Preparing method and application of laser cladding precipitation-hardening stainless steel wear-resisting anti-corrosion coating

A laser cladding and precipitation hardening technology, which is applied in the field of metal surface treatment, can solve the problems of many influencing factors and troublesome methods, and achieve the effects of simple cladding process, improved strength and hardness, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

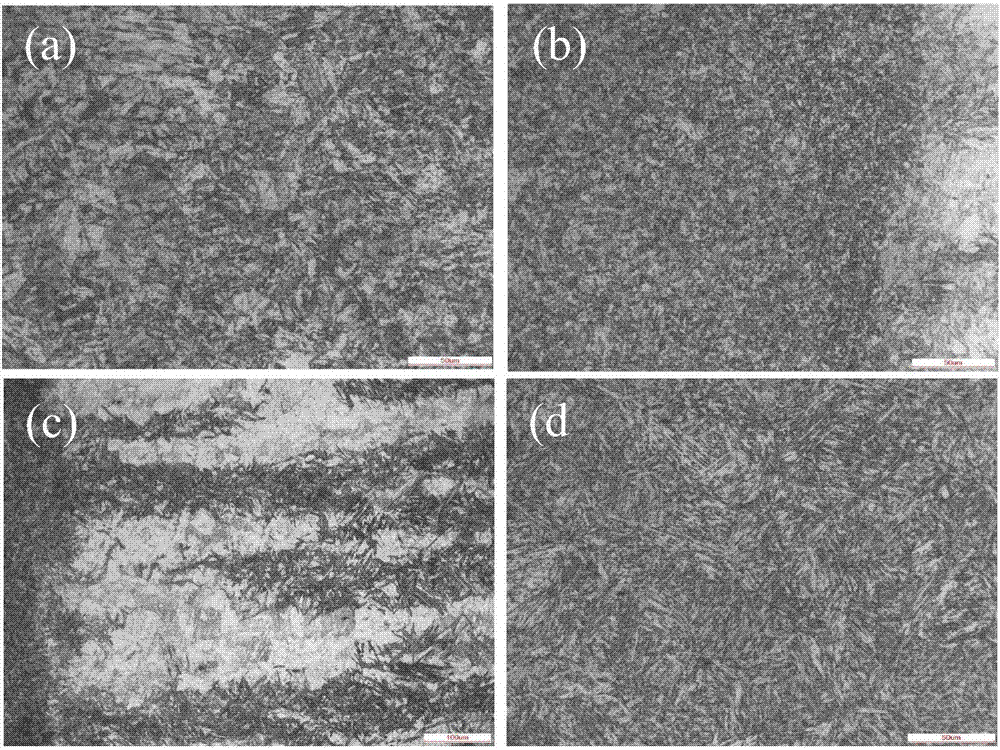

[0033] The preparation method of laser cladding precipitation hardening stainless steel wear-resistant and corrosion-resistant coating comprises the following steps:

[0034] (1) Base material pretreatment: The base material 1Cr15Ni4Mo3N precipitation hardening stainless steel is made into a circular steel plate with a diameter of 12 cm and a height of 1 cm. First, it is vacuum quenched at 1050 ° C and kept for 40 min in an oil bath, and then ice-cooled at -70 ° C. Air cooling after heat preservation for 100min; then tempering at 350°C and heat preservation for 100-120min in air cooling, the matrix material structure after tempering is martensite and a small amount of carbide, preparing for subsequent laser cladding; among them, 1Cr15Ni4Mo3N precipitation hardening Stainless steel consists of the following components and weight percentage content: C 0.11wt%, Mn 0.5wt%, Mo 2.3wt%, Ni 4.0wt%, Cr14.0wt%, N 0.05wt%, Si not more than 0.7wt%, S Not more than 0.02wt%, P not more than...

Embodiment 2

[0039] The preparation method of laser cladding precipitation hardening stainless steel wear-resistant and corrosion-resistant coating comprises the following steps:

[0040] (1) Base material pretreatment: The base material 1Cr15Ni4Mo3N precipitation hardening stainless steel is made into a circular steel plate with a diameter of 12cm and a height of 1cm. First, it is vacuum quenched at 1070°C and kept warm for 40-60min, then in an oil bath, and then ice-cooled at -75°C After treatment and heat preservation for 120 minutes, air cooling; then tempering at 400°C and heat preservation for 120 minutes in air cooling, the matrix material structure after tempering is martensite and a small amount of carbides, preparing for subsequent laser cladding; among them, 1Cr15Ni4Mo3N precipitation hardening Stainless steel consists of the following components and weight percentages: C 0.16wt%, Mn 1.0wt%, Mo 2.3-2.8wt%, Ni 5.0wt%, Cr 15.5wt%, N 0.10wt%, Si not more than 0.5wt% , S is not more...

Embodiment 3

[0045] The preparation method of laser cladding precipitation hardening stainless steel wear-resistant and corrosion-resistant coating comprises the following steps:

[0046] (1) Base material pretreatment: The base material 1Cr15Ni4Mo3N precipitation hardening stainless steel is made into a circular steel plate with a diameter of 12 cm and a height of 1 cm. First, it is vacuum quenched at 1060 ° C and kept for 50 min in an oil bath, and then ice-cooled at -72 ° C. Air cooling after heat preservation for 110min; then tempering at 380°C and heat preservation for 110min in air cooling, the matrix material structure after tempering is martensite and a small amount of carbide, in preparation for subsequent laser cladding; among them, C 0.12wt%, Mn 0.7wt%, Mo 2.5wt%, Ni4.4wt%, Cr 14.5wt%, N 0.07wt%, Si not more than 0.5wt%, S not more than 0.01wt%, P not more than 0.02wt%, the balance is Fe .

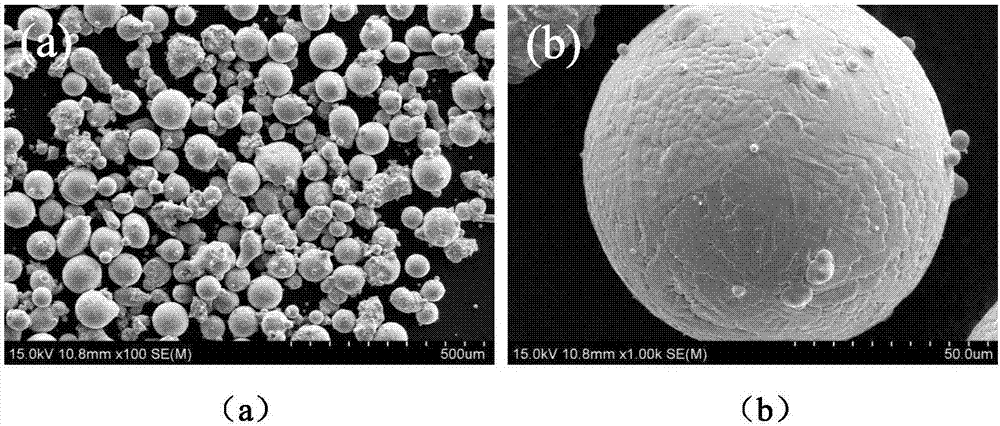

[0047] (2) Cladding layer material selection: the cladding layer is selected from powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com