Patents

Literature

161results about How to "Improve wearing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical-mechanical abrasive composition and method

InactiveUS6436834B1Improve wearing rateHigh purityOther chemical processesDecorative surface effectsAtomic groupCompound (substance)

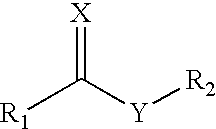

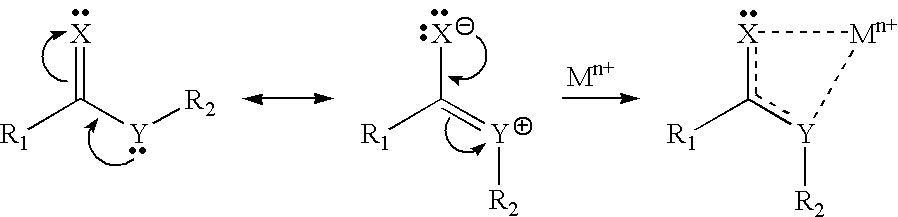

The invention provides a chemical-mechanical abrasive composition for use in semiconductor processing, which comprises an aqueous medium, an abrasive, and an abrasion accelerator. The abrasion accelerator mainly functions to enhance the removal rate of the substances to be removed, and selected from the compounds of the following formula, the acid-addition salts thereof, or mixtures of two or more of the foregoing compounds and salts:wherein X and Y are independently lone-pair electrons containing atoms or atomic groups; and R1 and R2 are independently H, alky, amino, aminoalkyl, or alkoxy. The chemical-mechanical abrasive composition of the invention may optionally comprise an acidic component and / or a salt thereof, so as to further enhance the abrasion rate. The invention further provides a method of using the above chemical-mechanical abrasive composition for polishing the surface of a semiconductor wafer.

Owner:EPOCH MATERIAL CO LTD

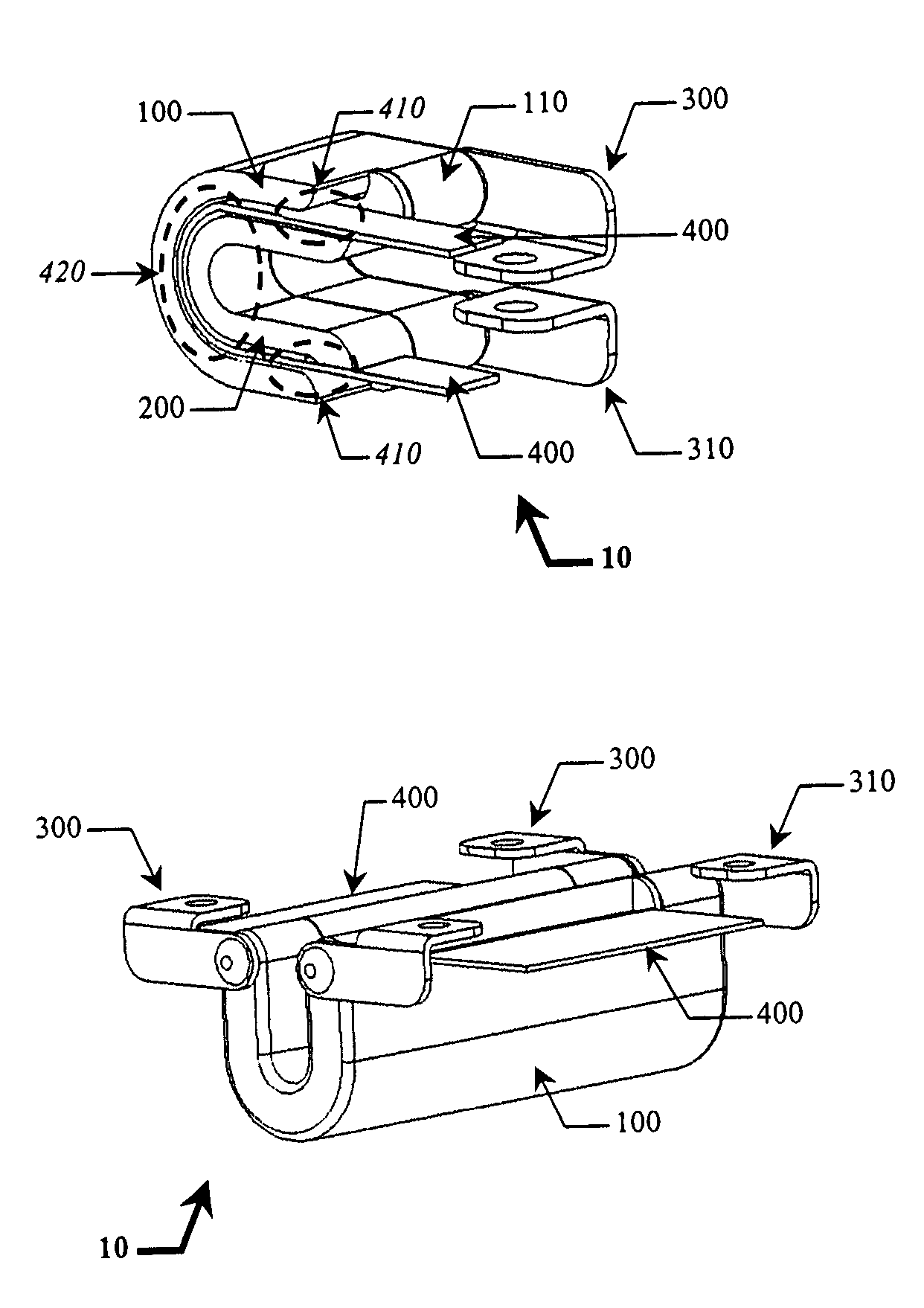

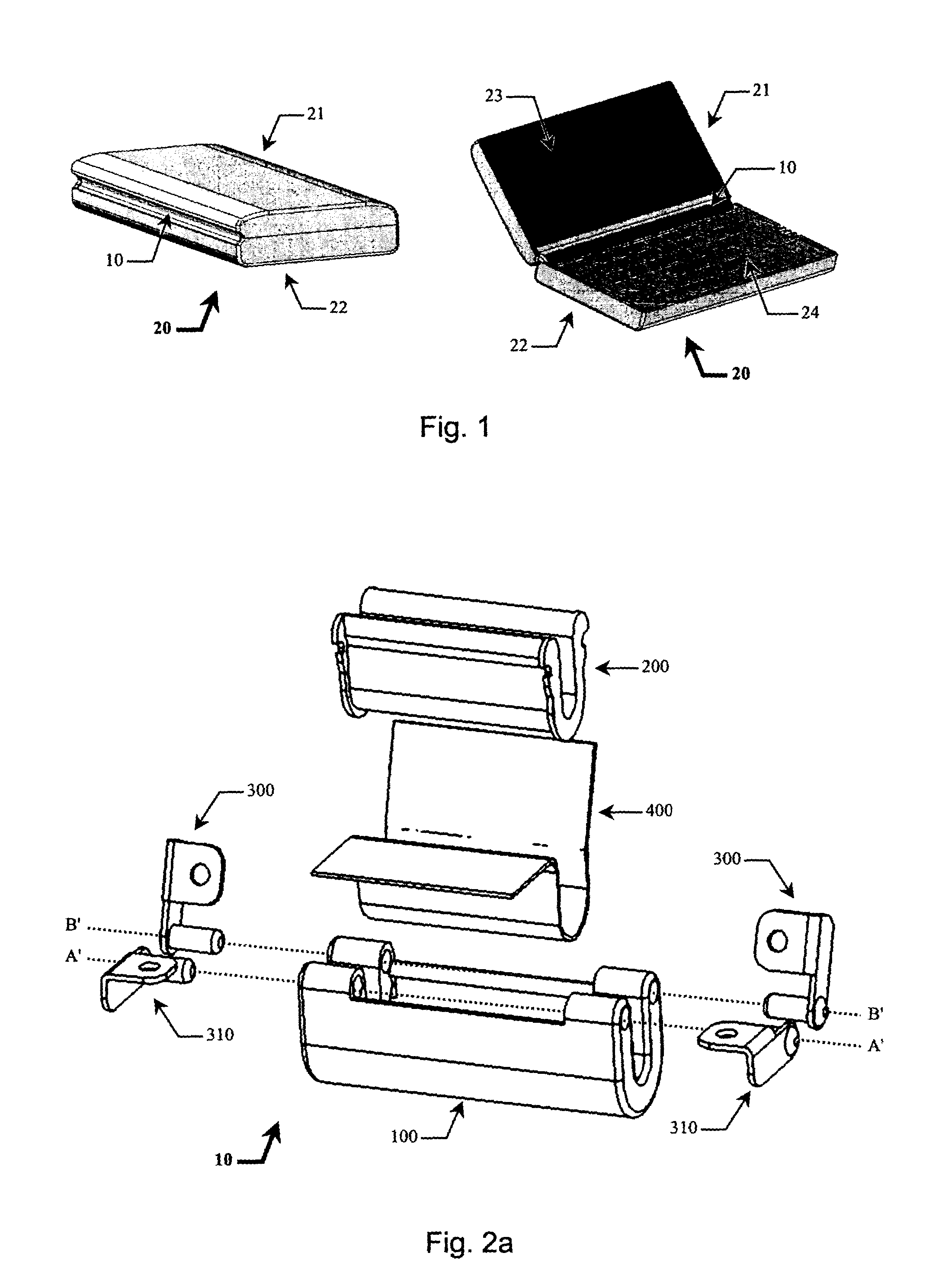

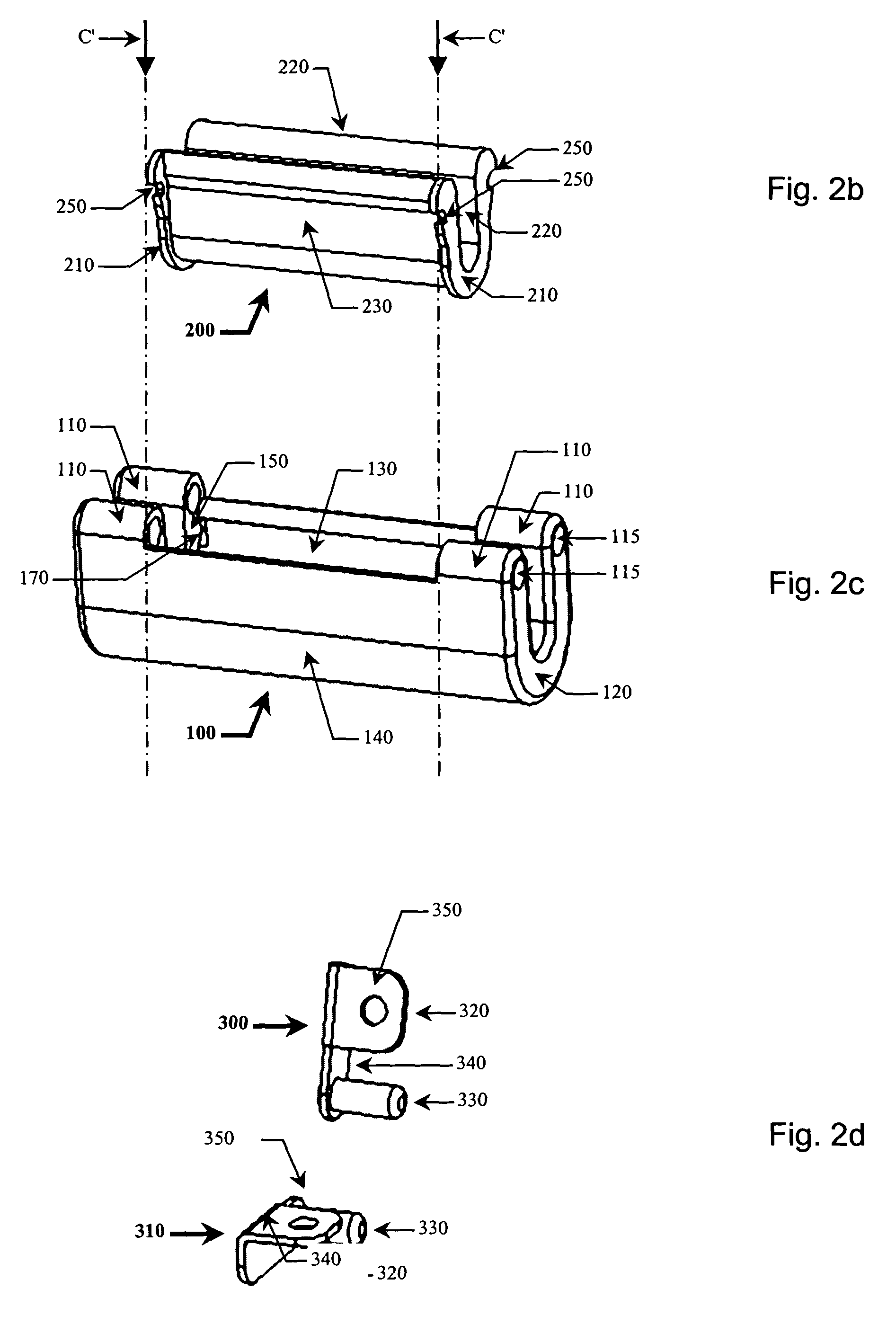

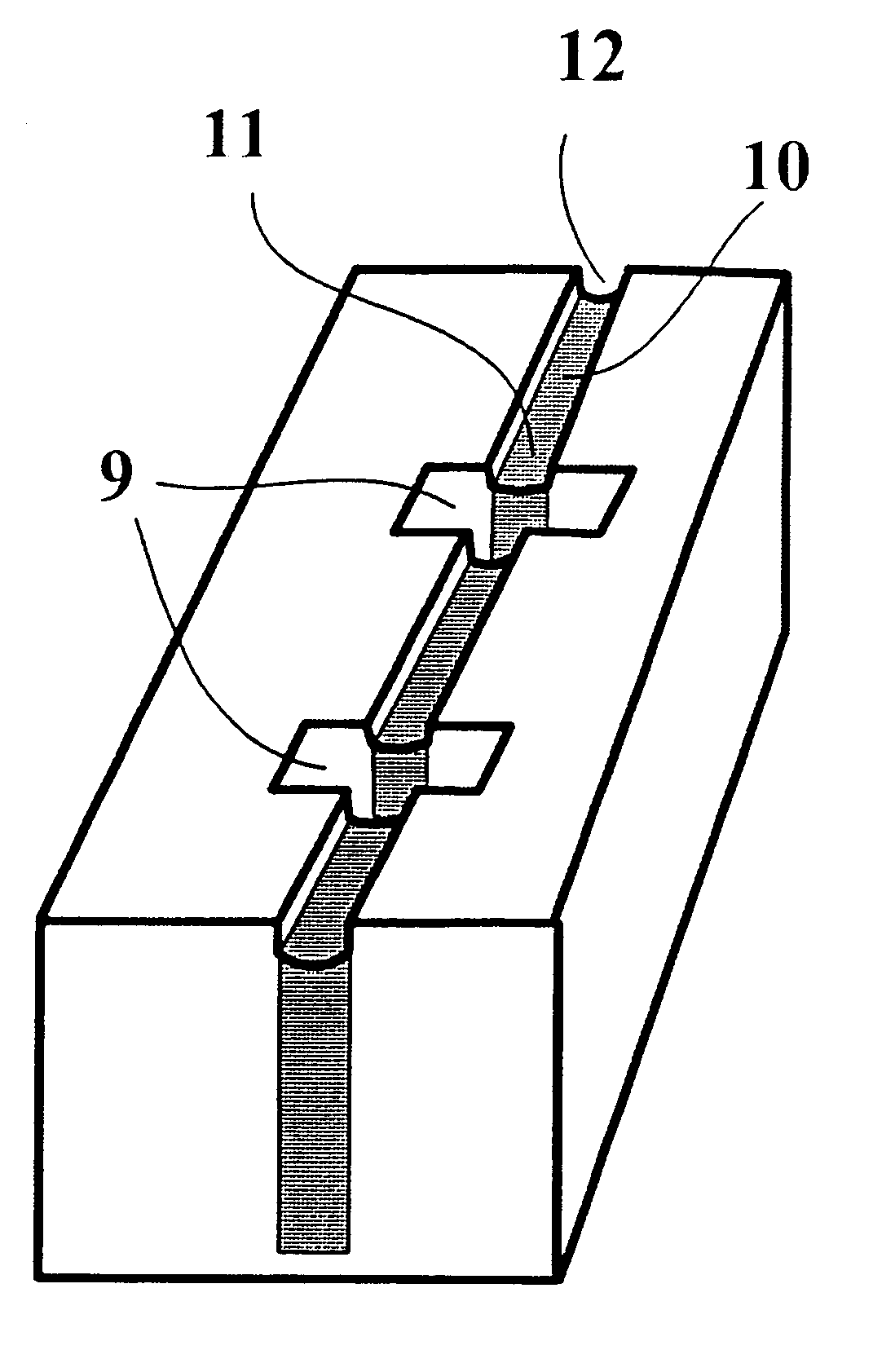

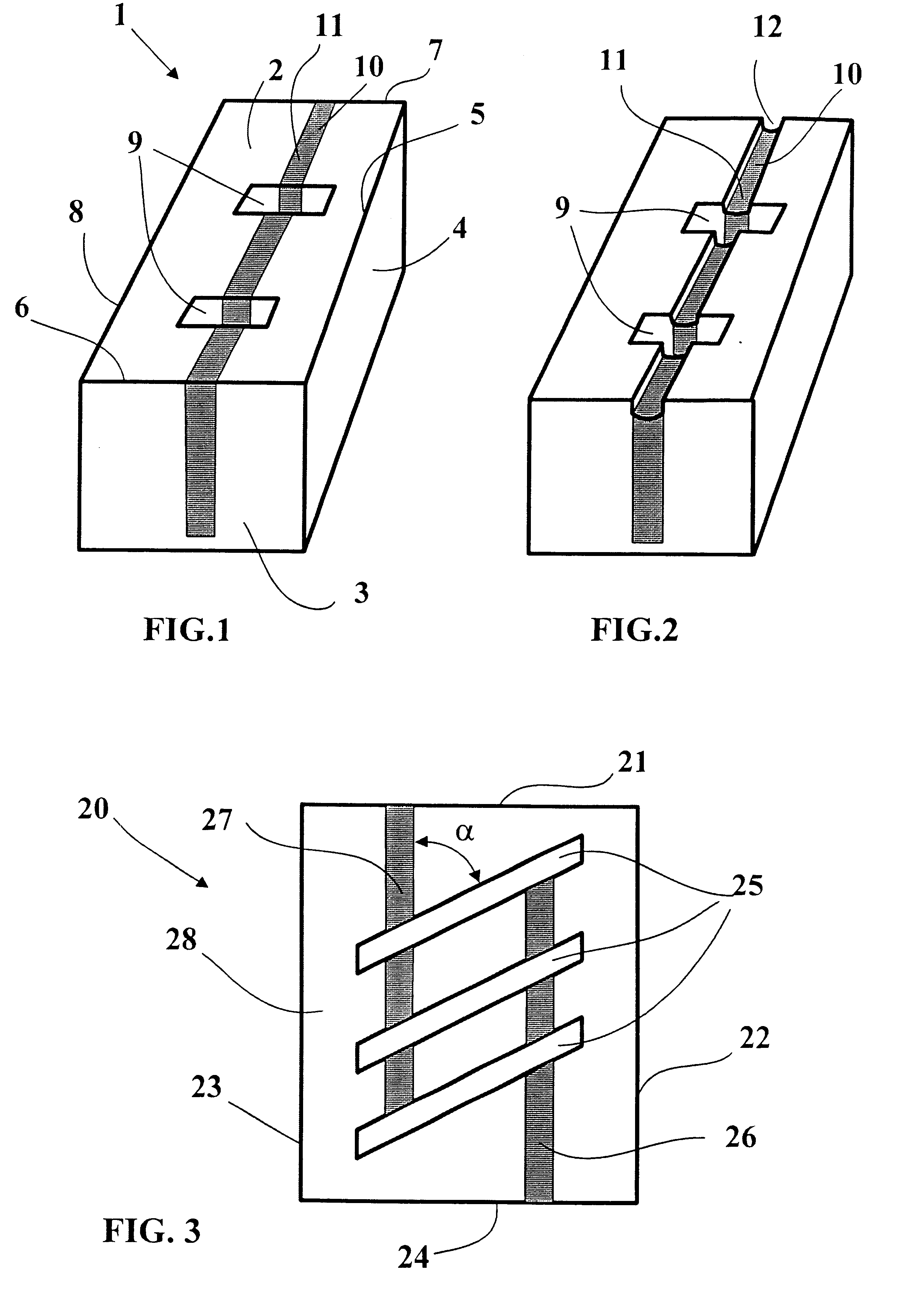

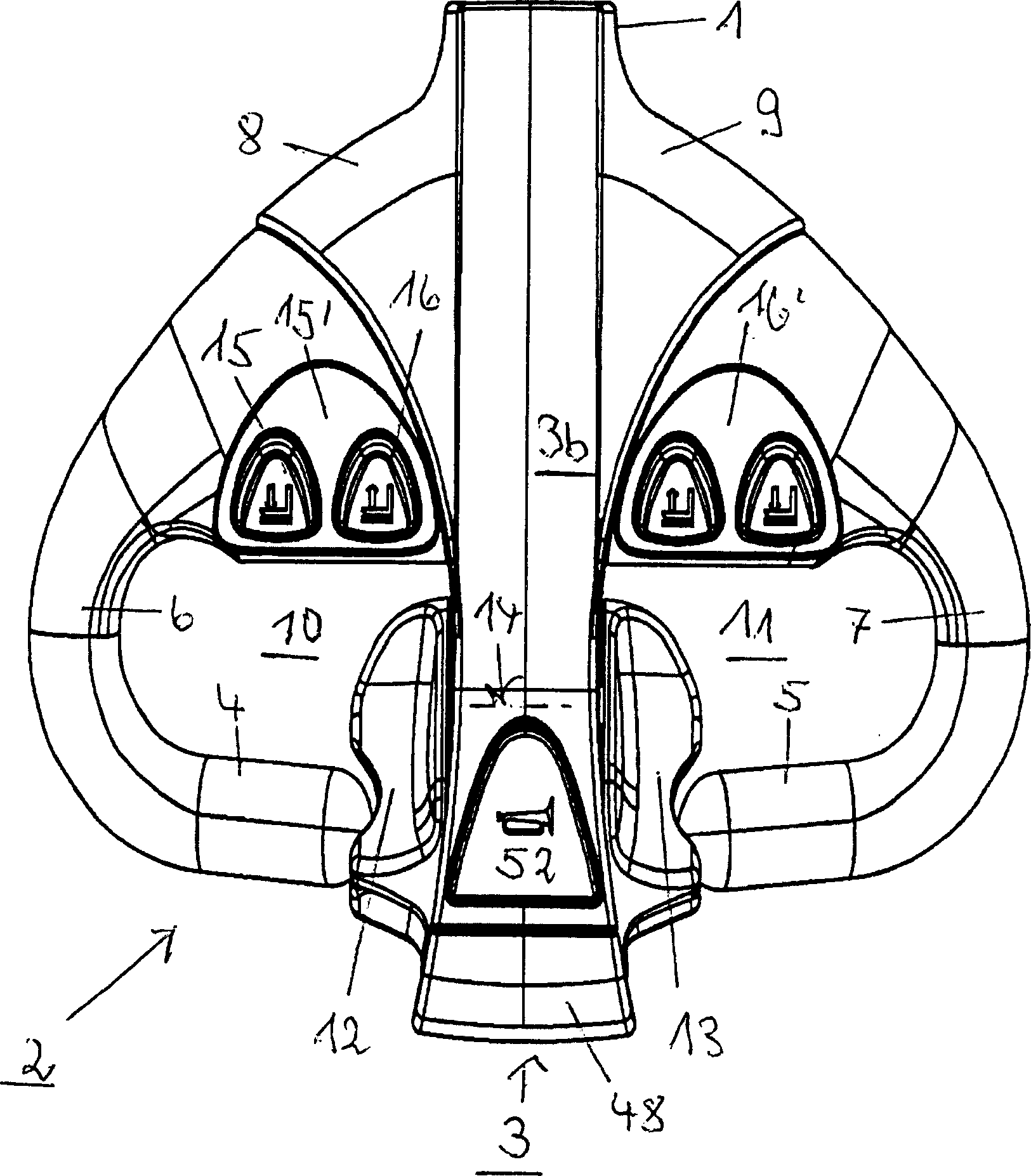

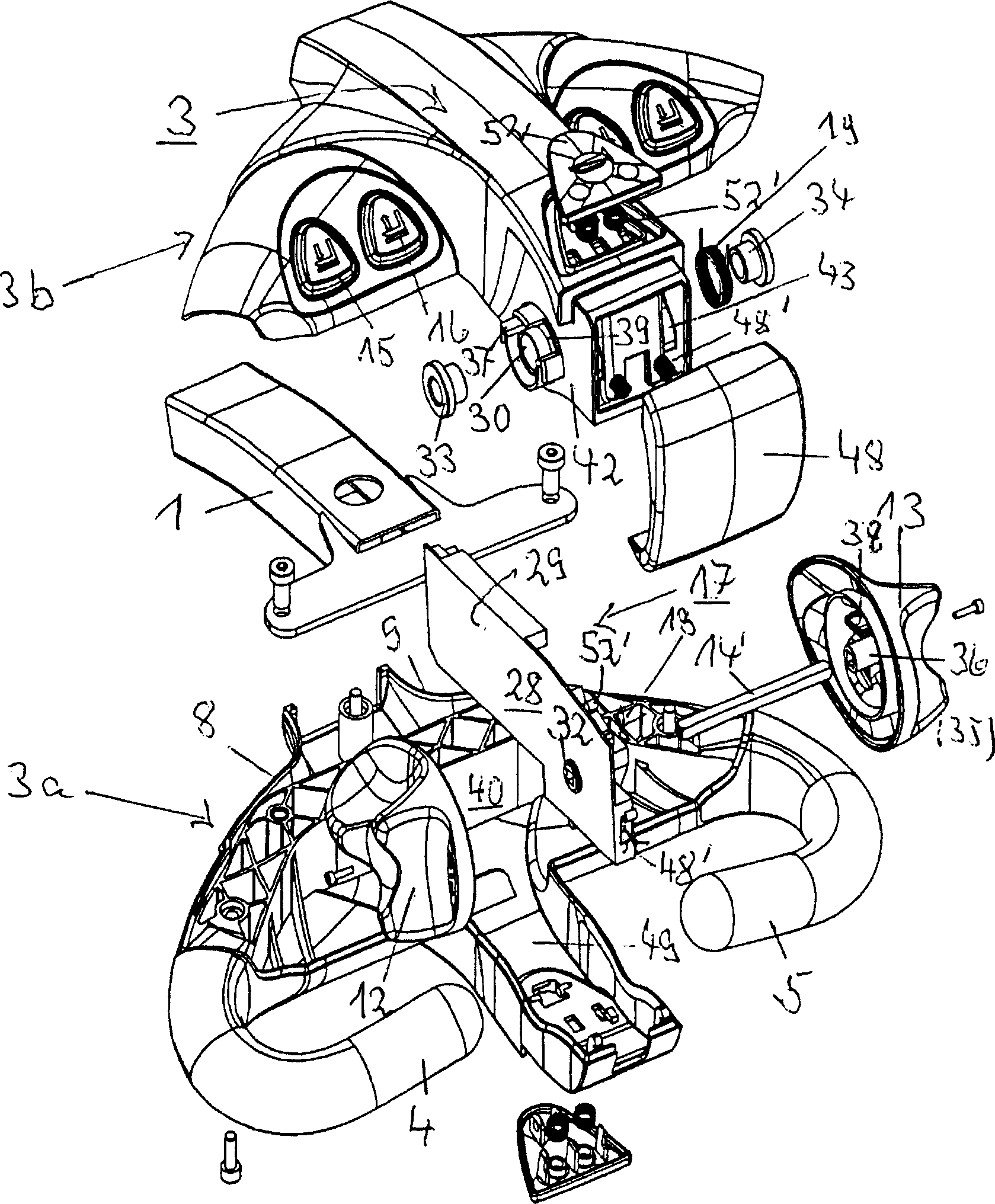

Double articulated hinge mechanism for electronic devices

InactiveUS7054147B2High frequent utilization of the hinge mechanismImprove wearing rateInsulated cablesDetails for portable computersElectrical conductorEngineering

Owner:INTELLECTUAL VENTURES I LLC

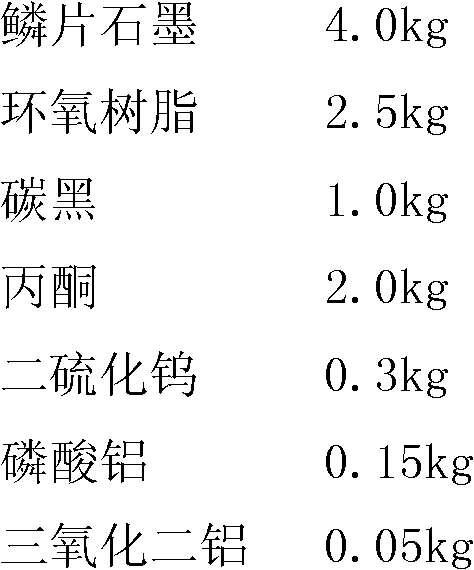

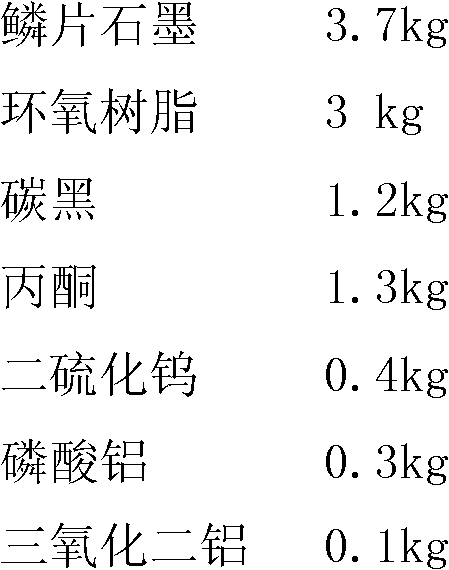

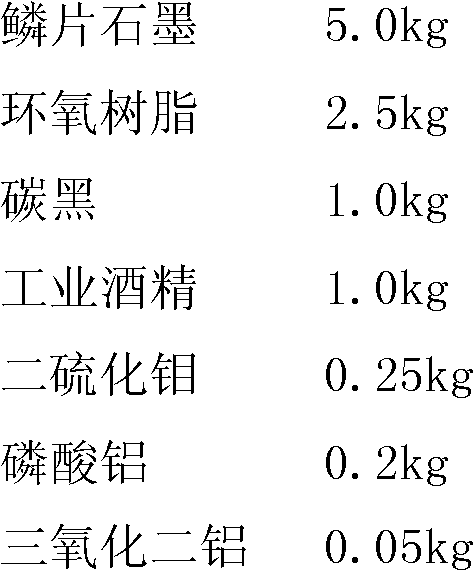

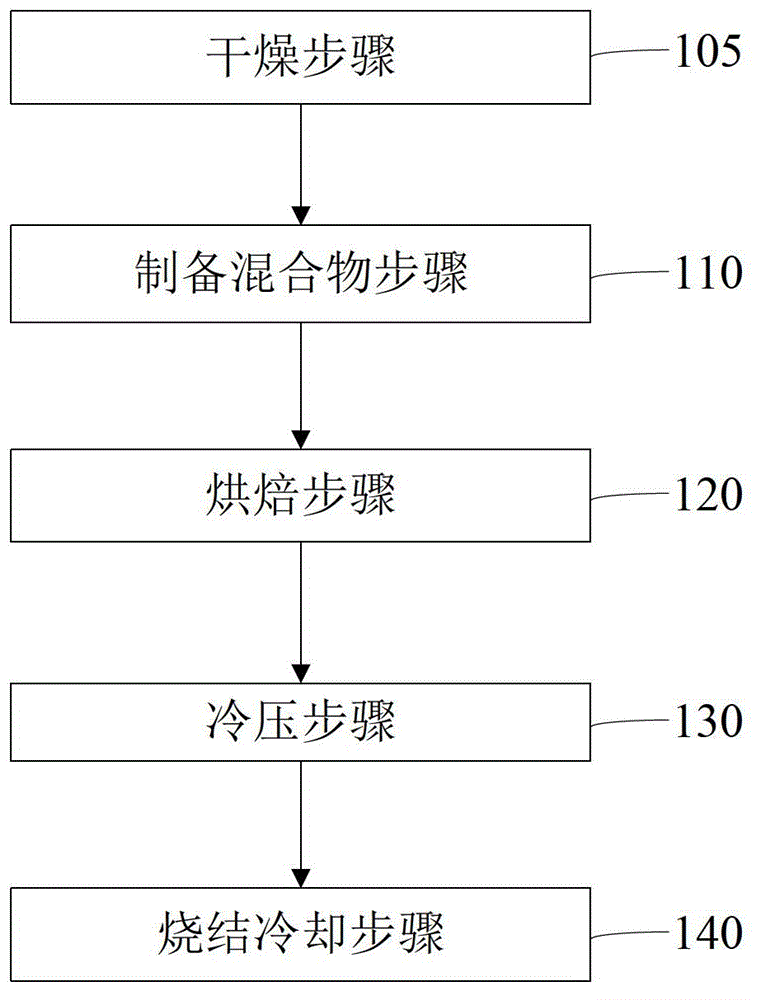

Electric brush for electric tool motor and preparation method thereof

ActiveCN103259150ALow resistivityImprove wear resistanceRotary current collectorBrushes manufactureElectric machineryEngineering

The invention discloses an electric brush for an electric tool motor and a preparation method thereof. Electric brush mixture is roasted and then compressed to form the electric brush. The electric brush mixture comprises, part by weight, 30-60 parts of natural graphite, 25-40 parts of binder, 10-15 parts of amorphous carbon, 10-25 parts of solvent and 4-8 parts of additive. According to the electric brush for the electric tool motor and the preparation method thereof, preparation technologies are simple, operation is easy, the electric brush is low in resistivity, good in abrasion resistance, good in reversing performance, strong in anti-interference capability and long in service life, various requirements of the electric tool motor for the electric brush can be met better, and application ranges are wide.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Steel member and a method of hard-facing thereof

InactiveUS20060177689A1Improve softeningSuperior metal grain structure refinementMolten spray coatingArc welding apparatusAqueous solutionHeat treated

A method of hard-facing a steel casting is described in which a hard-facing, which comprises a weld alloy matrix and a hard particulate substance, is attached to the casting by welding. In some embodiments the matrix can be of a similar composition to the casting, and in other embodiments the hard particulates can be rounded and / or substantially spherical, or of a substantially even size. A method is also described for hardening and tempering a steel casting after attaching the hard-facing to the casting by welding. After hard-facing the casting is hardened and tempered by heat treatment. In one embodiment the hard-faced casting is heat treated by heating to a temperature in excess of the austenitising temperature of the steel and then cooled by quenching in an aqueous solution, followed by tempering. In one embodiment the steel casting is tempered at a temperature in the range about 550° C. to about 700° C. prior to hard-facing the casting.

Owner:BRADKEN RESOURCES

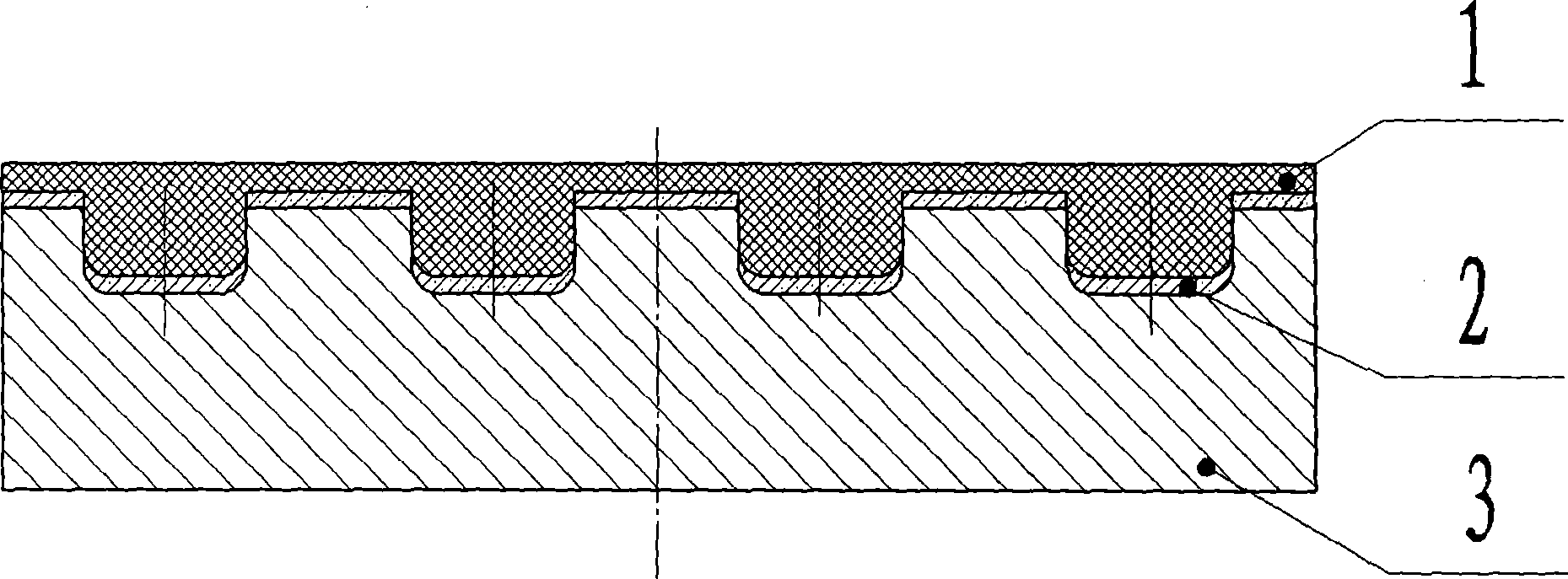

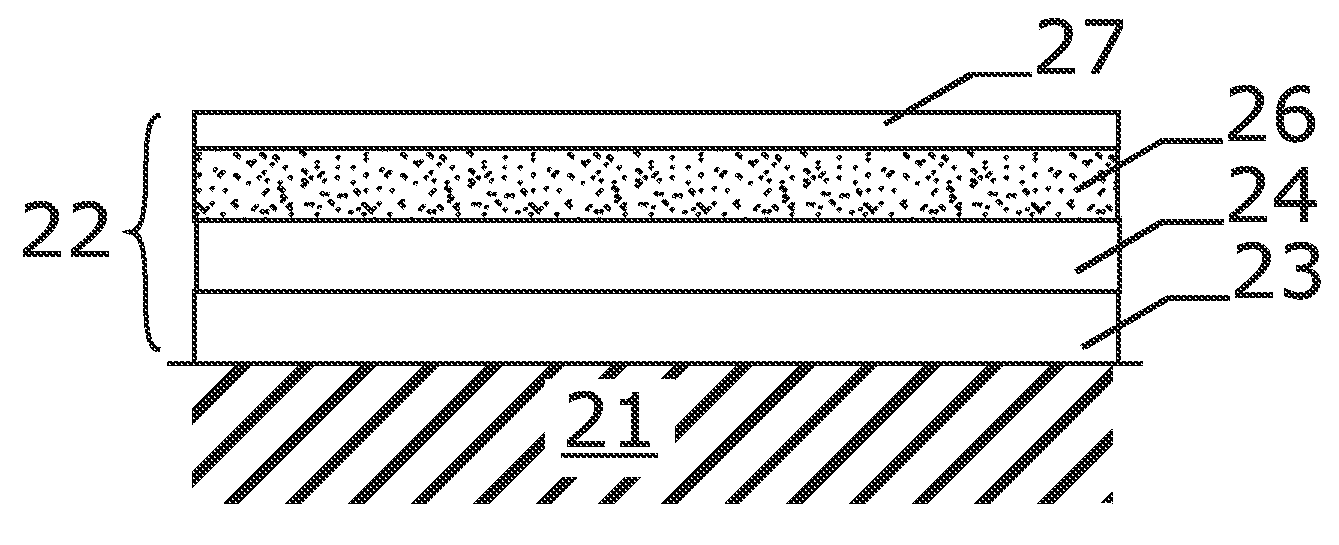

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

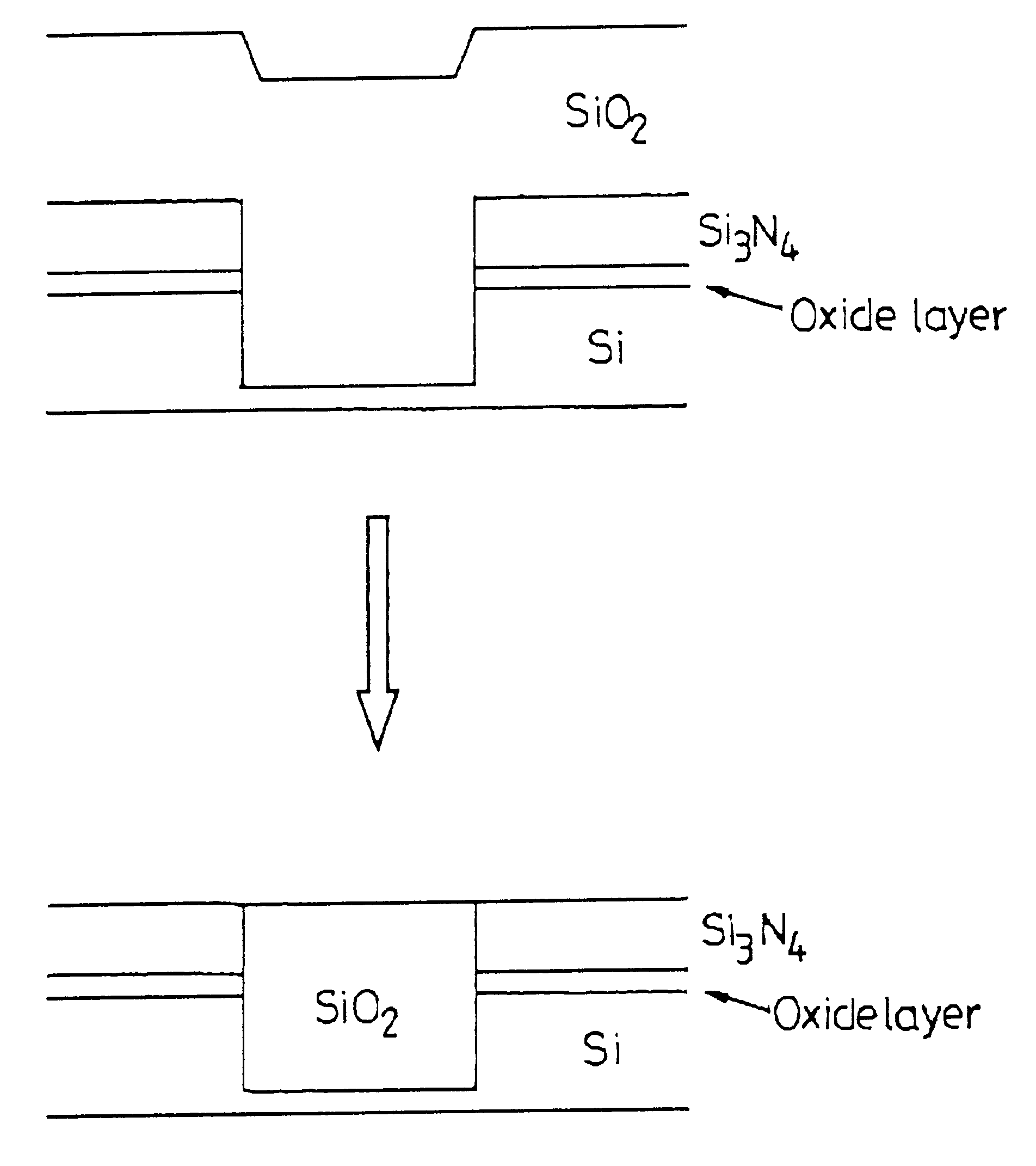

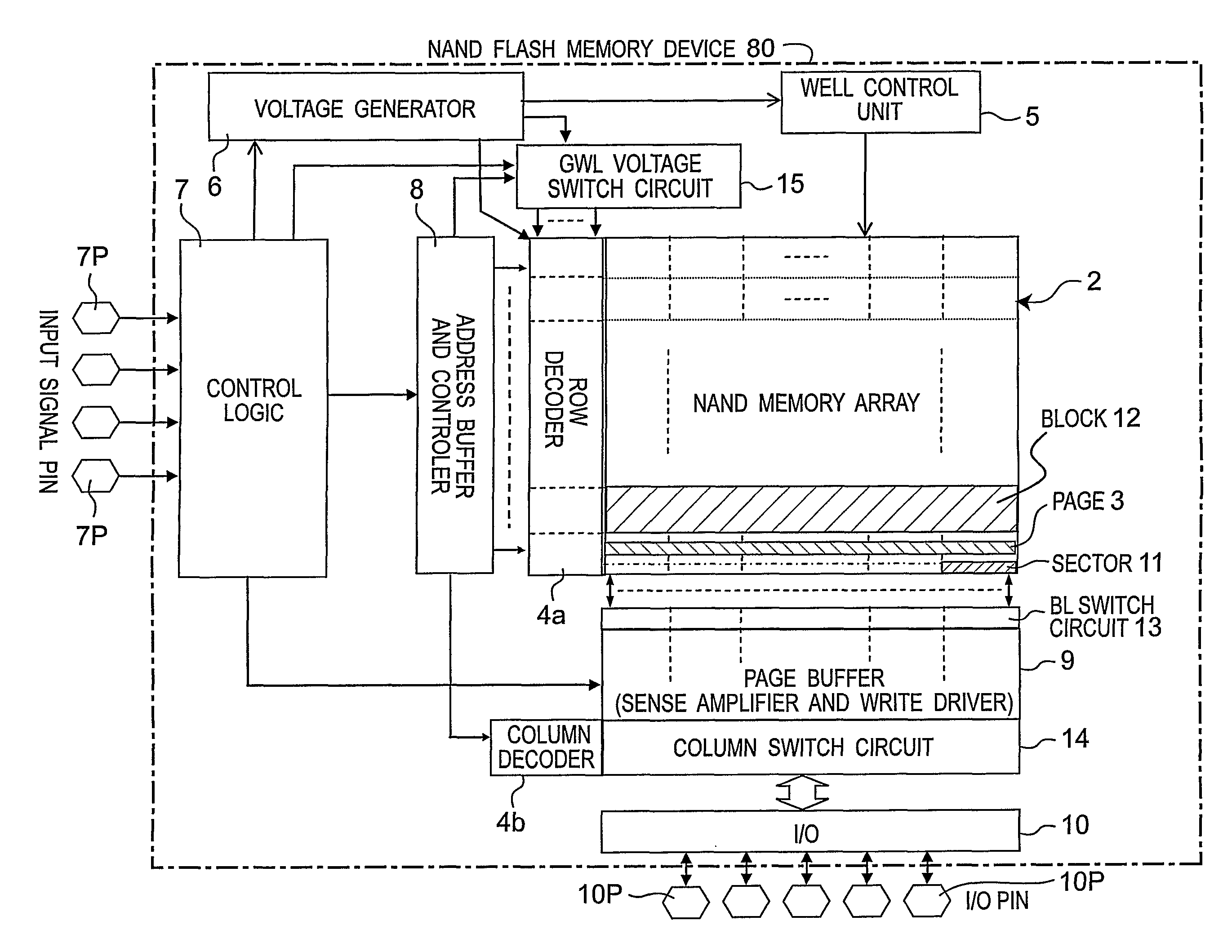

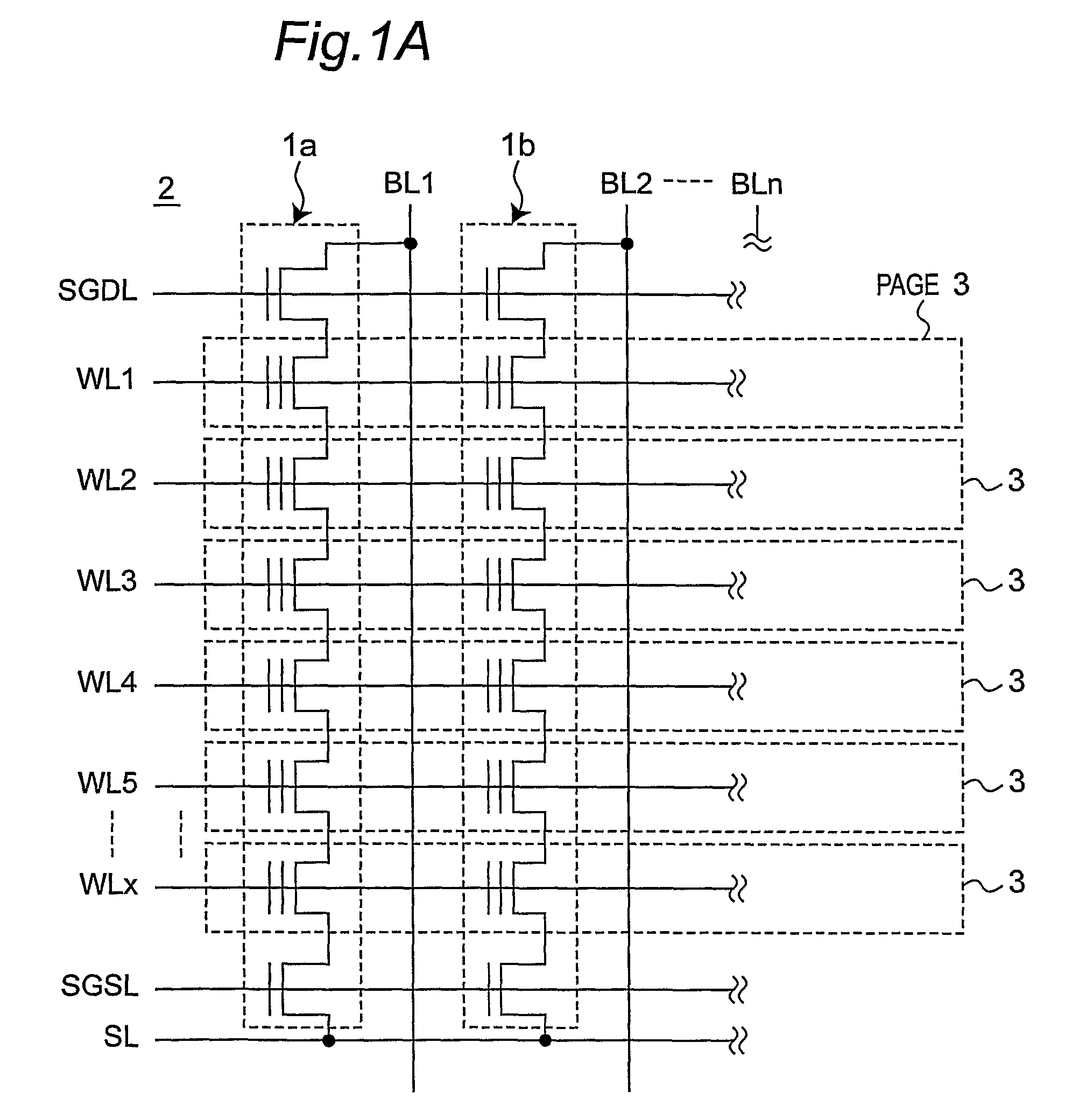

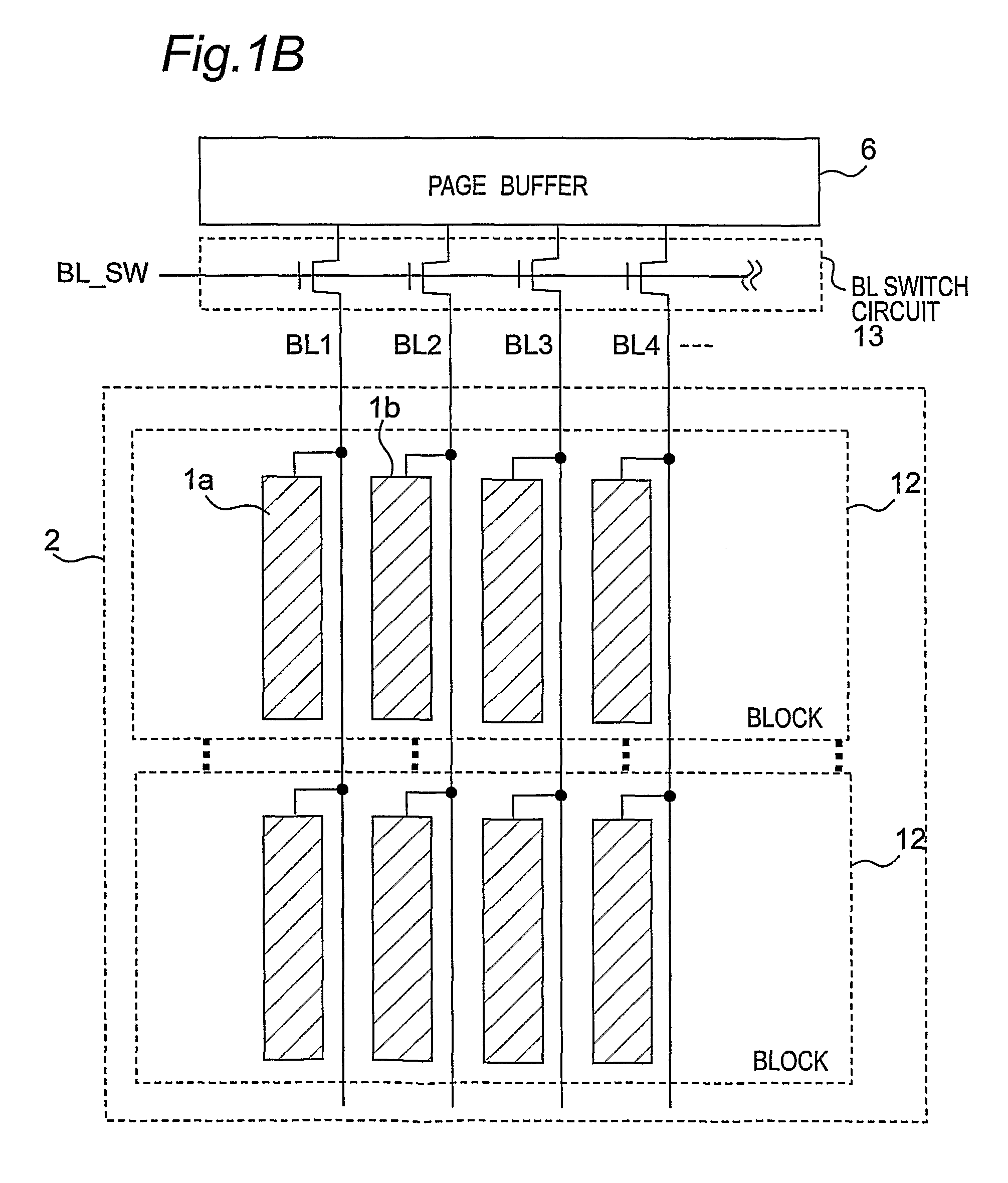

Programming method for NAND flash memory device to reduce electrons in channels

ActiveUS8599614B2Reducing or preventing the programming disturbReduce frequencySolid-state devicesRead-only memoriesFile systemElectron

In a programming method for a NAND flash memory device, a self-boosting scheme is used to eliminate excess electrons in the channel of an inhibit cell string that would otherwise cause programming disturb. The elimination is enabled by applying a negative voltage to word lines connected to the inhibit cell string before boosting the channel, and this leads to bringing high program immunity. A row decoder circuitry to achieve the programming operation and a file system architecture based on the programming scheme to improve the efficiency of file management are also described.

Owner:POWERCHIP SEMICON MFG CORP

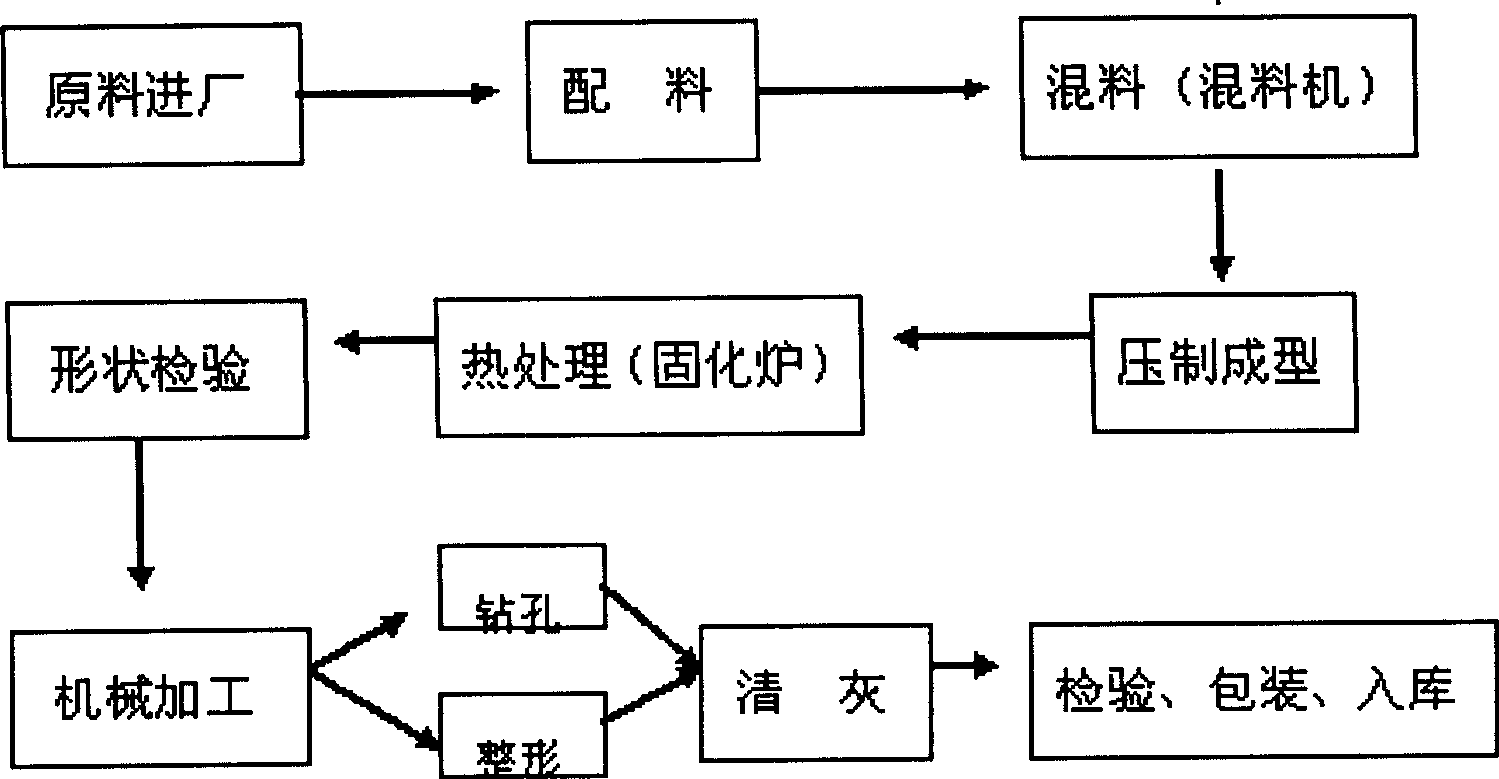

Asbestos-free clutch facing used in vehicle and manufacture method therefor

InactiveCN101033786AImprove performanceHigh strengthFriction liningHeat treatedTemperature and pressure

The invention discloses a kind of none asbestos clutch facing used in cars and its production technology. The recipe of the component is that: E-glass fiber 30~50%, fragrance fiber 1~4%, polyacrylonitrile fiber 0.6~1.2%, the oil of cashew shell friction-type mix 3~6%, oil coke blacking 3~5%, particle graphite 5~8%, zinc oxide 0.2~1%, calcium sulfate 5~15%, heavy calcium carbonate 10~20%, flour acrylonitrile butadiene rubber 15~25%, anti-aging protective TMQ 0.2~0.5%, curing accelerator MBTS 0.2~0.5%, the oil of cashew shell resin modified 6~12%. Banburying mix the component told above in proportions at the proper temperature then make up pellicle by smelting and at last rolls in with the E-glass fiber then forms different ordinance blanks by winding. The blanks confect by heat pressing at the proper temperature and pressure then make into production by grinding and drilling holes. It has the merits like that: high strength, good ductility and stabilize coefficient of friction and so on.

Owner:福建冠良汽车配件工业有限公司

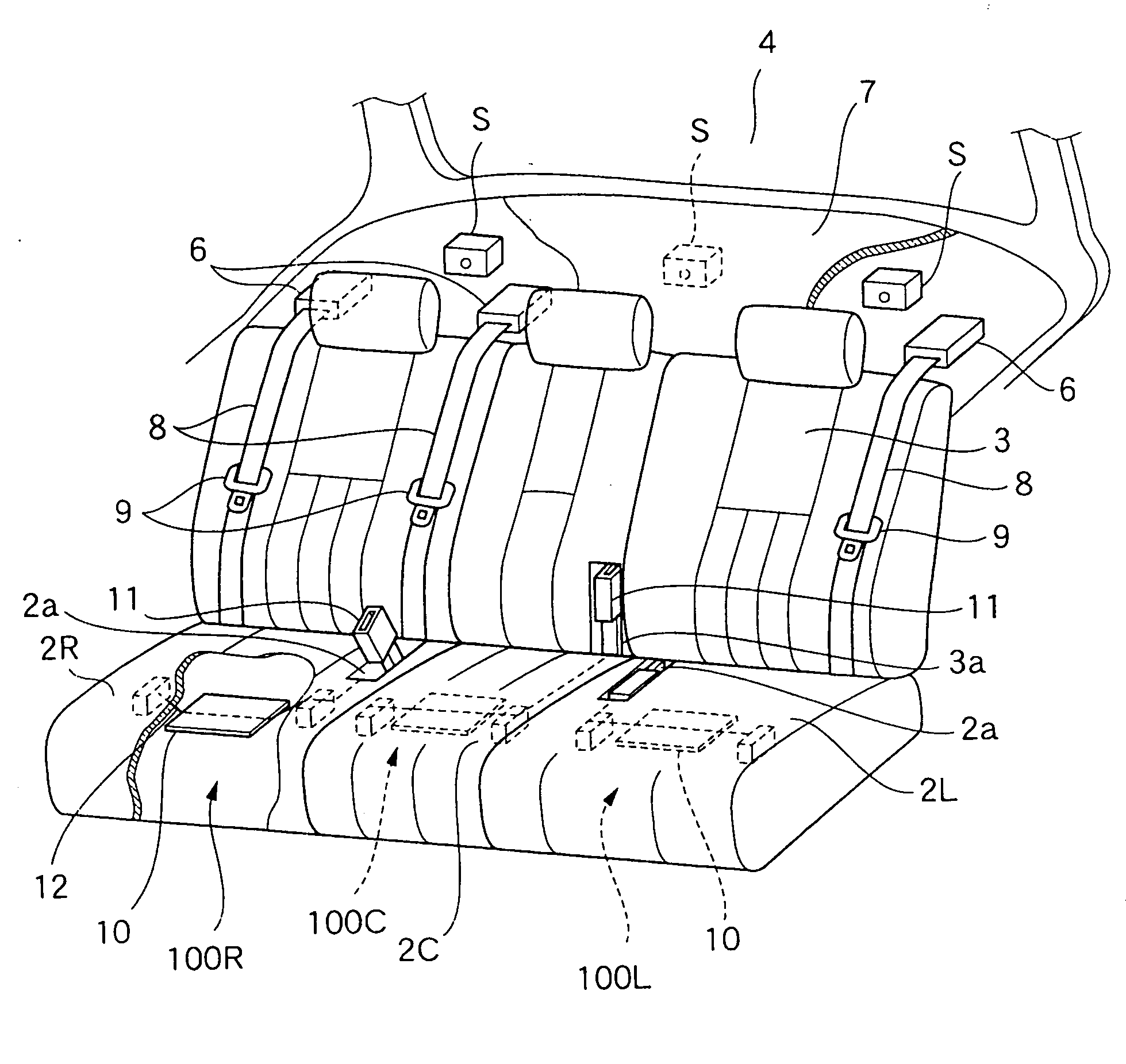

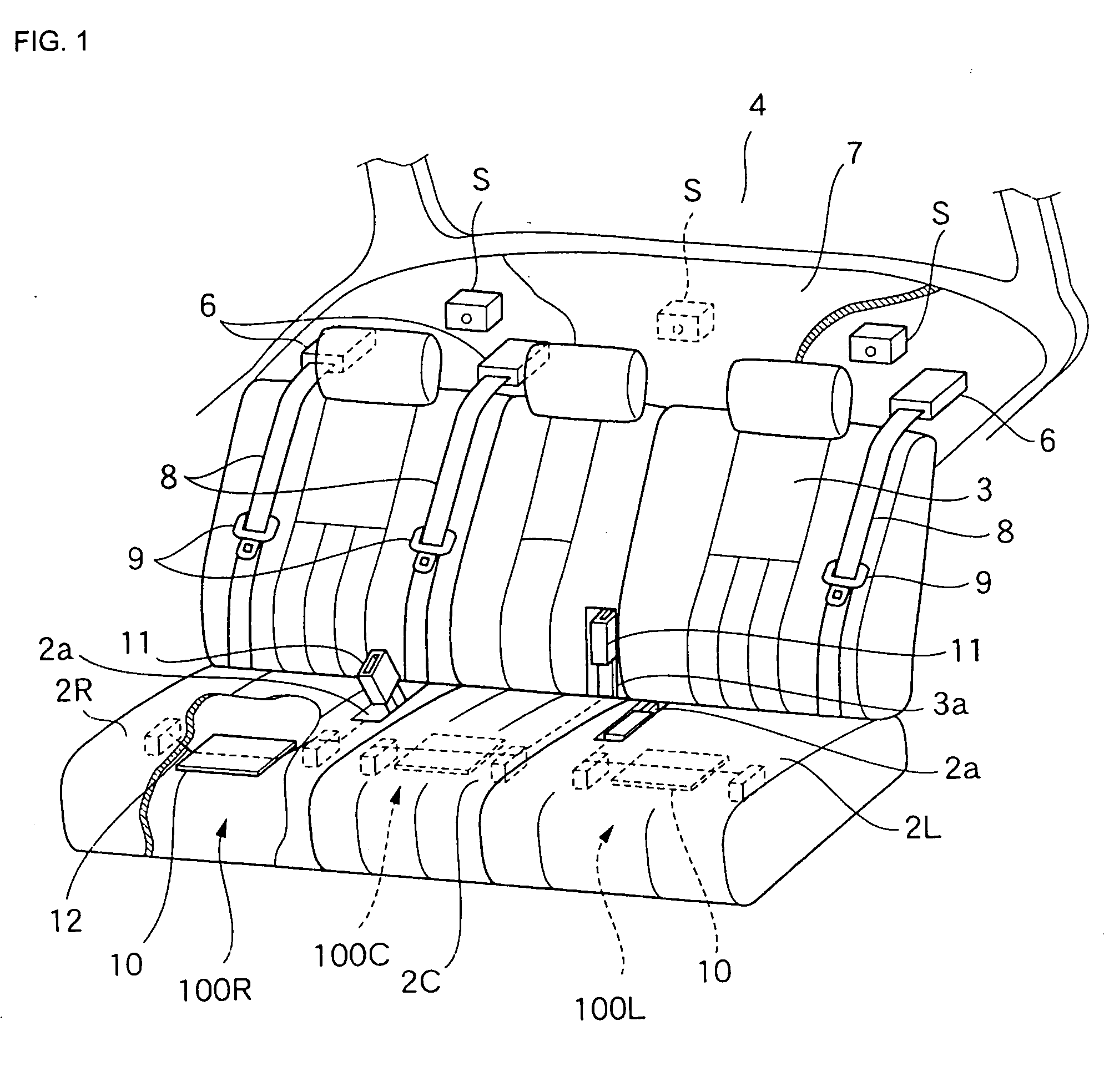

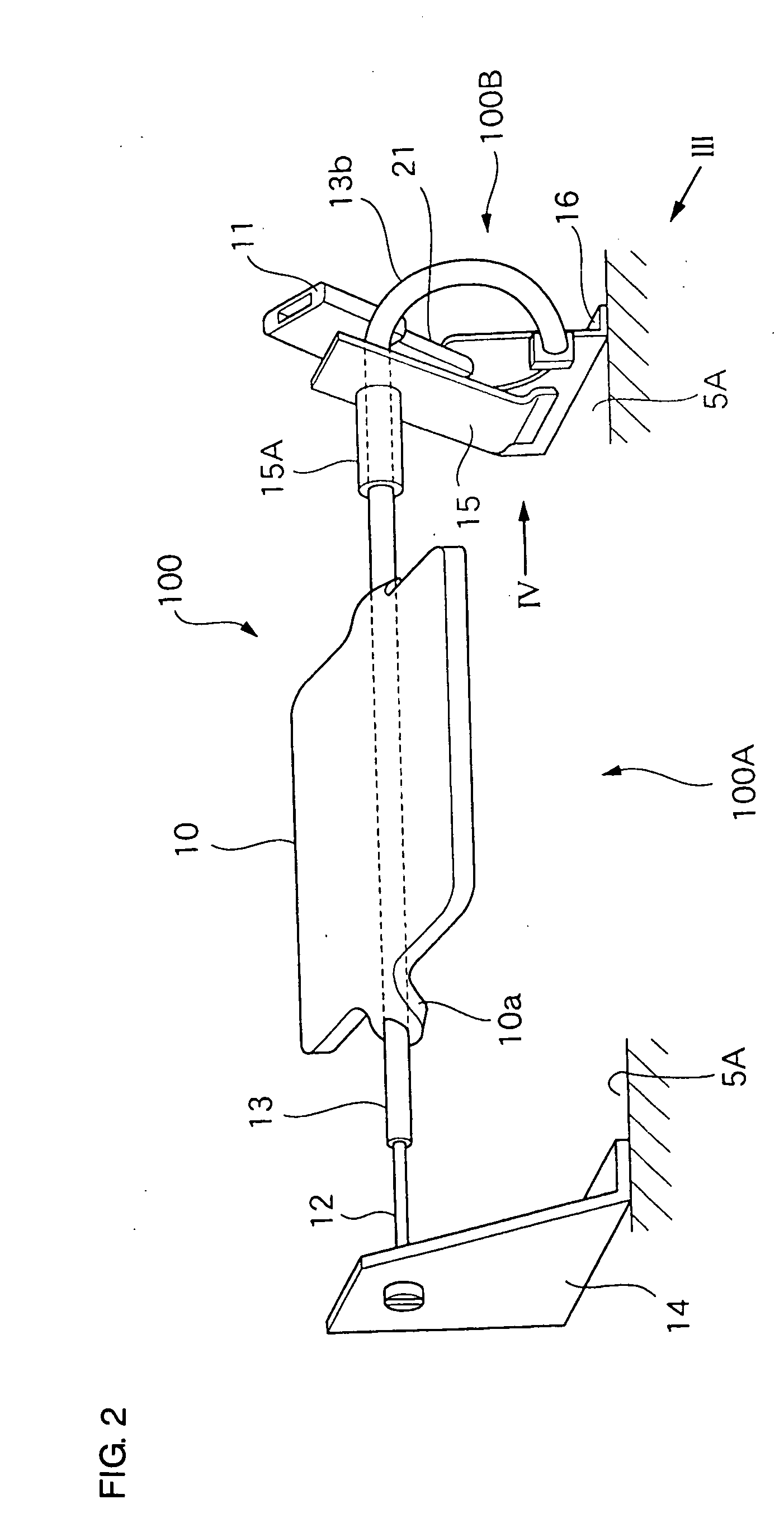

Seatbelt buckle apparatus

InactiveUS20090094807A1Avoid damageSuffer damageDigital data processing detailsBelt control systemsEngineeringBelt safety

Owner:TAKATA CORPORATION

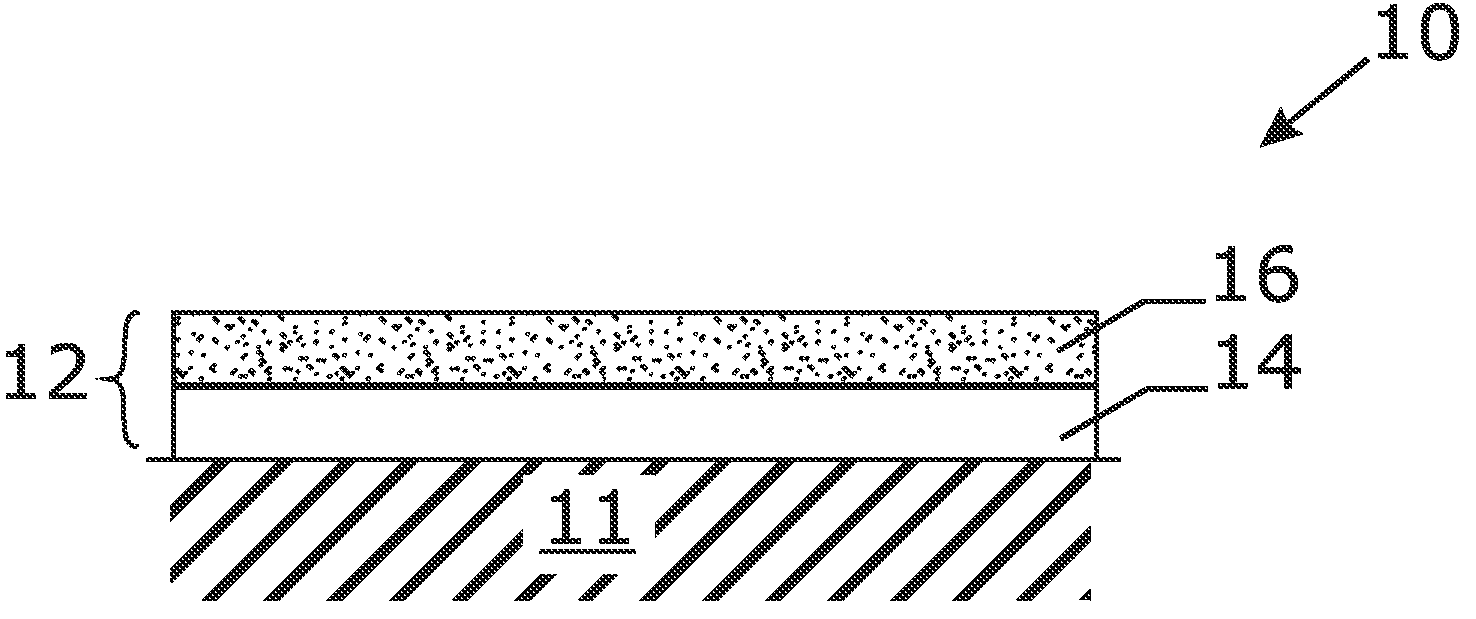

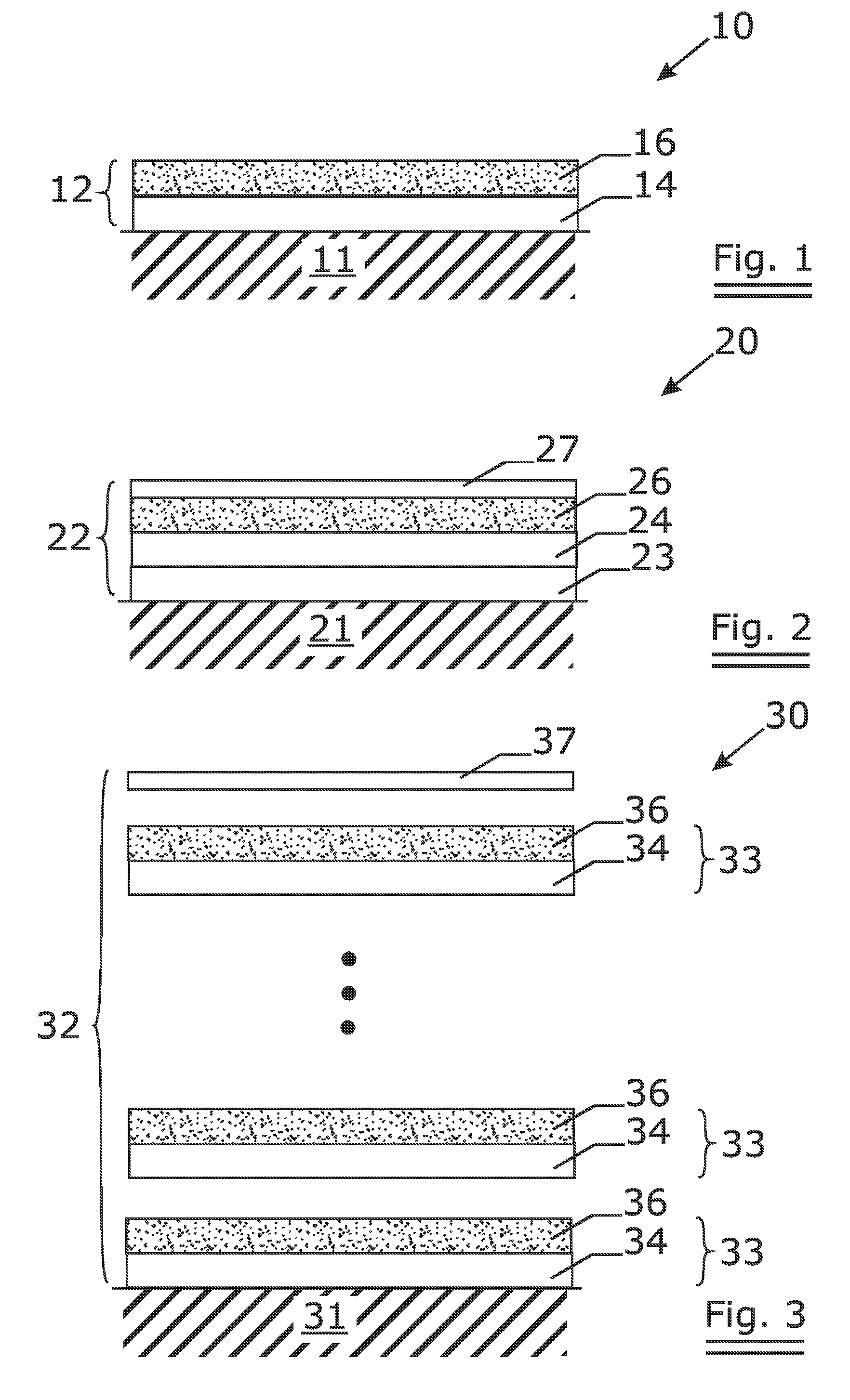

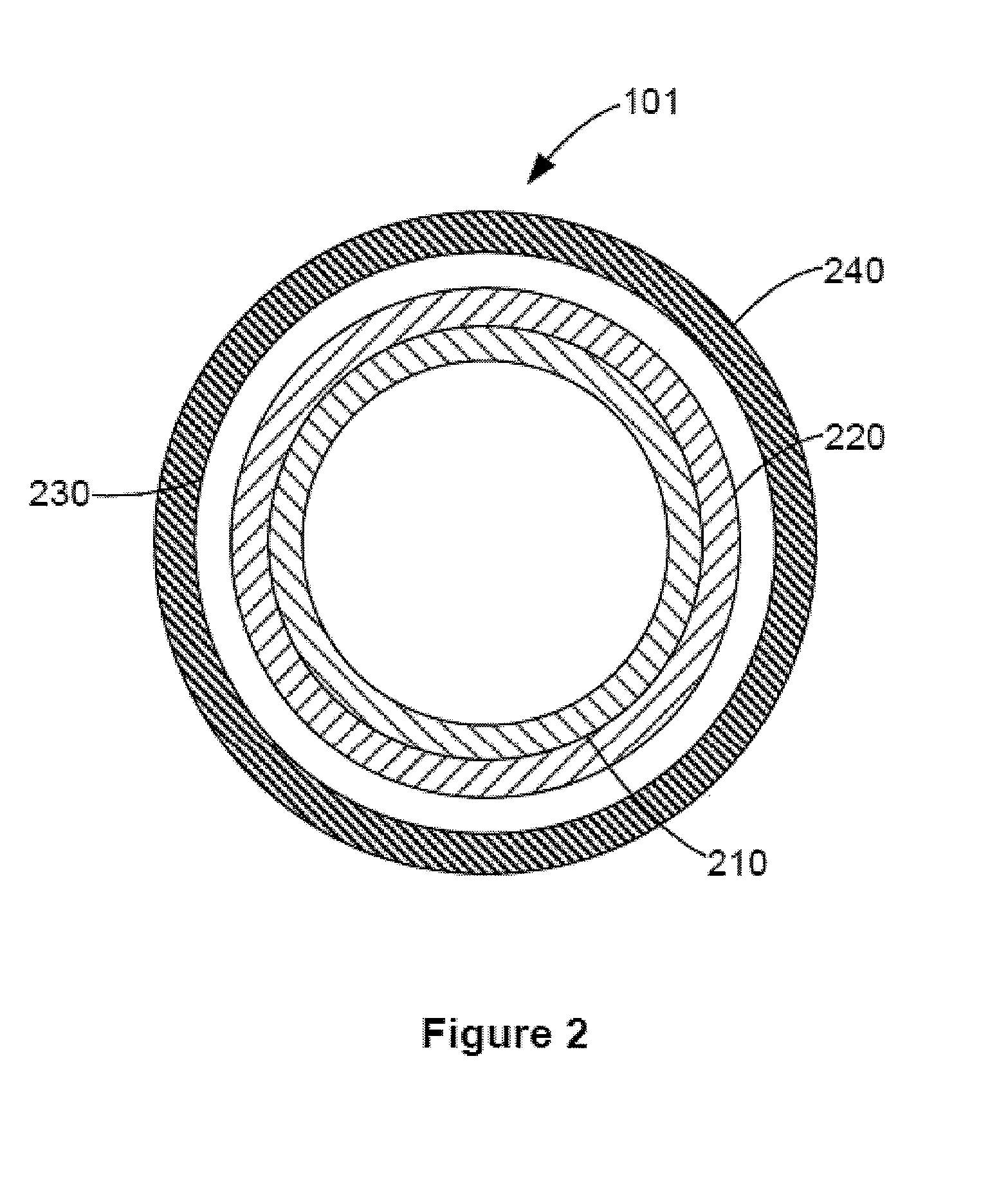

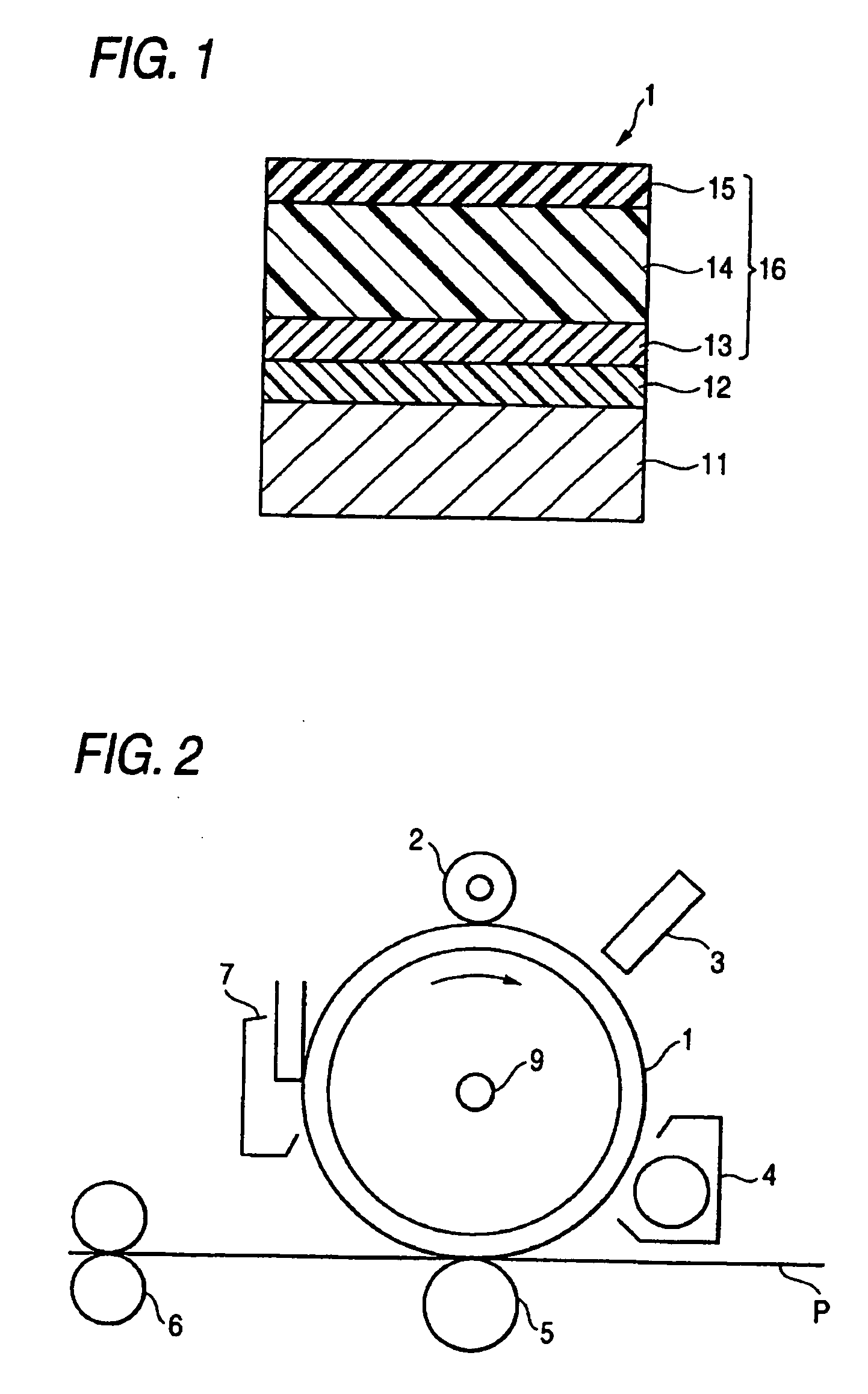

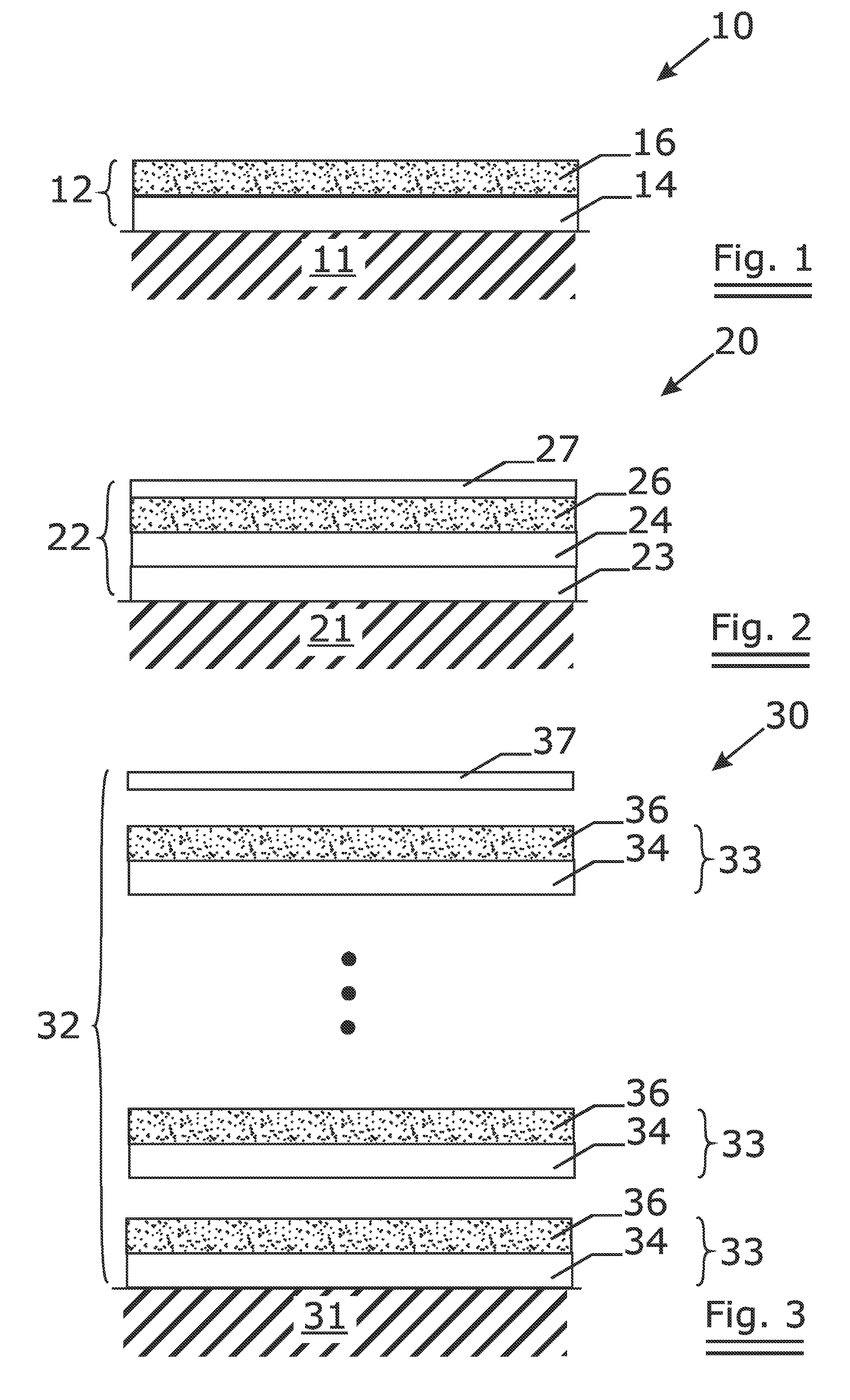

Substrate coated with a layered structure comprising a tetrahedral carbon coating

ActiveUS7820293B2Improve adhesionReduce roughnessPretreated surfacesNatural mineral layered productsCarbon layerCarbon coating

The invention relates to a metal substrate (11) coated at least partially with a layered structure. The layered structure comprises an intermediate layer (14) deposited on said substrate (11) and a tetrahedral carbon layer (16) deposited on said intermediate layer. The intermediate layer comprises at least one amorphous carbon layer having a Young's modulus lower than 200 GPa and the tetrahedral carbon layer has a Young's modulus higher than 200 GPa. The invention further relates to a method to improve the adhesion of a tetrahedral carbon layer to a substrate and to a method to bridge the gap in Young's modulus of the metal substrate and the Young's modulus of a tetrahedral carbon coating deposited on said metal substrate.

Owner:SULZER METAPLAS

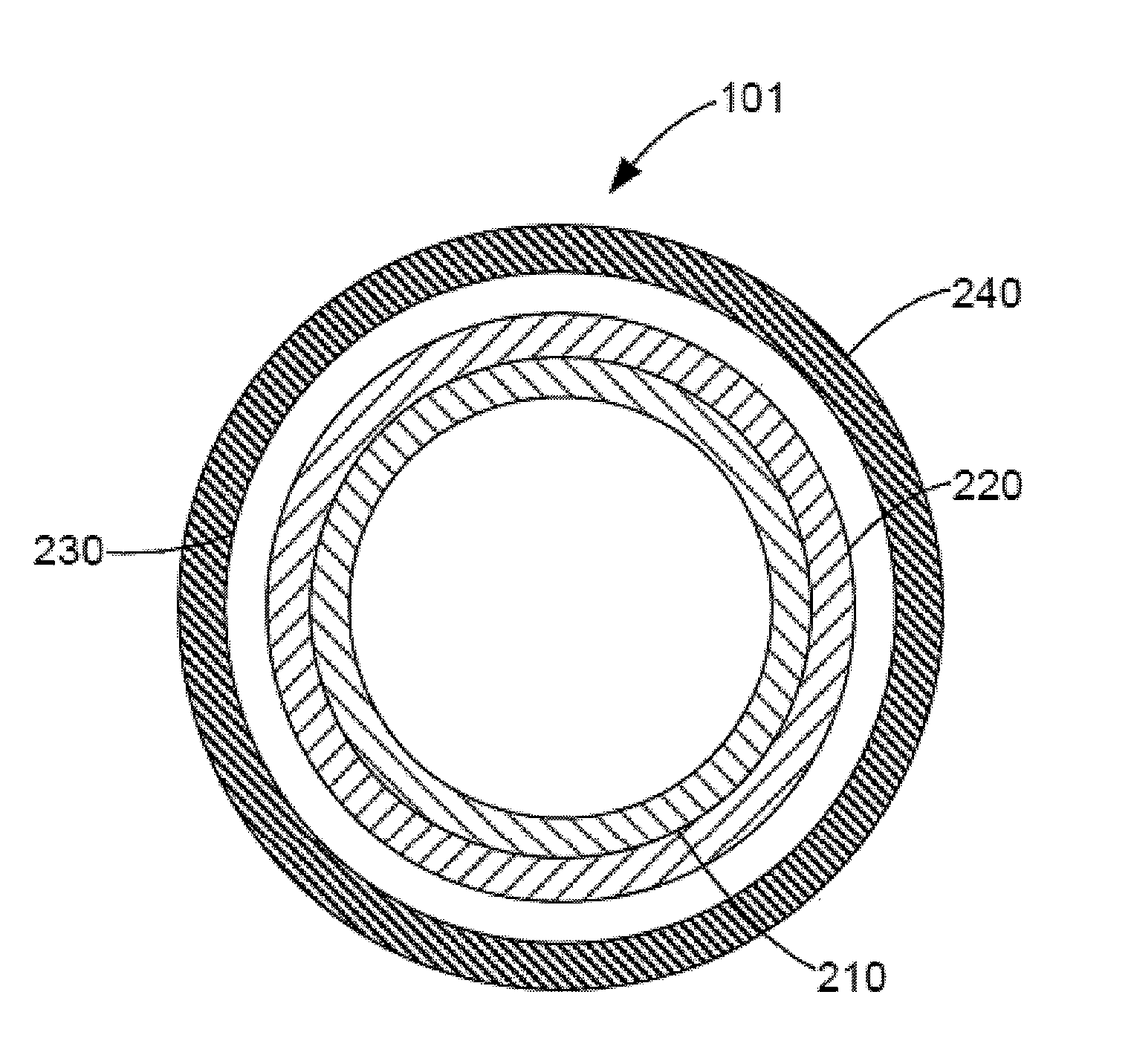

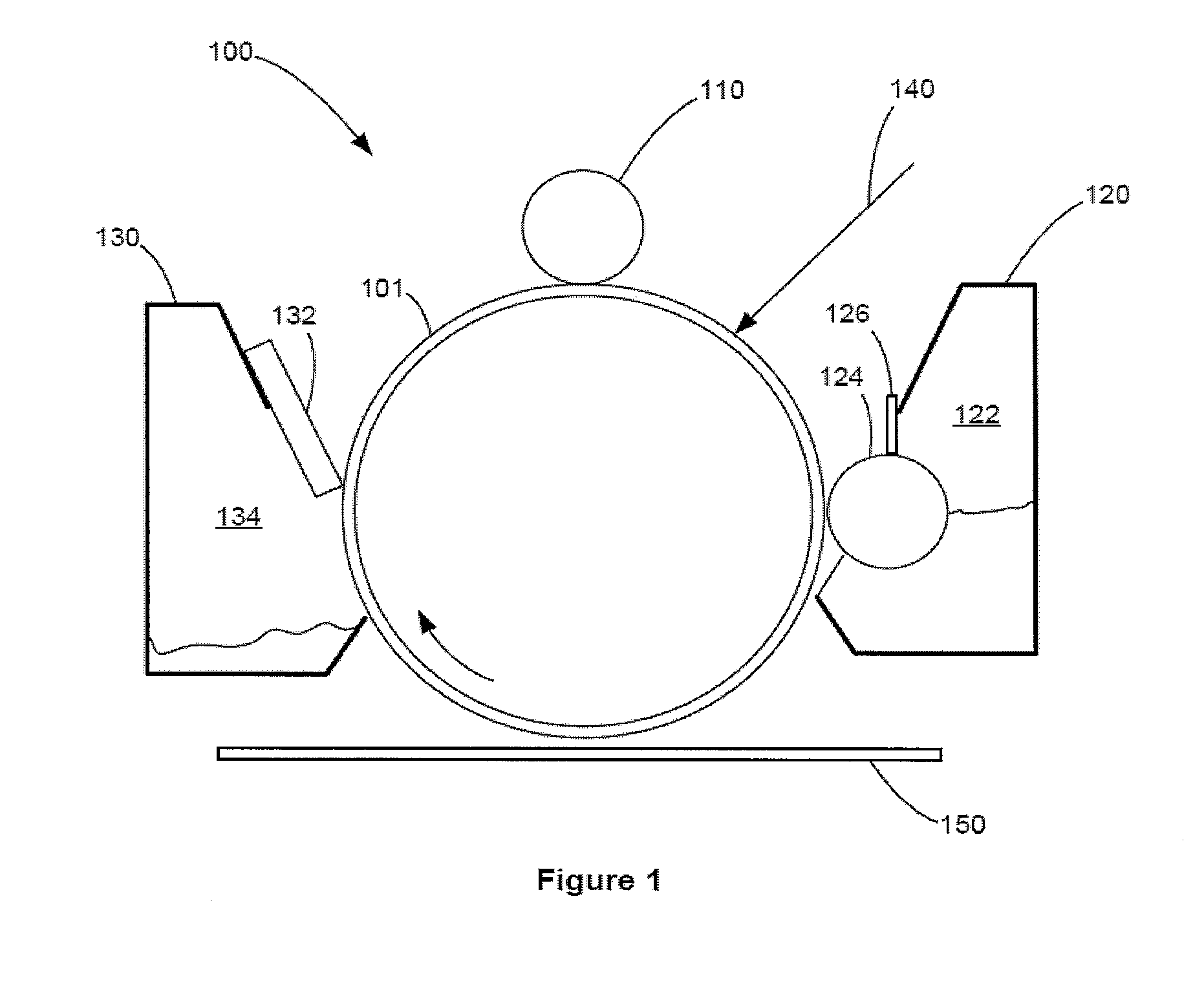

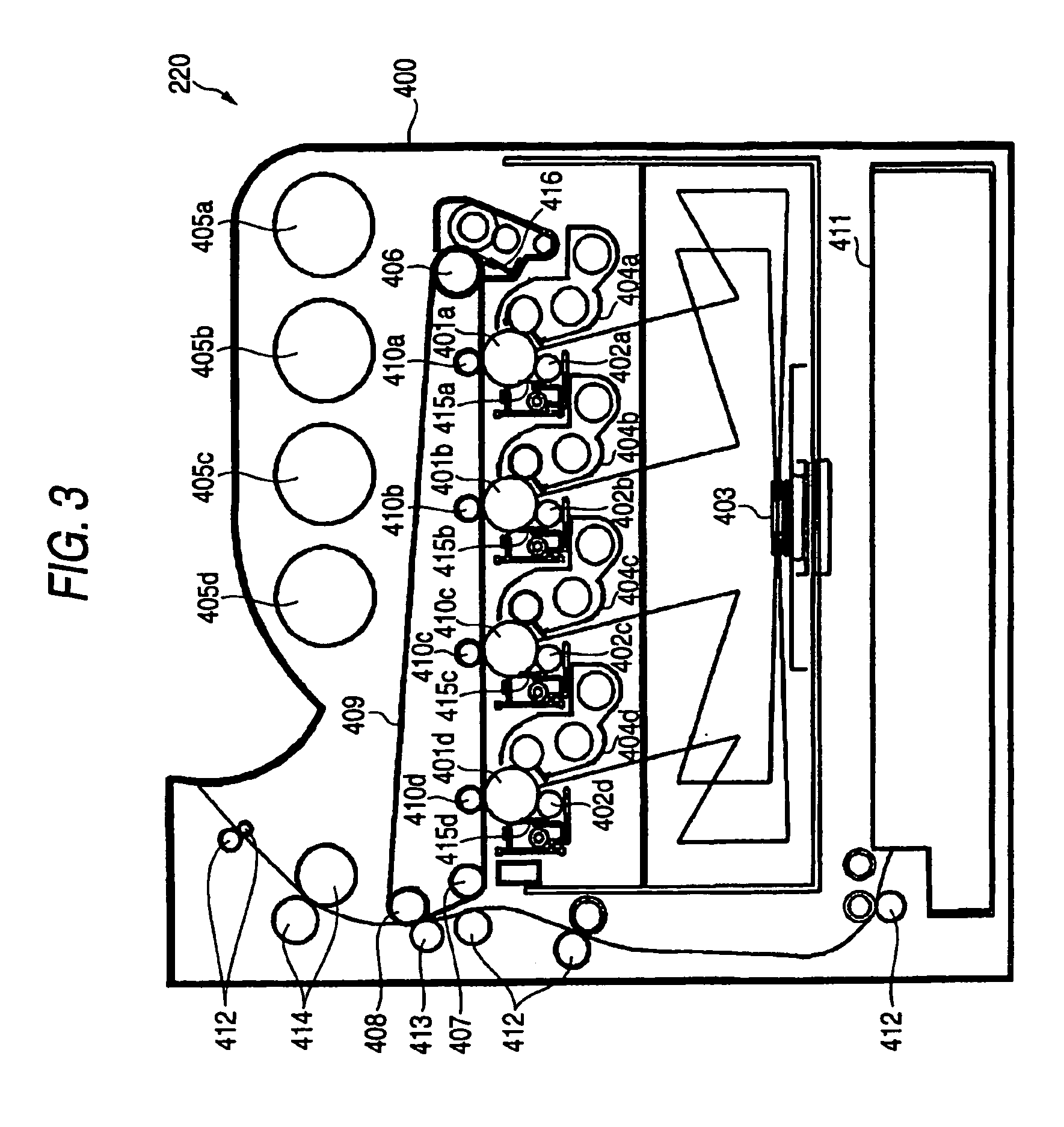

Overcoat Formulation for Long-Life Electrophotographic Photoconductors and Method for Making the Same

ActiveUS20150185642A1Good wear rateRapidly transportElectrographic process apparatusCoatingsEngineeringElectrical conductor

An overcoat layer and method to make an overcoated photoconductor drum of an electrophotographic image forming device using irradiation such as with electron beam (EB) or ultraviolet (UV) light is provided. The photoconductor drum is then cured using EB dose of between 10 and 100 kiloGrays (kGy), preferably between 20 and 40 kGys or UV irradiation with an exposure of between 0.1 and 2 J / cm2. The unique overcoat layer of the present invention is formed having a biphasic morphology comprised of a highly cured crosslinked phase and a second phase enriched in uncured material. The desired amount of uncured uncrosslinked material found in the second phase of the biphasic structure, is between 2-70 wt % range, with particularly good combination of long-life and electrical performance when present at the 5-50 wt % level, and the best performance at the 15-40 wt % level. The biphasic morphology of the overcoat layer using the method of the present invention gives rise to the good wear rates while allowing rapid transport of the electrical charge and thus fast discharge properties of the photoconductor drum.

Owner:LEXMARK INT INC

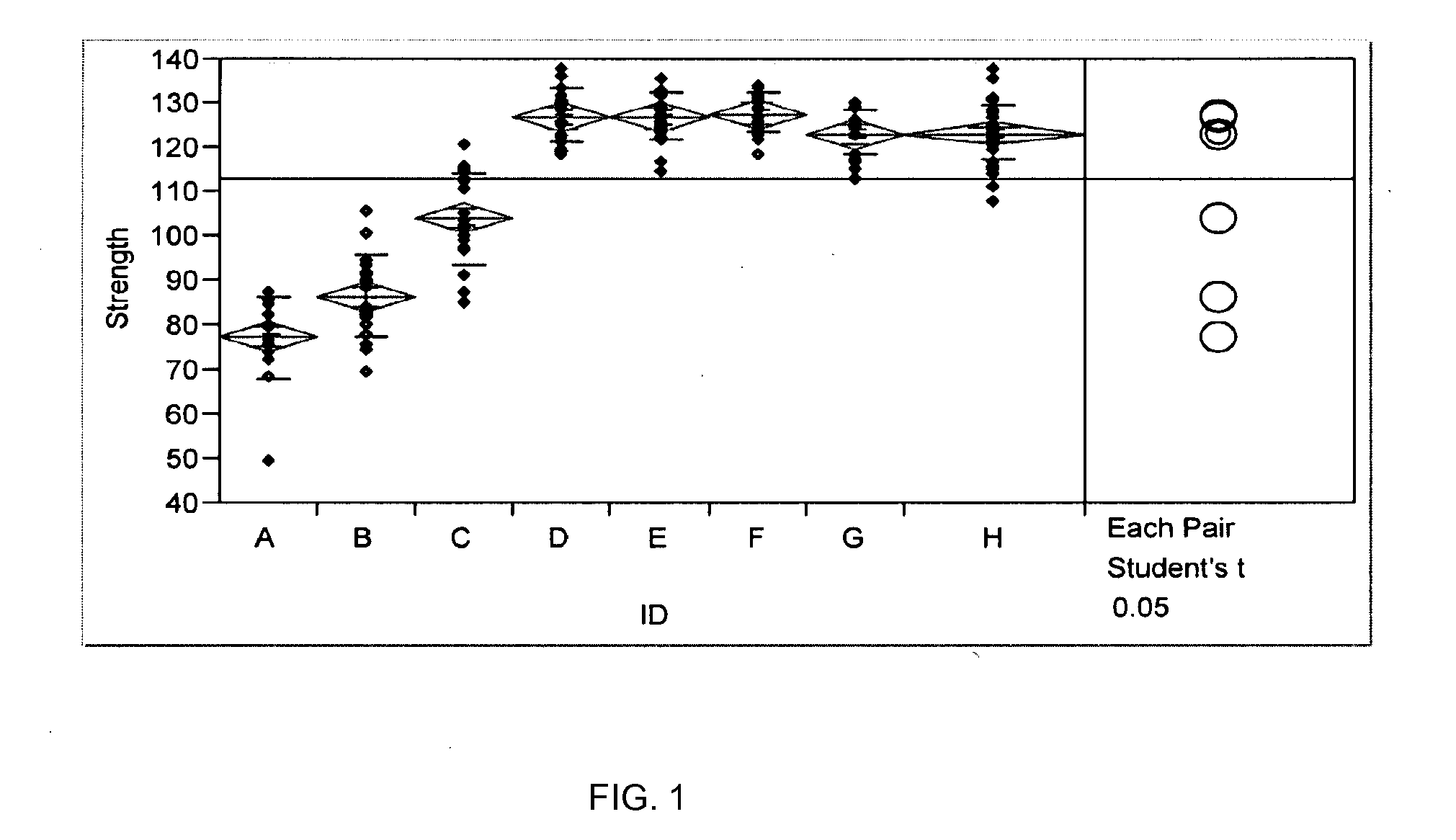

Microfiber Reinforcement for Abrasive Tools

InactiveUS20120100784A1Improved wheel lifeProlong lifePigmenting treatmentOther chemical processesMaterials scienceMicrofiber

An abrasive article includes an organic bond material, an abrasive material dispersed in the organic bond material, mineral wool microfibers uniformly dispersed in the organic bond material, the mineral wool microfibers being individual filaments, one or more reinforcement and / or chopped strand fibers dispersed in the organic bond material and one or more active fillers including, for example, a manganese compound. The abrasive article can be used in the abrasive processing of a workpiece.

Owner:SAINT GOBAIN ABRASIVES INC +1

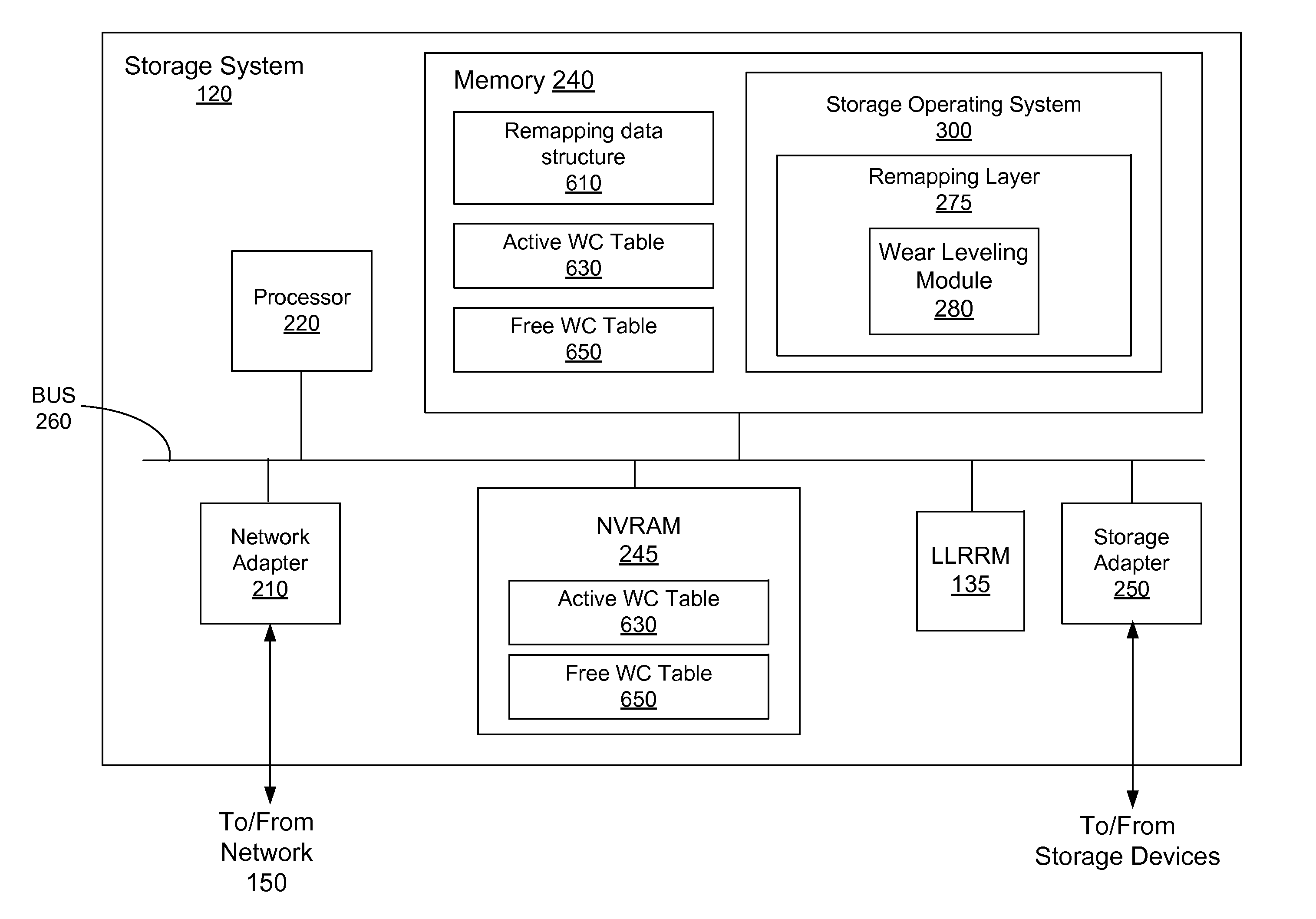

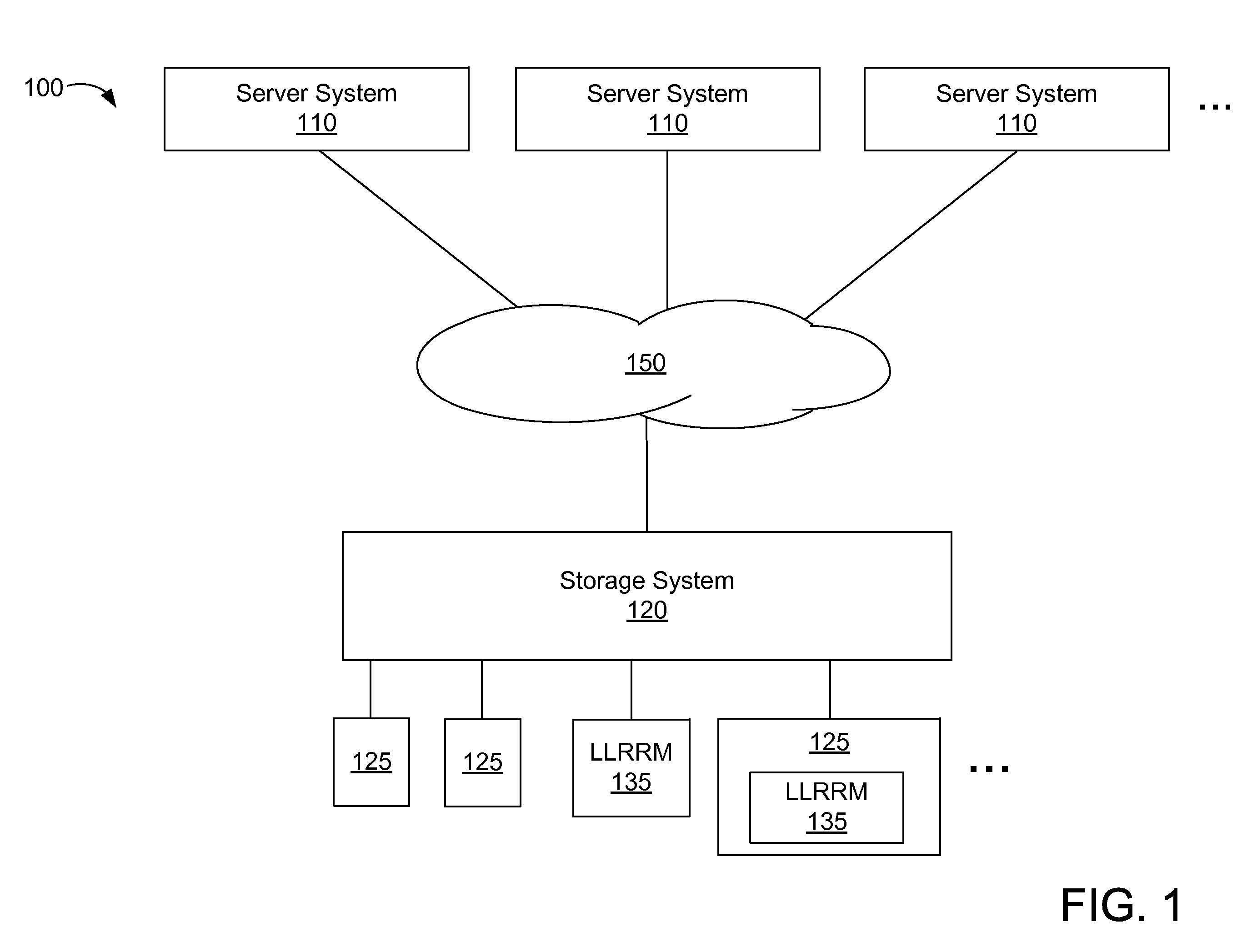

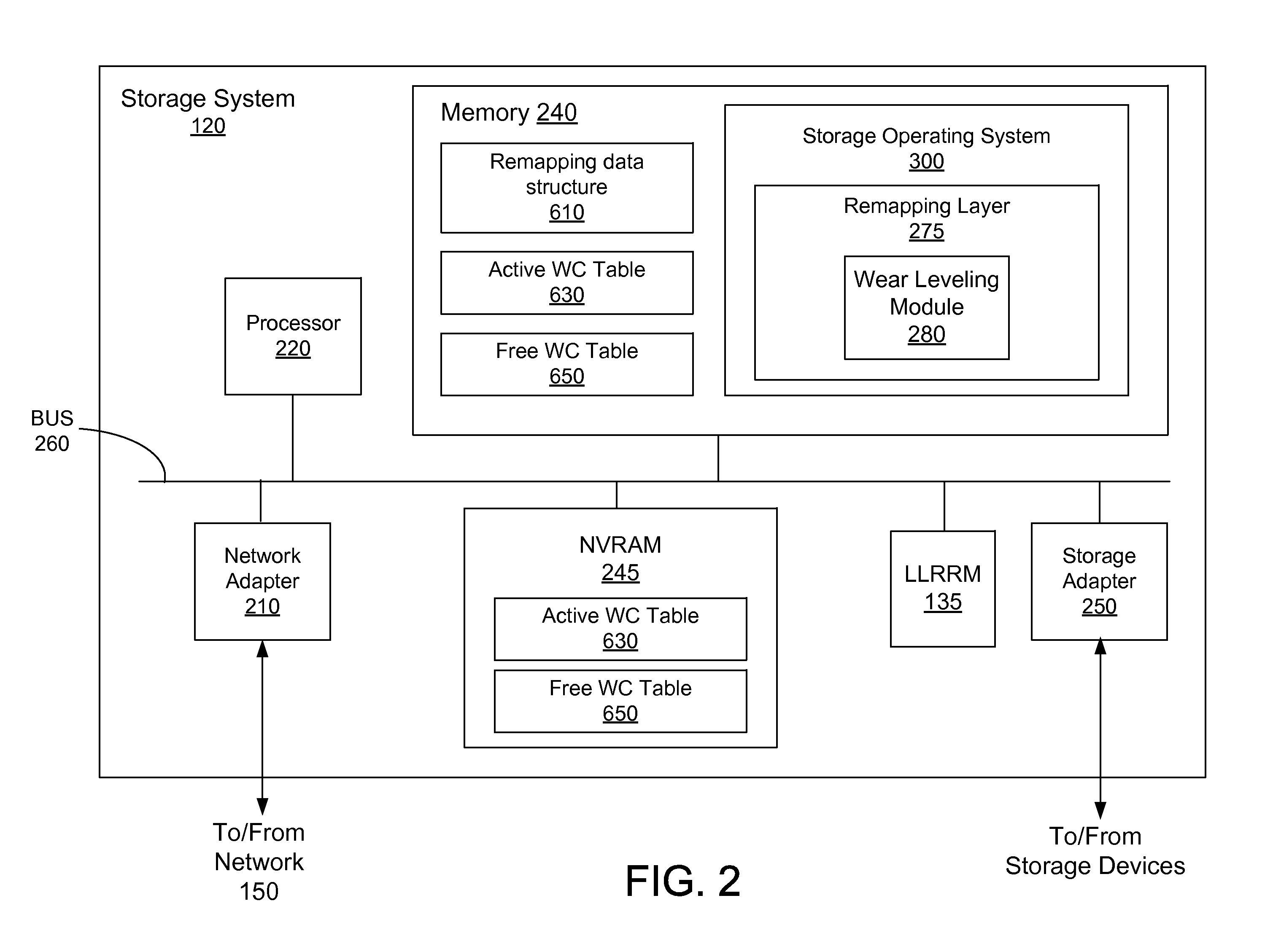

Wear leveling for low-wear areas of low-latency random read memory

ActiveUS20110271046A1Low wear countReduce current rate of wearMemory architecture accessing/allocationError detection/correctionLatency (engineering)Data content

Described herein are method and apparatus for performing wear leveling of erase-units of an LLRRM device that considers all active erase-units. Wear counts of all active erase-units (containing client data) and free erase-units (not containing client data) are tracked. Wear counts are used to determine low-wear active erase-units having relatively low wear counts and high-wear free erase-units having relatively high wear counts. In some embodiments, data contents of low-wear active erase-units are transferred to high-wear free erase-units, whereby the low-wear active erase-units are converted to free erase-units and may later store different client data which may increase the current rate of wear for the erase-unit. The high-wear free erase-units are converted to active erase-units that store client data that is infrequently erased / written, which may reduce the current rate of wear for the erase-unit. As such, wear is spread more evenly among erase-units of the LLRRM device.

Owner:NETWORK APPLIANCE INC

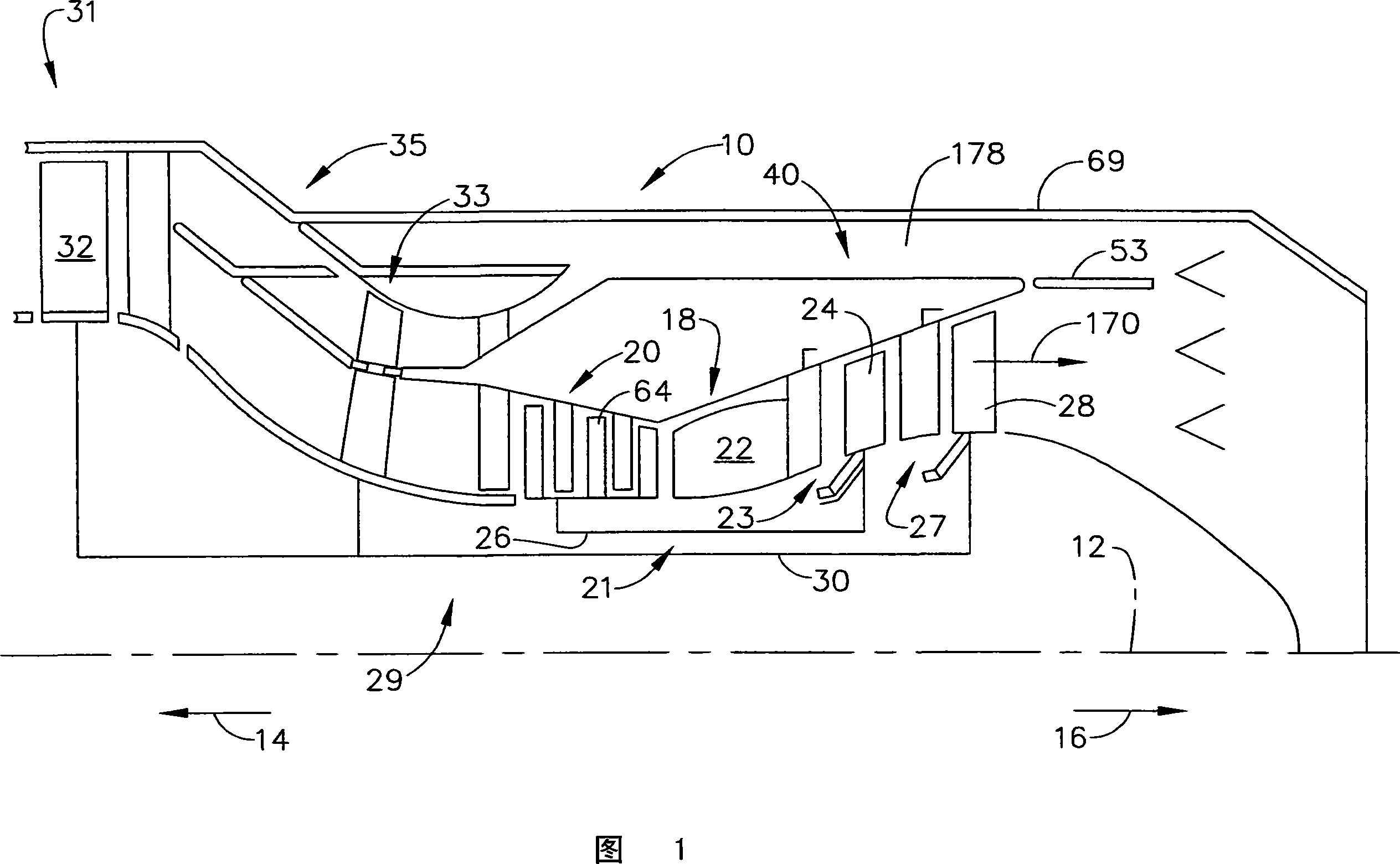

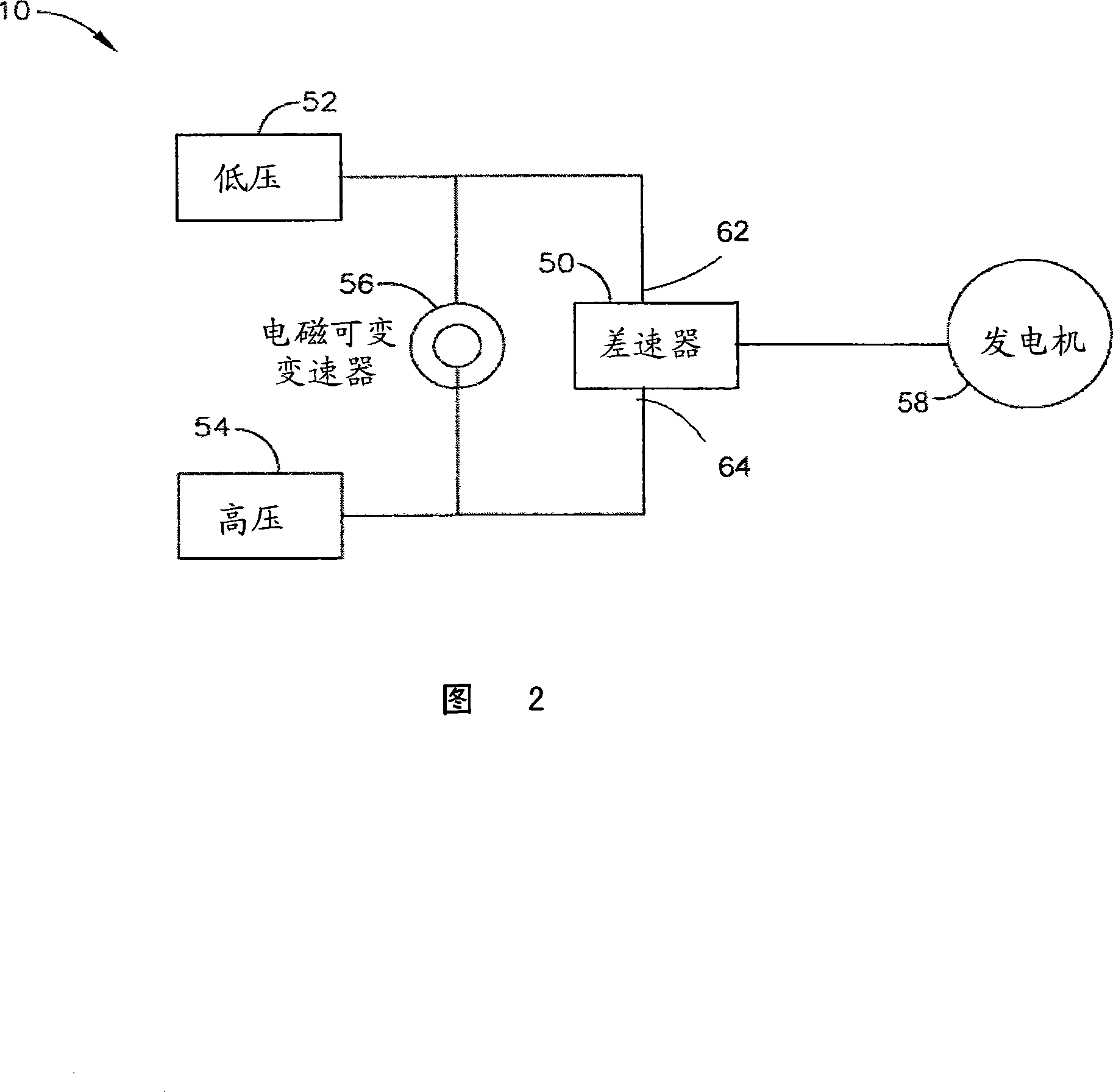

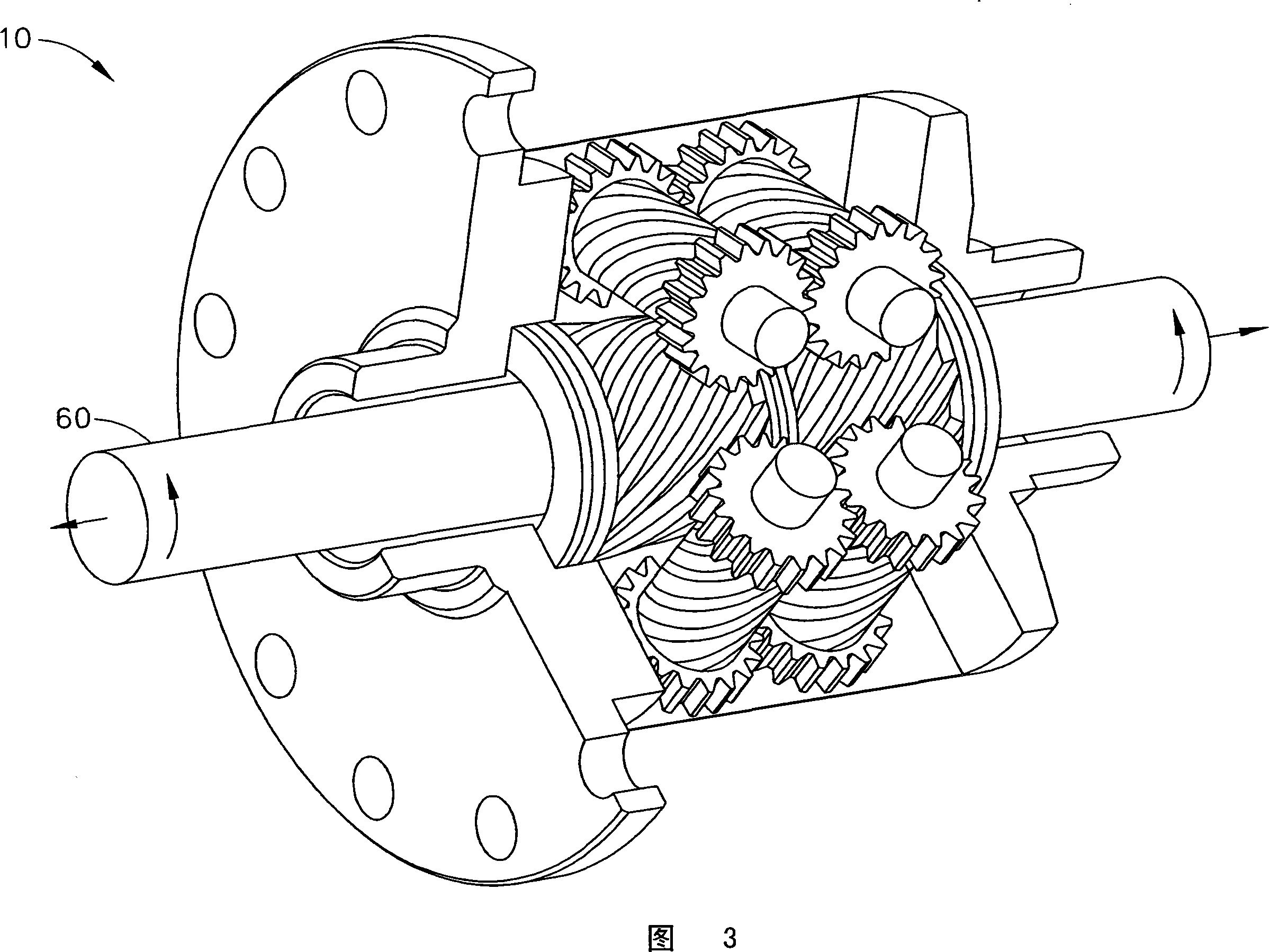

Variable coupling of high pressure rotor and low pressure rotor of turbofan engine

InactiveCN101230802APrevent deviationImprove wearing rateEngine fuctionsGearingRotational axisGear drive

A system for transferring mechanical torque variably between a plurality of rotating machines in a turbofan engine (10). Two devices are used, where the first device relies upon magnetic properties of a planetary magnetic gearbox (50) to couple the magnetic machines. The second device is used to variably control the torque transfer between the magnetic machines. The system couples rotating shafts(52, 54) rotating at differing speeds within a turbofan engine (10) for controllably transferring power. To transfer power in the system, a fixed gear ratio is obtained by coupling the relatively high- and low-speed engine shafts (52, 54) to an epicyclic magnetic gearbox (50).

Owner:GENERAL ELECTRIC CO

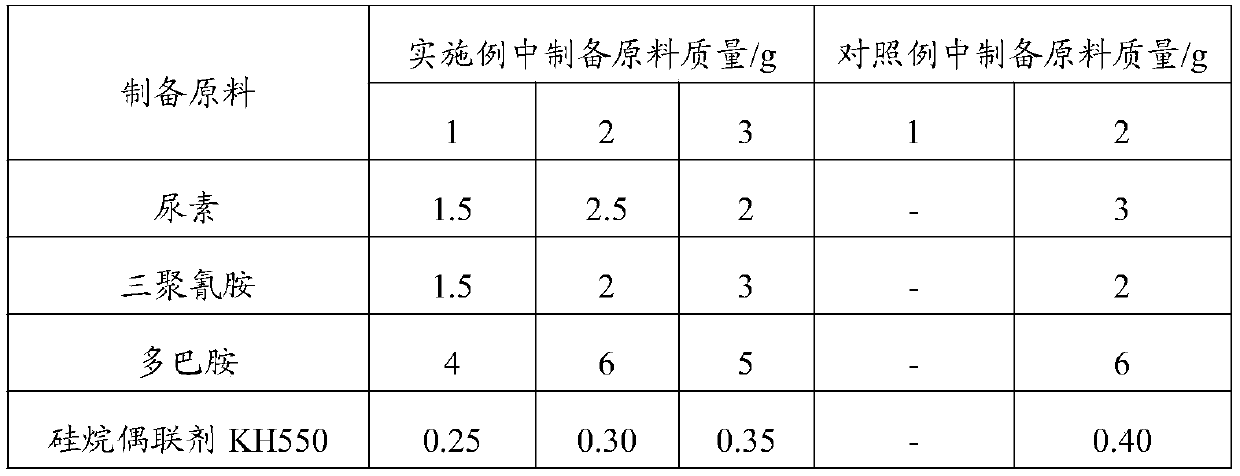

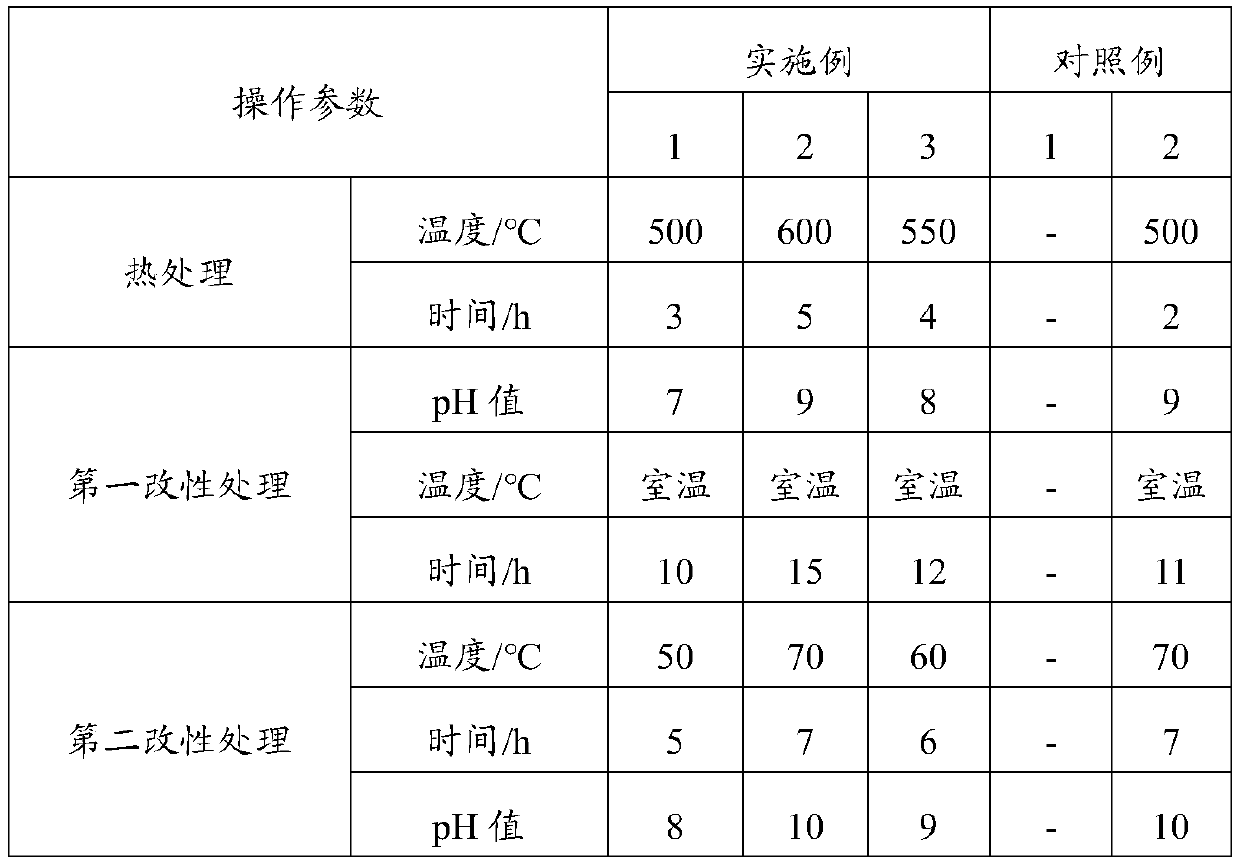

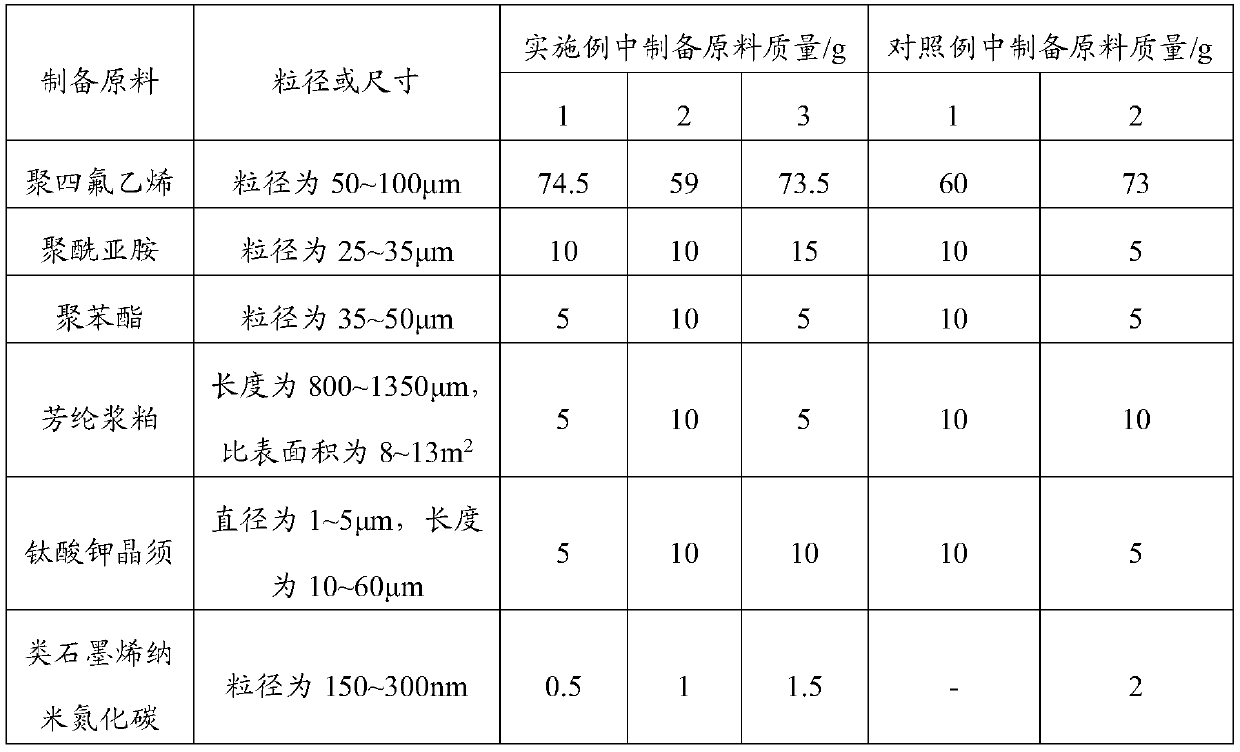

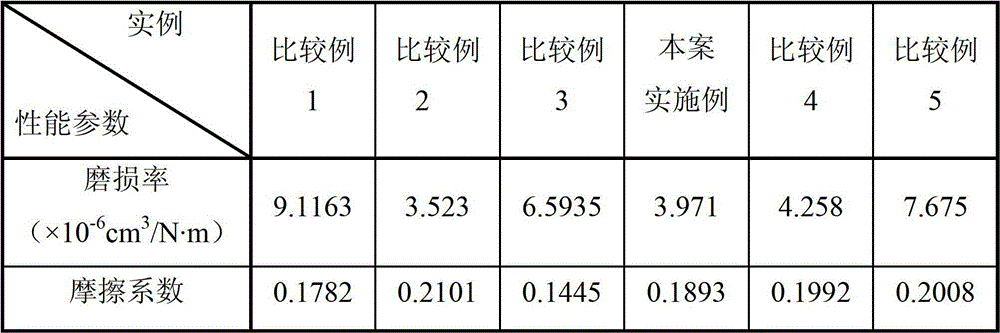

Graphene-like nano carbon nitride modified polytetrafluoroethylene friction material as well as preparation method and application thereof

ActiveCN109851962AStable coefficient of frictionHigh modulus of elasticityOther chemical processesAramidUltrasonic motor

The invention relates to the technical field of composites and specifically relates to a graphene-like nano carbon nitride modified polytetrafluoroethylene friction material as well as a preparation method and application thereof. The graphene-like nano carbon nitride modified polytetrafluoroethylene friction material provided by the invention comprises the following preparation raw materials in parts by mass: 50-80 parts of polytetrafluoroethylene, 5-15 parts of polyimide, 5-10 parts of polybenzoate, 5-20 parts of aramid pulp, 5-15 parts of potassium titanate whiskers and 0.5-1.3 parts of graphene-like nano carbon nitride. The graphene-like nano carbon nitride modified polytetrafluoroethylene friction material prepared by adopting the raw materials with the proportions also has relativelylow mass wear rate and relatively high conversion efficiency on the basis of stable friction coefficient and is capable of meeting the demand for the friction material in an ultrasonic motor.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Tread pattern which reduces the running noise of a tire

InactiveUS6484773B1Satisfied with the effectImprove wearing rateSpecial tyresTyre tread bands/patternsFilling materialsEngineering

A tread pattern for a tire, the tread pattern being formed by elements in relief defined by grooves, some of these elements in relief being provided with at least one blind incision, that is to say, one which does not open into the grooves. These elements in relief include at least one cutout which opens into at least one groove defining these elements, and such that, on the running surface, each blind incision crosses at least one open-ended cutout of the same element, whatever the level of wear of the tire. Each of these open-ended incisions has a depth substantially equal to the depth of the blind incisions which it crosses and is filled with a filler material, the filler material having the characteristic of being gradually eliminated under the action of frictional contact with the ground during travel to form a channel of low depth which enables the air trapped in the blind incisions to escape.

Owner:MICHELIN RECH & TECH SA

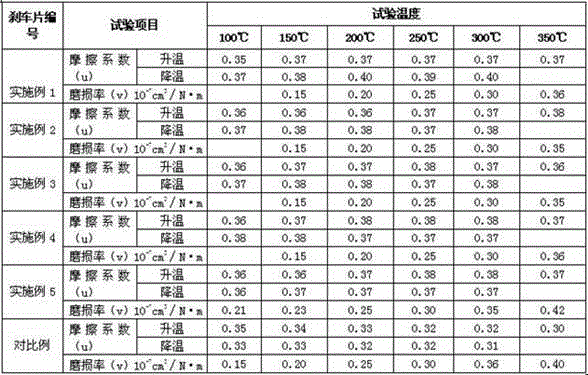

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

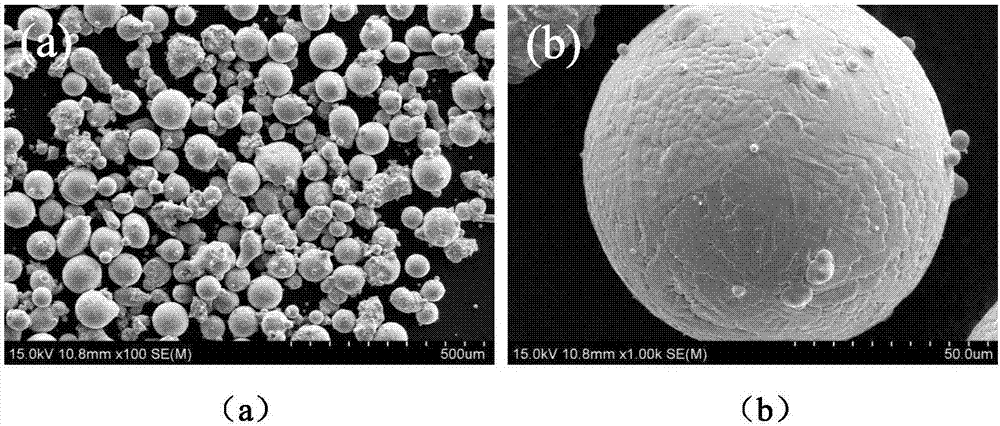

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

C-c composite brakes with improved wear rates

InactiveUS20100018815A1High surface areaReadily adsorbBraking discsChemical vapor deposition coatingSolventActivated carbon

Carbon-carbon composite brake discs are manufactured by processes that include the use of PAN or pitch fibers and their combinations, combined with pitch, resin, or CVD / CVI matrix carbons. An additional process step is provided, in which a controlled amount of a carbon additive, such as carbon black and / or activated carbon, is infiltrated in to the bulk porosity of the composite prior to one or more of the densification cycles. Typical methods of infiltration include use of a solution or suspension of the powdered carbon in water or solvent solution so as to uniformly distribute the particulates throughout porosity within the carbon fiber preform prior to one or more of the densification cycles. The presence of the activated carbon and / or carbon black additive, distributed throughout the carbon-carbon composite brake disc, facilitates the adsorption and retention of available moisture in the composite. In use, the moisture is released into friction films which form on the composite brake discs, so that their lubricating properties are obtained, for instance during cold taxi stops, thereby lowering wear rates.

Owner:HONEYWELL INT INC

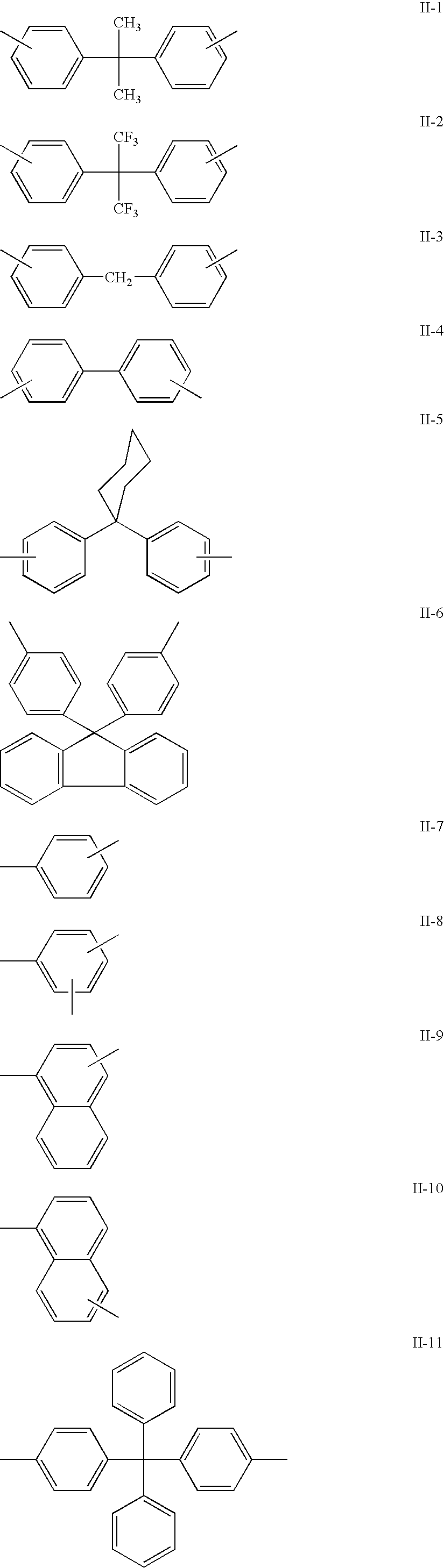

Crosslinked siloxane outmost layer having aromatic siliconcontaining compounds for photoreceptors

ActiveUS20060154161A1Improve wearing rateSacrificing electrographic performanceSilicon organic compoundsElectrographic process apparatusArylHydrogen atom

An aromatic silicon-containing compound has the formula: Ar—[X-L-SiRn(OR′)3-n]m where Ar represents an aromatic group, X represents a divalent or trivalent group; L represents a divalent linking group; R represents a hydrogen atom, an alkyl group or an aryl group; R′ represents an alkyl group having 1 to 5 carbon atoms; n is an integer of from 0 to 2; and m is an integer of from 1 to 5. The aromatic silicon-containing compound can be used in electrophotographic photoreceptors, particularly in outmost protective layers of such electrophotographic photoreceptors.

Owner:XEROX CORP

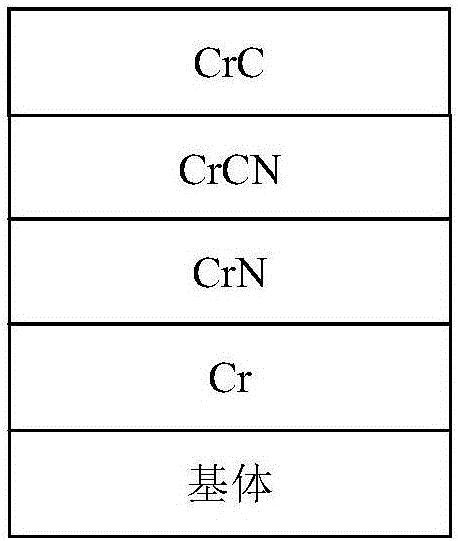

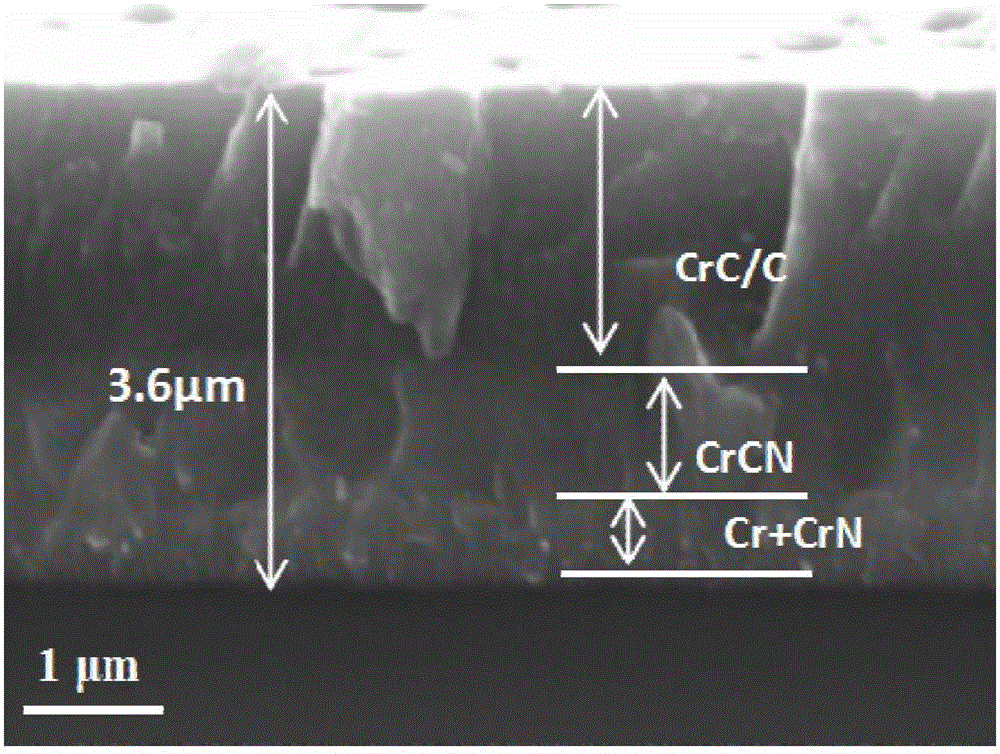

Multilayered gradient composite chromium carbide coating on substrate surface and preparation method of multilayered gradient composite chromium carbide coating

ActiveCN106544631APermeation barrierHigh bonding strengthVacuum evaporation coatingSputtering coatingChromium carbideSubstrate surface

The invention provides a multilayered gradient composite chromium carbide coating on a substrate surface. The composite coating comprises a Cr layer, a CrN layer, a CrCN layer and a CrC layer that are upwards laminated in sequence on the substrate surface. Compared with an existing single-layer CrC coating, the multilayered gradient structure can alleviate the differences of the coating and a substrate in constitution, structure and physical property, reduce the stress of the coating and remarkably improve the frictional wear performance of the coating. The invention also provides a method for preparing the multilayered gradient composite chromium carbide coating by adopting a multi-arc ion plating technique in which the metal Cr is taken as a target material, high-purity Ar is taken as a working gas and C2H2 and N2 are taken as reacting gases; and the constituents and structure of each layer can be controlled by regulating the flow rate of each type of gas.

Owner:宁波奥深科技有限公司

Calcium carbonate crystal whisker reinforced high performance brake disc

InactiveCN101440849AHigh temperature resistanceWear-resistantOther chemical processesFriction liningThermal fatigueAdhesive

The invention relates to a calcium carbonate whisker reinforced high-performance brake disc. The compositions of the brake disc in percentage by weight are: 10 to 20 percent of calcium carbonate whisker, 10 to 15 percent of adhesive, 20 to 30 percent of mineral fiber, 15 to 25 percent of graphite, 2 to 5 percent of high-temperature adhesive, 1 to 3 percent of aramid reinforced fiber, 5 to 10 percent of friction-increasing material and the balance being mineral fillings. The brake disc does not contain substances harmful to human body, and has the characteristics of high temperature resistance, abrasion resistance, soft material and good toughness, and so on. Moreover, the brake disc has the advantages that even at high temperature of between 300 and 350 DEG C, the brake disc can still maintain higher friction coefficient and lower abrasion rate with the average hardness value equal to 35HRM; the brake disc can resist frequent thermal changes and has excellent thermal fatigue resistance and long service life; and the material can be recycled and the brake disc has high recycling rate; in addition, the brake disc has abundant raw material sources and low cost.

Owner:江西元邦摩擦材料有限责任公司

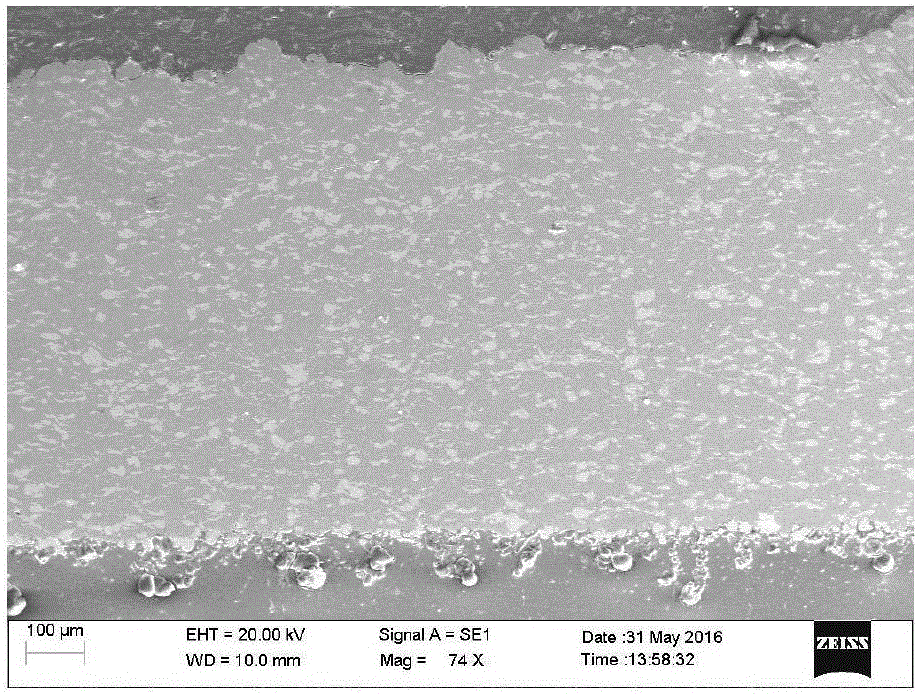

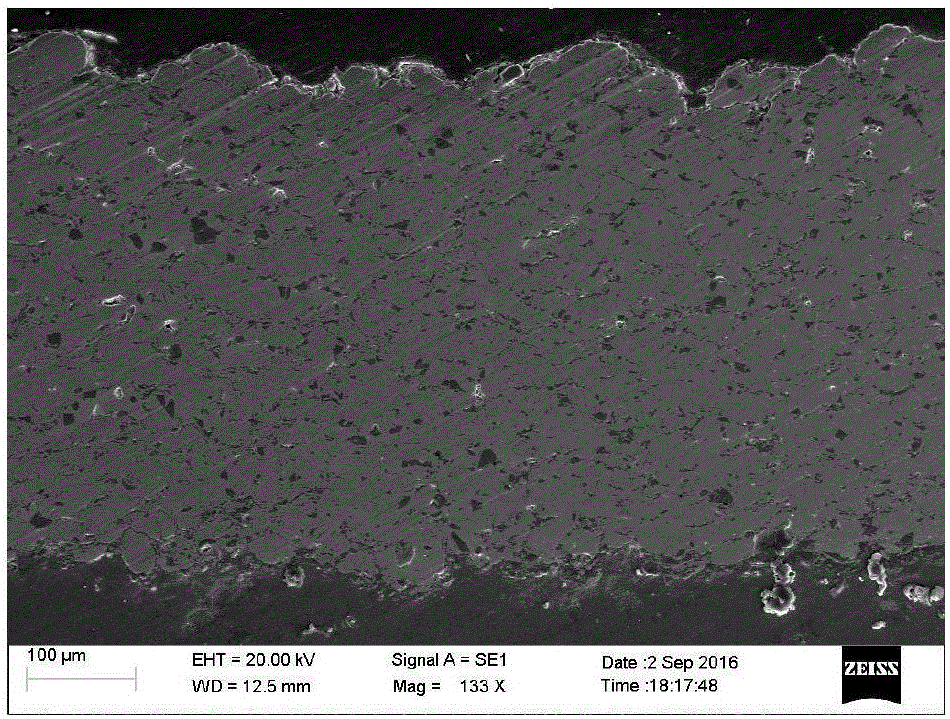

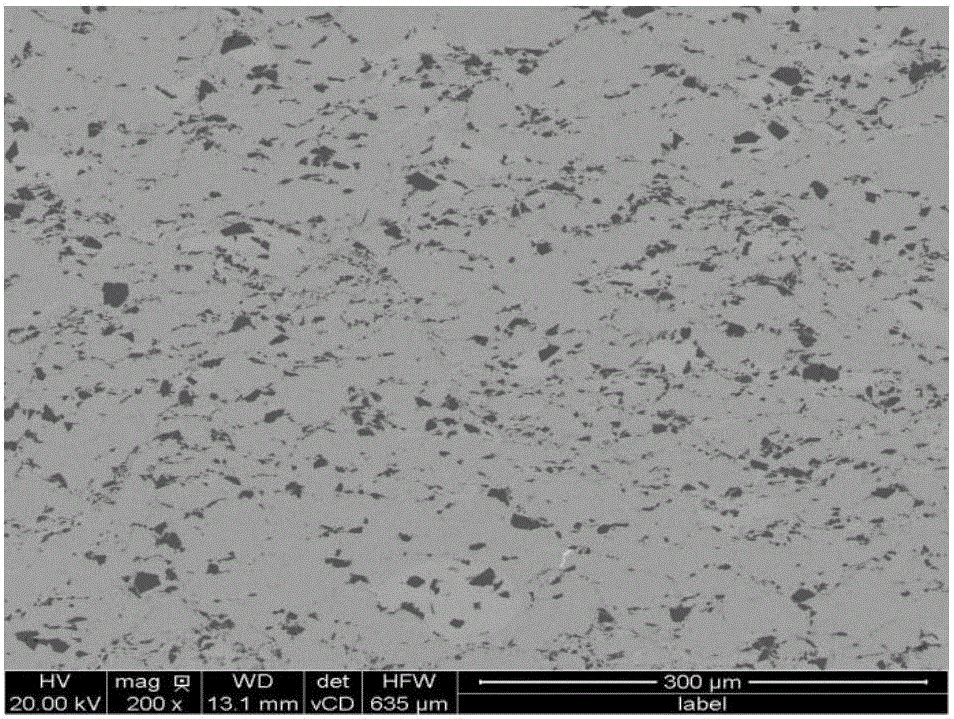

Preparation method for 420 stainless steel composite coating cold-sprayed on magnesium alloy surface

InactiveCN106835112ACompact structureGuaranteed wear resistancePressure inorganic powder coatingSand blastingMaterials science

The invention relates to a preparation method for a 429 stainless steel composite coating sprayed on a magnesium alloy surface. The preparation method comprises the steps that 95-40wt% of 420 stainless steel powder and 5-60wt% of hard reinforcement phase material powder according to a powder mixing ratio; the above two kinds of powder are placed in a mechanical material mixing machine to be mixed so that coating powder is prepared; the magnesium alloy base material surface is sequentially subjected to acetone cleaning and sand-blasting roughening treatment; the coating powder is arranged in a powder conveying device of cold-spraying equipment; then a magnesium alloy base material is fixed on a spraying clamp, and the 420 stainless steel composite coating is manufactured on the magnesium alloy base material surface with a cold-spraying technique; and the hard reinforcement phase material is one or more of SiC, Al2O3, TiC, WC-12Co, WC-17Co, WC-CoCr, WC-NiCr. The preparation method is simple in technique; thermal influence on the magnesium alloy base material is small by adopting the cold-spraying technique; the prepared composite coating is combined with the base body firmly; the structure is compact and uniform; the coating has good corrosion-resistance and abrasion-resistance, and is an ideal surface reinforcement coating for surfaces of the magnesium alloy and components of the magnesium alloy.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Substrate Coated With a Layered Structure Comprising a Tetrahedral Carbon Coating

ActiveUS20080233425A1Bridging the gapImprove adhesionPretreated surfacesNatural mineral layered productsCarbon coatingCarbon layer

The invention relates to a metal substrate (11) coated at least partially with a layered structure. The layered structure comprises an intermediate layer (14) deposited on said substrate (11) and a tetrahedral carbon layer (16) deposited on said intermediate layer. The intermediate layer comprises at least one amorphous carbon layer having a Young's modulus lower than 200 GPa and the tetrahedral carbon layer has a Young's modulus higher than 200 GPa. The invention further relates to a method to improve the adhesion of a tetrahedral carbon layer to a substrate and to a method to bridge the gap in Young's modulus of the metal substrate and the Young's modulus of a tetrahedral carbon coating deposited on said metal substrate.

Owner:SULZER METAPLAS

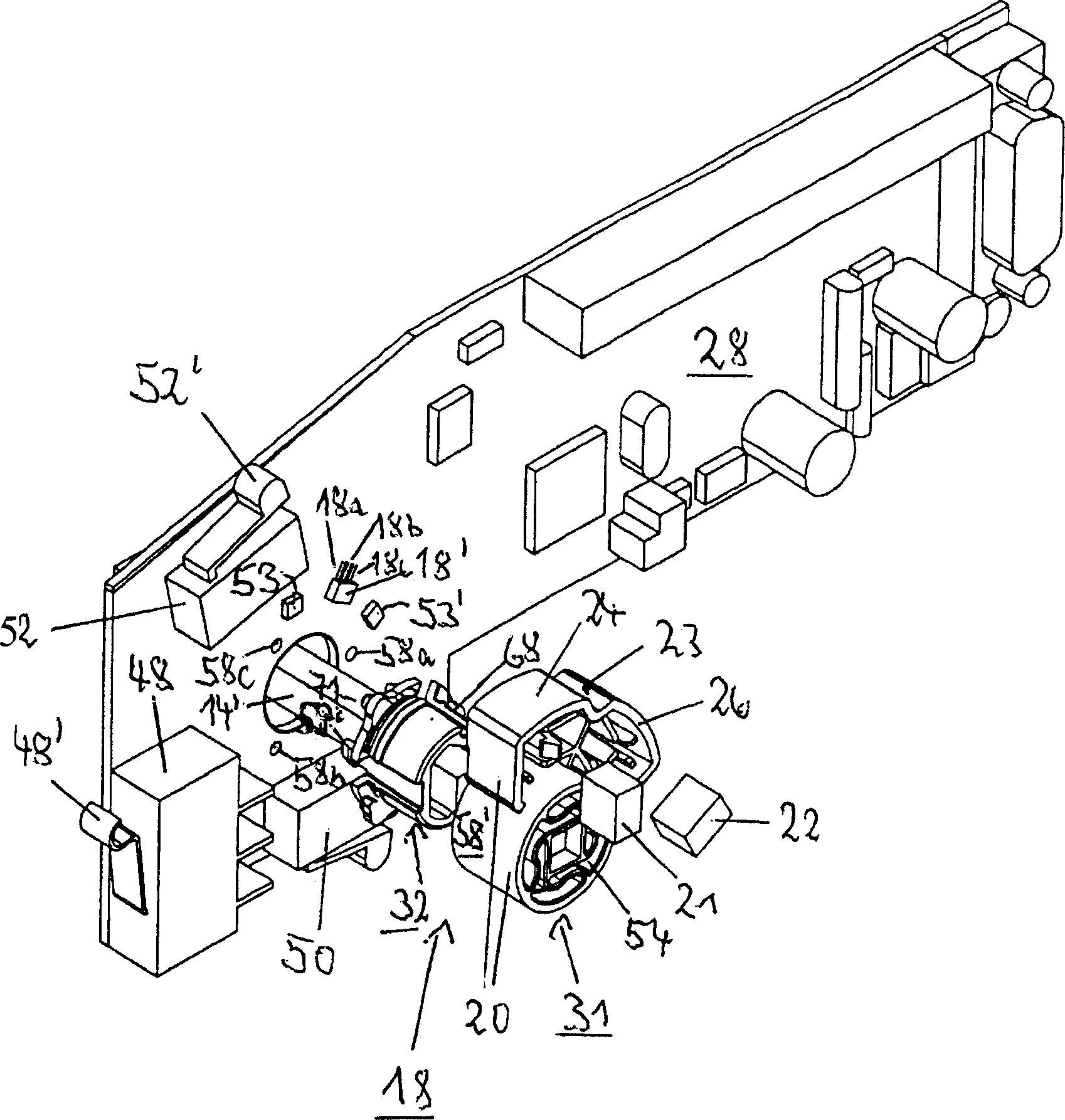

Control handle head of mobile floor delivery tool and moving speed conveyor

ActiveCN1736752AImprove wearing rateLow mobilityLifting devicesPropulsion unit arrangementsControl systemControl signal

The device contains a Hall sensor (18') for controlling traveling movement of the vehicle, whose output signal is proportional to the angle of rotation of the drive switch handle and / or a magnet carrier (20) with two permanent magnets (21,22). The Hall sensor is securely mounted so that faulty radial and axial movements transferred to the rotation shaft (14') of the magnet carrier do not cause drive signal errors. An independent claim is also included for a drive value generator for a measurement arrangement for generating control signals for propulsion drive control.

Owner:REMA LIPPRANDT GMBH & CO KG

Polytetrafluoroethylene composite material and preparation method thereof

InactiveCN102719044AGood mechanical properties and wear resistanceHigh modulusPolyimidePolytetrafluoroethylene

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

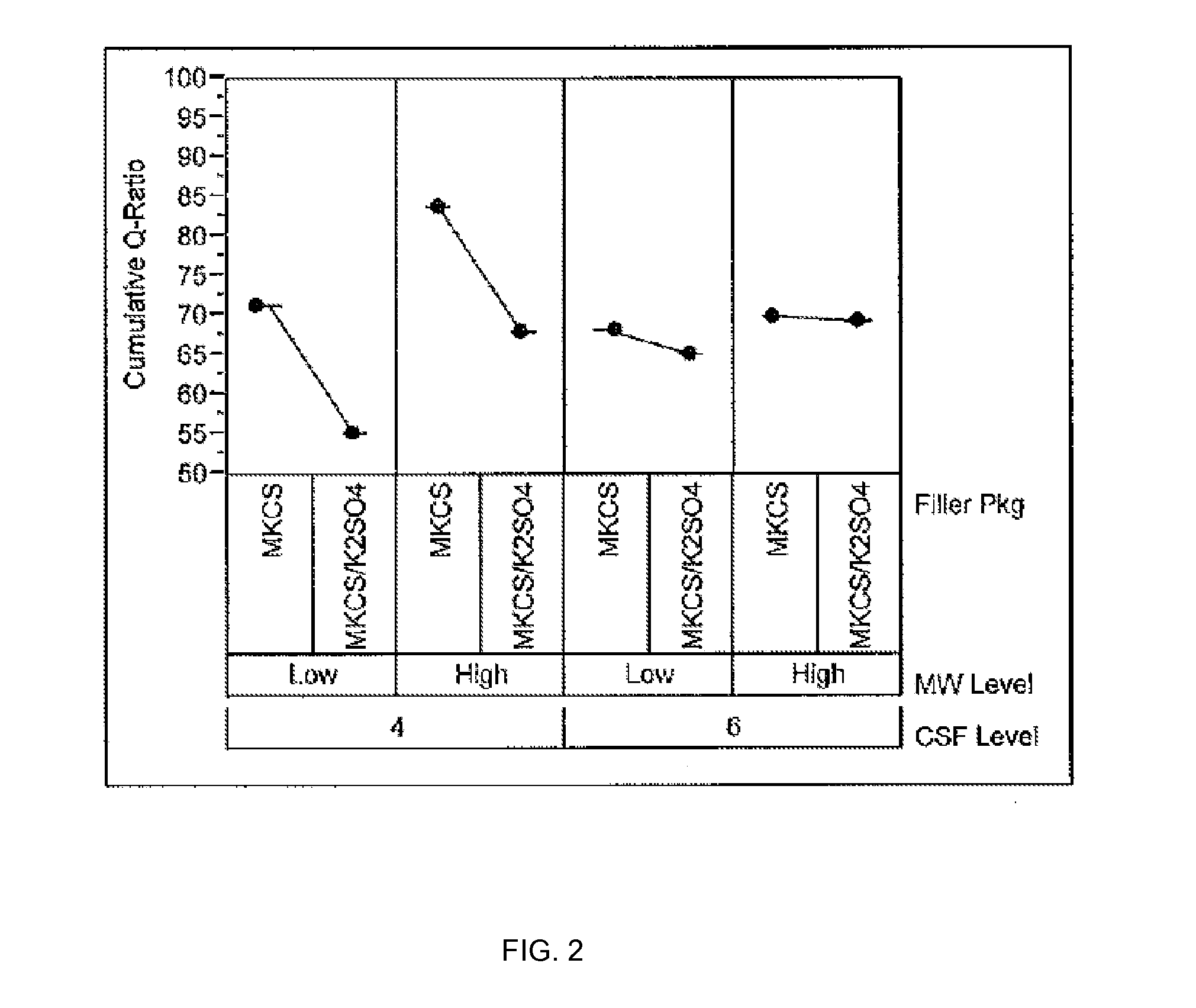

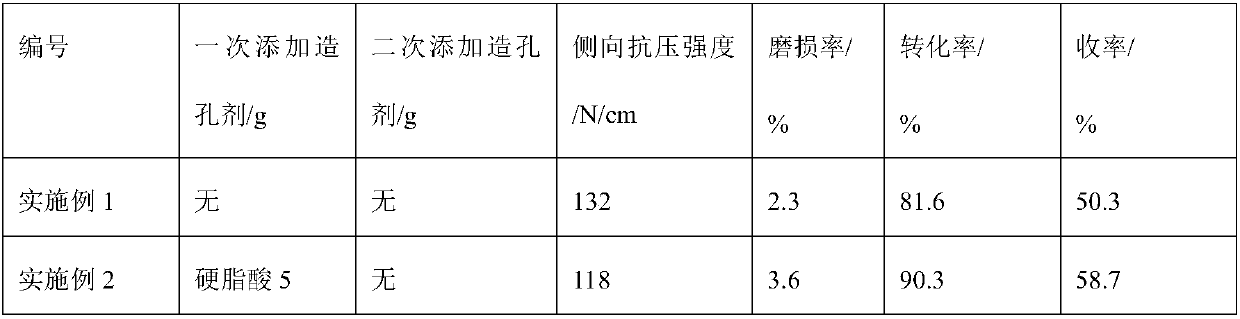

Catalyst for preparing maleic anhydride from n-butane through oxidation and preparation method thereof

ActiveCN107866245AHigh lateral compressive strengthReduce wear rateOrganic compound preparationCatalyst activation/preparationButaneMaleic anhydride

The invention relates to a catalyst for preparing maleic anhydride from n-butane through oxidation. The catalyst mainly overcomes the problem of low catalytic activity in the prior art. According to the invention, three elements consisting of vanadium, phosphorus and oxygen are used as the main body of the catalyst, and a certain amount of a metal additive is cooperatively used. The catalyst comprises, by weight, 26 to 35% of elemental vanadium, 14 to 20% of elemental phosphorus, 30 to 50% of elemental oxygen and 0.02 to 7% of the metal additive. The catalyst is subjected to constant-temperature constant-humidity treatment, doping of a pore forming agent and secondary molding, so the catalysis performance and strength of the catalyst are improved, and the catalyst is applicable to the field of preparation of maleic anhydride from n-butane through oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

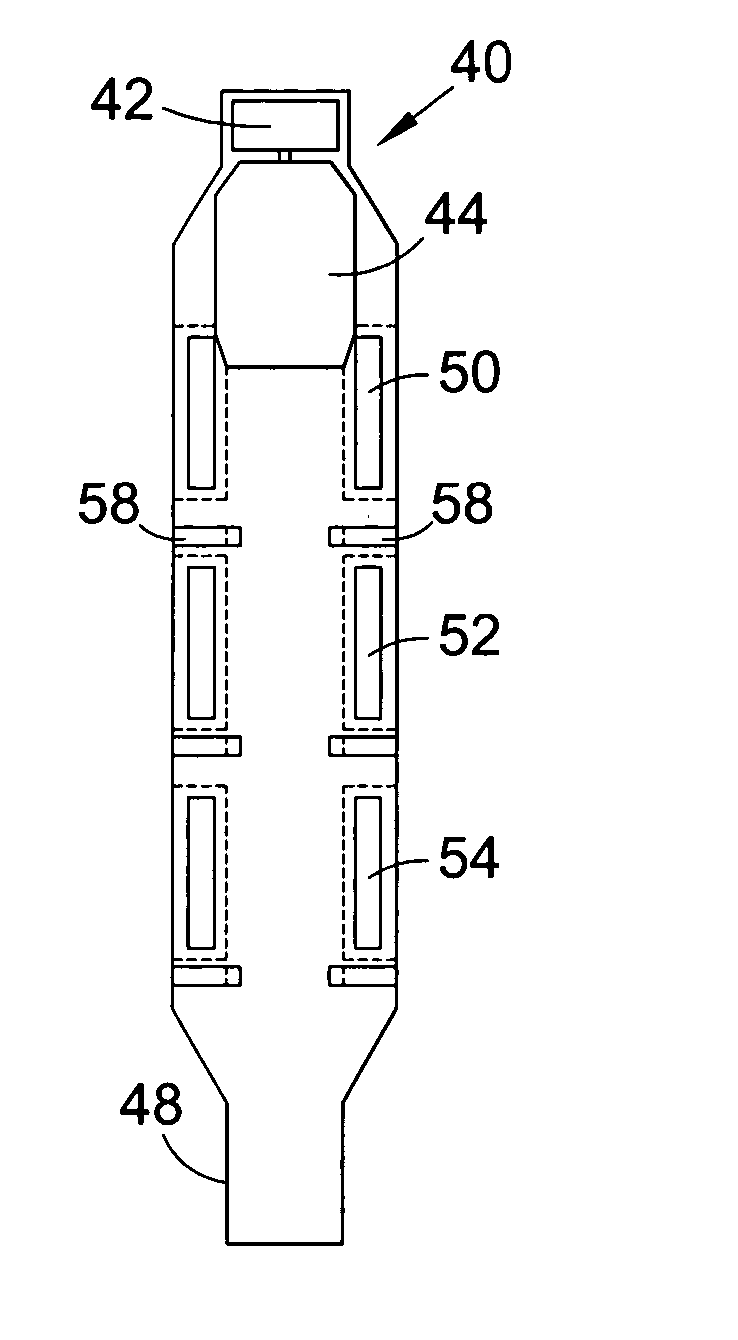

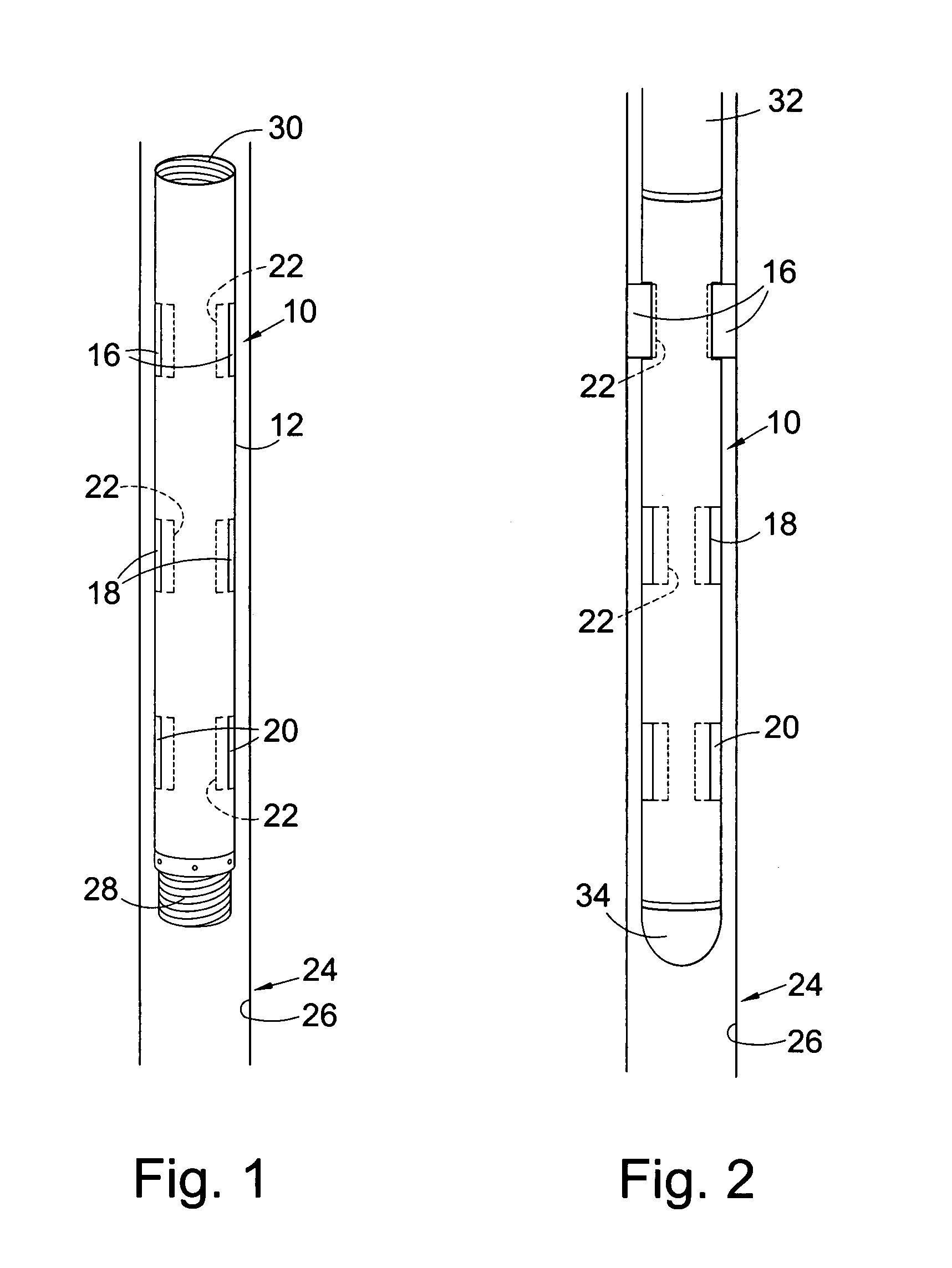

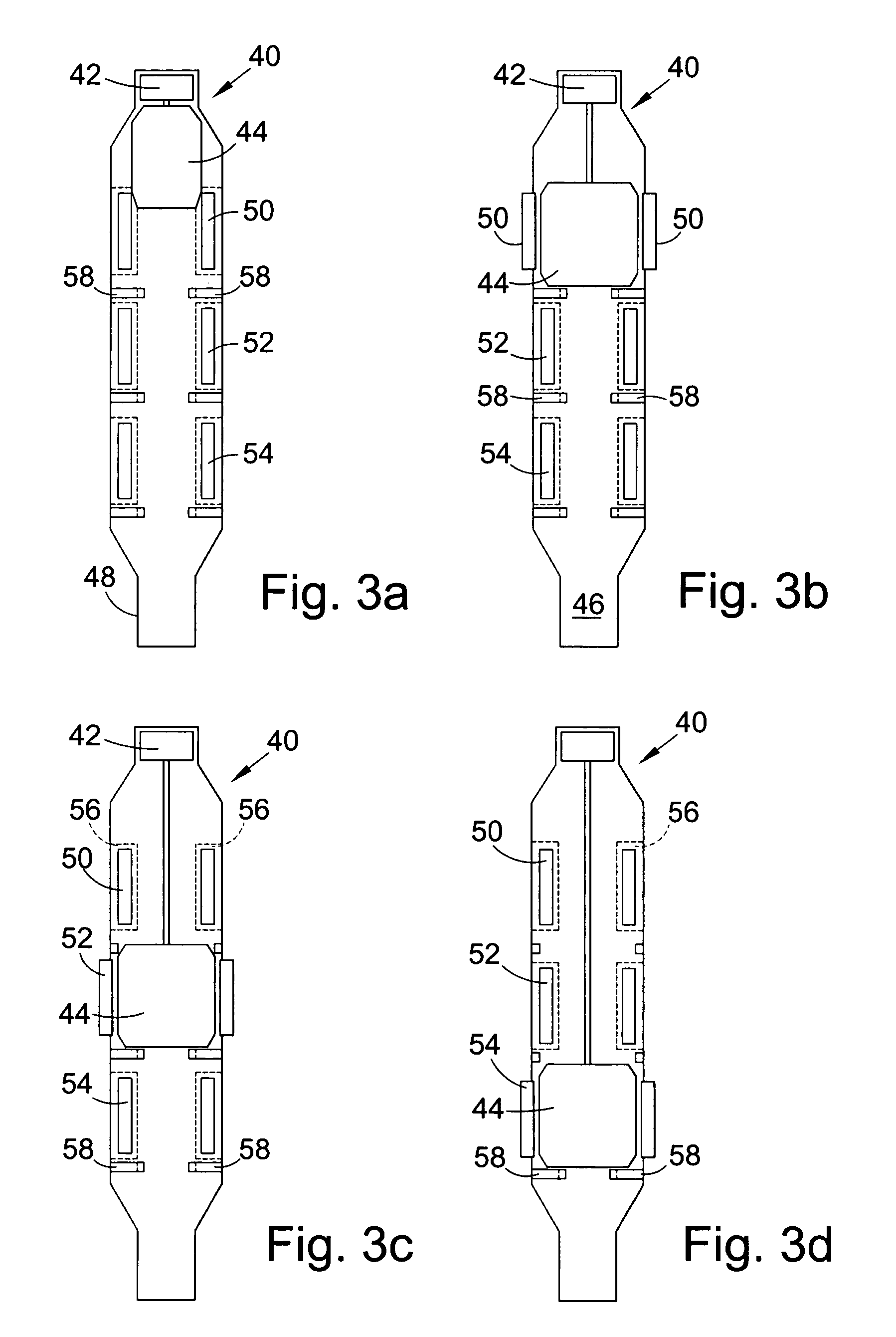

Expansion apparatus

Owner:WEATHERFORD TECH HLDG LLC

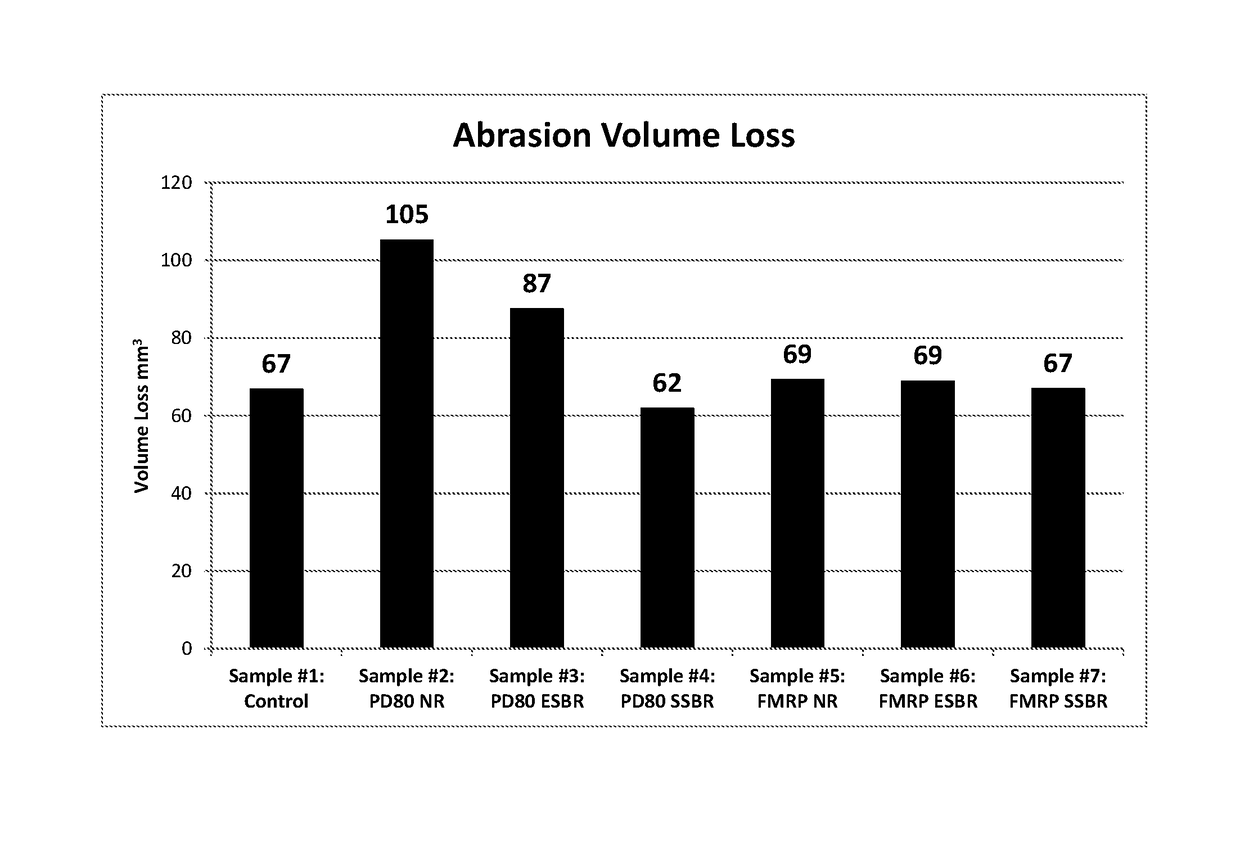

Recycled micronized rubber formulation having improved abrasion resistance

ActiveUS9815974B2Without significantly compromising the abrasion resistance of the rubber formulationSeverely abrasion resistanceProductsConveyorsEngineeringSynthetic rubber

This invention is based upon the discovery that micronized solution styrene-butadiene rubber from postconsumer sources can be included in rubber formulations without severely compromising abrasion resistance. The micronized solution styrene-butadiene rubber utilized in the rubber formulations of this invention can be made by cryogenic grinding postconsumer rubber products using conventional procedures. For instance, it can be made by cryogenically grinding a tire tread containing a high level of solution styrene-butadiene rubber. The micronized solution styrene-butadiene rubber can then be blending into desired virgin rubbers and cured without significantly compromising the abrasion resistance of the rubber formulation. The rubber formulation of this invention is comprised of a natural or synthetic rubber and from 1 weight percent to 30 weight percent of a micronized rubber composition containing at least 10 weight percent solution styrene-butadiene rubber and having a particle size of 40 mesh to 200 mesh.

Owner:LEHIGH TECH INC

Micro-copper-formulated ceramic brake pad

InactiveCN103821859ALight weightUniform surface distributionOther chemical processesFriction liningSulfideBoron nitride

A micro-copper-formulated ceramic brake pad is made with aramid pulp, carbon fiber, magnesium hydroxide, copper fiber, brown fused alumina, antimony sulfide, ceramic fiber, superfine iron oxide powder, calcium sulfate whisker, potassium titanate, barite, crystalline flake graphite, calcined petroleum coke, nano hollow float beads, flake aluminum powder, nitrile butadiene rubber powder, cashew nut shell oil modified phenolic resin, zirconite, boron nitride, zinc oxide, and benzoxazine resin. The components are reasonably matched, and advantages of the materials can be given to full play in abrasive materials. The novel fiber materials are reasonably composited, performance defects of the materials can be mutually complemented, and high performance is achieved through mutual connective action. The micro-copper-formulated ceramic brake pad has low content of heavy metals and smaller than 0.5% of copper content and therefore, is very environment friendly.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Preparing method and application of laser cladding precipitation-hardening stainless steel wear-resisting anti-corrosion coating

InactiveCN107058998AImproves strength and hardnessImprove wear resistanceMetallic material coating processesCorrosion resistantWear resistant

The invention discloses a preparing method and application of a laser cladding precipitation-hardening stainless steel wear-resisting anti-corrosion coating. A basis material is 1Cr15Ni4Mo3N precipitation-hardening stainless steel and comprises, by weight percentage, 0.11%-0.16% of C, 0.5%-1.0% of Mn, 2.3%-2.8% of Mo, 4.0%-5.0% of Ni, 14.0%-15.5% of Cr, 0.05%-0.10% of N, not larger than 0.7% of Si, not larger than 0.02% of S, not larger than 0.03% of P and the balance Fe; and a cladding layer material comprises, by weight percentage, 10.65%-12.50% of C, 2.36%-2.77% of Mo, 4.08%-4.79% of Ni, 11.18%-13.12% of Cr, 1.96%-6.02% of N, 0.23%-0.37% of Al, 0.16%-0.25% of Si, not larger than 0.05% of S, not larger than 0.05% of P and the balance Fe. A synchronous powder feeding manner is adopted for feeding cladding layer powder to the positions below laser beams through a powder feeder to be melted, the cladding layer powder solidifies on the base surface to form a cladding layer, and the laser cladding precipitation-hardening stainless steel wear-resisting anti-corrosion coating is used for rotor hubs of large business machines, air battle machines and helicopters in the field of spaceflight, aviation and ocean and is used for fasteners and force bearing parts with high wear resistant and corrosion resistant requirements.

Owner:国营芜湖机械厂

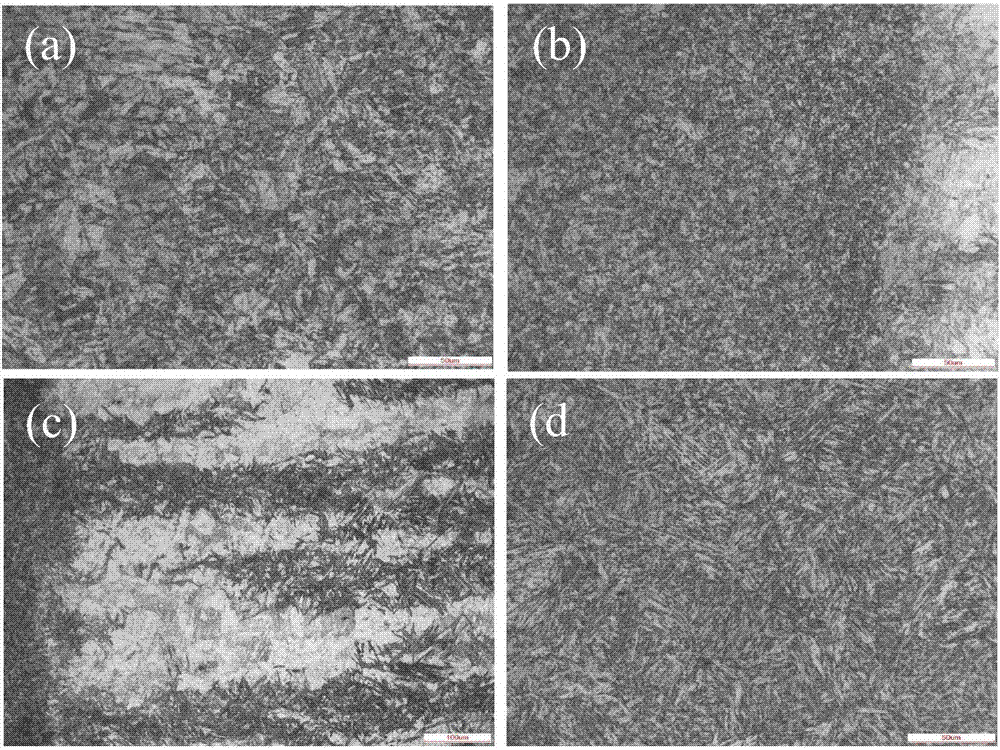

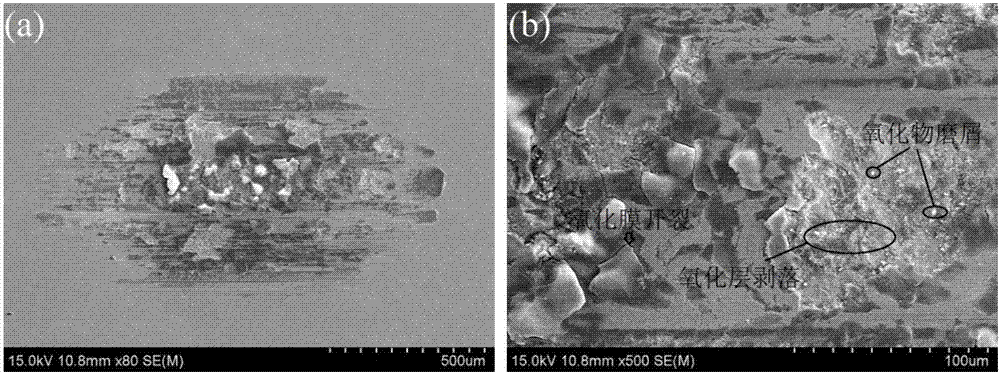

Carbon-based friction material for automobile disc brake and preparation method thereof

The invention relates to a composition and a preparation method of an asbestos-free friction material taking carbon fibre or other carbon materials as a main body, and in particular to a carbon-based friction material for an automobile disc brake and a preparation method of the carbon-based friction material. The friction material and the preparation method of the friction material mainly aim at solving the technical performance problems that a brake pad is high in the heat fading of friction coefficient and wear rate and is easy in the production of brake noises, and as a formulation of the brake pad often contains asbestoid fibre, the brake pad does not meet the requirement of environment-friendliness, etc. The friction material is a novel friction material with a carbon base between a carbon-carbon base and an NAO or ceramic base. The friction material mainly comprises carbon materials such as the carbon fibre and graphite, and comprises accessories such as a resin binder and a small number of inorganic or organic fillers. The friction material is produced by hot press moulding. Compared with a friction material with an NAO or ceramic base, the carbon-based friction material for the automobile disc brake disclosed by the invention has the advantages of being reliable in brake performance, low in brake noises and long in service life, and preventing friction coupling from being damaged.

Owner:杭州吉成汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com