Preparation method of layered gradient graphite film/aluminum composite material

A technology of aluminum composite material and graphite film, which is applied in the field of preparation of layered gradient graphite film/aluminum composite material, can solve the problems of unrelieved chip thermal stress, single thermal expansion coefficient, undesignability, etc., and achieve in-plane thermal conductivity Excellent, excellent thermophysical properties, short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

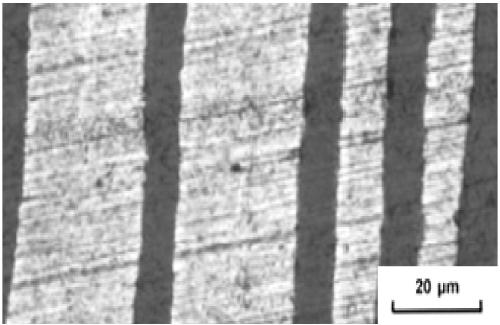

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the preparation method of a kind of layered gradient graphite film / aluminum composite material of this embodiment is carried out according to the following steps:

[0019] 1. Pretreatment graphite film and aluminum foil

[0020] Remove the residual organic matter on the surface of the graphite film, and then put it in an electric blast drying oven to dry for 5 to 10 minutes. After drying, wipe off the amorphous graphite powder on the surface of the graphite film to obtain a pretreated graphite film; remove the oxidation on the surface of the aluminum foil layer, and then put it into a vacuum drying oven to dry for 30-60 minutes to obtain a pretreated aluminum foil;

[0021] 2. Preparation of preforms

[0022] The pre-treated graphite film and aluminum foil are stacked crosswise to obtain a prefabricated block, wherein the volume fraction of the graphite film in the prefabricated block is 30-80%; the above prefabricated blocks with n different g...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the graphite film is a high crystallinity graphite film in step one, the thickness of the graphite film is 0.012~0.1mm, and the thermal conductivity is 600~1900W / (m· K). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum foil in step 1 is 1050, 1060, 1070, 1100, 1145, 1200, 1235, 2A11, 2A12, 3003, 3A21, 4A13, 5A02, 5052, 5082, 5083, 8006, 8011, 8011A or 8079 aluminum foil, the thickness of the aluminum foil is 0.016 ~ 0.2mm. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com