Microfiber Reinforcement for Abrasive Tools

a technology of microfiber reinforcement and abrasive tools, which is applied in the direction of manufacturing tools, other chemical processes, chemistry apparatus and processes, etc., can solve the problems of reducing the g-ratio of abrasive tool face, affecting the life of the chopping strand reinforced wheel, and affecting the grinding performance of the abrasive tool face, etc., to achieve the effect of improving the g-ratio, improving the life of the chopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0042]Example 1, which includes Tables 3, 4, and 5, demonstrates properties of bond bars and composite bars with and without mineral wool fibers. Note that the bond bars contain no grinding agent, whereas the composite bars include a grinding agent and reflect a grinding wheel composition. As can be seen in Table 3, components of eight sample bond compositions are provided (in volume percent, or vol %). Some of the bond samples include no reinforcement (sample #s 1 and 5), some include milled glass fibers or chopped strand fibers (sample #s 3, 4, 7, and 8), and some include Sloss PMF® mineral wool (sample #s 2 and 6) in accordance with one embodiment of the present invention. Other types of individual filament fibers (e.g., ceramic or glass fiber) may be used as well, as will be apparent in light of this disclosure. Note that the brown fused alumina (220 grit) in the bond is used as a filler in these bond samples, but may also operate as a secondary abrasive (primary abrasive may be...

example 2

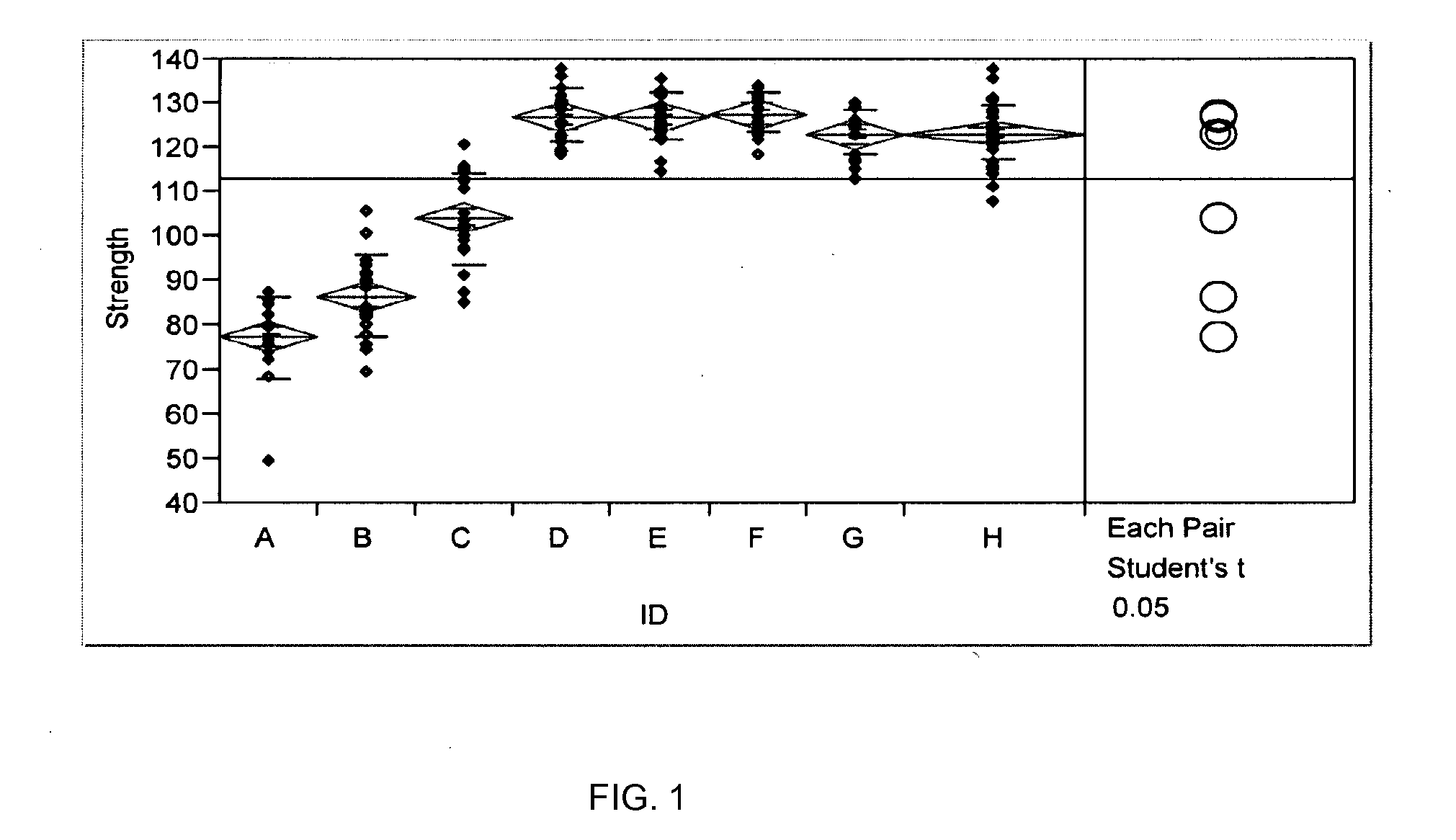

[0047]Example 2, which includes Tables 6, 7, and 8, demonstrates composite properties as a function of mix quality. As can be seen in Table 6, components of eight sample compositions are provided (in vol %). Sample A includes no reinforcement, and samples B through H include Sloss PMF® mineral wool in accordance with one embodiment of the present invention. Other types of single filament microfiber (e.g., ceramic or glass fiber) may be used as well, as previously described. The bond material of sample A includes silicon carbide (220 grit) as a filler, and the bonds of samples B through H use brown fused alumina (220 grit) as a filler. As previously noted, such fillers assist with dispersal and may also operate as secondary abrasives. In each of samples A through H, the primary abrasive used is a combination of brown fused alumina 60 grit and 80 grit. Note that a single primary abrasive grit can be mixed with the bond as well, and may vary in grit size (e.g., 6 grit to 220 grit), dep...

example 3

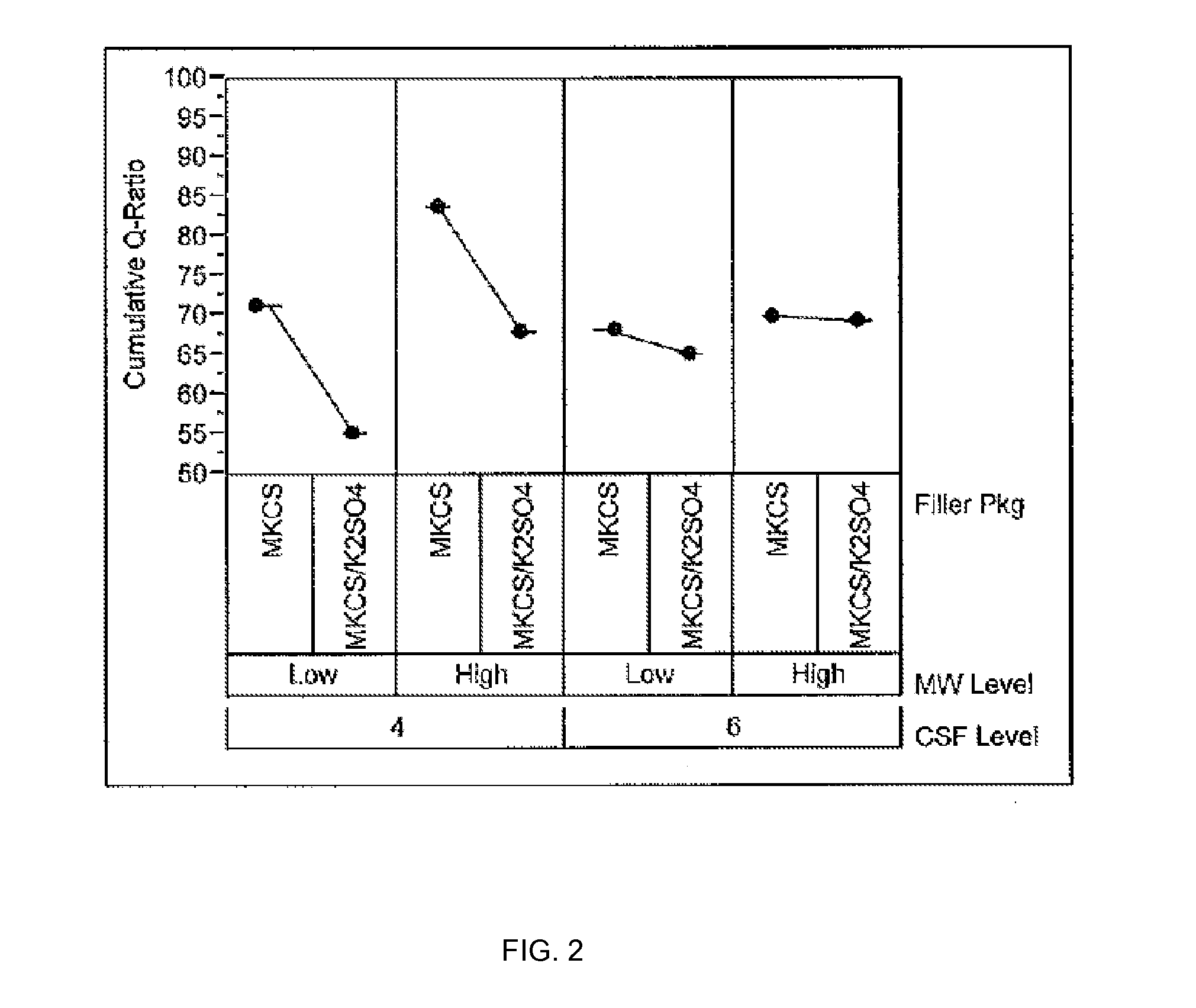

[0052]Example 3, which includes Tables 9 and 10, demonstrates grinding performance as a function of mix quality. As can be seen in Table 9, components of two sample formulations are provided (in vol %). The formulations are identical, except that Formulation 1 was mixed for 45 minutes and Formulation 2 was mixed for 15 minutes (the mixing method used was identical as well, except for the mixing time as noted). Each formulation includes Sloss PMF® mineral wool, in accordance with one embodiment of the present invention. Other types of single filament microfiber (e.g., glass or ceramic fiber) may be used as well, as previously described.

TABLE 9Grinding Performance as a Function of Mix QualityFormulation Formulation SequenceComponent1 (vol %)2 (vol %)Step 1: BondDurez 2972222.3822.38PreparationBrown Fused 3.223.22Alumina-220 gritSloss PMF ®3.223.22Iron Pyrite5.065.06Zinc Sulfide1.191.19Cryolite3.283.28Lime1.191.19Tridecyl alcohol1.111.11Step 2: Mixing45 minutes15 minutesBond QualityWt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com