Preparation method of wear-resistant carbon/ceramic brake material

A brake material and anti-wear technology, applied in mechanical equipment, friction linings, gear shifting mechanisms, etc., can solve the problems of aggravating oxidation and wear of friction interface, affecting the runout of the end face of the brake disc, affecting the performance and life of the brake disc, etc. The effect of improving densification speed, good friction and wear resistance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

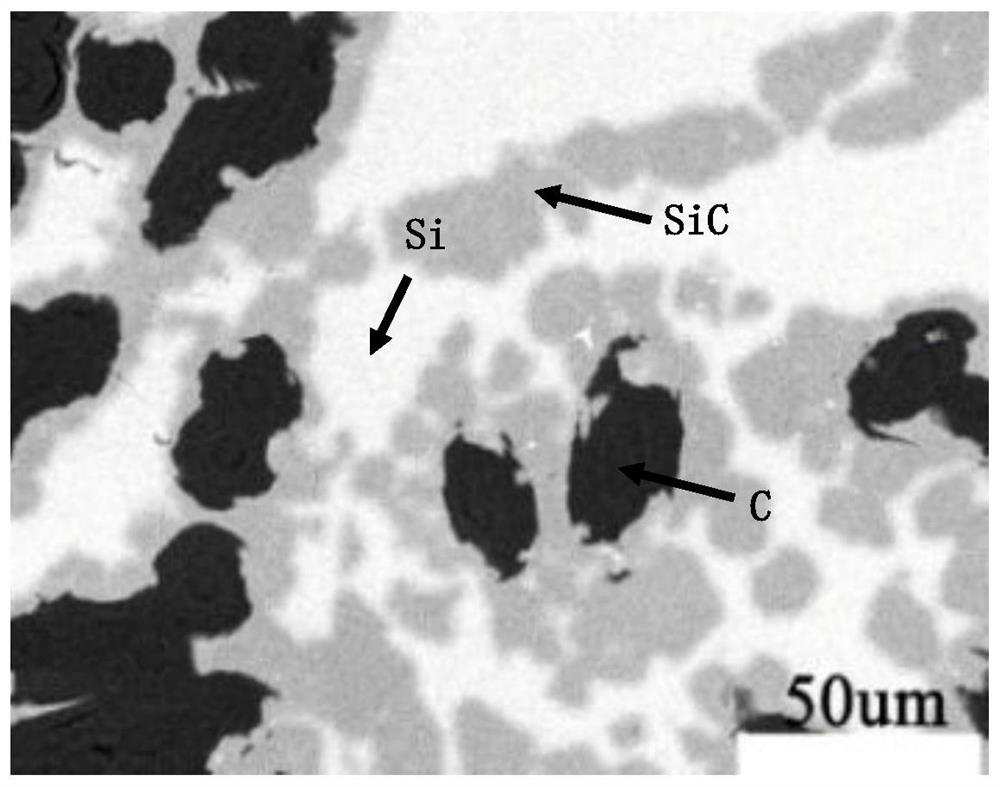

Image

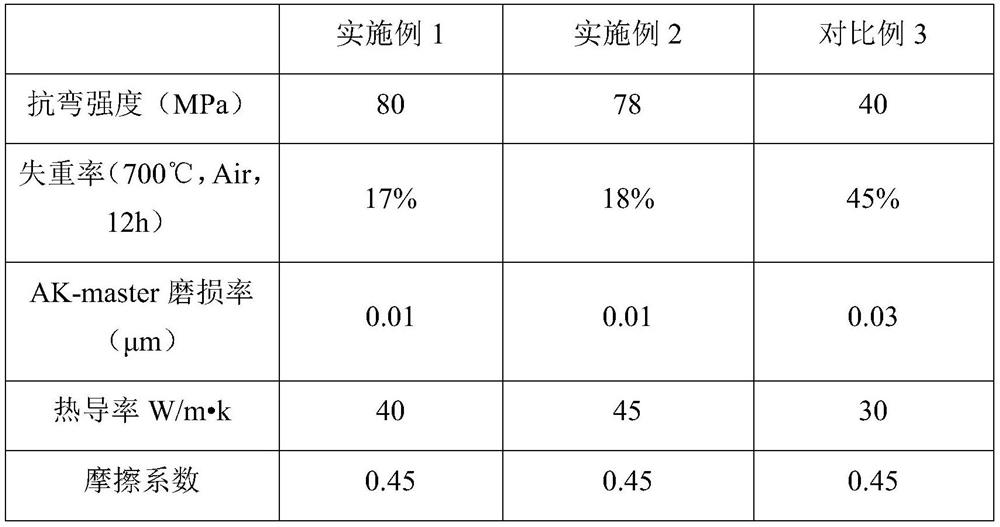

Examples

Embodiment 1

[0039] A method for preparing an anti-wear carbon / ceramic brake material, comprising the steps of:

[0040] (1) Firstly, the purchased T700 chopped carbon fiber is made into a short-fiber tire mesh, and the tire mesh is stacked in sequence, and then the relay-type needling method is used to needle the above-mentioned layered and stacked tire mesh with barbs. During the acupuncture process, the claws of the barbed needles bring the fibers of each tire mesh layer to the vertical direction, so that the tire meshes are connected into one body, and the three-dimensional tire mesh needle-punched prefabricated body is obtained. Cut the three-dimensional tire mesh needle-punched preform into a ring shape with an outer diameter of 400mm, an inner diameter of 150mm, and a thickness of 60mm. The needle-punched hole density in the three-dimensional tire mesh prefabricated body is 10 holes / cm 2 , the volume content of carbon fiber is about 15%, and the density of the three-dimensional tir...

Embodiment 2

[0048] A method for preparing an anti-wear carbon / ceramic brake material, comprising the steps of:

[0049] (1) Firstly, the purchased T700 chopped carbon fiber is made into a short-fiber tire mesh, and the tire mesh is stacked in sequence, and then the relay-type needling method is used to needle the above-mentioned layered and stacked tire mesh with barbs. During the acupuncture process, the claws of the barbed needles bring the fibers of each tire mesh layer to the vertical direction, so that the tire meshes are connected into one body, and the three-dimensional tire mesh needle-punched prefabricated body is obtained. Cut the three-dimensional tire mesh needle-punched prefabricated body into a ring shape, with an outer diameter of 350mm, an inner diameter of 150mm, and a thickness of 70mm. The needle-punched hole density in the three-dimensional tire mesh prefabricated body is 8 holes / cm 2 , the volume content of carbon fiber is about 15%, and the density of the three-dime...

Embodiment 3

[0056] A method for preparing an anti-wear carbon / ceramic brake material, comprising the steps of:

[0057](1) Firstly, the purchased T700 chopped carbon fiber is made into a short-fiber tire mesh, and the tire mesh is stacked in sequence, and then the relay-type needling method is used to needle the above-mentioned layered and stacked tire mesh with barbs. During the acupuncture process, the claws of the barbed needles bring the fibers of each tire mesh layer to the vertical direction, so that the tire meshes are connected into one body, and the three-dimensional tire mesh needle-punched prefabricated body is obtained. Cut the three-dimensional tire mesh needle-punched preform into a ring shape with an outer diameter of 300mm, an inner diameter of 120mm, and a thickness of 50mm. The needle-punched hole density in the three-dimensional tire mesh prefabricated body is 9 pcs / cm 2 , the volume content of carbon fiber is about 15%, and the density of the three-dimensional tire me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com