Control handle head of mobile floor delivery tool and moving speed conveyor

A technology for controlling handles and ground transportation, which is applied to the layout of power plant control mechanisms, motor vehicles, transportation and packaging, etc. It can solve the problems of high wear and failure of micro switches, collision between magnet bracket and Hall sensor, labor-intensive problems, etc. , to achieve the effect of improving mechanical stability, firm and mechanical connection, and stable mechanical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

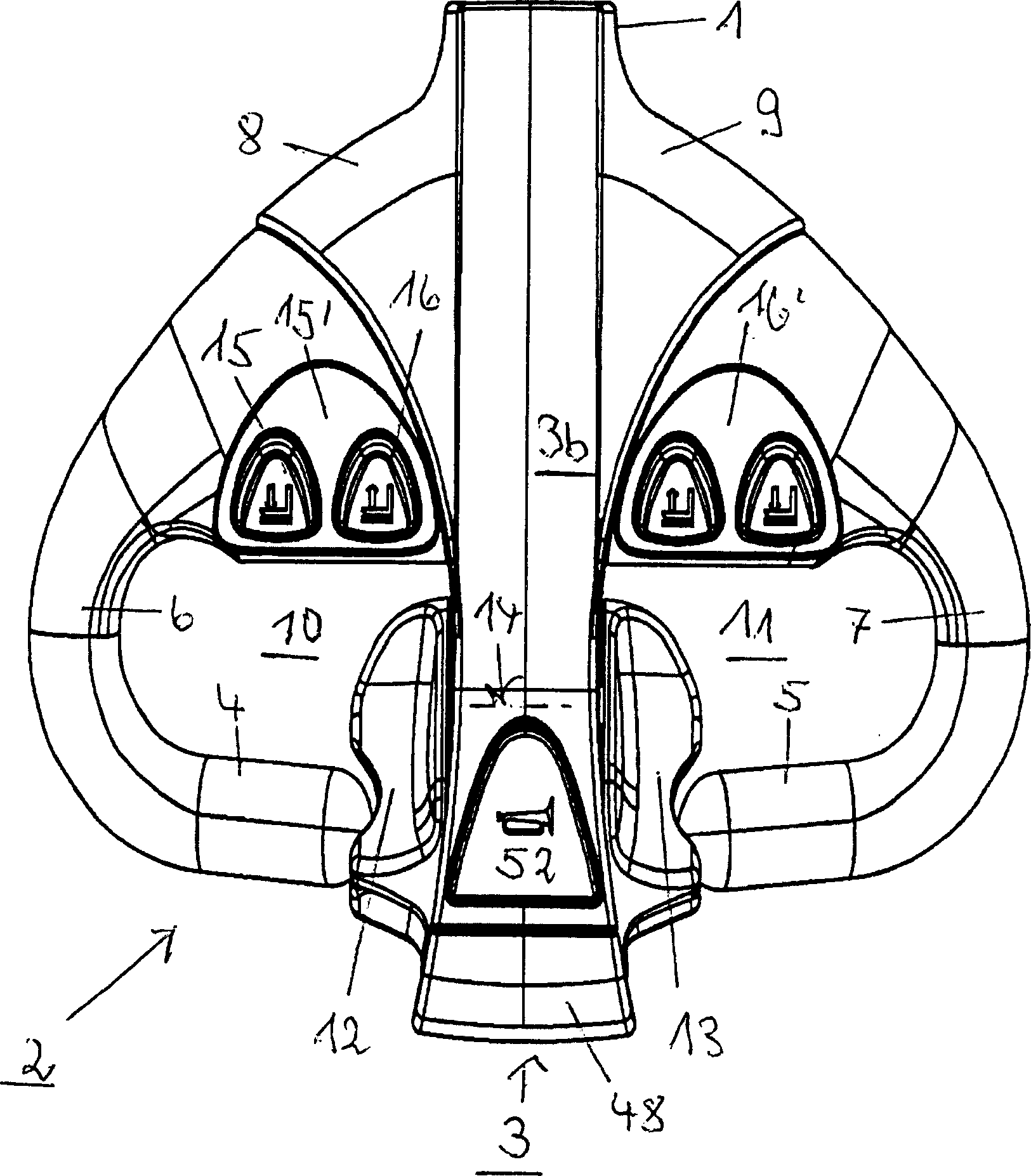

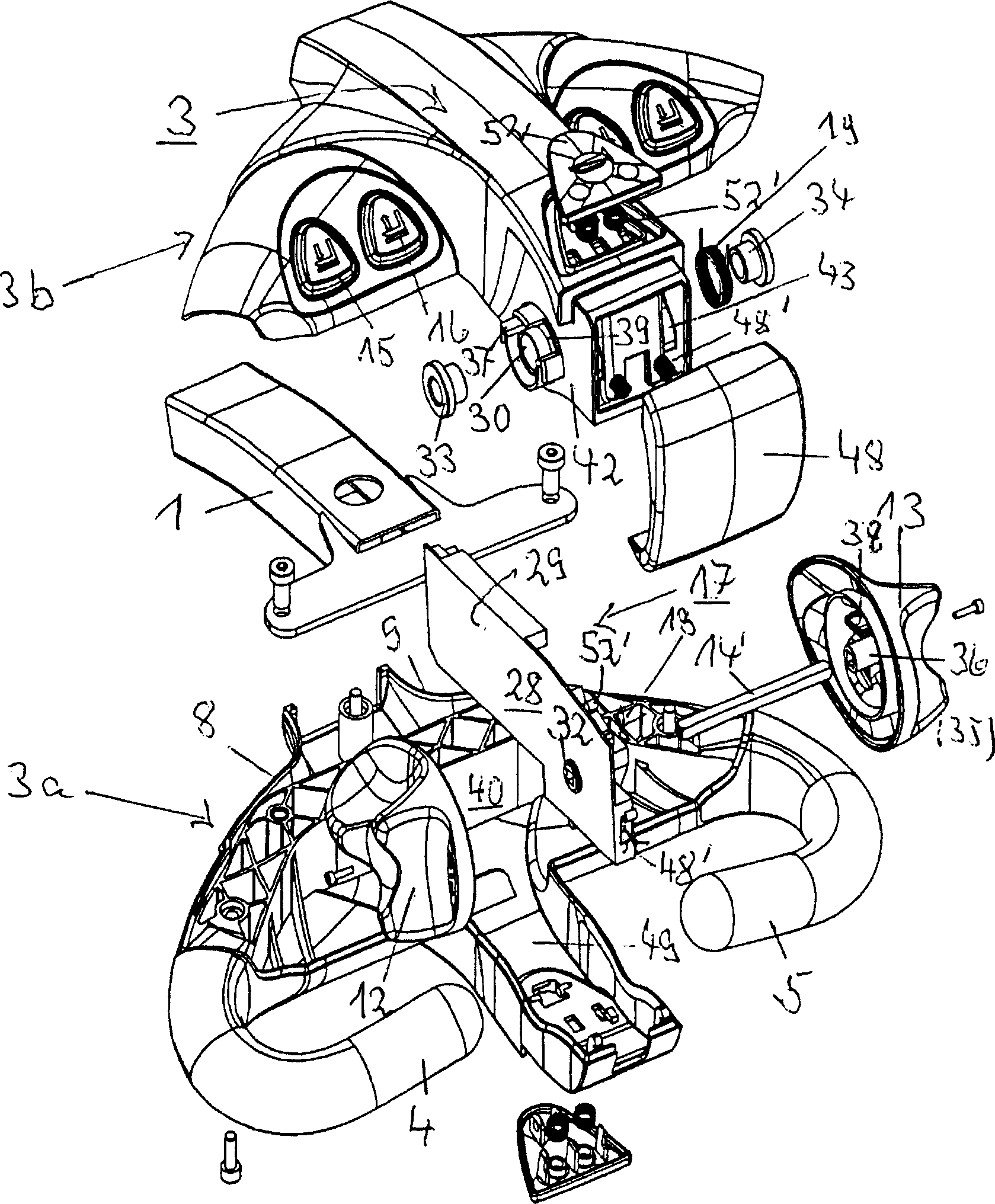

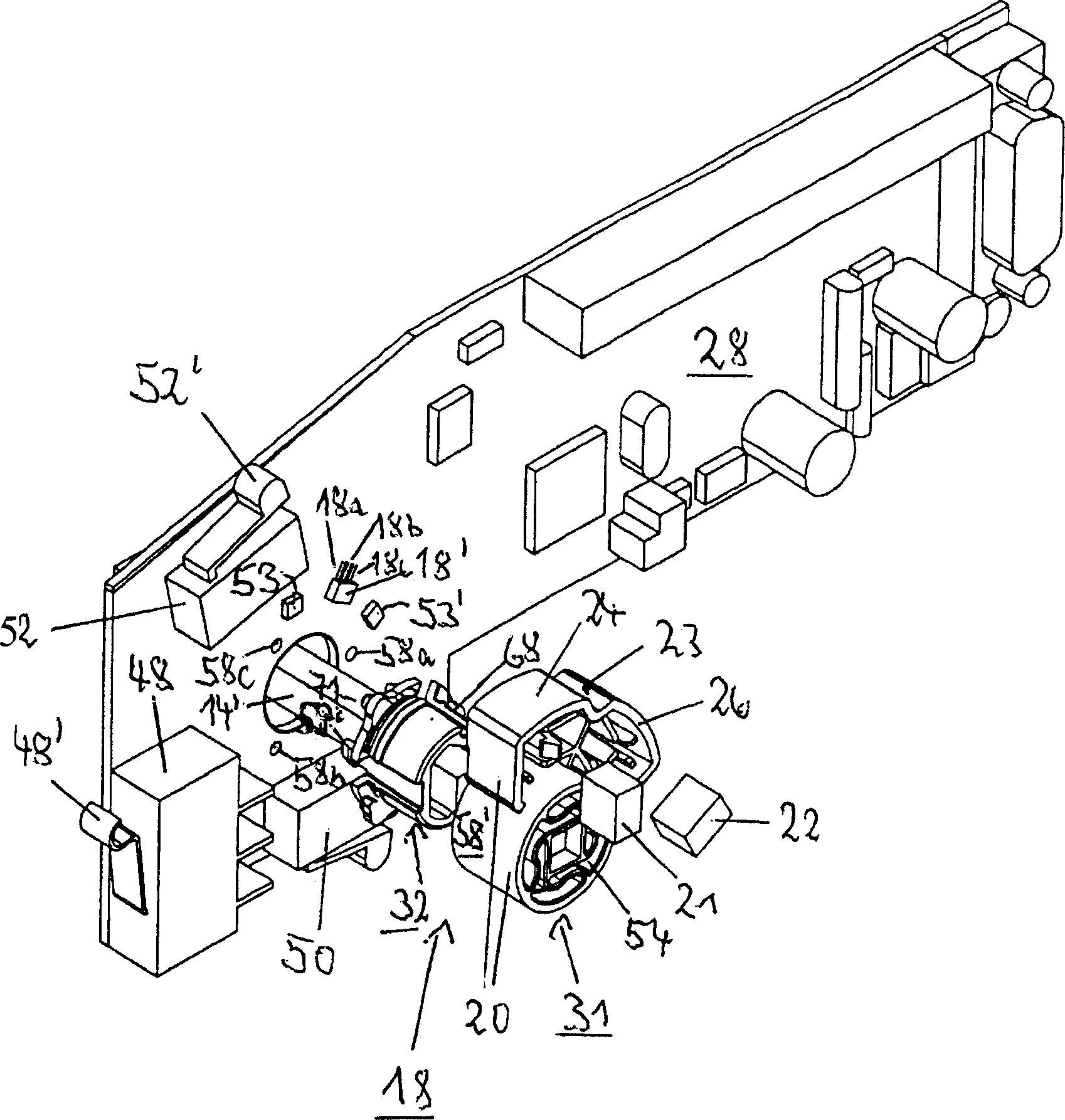

[0164] figure 1 and figure 2 The control handle head (2) of the ground vehicle shown in (3) centerline both sides left and right are the variable-speed handwheels (12,13) that are formed by two cams for manipulation, like a wing wheel. In addition, there are control buttons (15, 16) concentrated on both sides of the control handle horn (3) at the control handle head (2), so that it is convenient for both hands to hold on the handle (4, 5) with one hand or two hands thumb to operate. As the common practice of ground vehicles, there is a body protection switch (48) at the outer end of the control handle horn (3) of the control handle head (2).

[0165] according to figure 1 and figure 2 , the head of the control handle (2) has an inclined surface or a basin-shaped surface (15', 16') to protect the control switch (15, 16) within the range of the control handle horn (3), and the basin-shaped surface is preset to control The handles (4, 5) of the device horns are tilted. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com