Preparation method for 420 stainless steel composite coating cold-sprayed on magnesium alloy surface

A composite coating and stainless steel technology, applied in the direction of pressure inorganic powder coating, etc., to achieve the effect of optimized wear resistance, low porosity, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A: Weigh 500g of 420 stainless steel powder with a particle size of 5-30μm and a spherical shape; weigh 500g of WC-12Co powder with a particle size of 5-30μm and a spherical shape. Spray powders are obtained after mixing in a mechanical mixer.

[0022] B: Perform acetone cleaning and sandblasting roughening treatment on the surface of the magnesium alloy substrate in sequence to obtain a treated substrate. The sandblasting pressure is 1.0 MPa, the sandblasting time is 30s, and the number of sand shot used for sandblasting is 200 mesh.

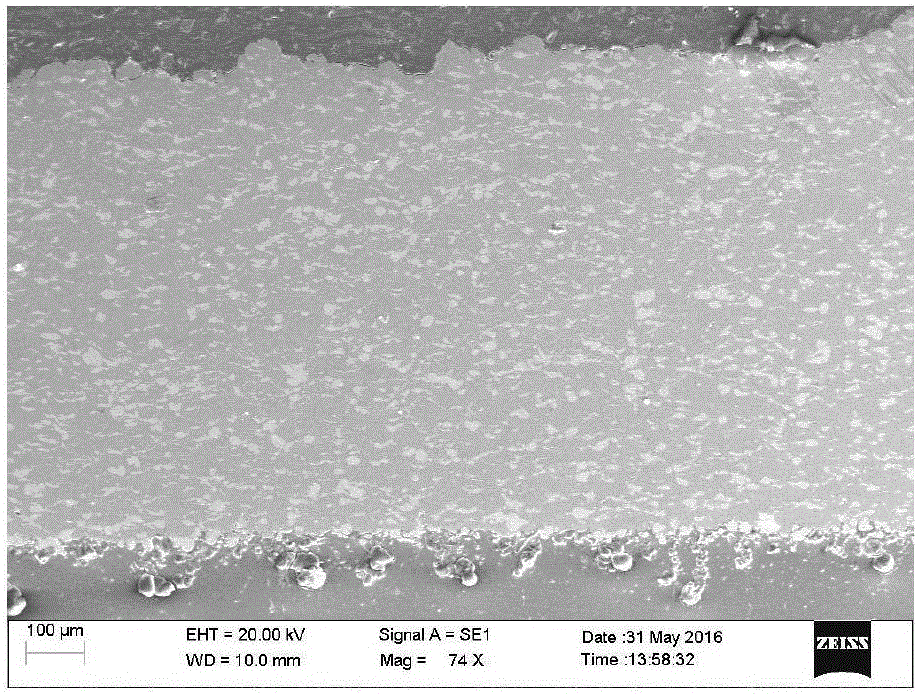

[0023] C: Put the spraying powder prepared in step A into the powder feeder, then fix the magnesium alloy substrate treated in step B on the spraying fixture, and prepare 420 stainless steel / WC-12Co composite coating by cold spraying process, The specific spraying parameters are: the working gas is helium, the spraying pressure is 3.0MPa, the temperature is 600°C, the spraying distance is 20mm, the moving speed of the spray gun is 200mm / ...

Embodiment 2

[0028] A: Weigh 400g of 420 stainless steel powder, with a particle size of 5-30μm, and the powder shape is spherical; weigh 100g of SiC powder, with a particle size of 5-30μm, and the powder shape is irregular. Spray powders are obtained after mixing in a mechanical mixer.

[0029] B: The surface of the magnesium alloy substrate is cleaned with acetone and roughened by sandblasting in sequence to obtain a treated substrate; the sandblasting pressure is 0.3MPa, the sandblasting time is 10s, and the mesh number of the sand shot used for sandblasting is 40 mesh.

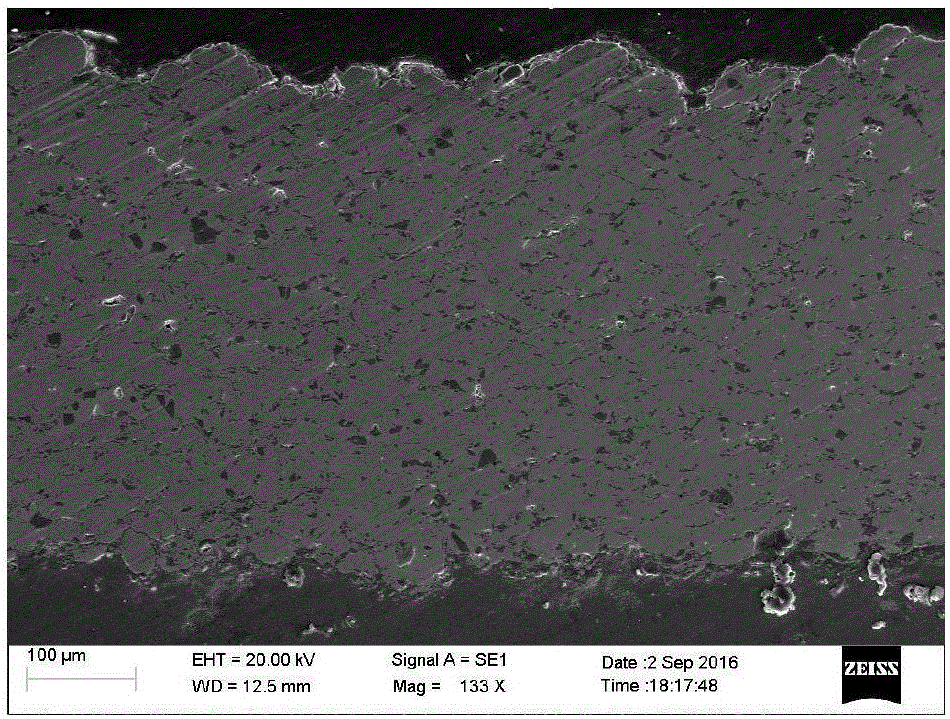

[0030] C: Put the spraying powder prepared in step A into the powder feeder, fix the magnesium alloy substrate treated in step B on the spraying fixture, and prepare 420 stainless steel / SiC composite coating by cold spraying process, the specific Spraying parameters are: working gas is nitrogen, spraying pressure is 3.5MPa, temperature is 700°C, spraying distance is 30mm, spray gun moving speed is 400mm / s, powder feedi...

Embodiment 3

[0036] A: Weigh 1.5kg of 420 stainless steel powder, the particle size is 5-30μm, the powder shape is spherical; weigh Al 2 o 3 The powder is 500g, the particle size is 5-30 μm, and the powder appearance is irregular. The above two powders are mixed in a mechanical mixer to obtain a spray powder.

[0037] B: Perform acetone cleaning and sandblasting roughening treatment on the surface of the magnesium alloy substrate in sequence to obtain a treated substrate. The sandblasting pressure is 0.5MPa, the sandblasting time is 10s, and the number of sand shot used for sandblasting is 40 mesh.

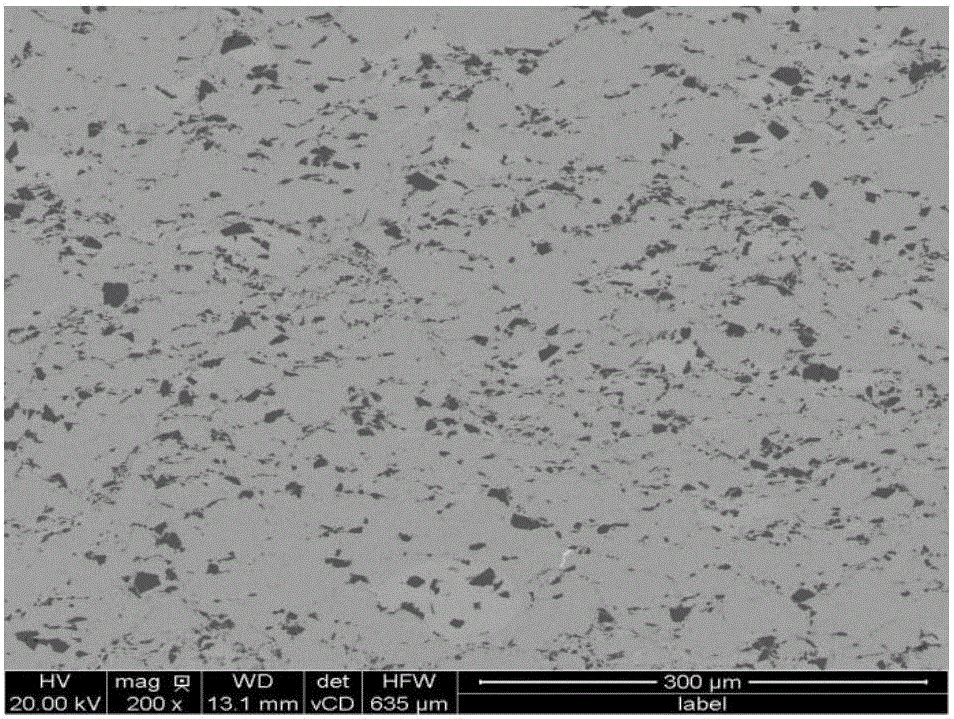

[0038] C: Put the spraying powder prepared in step A into the powder feeder, fix the magnesium alloy substrate treated in step B on the spraying fixture, and prepare 420 stainless steel / Al by cold spraying process 2 o 3 Composite coating; its specific spraying parameters are: working gas is nitrogen, spraying pressure is 2.5MPa, temperature is 800°C, spraying distance is 20mm, spray gun movi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com