Graphene-like nano carbon nitride modified polytetrafluoroethylene friction material as well as preparation method and application thereof

A PTFE, friction material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low mechanical strength, poor wear resistance, low hardness of pure PTFE, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

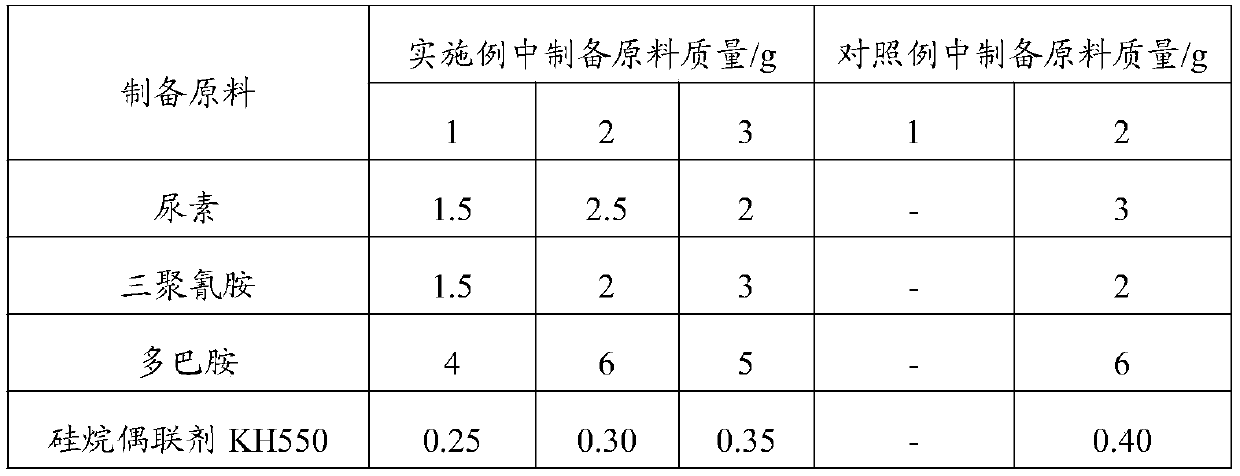

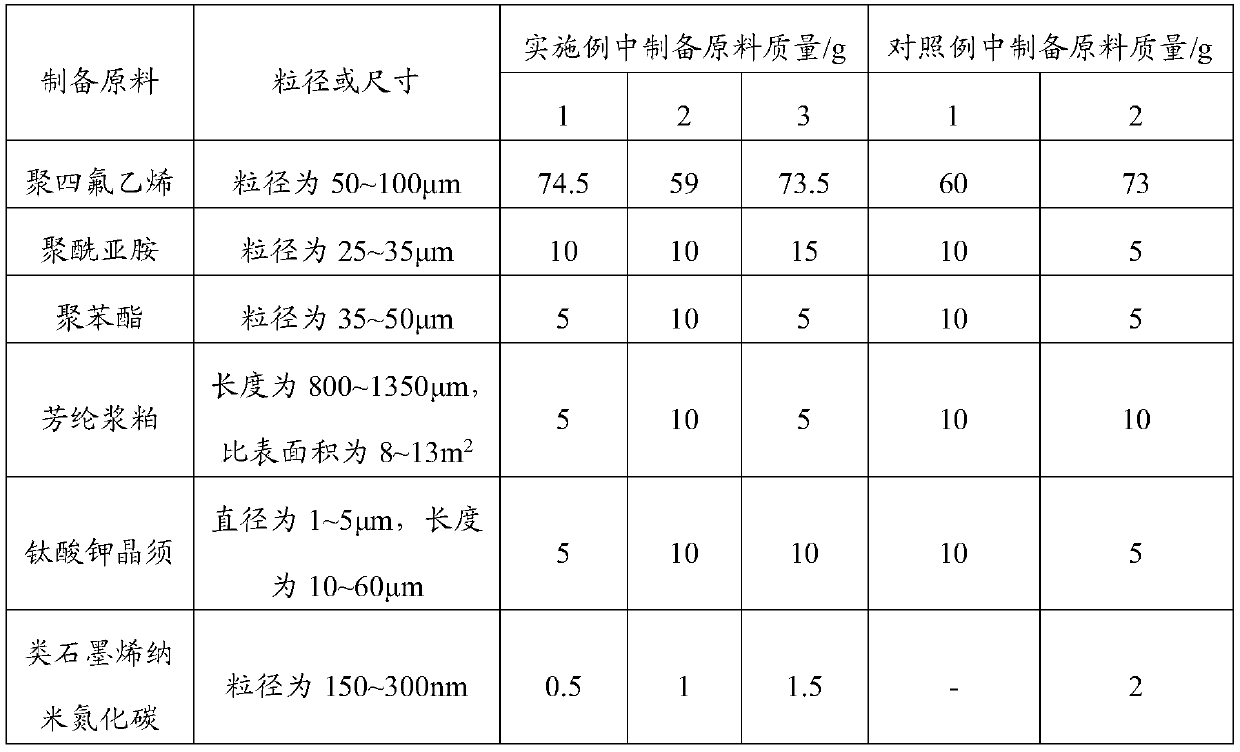

[0038] Based on the mass fraction of the polytetrafluoroethylene, the raw materials for the preparation of the graphene-like nano-carbon nitride modified polytetrafluoroethylene friction material include 0.5-1.3 parts of graphene-like nano-carbon nitride, preferably 0.7 to 1.1 parts. In the present invention, the particle size of the graphene-like nano-carbon nitride is preferably 150-300 nm. The present invention has no special limitation on the source of the graphene-like nano-carbon nitride, it can be prepared according to methods well known to those skilled in the art; in the present invention, the graphene-like nano-carbon nitride is preferably Adopt dopamine and silane coupling agent (preferably silane coupling agent KH550) to modify, and the specific preparation method preferably comprises the following steps:

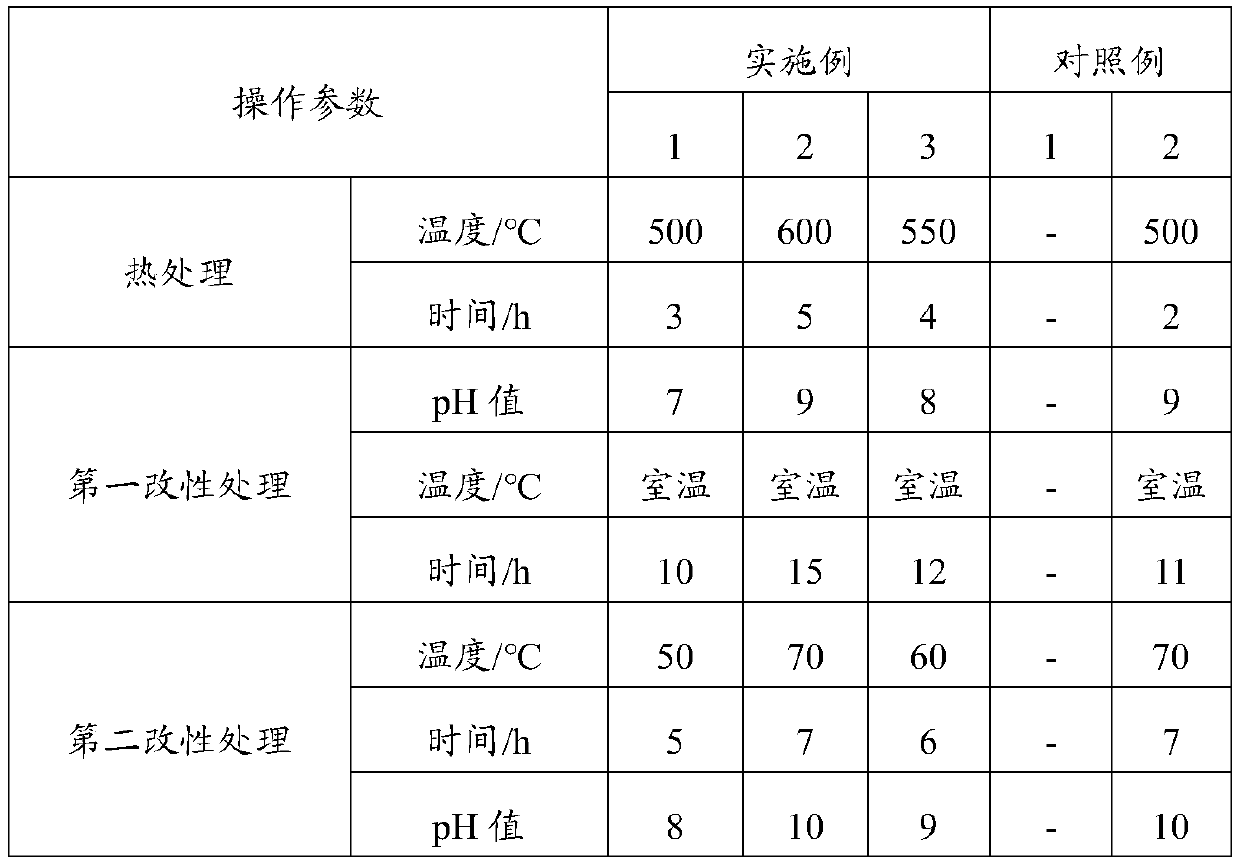

[0039] The mixture of urea and melamine (the molar ratio of urea and melamine is (1.5-2.5): (0.5-1.3)) is heat-treated at 500-600°C for 3-5 hours, cooled and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com