Patents

Literature

167results about How to "Removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

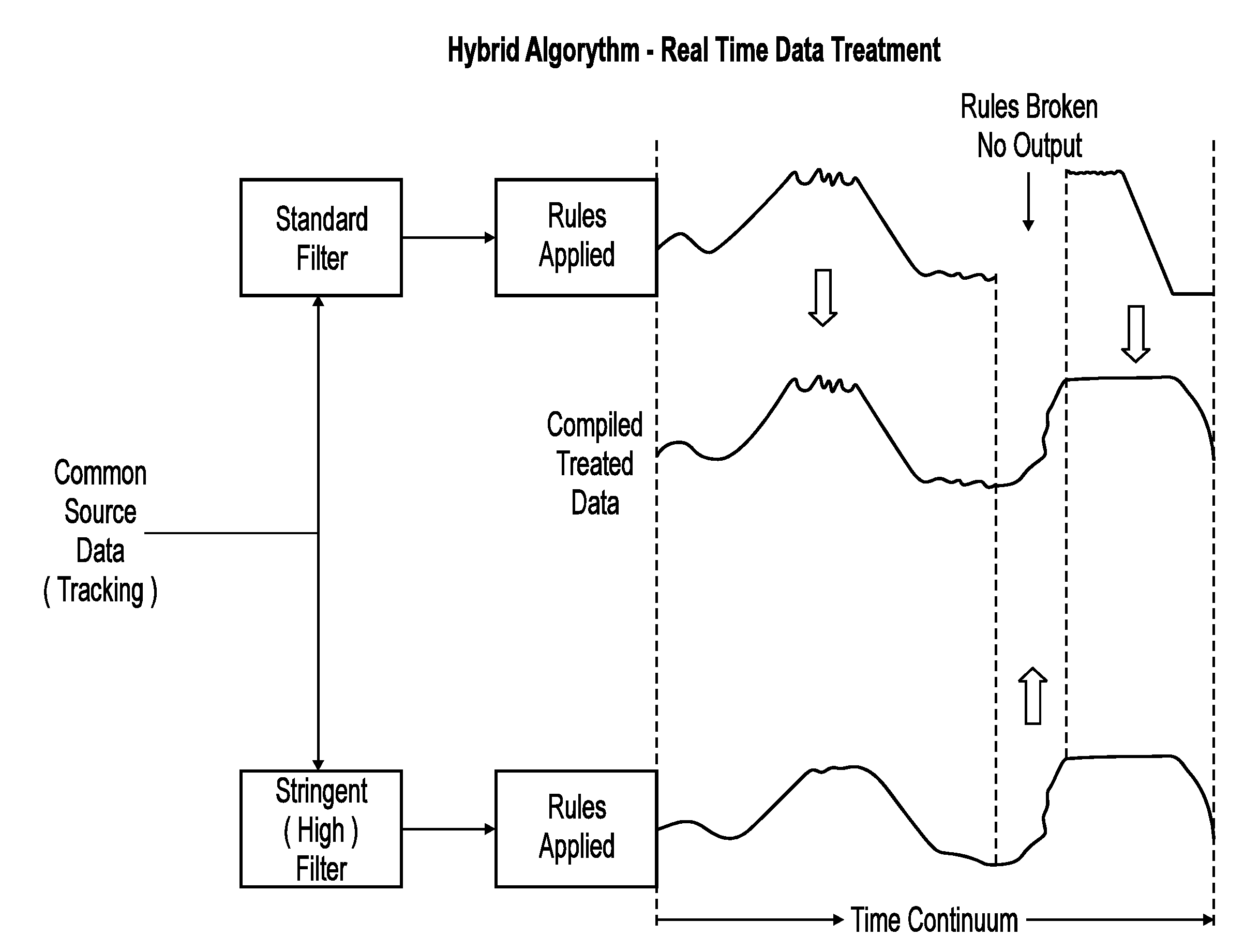

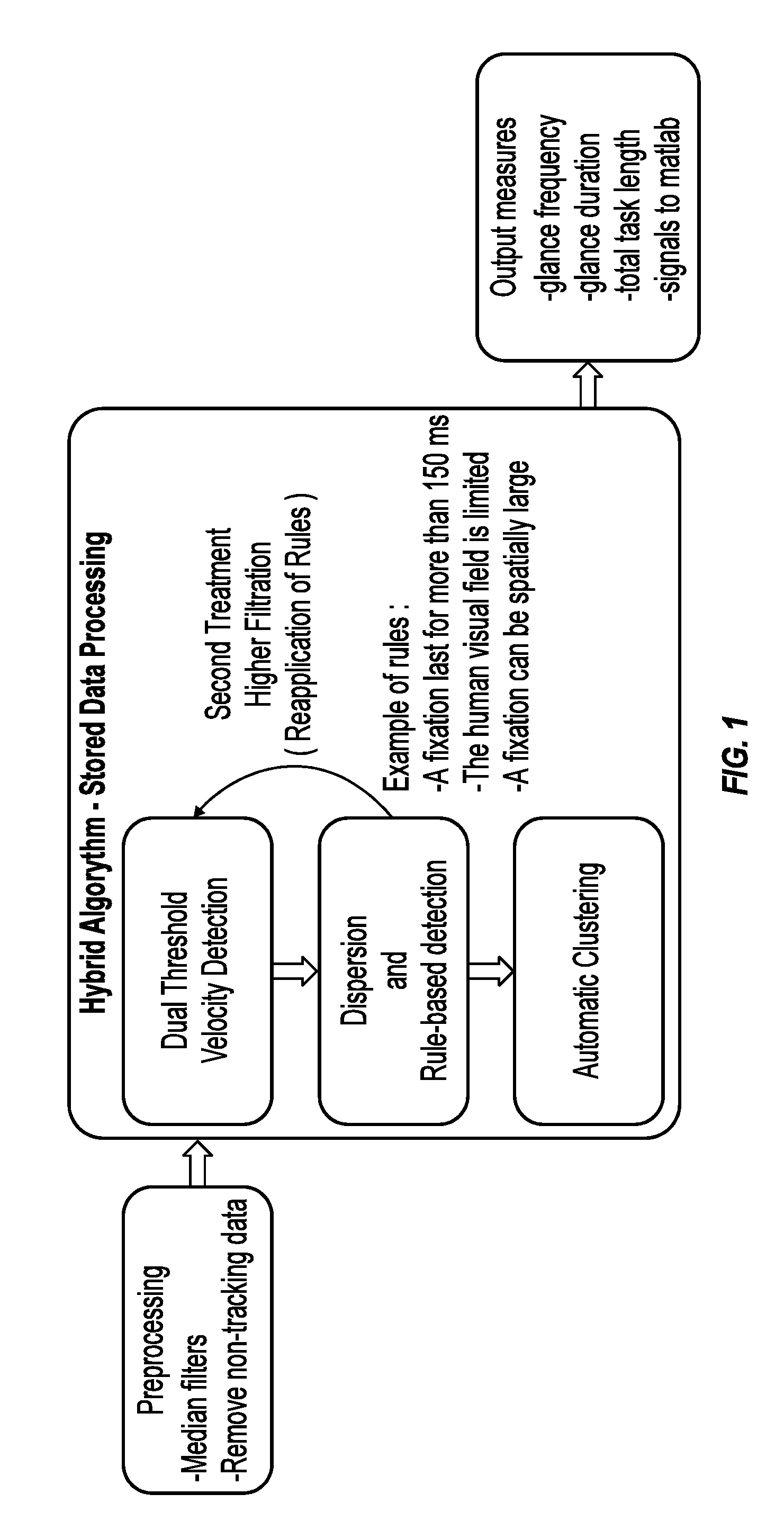

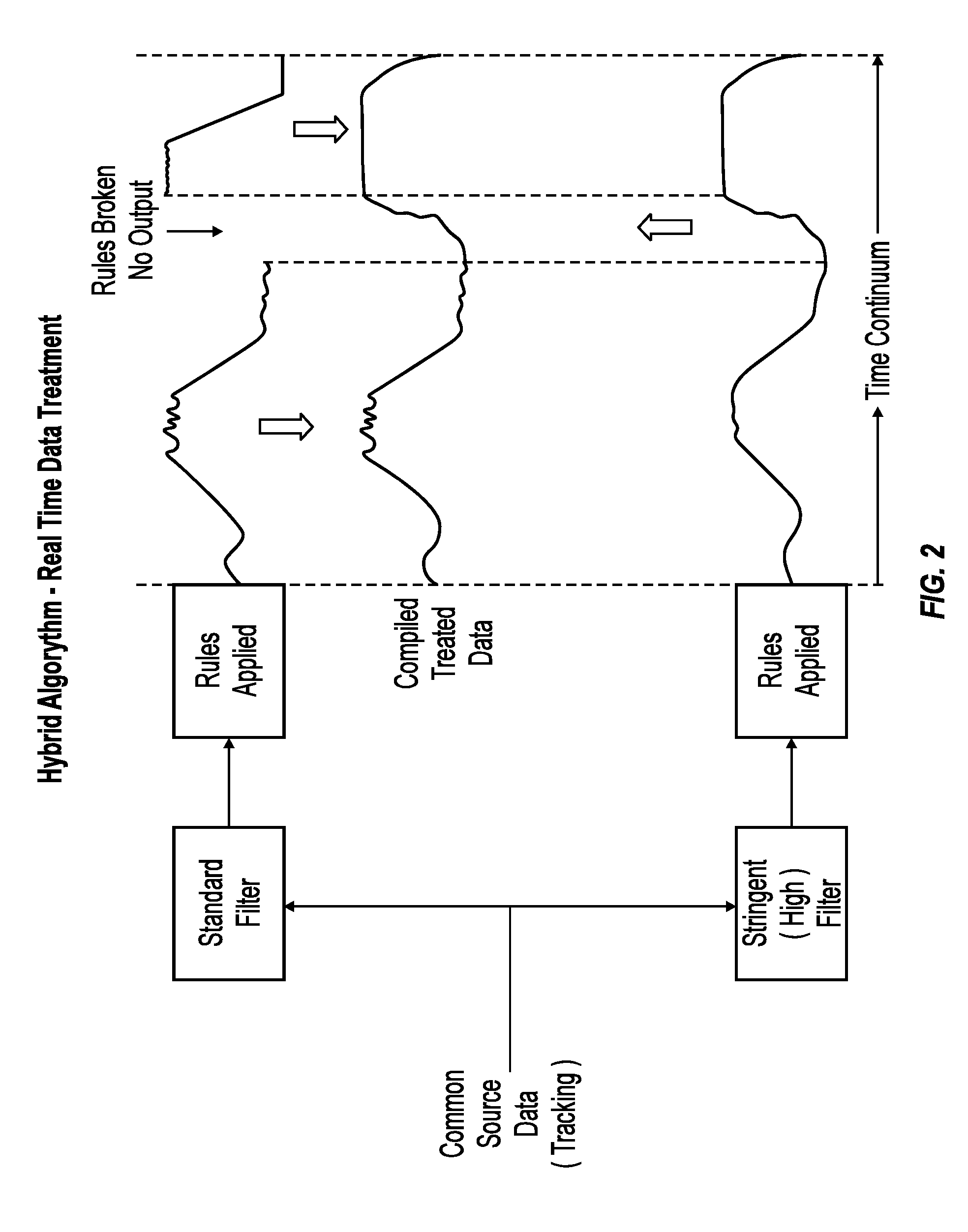

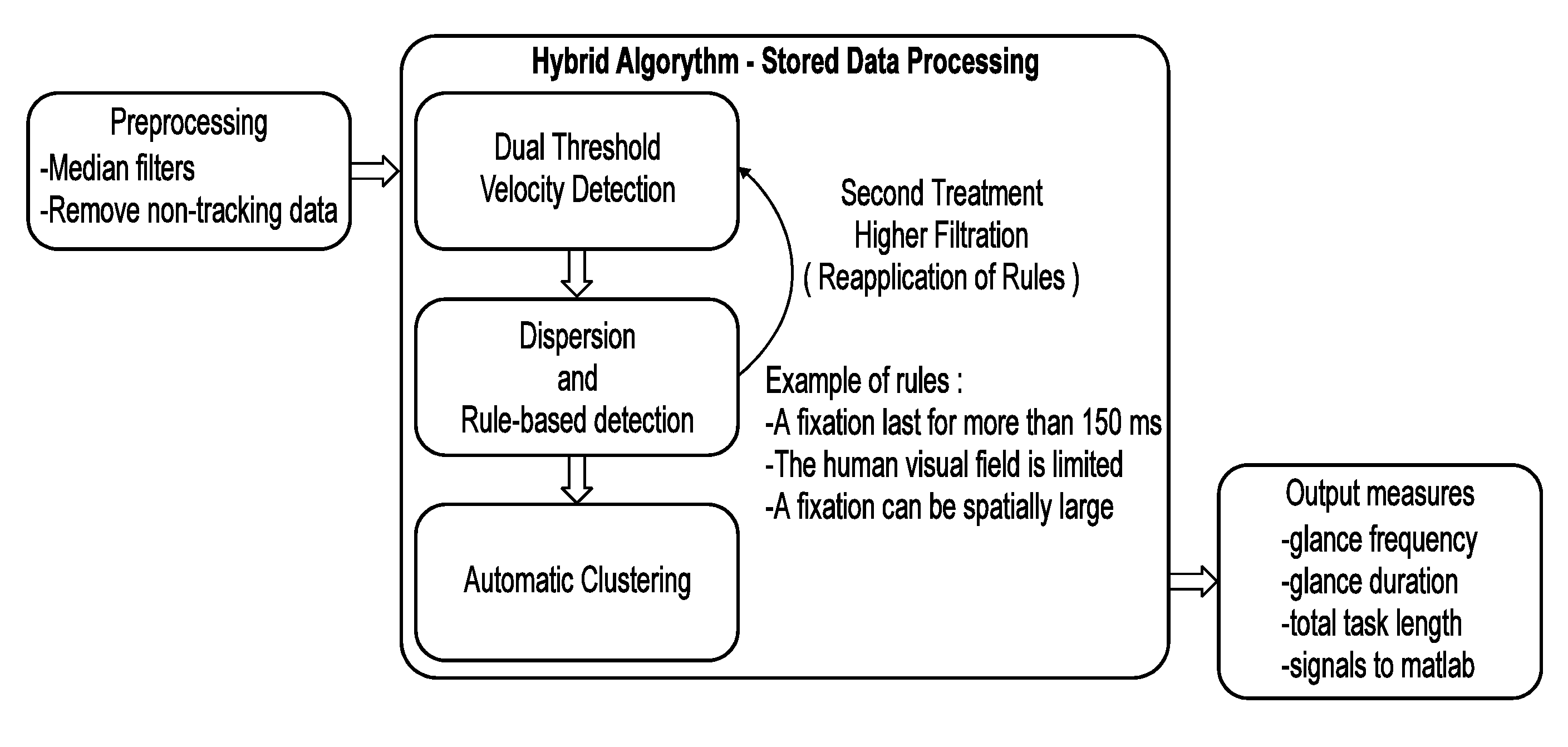

Method and arrangement for interpreting a subjects head and eye activity

ActiveUS20050073136A1Robust against errorNoise robustDigital data processing detailsCharacter and pattern recognitionDriver/operatorEngineering

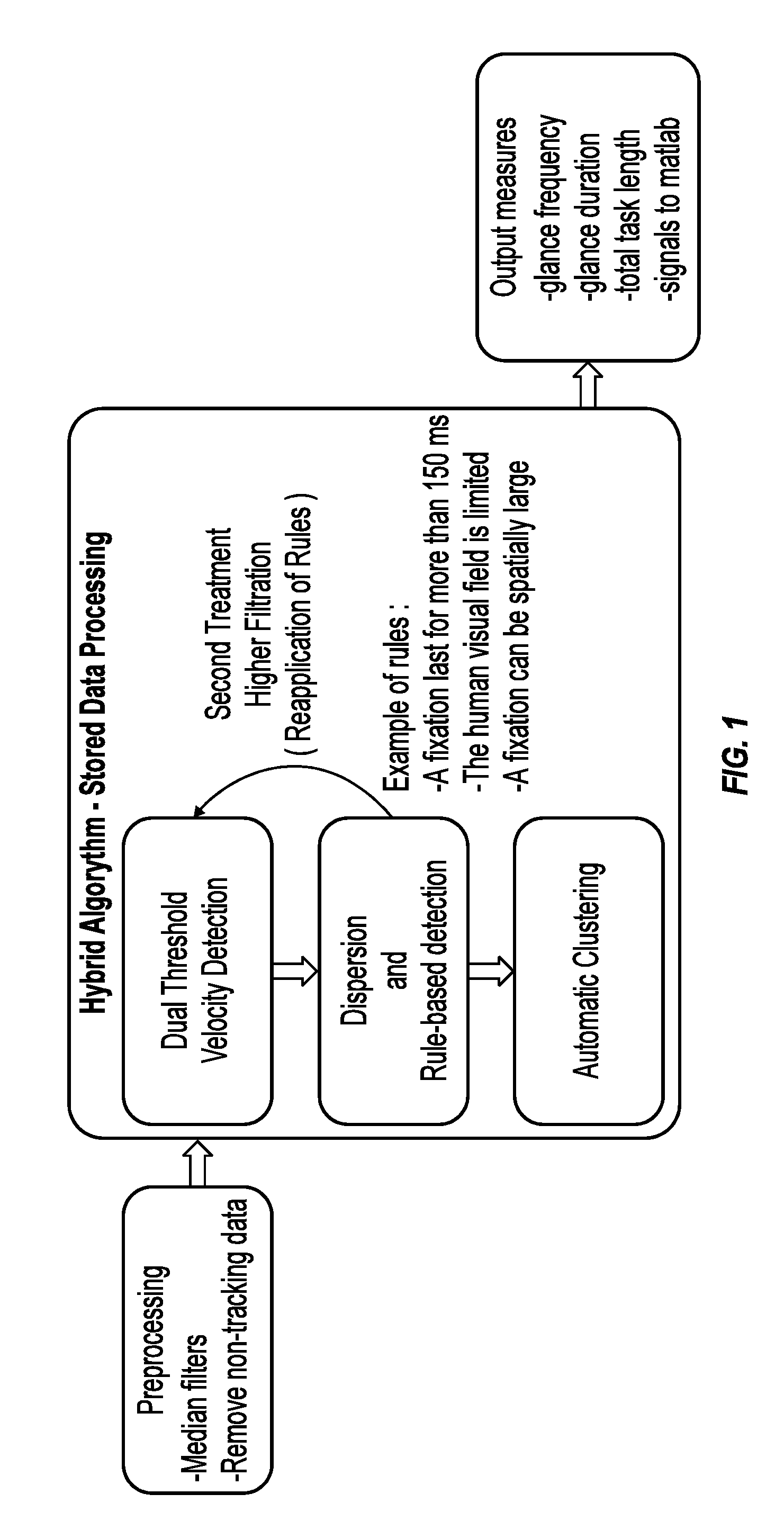

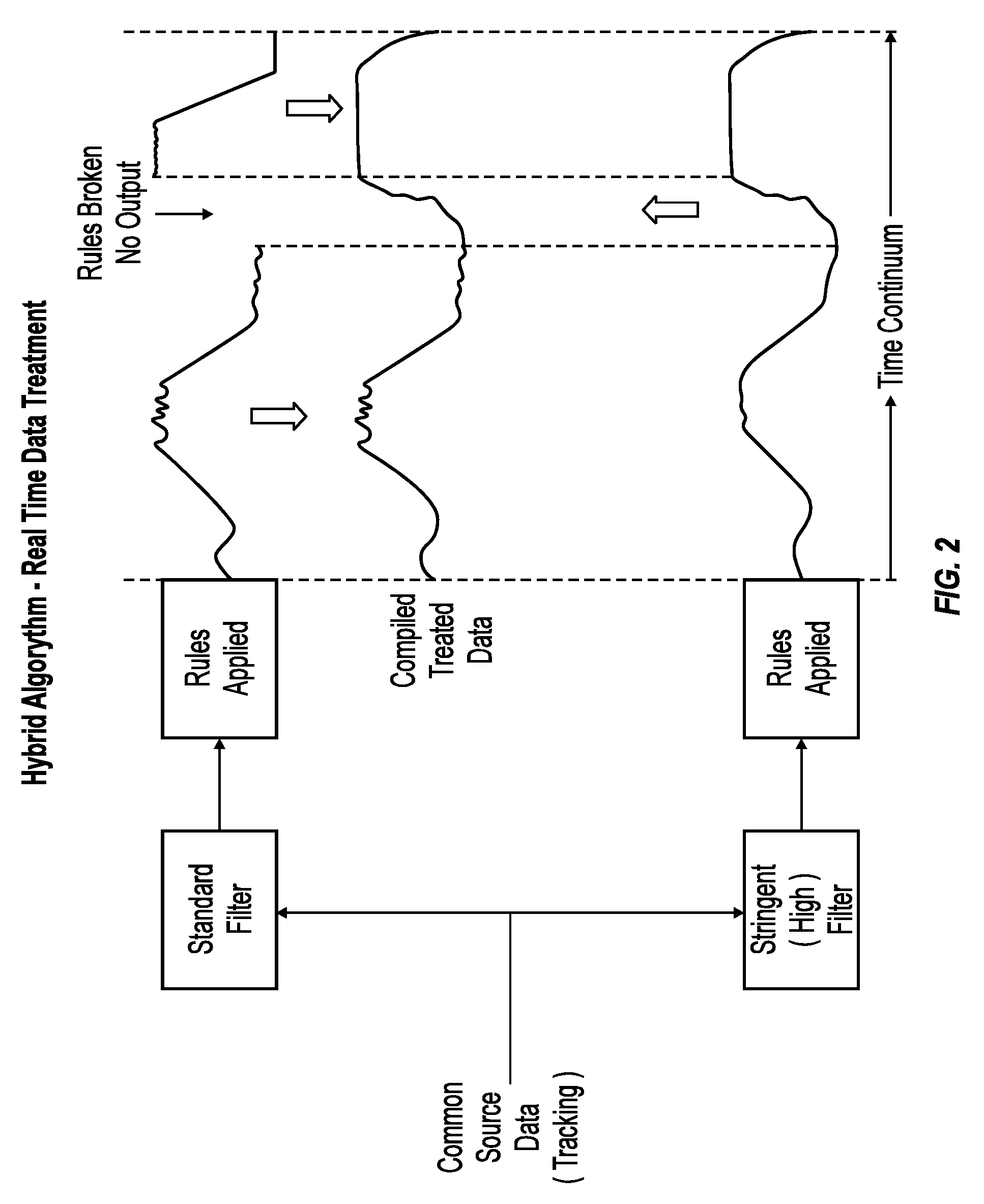

Method for analyzing ocular and / or head orientation characteristics of a subject. A detection and quantification of the position of a driver's head and / or eye movements are made relative to the environment. Tests of the data are made, and from the data, locations of experienced areas / objects-of-subject-interest are deduced. When a driver of a vehicle is the subject, these areas / objects-of-driver-interest may be inside or outside the vehicle, and may be constituted by (1) “things” such as audio controls, speedometers and other gauges, and (2) areas or positions such as “road ahead” and lane-change clearance space in adjacent lanes. In order to “standardize” the tracking data with respect to the vehicle of interest, the quantification of the position of the driver's head is normalized to the reference-base position thereby enabling deducement of location(s) where the driver has shown an interest based on sensed information regarding either, or both of (1) driver ocular orientation or (2) driver head orientation.

Owner:VOLVO TECH

Method and arrangement for interpreting a subjects head and eye activity

ActiveUS7460940B2Automate analysisRemoval rateDigital data processing detailsCharacter and pattern recognitionDriver/operatorComputer vision

Method for analyzing ocular and / or head orientation characteristics of a subject. A detection and quantification of the position of a driver's head and / or eye movements are made relative to the environment. Tests of the data are made, and from the data, locations of experienced areas / objects-of-subject-interest are deduced. When a driver of a vehicle is the subject, these areas / objects-of-driver-interest may be inside or outside the vehicle, and may be constituted by (1) “things” such as audio controls, speedometers and other gauges, and (2) areas or positions such as “road ahead” and lane-change clearance space in adjacent lanes. In order to “standardize” the tracking data with respect to the vehicle of interest, the quantification of the position of the driver's head is normalized to the reference-base position thereby enabling deducement of location(s) where the driver has shown an interest based on sensed information regarding either, or both of (1) driver ocular orientation or (2) driver head orientation.

Owner:VOLVO TECH

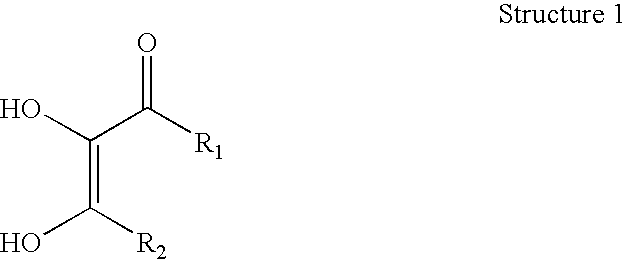

Chemical-mechanical abrasive composition and method

InactiveUS6436834B1Improve wearing rateHigh purityOther chemical processesDecorative surface effectsAtomic groupCompound (substance)

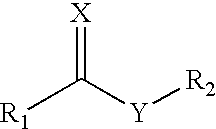

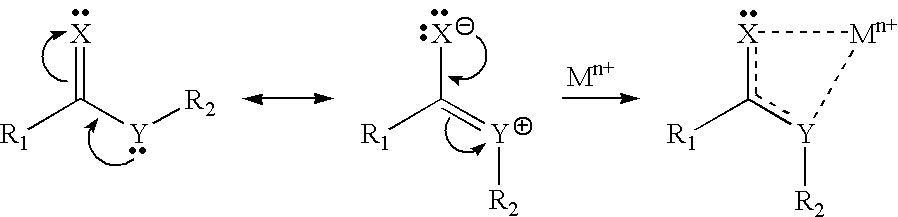

The invention provides a chemical-mechanical abrasive composition for use in semiconductor processing, which comprises an aqueous medium, an abrasive, and an abrasion accelerator. The abrasion accelerator mainly functions to enhance the removal rate of the substances to be removed, and selected from the compounds of the following formula, the acid-addition salts thereof, or mixtures of two or more of the foregoing compounds and salts:wherein X and Y are independently lone-pair electrons containing atoms or atomic groups; and R1 and R2 are independently H, alky, amino, aminoalkyl, or alkoxy. The chemical-mechanical abrasive composition of the invention may optionally comprise an acidic component and / or a salt thereof, so as to further enhance the abrasion rate. The invention further provides a method of using the above chemical-mechanical abrasive composition for polishing the surface of a semiconductor wafer.

Owner:EPOCH MATERIAL CO LTD

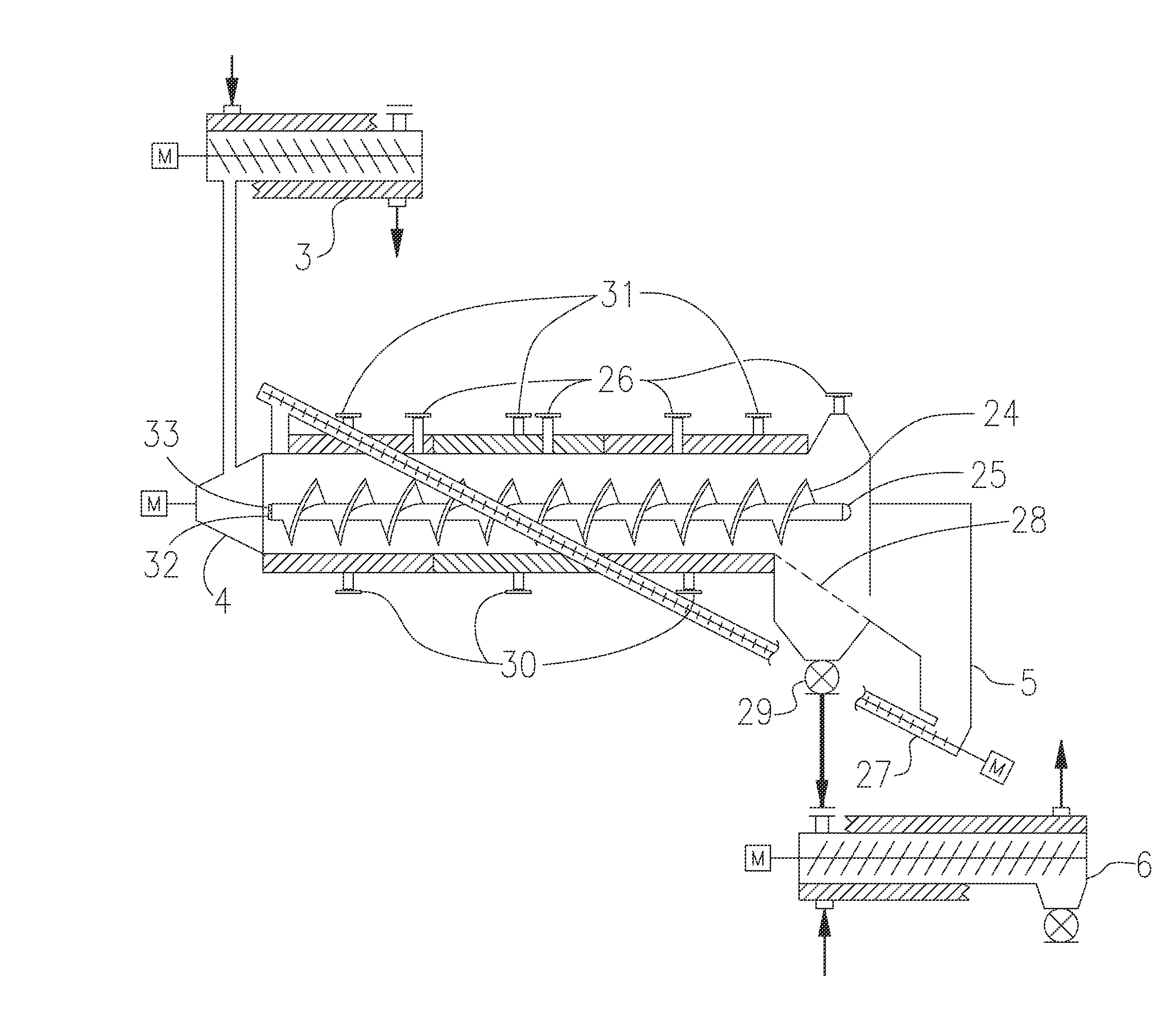

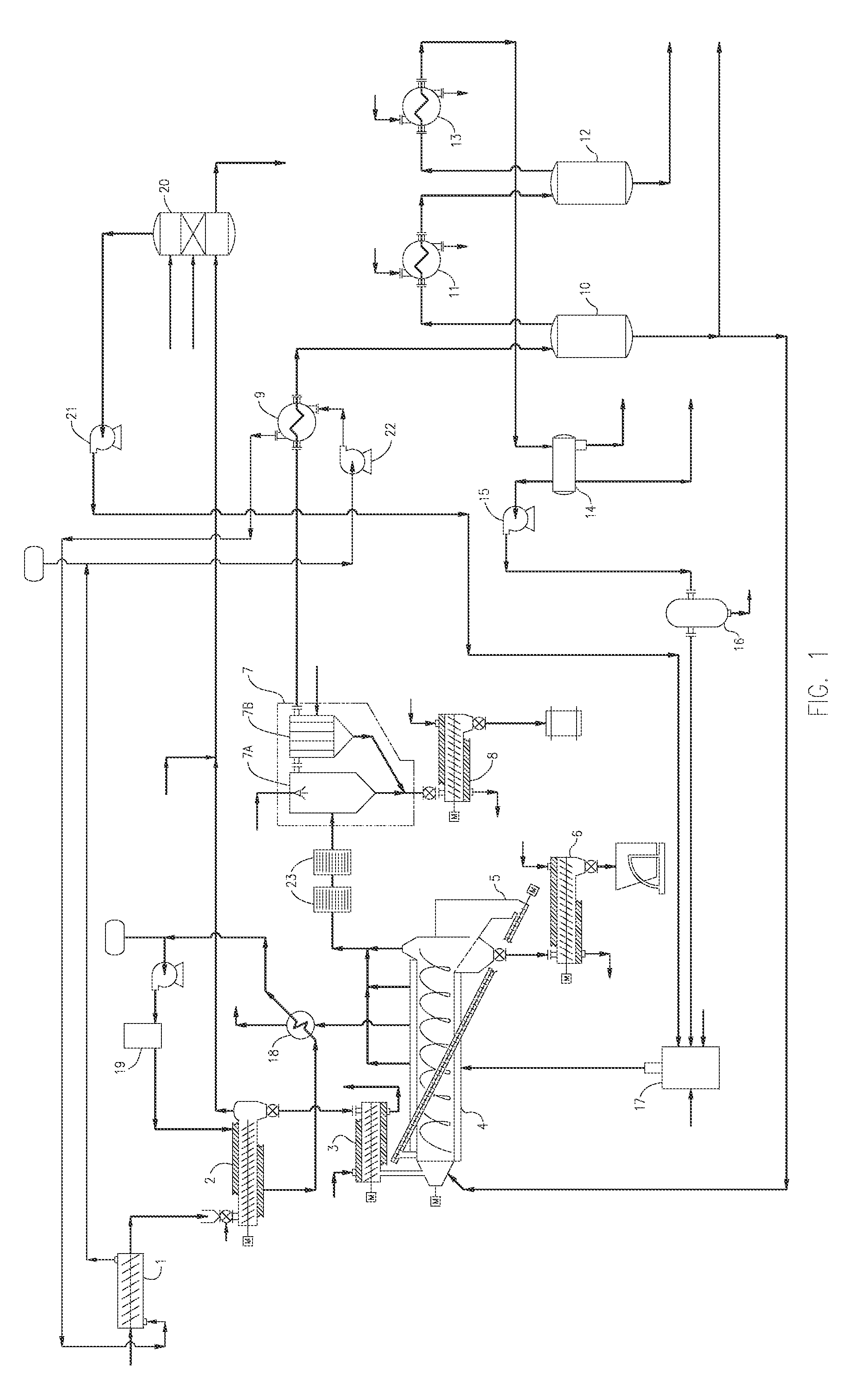

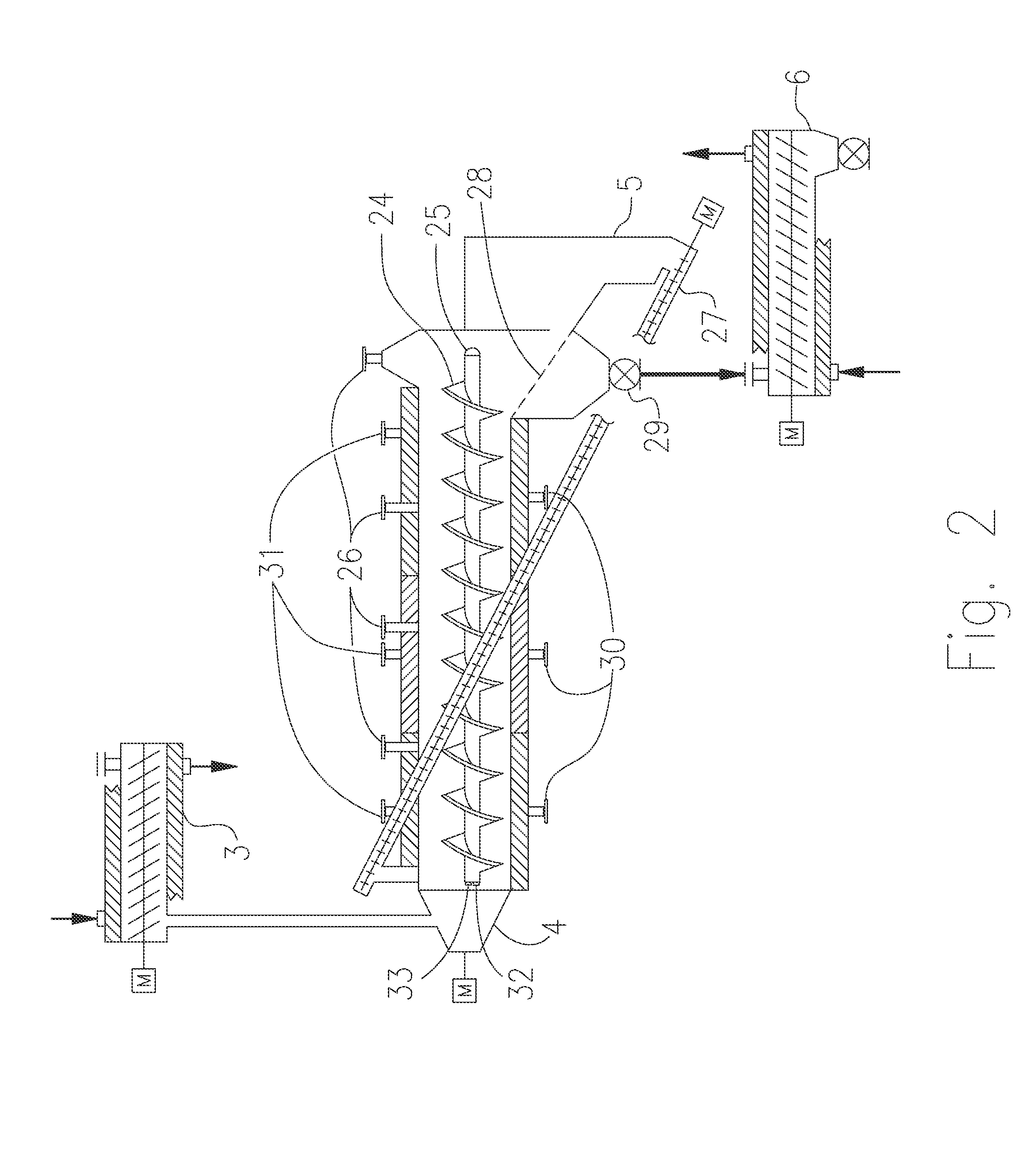

Process and Apparatus for producing Hydrocarbon Fuel from Waste Plastic

ActiveUS20150080624A1Prevent coke build-upSafe removalLiquid hydrocarbon mixture productionHydrocarbonsDecompositionProcess engineering

A process and apparatus for producing hydrocarbon oil from the thermal decomposition of waste plastics in a continuous process which comprises melting of a waste plastic feedstock into an auger assisted melt reactor to remove chlorine and organics contained in the waste plastic, and transferring the melted waste plastic into an heated screw pyrolysis reactor which includes a transitional metal heat transfer medium. The hydrocarbon gas from the pyrolysis reactor is fed into a vessel containing metal trays for a second decomposition which is connected with an alkali treatment 2-step process gas reactor to remove acidic gases, and any inorganic solids. The hydrocarbon gases are separated by three separate condensers. The hydrocarbon fraction of the first condenser is recycled back into the pyrolysis reaction for further thermal treatment, and the hydrocarbon fractions are collected in the remaining condensers.

Owner:VIRENS ENERGY LLC

Polymeric barrier removal polishing slurry

ActiveUS20070051917A1Decreasing static etchHigh removal rateOther chemical processesDecorative surface effectsCopper interconnectCompound (substance)

The aqueous slurry is useful for chemical mechanical polishing semiconductor substrates having copper interconnects. The aqueous slurry includes by weight percent, 0.01 to 25 oxidizing agent, 0.1 to 50 abrasive particles, 0.001 to 3 polyvinyl pyrrolidone, 0.01 to 10 inhibitor for decreasing static etch of the copper interconnects, 0.001 to 5 phosphorus-containing compound for increasing removal rate of the copper interconnects, 0.001 to 10 complexing agent formed during polishing and balance water; and the aqueous slurry has a pH of at least 8.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Multi-step polishing solution for chemical mechanical planarization

InactiveUS20050194357A1Increase ratingsHigh removal rateEdge grinding machinesPigmenting treatmentInorganic saltsCopper

The present invention provides a multi-step aqueous composition useful for polishing a tantalum barrier material and copper from a semiconductor wafer, comprising by weight percent 0.1 to 30 oxidizer, 0.01 to 3 inorganic salt or acid, 0.01 to 4 inhibitor, 0.1 to 30 abrasive, 0 to 15 complexing agent and balance water, wherein the aqueous composition has a pH between 1.5 to 6.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

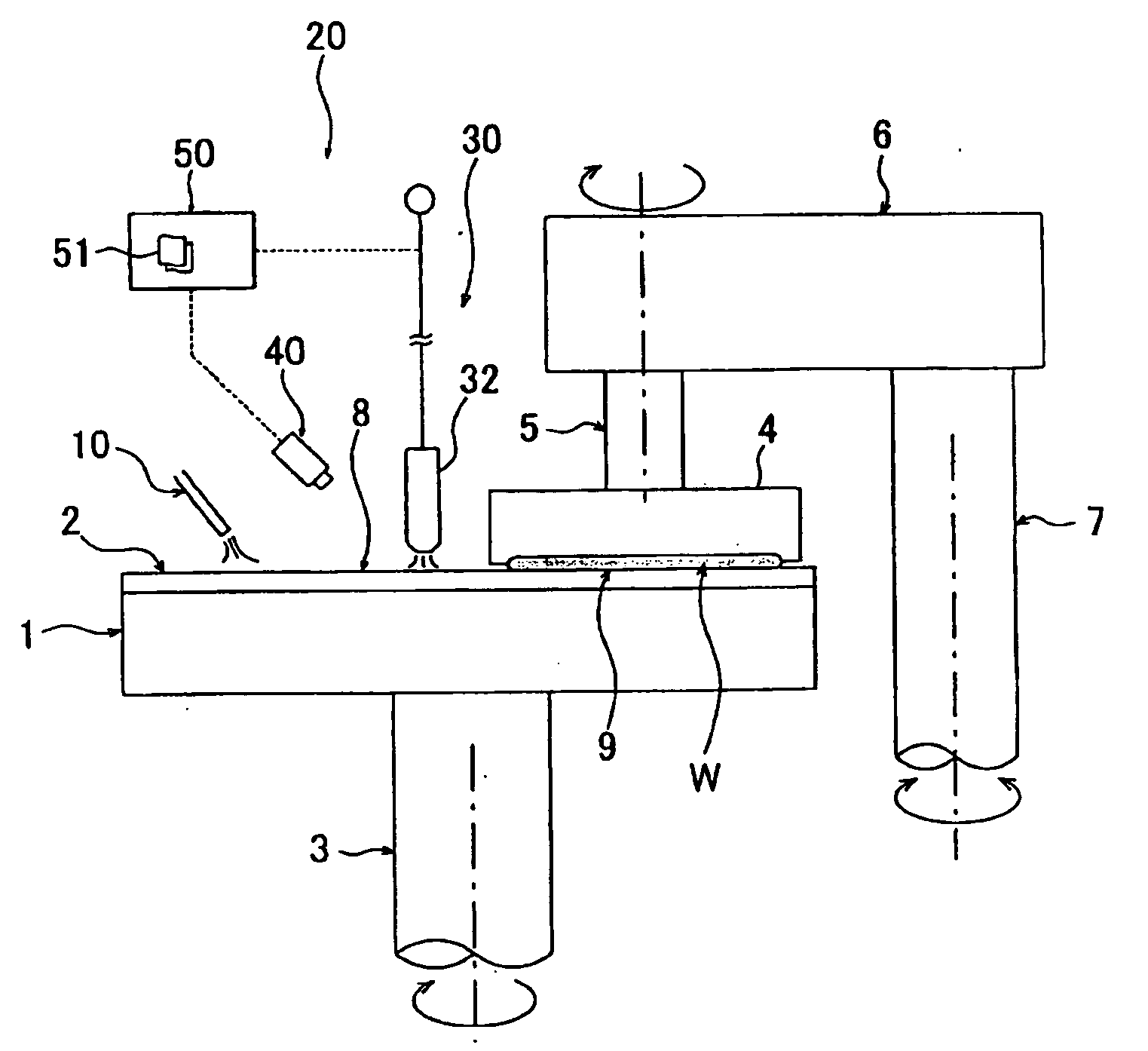

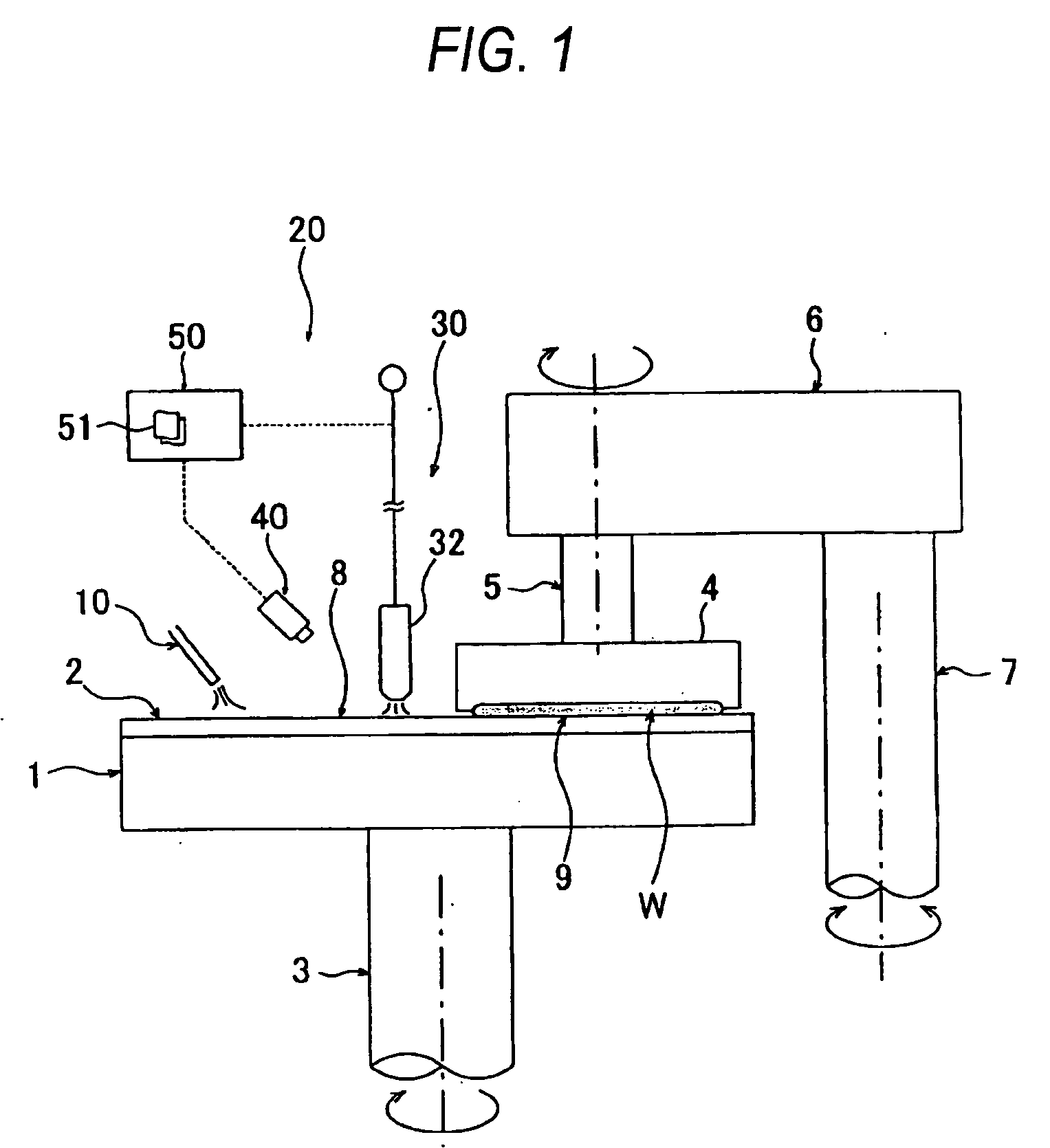

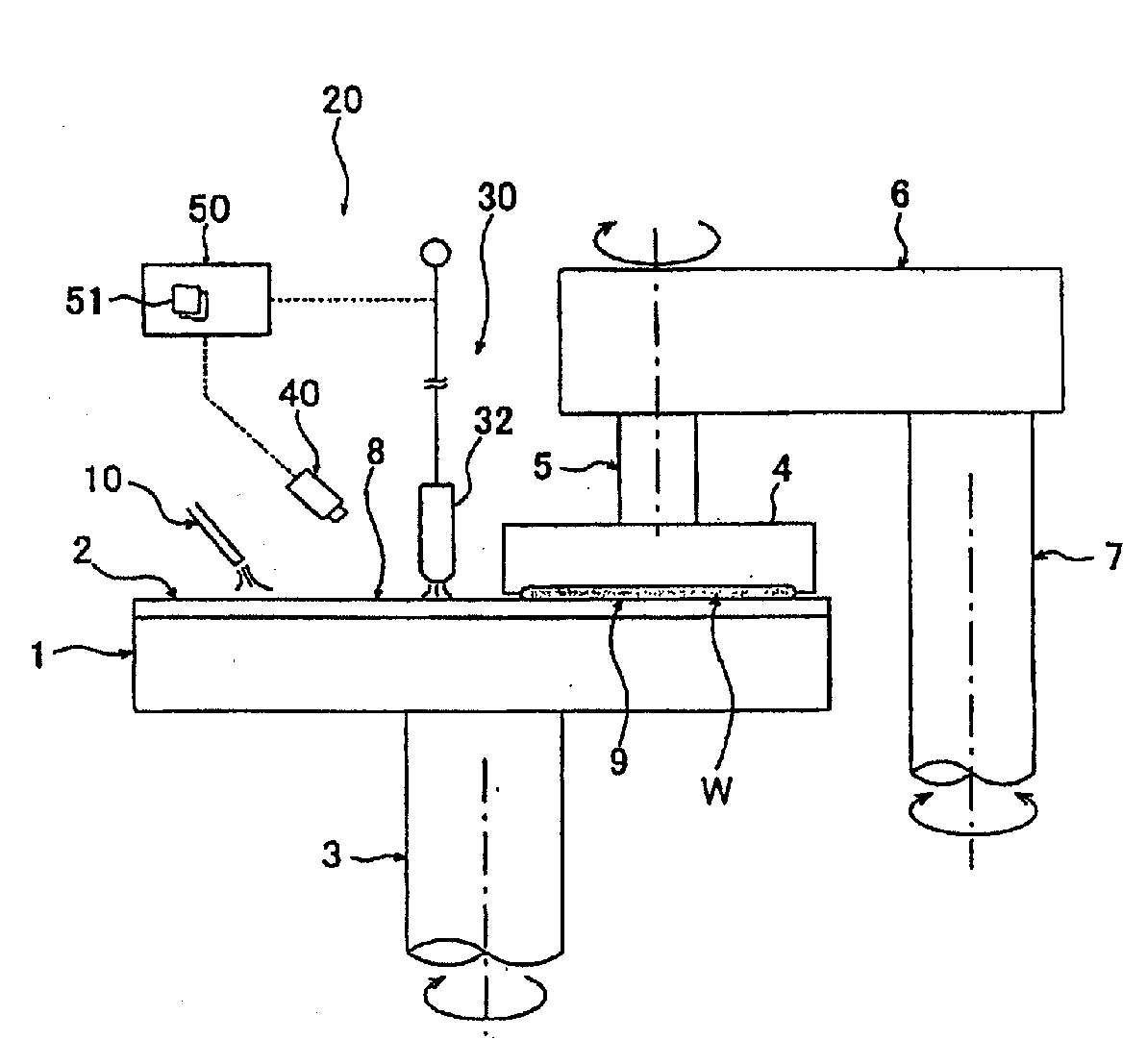

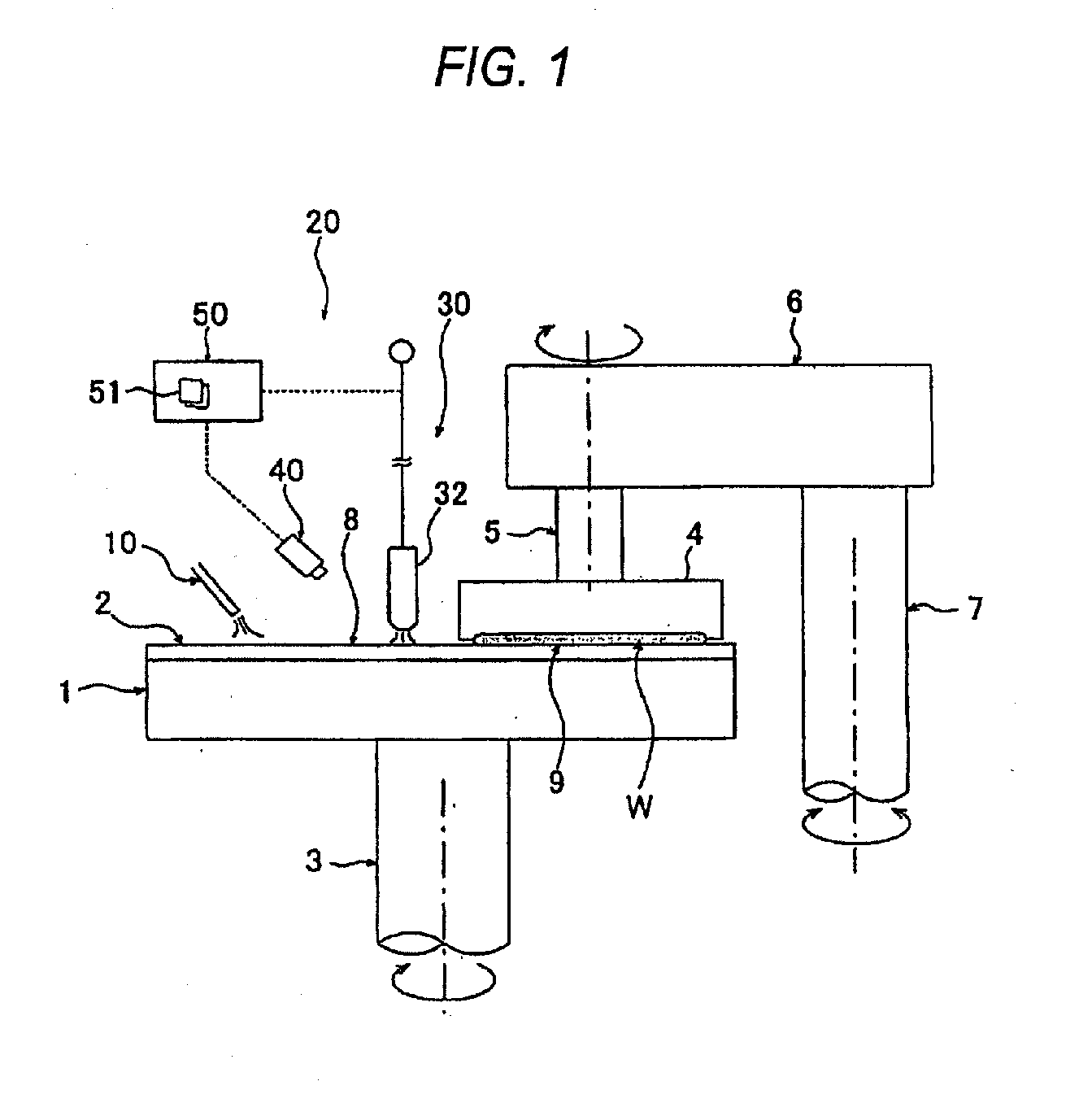

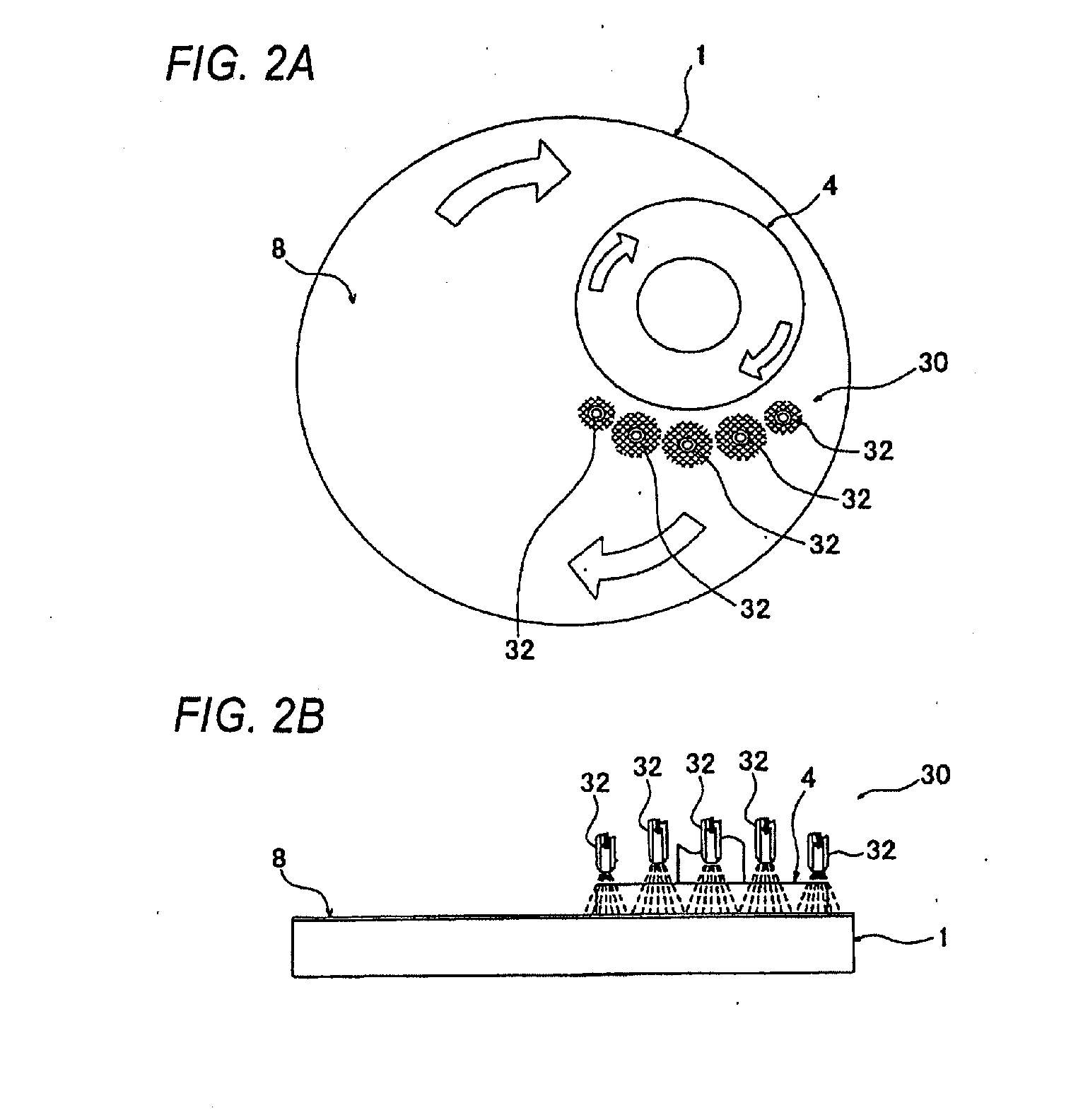

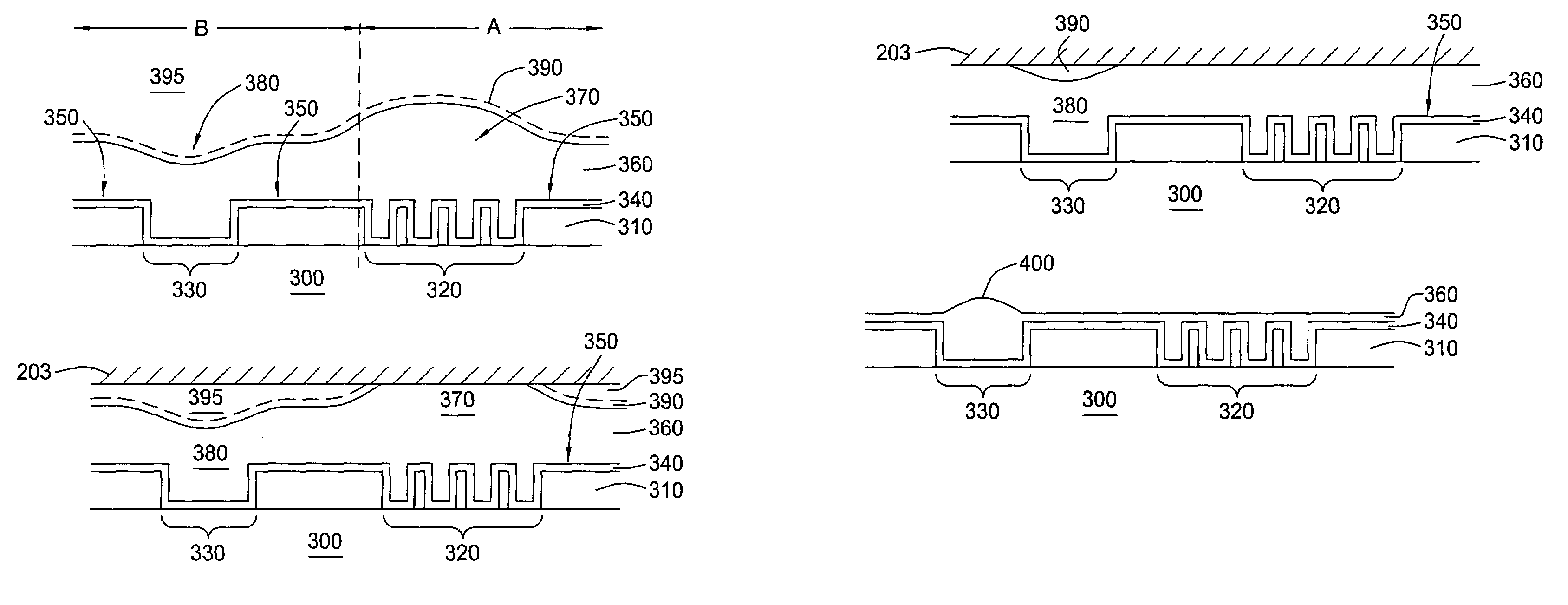

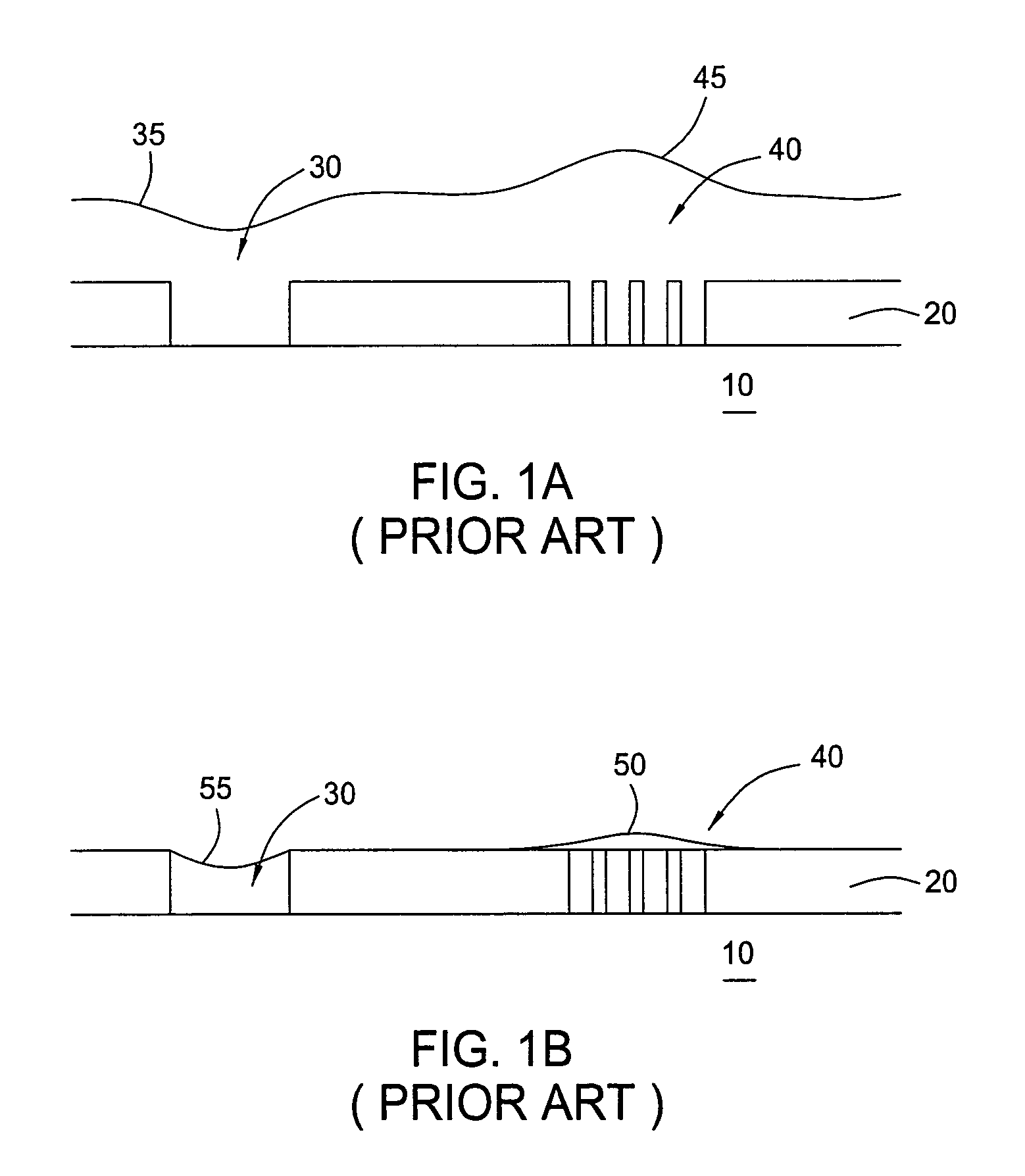

Polishing apparatus and polishing method

InactiveUS20070135020A1Uniform polishing profileHigh removal rateSemiconductor/solid-state device manufacturingLapping machinesEngineeringSemiconductor

A polishing apparatus polish a surface of a substrate, such as a semiconductor substrate. The polishing apparatus according to the present invention includes a substrate holding mechanism, a polishing table having a polishing surface, and a polishing surface temperature controller for controlling a temperature distribution of the polishing surface. The substrate holding mechanism and the polishing table are operable to provide relative movement between the surface of the substrate and the polishing surface while the substrate holding mechanism presses the surface of the substrate against the polishing surface to thereby polish the surface of the substrate. The polishing surface temperature controller controls the temperature distribution so that the polishing surface has a predetermined temperature distribution to thereby control removal rates of portions of the surface of the substrate.

Owner:EBARA CORP

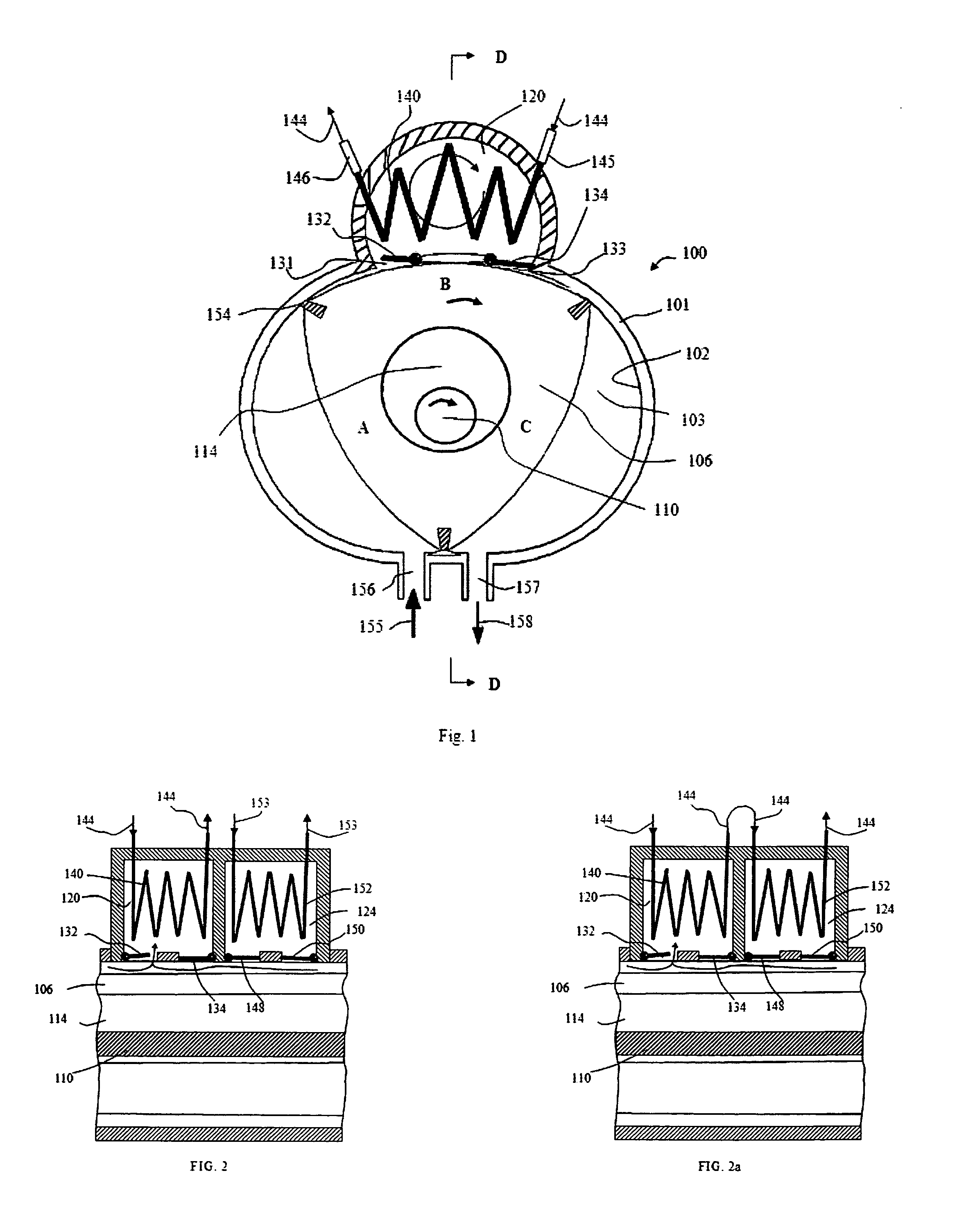

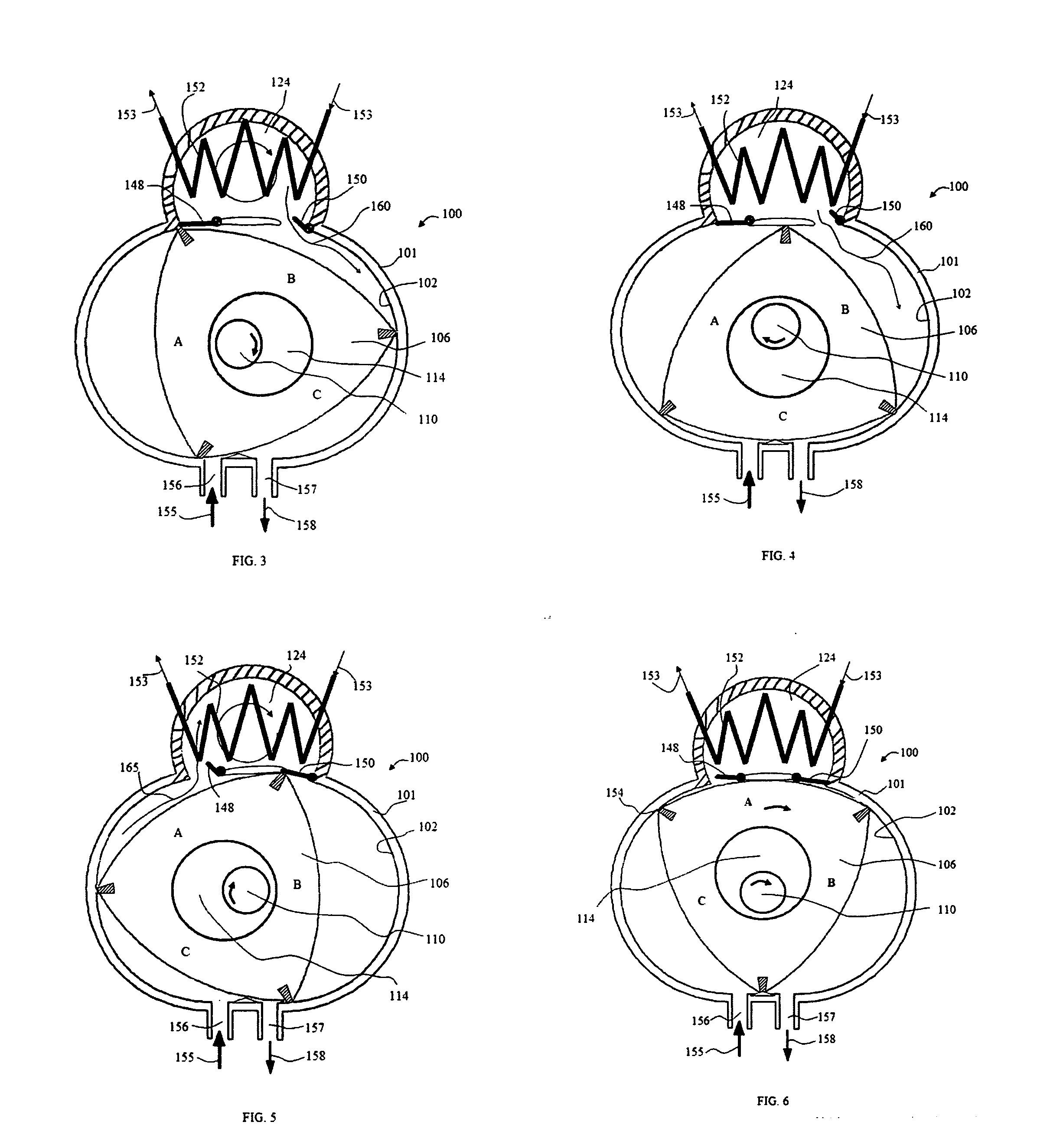

Cao heat engine and refrigerator

InactiveUS20100089062A1Increase the number ofExtended durationAuxillary drivesInternal combustion piston enginesThermal energyAir cycle machine

Owner:CAO YIDING

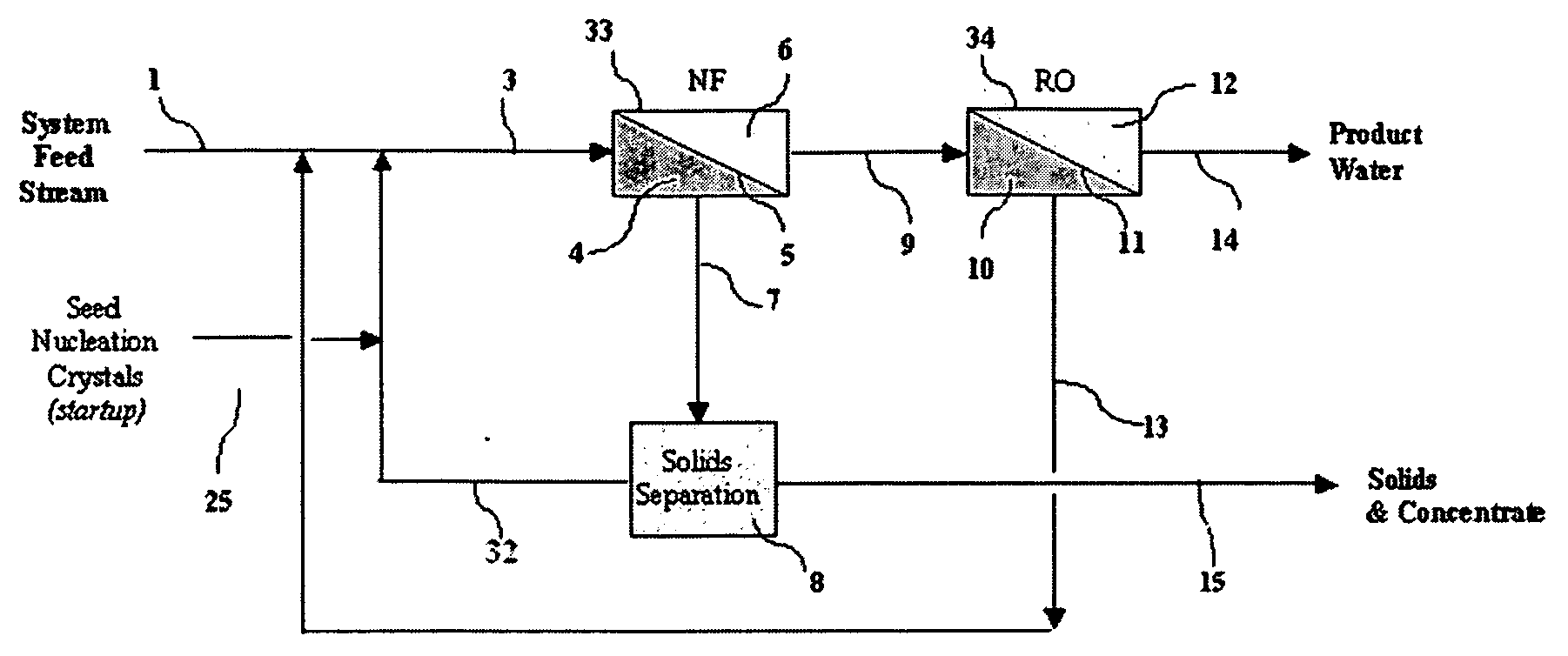

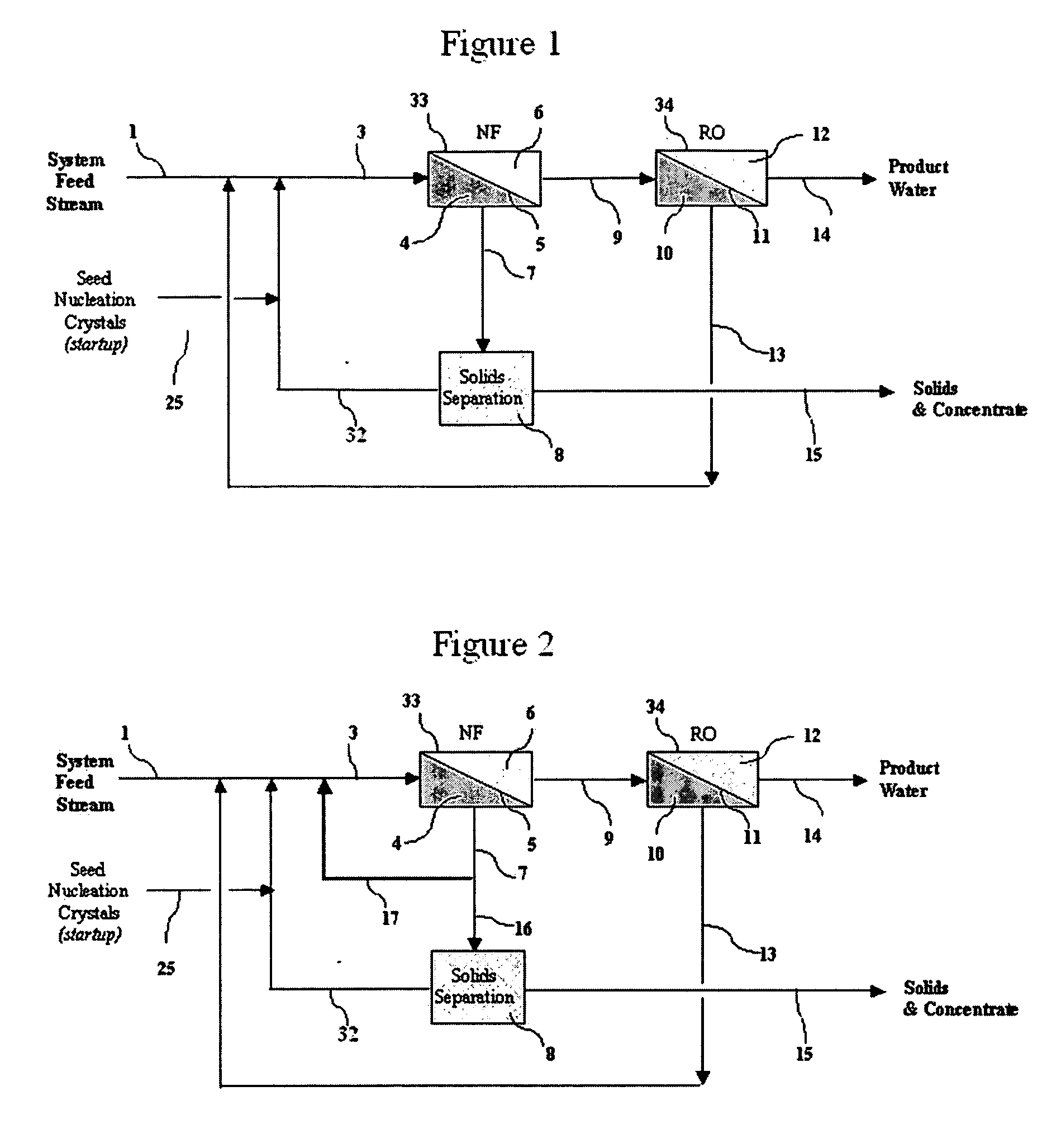

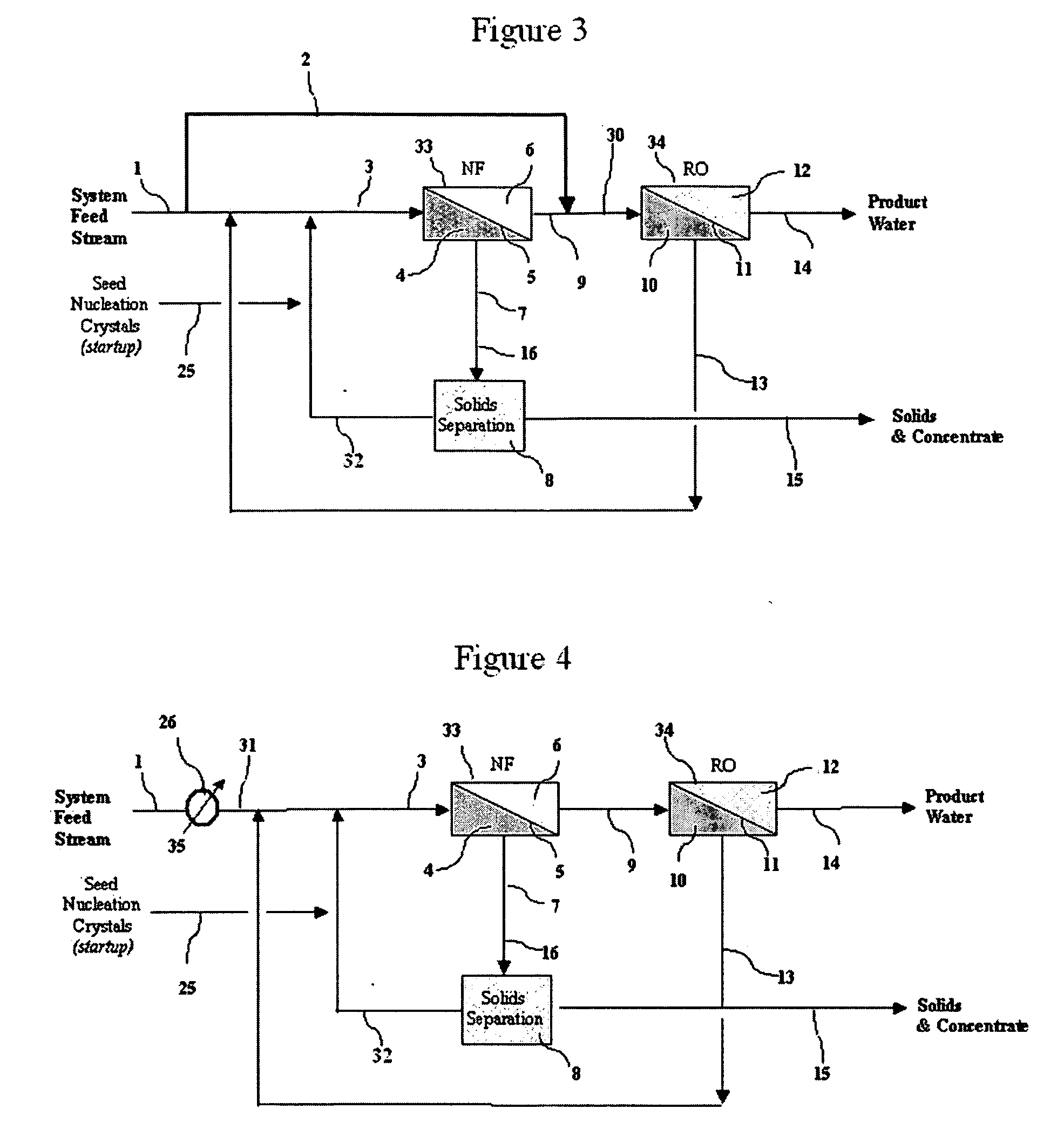

Preferential precipitation membrane system and method

InactiveUS20050016922A1High recovery rateHigh removal rateGeneral water supply conservationSolvent extractionSulfateHigh pressure

A system and method for desalinating a feed solution containing a high level of sparingly soluble solutes, such as calcium sulfate, in which a high percentage of the water content of the feed solution is recovered as purified water. The method and system comprise introducing a sufficient quantity of nucleation crystals on the low pressure side of a first-pass membrane separation unit so that the sparingly soluble solutes precipitate on the suspended nucleation crystals, instead of on the surface of the first-pass semi-permeable membrane barrier. The permeate from the first-pass membrane separation unit is then sent to the high pressure side of a second-pass membrane separation unit. The second-pass semi-permeable membrane barrier rejects additional dissolved solutes, some of which can be recycled back to the first-pass membrane, so that permeate with a low level of dissolved solutes is produced on the low pressure side of the second-pass membrane barrier.

Owner:ITT MFG ENTERPRISES LLC

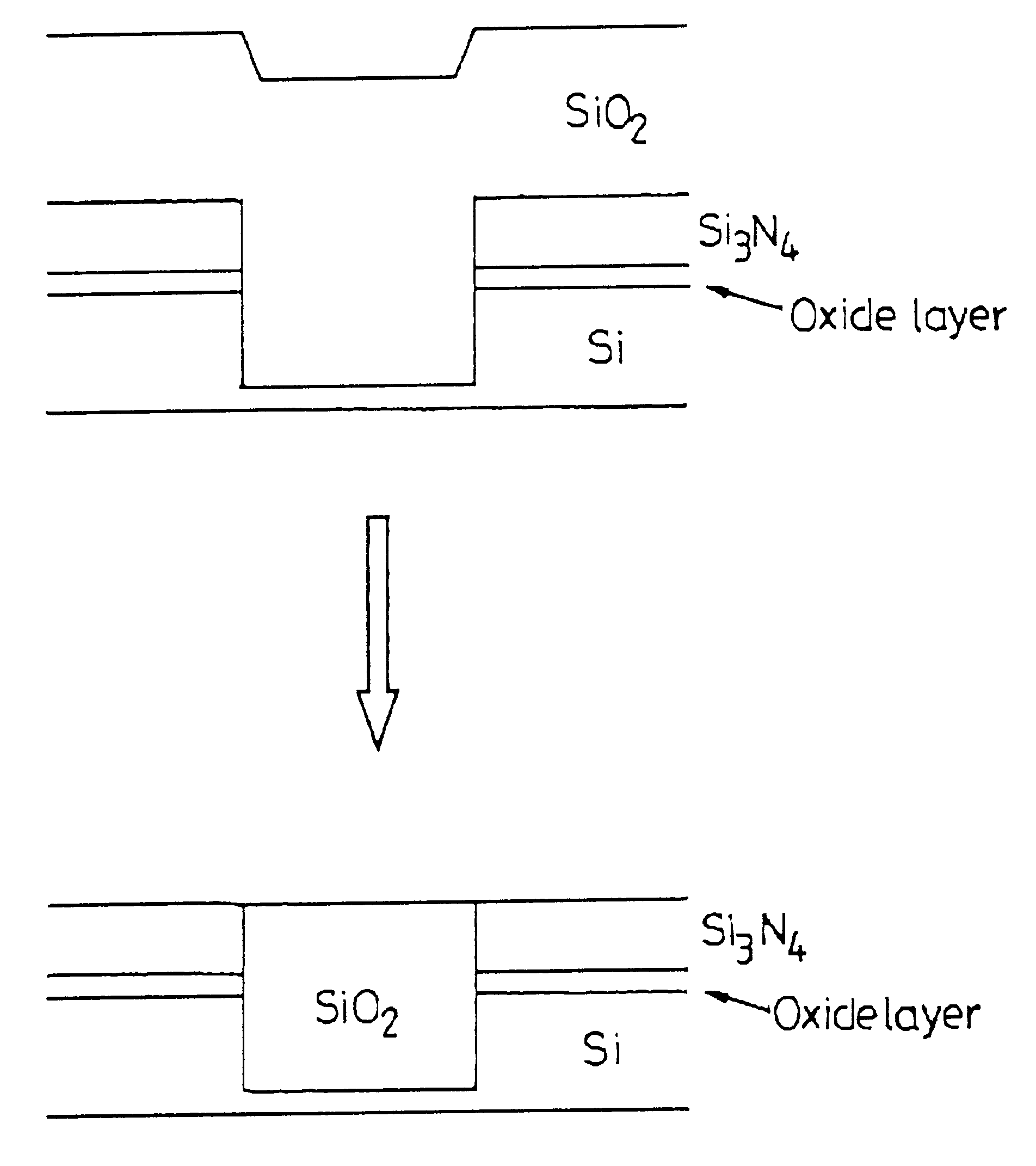

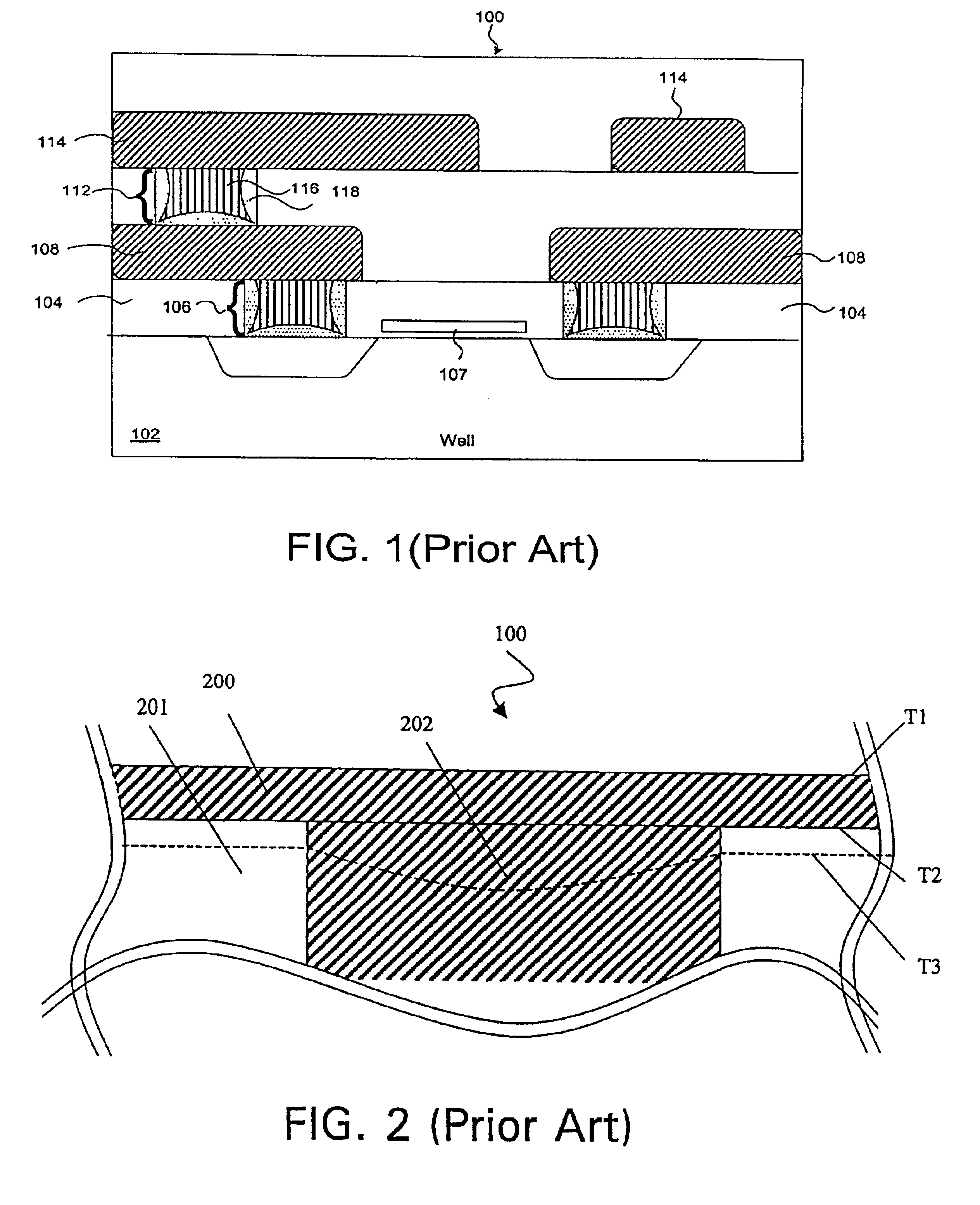

Chemical-mechanical polishing slurry and method

InactiveUS6702954B1Suppresses rateRemoval rateOther chemical processesSemiconductor/solid-state device manufacturingCompound (substance)Slurry

The present invention provides a chemical-mechanical polishing slurry for use in removing a barrier layer during the fabrication of a damascene structure. The slurry according to the invention includes an agent that suppresses the rate at which an underlying silicon-containing dielectric layer is removed. In the presently most preferred embodiment of the invention, the agent that suppresses the rate at which an underlying silicon-containing dielectric layer is removed is <SMALLCAPS>L< / SMALLCAPS>-lysine and / or <SMALLCAPS>L< / SMALLCAPS>-arginine. The present invention also provides a method of suppressing the removal rate of an underlying silicon-containing dielectric layer during the chemical-mechanical polishing of a barrier layer in a damascene structure. The method according to the invention includes polishing the barrier layer with a slurry comprising an agent that suppresses the rate at which said underlying silicon-containing dielectric layer is removed.

Owner:FERRO CORP

Polishing composition for semiconductor wafers

InactiveUS20050056810A1Removal rateOther chemical processesSemiconductor/solid-state device manufacturingCarbon chainNitride

An aqueous composition is useful for polishing semiconductor wafers. The composition comprises a nonionic surfactant that suppresses removal rate of silicon carbide-nitride and has a hydrophilic group and a hydrophobic group. The hydrophobic group has a carbon chain length of greater than three. And the nonionic surfactant suppresses silicon carbide-nitride removal rate at least 100 angstroms per minute greater than its decrease in silicon nitride removal rate as measured with a microporous polyurethane polishing pad pressure measured normal to a wafer of 13.8 kPa.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Polishing apparatus and polishing method

InactiveUS20100151771A1Uniform polishing profileHigh removal rateSemiconductor/solid-state device manufacturingLapping machinesTemperature controlEngineering

A polishing apparatus polishing a surface of a substrate, such as a semiconductor substrate. The polishing apparatus including a substrate holding mechanism, a polishing table having a polishing surface, and a polishing surface temperature controller for controlling a temperature distribution of the polishing surface. The substrate holding mechanism and the polishing table provide relative movement between the surface of the substrate and the polishing surface while the substrate holding mechanism presses the surface of the substrate against the polishing surface to thereby polish the surface of the substrate. The polishing surface temperature controller controls the temperature distribution so that the polishing surface has a predetermined temperature distribution to thereby control removal rates of portions of the surface of the substrate.

Owner:NABEYA OSAMU

Polishing composition for semiconductor wafers

InactiveUS20050282390A1Removal rateOther chemical processesSemiconductor/solid-state device manufacturingCarbon chainNitride

An aqueous composition is useful for polishing semiconductor wafers. The composition comprises a nonionic surfactant that suppresses removal rate of silicon carbide-nitride and has a hydrophilic group and a hydrophobic group. The hydrophobic group has a carbon chain length of greater than three. And the nonionic surfactant suppresses silicon carbide-nitride removal rate at least 100 angstroms per minute greater than its decrease in silicon nitride removal rate as measured with a microporous polyurethane polishing pad pressure measured normal to a wafer of 13.8 kPa.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

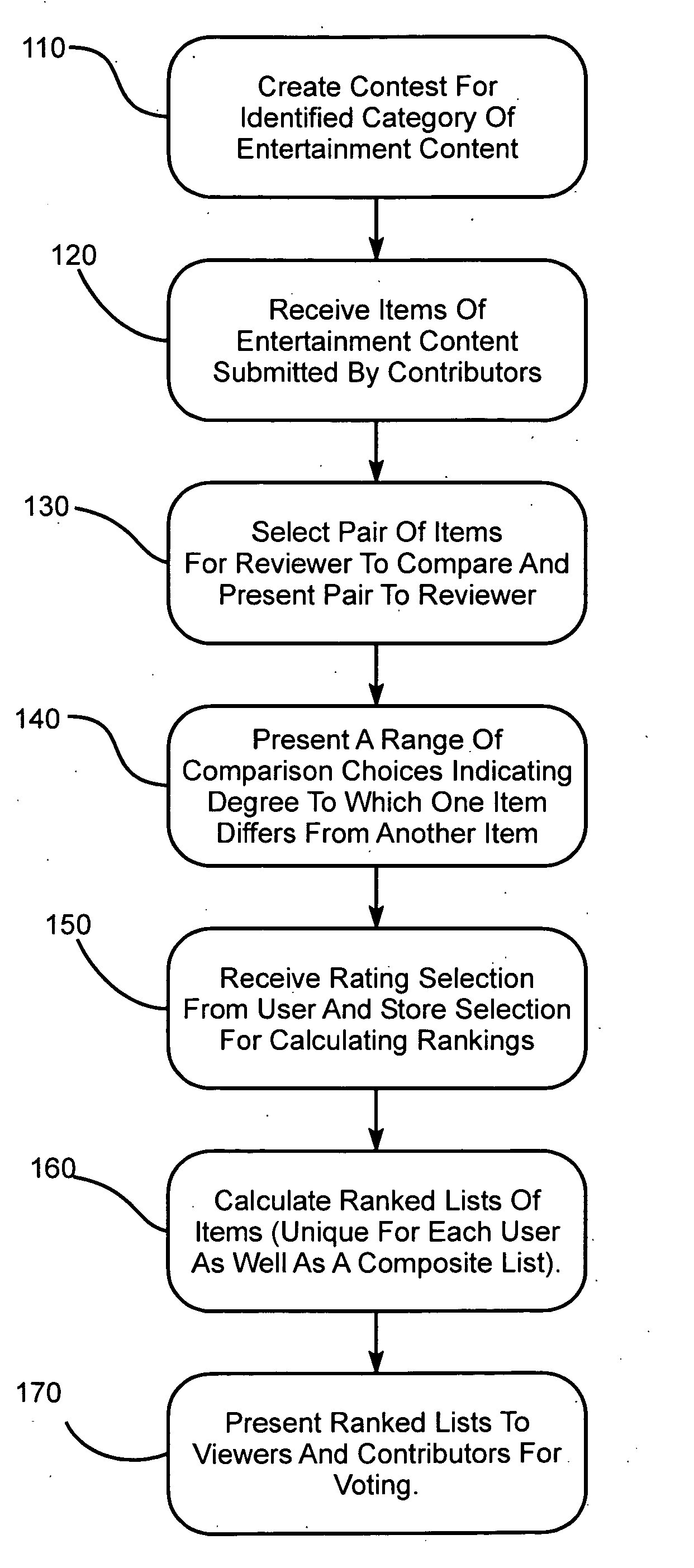

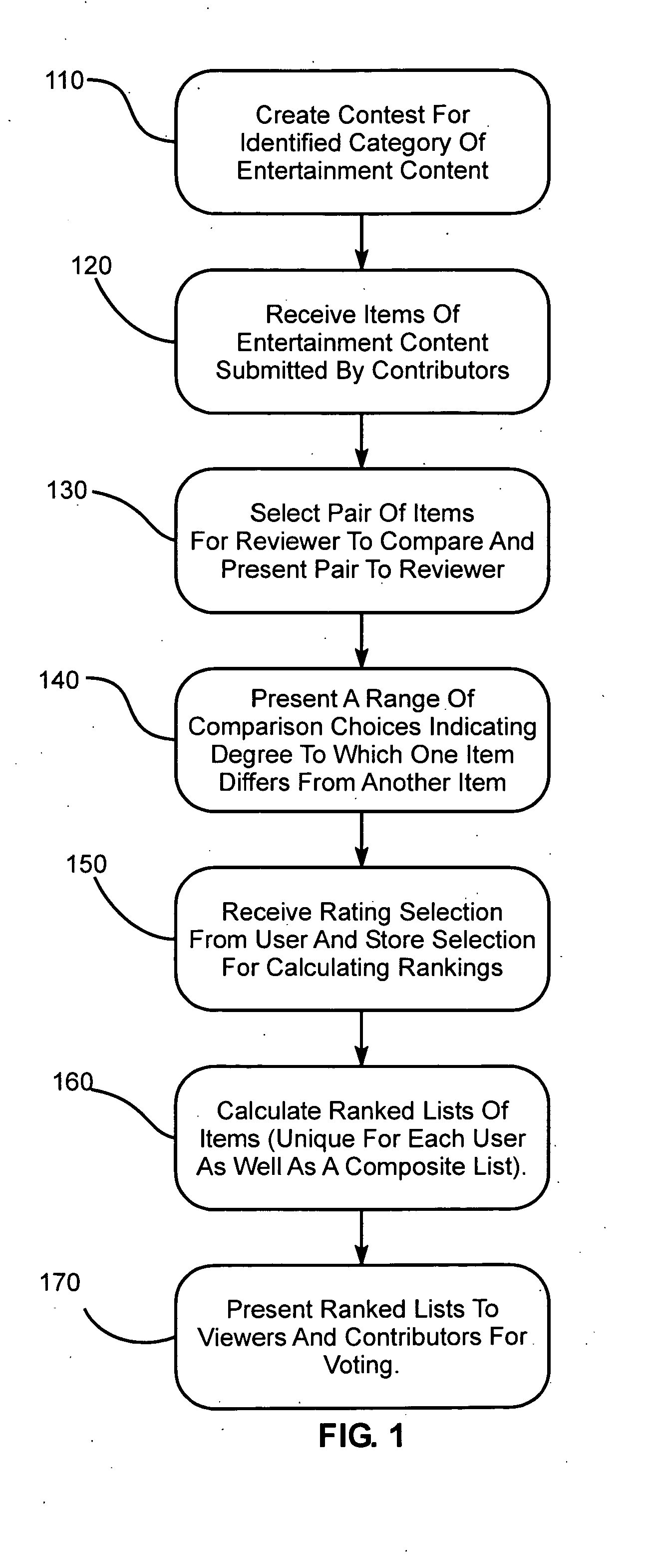

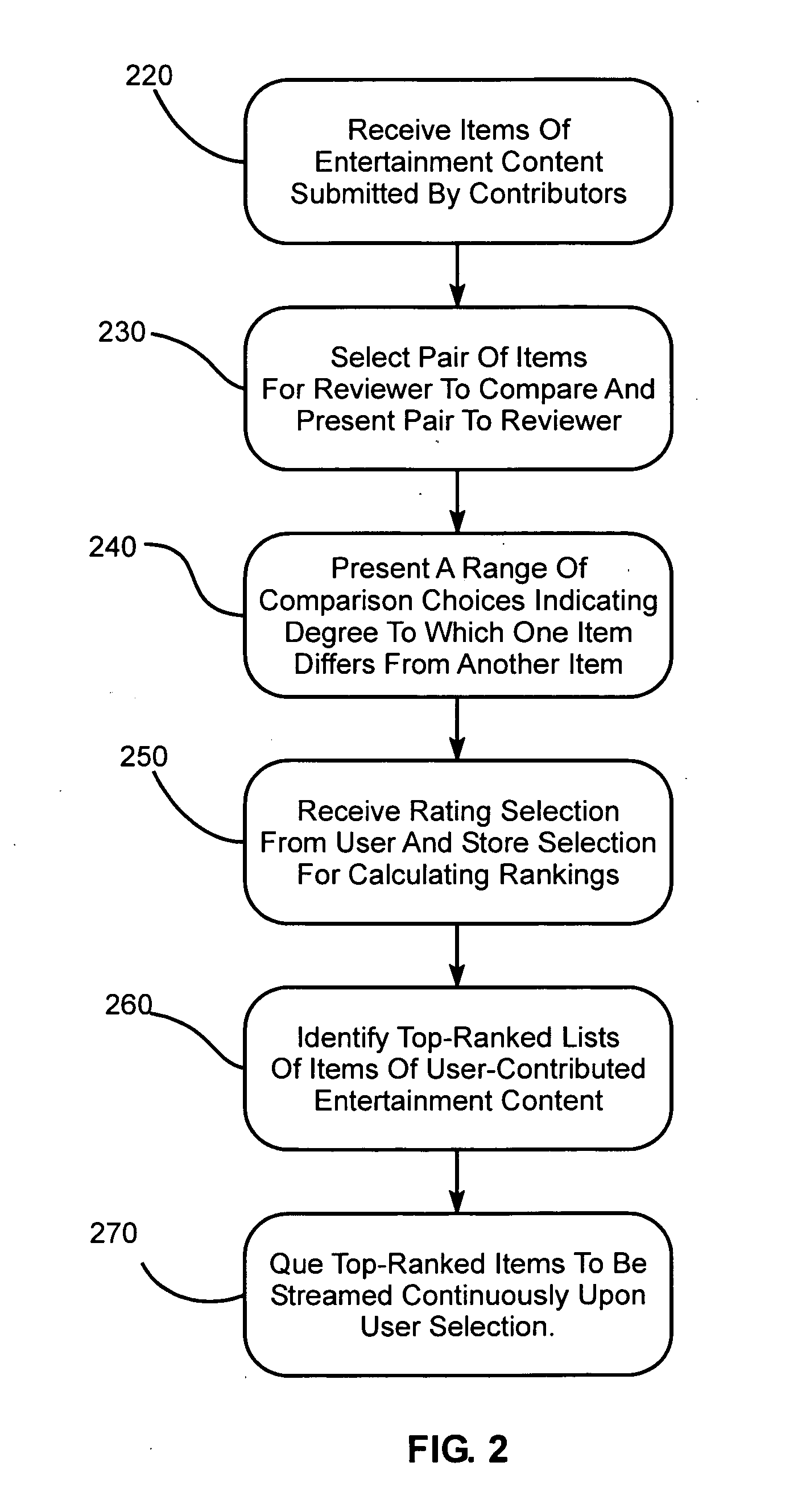

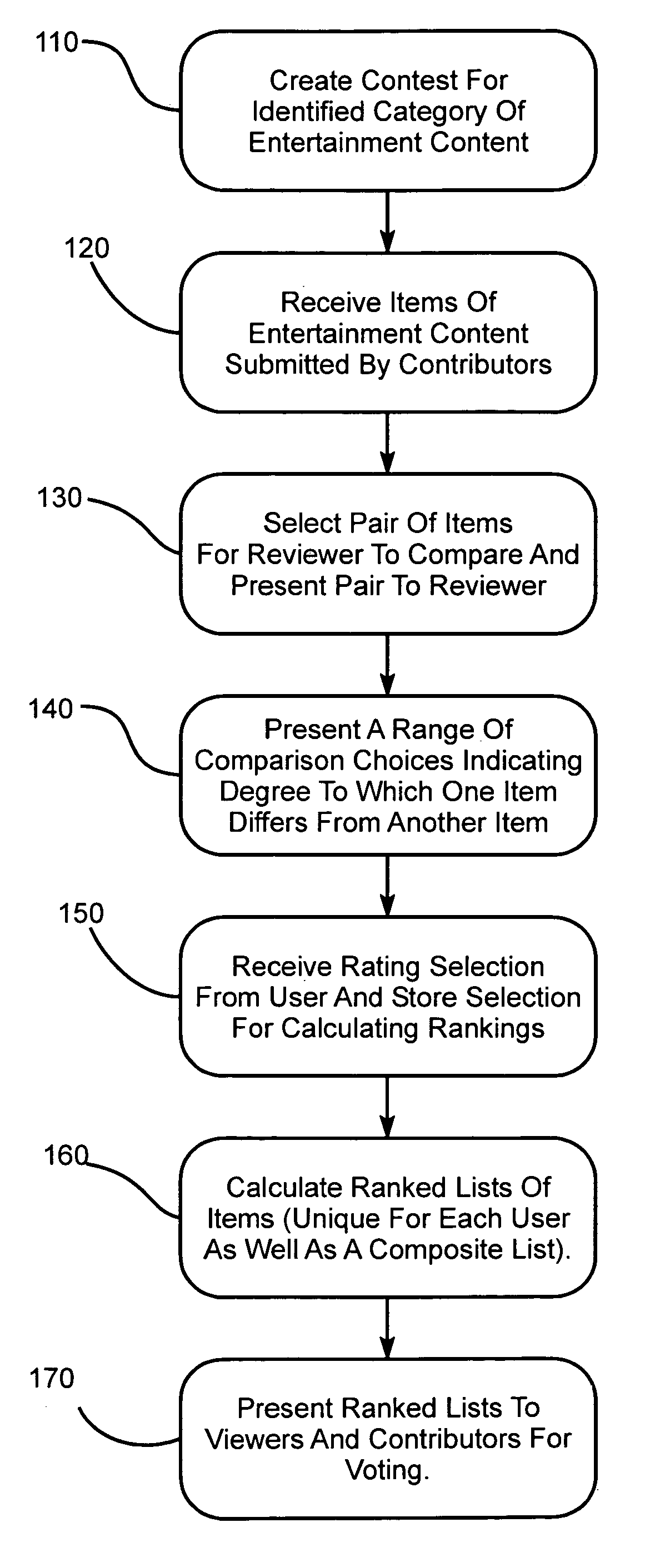

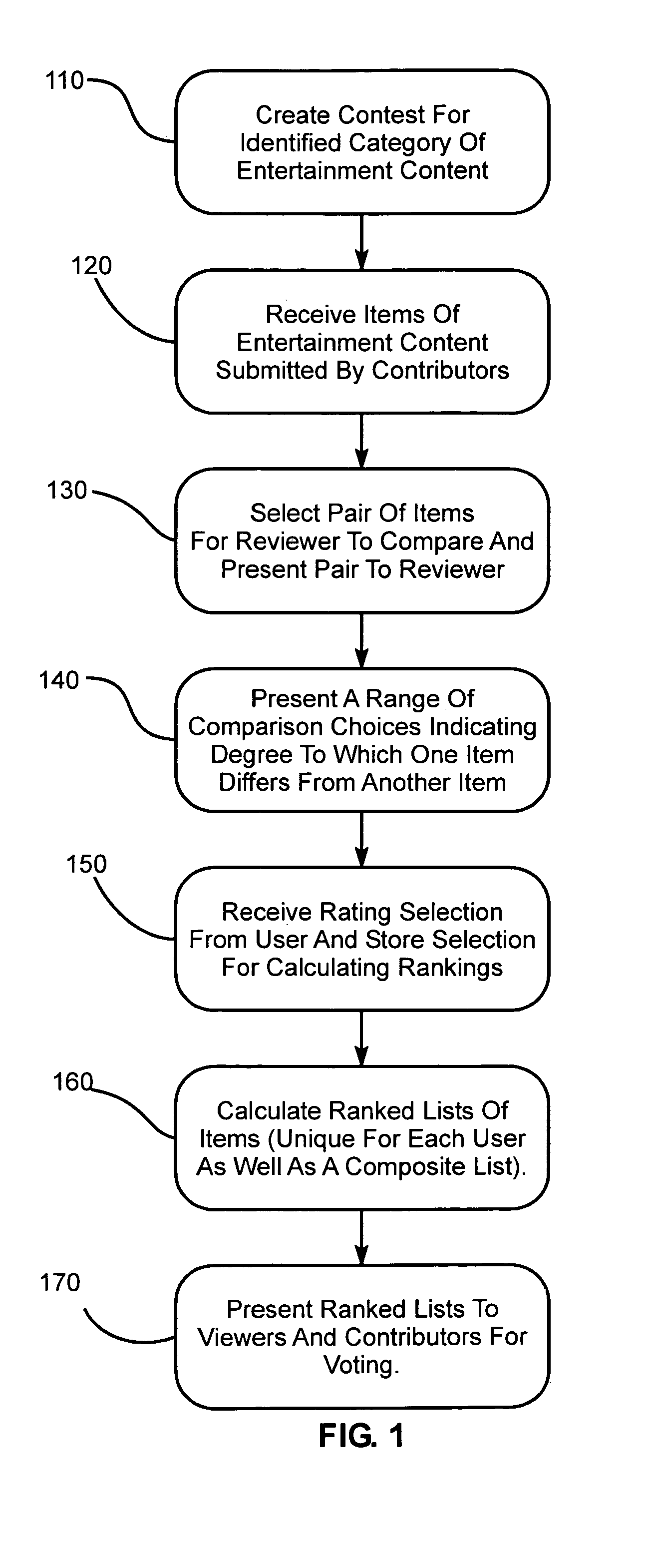

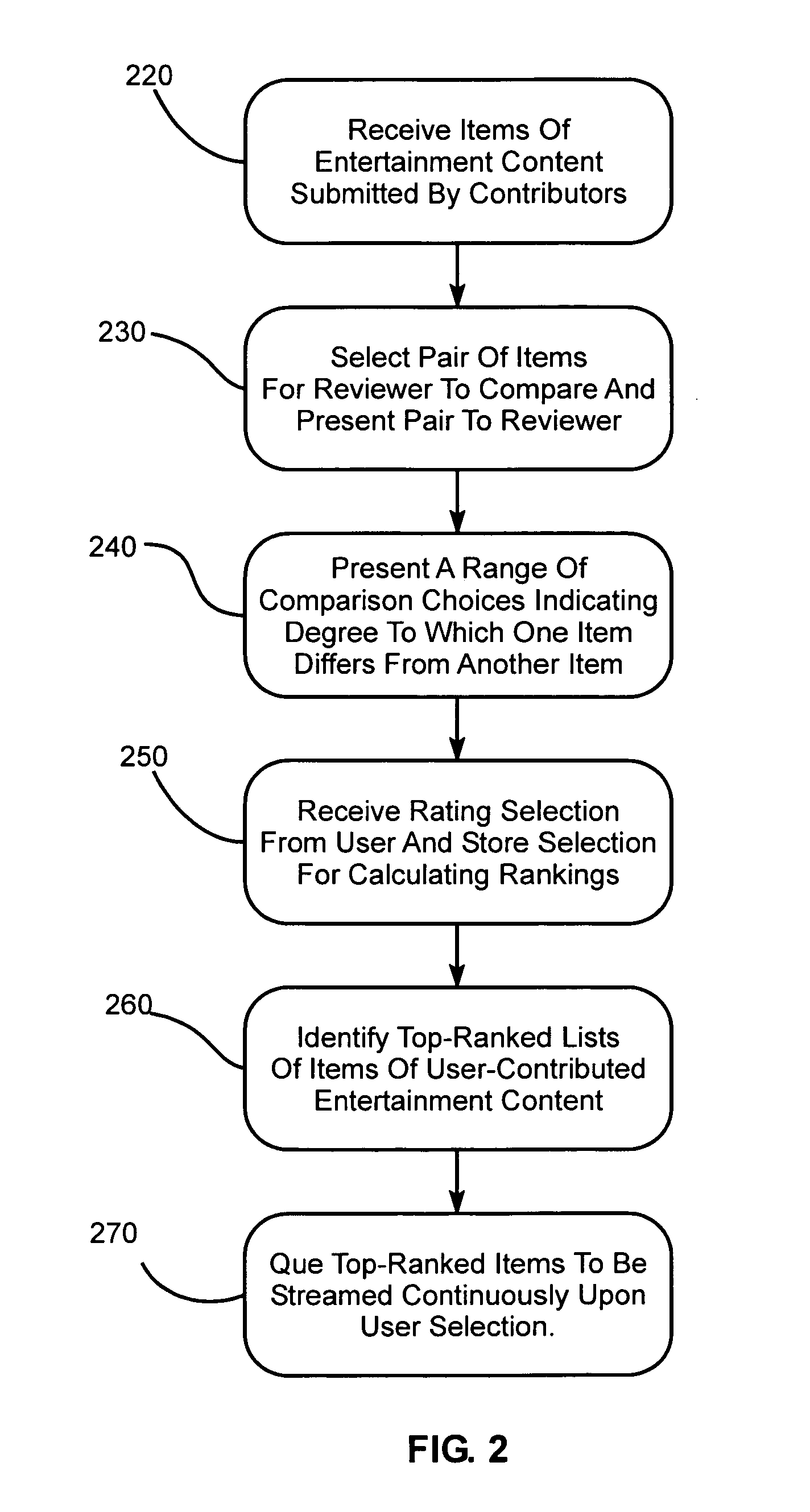

Online entertainment network for user-contributed content

InactiveUS20080091509A1Reduce in quantityMinimize workMarket predictionsVoting apparatusSocial webTesting equipment

The invention includes a system for providing an online entertainment network for user-contributed entertainment content. The system quickly and accurately identifies quality content from a vast pool of user-contributed content. User-contributed content is rated by those who contribute and those who view content. Fraud detection devices automatically detect and remove fraudulent ratings. Contests and prizes associated with specific categories of content provide incentives for contributors to provide quality content and rate many pairs of items. Contests may be localized by geography, organization, social network, and other relationships. Identified top-rated content is made available individually, or as a continuous stream of user-contributed entertainment content.

Owner:OUSGE

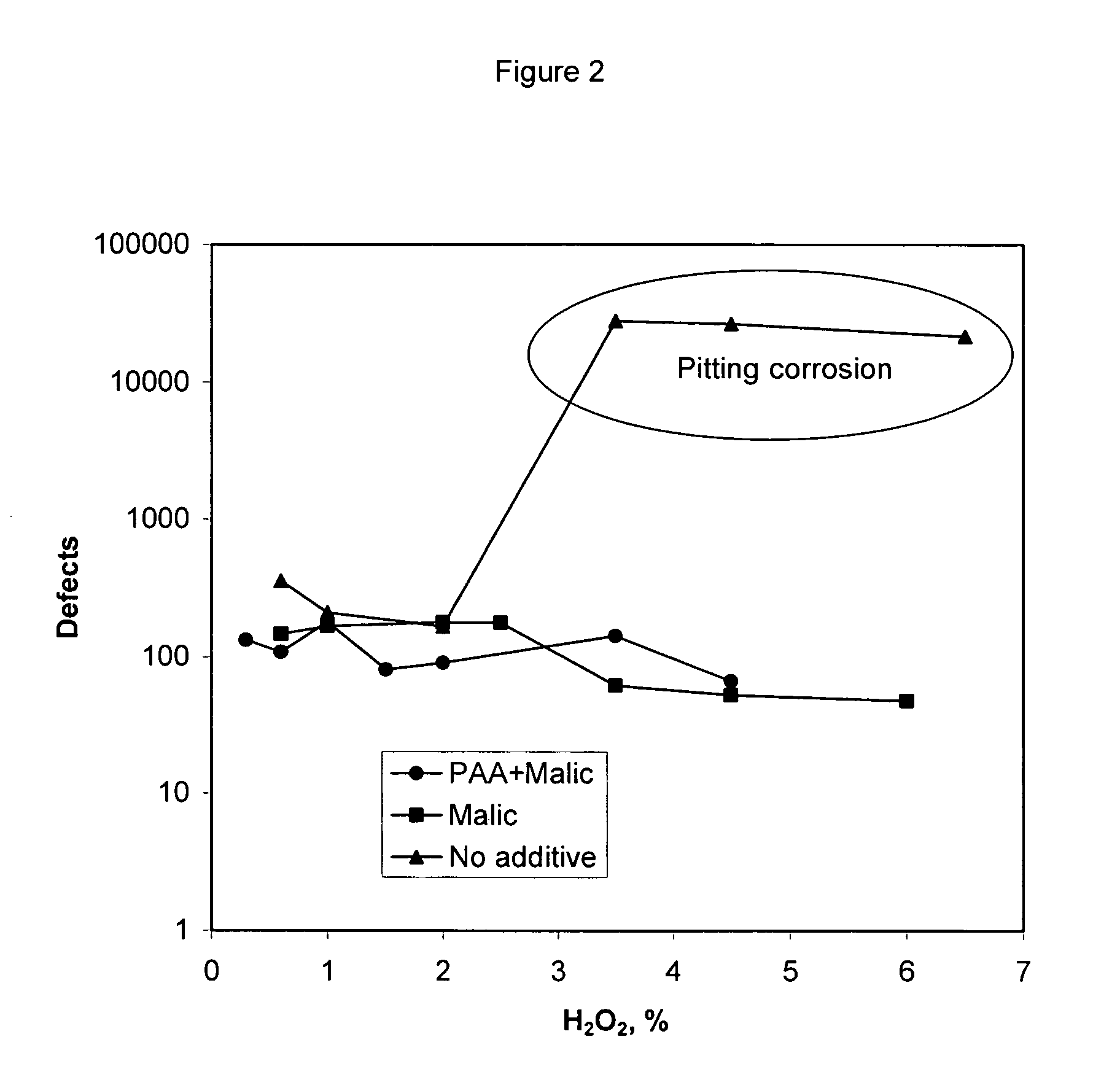

Corrosion-resistant barrier polishing solution

ActiveUS20060163530A1Control erosionRemoval rateDecorative surface effectsSemiconductor/solid-state device manufacturingWater soluble polymersCorrosion resistant

The polishing solution is useful for removing barrier materials in the presence of at least one nonferrous interconnect metal with limited erosion of dielectrics. The polishing solution contains 0 to 20 weight percent oxidizer, at least 0.001 weight percent inhibitor for reducing removal rate of the nonferrous interconnect metals, 0.0005 to 5 weight percent of at least one nonferrous accelerator selected from the group of a complexing agent for complexing the nonferrous metal and a water-soluble polymer containing an acrylic acid functional group and having a number average molecular weight of 100 to 1,000,000, 0 to 50 weight percent abrasive and balance water at a pH less than 7.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

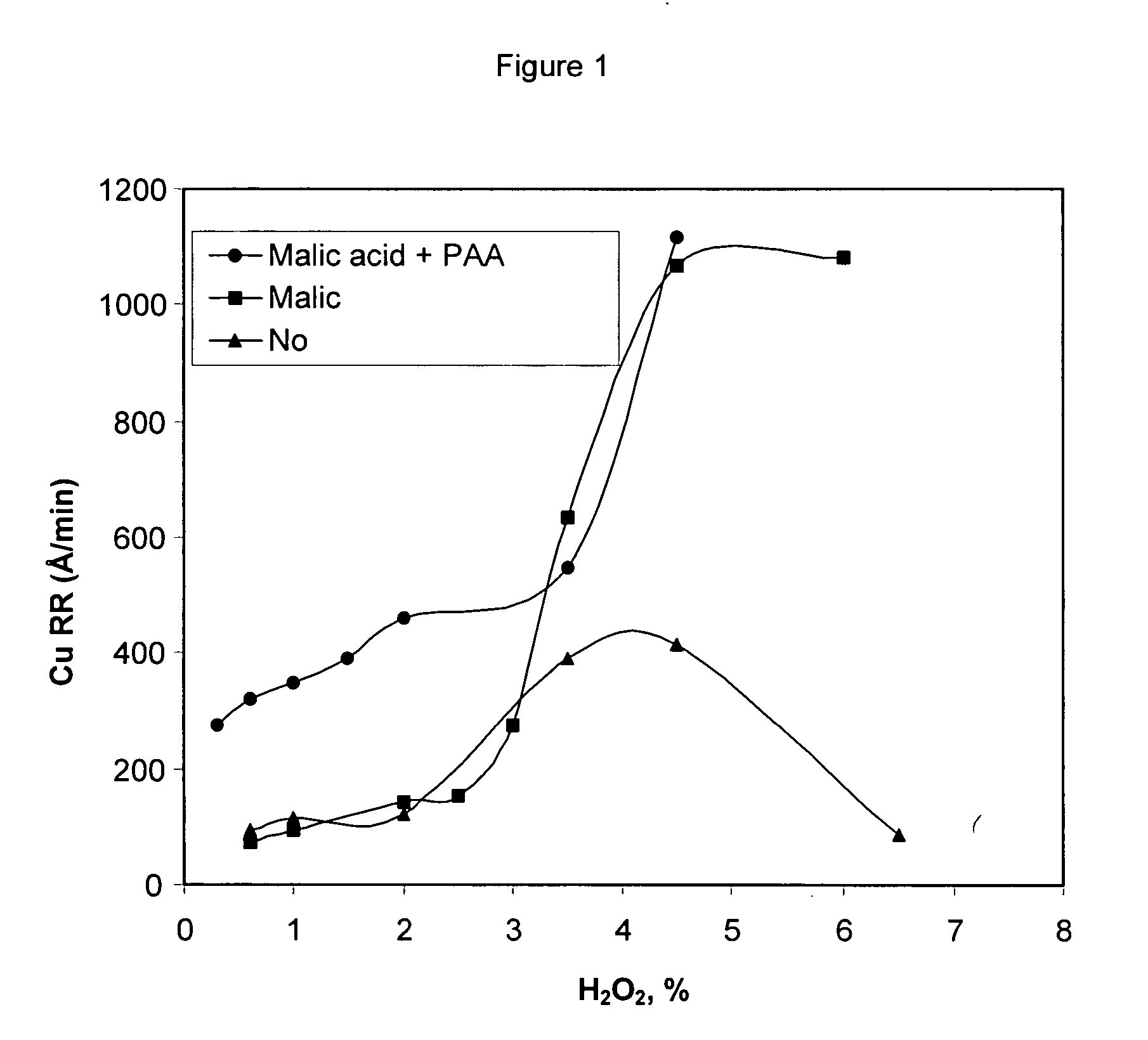

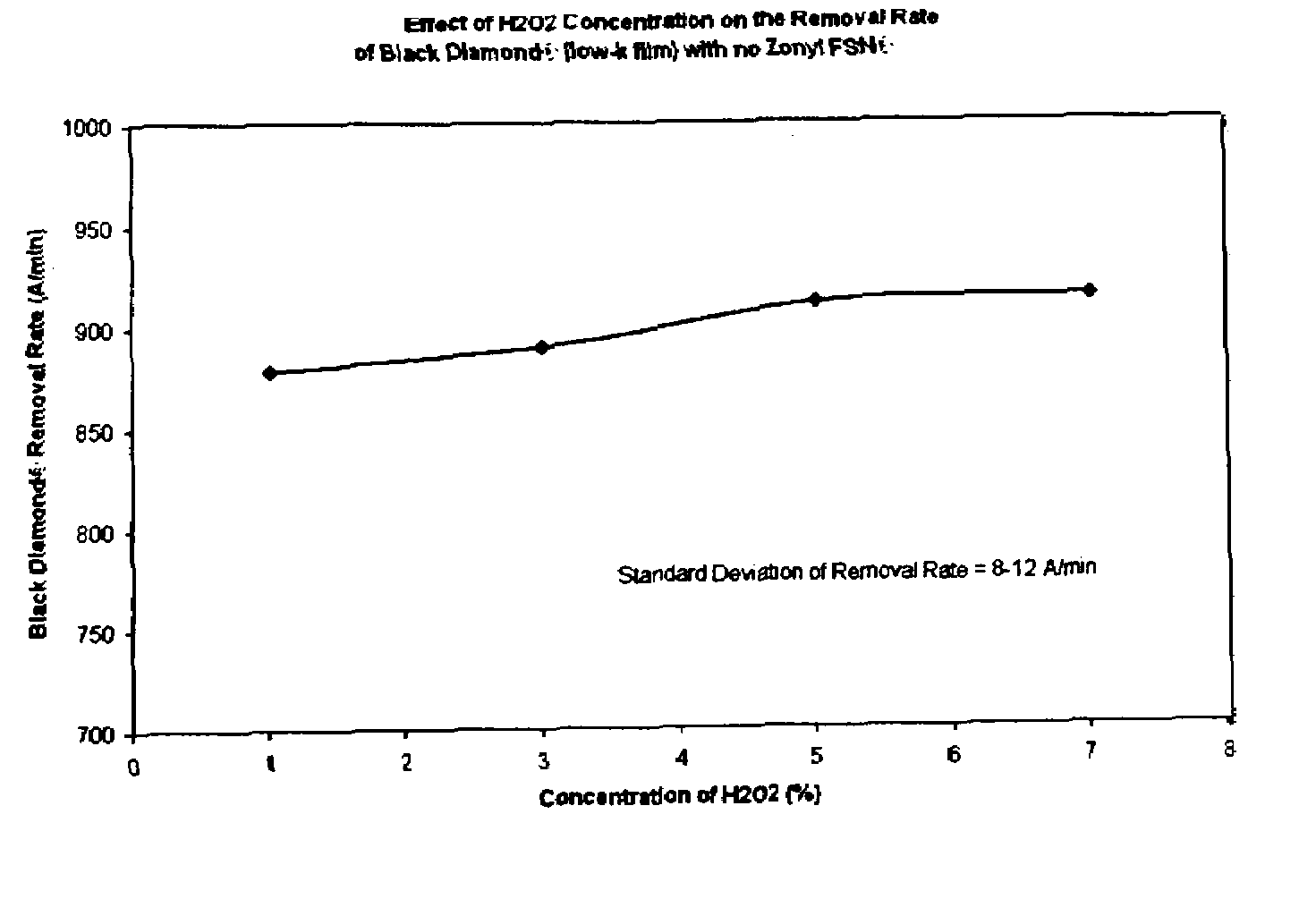

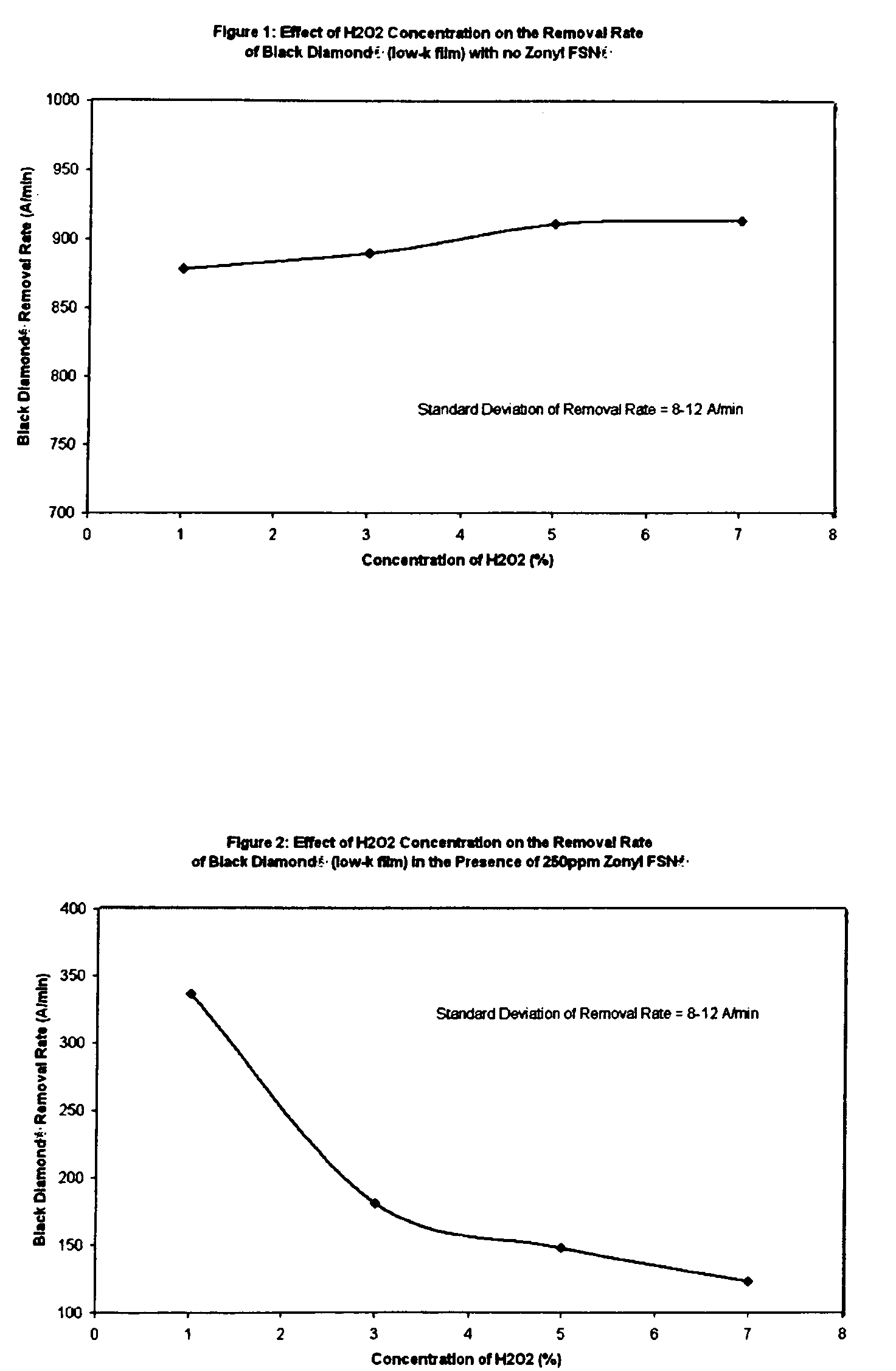

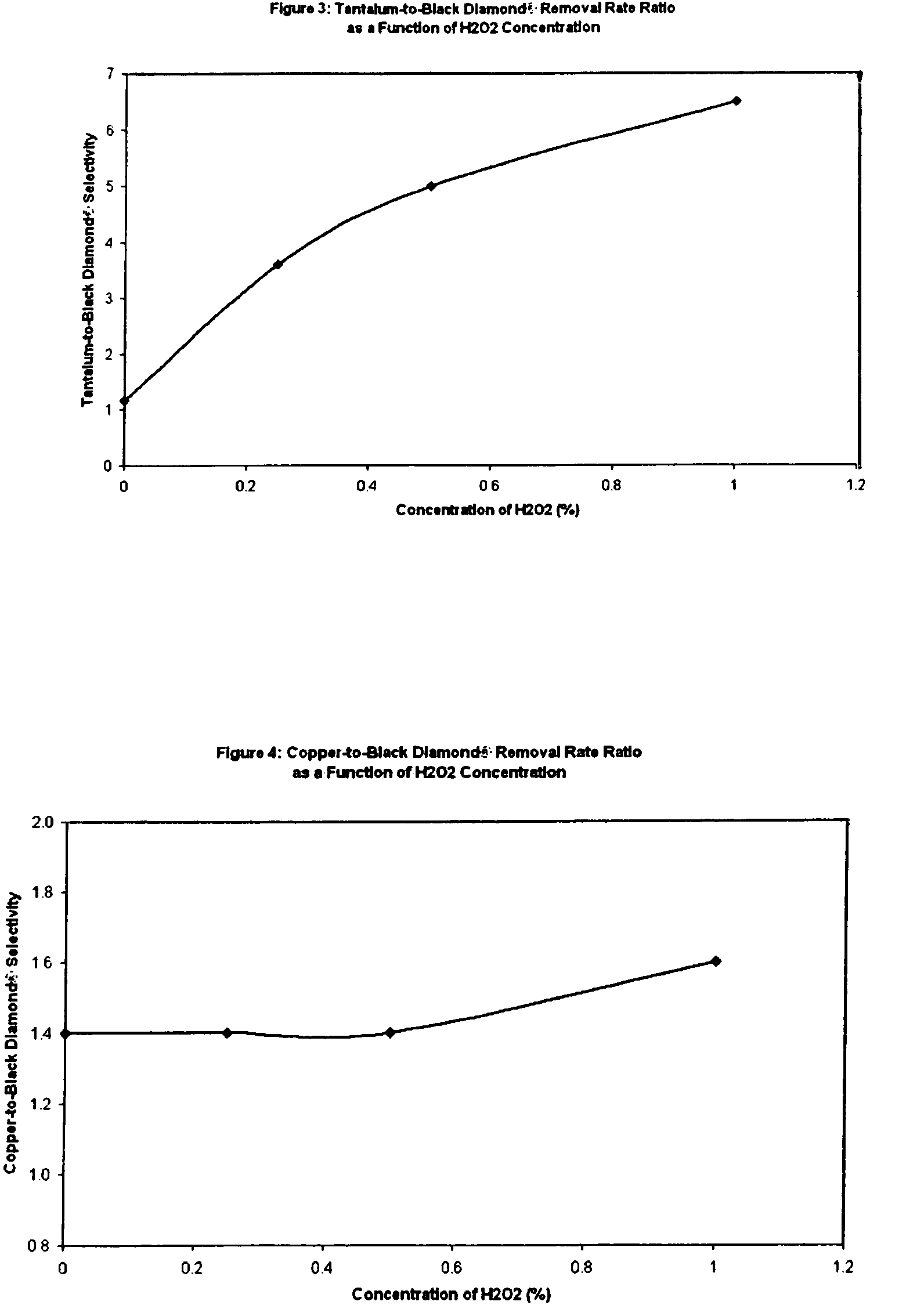

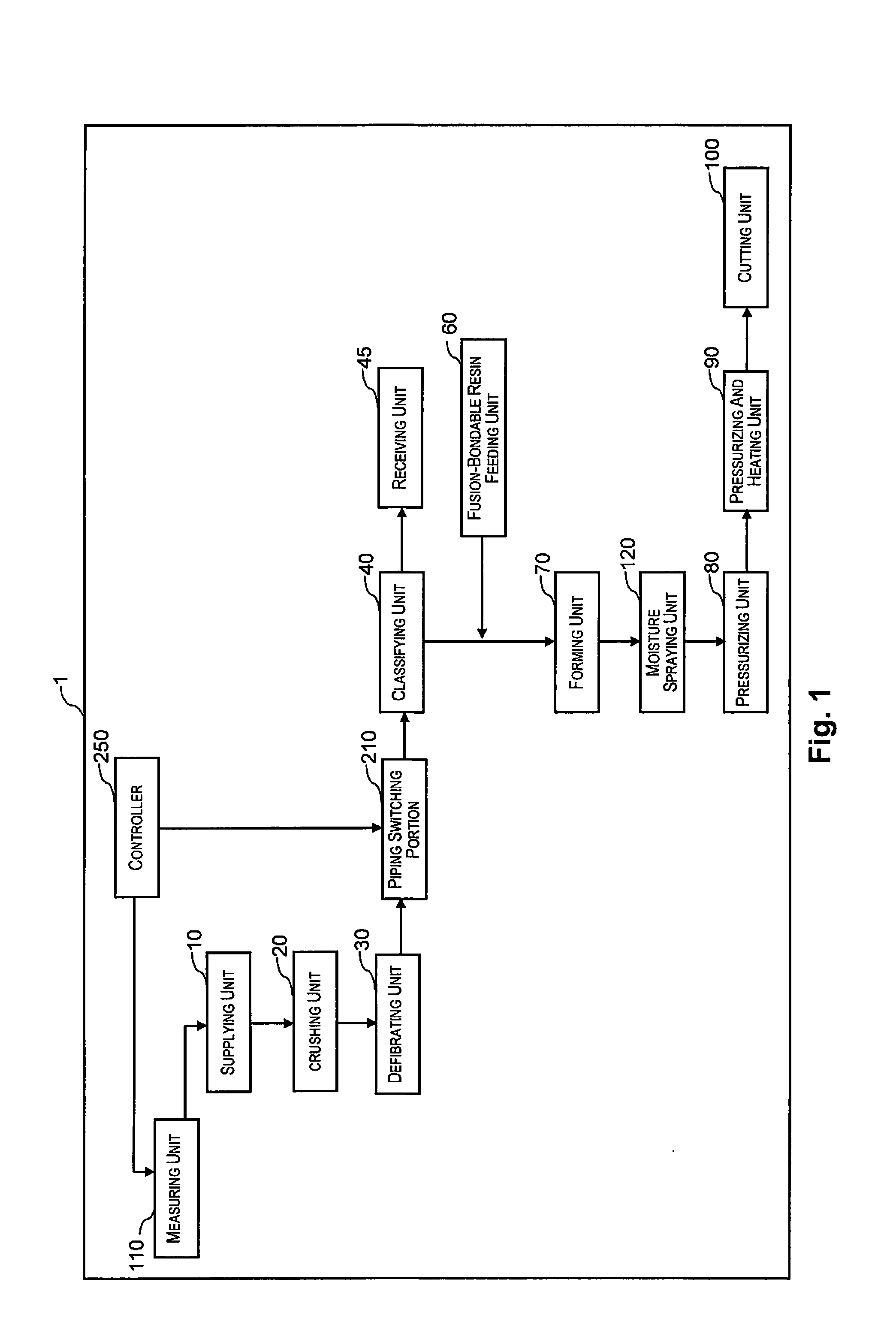

Method and slurry for tuning low-k versus copper removal rates during chemical mechanical polishing

InactiveUS20080149884A1Efficiency tuningRemoval rateDecorative surface effectsSemiconductor/solid-state device manufacturingPeroxideHydrogen peroxide

A composition and associated method for the chemical mechanical planarization (CMP) of metal substrates on semiconductor wafers are described. The composition contains a nonionic fluorocarbon surfactant and a per-type oxidizer (e.g., hydrogen peroxide). The composition and associated method are effective in controlling removal rates of low-k films during copper CMP and provide for tune-ability in removal rates of low-k films in relation to removal rates of copper, tantalum, and oxide films.

Owner:VERSUM MATERIALS US LLC

Multi-step polishing solution for chemical mechanical planarization

InactiveUS6971945B2Increase ratingsHigh removal rateEdge grinding machinesPigmenting treatmentInorganic saltsCopper

The present invention provides a multi-step aqueous composition useful for polishing a tantalum barrier material and copper from a semiconductor wafer, comprising by weight percent 0.1 to 30 oxidizer, 0.01 to 3 inorganic salt or acid, 0.01 to 4 inhibitor, 0.1 to 30 abrasive, 0 to 15 complexing agent and balance water, wherein the aqueous composition has a pH between 1.5 to 6.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

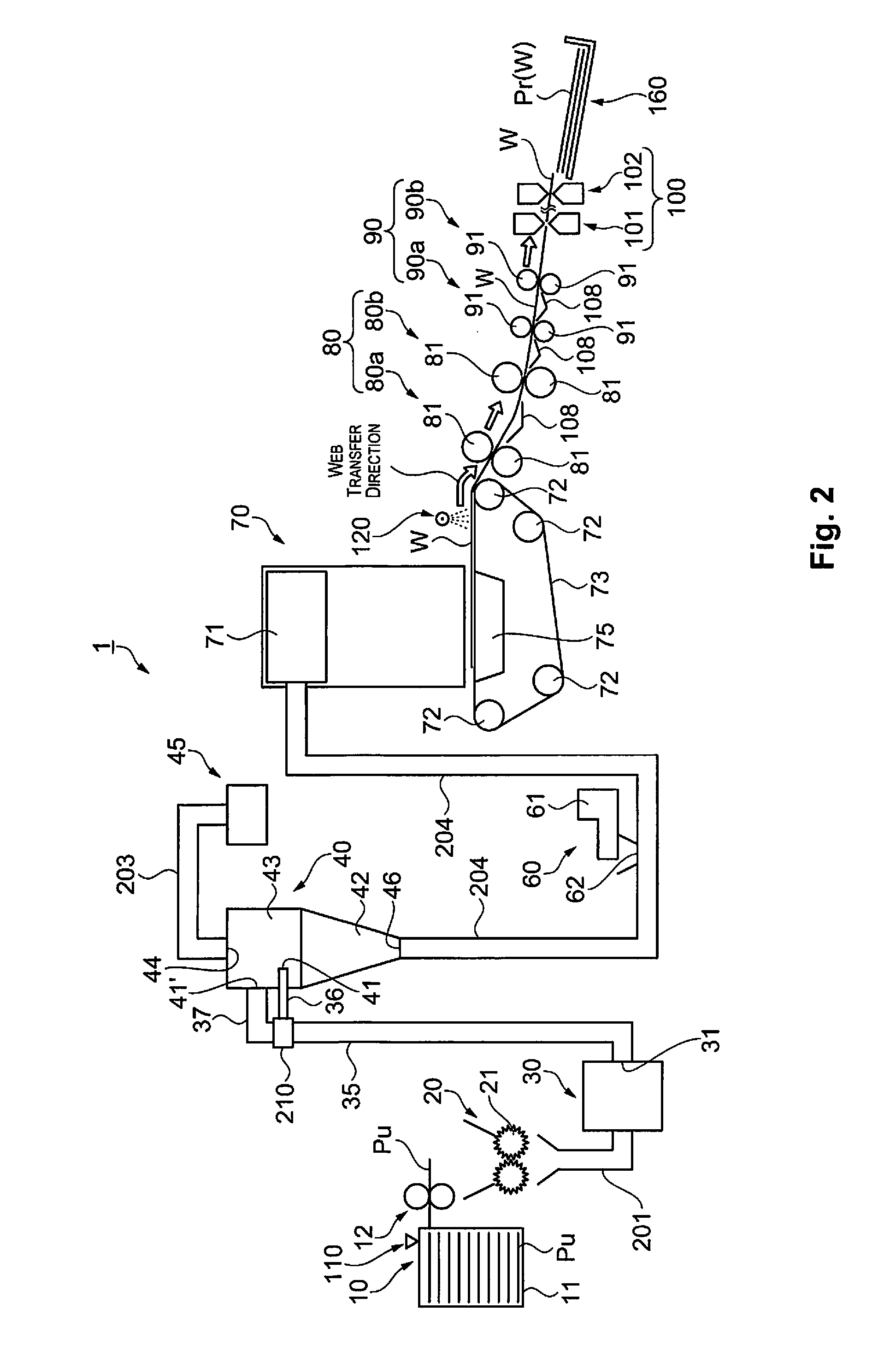

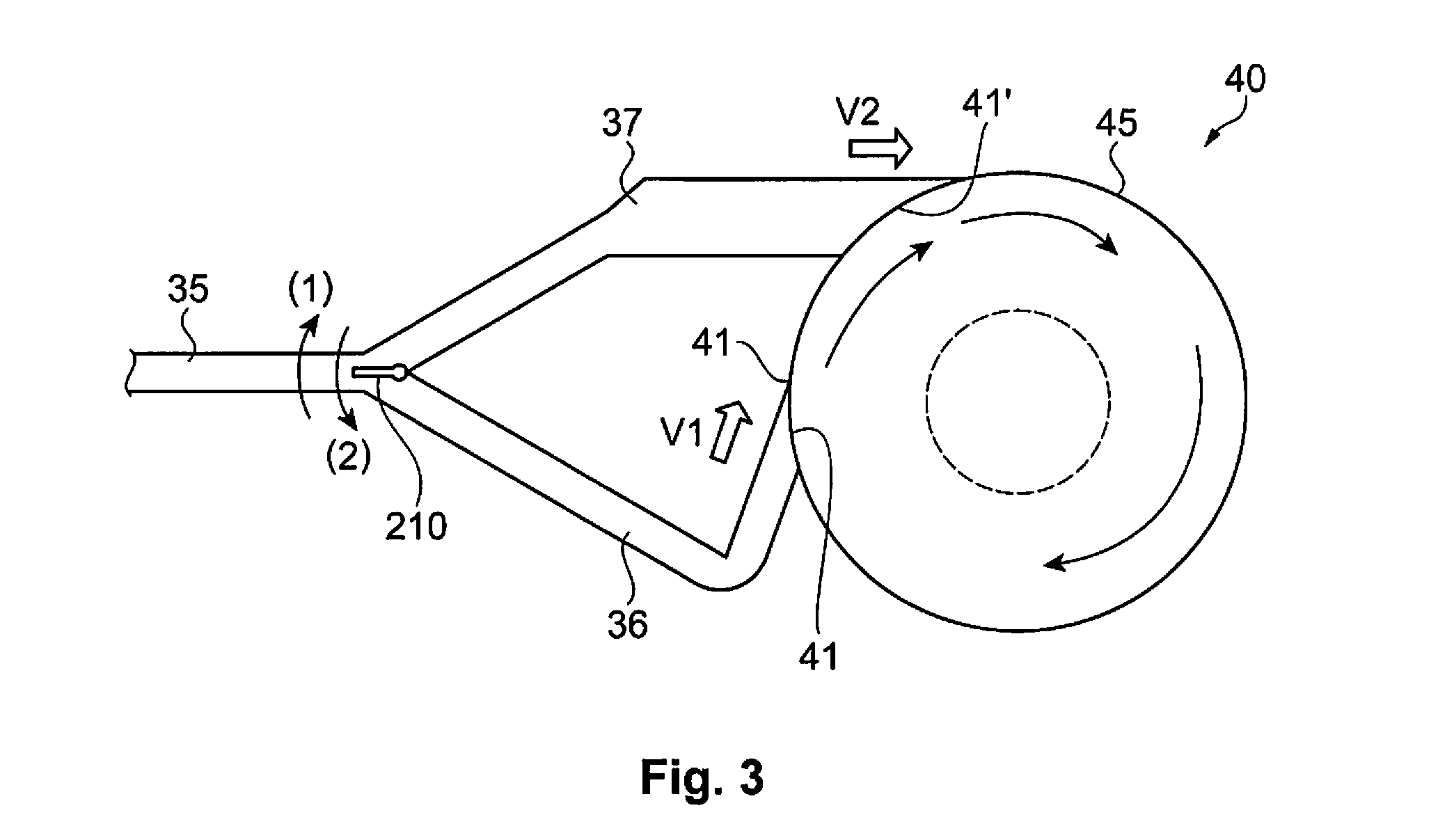

Sheet manufacturing apparatus

ActiveUS20140290888A1Low content rateReduced removal rateMachine wet endDirt cleaningFiberForeign matter

A sheet manufacturing apparatus includes a measuring unit configured to measure thickness and air permeability of a defibration object containing fibers, a defibrating unit configured to dry-defibrate the defibration object, and a classifying unit configured to separate and remove, by airflow classification, foreign substances other than the fibers from the defibrated material defibrated at the defibrating unit.

Owner:SEIKO EPSON CORP

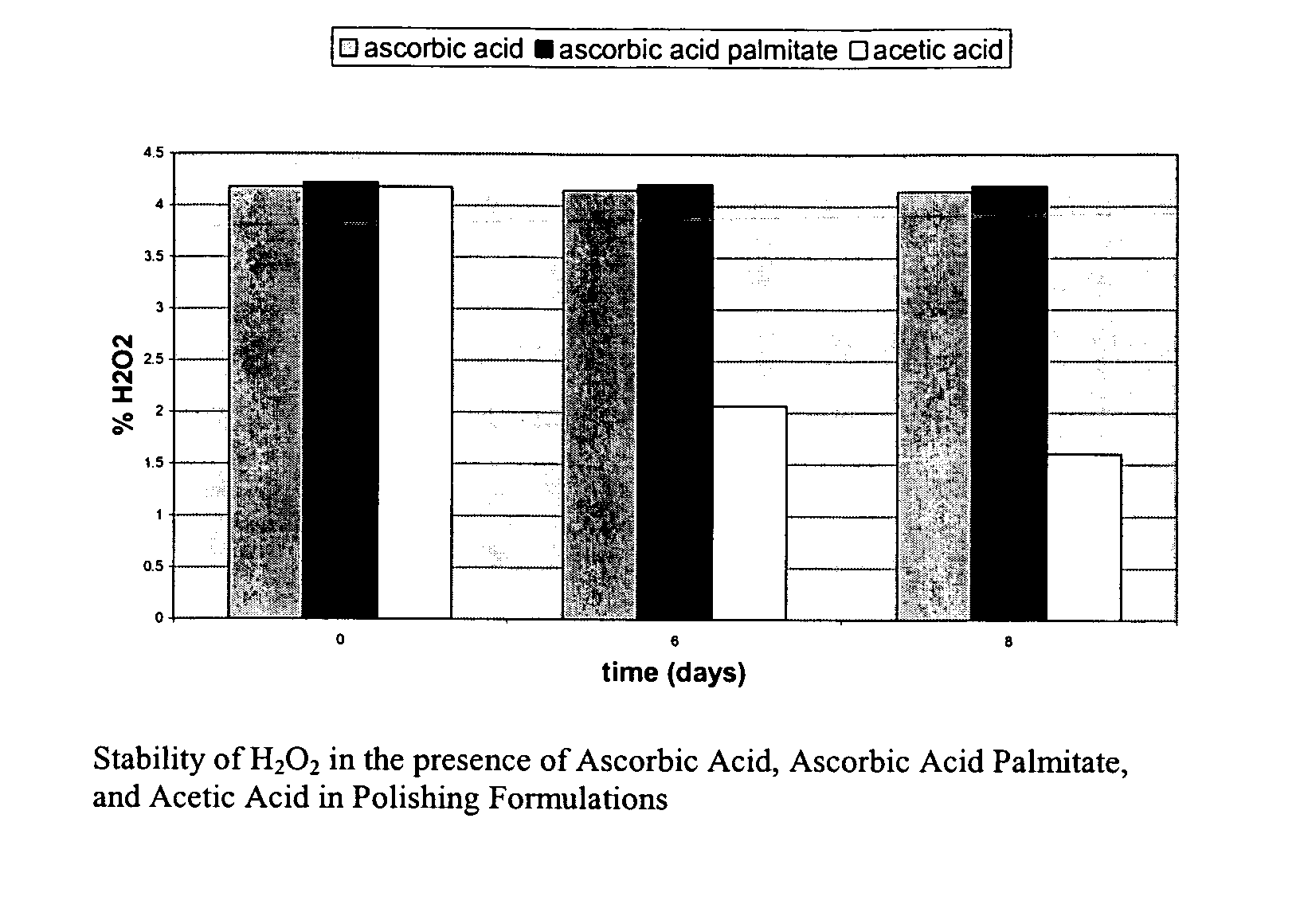

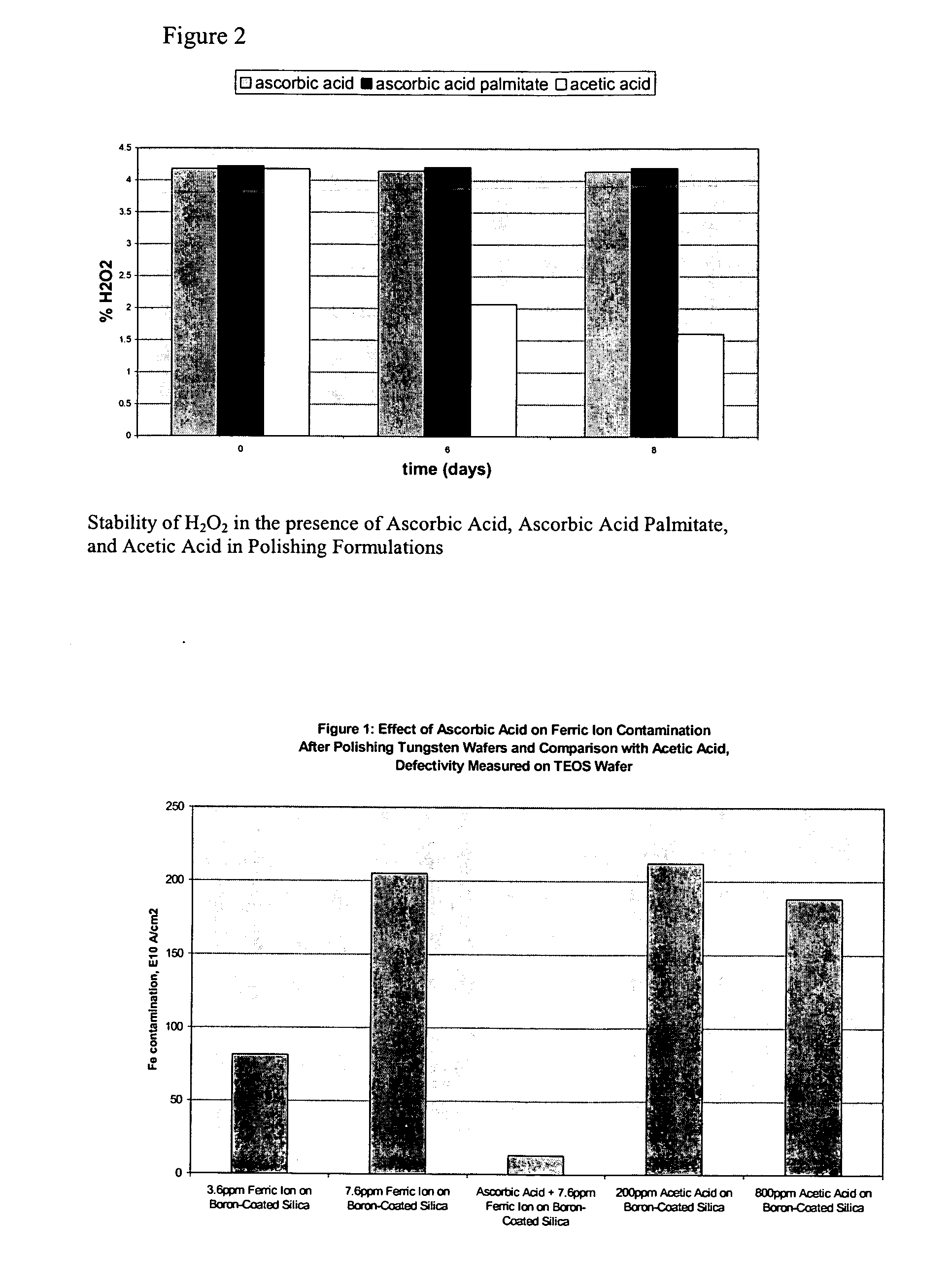

Dihydroxy enol compounds used in chemical mechanical polishing compositions having metal ion oxidizers

ActiveUS20060270235A1Improve polishing rateRemoval rateOther chemical processesDecorative surface effectsCompound (substance)Slurry

A chemical mechanical polishing composition contains 1) water, 2) optionally an abrasive material, 3) an oxidizer, preferably a per-type oxidizer, 4) a small amount of soluble metal-ion oxidizer / polishing accelerator, a metal-ion polishing accelerator bound to particles such as to abrasive particles, or both; and 5) at least one of the group selected from a) a small amount of a chelator, b) a small amount of a dihydroxy enolic compound, and c) a small amount of an organic accelerator. Ascorbic acid in an amount less than 800 ppm, preferably between about 100 ppm and 500 ppm, is the preferred dihydroxy enolic compound. The polishing compositions and processes are useful for substantially all metals and metallic compounds found in integrated circuits, but is particularly useful for tungsten. The present invention also pertains to surface-modified colloidal abrasive polishing compositions and associated methods of using these compositions, particularly for chemical mechanical planarization, wherein the slurry comprises low levels of chelating free radical quenchers, non-chelating free radical quenchers, or both.

Owner:VERSUM MATERIALS US LLC

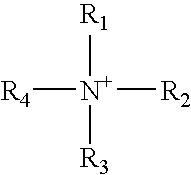

Anionic abrasive particles treated with positively charged polyelectrolytes for CMP

InactiveUS7306637B2Increase chanceReduce reunionPigmenting treatmentPolishing machinesPolyelectrolyteChemistry

The invention provides chemical-mechanical polishing systems, and methods of polishing a substrate using the polishing systems, comprising (a) an abrasive, (b) a liquid carrier, and (c) a positively charged polyelectrolyte with a molecular weight of about 15,000 or more, wherein the abrasive comprises particles that are electrostatically associated with the positively charged polyelectrolyte.

Owner:CMC MATERIALS INC

Chemical mechanical polishing slurry

InactiveUS20080003829A1Shorten the timeReduction of overpolishing timeOther chemical processesDecorative surface effectsCompound (substance)Carboxylic acid

Disclosed is chemical mechanical polishing (CMP) slurry comprising: abrasive particles; an oxidant; a compound having at least two amine groups; a polycarboxylic acid; and water. The CMP slurry comprising a compound having at least two amine groups and a polycarboxylic acid provides an improved removal rate and selectivity of copper, while not adversely affecting the overall polishing rate, increases the planarization, and minimizes dishing and erosion problems.

Owner:LG CHEM LTD

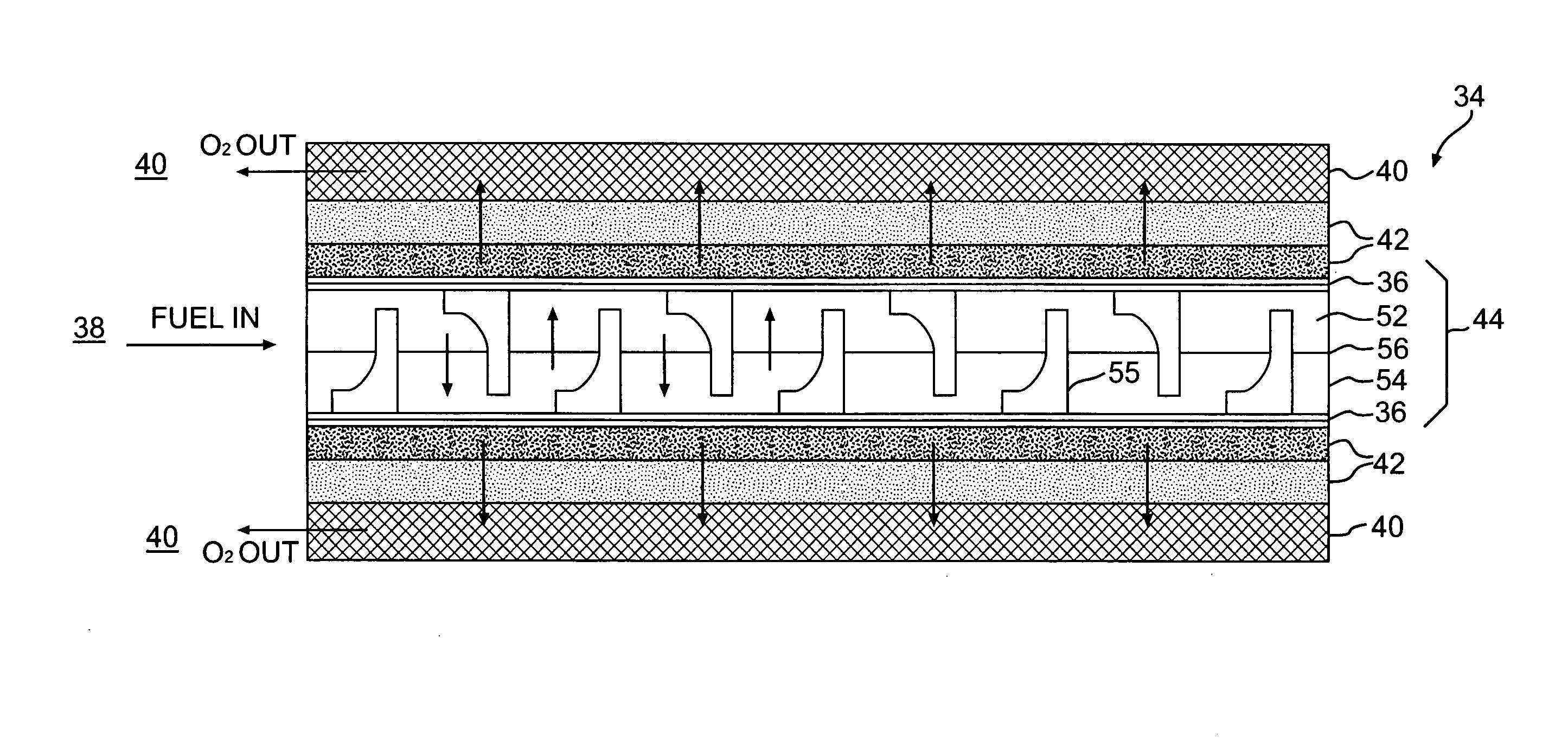

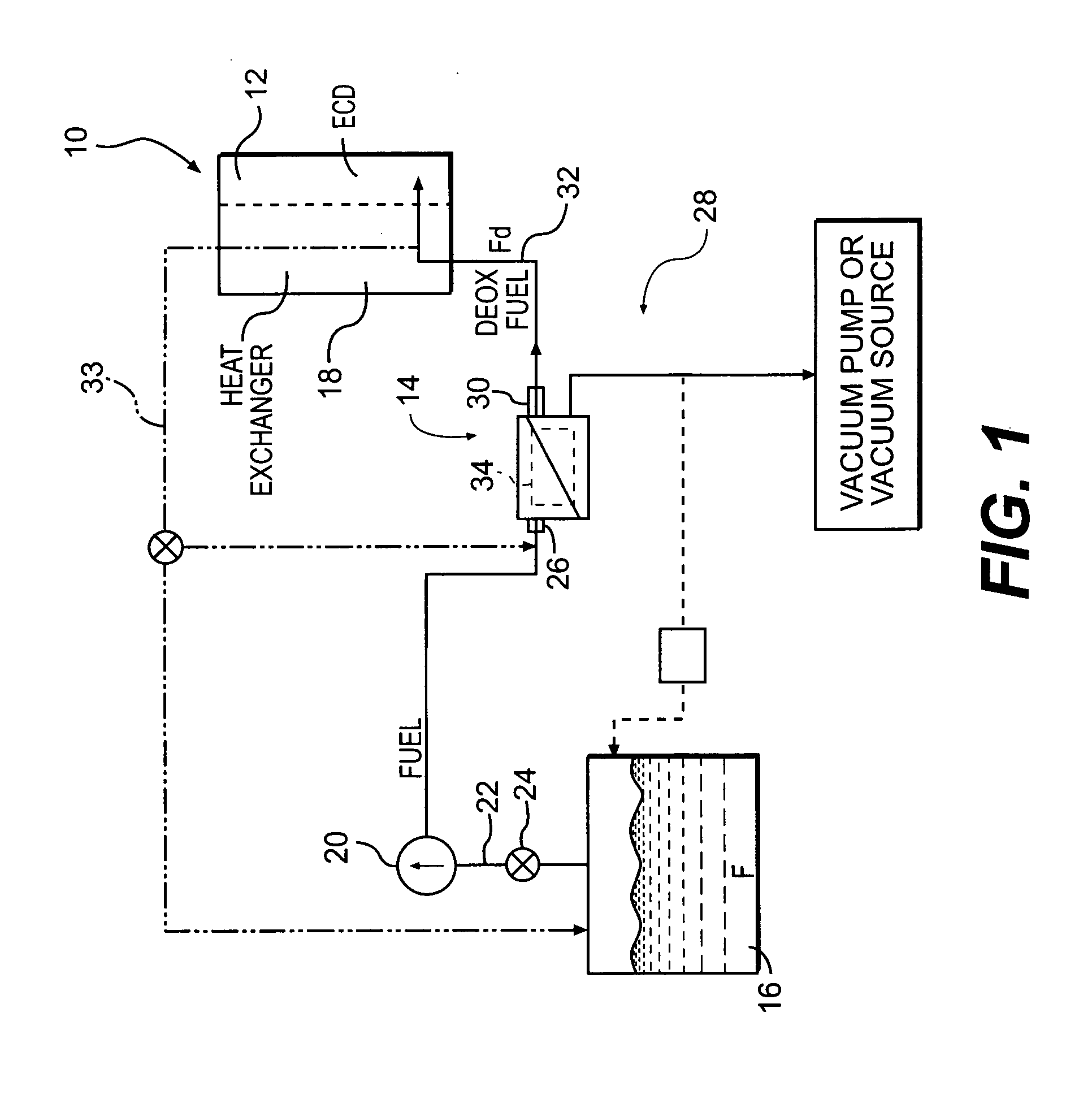

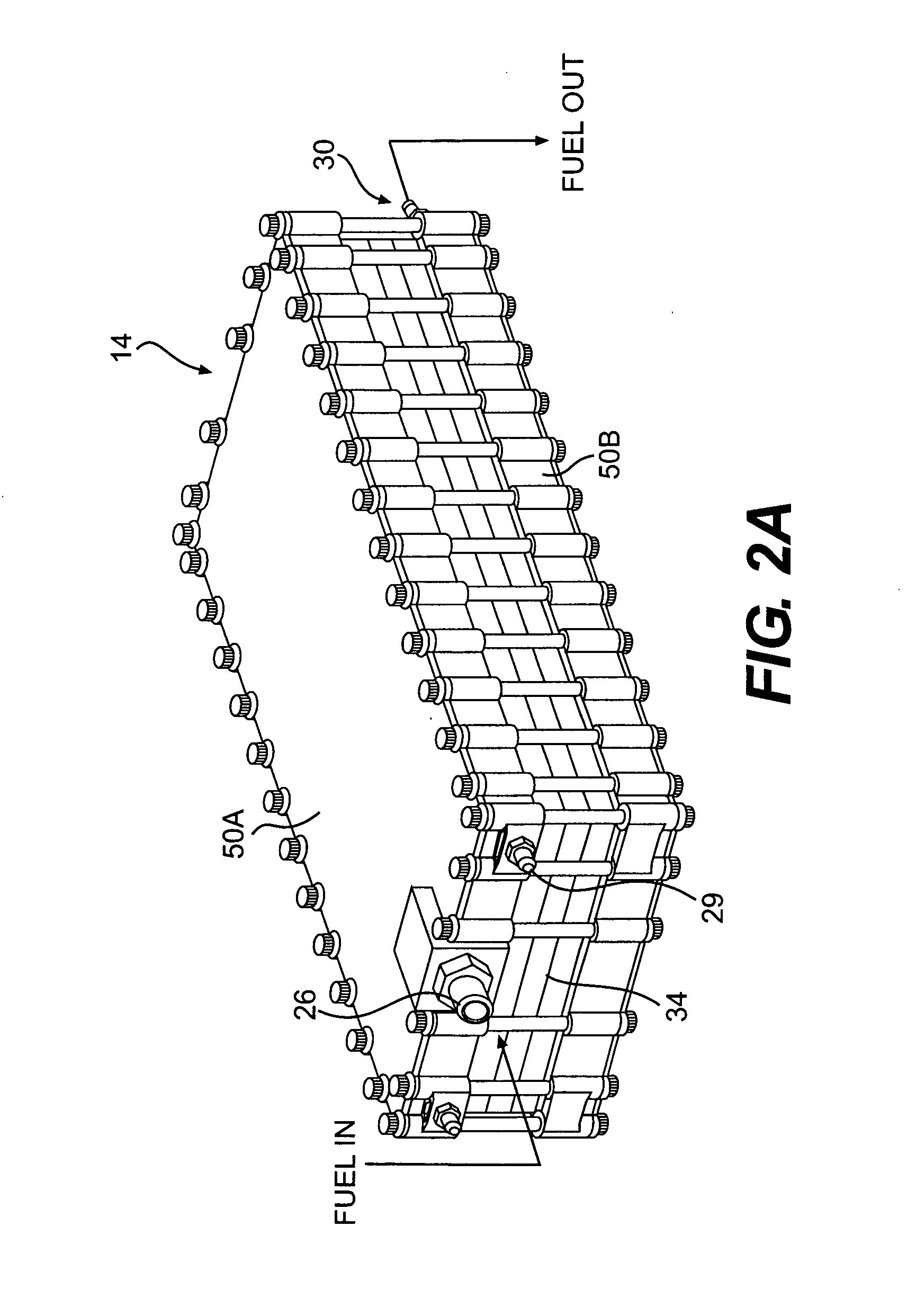

Method for enhancing mass transport in fuel deoxygenation systems

ActiveUS7824470B2Increase mass transportEasy to transportSemi-permeable membranesFlow mixersMembrane surfaceEngineering

A fuel system for an energy conversion device includes a deoxygenator system with a multitude of flow impingement elements which are interleaved to provide a fuel channel with intricate two-dimensional flow characteristics. The flow impingement elements break up the boundary layers and enhance the transport of oxygen from the core of the of the fuel flow within the fuel channel to the oxygen permeable membrane surfaces by directing the fuel flow in a direction normal to the oxygen permeable membrane. The rapid mixing of the relatively rich oxygen core of the fuel with the relatively oxygen-poor flow near the oxygen permeable membrane enhances the overall removal rate of oxygen from the fuel. Because this process can be accomplished in fuel channels of relatively larger flow areas while maintaining laminar flow, the pressure drop sustained is relatively low.

Owner:RTX CORP

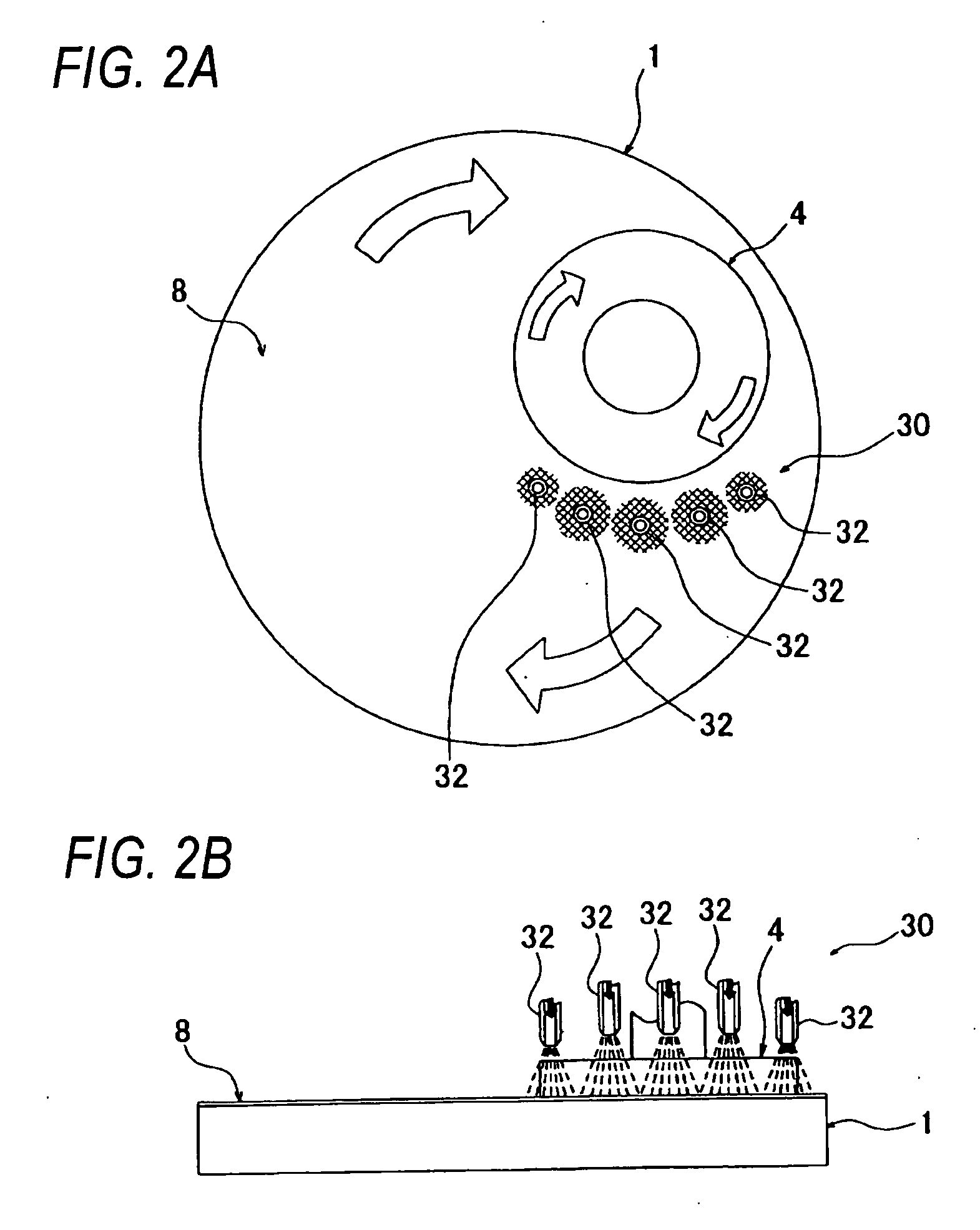

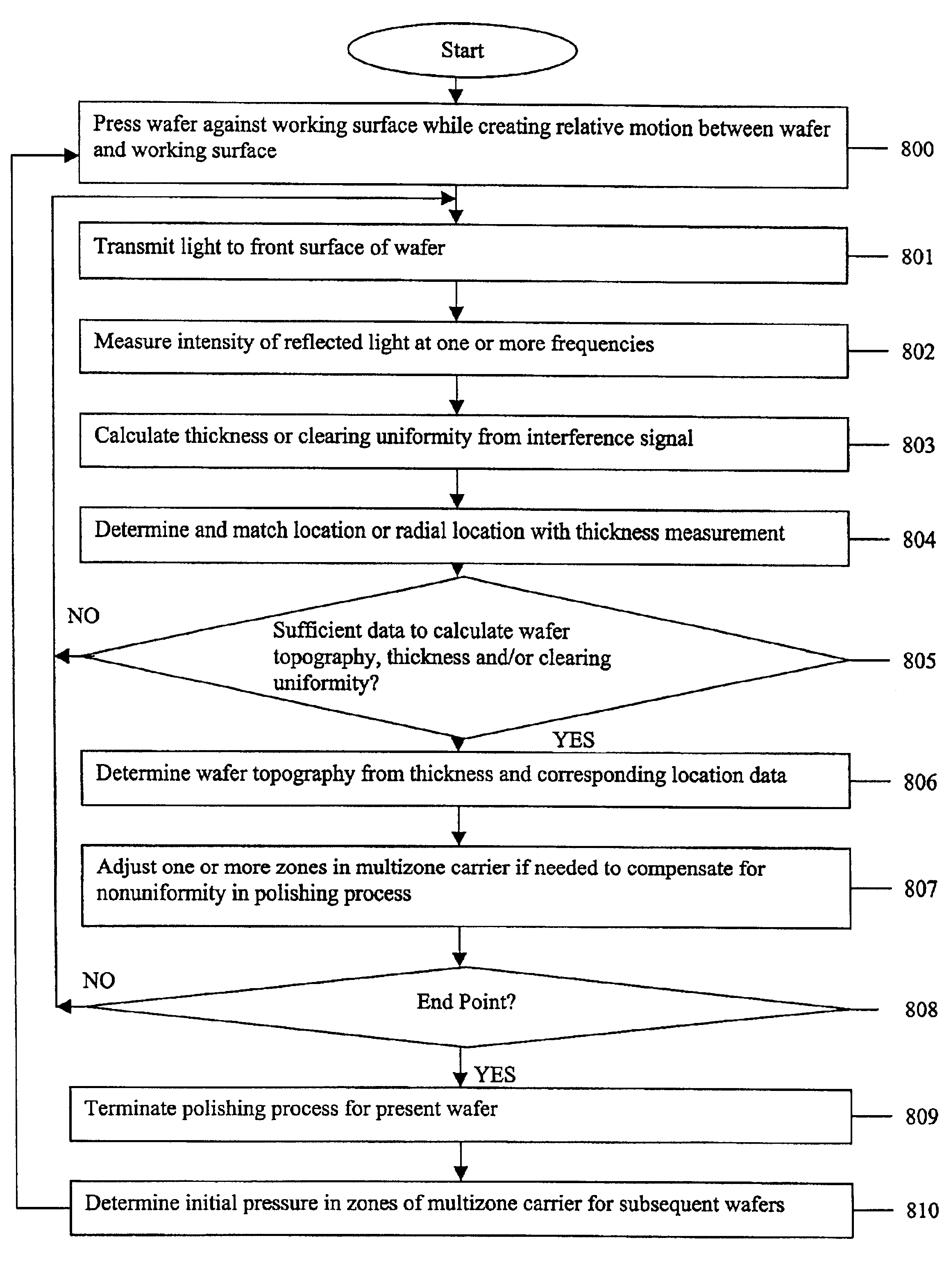

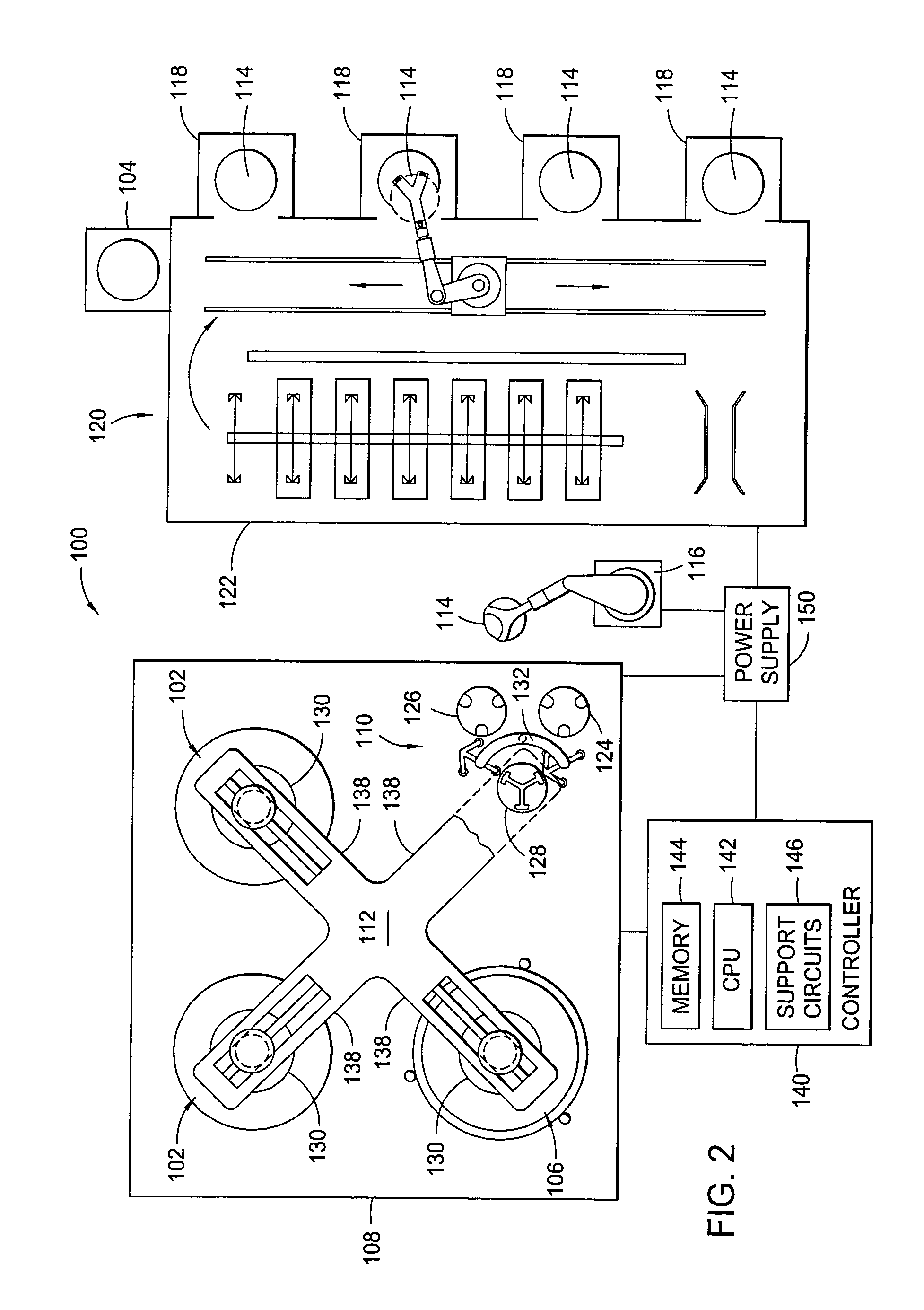

Multizone carrier with process monitoring system for chemical-mechanical planarization tool

InactiveUS6923711B2Increase downforceHigh removal ratePolishing machinesRevolution surface grinding machinesMetrologyRadial position

The invention improves a polishing process for a wafer retained in a multizone carrier in a chemical mechanical polishing tool. A light signal is communicated to the front surface of the wafer and the reflected light signal is captured by a metrology instrument. The metrology instrument communicates the intensity of the reflected light to a control system. The location or radial position corresponding to the reflected light signal from the front surface of the wafer may be determined by the control system. From the intensity measurements and corresponding locations, the control system is able to determine an approximate topography of the wafer. The control system may alter the pressure within one or more zones within the multizone carrier to improve the polishing process. The control system may also alter the initial pressures within the multizone carrier for future wafers based on the polishing results from the present wafer.

Owner:NOVELLUS SYSTEMS

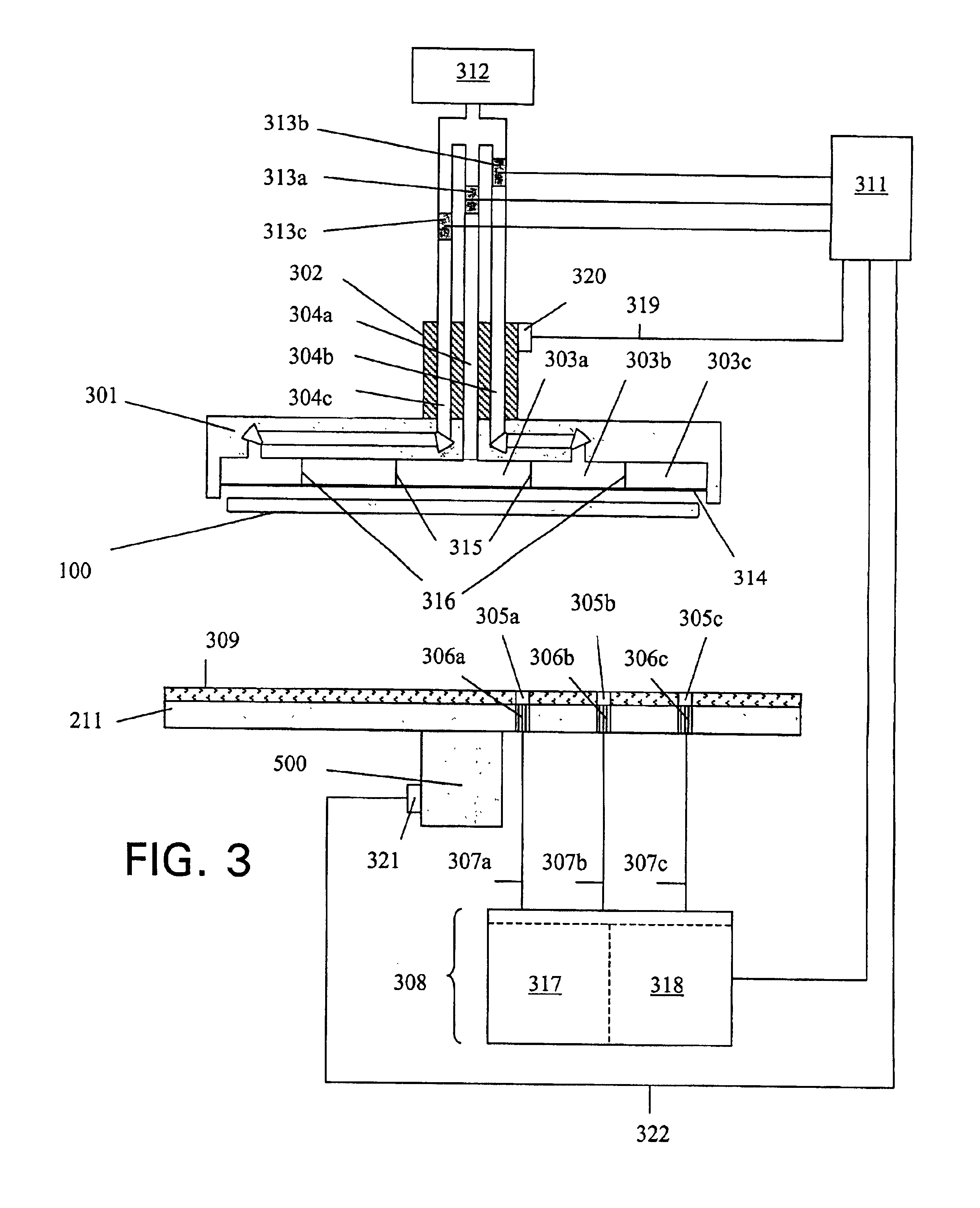

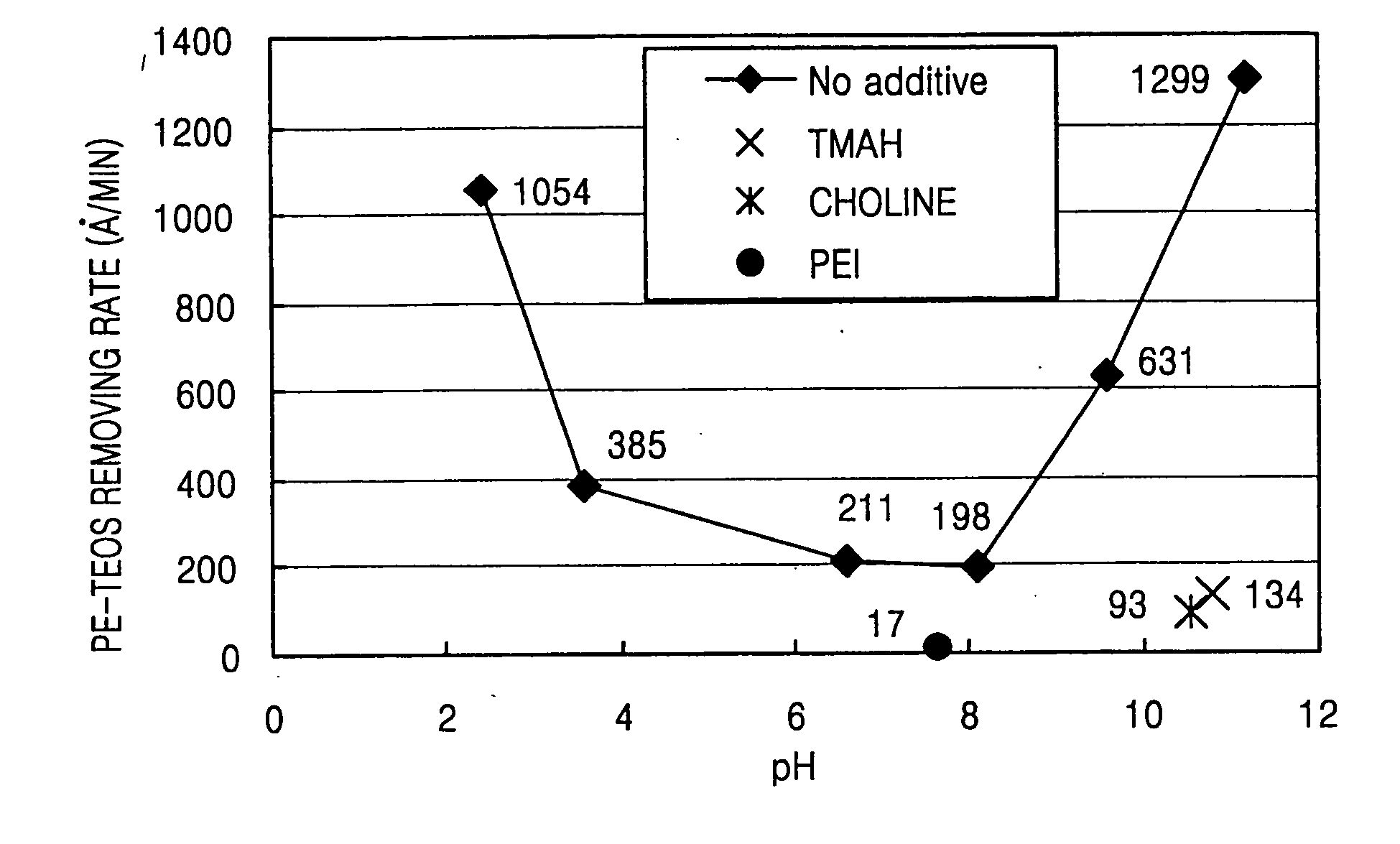

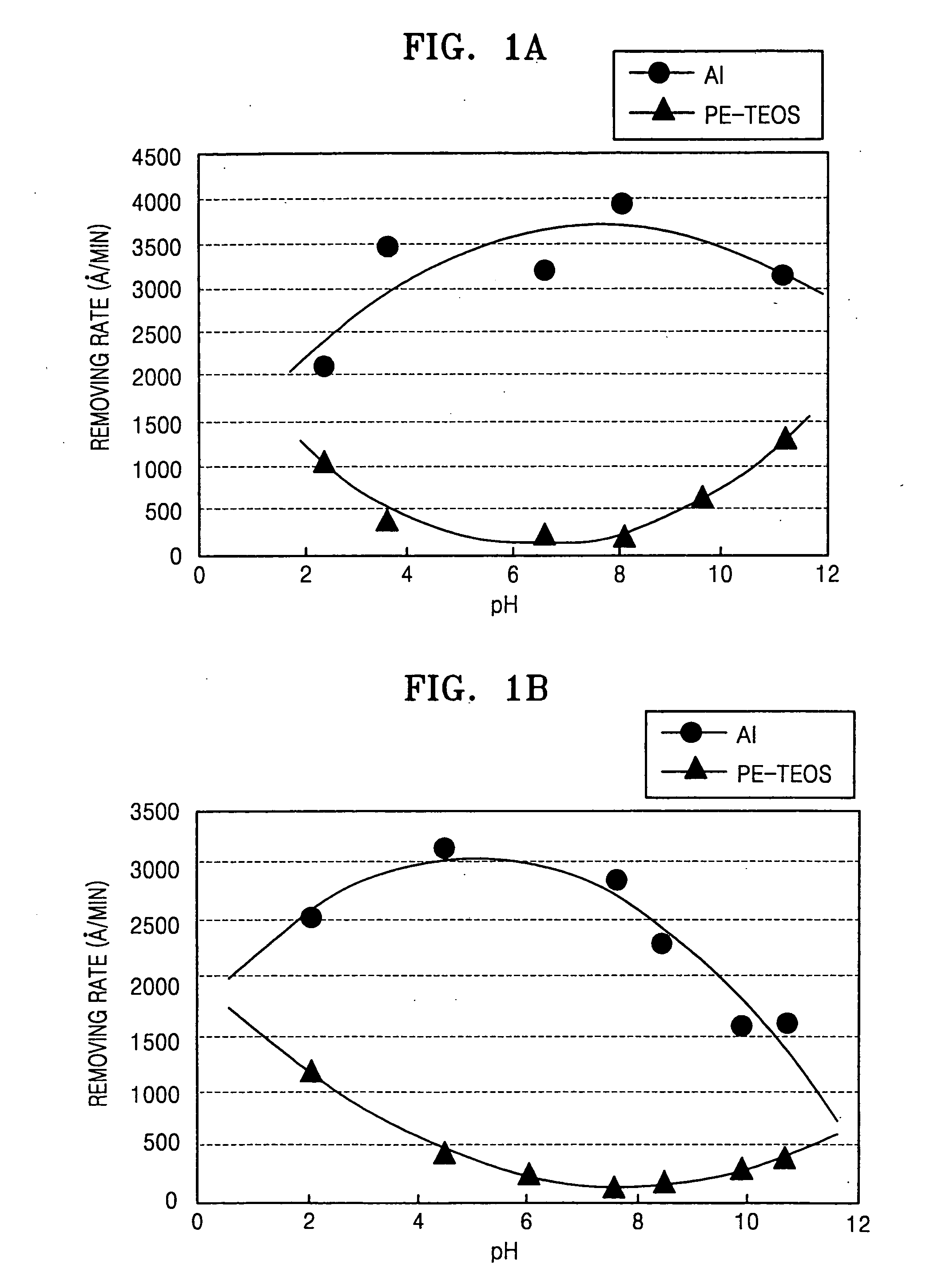

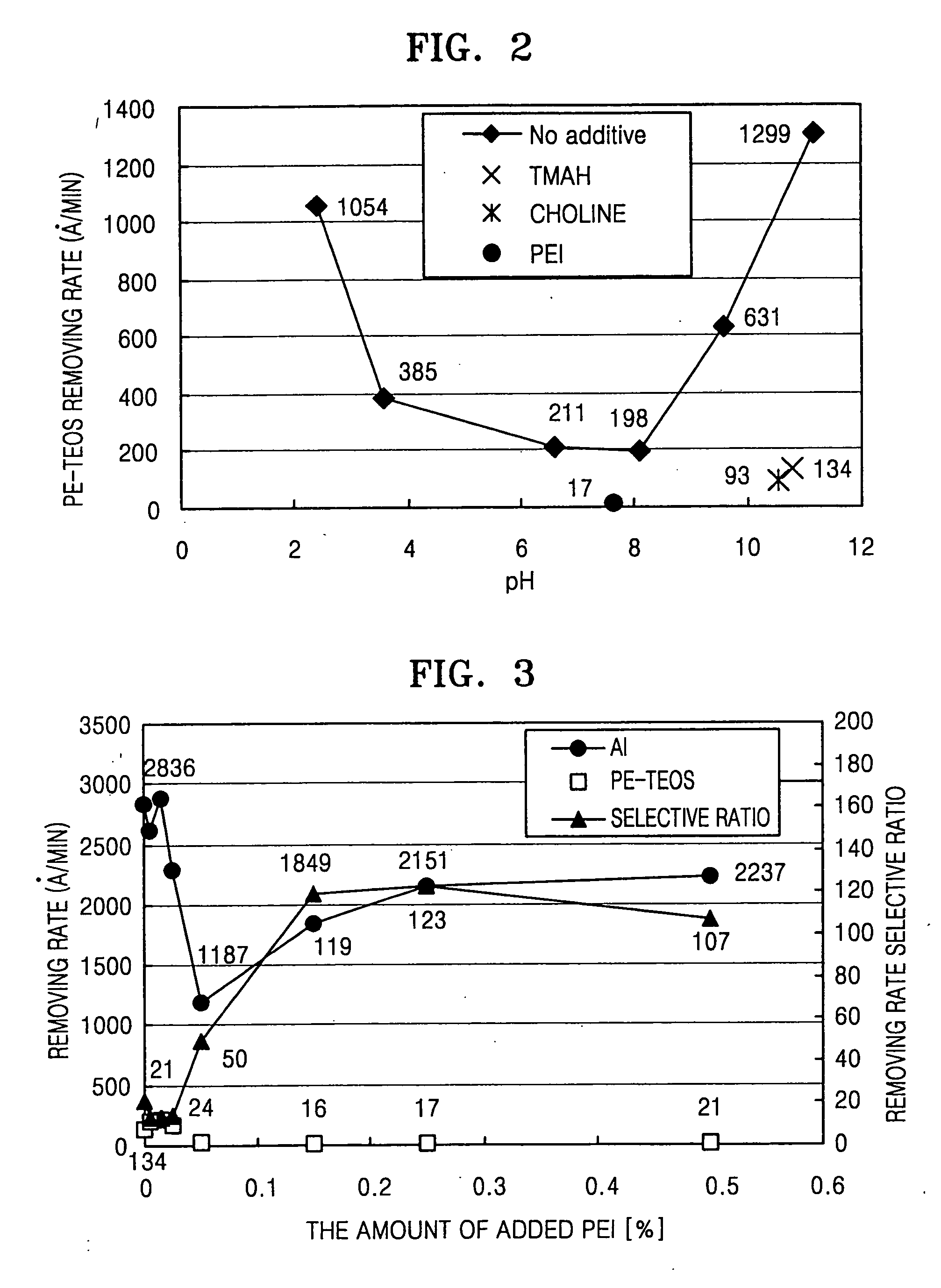

CMP slurry for forming aluminum film, CMP method using the slurry, and method for forming aluminum wiring using the CMP method

ActiveUS20050112894A1Reduces removal rateRemoval rateDecorative surface effectsSemiconductor/solid-state device manufacturingDefect preventionCorrosion

A first chemical mechanical polishing (CMP) slurry includes a polishing agent, an oxidant, a pH control additive, and an oxide film removal retarder which reduces a removal rate of the silicon oxide film. A second chemical mechanical polishing (CMP) slurry includes a polishing agent, an oxidant, a pH control additive, an oxide film removal retarder which reduces a removal rate of silicon oxide, and a defect prevention agent which inhibits scratch defects and / or corrosion defects at a surface of an aluminum film. In a one-step CMP process, either of the first or second slurry is used throughout CMP of an aluminum layer until an upper surface of an underlying silicon oxide layer is exposed. In a two-step CMP process, the first slurry is used in an initial CMP of the aluminum layer, and then the second slurry is used in a subsequent CMP until the upper surface of the underlying silicon layer is exposed.

Owner:SAMSUNG ELECTRONICS CO LTD

Online entertainment network for user-contributed content

InactiveUS7827054B2Reduce in quantityHighly accurateMarket predictionsVoting apparatusSocial webMultimedia

The invention includes a system for providing an online entertainment network for user-contributed entertainment content. The system quickly and accurately identifies quality content from a vast pool of user-contributed content. User-contributed content is rated by those who contribute and those who view content. Fraud detection devices automatically detect and remove fraudulent ratings. Contests and prizes associated with specific categories of content provide incentives for contributors to provide quality content and rate many pairs of items. Contests may be localized by geography, organization, social network, and other relationships. Identified top-rated content is made available individually, or as a continuous stream of user-contributed entertainment content.

Owner:OUSGE

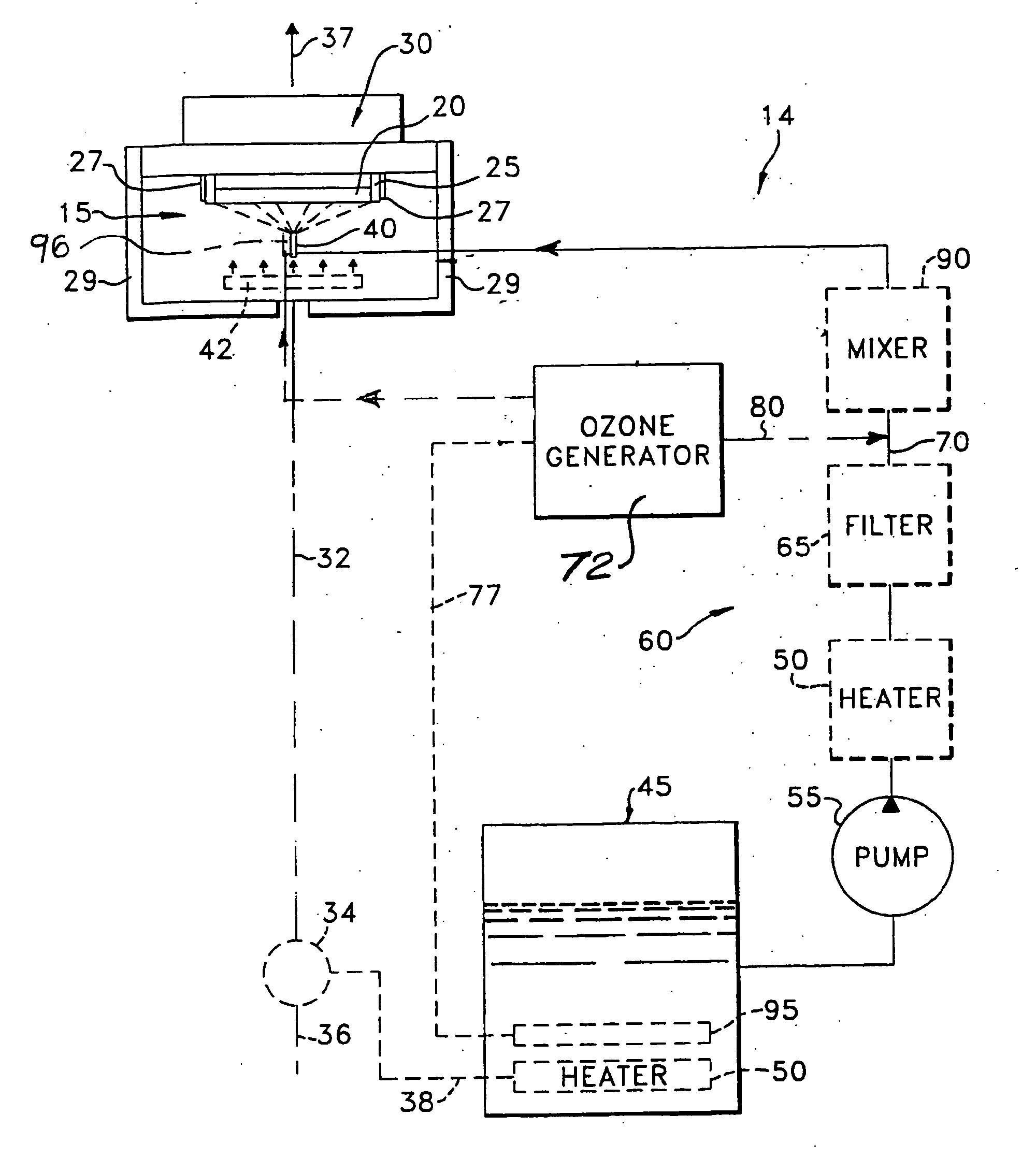

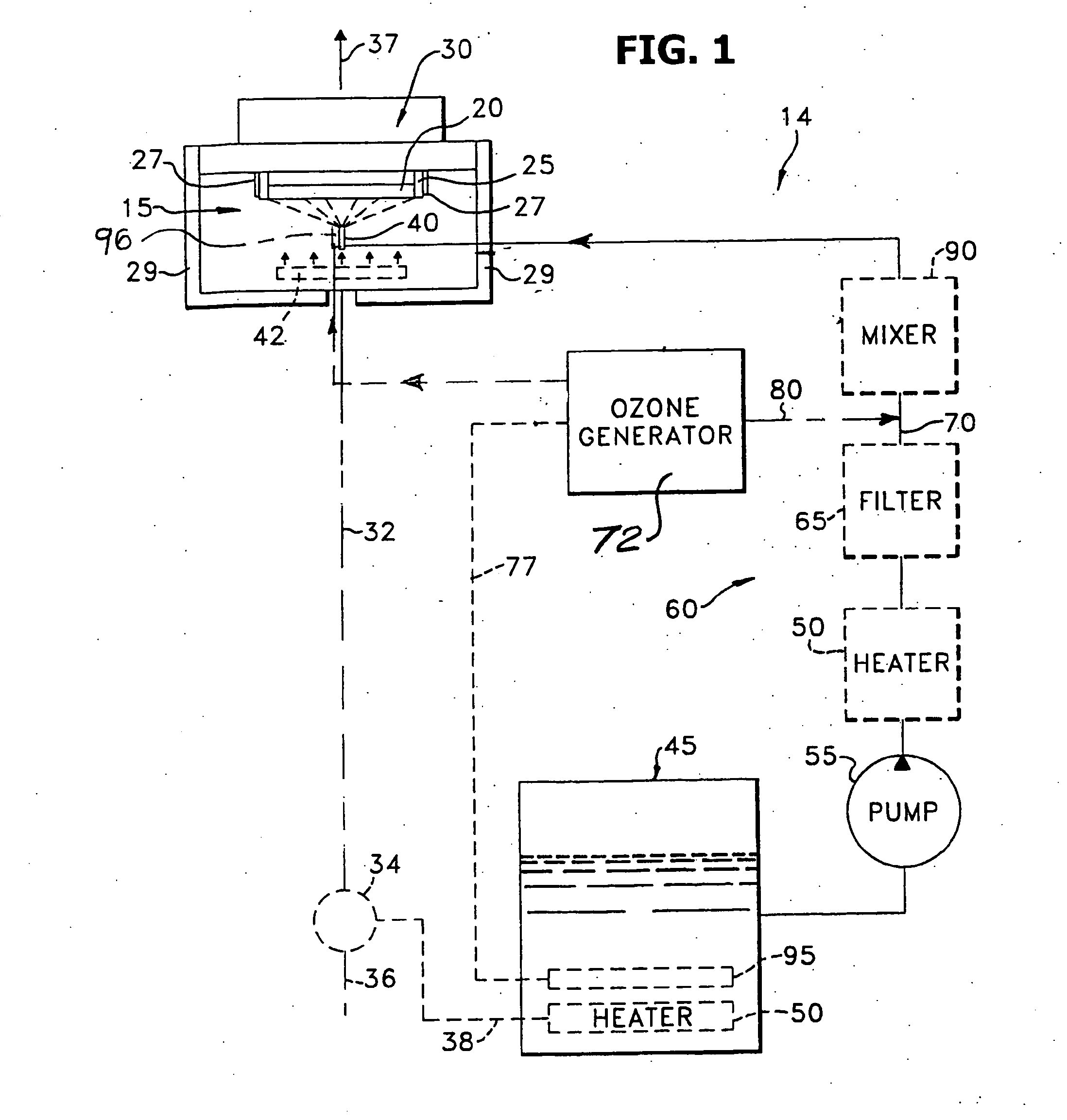

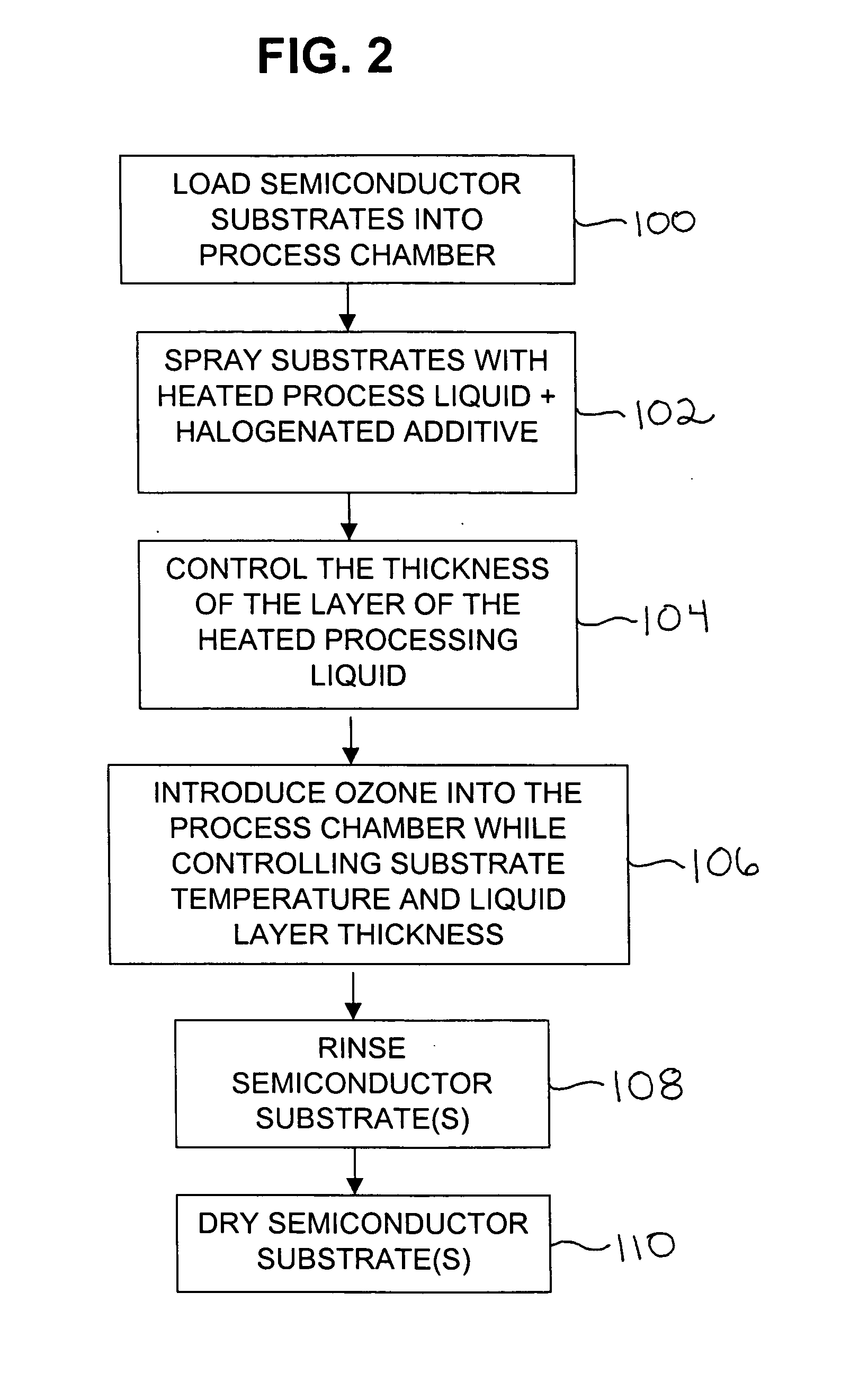

Processing a workpiece with ozone and a halogenated additive

InactiveUS20050034745A1Efficient removalEasy to removeFinal product manufactureSemiconductor/solid-state device detailsLiquid layerAnti-reflective coating

In a process for removing an anti-reflective coating, a workpiece such as a semiconductor wafer is placed in a support in a process chamber. A heated liquid including a halogenated additive is applied onto the workpiece, forming a liquid layer on the workpiece. The thickness of the liquid layer is controlled. Ozone is introduced into the process chamber by injection into the liquid or directly into the process chamber. Ozone oxidizes and removes the film on the workpiece. The methods are especially useful for anti-reflective coating or sacrificial light absorbing layers.

Owner:SEMITOOL INC

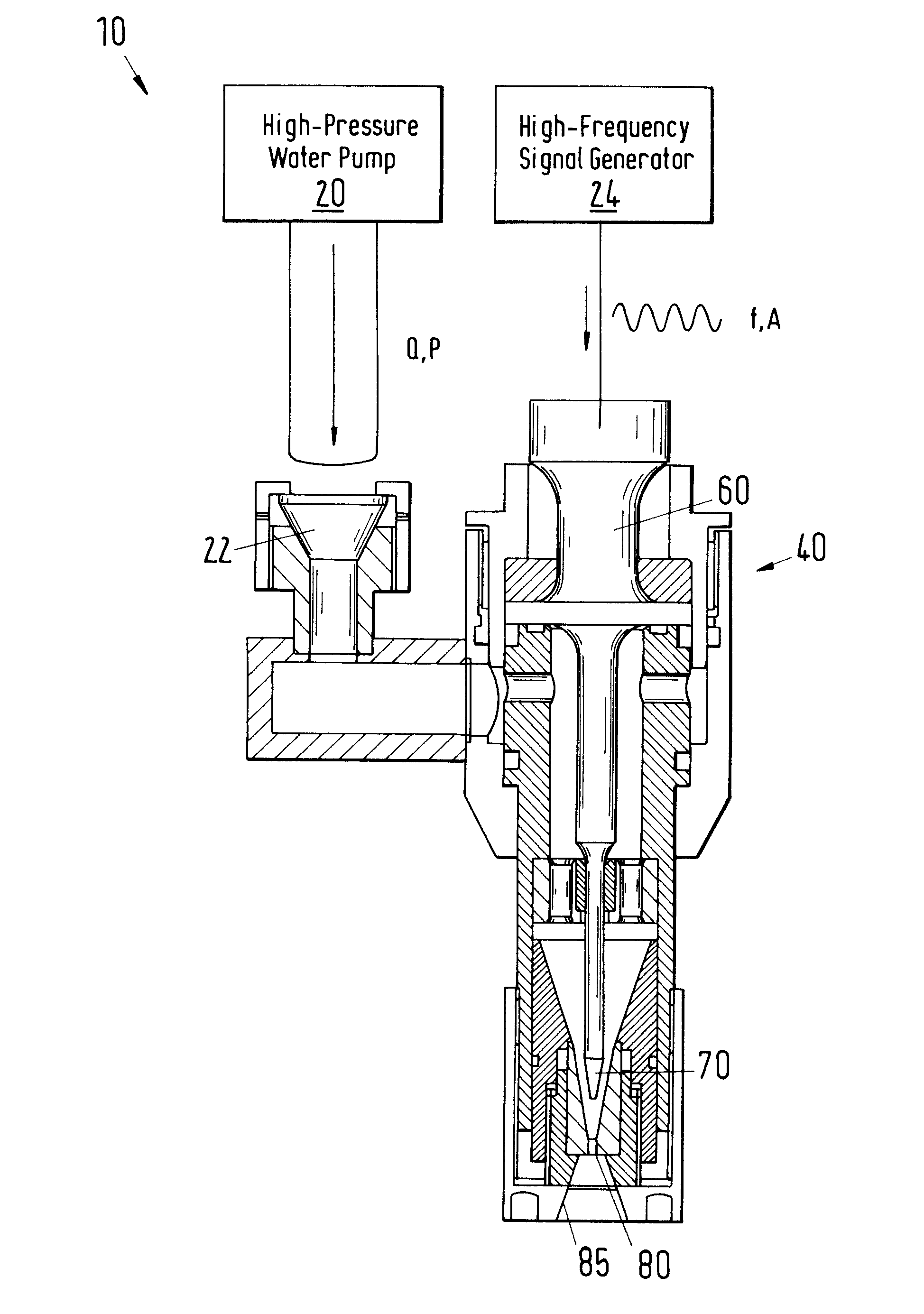

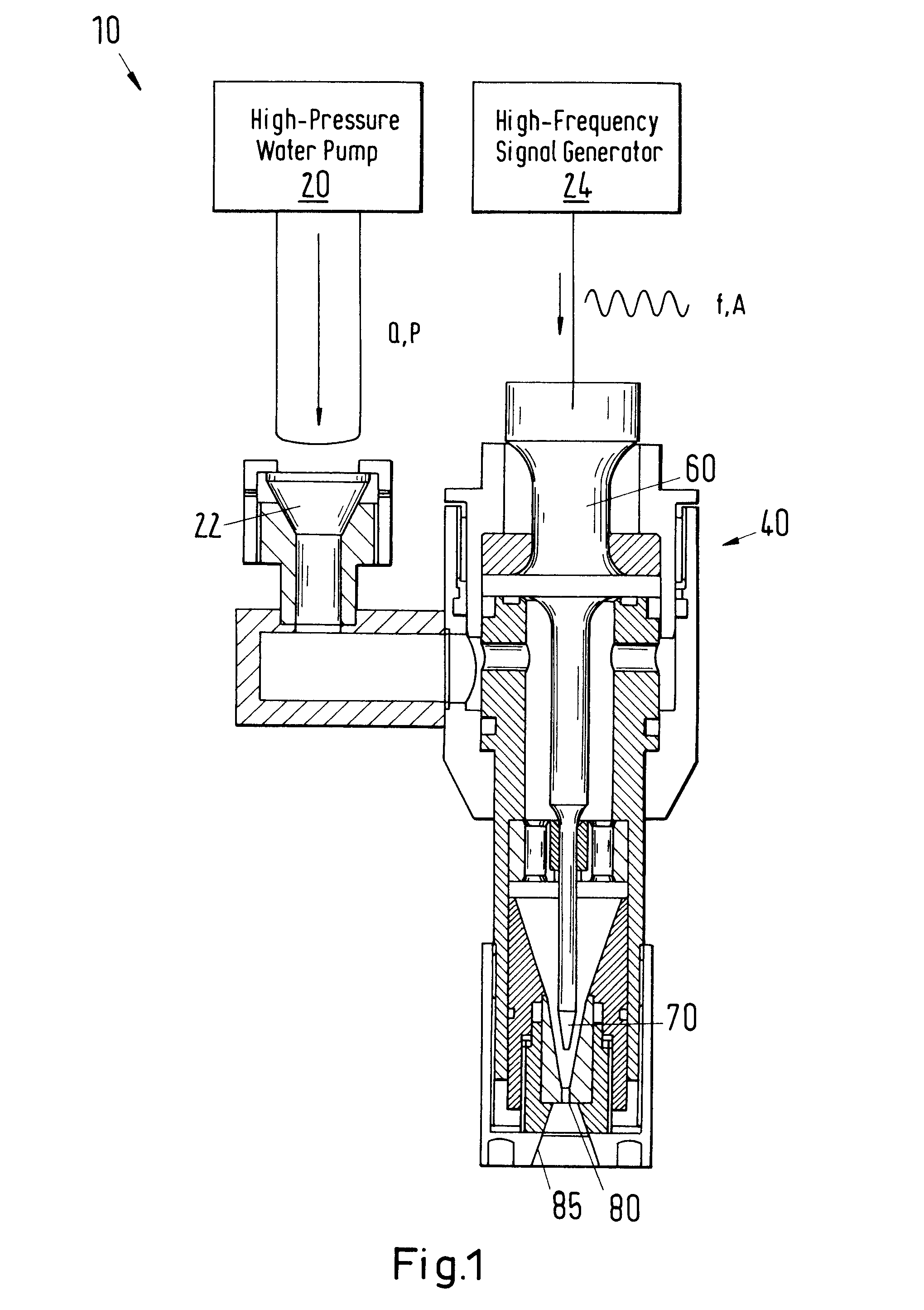

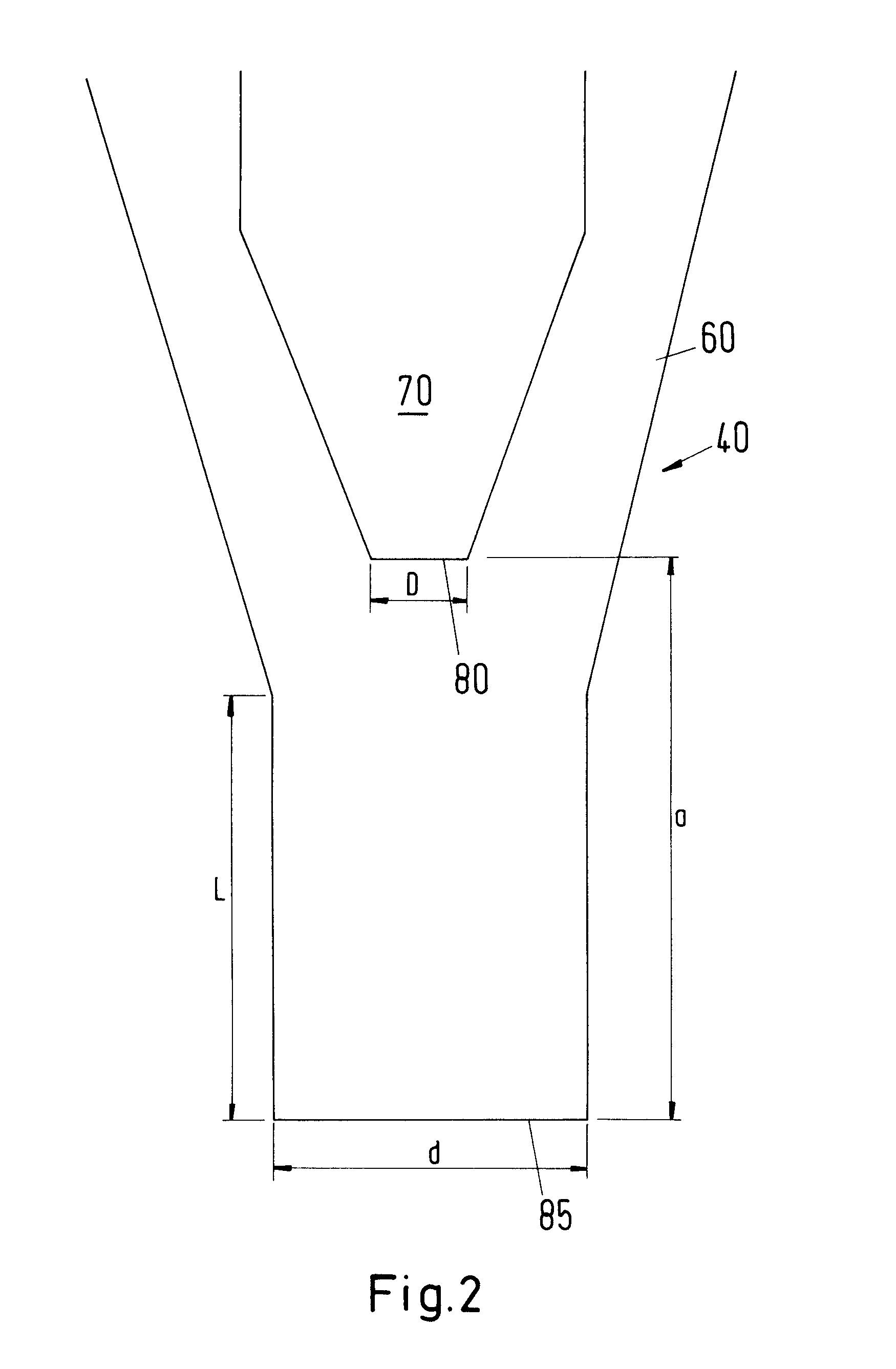

Method and apparatus for preparation of cylinder bore surfaces with a pulsed waterjet

InactiveUS20120322347A1Exact and highly uniform surface roughness characteristicHighly predictableBlast gunsMolten spray coatingSpray nozzleWater flow

An apparatus for and a method of prepping a surface of a cylinder bore using a pulsed waterjet entails generating a signal having a frequency f using a signal generator, applying the signal to generate a pulsed waterjet through an exit orifice of a nozzle having an exit orifice diameter d and a length L. The pulsed waterjet prepares the surface to within a predetermined range of surface roughness. The surface roughness is determined by selecting operating parameters comprising a standoff distance (SD), a traverse velocity VTR of the nozzle, a water pressure P, a water flow rate Q, a length-to-diameter (L / d) ratio, the frequency f, and an amplitude A of the signal.

Owner:SULZER METCO (US) INC

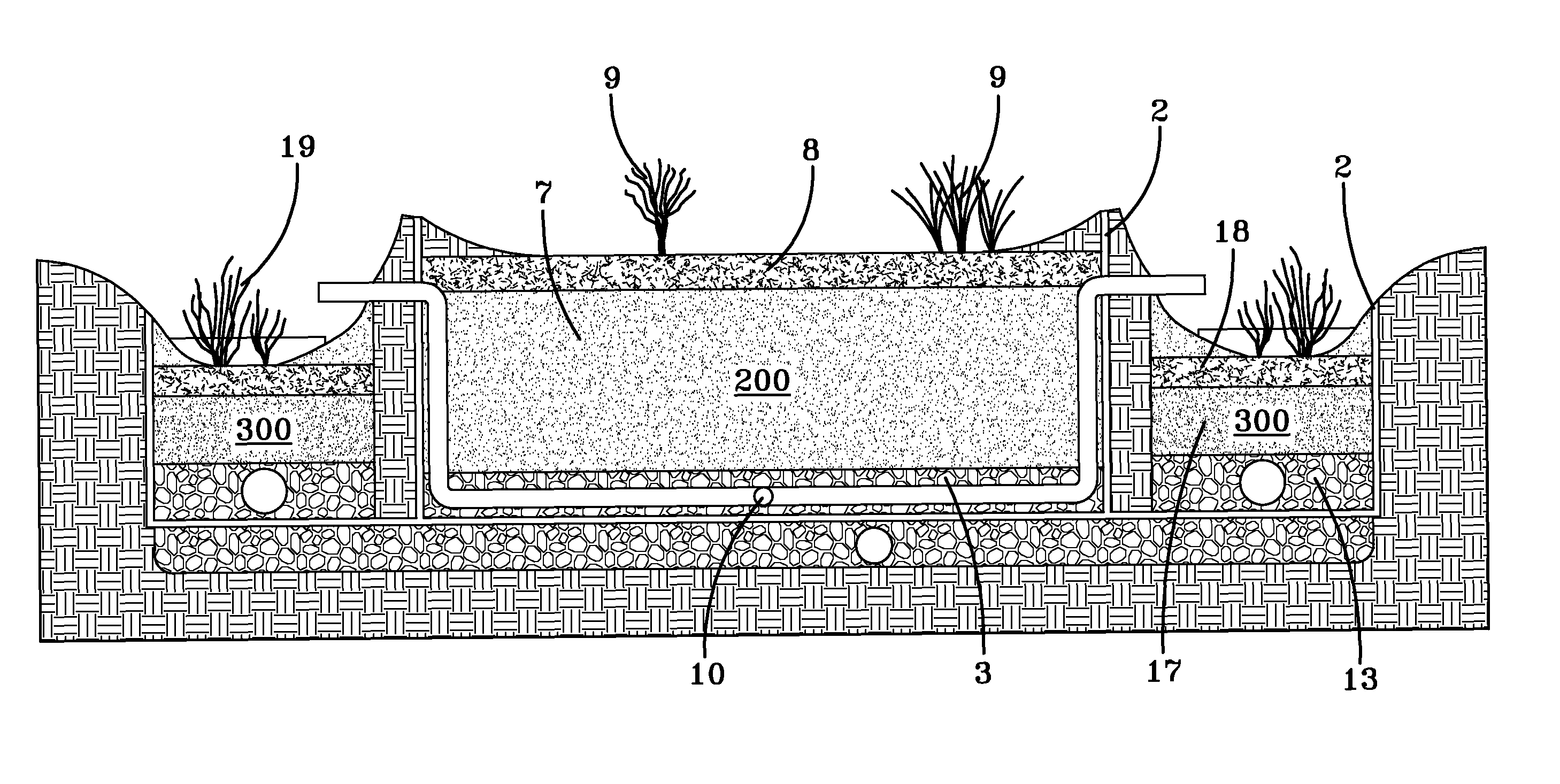

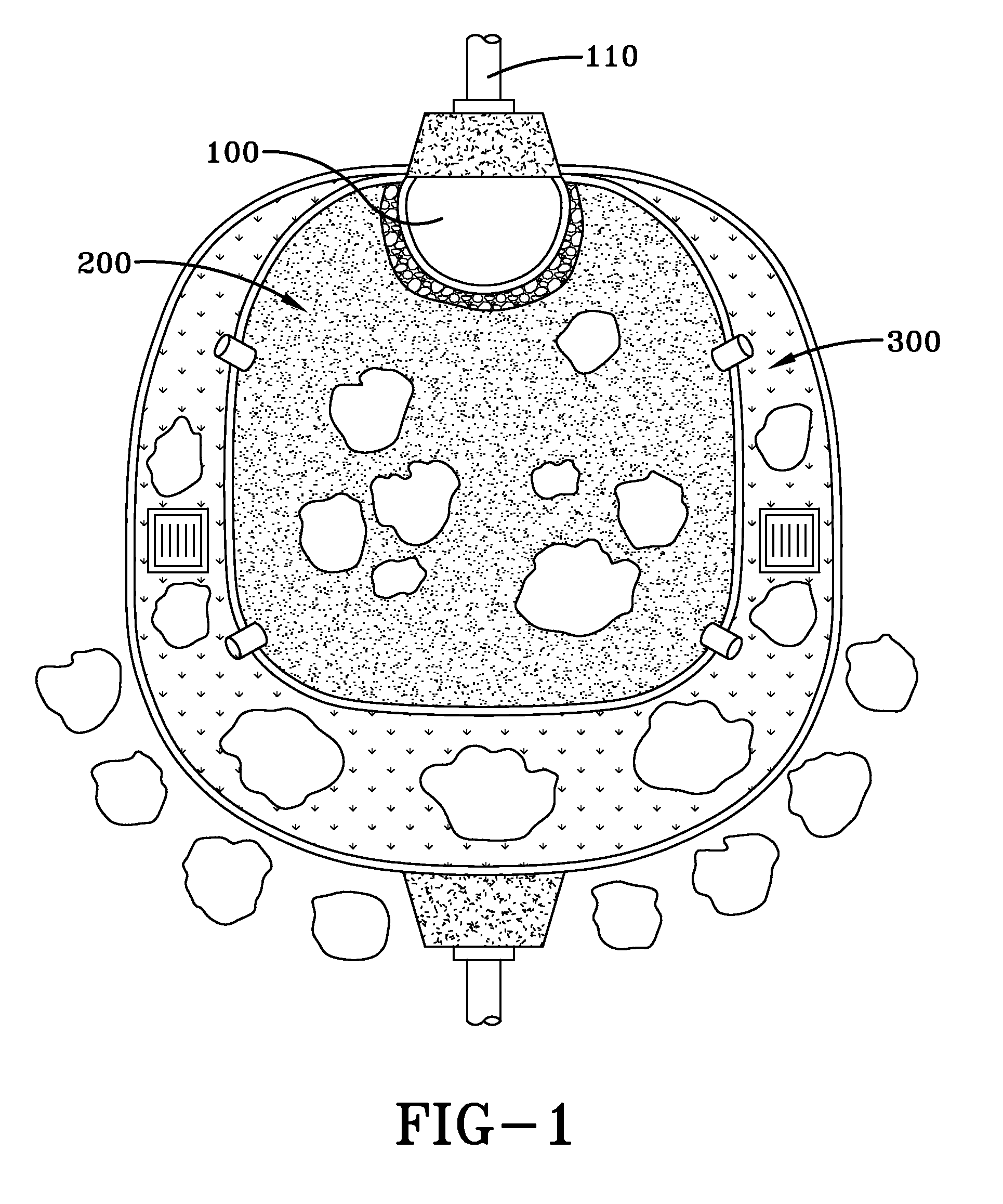

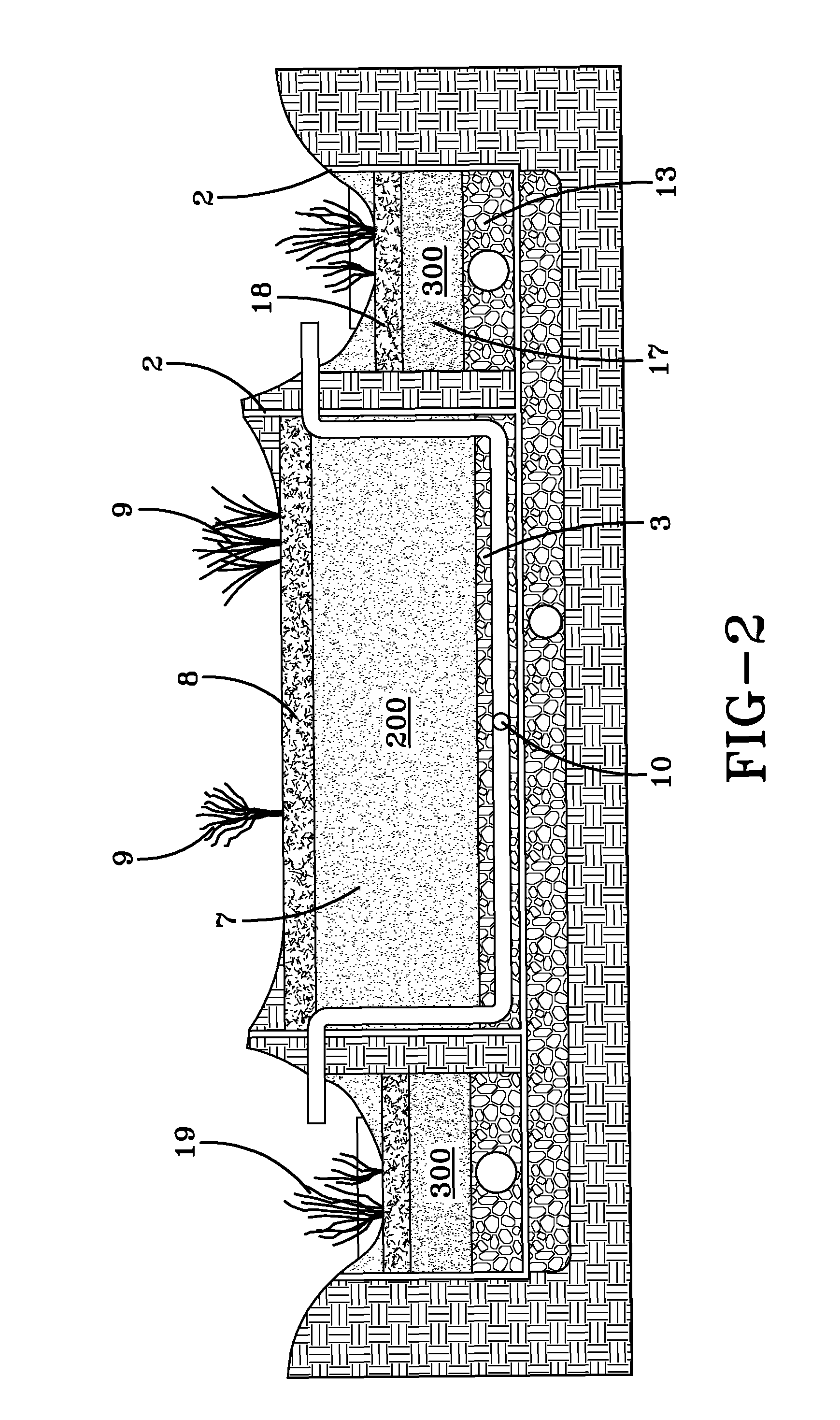

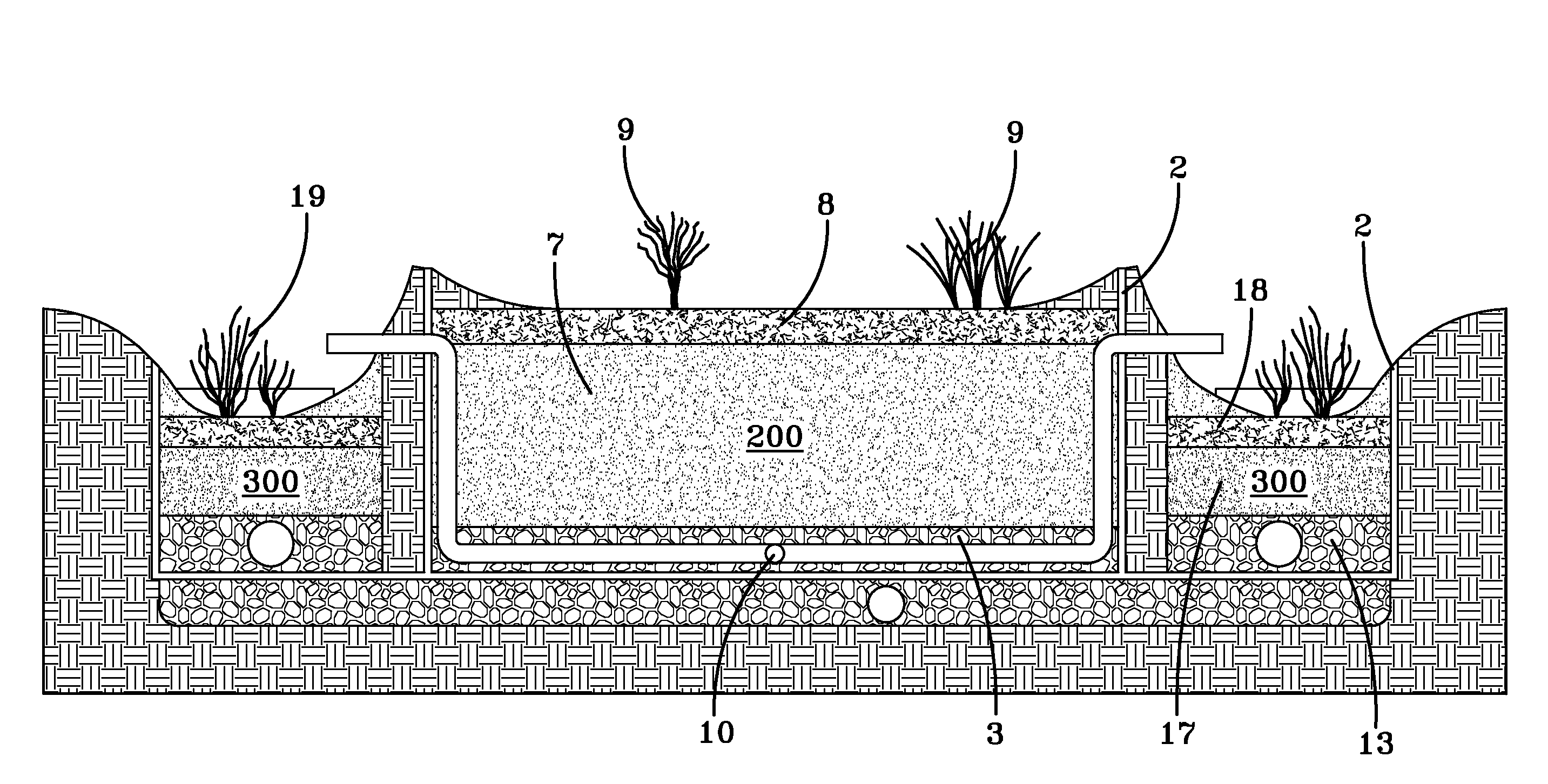

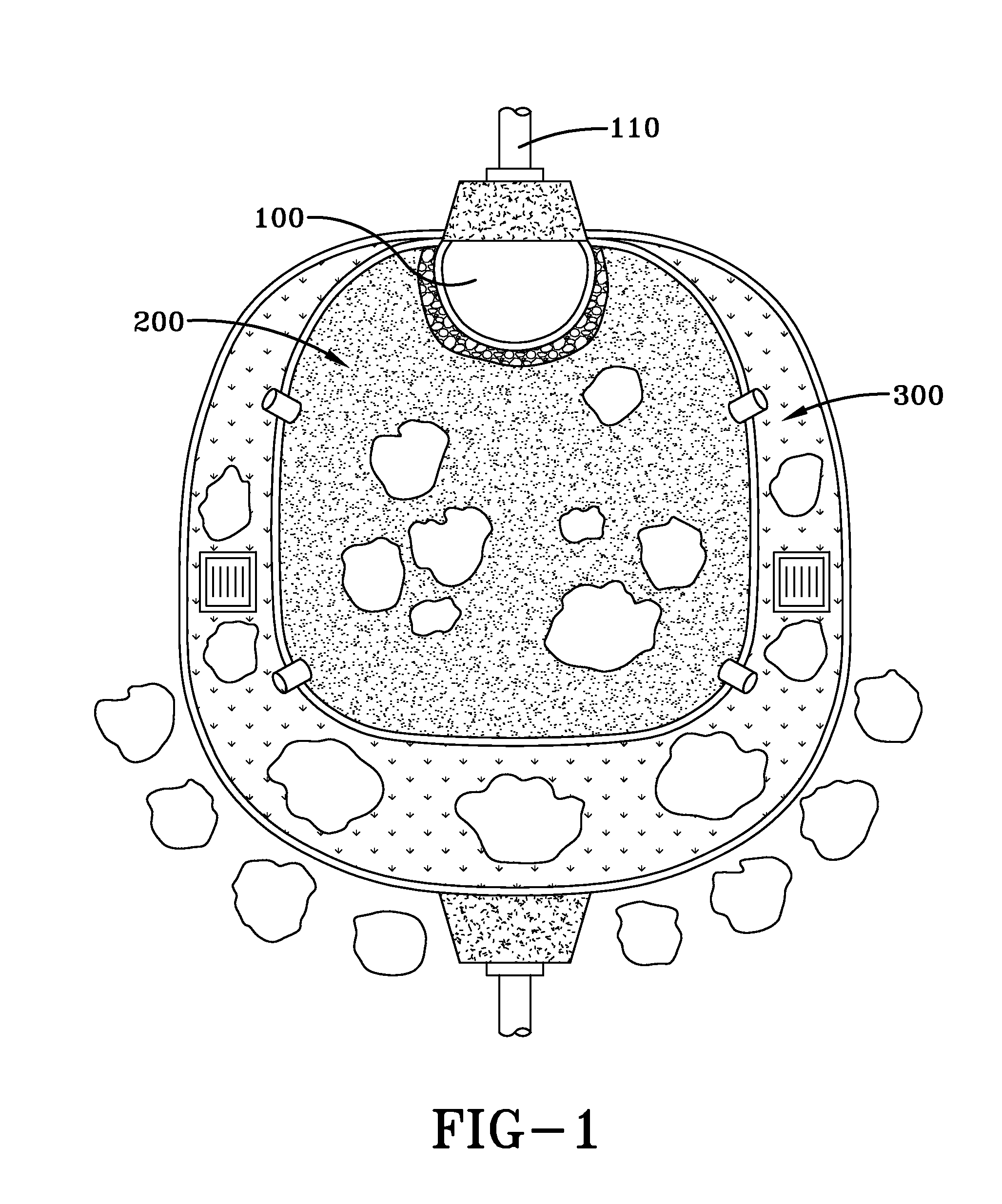

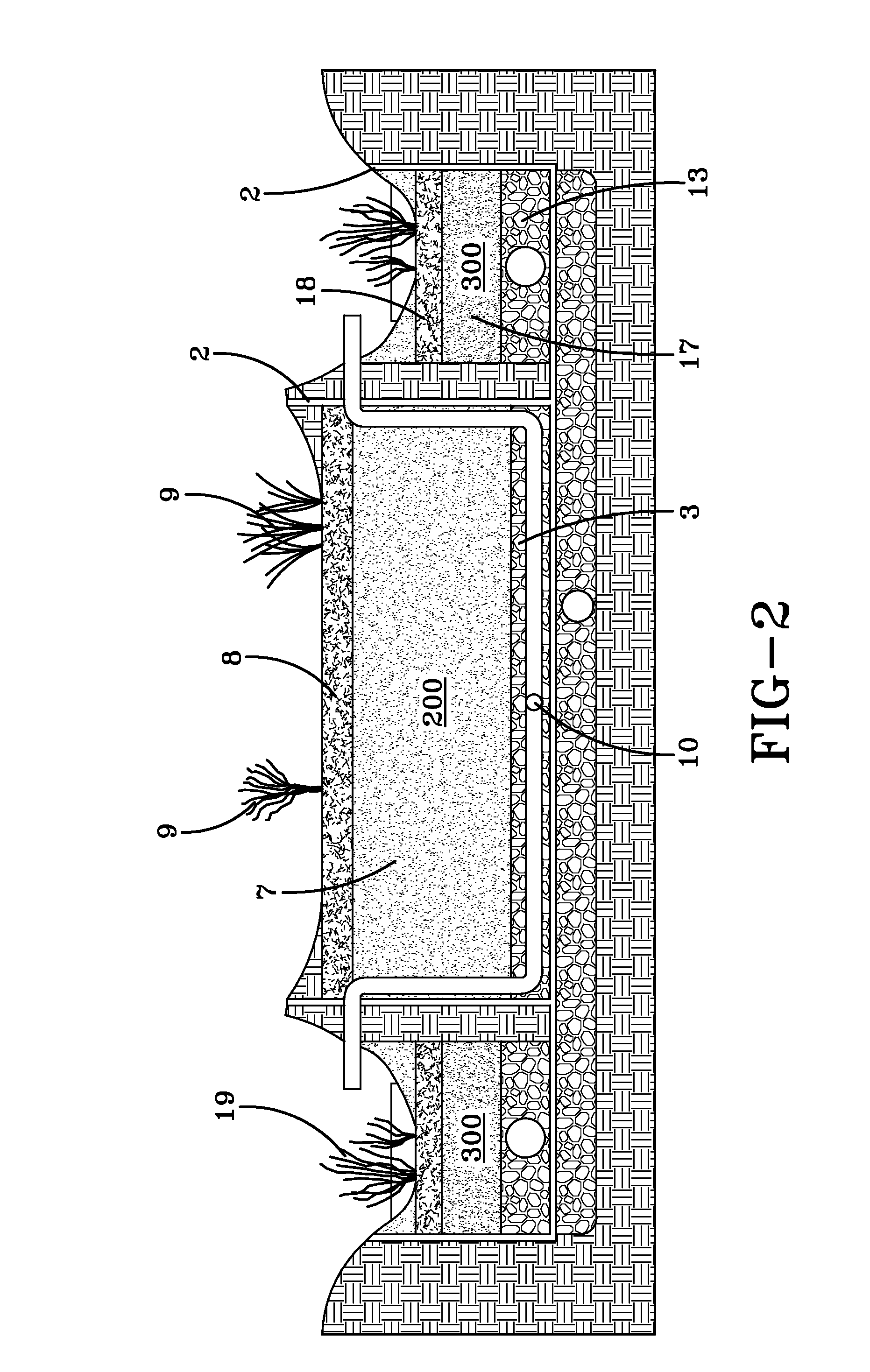

Bi-phasic bioretention system

InactiveUS7967979B2Improve efficiencyExtension of timeWater cleaningWater/sewage treatmentFiltrationRetention time

An anaerobic to aerobic sequence enhances biological degradation of many organic pollutants. Exemplary embodiments provide systems and methods for effective treatment of storm-water runoff pollutants such as hydrocarbons, nitrates, phosphorus, and heavy metals using sediment filtration and adsorption, and biochemical processes under bi-phasic bioretention conditions. By integrating these pollution cleanup pro-usages into a single unit, this apparatus optimizes retention time of the runoff through the system and maximizes removal rates of runoff pollutants, resulting in more reliable and efficient treatment mechanism than previous systems.

Owner:THE OHIO STATES UNIV

Method and composition for polishing a substrate

InactiveUS7160432B2High removal rateRemoval rateMachining working mediaElectrolysis componentsOrganic acidConductive materials

Polishing compositions and methods for removing conductive materials from a substrate surface are provided. In one aspect, a method is provided for processing a substrate to remove conductive material disposed over narrow feature definitions formed in a substrate at a higher removal rate than conductive material disposed over wide feature definitions formed in a substrate by an electrochemical mechanical polishing technique. The electrochemical mechanical polishing technique may include a polishing composition comprising an acid based electrolyte system, one or more chelating agents, one or more corrosion inhibitors, one or more inorganic or organic acid salts, one or more pH adjusting agents to provide a pH between about 2 and about 10, and a solvent.

Owner:APPLIED MATERIALS INC

Bi-phasic bioretention system

InactiveUS20090261026A1Biological degradation of manyBroad marketTreatment with aerobic and anaerobic processesSustainable biological treatmentRetention timeFiltration

An anaerobic to aerobic sequence enhances biological degradation of many organic pollutants. Exemplary embodiments provide systems and methods for effective treatment of storm-water runoff pollutants such as hydrocarbons, nitrates, phosphorus, and heavy metals using sediment filtration and adsorption, and biochemical processes under bi-phasic bioretention conditions. By integrating these pollution cleanup pro-usages into a single unit, this apparatus optimizes retention time of the runoff through the system and maximizes removal rates of runoff pollutants, resulting in more reliable and efficient treatment mechanism than previous systems.

Owner:THE OHIO STATES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com