Electric brush for electric tool motor and preparation method thereof

A technology of electric tools and electric brushes, which is used in the manufacture of brushes, circuits, current collectors, etc., can solve the problems of poor use performance of electric brushes, poor anti-interference ability, poor commutation performance, etc., and achieve good commutation performance and easy operation. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

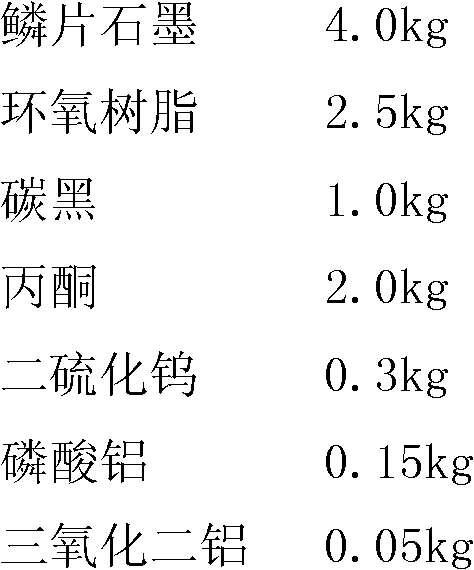

[0030] 1. Prepare materials according to the following ratio:

[0031]

[0032] 2. Raw material pretreatment

[0033] Add 0.625kg of acetone to all the above epoxy resins and stir to dissolve the epoxy resin in the acetone to prepare epoxy resin glue;

[0034] 3. Mixed treatment

[0035] Towards 15m 3 Add all of the above-mentioned flake graphite, epoxy resin glue, carbon black, aluminum phosphate, tungsten disulfide and aluminum oxide to the kneading pot in sequence, and stir and mix for 60 minutes at room temperature to prepare a premix;

[0036] Turn on the heating device of the kneading pot to mix and heat the premix at the same time. When the temperature of the premix reaches 120℃, add the remaining acetone to the mixture, mix and continue heating to make the temperature of the premix Reach and keep at 130℃ and continue mixing treatment for 3h, stop heating, when the mixture is freely cooled to a temperature ≤100℃, discharge it from the kneading pot, and then freely cool to room t...

Embodiment 2

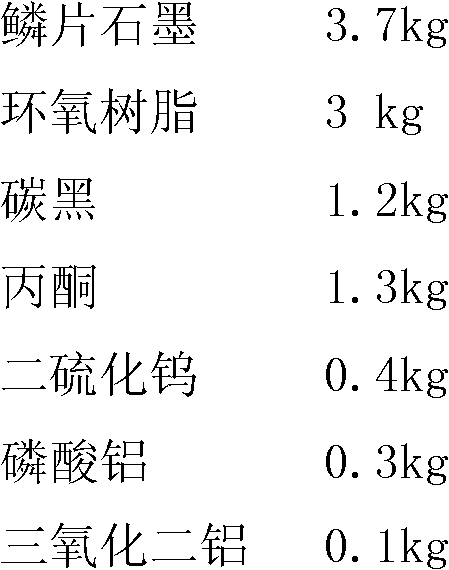

[0043] 1. Prepare materials according to the following ratio:

[0044]

[0045] 2. Raw material pretreatment

[0046] Add 0.6kg of acetone to all the above epoxy resins, stir, dissolve the epoxy resin in the acetone, and prepare an epoxy resin glue;

[0047] 3. Mixed treatment

[0048] Towards 15m 3 Add all of the above-mentioned flake graphite, epoxy resin glue, carbon black, aluminum phosphate, tungsten disulfide and aluminum oxide to the kneading pot, and stir and mix at room temperature for 80 minutes to prepare a premix;

[0049] Turn on the heating device of the kneading pot to mix and heat the premix at the same time. When the temperature of the premix reaches 130°C, add the remaining acetone to the mixture, mix and continue heating to make the temperature of the premix Reach and keep it at 140℃ and continue mixing for 3h, stop heating, when the mixture is freely cooled to a temperature of ≤100℃, discharge it from the kneading pot, and then freely cool to room temperature to obt...

Embodiment 3

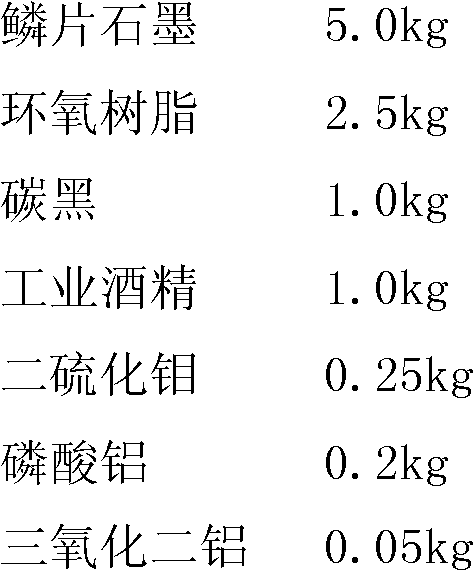

[0056] 1. Prepare materials according to the following ratio:

[0057]

[0058] 2. Raw material pretreatment

[0059] Add 0.375kg of industrial alcohol to all the above epoxy resins and stir to dissolve the epoxy resin in the industrial alcohol to prepare epoxy resin glue;

[0060] 3. Mixed treatment

[0061] Towards 15m 3 Add all the above-mentioned flake graphite, epoxy resin glue, carbon black, aluminum phosphate, molybdenum disulfide and aluminum oxide to the kneading pot, and stir and mix at room temperature for 80 minutes to prepare a premix;

[0062] Turn on the heating device of the kneading pot to mix and heat the premix at the same time. When the temperature of the premix reaches 110℃, add the remaining industrial alcohol to the mixture, mix and continue heating to make the premix The temperature is reached and kept at 120℃ for continuous mixing treatment for 2h, stop heating, when the mixture is freely cooled to a temperature of ≤100℃, discharge it from the kneading pot, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com