manufactureNuclear reactor coreNuclear reactor

The invention belongs to the field of preparation of nuclear reactor fuels, and provides a preparation technology of a UO2-graphene composite fuel pellet in order to solve the problems of uneven physical mixing, low production efficiency and high production cost existing in existing preparation technologies of a UO2-graphene composite fuel and low density of fuels prepared through other sintering technologies. The technology mainly comprises the following steps: 1, synthesizing UH3 powder; 2, synthesizing a uranyl nitrate solution; 3, synthesizing (NH4)2U2O7-graphene composite powder; 4, synthesizing UO2-graphene composite powder; 5, mixing the UO2-graphene composite powder with the UH3 powder; 6, carrying out cold press molding to form a green body of the fuel pellet; and 7, carrying out pressureless sintering to form the fuel pellet. The technology adopting a chemical method has the advantages of high production efficiency and low cost, and solves the problems of uneven elements and low density of the composite fuel, the relative density of the prepared composite fuel is about 95%, and the composite fuel has excellent thermophysical performances.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

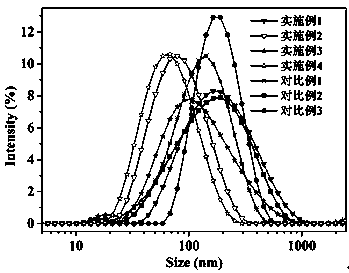

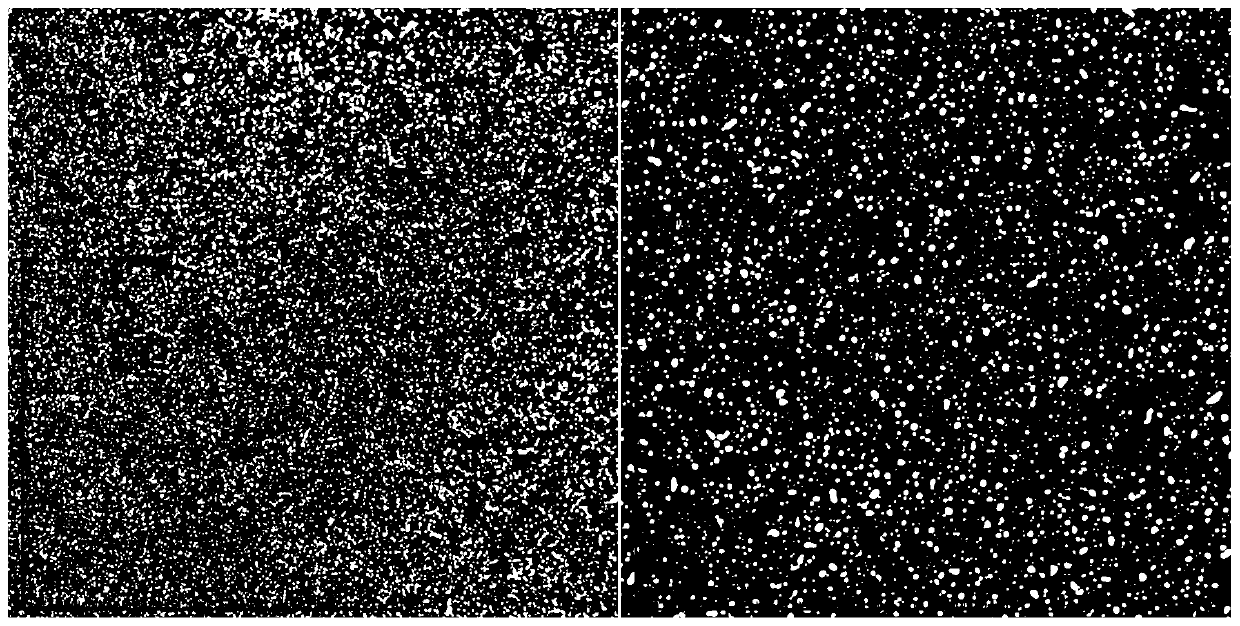

Nanometer uranium dioxide and preparation method of composite material powder thereof

ActiveCN108298587ALow priceSimple manufacturing methodMaterial nanotechnologyNuclear energy generationNuclear powerCarbon nanotube

The invention discloses nanometer UO2 used for the preparation of a novel nuclear fuel pellet and a preparation method of compound powder thereof. According to the nanometer UO2 and compound powder thereof (including but not limited to nanometer UO2 powder, nanometer UO2 / SiC, nanometer UO2 / carbon nanotubes, nanometer UO2 / graphene, nanometer UO2 / nanometer diamond composite material powder) preparedand obtained by adopting a hydrothermal method or a precipitation method, the prepared and obtained powder can serve as a raw material for preparing the novel nuclear fuel pellet in a nuclear power station, and has the characteristics of high melting point, high heat conduction, good anti-radiation performance, high fission gas accommodating capacity and excellent mechanical property.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

High-strength high-silicon aluminum alloy containing trace rare earth and preparation method thereof and application

The invention relates to a high-strength high-silicon aluminum alloy containing trace rare earth and a preparation method thereof and an application, and belongs to the technical field of functional materials. The alloy involved in the invention is prepared from, by mass percent, 48.0-52.0% of silicon, 0.1-0.9% of rare earth X, and the rest of aluminum, wherein X is Sc or Zr. According to the invention, a billet is prepared by using an ultrasound atomizing spraying sedimentation method, and then the deposited billet is compacted and thermally treated, the obtained silicon aluminum alloy tissue is uniform and free from hole; the compaction degree is 99.9% above, the silicon grain is round and fine, and its size is less than 10 miu m. The composite material designed in the invention has outstanding physical performance, low manufacturing cost, and is applicable to the large-scale industrial production.

Owner:长沙博朗思达金属材料有限公司

Method for manufacturing high-alumina-quality high-temperature crucible pot

The invention provides a method for preparing a high alumina heat resistant crucible, relating to a method for preparing the high alumina ceramic crucible which is applied to experiment manufacturing processes such as the high temperature sintering and high temperature chemical synthesis. The method is characterized by comprising the following steps that: raw materials of alumyte grog refractory, alpha-Al2O3, Suzhou clay, carborundum, cooked pencil stone, zirconite, an appropriate amount of a caking agent of Arabian gum dry powder are subject to matching, grinding and watering to prepare slurry; after the casting process, the proximate matter is dried and calcined so that the high alumina heat resistant crucible is prepared. The high alumina heat resistant crucible has good chemical stability, good thermal physics properties such as the heat-resistant stability and the quake-resistance stability, long service life and easy popularization in industry.

Owner:中铝矿业有限公司 +1

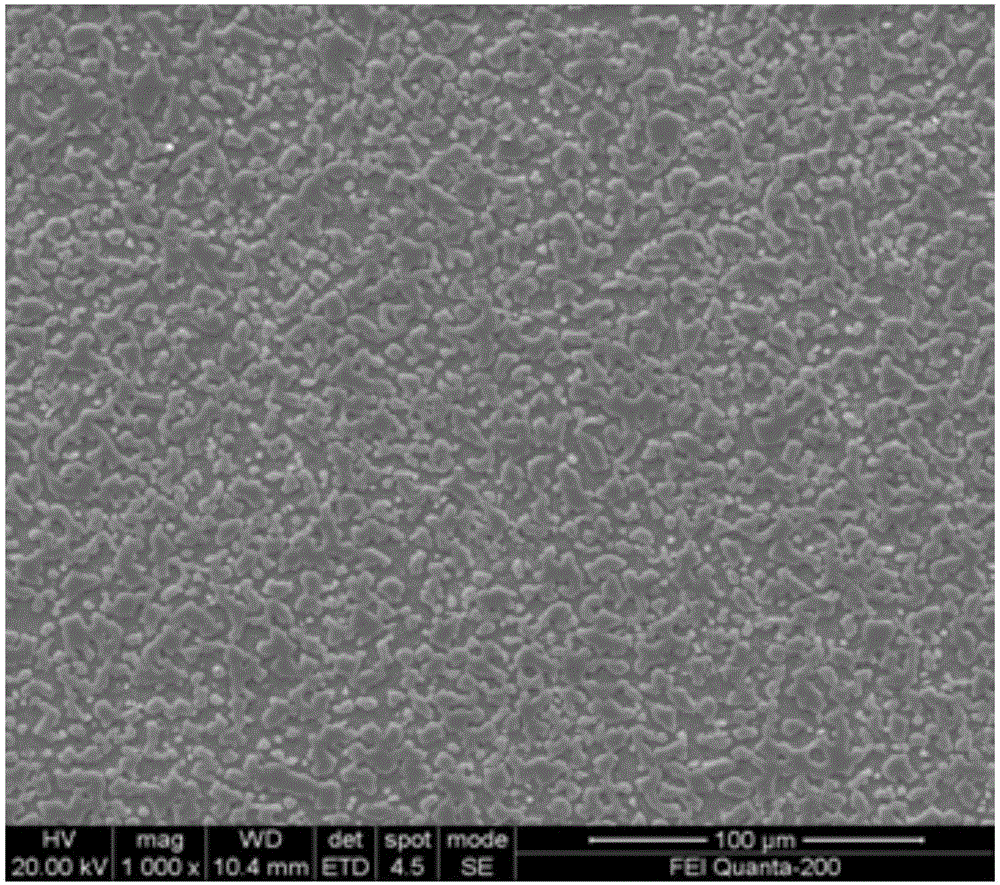

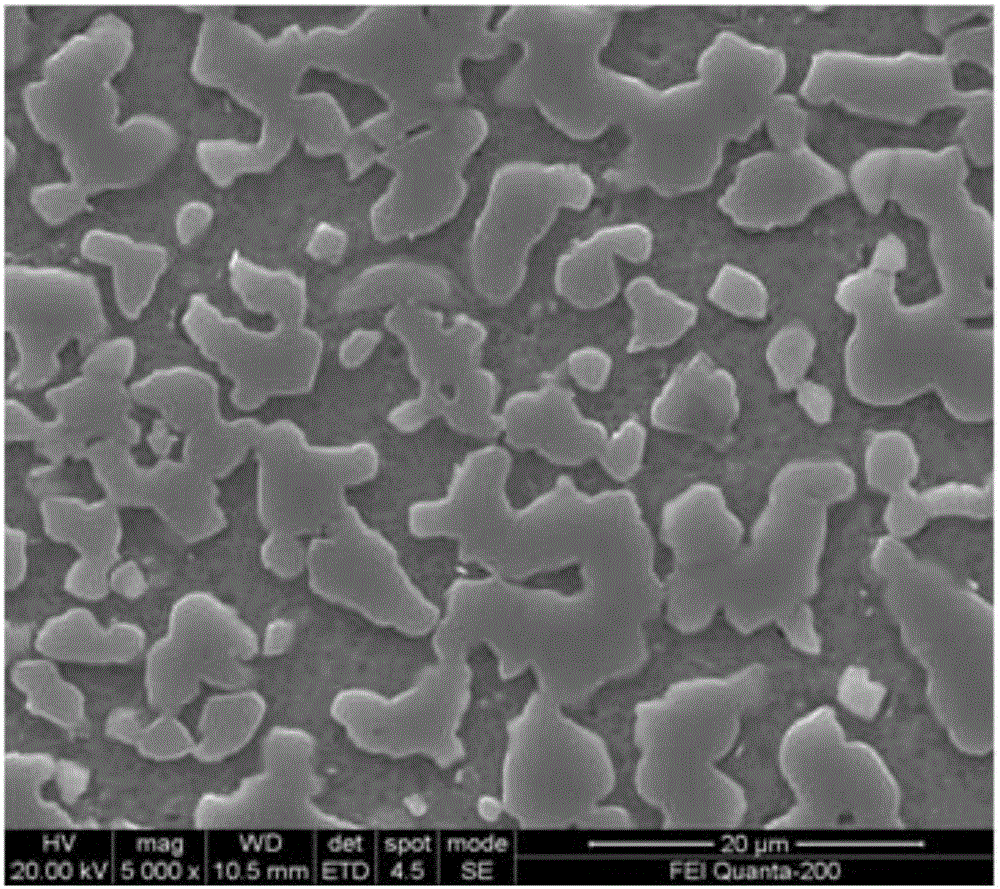

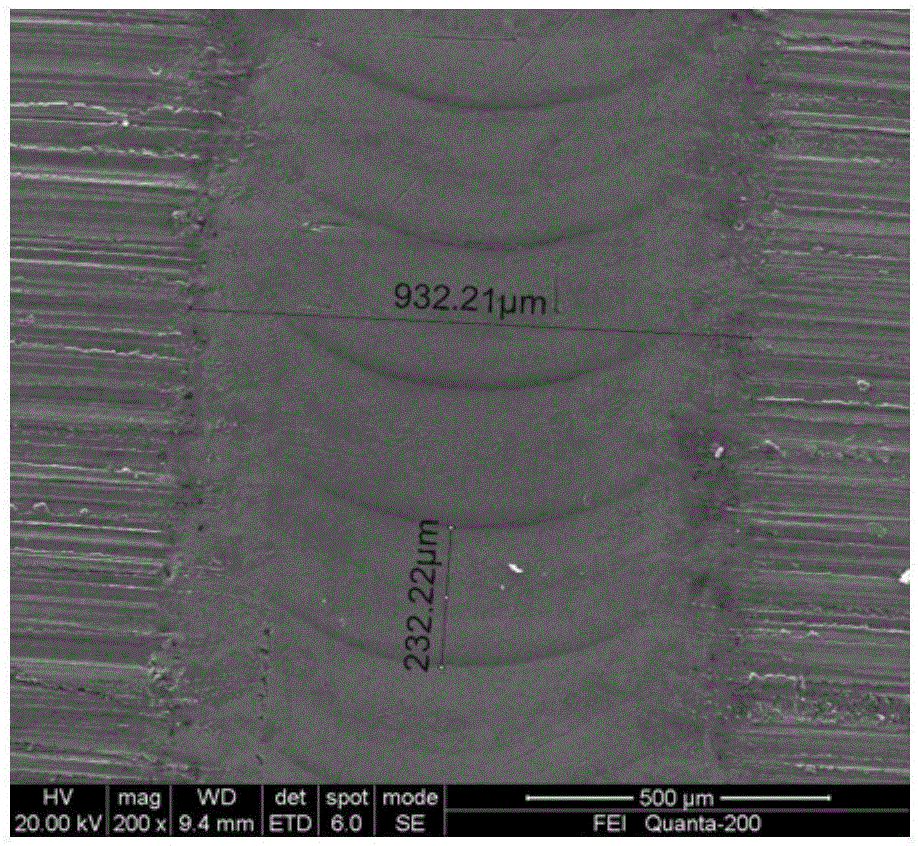

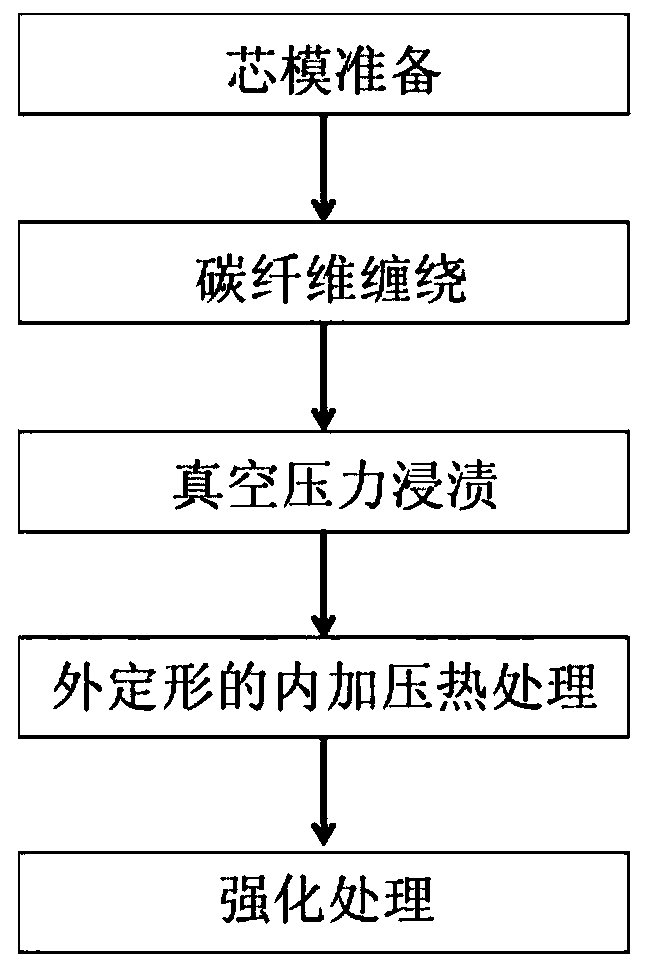

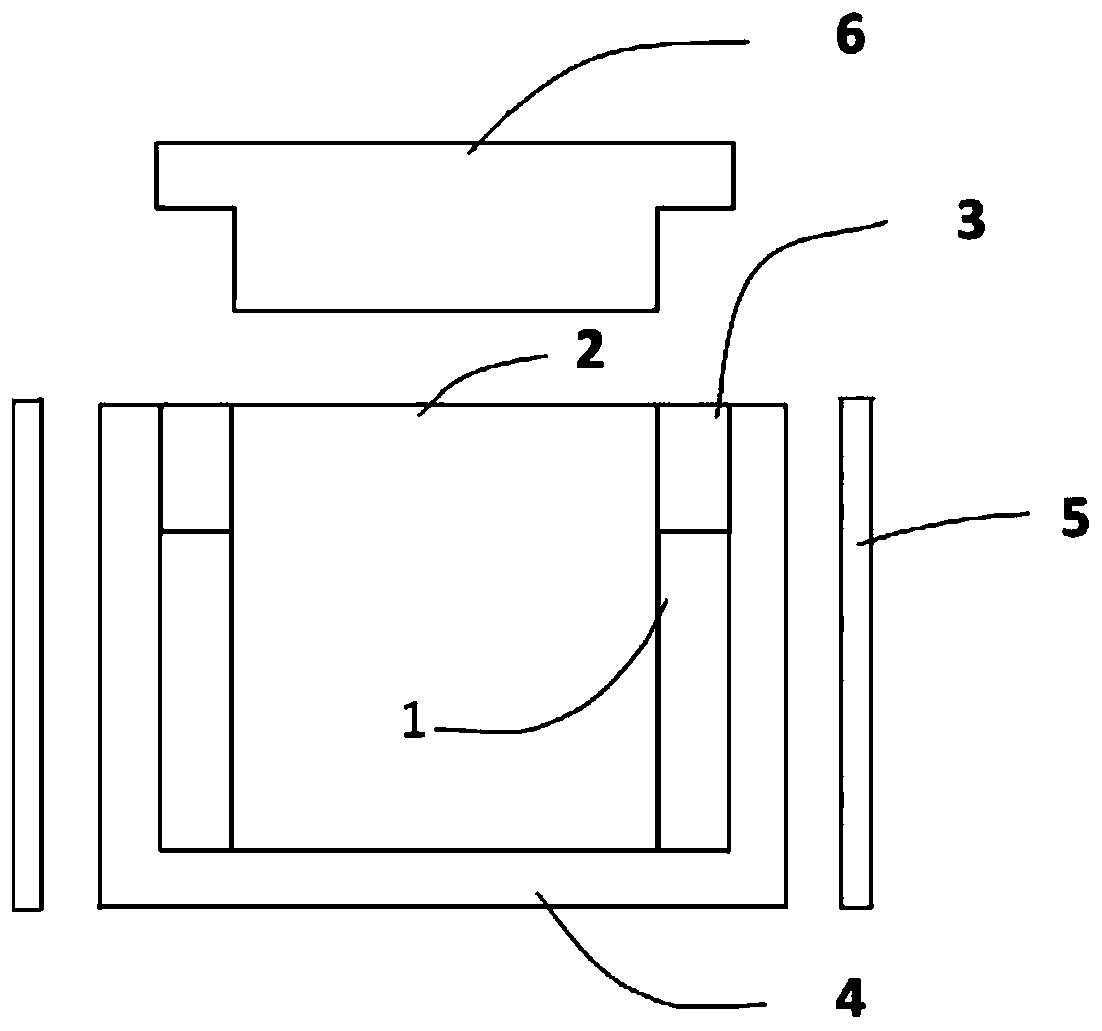

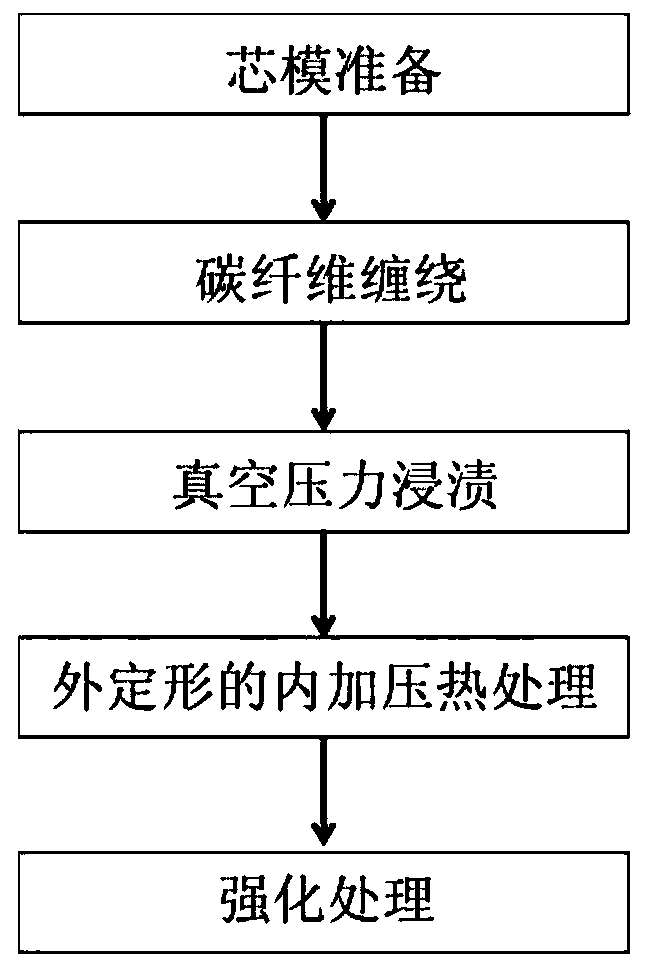

Preparation method of revolved body type carbon/carbon composite material

The invention discloses a preparation method of a revolved body type carbon / carbon composite material. The method comprises the following steps: 1, cleaning a core mold, paving demolding cloth in thecore mold, and brushing the demolding cloth with a release agent; 2, winding continuous carbon fibers on the core mold coated with the release agent to form a wound part; 3, carrying out vacuum pressure impregnation on the wound part, performing demolding, and carrying out machining treatment to obtain an impregnated part; 4, applying a shaping tool to the outer surface of the impregnated part, and carrying out internal-pressurization heat treatment to obtain a green body of the revolved body type carbon / carbon composite material; and 5, strengthening the revolved body type carbon / carbon composite material blank to obtain the revolved body type carbon / carbon composite material. The thickness of the target composite material is achieved by introducing asphalt and adopting an external-shaping internal-pressurization heat treatment process and strengthening treatment; the volume content of carbon fibers in the revolved body type carbon / carbon composite material is increased, the performance of the revolved body type carbon / carbon composite material is improved, a densification period is shortened, and the preparation efficiency of the revolved body type carbon / carbon composite material is improved.

Owner:XIAN CHAOMA SCI TECH

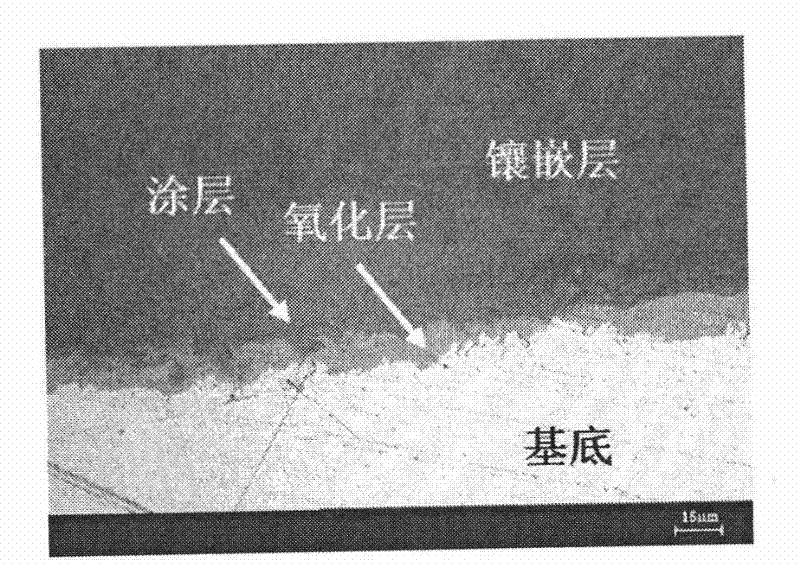

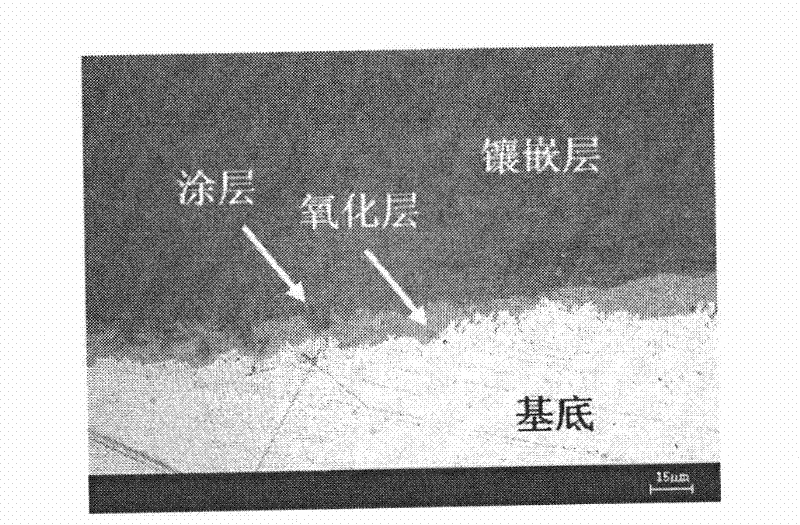

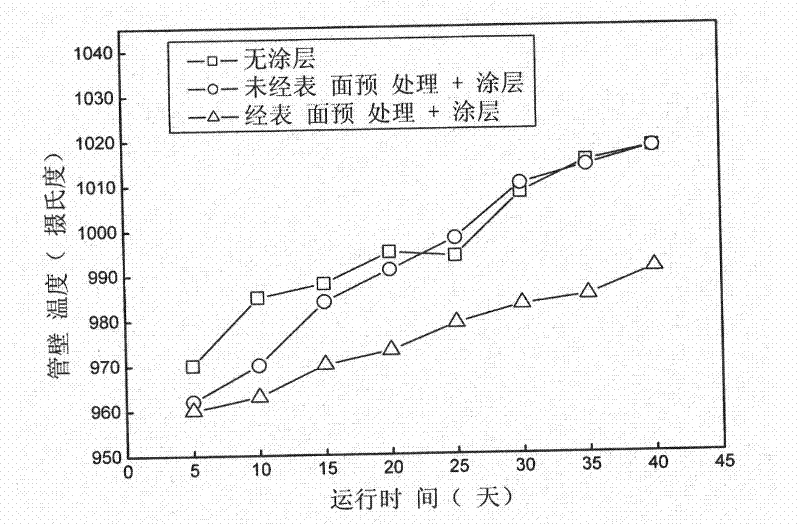

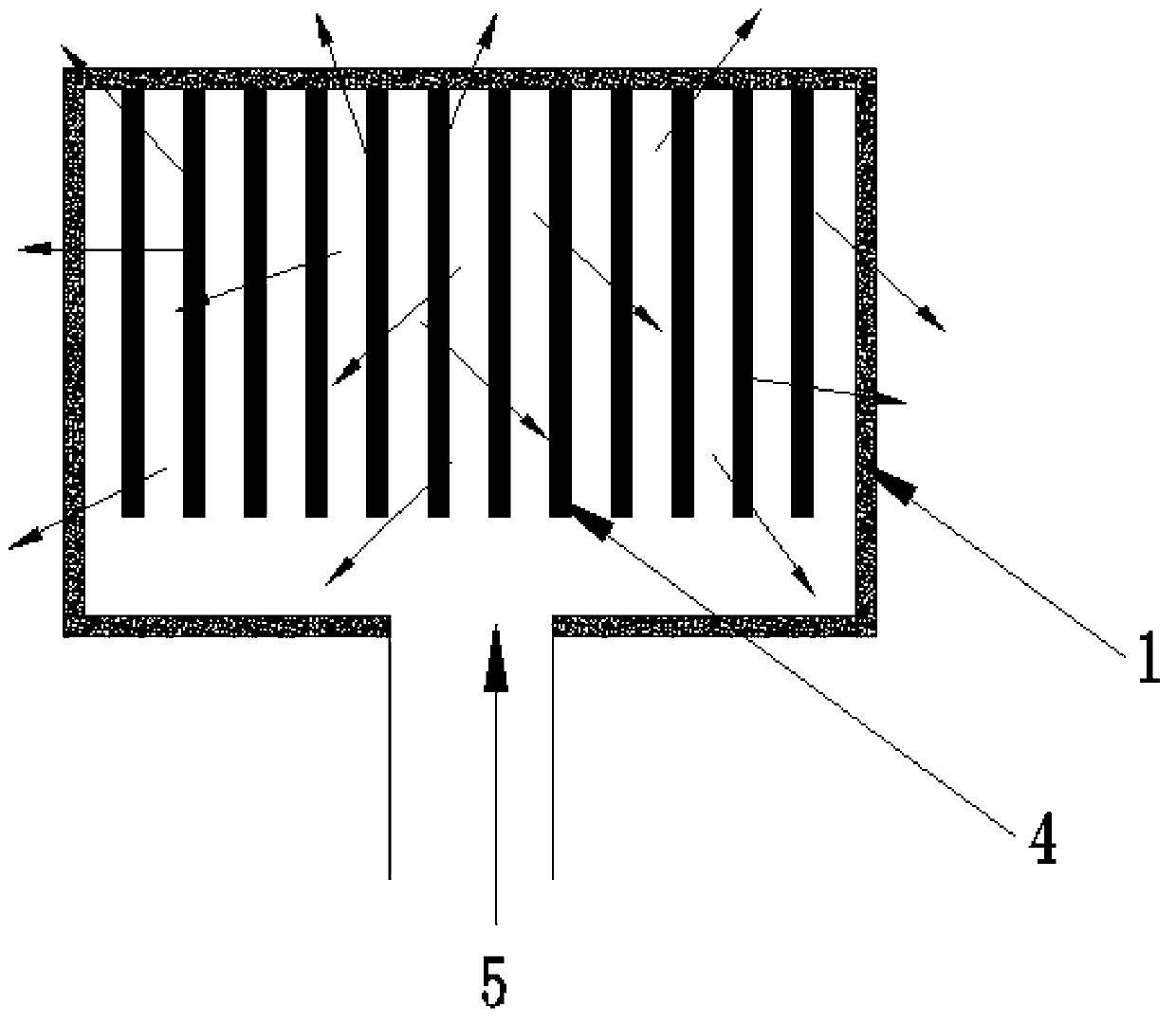

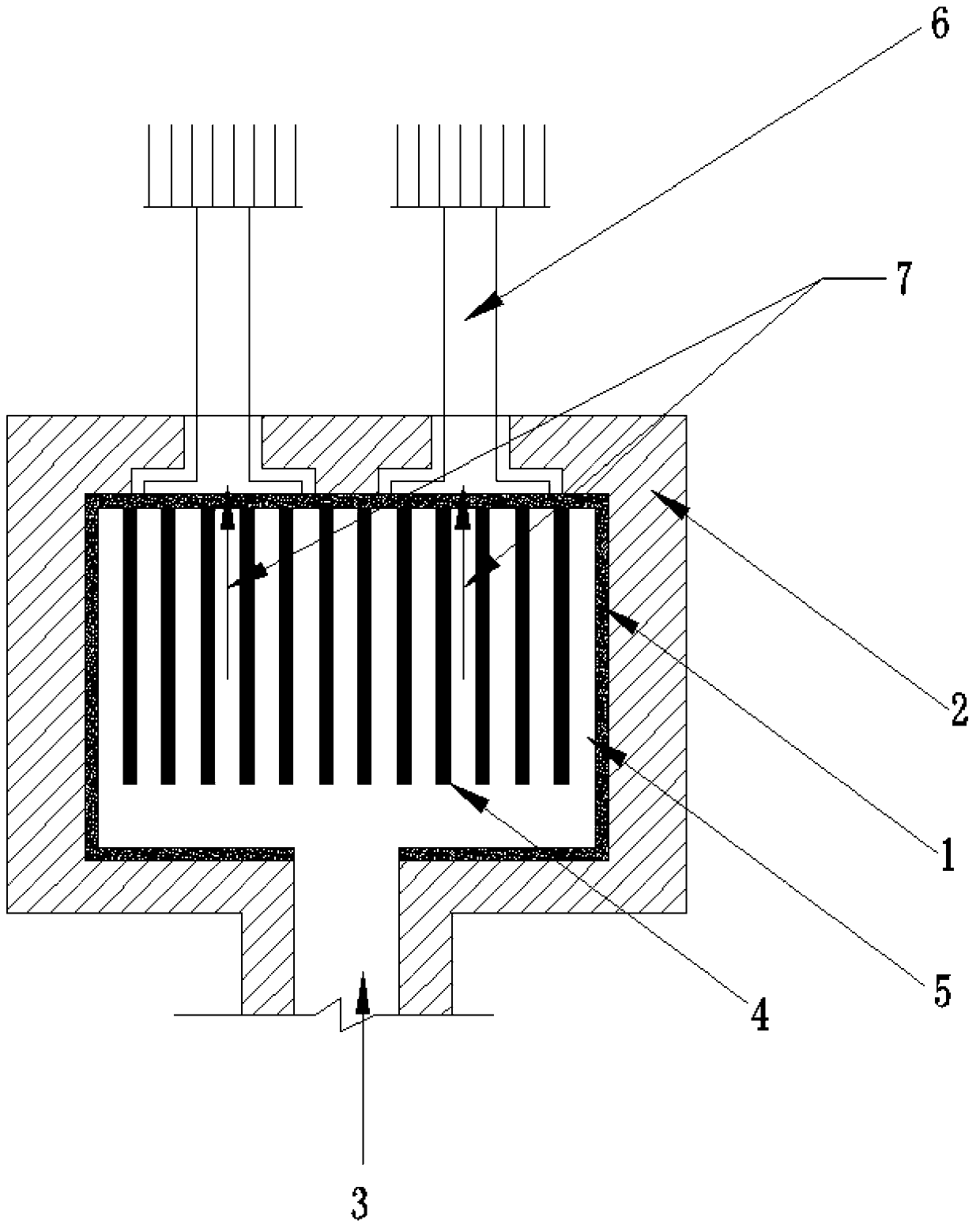

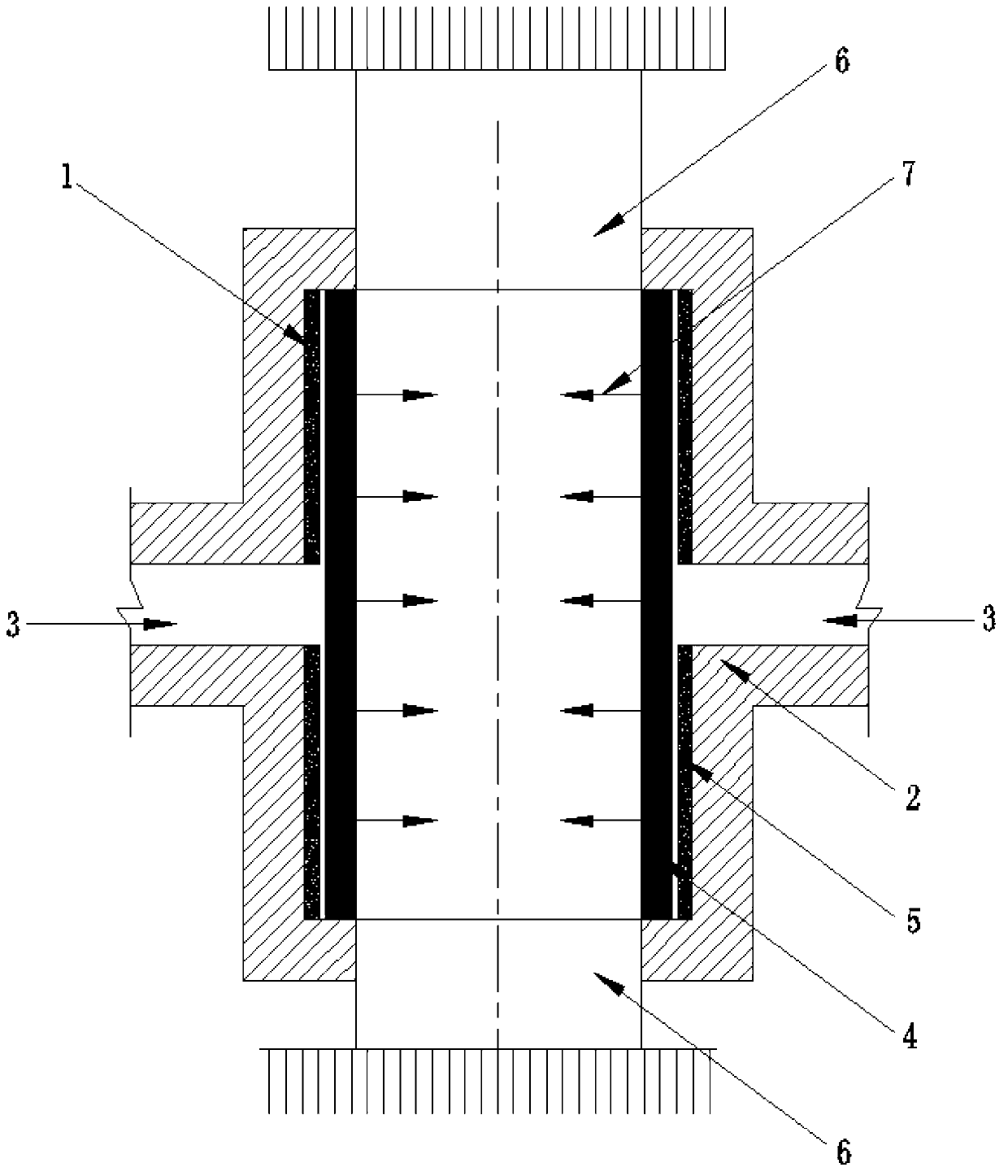

Method for improving thermophysical property of coking inhibition silicon/sulfur composite coating of ethene cracking apparatus

InactiveCN102226260AImprove thermophysical propertiesExtended service lifeThermal non-catalytic crackingSolid state diffusion coatingOxideHardness

The invention provides a method for improving thermophysical property of a coking inhibition silicon / sulfur composite coating of an ethene cracking apparatus. The method is characterized by: carrying out a coke cleaning for a furnace tube prior to coating the coking inhibition coating, then carrying out an oxidation pretreatment for metal base on inner surface of the furnace tube. With the method, the silicon / sulfur composite coating provides improved wetting for the metal base through the formed oxide layer on the surface of the metal base, and a chemical combination between the coating and the base metal is improved. According to the present invention, a combination intensity of the coking inhibition silicon / sulfur composite coating and the metal base, thermal shock resistance of the coating and micro-penetration hardness of the coating are effectively raised, and service life of the coating is prolonged.

Owner:EAST CHINA UNIV OF SCI & TECH

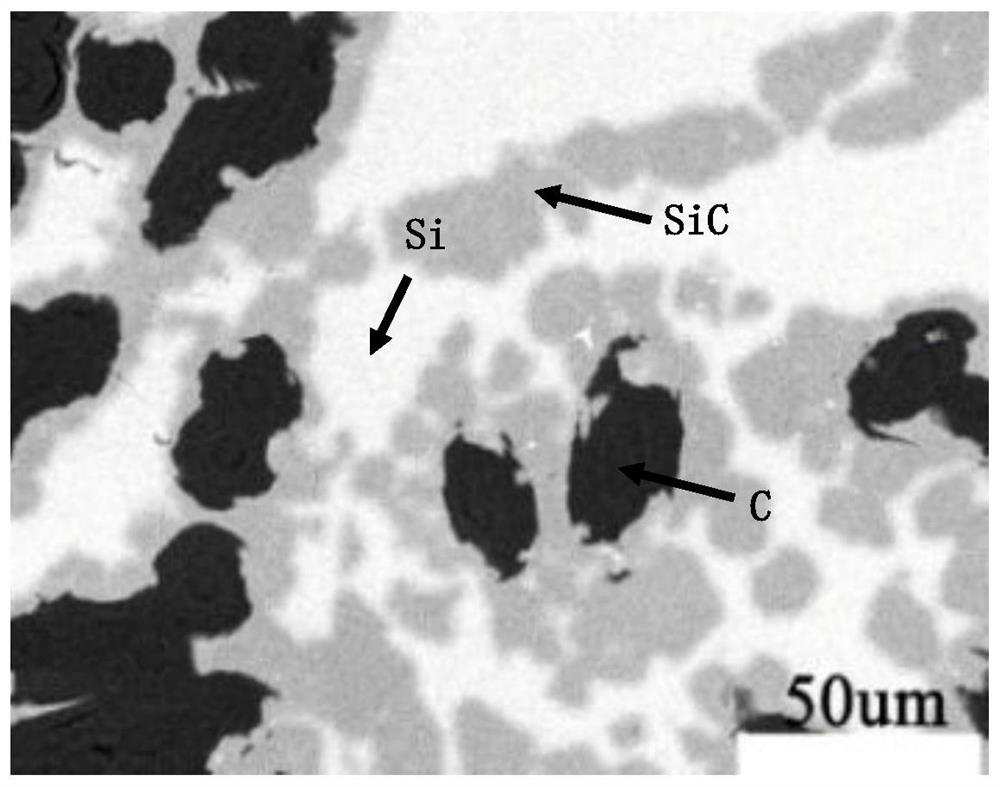

Preparation method and device of high-volume fraction and high-intensity aluminum silicon carbide composite material

The invention discloses a preparation method and device of a high-volume fraction and high-intensity aluminum silicon carbide composite material. A silicon carbide porous preformed blank with the porosity of 20%-80% is degassed in vacuum in a mold with an insulation device, then melt aluminum liquid permeates into pores of the silicon carbide porous preformed blank under the co-action of a capillary force, an external pressure and a solidification contraction force, and then heat in the melt aluminum liquid is quickly conducted out by using a directional heat conduction technique so that the melt aluminum liquid is solidified along a direction opposite to the heat conduction direction; the melt aluminum liquid forms a great number of microcrystal in the micro-pores, and a stretch prestress is generated on the surface of a SiC frame after the melt aluminum liquid is solidified completely, and thus the mechanical properties, density and thermo-physical properties of the material are greatly improved; the method is simple in technique; and the prepared material has high density, good mechanical properties, high heat conductivity, low thermal expansion coefficient and good dimensional stability.

Owner:CHANGSHA AISIKE NEW MATERIAL SCI & TECHCO

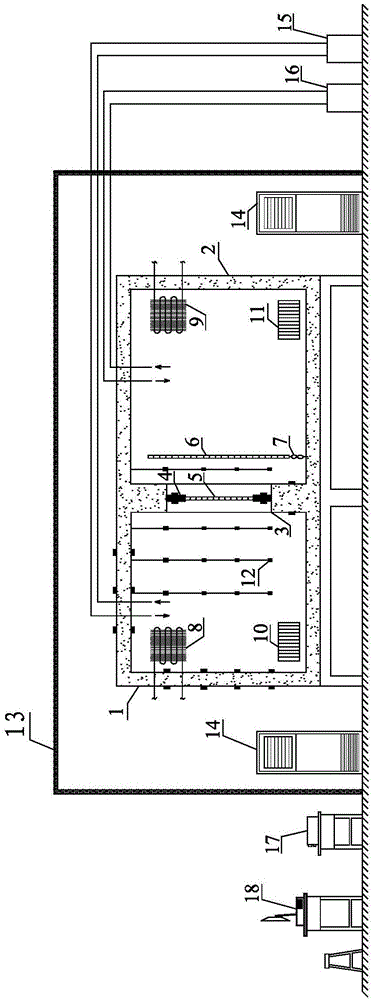

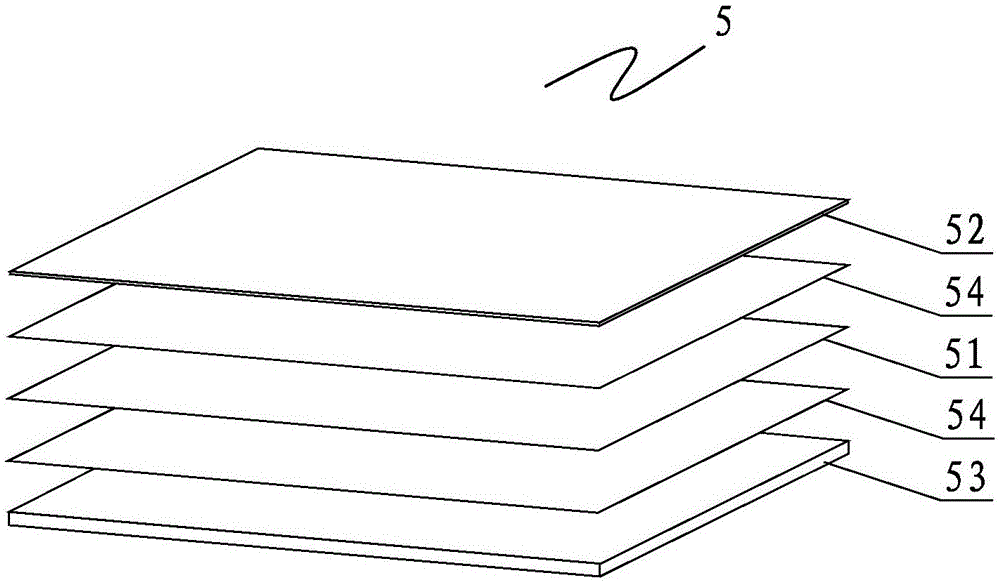

Photovoltaic member heat-transfer coefficient testing device and method thereof

ActiveCN106018476AImprove thermophysical propertiesSave construction investmentMaterial heat developmentData acquisitionCurrent technology

The invention provides a photovoltaic member heat-transfer coefficient testing device and a method thereof. The testing device comprises an indoor case, an outdoor case, a test piece frame, a filling plate, an electrothermal membrane member, a wind-separating board, a blower fan, a first evaporator, a second evaporator, a first electric heater, a second electric heater, plural temperature sensors, an environment space case, an air conditioner, a first humidity-control apparatus, a second humidity-control apparatus, an electrothermal membrane power supply, and a control and data acquisition system. The electrothermal membrane member comprises an electrothermal membrane, a panel and a backboard, the upper and lower surfaces of the electrothermal membrane are adhered with the panel and the backboard by an EVA adhesive layer; the plural temperature sensors are uniformly distributed on the electrothermal membrane, and the thermocouples are connected with the control and data acquisition system. The device and the method overcome the disadvantage that the current technology cannot test the heat-transfer coefficient under photoreceptive power generation state, and can provide reference for testing heat-transfer coefficient of an inner heat source building enclosing structure.

Owner:福建省建研工程顾问有限公司

Method for manufacturing high-alumina-quality high-temperature crucible pot

The invention provides a method for preparing a high alumina heat resistant crucible, relating to a method for preparing the high alumina ceramic crucible which is applied to experiment manufacturing processes such as the high temperature sintering and high temperature chemical synthesis. The method is characterized by comprising the following steps that: raw materials of alumyte grog refractory,alpha-Al2O3, Suzhou clay, carborundum, cooked pencil stone, zirconite, an appropriate amount of a caking agent of Arabian gum dry powder are subject to matching, grinding and watering to prepare slurry; after the casting process, the proximate matter is dried and calcined so that the high alumina heat resistant crucible is prepared. The high alumina heat resistant crucible has good chemical stability, good thermal physics properties such as the heat-resistant stability and the quake-resistance stability, long service life and easy popularization in industry.

Owner:中铝矿业有限公司 +1

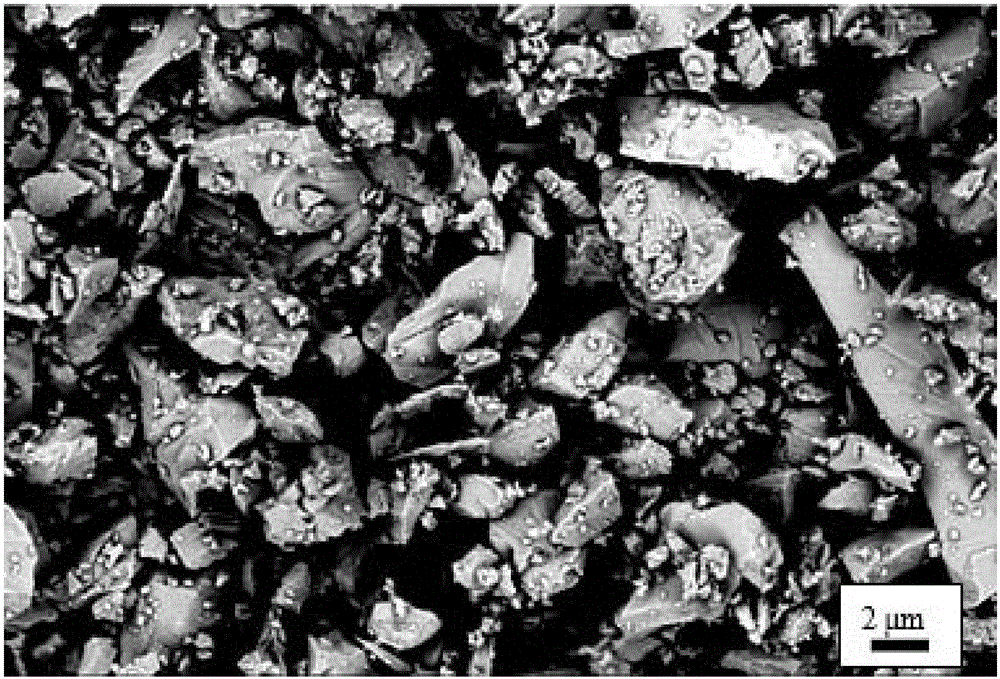

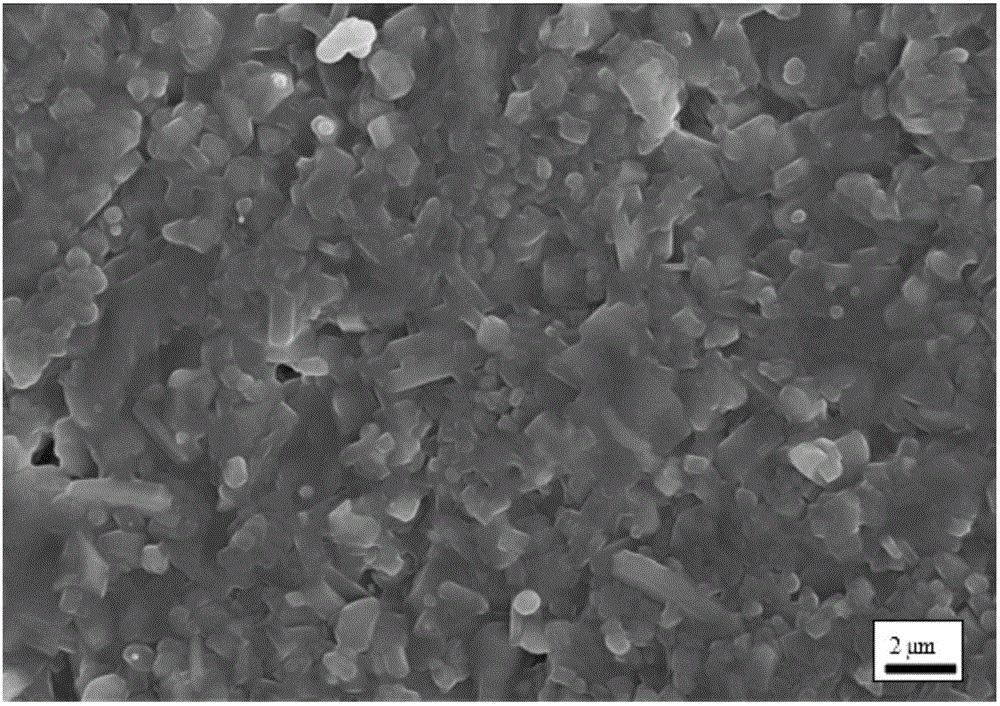

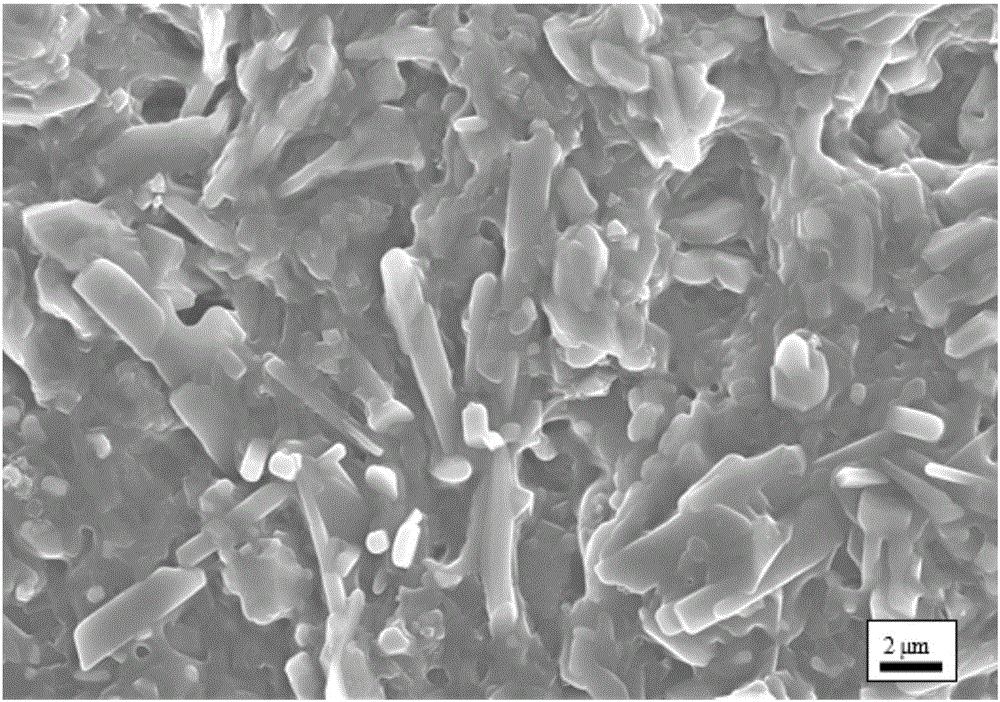

Preparation method for nanocrystalline alumina ceramic

The invention discloses a preparation method for a nanocrystalline alumina ceramic. According to the preparation method, the nanocrystalline alumina ceramic is prepared from micrometer alumina powder in a discharge plasma sintering furnace through low-temperature presintering and high-temperature sintering under a discharge plasma sintering condition. The method realizes refinement of micrometer crystals through low-temperature presintering and clotting of refined crystal grain through high-temperature sintering in virtue of the special condition that the discharge plasma sintering furnace has a pulse direct-current electric field. Since the micrometer powder is used as a raw material, production cost can be greatly reduced. The method is also capable of optimizing the microscopic structure of the alumina ceramic, so the alumina ceramic has more excellent mechanical performance and thermophysical characteristics.

Owner:SOUTHWEST JIAOTONG UNIV

Repairing composite layer of amorphous/nanocrystalline cooling roller and preparation method of repairing composite layer

ActiveCN103895280AGood workmanshipInhibit sheddingElectrolytic coatingsMetallic material coating processesHigh power lasersHigh energy

The invention belongs to the technical field of material science, and particularly relates to a repairing composite layer of an amorphous / nanocrystalline cooling roller and a preparation method of the repairing composite layer. The composite layer consists of two layers, namely a copper-based alloy layer connected with base materials and a nickel-based alloy layer, wherein the copper-based alloy layer comprises the following components by weight percent: 7-9% of Ni, 8-12% of Sn, 5-15% of Co, 0.8-2% of Si and the balance being Cu; the nickel-based alloy layer comprises one of Ni-Co alloy, Ni-P alloy, Ni-Fe alloy and Ni-Cr alloy, and the weight content of Ni in alloy is 60-75%. The preparation method comprises the following steps of pretreating the surface of the cooling roller, electroplating the copper-based alloy layer and performing wide-strip cladding on the nickel-based alloy layer by a high-power laser. The prepared composite coating is uniform and compact, and excellent in wear resistance and heat resistance, and has the characteristics of high cladding efficiency and high energy absorptivity of the cooling roller to the laser beam.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Electronic packaging device and preparation method thereof

InactiveCN101436573AGood thermophysical and mechanical propertiesRealize active and efficient coolingOther chemical processesSemiconductor/solid-state device detailsHigher PowerPre embedding

Owner:有研科技集团有限公司

Light and high-thermal conductivity Fe-Al-based alloy and preparation method thereof

The invention relates to a light and high-thermal conductivity Fe-Al-based alloy and a preparation method thereof. In the future, the requirement of armored assault equipment like novel main battle tanks on the maneuvering performance during air drop and air transportation in mountains and highlands is further improved, so that an engine is supposed to be higher in power and lighter in weight, and the study of the light and high-thermal conductivity material technology becomes an important development direction. The preparation method comprises the steps that Fe powder and Al powder are weighed; the Fe powder, the Al powder and grinding balls are put into a ball milling pot which is vacuumized and is inflated with argon to be subjected to mechanical alloying ball milling, the Fe powder and the Al powder are subjected to solid solution treatment and generate an Fe (Al) solid solution, then, graphene powder is put into the ball milling pot and is continuously mixed with the Fe (Al) solid solution uniformly, and fine and uniform graphene / Fe (Al) composite powder is obtained; and the graphene / Fe (Al) composite powder subjected to mechanical alloying is put into a graphite mold, and a required blocky composite is formed through hot press sintering. According to the preparation method, the preparation process is short in time, and an obtained product is high in purity, high in thermal conductivity and good in compactness.

Owner:XIAN TECHNOLOGICAL UNIV

Waterborne polyurethane as well as preparation method and application thereof

ActiveCN110294828AGood biocompatibilityGood flexibilityAntifouling/underwater paintsPaints with biocidesBiocompatibility TestingEnvironment Problem

The invention relates to the field of a high molecular material, in particular to waterborne polyurethane as well as a preparation method and application thereof. The waterborne polyurethane is prepared from the following ingredients in parts by weight: 30 to 200 parts of hydrophilic chain-extending agents, 100 to 500 parts of polyhydric alcohols, 40 to 400 parts of polyisocyanates, 0.25 to 3.4 parts of catalysts, 250 to 1000 parts of organic solvents, 500 to 3000 parts of water and 10 to 100 parts of neutralizers, wherein the neutralizers are amino acid and amino acid derivatives. The amino acid and amino acid derivatives are used as neutralizers; the positive effect is achieved on reducing or replacing the environment problems due to the use of hydrochloric acid, triethylamine, ammoniumhydroxide and the like as the neutralizers. The amino acid has good biocompatibility; the application field of the waterborne polyurethane, such as the fields of medicine carriers, heart stents and cosmetics is further expanded. In addition, more excellent performance is given to the waterborne polyurethane through the performance such as crystallization of the amino acid.

Owner:SOUTH CHINA AGRI UNIV

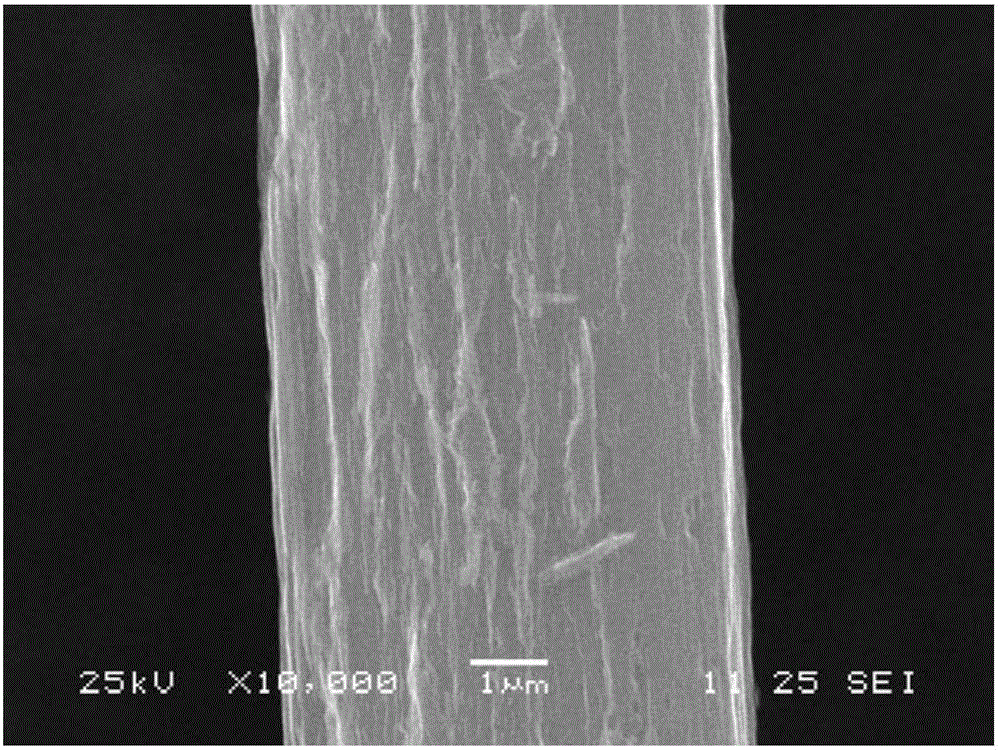

Compound interface layer modified C/C composite material as well as preparation method and application thereof

ActiveCN106830968AGood conditionSimple structureOther chemical processesCarbon fibersInterface layer

The invention relates to a compound interface layer modified C / C composite material as well as a preparation method and an application thereof, in particular to a carbon fiber / matrix carbon interface modified C / C composite material as well as a preparation method and an application thereof. The compound interface layer modified C / C composite material comprises carbon fibers, B-containing graphite layer, a SiC layer and a pyrolytic carbon layer, wherein the carbon fibers are coated with the B-containing graphite layer, the SiC layer is located between the B-containing graphite layer and the pyrolytic carbon layer, the B-containing graphite layer is coated with the SiC layer which is coated with the pyrolytic carbon layer, and the pyrolytic carbon layer contains graphite. The preparation method of the compound interface layer modified C / C composite material comprises the following steps: the carbon fibers dipped in boric acid aresubjected to first graphitization treatment, the treated carbon fibers are then coated with nano-SiC fibers, CVI densification is performed, and finally, graphitization treatment is performed once more. The composite material is reasonable in structural design, the preparation process is simple and easy to control, and the obtained product has excellent performance and is particularly applicable to friction materials.

Owner:CENT SOUTH UNIV

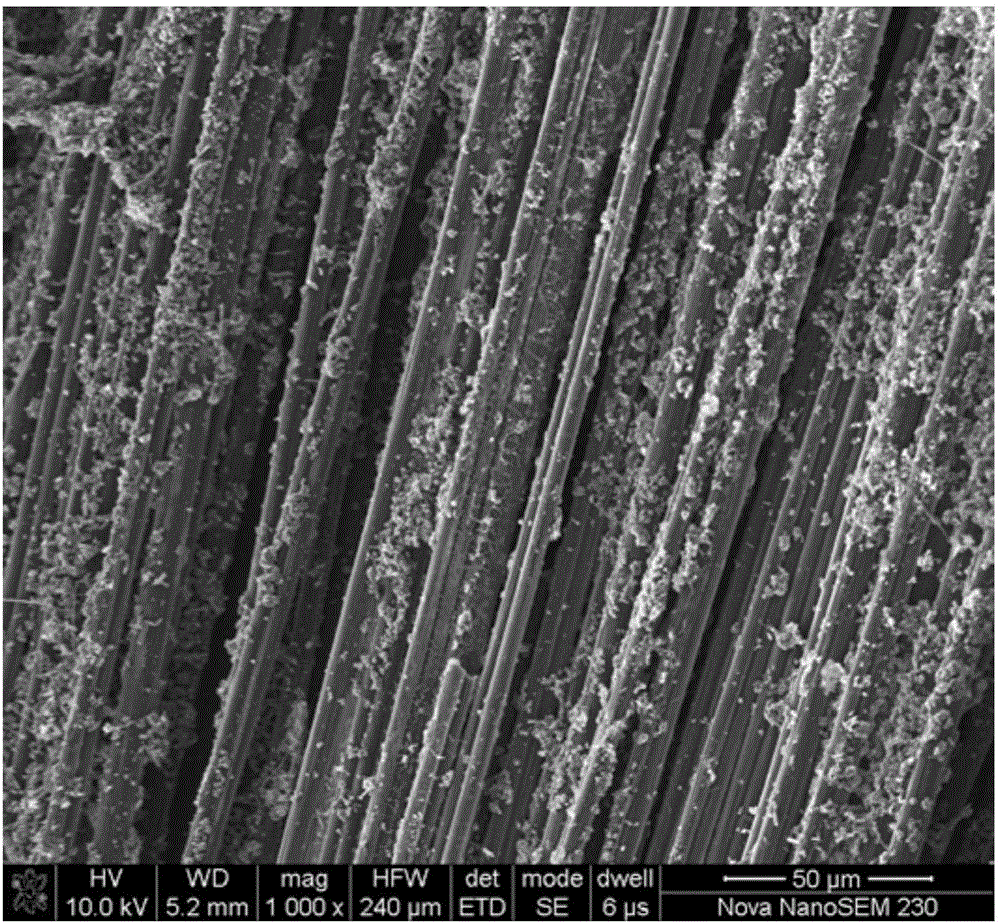

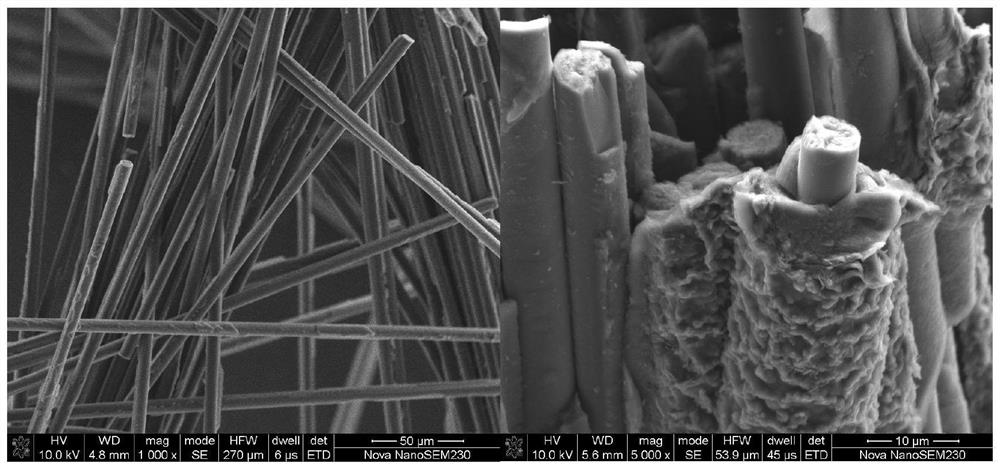

Preparation method of wear-resistant carbon/ceramic brake material

ActiveCN112409008AImprove mechanical propertiesImprove thermal conductivityFriction liningActuatorsCarbon compositesFiber

The invention provides a preparation method of an anti-wear carbon / ceramic brake material. The preparation method comprises the following steps: firstly, preparing a three-dimensional tire net needling prefabricated body by utilizing a short fiber tire net, and then carrying out high-temperature heat treatment, vacuum pressure impregnation in a resin solution, drying, hot-pressing curing and carbonization treatment to obtain a carbonized prefabricated body; then carrying out vacuum pressure impregnation on a phenolic resin solution containing ceramic powder or a furfuryl ketone resin solutioncontaining ceramic powder, carrying out curing and carbonization treatment, and repeating the above steps to prepare a carbon-carbon composite material with the density of 1.01.7 g / cm<3>; and finally,carrying out high-temperature heat treatment and siliconizing treatment to obtain the wear-resistant carbon / ceramic brake material with the density of 1.9 g / cm<3>-3.0g / cm<3>. According to the preparation method disclosed by the invention, on the basis of ensuring the mechanical properties and the thermal physical properties of the obtained material, the production period of the carbon / ceramic brake material is shortened, the wear resistance and the oxidation resistance of the material are improved, and the purposes of reducing the production cost and improving the brake performance are achieved.

Owner:山东道普安制动材料有限公司

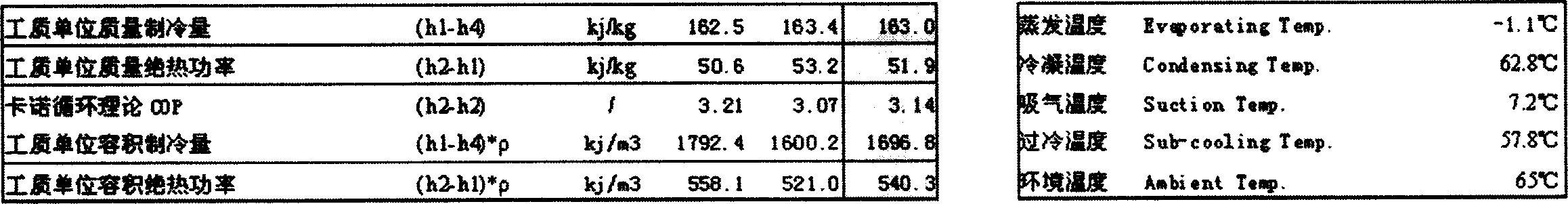

CMR-05 type ternary non-azeotropy environmental protective refrigerant

InactiveCN101003723AExcellent thermophysical propertiesGood compatibilityHeat-exchange elementsLubricationBenzene

This invention discloses environmentally friendly CMR-05 ternary non-azeotropic refrigerant with excellent thermal and physical properties. The refrigerant comprises: R152a 60-75 wt. %, R227ea 10-20 wt. %, and R125 10-25 wt. %. The refrigerant is a ternary near-azeotropic mixture, and is colorless, odorless and nontoxic. At the same evaporation or condensation temperature, the refrigeration parameter of the refrigerant is 1-8% higher than that of R134a. The refrigerant has similar molecular polarity to R12, thus has good low temperature miscibility and high temperature lubrication with mineral oil, alkyl benzene oil, cycloalkyl oil, and POE oil (ester oil). Besdies, the refrigerant has good compatibility with metal and nonmetal materials.

Owner:黄毓虾

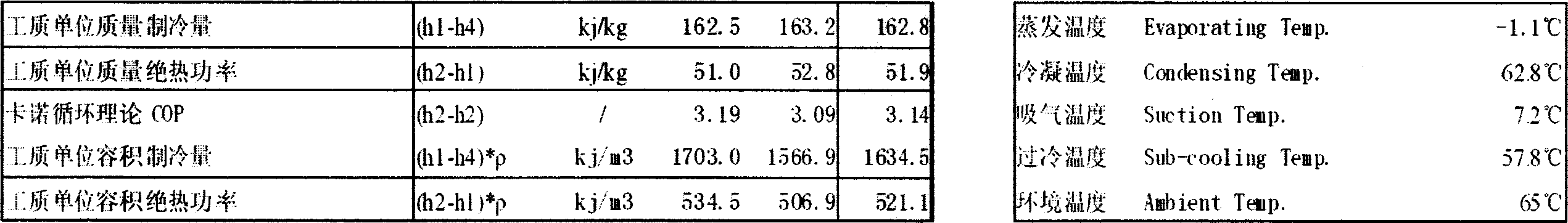

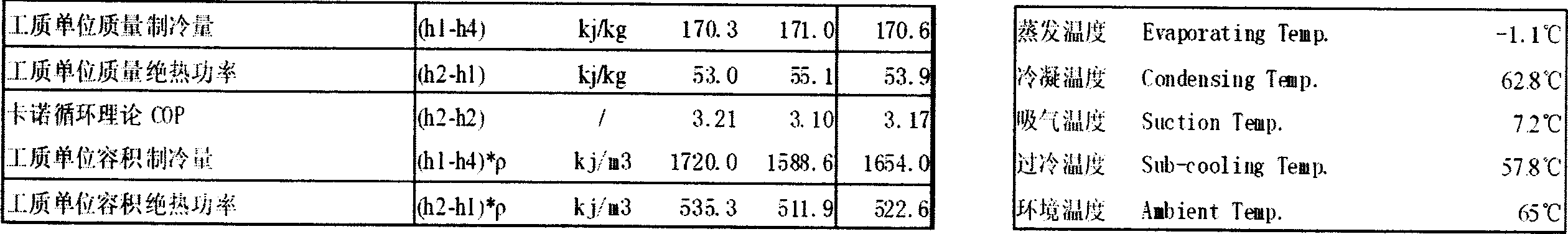

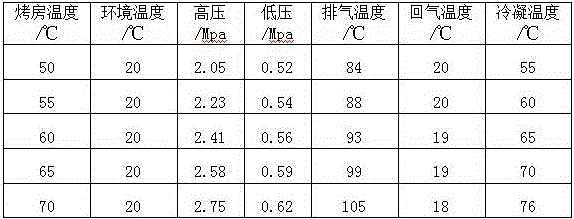

Environment-friendly ternary non-azeotropic high-condensing-temperature refrigerant and filling method thereof

InactiveCN106566476AImprove thermophysical propertiesHeat-exchange elementsRefrigerantsCondensation temperatureDry heat

The invention provides an environment-friendly ternary non-azeotropic high-condensing-temperature refrigerant. The environment-friendly ternary non-azeotropic high-condensing-temperature refrigerant comprises an R22 refrigerant, an R142b refrigerant and an R134a refrigerant, wherein the sum of mass percent concentration of components in the mixed refrigerant is 100%, the mass percent of the R22 is 60%-90%, the mass percent of the R142b is 5%-35%, and the mass percent of the R134a is 1%-10%. The environment-friendly ternary non-azeotropic high-condensing-temperature refrigerant is free of toxicity and harm, the environment is protected, excellent thermophysical performance is achieved, the condensation temperature of the environment-friendly ternary non-azeotropic high-condensing-temperature refrigerant can reach 80 DEG C or above, and the environment-friendly ternary non-azeotropic high-condensing-temperature refrigerant completely meets the requirements of high-condensation-temperature refrigerating systems of a high-temperature air conditioner, a high-temperature drying heat pump and a high-temperature hot water heat pump.

Owner:佛山市大芝热泵制冷设备有限公司

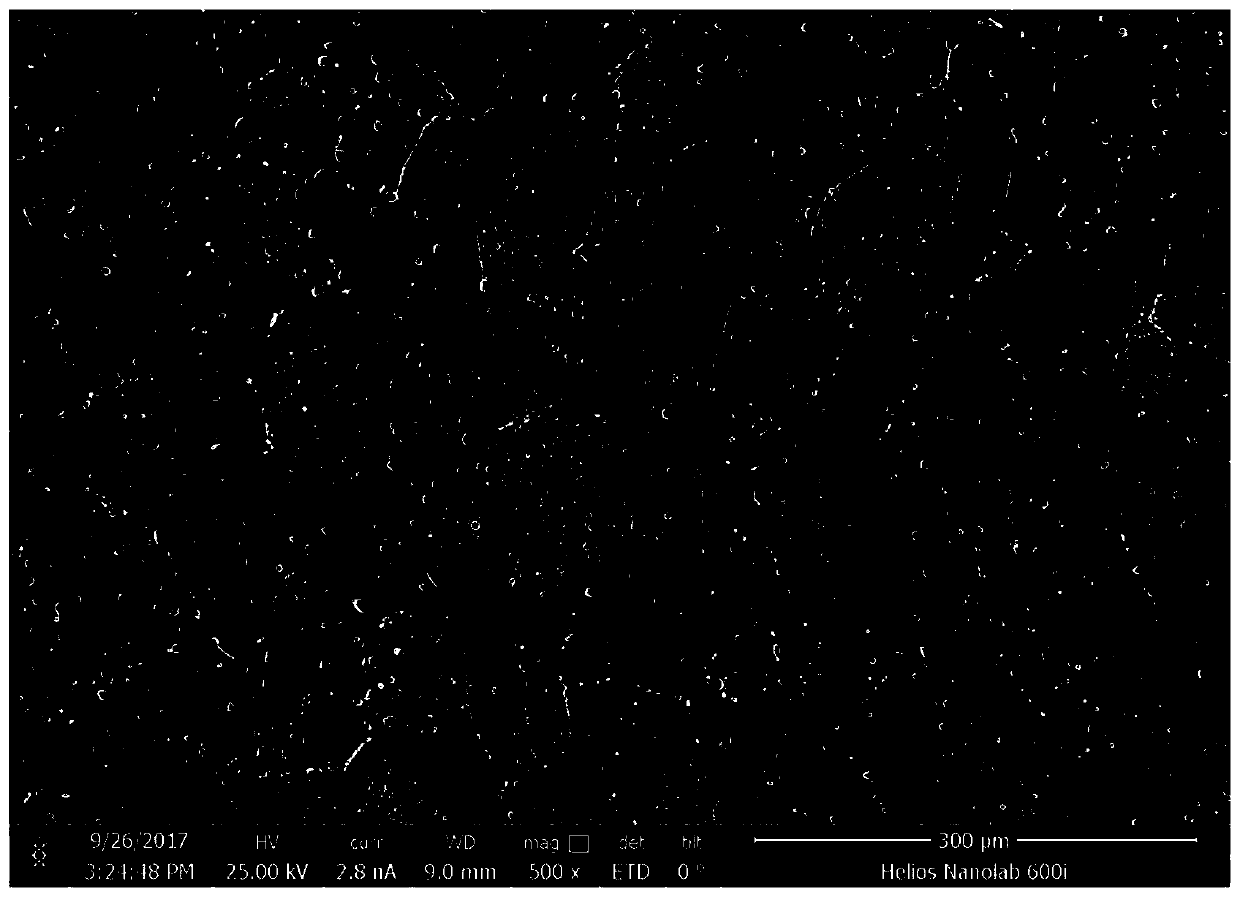

Preparation method of enhanced UO2 nuclear fuel pellet

InactiveCN109903869ASimple methodDesign scienceNuclear energy generationReactors manufactureAtmosphereMaterials science

The invention discloses a preparation method of an enhanced UO2 nuclear fuel pellet to solve the problems of rapid degrease of the thermal conductivity at a high temperature and rapid weakening of thegaseous fission product retention capacity of UO2 fuel pellets in the prior art. The preparation method comprises the following steps: cold-pressing shaping of UO2-reinforcing phase compound particles having good sphericility to obtain a nuclear fuel pellet blank, and sintering of the nuclear fuel pellet then in an active atmosphere at a high temperature to obtain the enhanced UO2 nuclear fuel pellet. The UO2-reinforcing phase compound particles are prepared from UO2 powder, a reinforcing phase and a lubricant; and the use amount of the reinforcing phase is 0.05-5% of the weight of the UO2 powder. The method is simple, and is scientifically designed; and the thermal conductivity at a high temperature and the gaseous fission product retention capacity of the enhanced UO2 fuel pellet are greatly higher than those of the existing UO2 fuel pellets.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

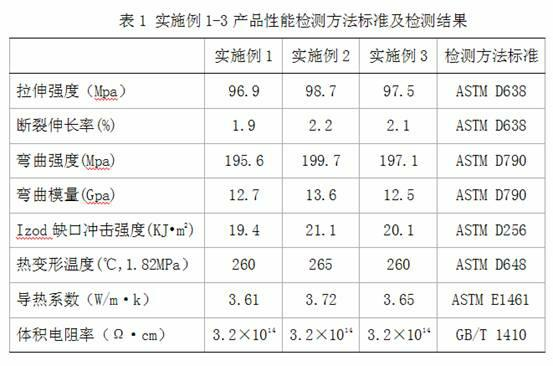

Calcium sulfate whisker modified polyphenylene sulfide composite material and preparation method thereof

The invention discloses a calcium sulfate whisker modified polyphenylene sulfide composite material and a preparation method thereof. The composite material comprising the following components in parts by weight: polyphenylene sulfide 35-50 parts, calcium sulfate whisker 10-20 parts, thermal conductive filler 30-40 parts, coupling agent 2-5 parts, antioxidant1010 0.2-0.5 part and lubricant 0.5-1.5 parts. The preparation method of the calcium sulfate whisker modified polyphenylene sulfide composite material comprises the steps of: pre-processing the thermal conductive filler and the calcium sulfate; adding the pre-processed thermal conductive filler, the polyphenylene sulfide, the antioxidant1010 and the lubricant into a high-speed mixer, and mixing for 5-15 min; and then adding the modified calcium sulfate whisker and mixing for 4-6 min; pelletizing the obtained mixture by extruding; and carrying out injection molding on the pellets to obtain the finished product. The calcium sulfate whisker modified polyphenylene sulfide composite material provided by the invention has the advantages of good insulation and thermal conductivity and excellent thermal physical property and is particularly applicable to electronic products and weaponry, electrical communication, electrical equipment and instruments.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

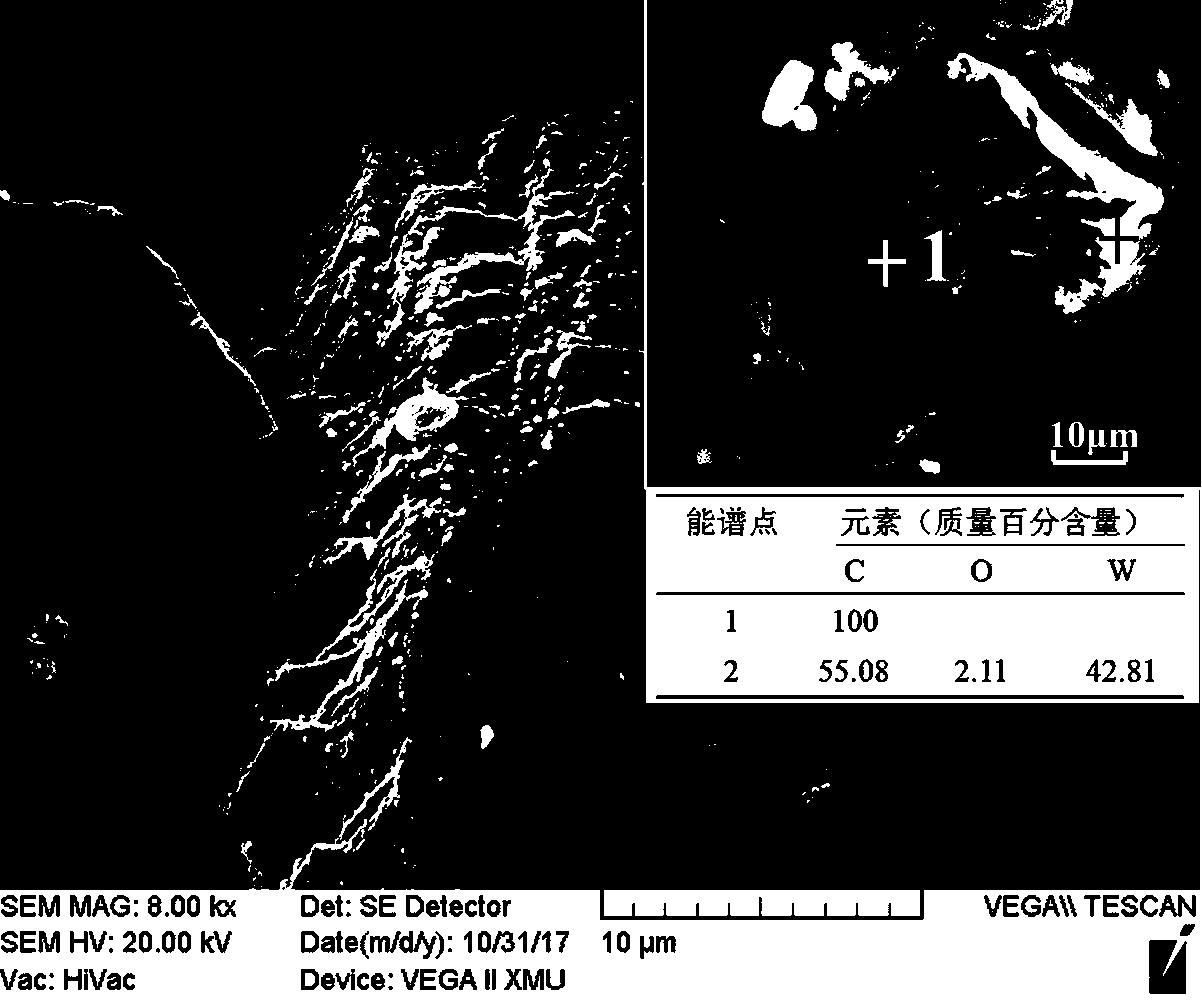

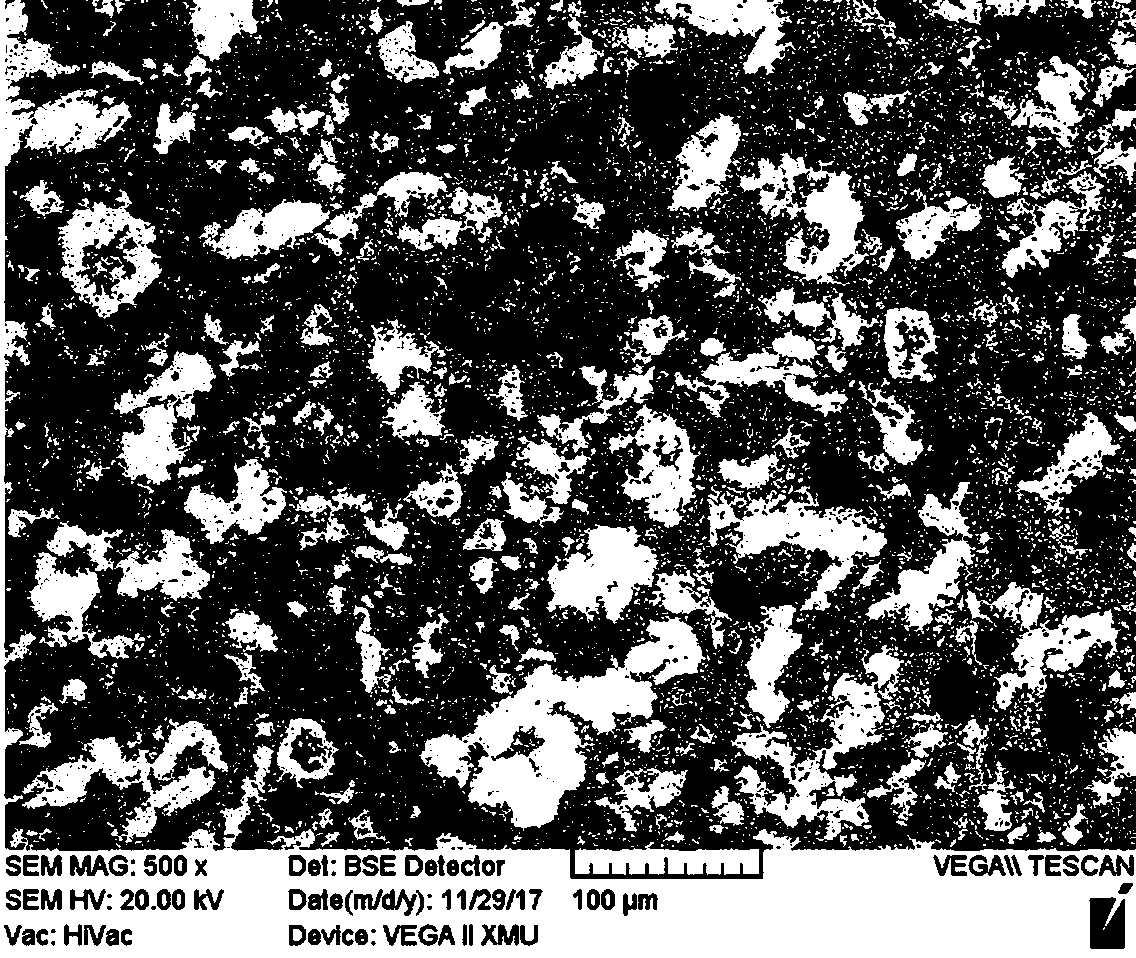

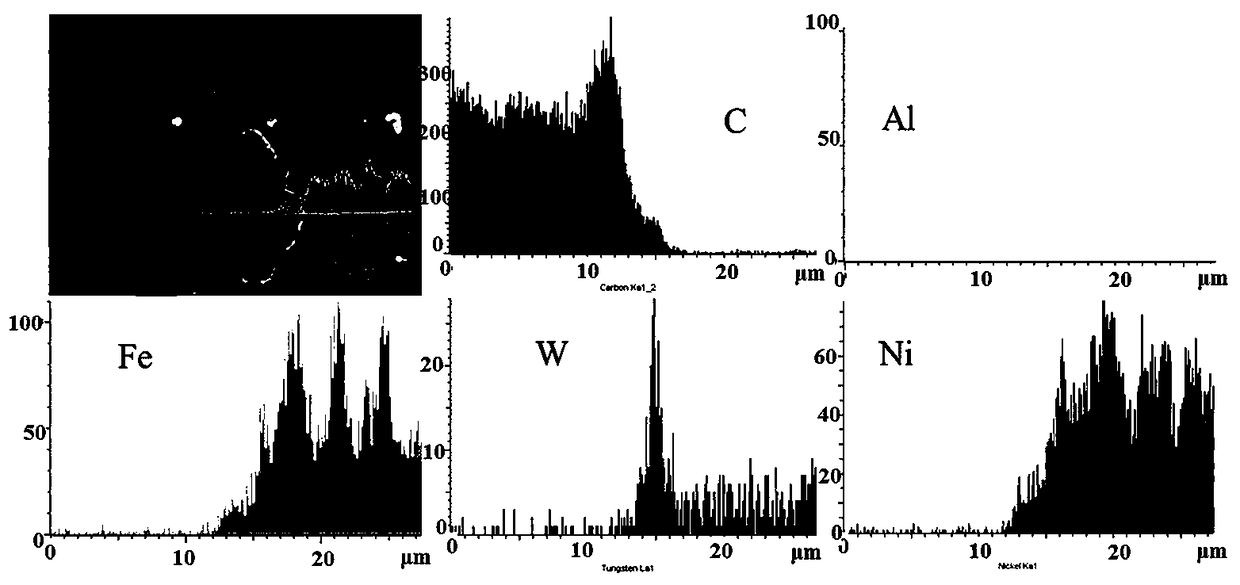

Low-density heat-resistant iron-based alloy and preparation method thereof

ActiveCN108588530ASmall particle sizeThorough responseTransportation and packagingMetal-working apparatusAl powderAlloy composite

The invention relates to a low-density heat-resistant iron-based alloy and a preparation method thereof. The NiAl powder particles with the ordered structure of nano B2 which are generated in the process of reacting between a Ni powder mechanical alloy and an Al powder mechanical alloy is adoptd, diamond is pretreated by a proper technology to enable the surface of the diamond form a uniform tungsten coating layer, and then the NiAl powder and the pretreated diamond powder are filled into a ball milling tank, and a Fe powder is continuously mixed with the NiAl powder and the pretreated diamondpowder in an uniform mode to obtain a fine and uniform NiAl or diamond-reinforced Fe-based alloy composite powder, and hot-pressing sintering is carried out to obtain a block composite material so asto obtain a high-density heat-resistant NiAl or diamond-reinforced Fe-based material, that is the low-density heat-resistant iron-based alloy. According to the alloy and the method, a mechanical alloying technology is combined with the hot-pressing sintering technology, a developed novel low-density heat-resistant NiAl or diamond-reinforced Fe-based alloy product is low in cost, high in purity, low in density, high in heat conductivity and has the application potential of being applied to a high-power-density diesel engine cylinder cover material.

Owner:XIAN TECH UNIV

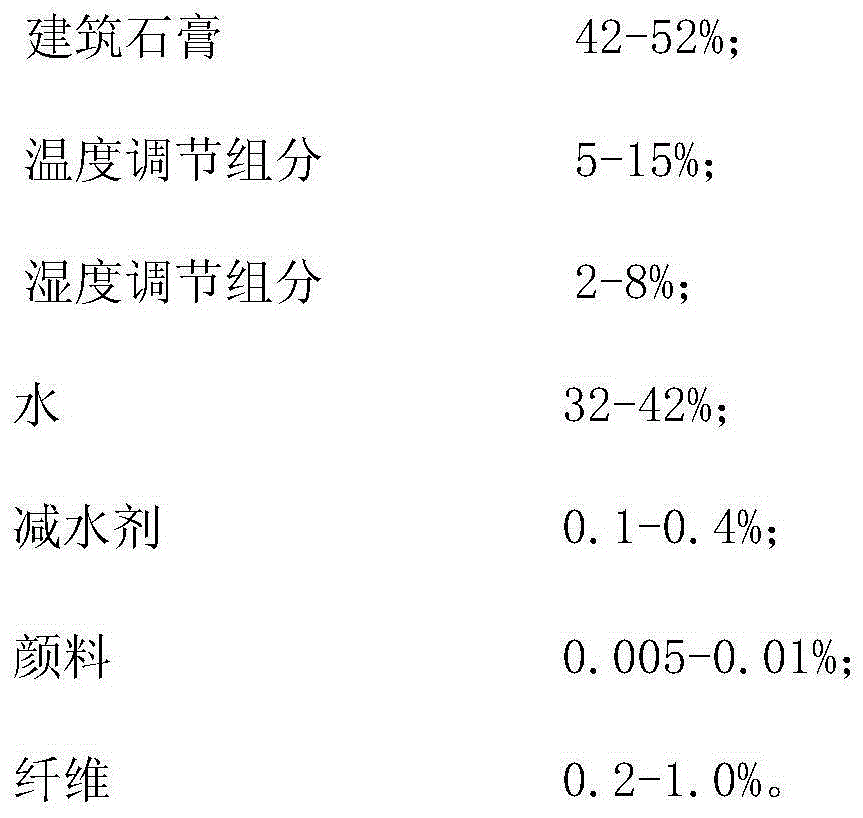

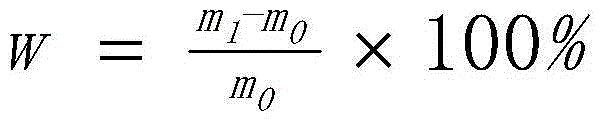

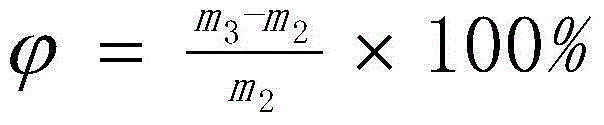

Wall material capable of adjusting indoor environmental temperature and humidity and preparation method of wall material

InactiveCN105218056ASimple preparation processImprove thermophysical propertiesFiberThermal insulation

The invention discloses a wall material capable of adjusting indoor environmental temperature and humidity and a preparation method of the wall material. The wall material is prepared from components in percentage by weight as follows: 42%-52% of building plaster, 5%-15% of temperature adjustment components, 2%-8% of humidity control components, 32%-42% of water, 0.1%-0.4% of water reducing agents, 0.005%-0.01% of pigments and 0.2%-1.0% of fiber. According to the wall material, the preparation process of a functional wall material is optimized, fluctuation of indoor environmental temperature and humidity is reduced, the durability, the anti-permeability, the anti-cracking performance and the fireproof performance of a wall body are improved, and energy consumption is reduced during construction; with the adoption of the temperature adjustment components and the humidity control components, the wall material has the function of indoor environmental temperature and humidity adjustment, the homogeneity of the wall material is guaranteed, and a product has high strength and seldom contracts; the thermal physical performance of the wall material is excellent, the wall body does not require a thermal-insulation layer, and construction procedures are reduced.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

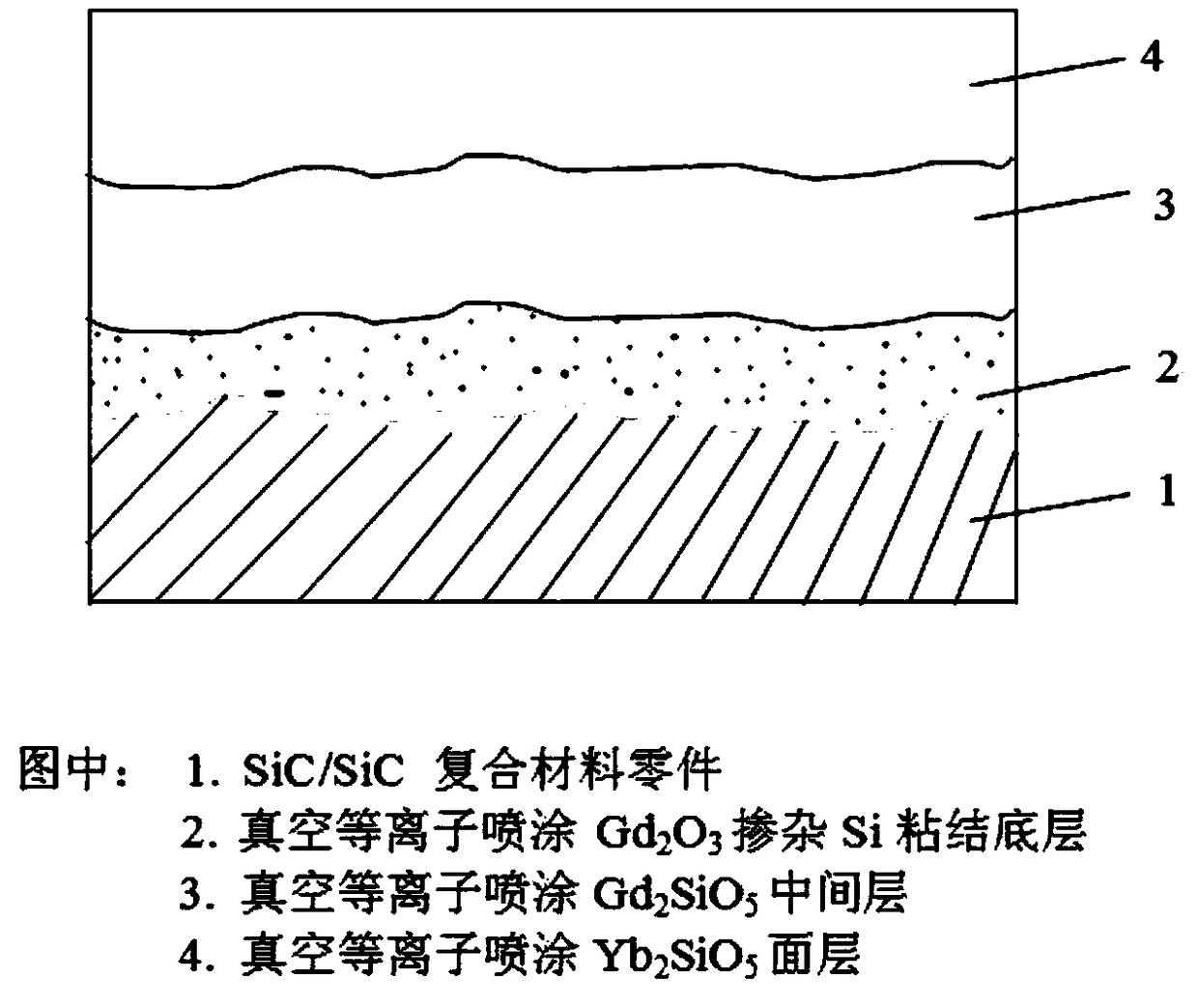

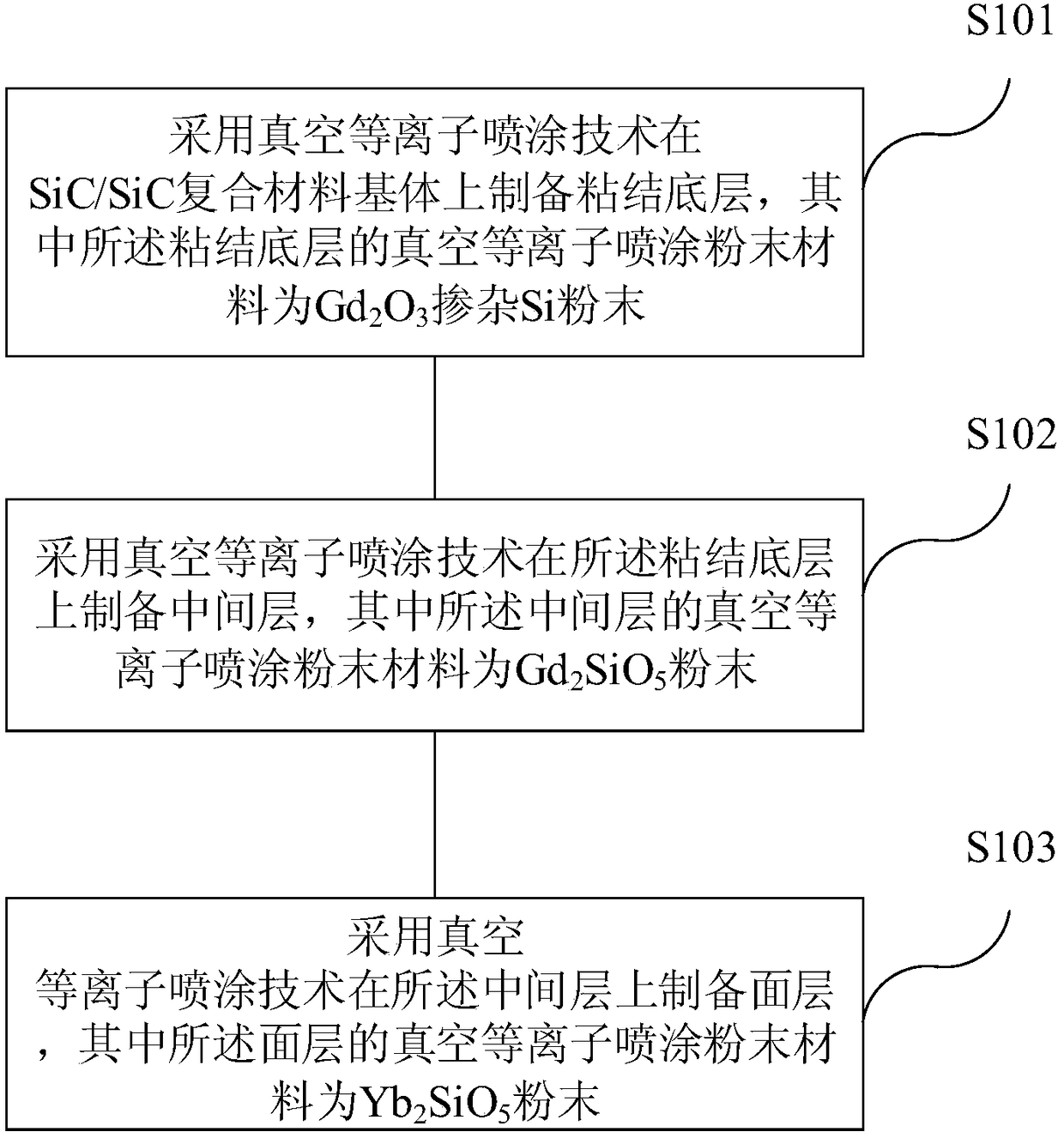

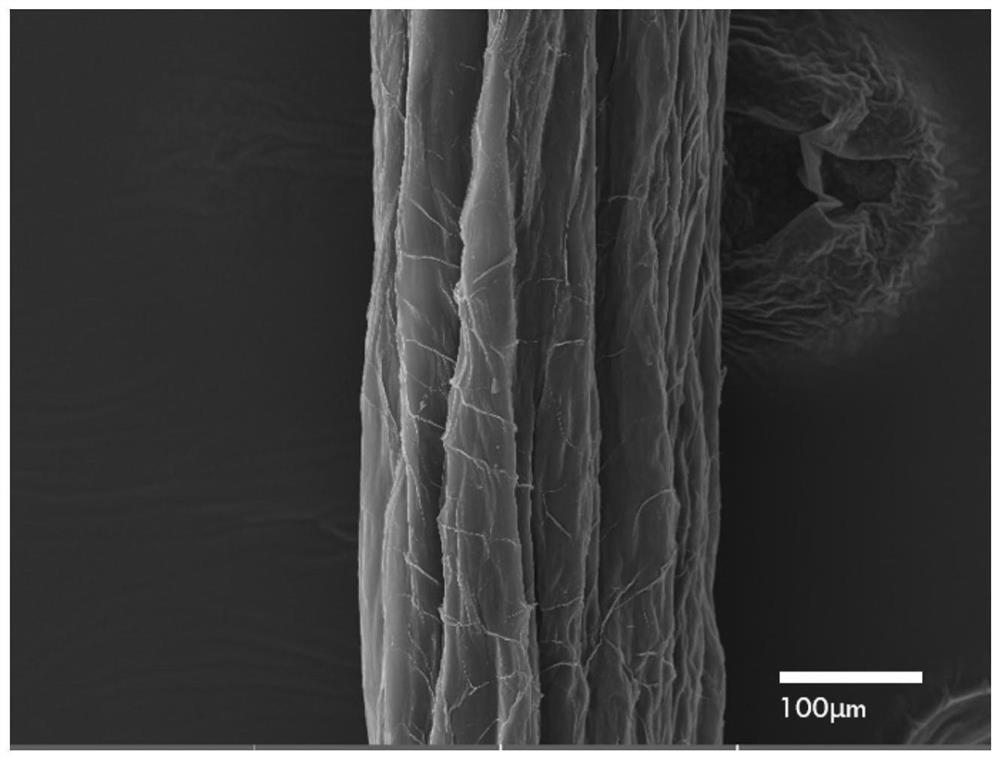

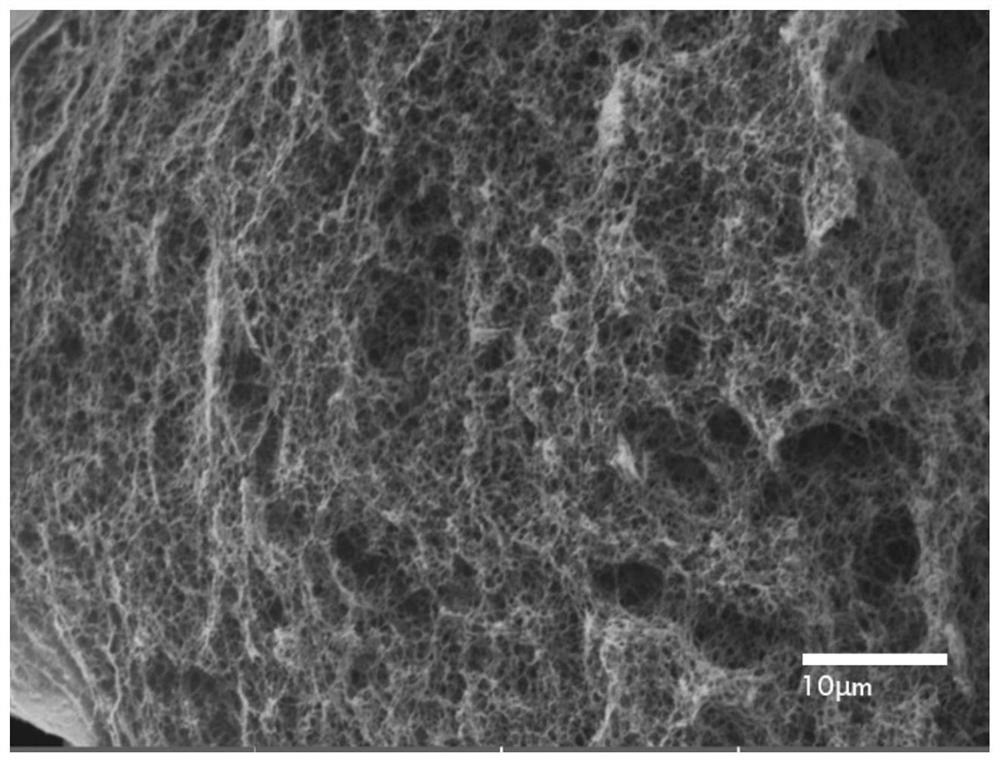

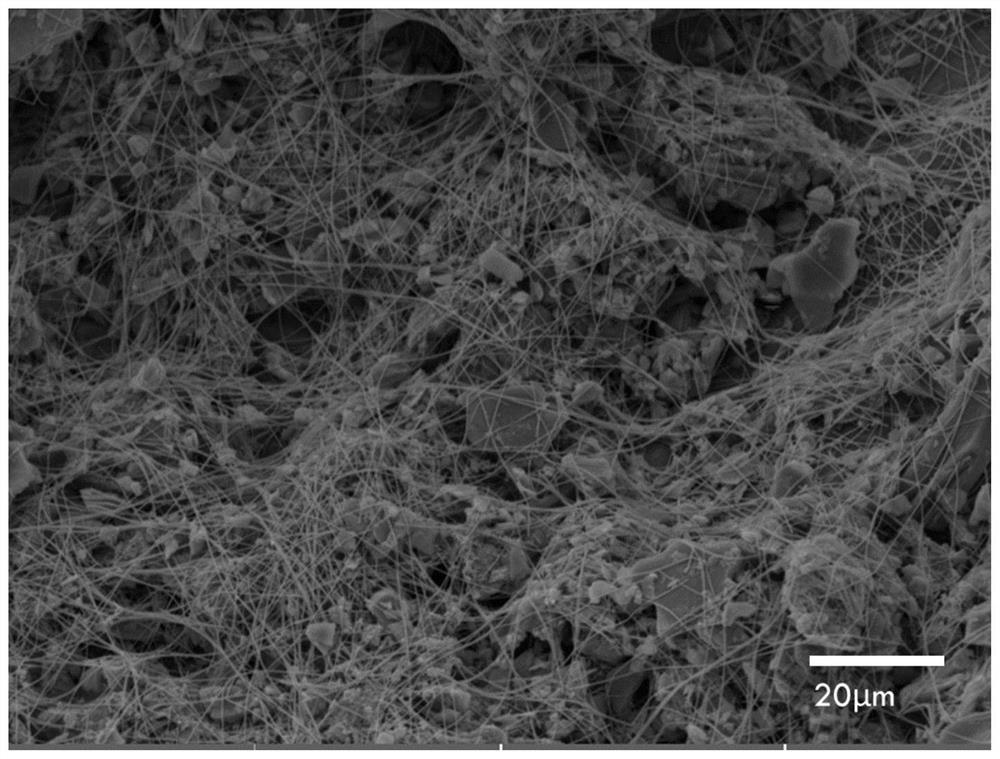

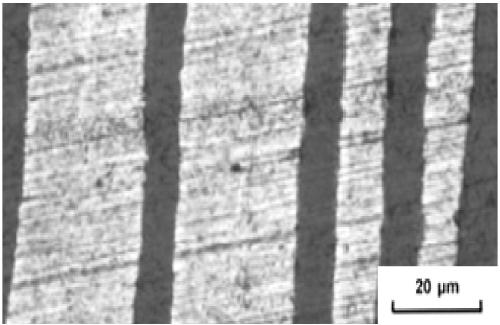

High-temperature environment barrier coating layer structure and preparation method thereof

ActiveCN108950463AExtend working lifeImprove use reliabilityMolten spray coatingSurface layerDecomposition

The invention provides a high-temperature environment barrier coating layer structure and a preparation method thereof. The structure comprises a Gd2O3 doped Si bonding bottom layer, a Gd2SiO5 middlelayer and a Yb2SiO5 surface layer laminated on the surface of a SiC / SiC composite material basal body in sequence. An environment barrier coating layer is of a three-layer structure of vacuum plasma spraying gadolinium oxide doped Si bonding bottom layer+vacuum plasma spraying gadolinium silicate middle layer+vacuum plasma spraying ytterbium silicate surface layer. A Gd2SiO5 coating layer and a Yb2SiO5 coating layer are prepared by adopting a vacuum plasma spraying process; components of the coating layers are maintained well; the material component loss and the silicate decomposition are hardly generated; the phase composition is stable; and the thermal shock resistance of the coating layers is excellent. The physical performance matchability of all the layers is excellent to effectivelyrelieve the thermal stress of the coating layers; the working temperature can reach 1400 DEG C; and the thermal shock resistance, the thermal circulation resistance and the service life of the environment barrier coating layer are greatly improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Preparation method and application of intelligent heat storage and temperature regulation nano aerogel fiber

ActiveCN113481718AImprove conductivityHigh phase change enthalpyFibre typesHeat-exchange elementsFiberSpinning

The invention particularly relates to a preparation method of intelligent heat storage and temperature regulation nano aerogel fiber. The preparation method comprises the following steps of S1, firstly preparing a nanofiber monomer dispersion liquid; S2, performing wet spinning on the nano monomer dispersion liquid to form nano fiber, so as to obtain nascent aerogel fiber; S3, freeze-drying the nascent aerogel fiber to obtain a nano aerogel fiber base material; S4, soaking and airing the nano aerogel fiber base material in a silver nanowire solution, and then soaking and airing the nano aerogel fiber base material in an MXene solution to obtain conductive aerogel fiber; and S5, soaking the conductive aerogel fiber in a phase change solution to obtain the intelligent heat storage and temperature regulation nano aerogel fiber. The invention further discloses application of the fiber in human heat management. The preparation method is simple and environment-friendly, and the intelligent heat storage and temperature regulation nano aerogel fiber prepared by the method has excellent conductivity, excellent heat storage and temperature regulation performance, excellent phase change stability and durability, simple preparation process and low preparation cost.

Owner:QINGDAO UNIV

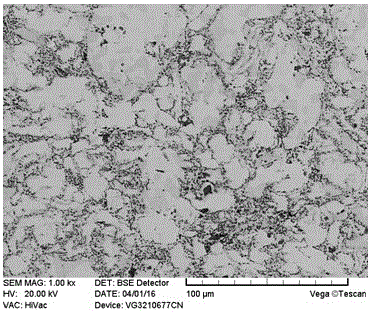

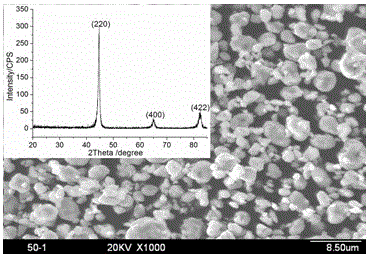

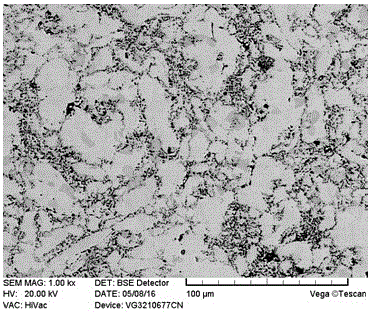

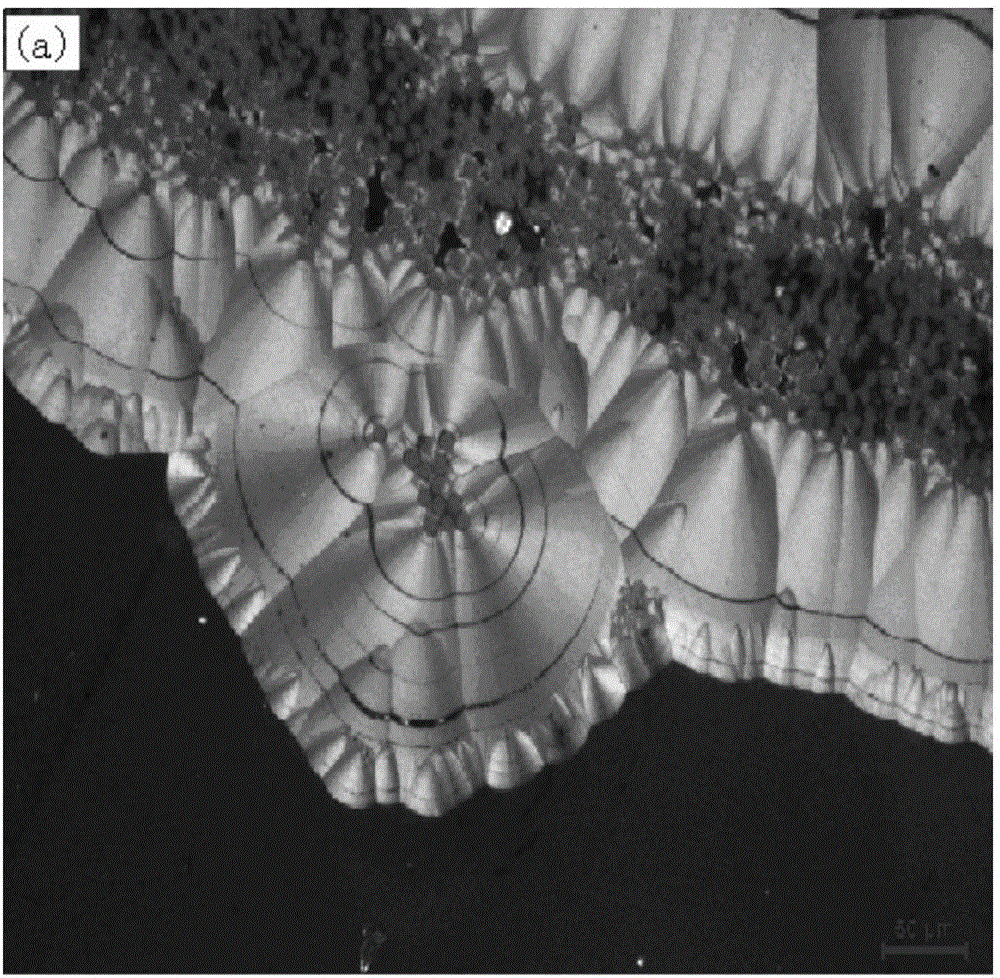

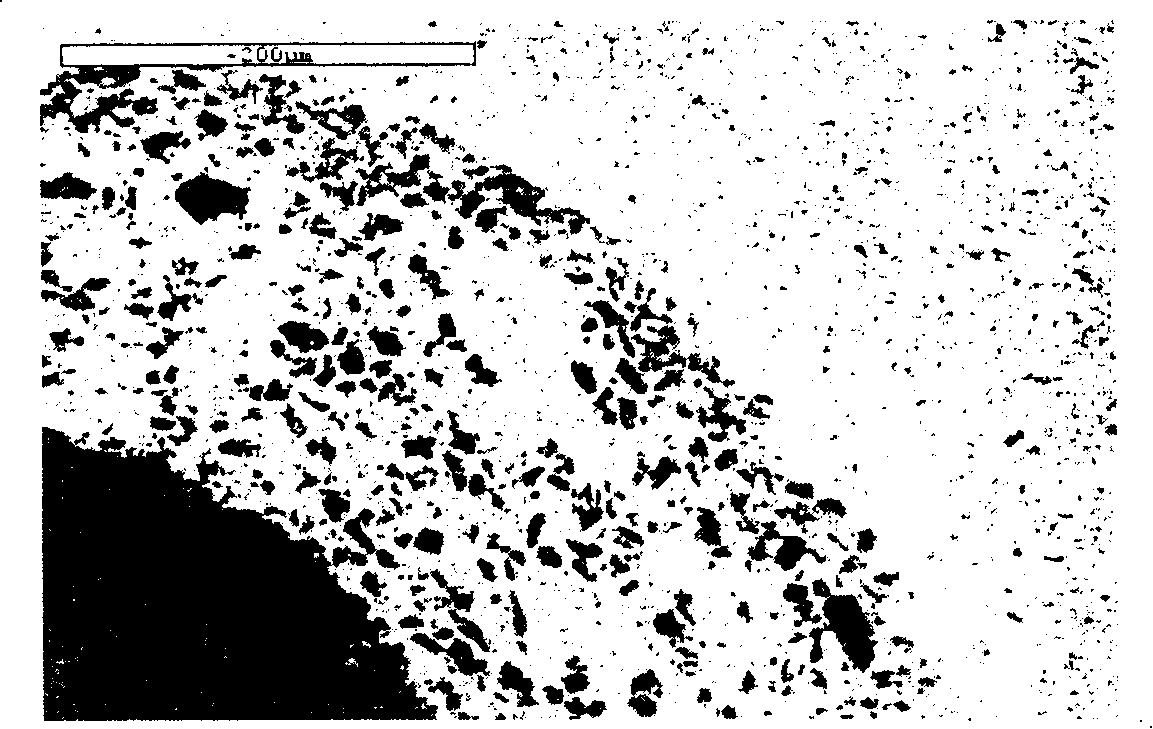

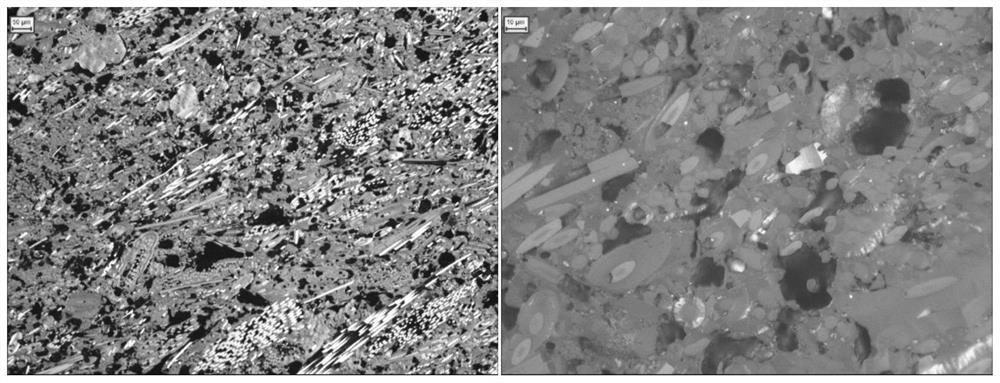

Powder metallurgy preparation method of high volume fraction SiCp/Al alloy composite

The invention discloses a powder metallurgy preparation method of a high volume fraction SiCp / Al alloy composite. SiC powder bought from the market is elutriated for removing fine SiC particles in the SiC powder, the elutriated SiC powder with the mean particle size being 10-30 micrometers is blended with Al alloy powder with the mean particle size being 5-20 micrometers, a double-shaft drum is used for mixing, 400-600MPa one-direction pressing is carried out in a steel mould, and atmospheric pressure sintering is carried out at 660-720 DEG C under high-purity N2 atmosphere protection. The density of the 50vol% SiCp / Al alloy composite prepared in such way can reach 98.5%, the flexural strength reaches 495MPa, the heat conductivity reaches 153W / (m.K), and the thermal expansion coefficient is as low as 8.1*10<-6> / K. The comprehensive performance of the high volume fraction SiCp / Al alloy composite exceeds that of a similar-component SiCp / Al alloy composite prepared by a cast infiltration or hot pressing method, and the high volume fraction SiCp / Al alloy composite can be used as a high-performance electronic packaging material.

Owner:HEFEI UNIV OF TECH

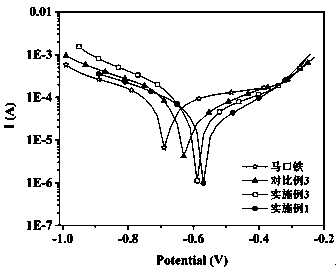

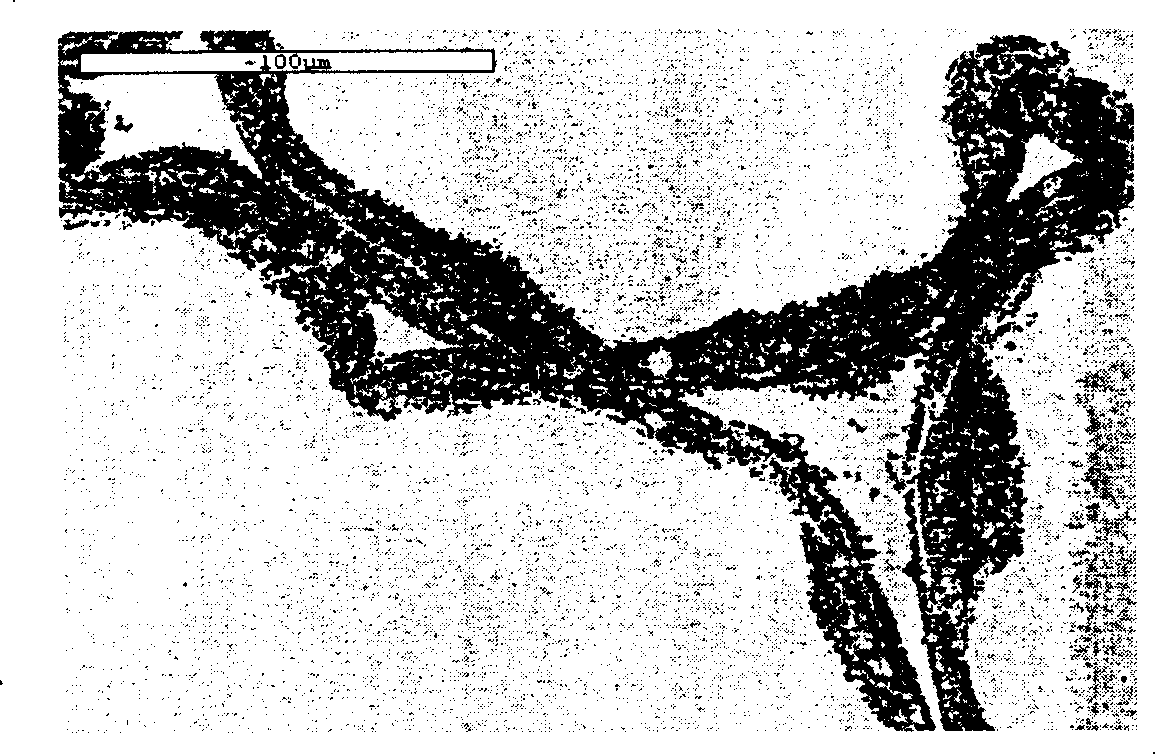

Wet type copper base friction material and its preparation method

InactiveCN100381536CHigh mechanical strengthImprove thermophysical propertiesOther chemical processesDynamic strengthUltimate tensile strength

The invention discloses a wet copper base friction material and preparing method, which is composed of three-dimensional, interconnect network carborundum ceramic skeleton, copper alloy and other inorganic fillers, wherein the bulk percentage of copper alloy is 60-70 vol. percent; the bulk percentage of network carborundum ceramic skeleton and inorganic filler is 40-30 vol. percent. The fusing high-temperature liquid alloy is squeezed in the three-dimensional network carborundum ceramic skeleton of inorganic filler under pressure, which possesses high dynamic strength. The invention can be applied in large power; high speed wet friction driving and braking device.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of layered gradient graphite film/aluminum composite material

The invention relates to a preparation method of a layered gradient graphite film / aluminum composite material, is applicable to the field of electronic packaging substrates and aims to solve the problems that when a meta-based composite material is used as an electronic packaging substrate, the substrate thermal expansion coefficient is single and cannot be designed, chip heat stress cannot be relieved, and chip service life is shortened. The preparation method includes the steps of firstly, preprocessing a graphite film and aluminum foil; secondly, preparing a preform; thirdly using a discharge plasma sintering method to perform sintering under atmosphere protection. The method has the advantages that two or more preform blocks of different graphite volume fractions are stacked, and thenpreform preparation and sintering are performed to allow the thermal expansion coefficient of the material to change in a gradient manner in a direction vertical to the layers; the heat stress of thechip can be effectively relieved through the gradient change, and chip service life can be prolonged.

Owner:HARBIN INST OF TECH

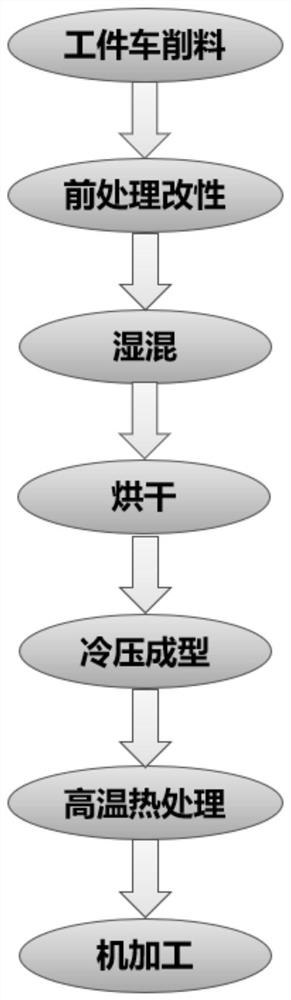

Preparation method of chopped carbon fiber composite material

The invention mainly relates to a method for preparing a carbon fiber composite material by taking a turning material of a carbon / carbon composite material as a main raw material and commercial chopped carbon fibers as a reinforcing phase, mainly aiming at the problems of resource recovery and reutilization in the production process of the carbon / carbon composite material. According to the method, turning materials and leftover materials generated in the workpiece turning process serve as main raw materials, the raw materials are subjected to pretreatment modification, wet mixing, drying, cold press forming, heat treatment and the like, the carbon / carbon composite material with high mechanical performance is prepared, and the material has wide application in the photovoltaic field, the heat treatment field, the friction field and the like. According to the invention, the effective utilization of resources is realized, the production cost is reduced, the solid wastes generated in the production process are effectively reduced, and the problem of environmental pollution is also well improved.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com