Patents

Literature

100results about How to "Excellent corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-nitrogen austenitic stainless steel

InactiveUS20060034724A1High strengthExcellent corrosion resistanceAustenitic stainless steelAl content

This invention provides a high-nitrogen austenitic stainless steel superior to the conventional one both in the corrosion resistance and strength, despite a low Ni content, characterized in having a Fe content of 50% by mass or more; containing Cr: 15.0% by mass to 35.0% by mass, Mo: 0.05% by mass to 8.0% by mass %, Mn: 0.2% by mass to 10.0% by mass, Cu: 0.01% by mass to 4.0% by mass and N: 0.8% by mass to 1.5% by mass, both ends inclusive, having a C content of 0.20% by mass or less, a Si content of 2.0% by mass or less, a P content of 0.03% by mass or less, a S content of 0.05% by mass or less, a Ni content of 0.5% by mass or less, an Al content of 0.03% by mass or less, and an 0 content of 0.020% by mass or less; wherein the contents of Cr, Mo, N and Mn are adjusted so that a compositional parameter η expressed by the equation: η≡(WCr+3.3WMo+16WN) / WMn where WCr is Cr content (% by mass), WMo is Mo content (% by mass) WN is N content (% by mass) and WMn is Mn content (% by mass) has a value of 5 or above. and optionally further containing either one of, or both of: W: 0.01% by mass to 1.0% by mass; and Co: 0.01% by mass to 5.0% by mass, both ends inclusive; and optionally further containing at least one of: Ti: 0.01% by mass to 0.5% by mass; Nb: 0.01% by mass to 0.5% by mass; V: 0.01% by mass to 1.0% by mass; and Ta: 0.01% by mass to 0.5% by mass, both ends inclusive; and optionally further containing at least one of: B: 0.001% by mass to 0.01% by mass; Zr: 0.01% by mass to 0.50% by mass; Ca: 0.001% by mass to 0.01% by mass; and Mg: 0.001% by mass to 0.01% by mass, both ends inclusive; and optionally further containing either one of, or both of: Te: 0.005% by mass to 0.05% by mass; and Se: 0.01% by mass to 0.20% by mass, both ends inclusive.

Owner:DAIDO STEEL CO LTD

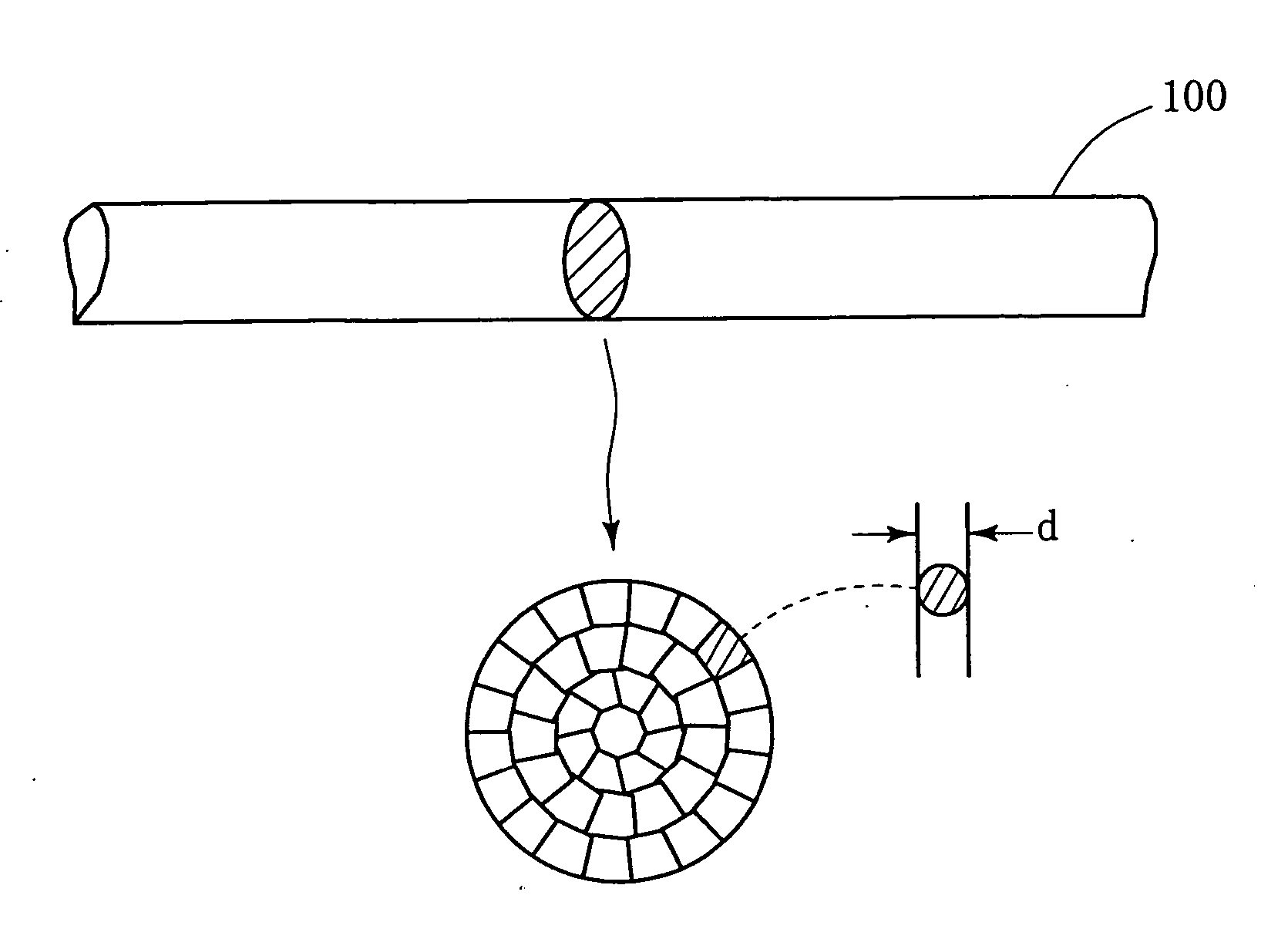

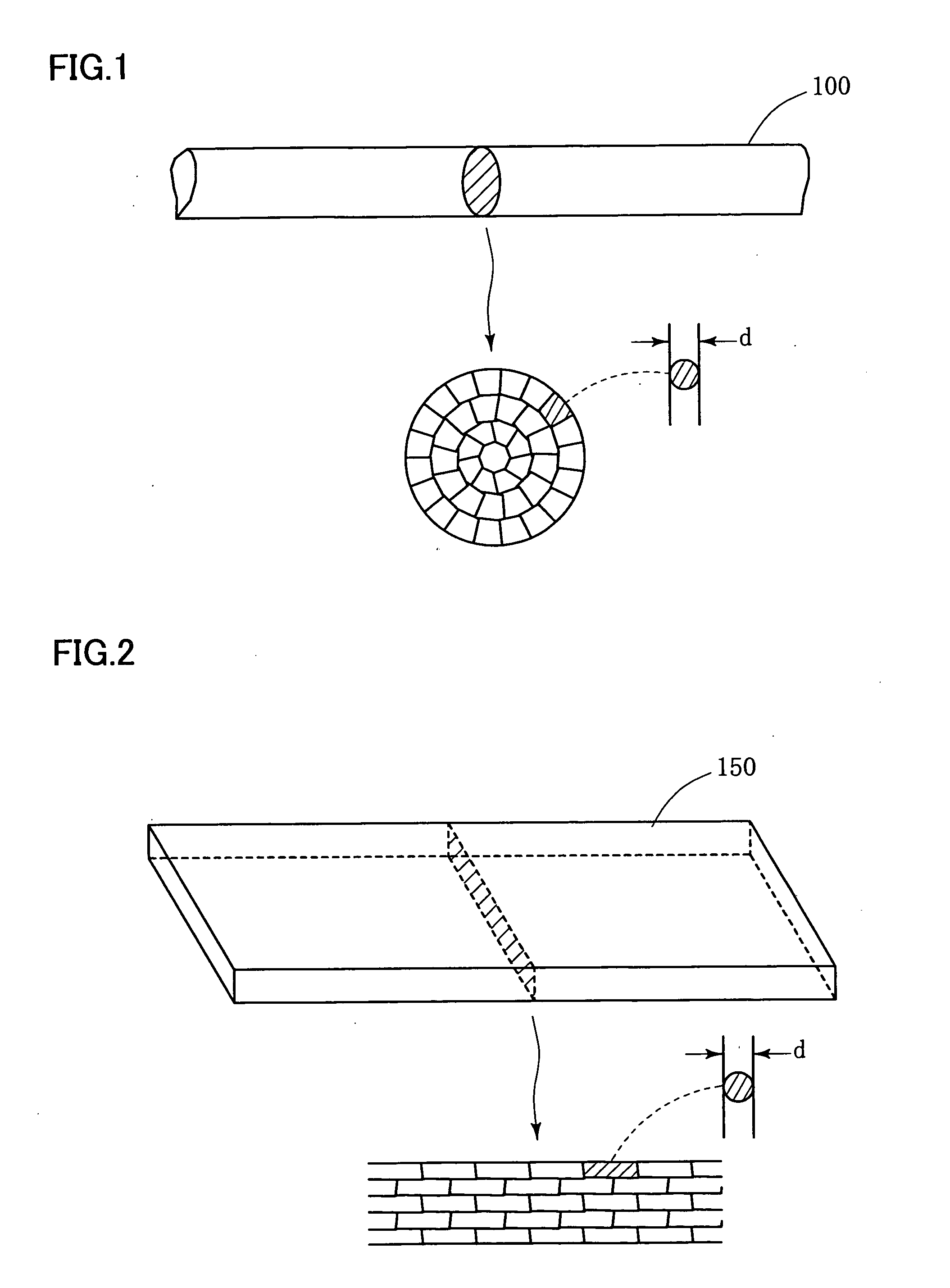

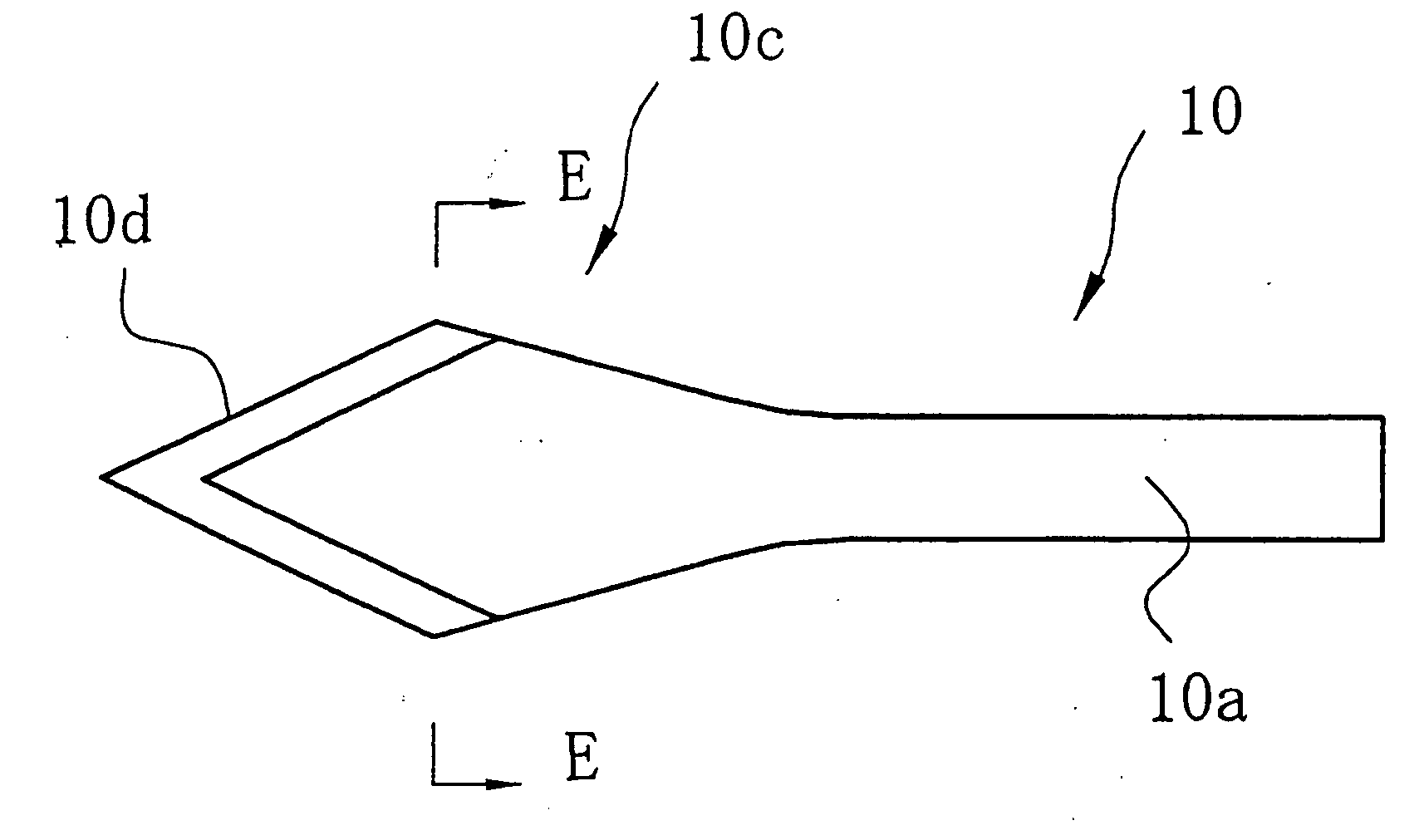

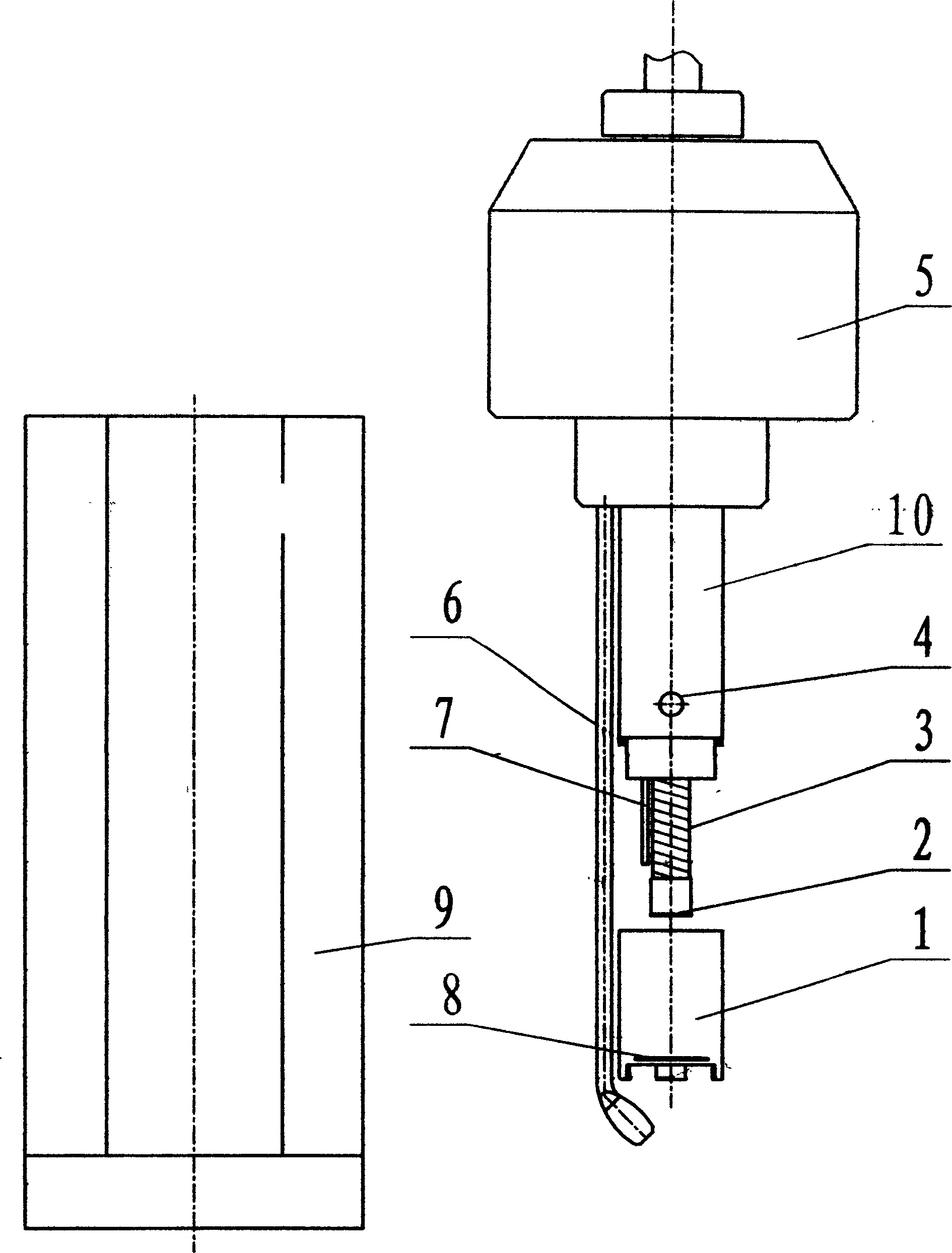

Medical knife

ActiveUS20070179515A1Excellent corrosion resistanceSufficient hardness and sharpnessIncision instrumentsEye surgeryCorrosion resistantAustenitic stainless steel

A work 10 made of a hard wire rod of austenitic-stainless steel is pressed at a rolling reduction of 60% or greater, into a paddle-shaped end 10b, and then subjected to work hardening, making the hardness of the end 10b 550 Hv or greater. Afterwards, the paddle-shaped end 10b is cut through machining, forming a main body 10c of a medical knife and cutting blades 10d. As a result, a medical knife, which is easily fabricated, is corrosion resistant, has sufficient hardness and sharpness, high toughness preventing cracks, can be provided.

Owner:MANI INC

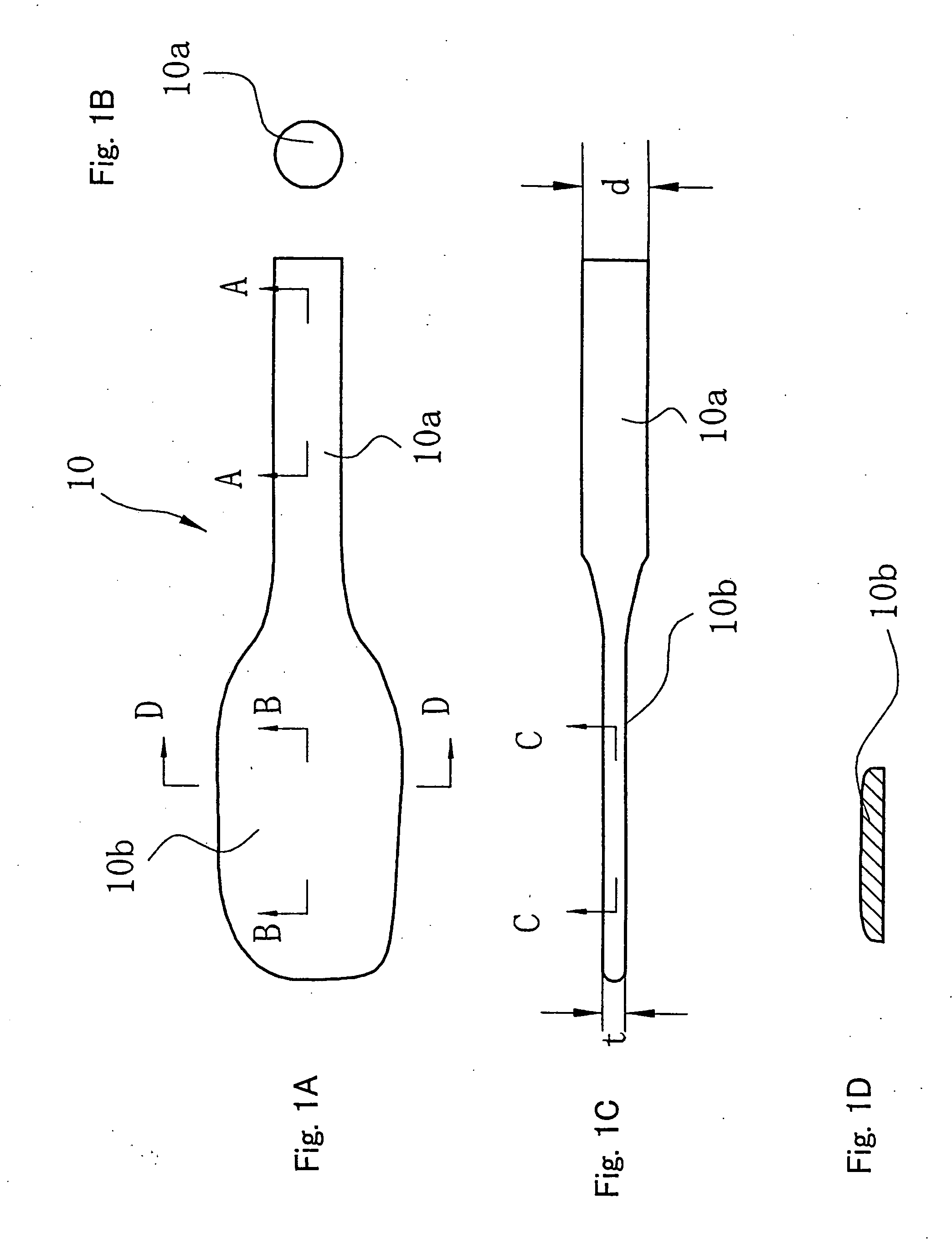

Perpendicular magnetic record medium and magnetic storage system

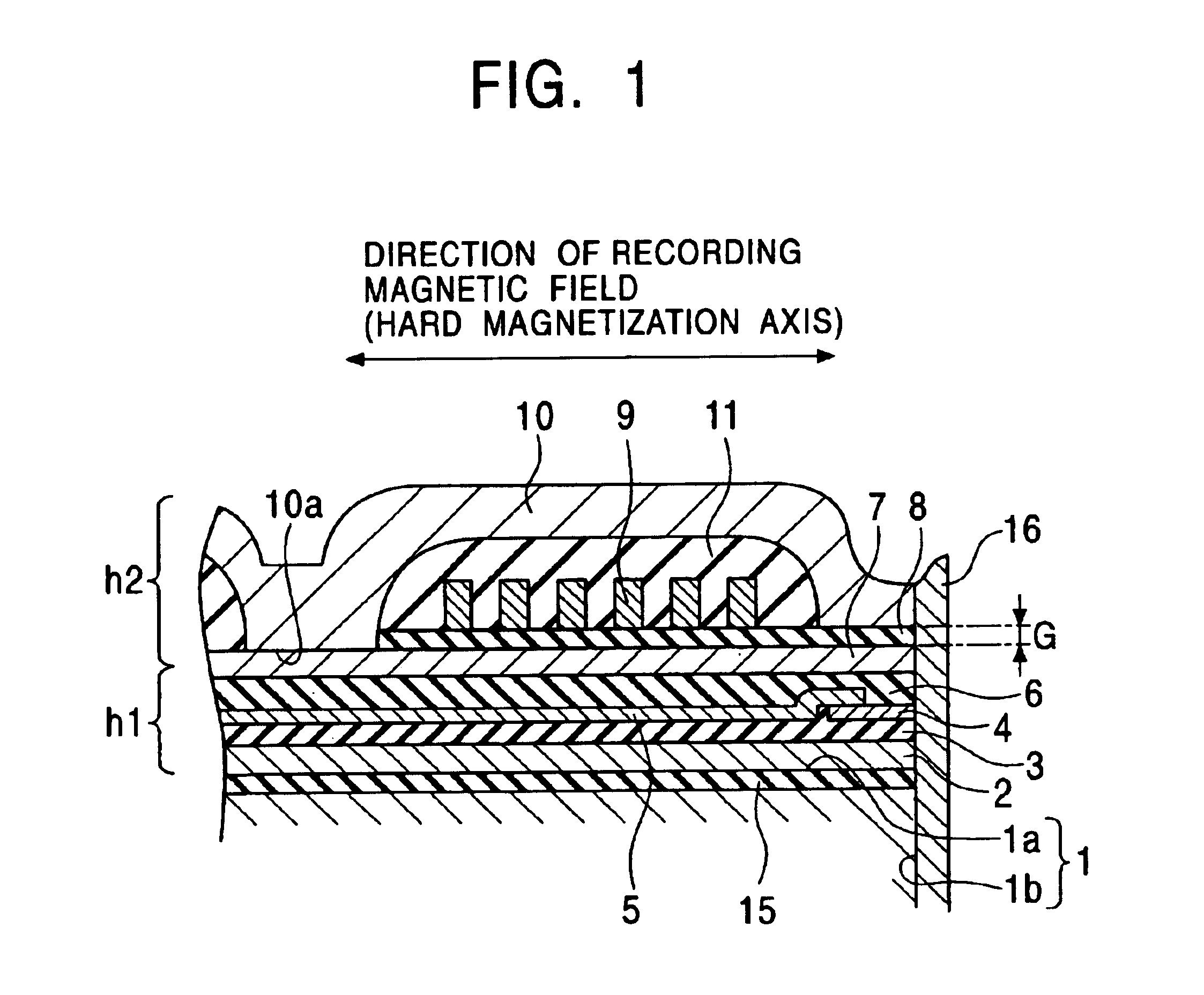

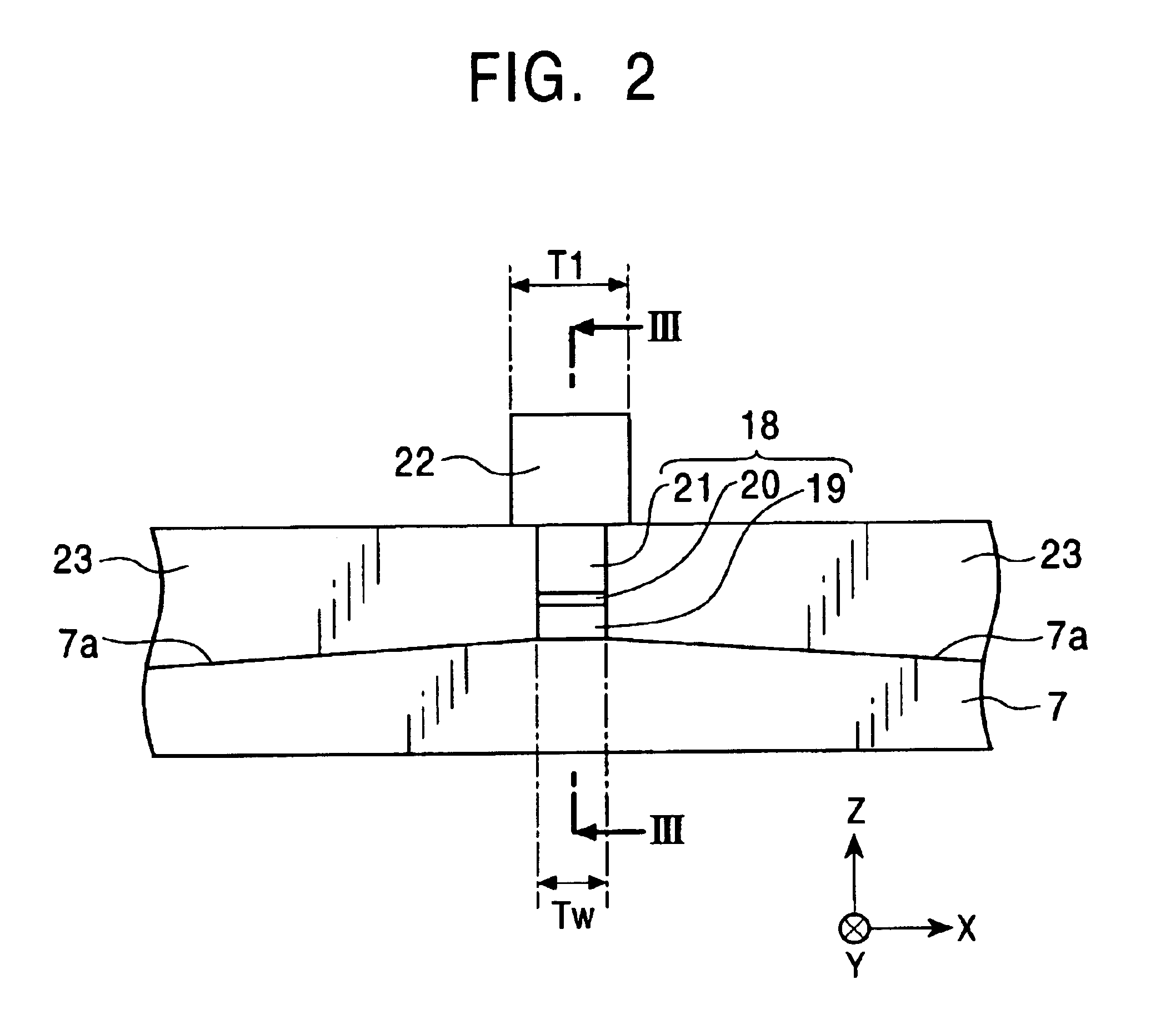

InactiveUS20070153419A1Excellent corrosion resistanceIncrease heightDifferent record carrier formsRecord information storagePhysicsMagnetic storage

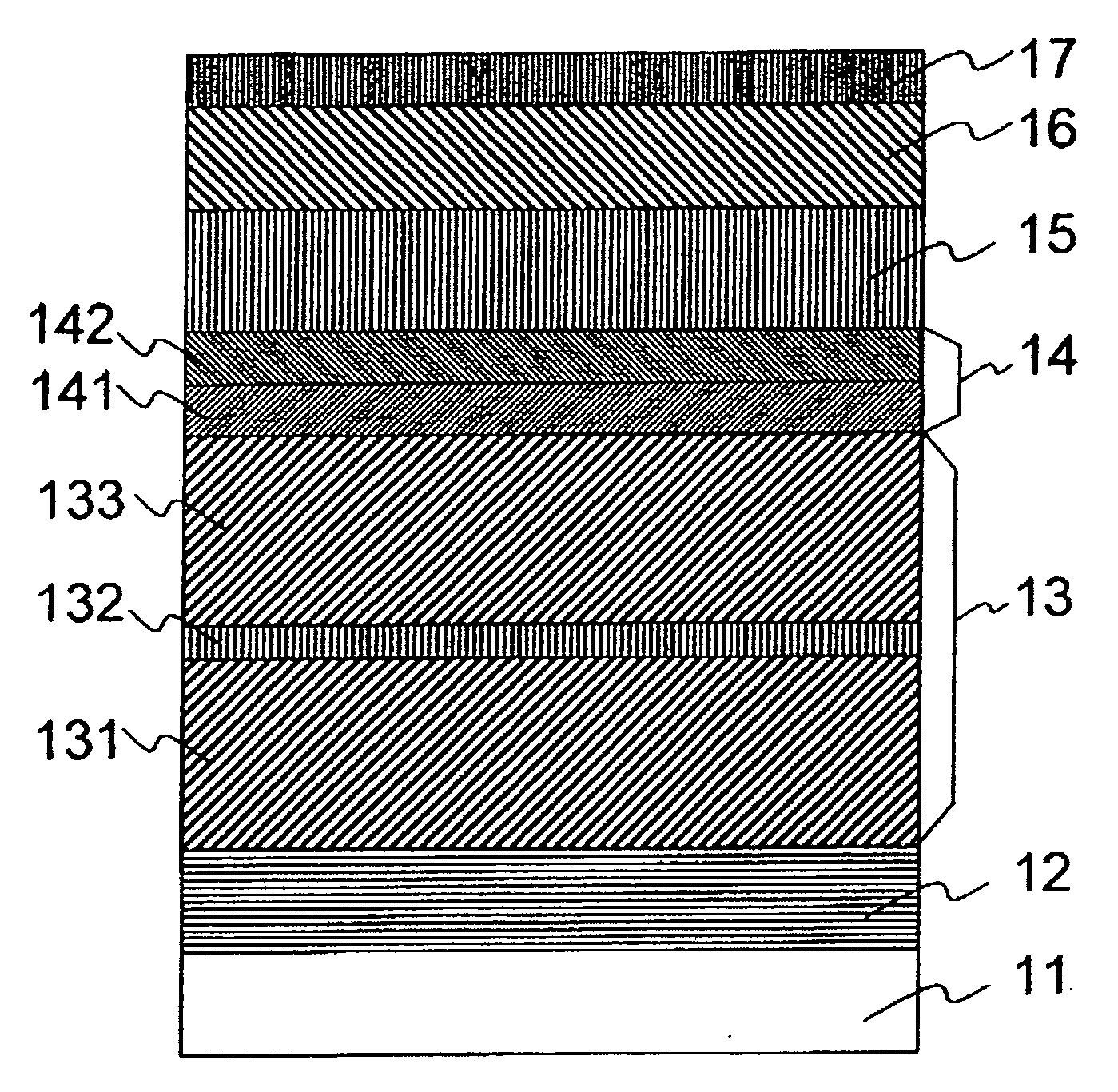

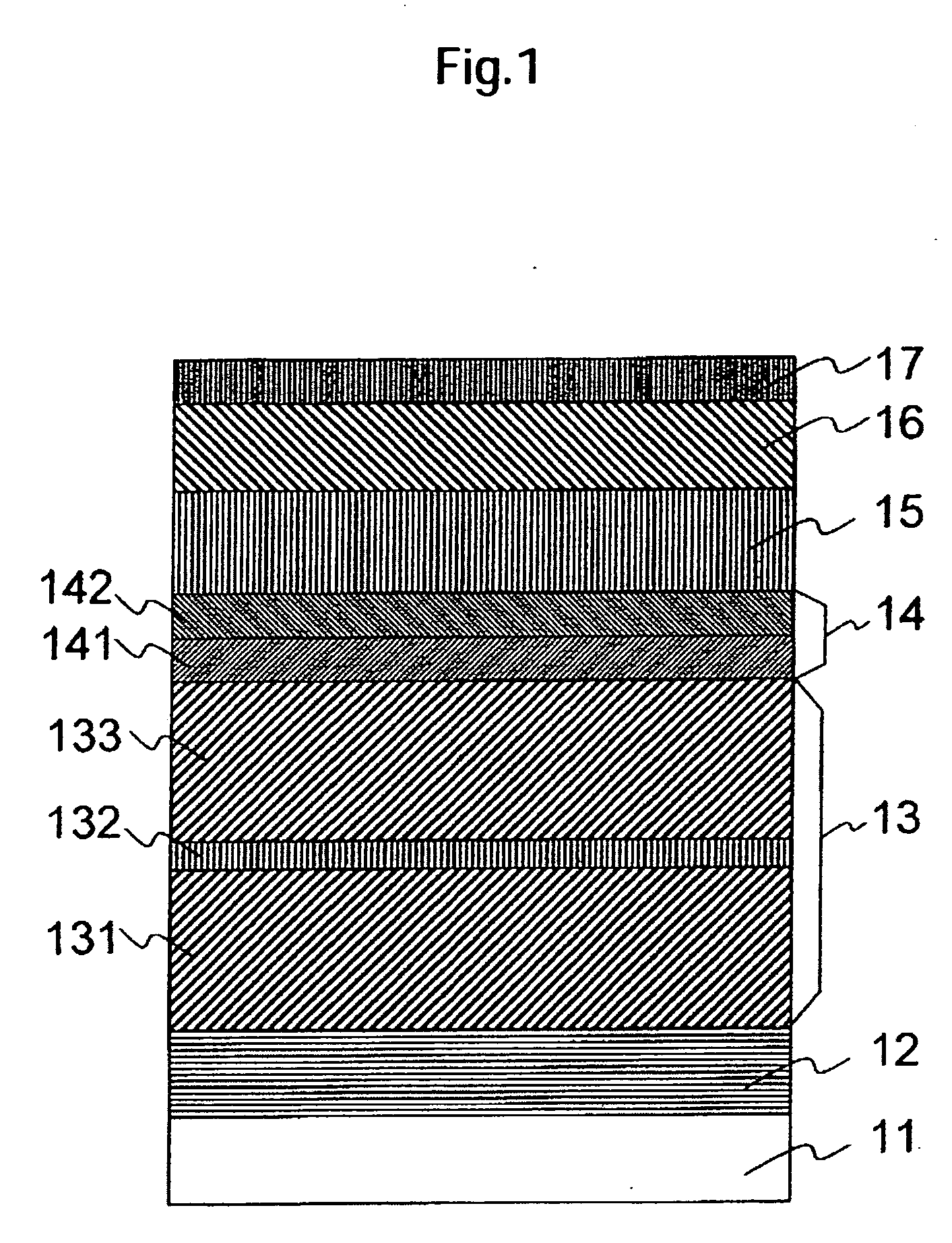

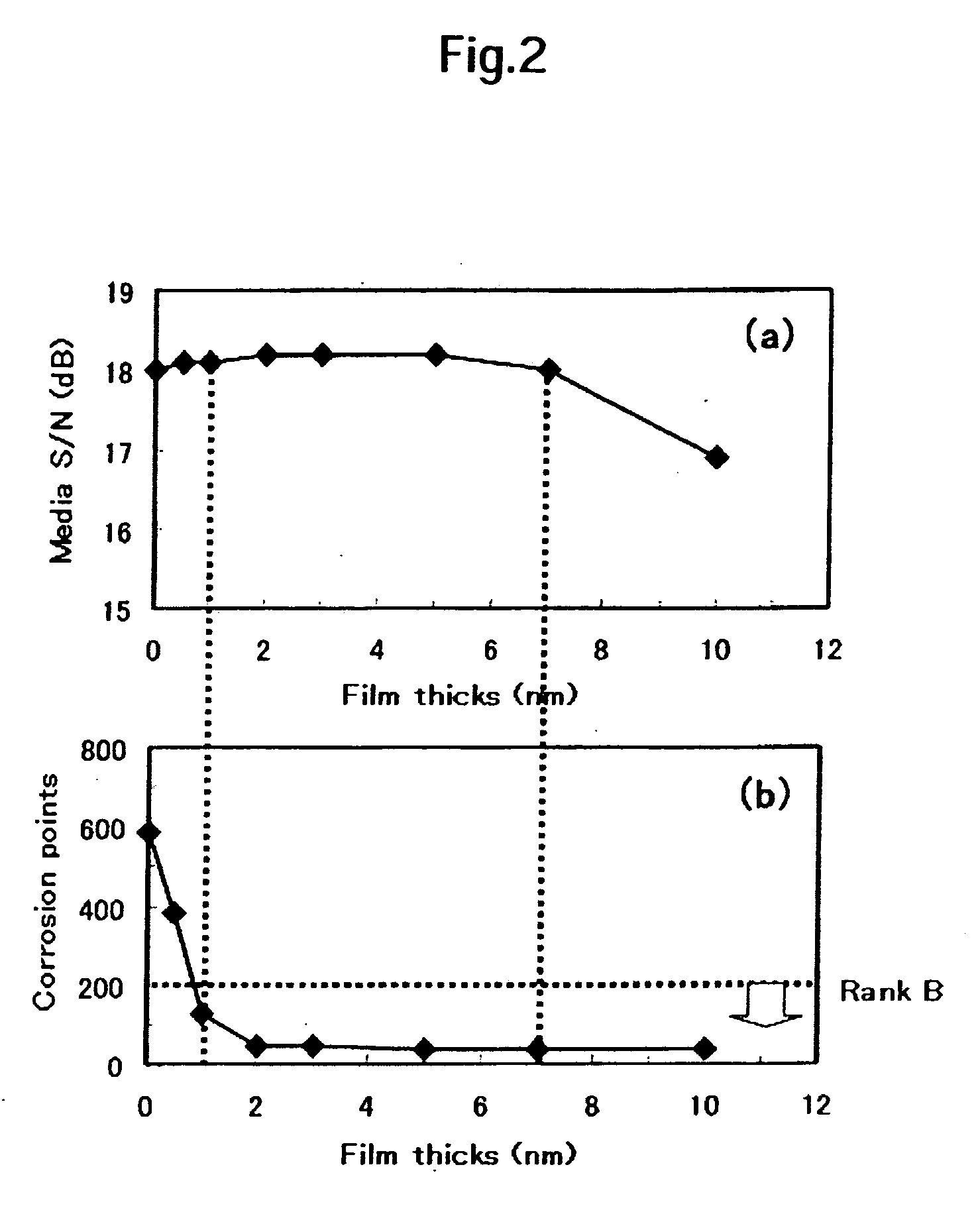

Embodiments in accordance with the invention realize a perpendicular magnetic record medium with a high media S / N and excellent corrosion resistance. In a perpendicular magnetic record medium in accordance with an embodiment of the present invention prepared by forming an adhesion layer, an underlayer, a seed layer, an intermediate layer, and a recording layer sequentially on a substrate, the seed layer is specified to have a laminated structure consisting of a first seed layer and a second seed layer. The first seed layer consists of an amorphous alloy containing Cr and the second seed layer consists of an amorphous alloy predominantly composed of Ni with an fcc structure.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

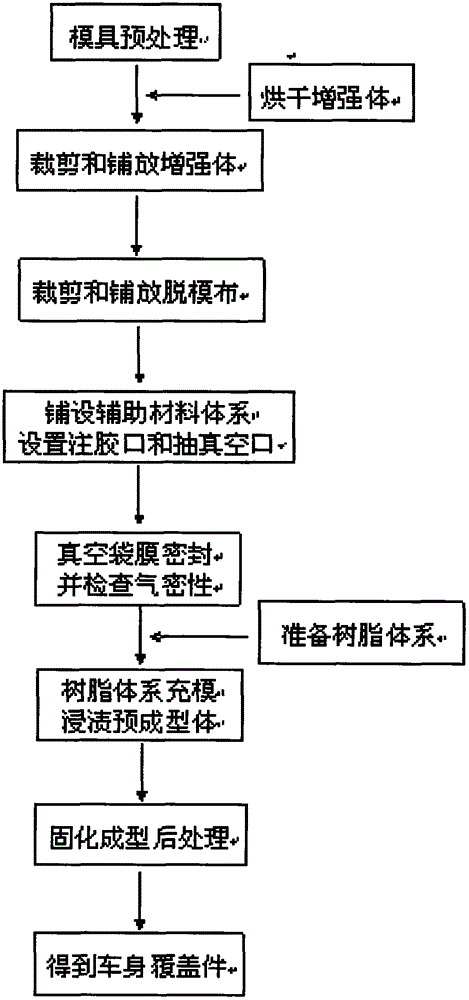

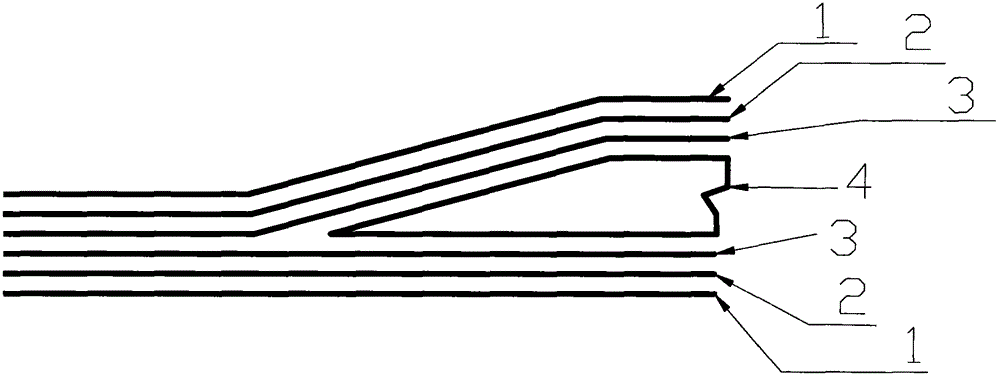

Carbon fiber hybrid resin-base composite material foam sandwich structure and preparation technique thereof

InactiveCN102744889ALow densityExcellent corrosion resistanceSuperstructure subunitsCorrosionMoisture resistance

The invention discloses an automobile body cover part. A vacuum introduction molding technique is utilized to form a carbon fiber hybrid resin-base composite material foam sandwich structure composite material. The carbon fiber hybrid reinforcing body comprises 60-90% (volume) of carbon fiber and 10-40% (volume) of glass fiber or second organic fiber. The invention can be used for obtaining an automobile body cover part which has the advantages of low density, high strength, high rigidity, high shock resistance, excellent fatigue property, excellent moisture resistance, excellent corrosion resistance, favorable surface effect and the like. The invention greatly prolongs the service life, enhances the safety and reliability, and saves the cost.

Owner:INNER MONGOLIA JINGANG HEAVY IND

Composition and process for treating surfaces or light metals and their alloys

InactiveUS6485580B1Excellent corrosion resistanceExcellent paint adhesionSolid state diffusion coatingCorrosion resistantConversion coating

Owner:NIHON PARKERIZING

Low-temperature nickel-based solder for soldering

InactiveCN101898283AExcellent high temperature strengthExcellent corrosion resistanceWelding/cutting media/materialsSoldering mediaDecompositionNitrogen

The invention discloses low-temperature nickel-based solder for soldering. The nickel-based solder based on a NiCrSiP system comprises the following components by weight percentage: 21.5%-28% of Cr, 2.0%-3.5% of Si, 7.0%-9.0% of P and 59.5%-69.5% of Ni. The solder of the invention is superior to BNi-5 solder in both high-temperature strength and corrosion resistance, and the nickel-based solder is applicable to both the vacuum-soldering method and the method for soldering in a continuous soldering furnace under the protective atmosphere (such as nitrogen and ammonia decomposition atmosphere) and particularly suitable for soldering the metal carriers (stainless steel materials) in the automobile exhaust purifiers and automobile EGR (exhaust gas recirculation) system, thus absolutely substituting the existing BNi-5 solder.

Owner:李昕

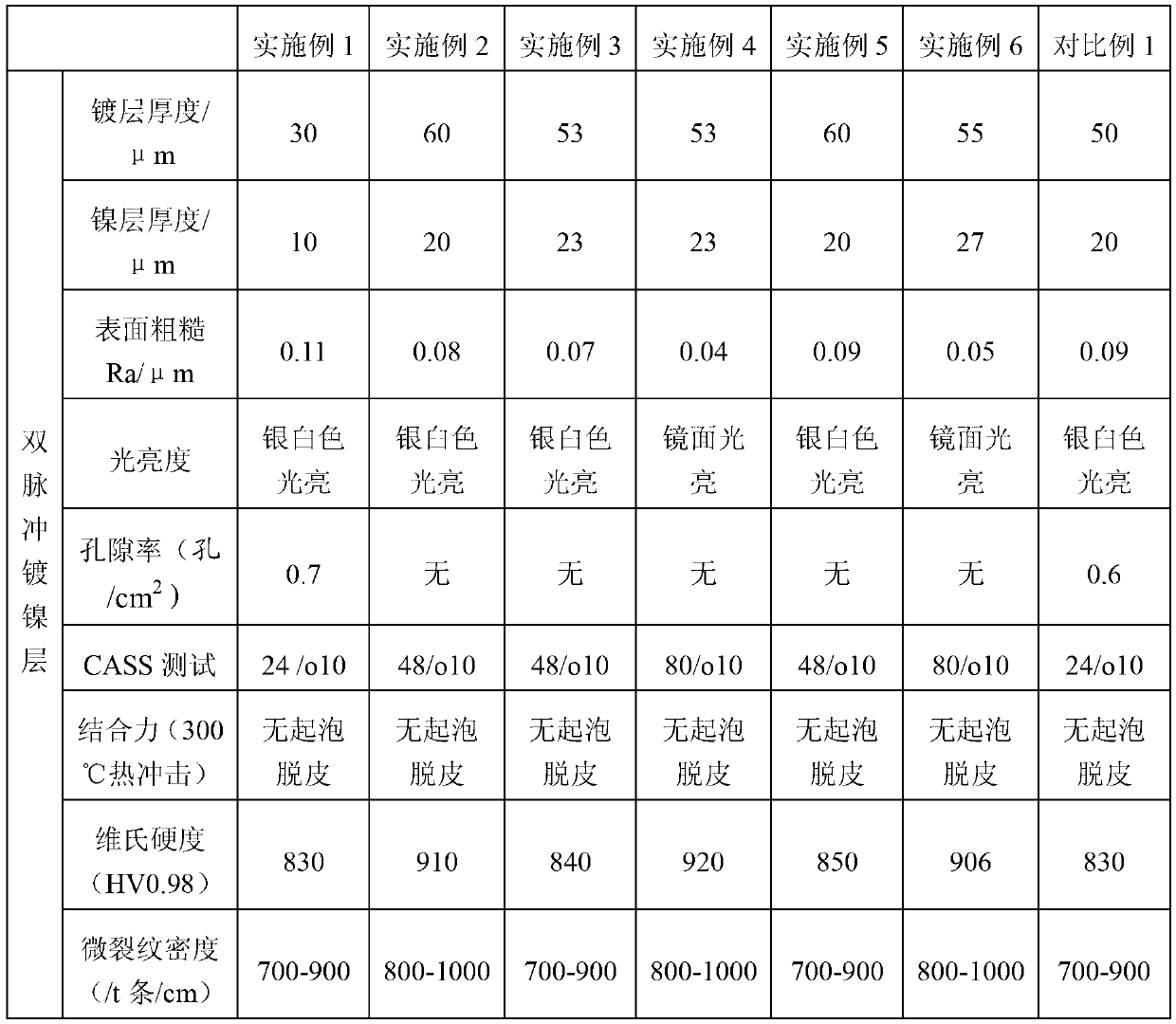

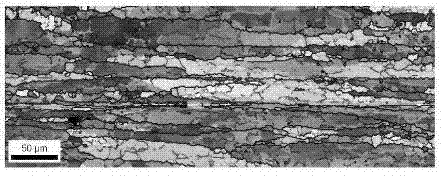

Wear-resistant worpiece and manufacturing method of wear-resistant coating thereof

The invention discloses a wear-resistant workpiece and a manufacturing method of a wear-resistant coating thereof. The preparation method of the wear-resistant coating comprises the following steps: forming a preparation piece according to the structure of a required wear-resistant workpiece; coating nickel on the surface of the preparation piece through a double-pulse method, thus forming a nickel-coated transition piece; and coating a hard chromium layer on the surface of the nickel-coated transition piece, thus forming the wear-resistant coating on the surface of the preparation piece. For the manufacturing method of the wear-resistant workpiece, a step of coating nickel on the surface of the workpiece through a double-pulse nickel coating method is added; and the double-pulse nickel coating method is characterized in that the magnitude of current or voltage is regulated by an external control means, the current is additionally controlled by controlling the pulse switch-on time, the pulse switch-off time, the pulse duty factor, the pulse current density and the like, and corresponding variables are changed to respectively achieve the effects of increasing the cathode current density, inhibiting the generation of side reaction, reducing the impurity content in the coating, improving the current distribution and the like, thus improving the quality of the coated nickel layer and prolonging the service life of the wear-resistant workpiece.

Owner:HUNAN TELI HYDRAULIC +1

Industrial waste residue activating grinding aid

InactiveCN1451624APromotes hydration activityAchieve clinker effectOther chemical processesSolid waste disposalBiochemical engineeringElectric consumption

An activating grinding aid for industrial waste residues is prepared from catalyst (1-8 wt.%), activating agent (30-80 wt.%), setting regulator (0-20 wt.%), grinding aid (3-12 wt.%) and carrier (3-30wt.%). Its advantages are effective use of industrial waste residues, low electric consumption of grinder, and improve cement performance.

Owner:尹小林

Solid-phase sintering silicon carbide bulletproof ceramic and preparation method thereof

The invention relates to a preparation method of silicon carbide ceramic, and particularly relates to solid-phase sintering silicon carbide bulletproof ceramic and a preparation method thereof. The silicon carbide bulletproof ceramic comprises the following raw materials by weight percent: 70-90% of submicron alpha-silicon carbide, 0.1-5% of boron carbide, 4-20% of resin and 5-20% of organic binder, wherein the density of the solid-phase sintering silicon carbide bulletproof ceramic is 3.14-3.16 g / cm<3>; the relative density is 97-98%; the three-point bending strength is 480-560 Mpa. The preparation method of the solid-phase sintering silicon carbide bulletproof ceramic comprises the following steps: mixing the raw materials, spray drying, compression molding and vacuum sintering. The technical scheme disclosed by the invention has simple and reasonable craft processes; the production cost can be effectively reduced; the density, the HRA hardness and three-point bending of the product are higher than the performance of the existing solid-phase sintering and reaction sintering silicon carbide ceramic; meanwhile, the corrosion resistance and the surface quality are also superior to those of the product produced by the existing method.

Owner:NINGXIA MACHINERY RES INST

Production formula and production process for fiberglass-reinforced plastic container equipment

InactiveCN102212261AExcellent corrosion resistanceGood anti-static performanceChemistryAging property

The invention provides a production formula and a production process for fiberglass-reinforced plastic container equipment. The preparation raw materials include a surface mat, a chopped strand mat, base-free fiberglass, spray yarns, resins, a curing agent, an accelerator, an anti-static agent and an anti-UV absorbent, wherein the weight ratio of the resins to the accelerator to the curing agent is 100: (1-3): (1-3), and the optimal weight ratio of the resins to the accelerator to the curing agent is 100: 1: 1. The lining forming process adopts an injection molding process; the demoulding process adopts a pneumatic ejection demoulding method; the inner lining butting process is performed by trimming, affixing of a support plate and precise alignment treating; the inner lining in the winding process is subjected to charging supporting and pressing; and the winding process uses 360-degree all-round three-dimensional envelope winding. The fiberglass-reinforced plastic container equipment provided by the invention has the advantages of excellent corrosion resistance, good anti-static property, excellent anti-aging property, long service life and so on.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

High-strength high-toughness Al-Mg-Si-Cu wrought aluminum alloy and preparation method thereof

The invention relates to high-strength high-toughness Al-Mg-Si-Cu wrought aluminum alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 0.6-1.5wt% of Mg, 0.8-1.6wt% of Si, 0.2-0.8wt% of Cu, 0.2-1.0wt% of Mn, 0.1-0.4wt% of Cr, 0.01-0.1wt% of Ti, not more than 0.25wt% of Fe, not more than 0.15wt% of all inevitable impurities and the balance of Al. The preparation method of the alloy comprises the following steps of: preparing an alloy cast ingot by adopting a semi-continuous casting mode; then homogenizing: heating the cast ingot along with a circulating air furnace to 520-570 DEG C, carrying out heat insulation for 4-10 hours, and cooling in air; then carrying out heat processing and heat deformation: carrying out heat processing on the homogenized cast ingot in heat processing equipment, wherein the final heat processing temperature is not lower than 350 DEG C and the strain amount is not lower than 0.5; and finally carrying outheat treatment.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

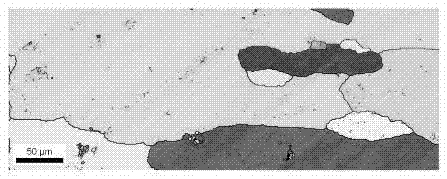

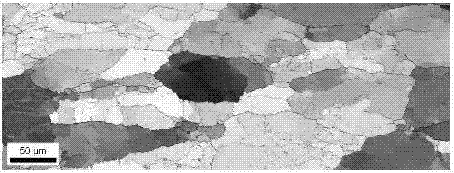

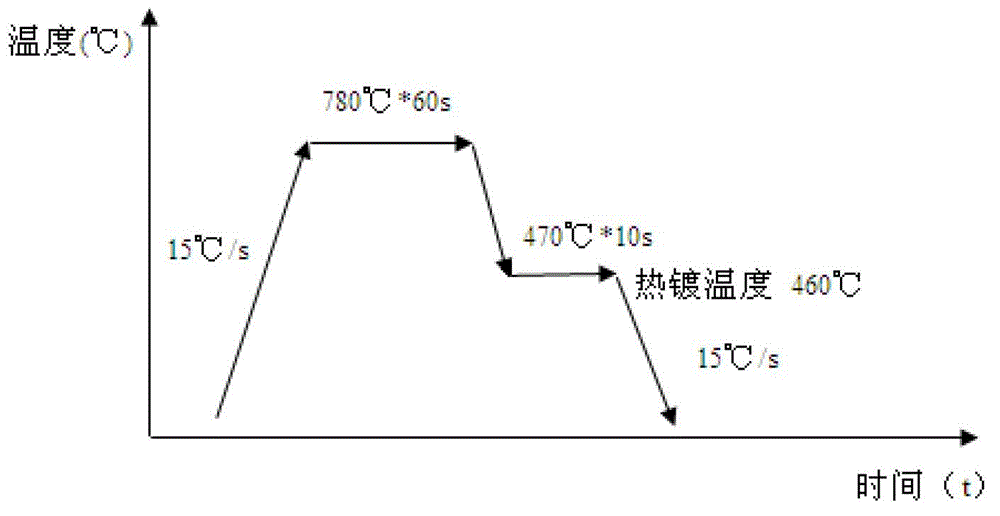

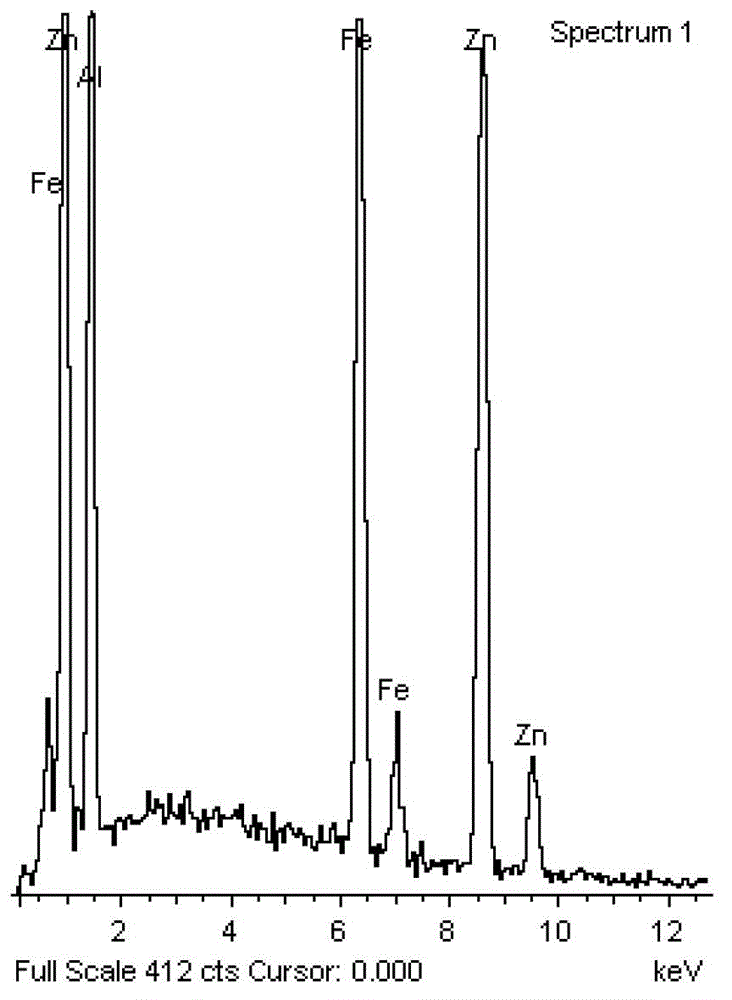

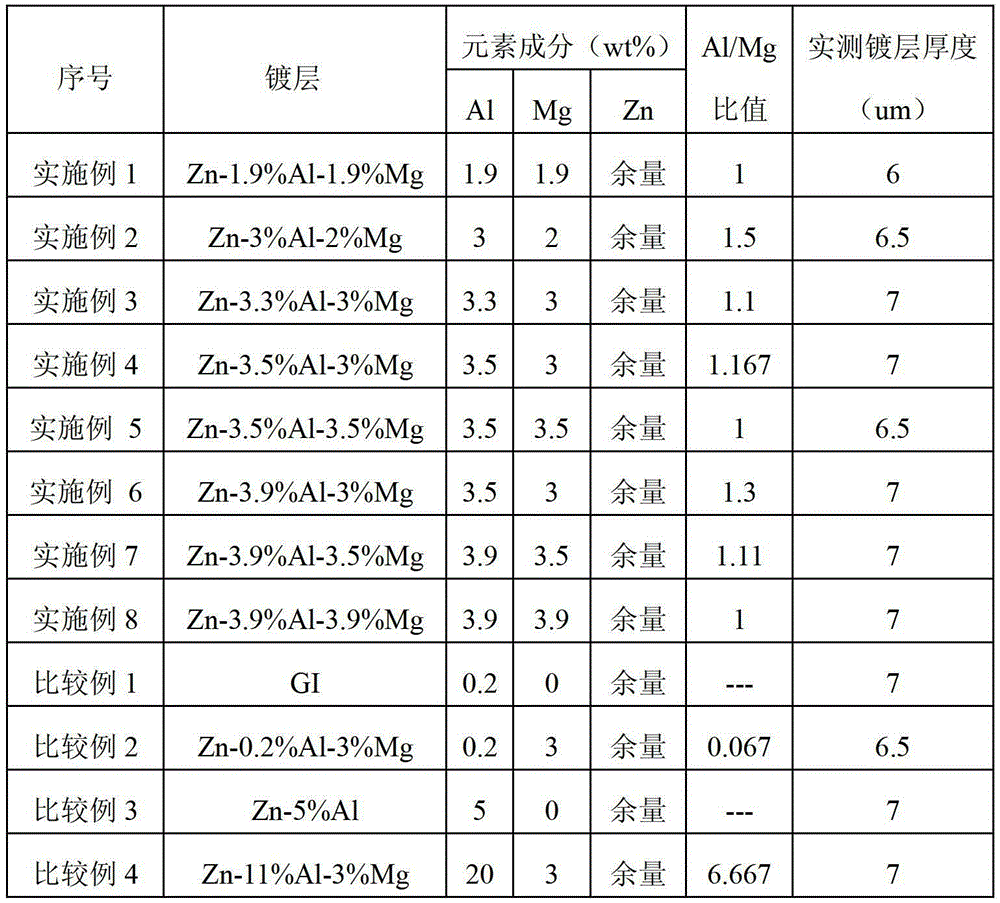

Galvalized aluminum magnesium steel plate and manufacture method thereof

InactiveCN104060209AExcellent corrosion resistanceExcellent qualityHot-dipping/immersion processesSheet steelDross

The invention discloses a galvalized aluminum magnesium steel plate, which comprises a substrate and a coating layer coating on the substrate, the coating layer comprises the following chemical element components: 1.9-3.9wt% of Al, 1.9-3.9wt% of Mg, and the balance of Zn and other inevitable impurities; and the mass percentage of Al to Mg is greater than or equal to 1. The invention also discloses a method for manufacturing the galvalized aluminum magnesium steel plate, which comprises the following steps: 1)manufacturing the substrate; 2)degreasing and cleaning the surface of the substrate; 3)continuously annealing; 4)galvalizing the substrate in a heat galvalizing pool; and 5)galvalizing and cooling. The galvalized aluminum magnesium steel plate has good corrosion resisting performance, clunging performance, weldability and manufacturability, can satisfy the plate usage requirement in automobile industry, building field and household electrical appliance industry, the manufacture method of the galvalized aluminum magnesium steel plate can avoid the scum problem of a plating liquid due to addition of Mg, production cost is reduced, and equipment life is prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD

High-temperature-resistant high-performance alloyed fastener and manufacturing technique thereof

The invention provides a high-temperature-resistant high-performance alloyed fastener comprising following ingredients: 0.42% of C, 0.33% of Si, 0.70% of Mn, 0.030% or less of S, 0.030% or less of P, 1.10% of Cr, 0.025% or less of Ni, 0.025% or less of Cu, 0.20% of Mo, 0.24% of V, and 0.03% of Nb. The invention also provides a manufacturing technique used for production of the alloyed fastener. The manufacturing technique of the high-temperature-resistant high-performance alloyed fastener helps to solve a problem that: manufacturing techniques used for production of alloyed fasteners with a level of 12.9 or above have not been invented in domestic at present. The alloyed fastener produced by the manufacturing technique possesses high strength and hardness which are not possessed by common fasteners, and excellent plasticity, toughness, corrosion resistance, tensile strength, fatigue strength and delayed fracture resistance. The alloyed fastener is capable of ensuring that failures such as break and damage are not easy to happen in manufacturing process and using procedures, and can function normally at a highest temperature of 500 DEG C. Service life of the fastener is extremely prolonged.

Owner:汕头经济特区超艺螺丝工业有限公司

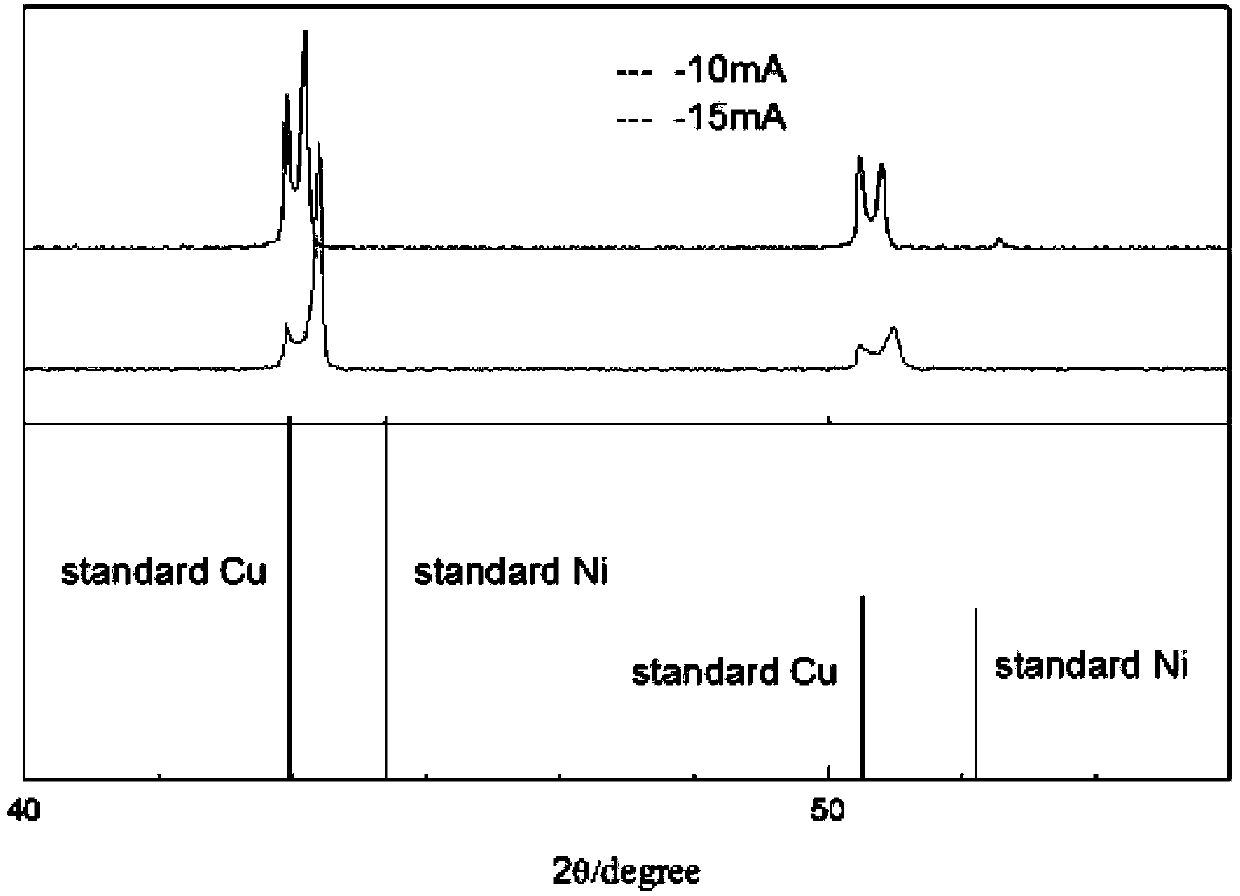

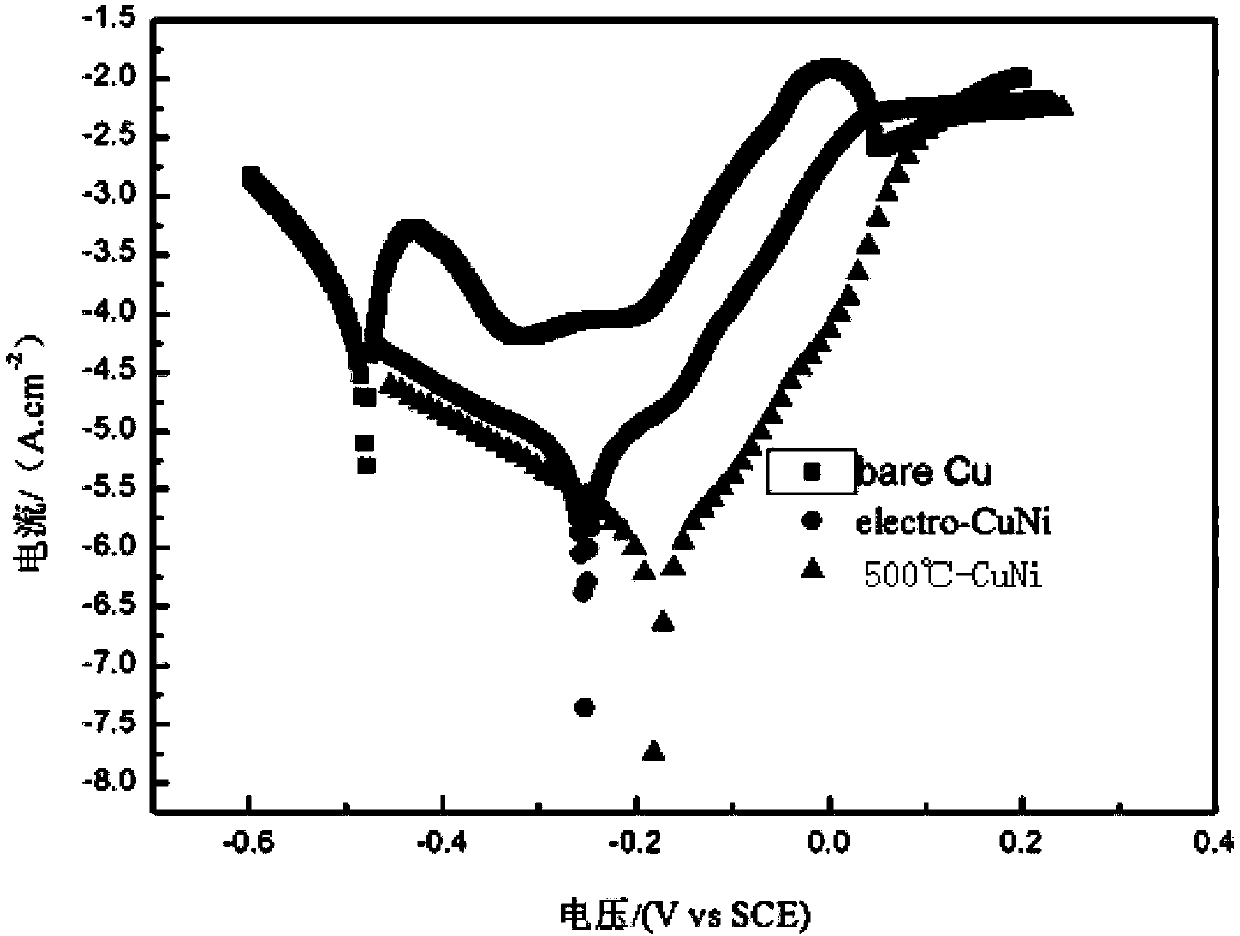

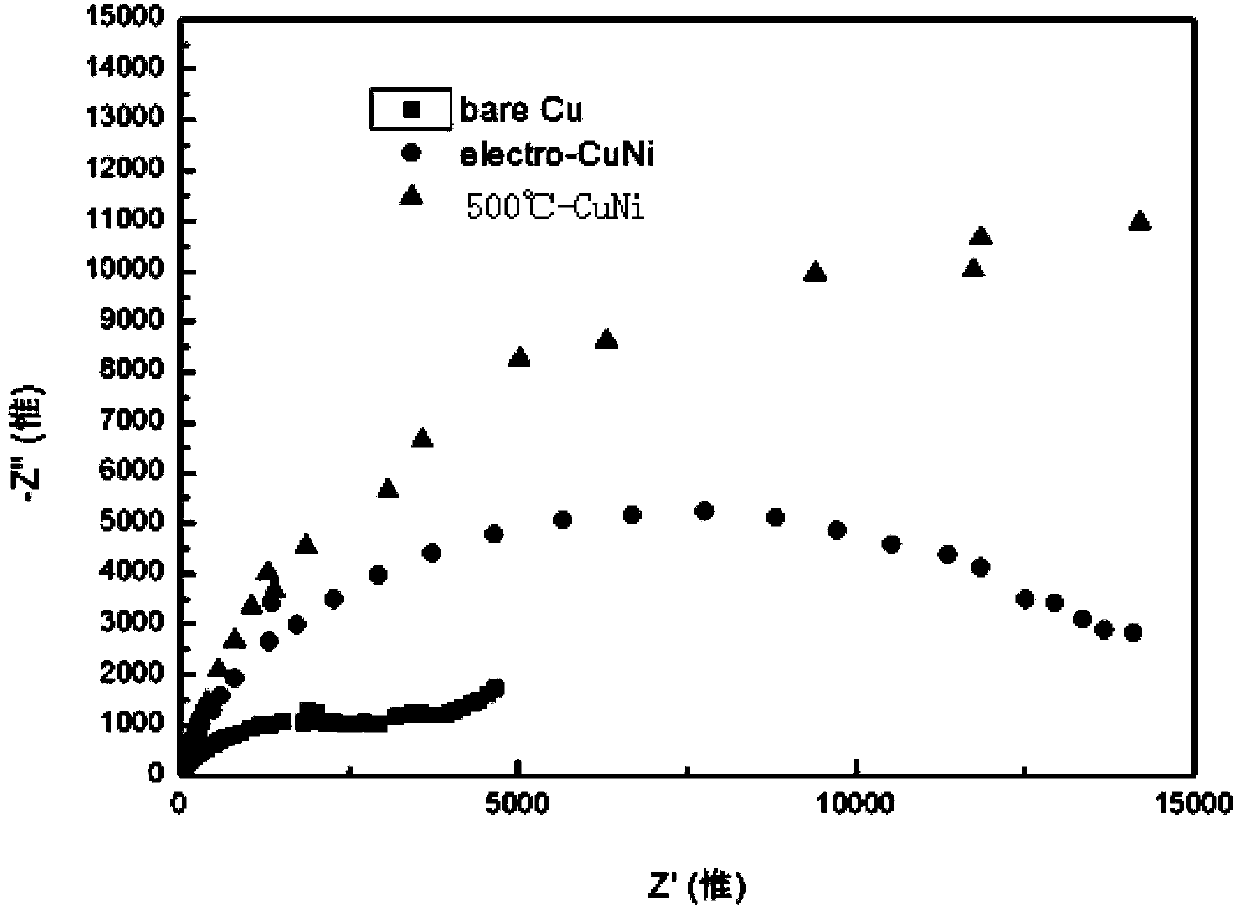

Preparation method of metal surface copper-nickel alloy

The invention discloses a preparation method of a metal surface copper-nickel alloy, which comprises the following steps: (1) metal surface pretreatment; (2) solution preparation; (3) constant-current deposition of copper-nickel alloy; and (4) surface heat treatment. The preparation method has the advantages of simple process, controllable temperature and components, low cost, high efficiency, no pollution and no risk. The electrochemical testing proves that the copper-nickel alloy film has better corrosion resistance than the metal bare sample. The copper-nickel alloy has the advantages of low heat treatment temperature, short holding time and more compact and uniform film; and the electrochemical testing proves that the corrosion resistance is further enhanced.

Owner:OCEAN UNIV OF CHINA

17-4PH steel surface reinforcement method

ActiveCN1844415AMeet the hardness conditionsExcellent corrosion resistanceFurnace typesIncreasing energy efficiencyHardnessSolid solution

The invention provides a method of strengthening 17-4PH steel surfaces; the method can solved the problem as follow: 17-4PH steel often use in two kinds of heat treatment condition as follow: first, solid solution time-effect condition; second, solid solution over aging condition. The first condition, the machine member strength machine member 1200Mpa, stress corrosion trend seriously, general solution method of adopting decrease working efficiency or enlarge the section size of machine member. The second condition, the machine member in low degree of hardness, badly abrasion-resistance, the shortly operating life of equipment. The invention key point as follow: firstly, pre-heating treatment: contain preventing internal break anneal after smith and solid solution + time-effect treatment, then stabilizing treatment; finally, final thermal treatment: contain surface solid solution treatment and surface time-effect treatment. The initiative effect of invention as follow: heating solid solution time-effect treatment though machine member surface induction, the hardness of machine member core less then 33, fitting the hardness condition that the steel utilize in acidic medium; the surface deck hardness 42-45 in the area of 0.8-1.5mm, the deck resistance to corrosion stress cracking function and abrasion-resistance are good.

Owner:SHENYANG BLOWER WORKS GROUP CORP

High-toughness and corrosion-resistant aluminum alloy profile for aerospace and preparation method thereof

ActiveCN108385003AHigh tensile strengthExcellent corrosion resistanceZirconium alloyCorrosion resistant

The invention relates to a high-toughness and corrosion-resistant aluminum alloy profile for aerospace and a preparation method thereof. The problem that an existing aluminum alloy profile can not meet the use requirements of aerospace is solved. The aluminum alloy profile is made from smelting raw materials including Cu, Mg, Zn, Zr and Al, and the aluminum alloy profile made from an aluminum ingot, cathode copper, a primary magnesium ingot, a zinc ingot and an aluminum zirconium alloy ingot by smelting, casting, homogenizing annealing, hot extrusion, quenching, drawing and aging. According tothe high-toughness and corrosion-resistant aluminum alloy profile for the aerospace and the preparation method thereof, by optimizing of alloy composition, controlling of ingot casting quality, multi-stage homogenizing treatment technology, extrusion molding technology, and two-stage quenching and three-stage aging technology of strengthening-toughening heat treatment, the high-toughness and corrosion-resistant aluminum alloy profile is produced, the residual stress of the profile is effectively reduced by increasing the tension straightening quantity, and the subsequent machining precision of the profile is improved. The high-toughness and corrosion-resistant aluminum alloy profile for the aerospace is applied to the field of aluminum alloy profile preparation.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Aluminum-alloy clad material and production method therefor, and heat exchanger using said aluminum-alloy clad material and production method therefor

InactiveUS20160319401A1Excellent corrosion resistanceExcellent thermal conductivityWelding/cutting media/materialsWelding/soldering/cutting articlesCrystalliteCorrosion resistant

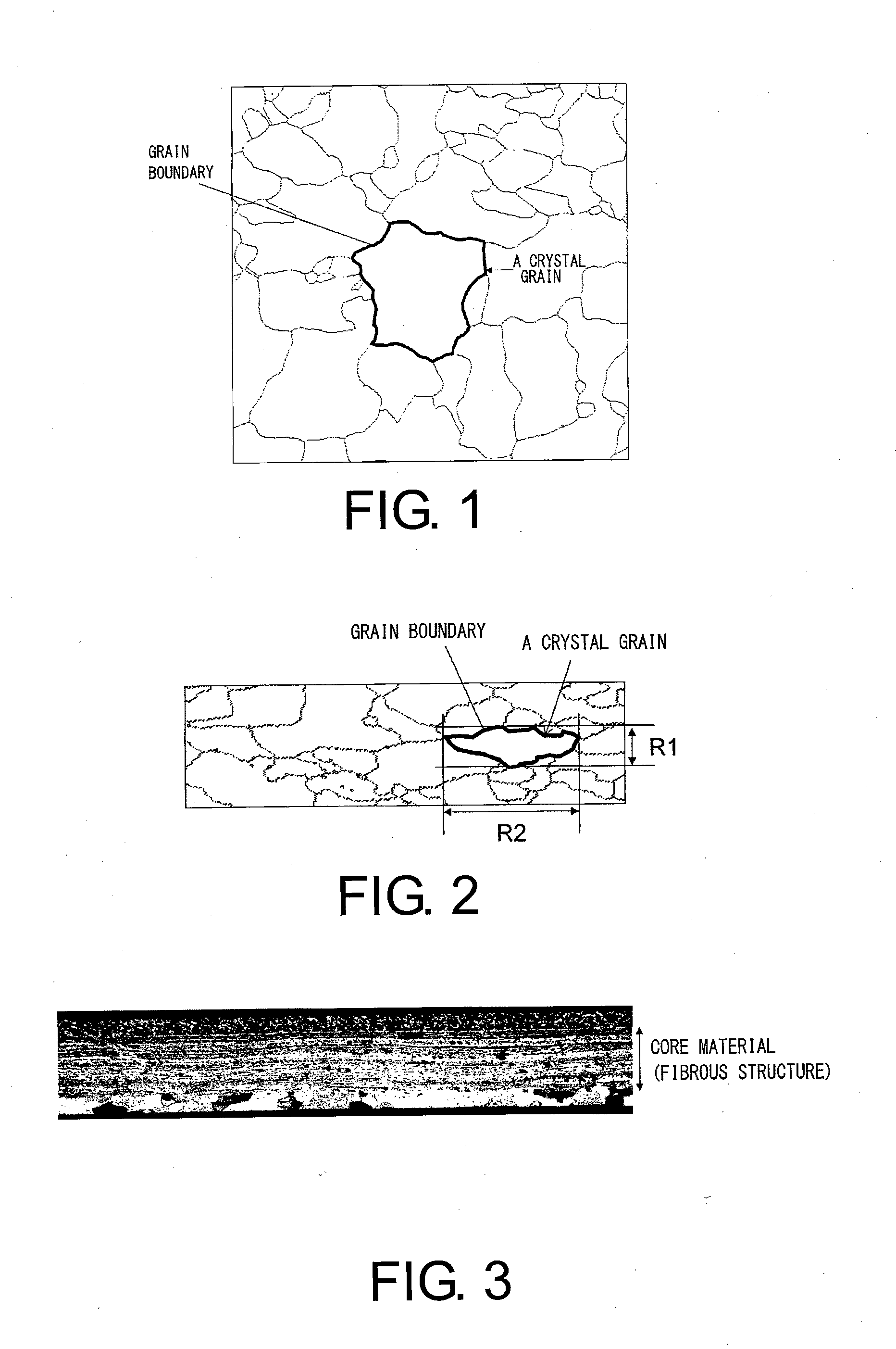

A highly corrosion resistant and highly formable aluminum-alloy clad material, a method for producing the same, a heat exchanger using the same and a method for producing the same are shown. The present aluminum-alloy clad material has an aluminum alloy core material, an intermediate layer material clad on one surface of the core material and a brazing filler metal clad on the surface of the intermediate layer material that is not on the core material side, wherein a crystal grain size of the intermediate layer material before brazing heating is 60 μm or more, and in a cross section of the core material in a rolling direction before brazing heating, when R1 (μm) represents the crystal grain size in a plate thickness direction, and R2 (μm) represents the crystal grain size in the rolling direction, R1 / R2 is 0.30 or less.

Owner:FURUKAWA SKY ALUMINUM CORP

Ultrahigh strength steel wire dip-coated with Zn-Al-Mg-Si alloy coating, preparation method thereof and application thereof

InactiveCN105331918AHigh strengthImprove toughnessHot-dipping/immersion processesHigh intensityAlloy coating

The invention relates to an ultrahigh strength coating steel wire dip-coated with a Zn-Al-Mg-Si alloy coating, a preparation method thereof and an application thereof. The alloy coating consists of the following components in percentage by mass: 30-97% of Zn, 5-80% of Al, 0.02-11% of Mg, and 0.05-5.0% of Si, based on 100% in total. The preparation method comprises the following steps: inspecting performances of an original coil rod; carrying out surface treatment; carrying out wire drawing; preparing a hot dipping Zn-Al-Mg-Si alloy coating; and carrying out stabilization treatment. The ultrahigh strength coating steel wire with the Zn-Al-Mg-Si alloy coating provided by the invention has corrosion resistance and mechanical performance superior to those of a current high-strength zinc-coated steel wire; the preparation method is easy to implement, meets needs of special environments such as a marine corrosion environment and the like on a bridge steel wire, and has a wide market prospect.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

High-strength aluminum alloy extruded material and method for manufacturing the same

InactiveUS20140096878A1Excellent corrosion resistanceExcellent surface qualityHigh intensityAluminium alloy

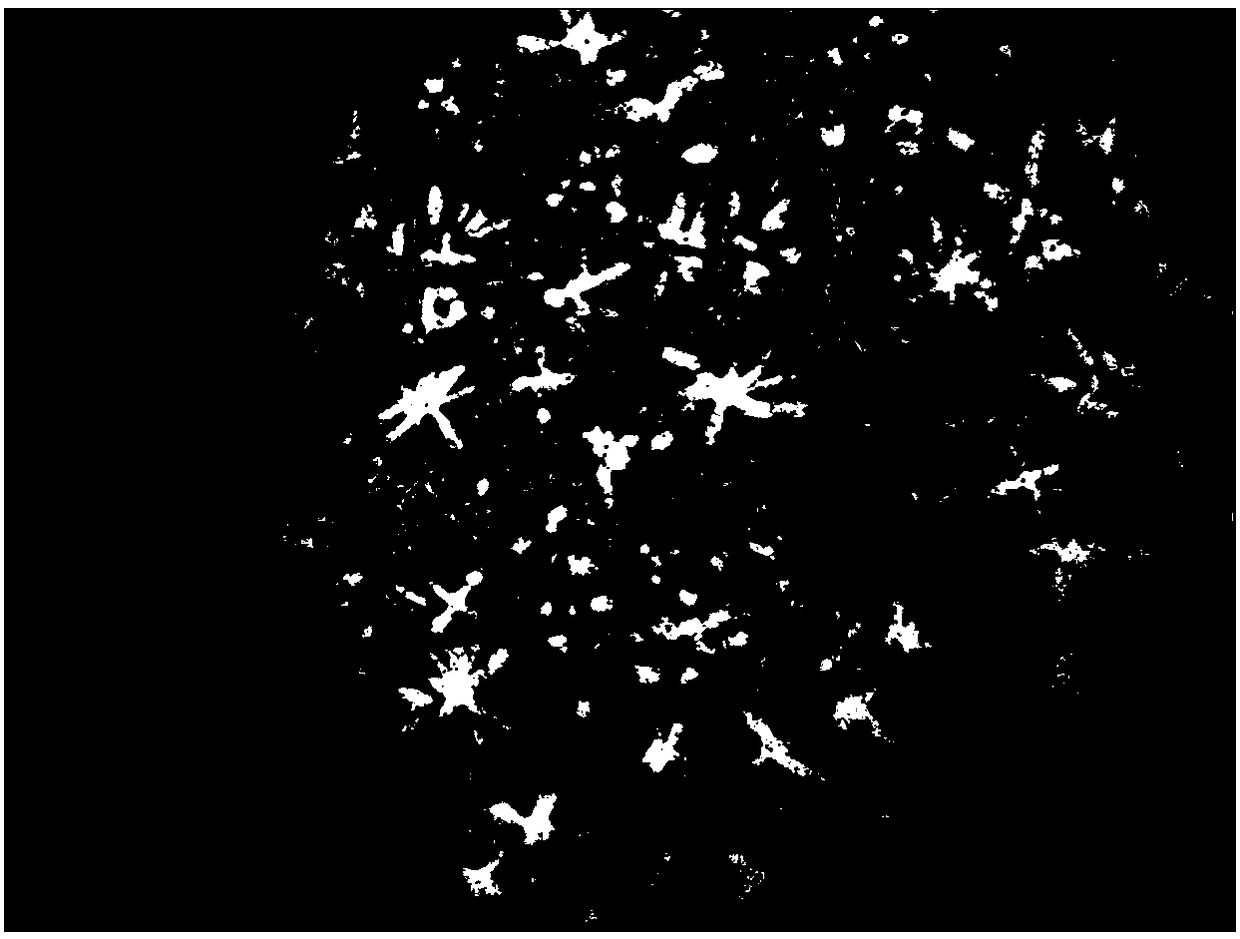

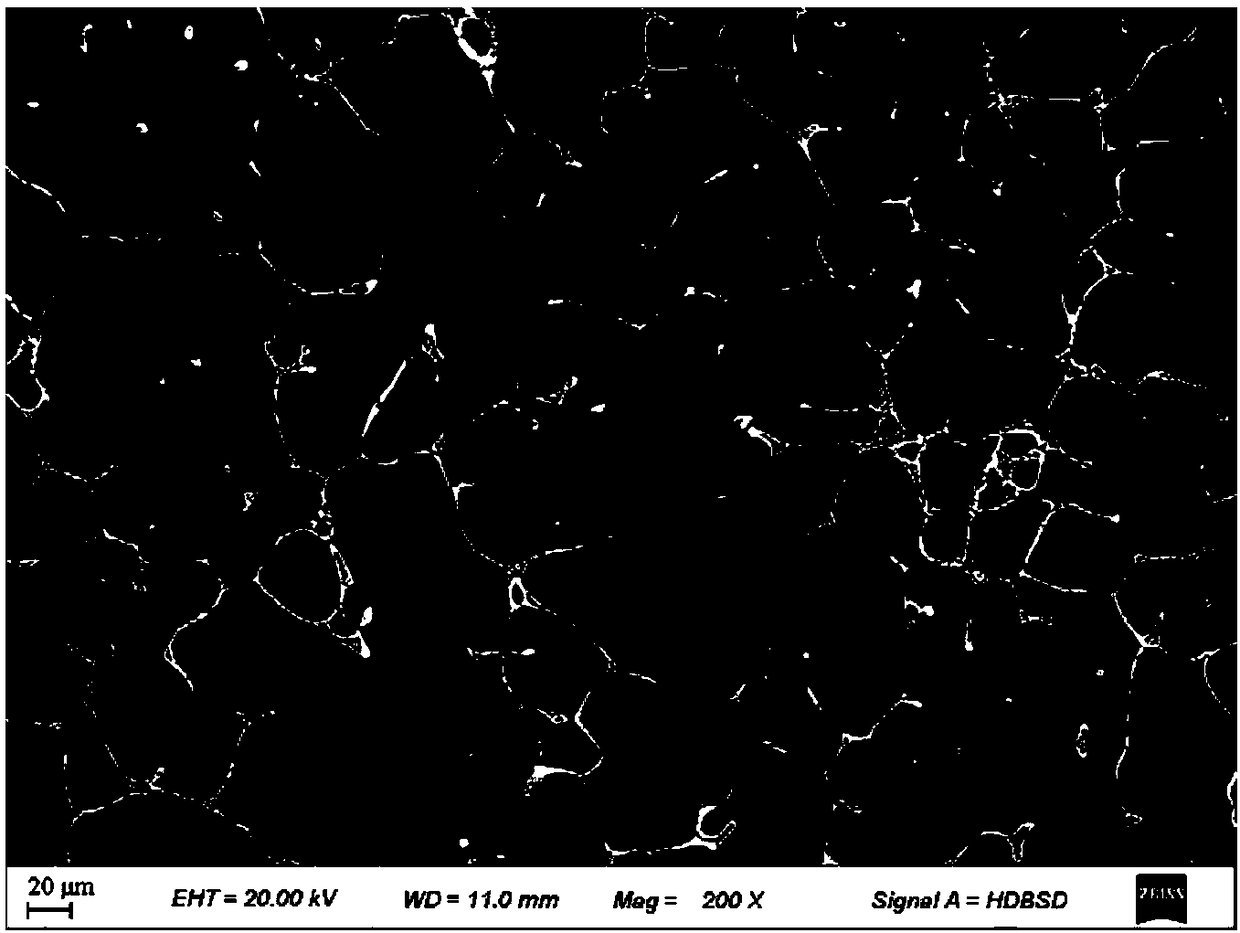

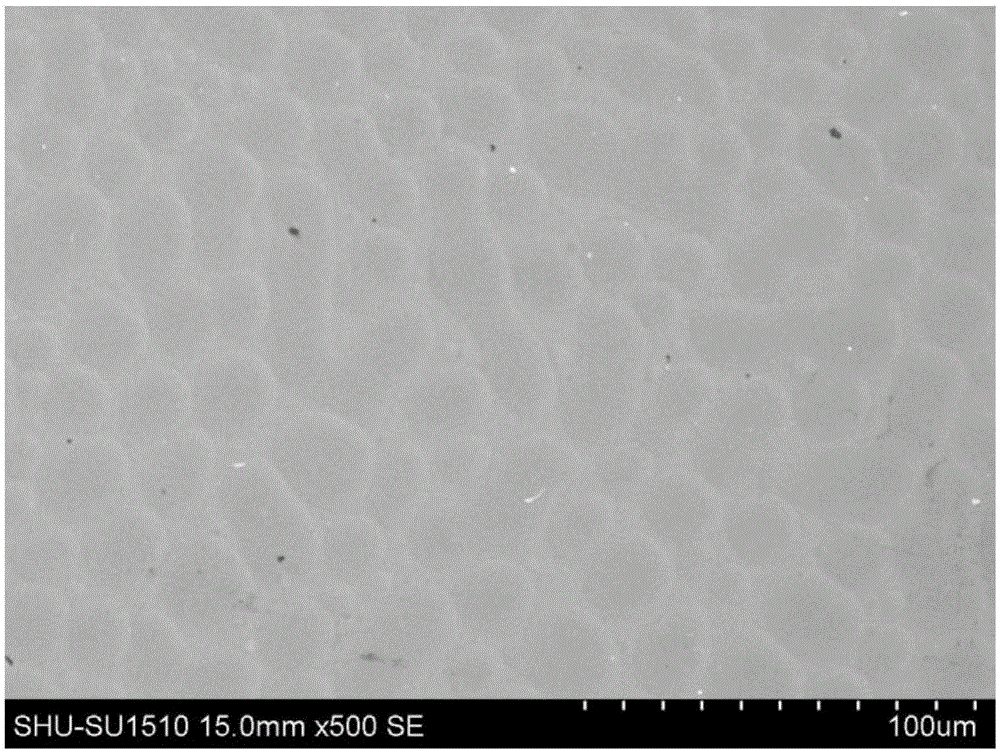

A high-strength aluminum alloy extruded material contains Si: 0.70 to 1.3 mass %; Mg: 0.45 to 1.2 mass %; Cu: 0.15 to less than 0.40 mass %; Mn: 0.10 to 0.40 mass %; Cr: more than 0 to 0.06 mass %; Zr: 0.05 to 0.20 mass %; Ti: 0.005 to 0.15 mass %, Fe: 0.30 mass % or less; V: 0.01 mass % or less; the balance being Al and unavoidable impurities Crystallized products in the alloy have a particle diameter of a is 5 μm or less. Furthermore, an area ratio of a fibrous structure in a cross section parallel to an extruding direction during hot extrusion is 95% or more.

Owner:SUMITOMO LIGHT METAL INDS LTD

Method for preparing chromium-carbon nano tube composite coating in trivalent chromium plating solution

InactiveCN101768772AImprove wear resistanceImprove corrosion resistanceElectrolytic coatingsCarbon nanotubeChloride

The invention discloses an electrodeposition method for preparing a chromium-carbon nano tube composite coating in trivalent chromium plating solution. The invention adds a carbon nano tube in a basis electrolyte comprising chromic chloride to prepare the chromium-carbon nano tube composite coating with smooth surface and firm combination with the substrate by controlling the proper process conditions. The invention has the advantages that the prepared chromium-carbon nano tube composite coating has a thickness of more than 5mum, and has higher hardness, abrasion resistance and corrosion resistance than the hexavalent chromium plating coating; and the method can replace the conventional hexavalent chromium plating process under a certain friction working condition.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

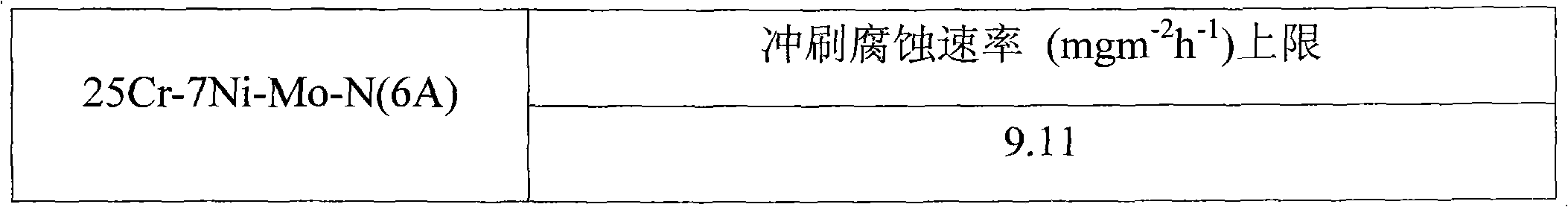

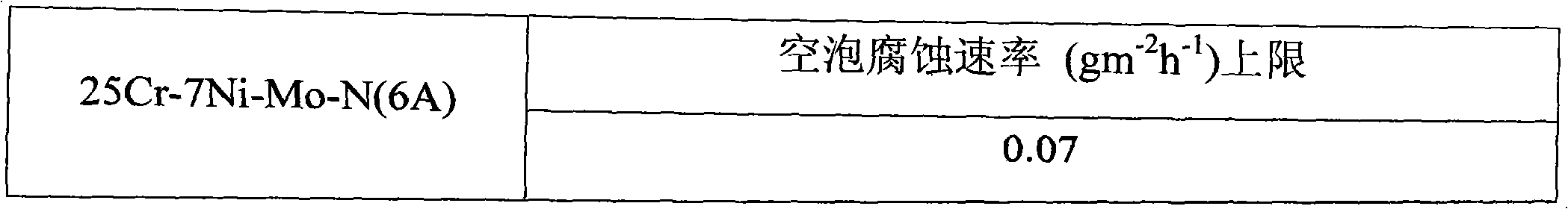

Repair welding wire for flaws of cast two-phase stainless steel 6A

ActiveCN101972903AIncrease content ratioPromote precipitationWelding/cutting media/materialsSoldering mediaCavitationManganese

The invention discloses a repair welding wire for flaws of cast two-phase stainless steel 6A. The two-phase stainless steel 6A refers to 25Cr-7Ni-Mo-N(6A), and the repair welding wire basically comprises: carbon: not larger than 0.03%, silicon: not larger than 0.7%, manganese: not larger than 0.7%, chrome: 25.0-26.0%, molybdenum: 3.0-3.2%, copper:0.5-0.7%, tungsten: 0.5-1.0%, nickel: larger than 8.5-9.0%, nitrogen: 0.30-0.40%, other unavoidable impurities and elements: smaller than 0.06%, and the balance of iron. The repair welding wire with phi 2mm is finally formed by carrying the steps of refining, hot forging, multiple cold pulling and annealing on the basic constituents, satisfies the requirements of the two-phase stainless steel 6A on erosion corrosion resistance and cavitation corrosion resistance, and guarantees that a flawed repair welded position of the cast two-phase stainless steel 6A has favorable erosion corrosion resistance and cavitation corrosion resistance.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

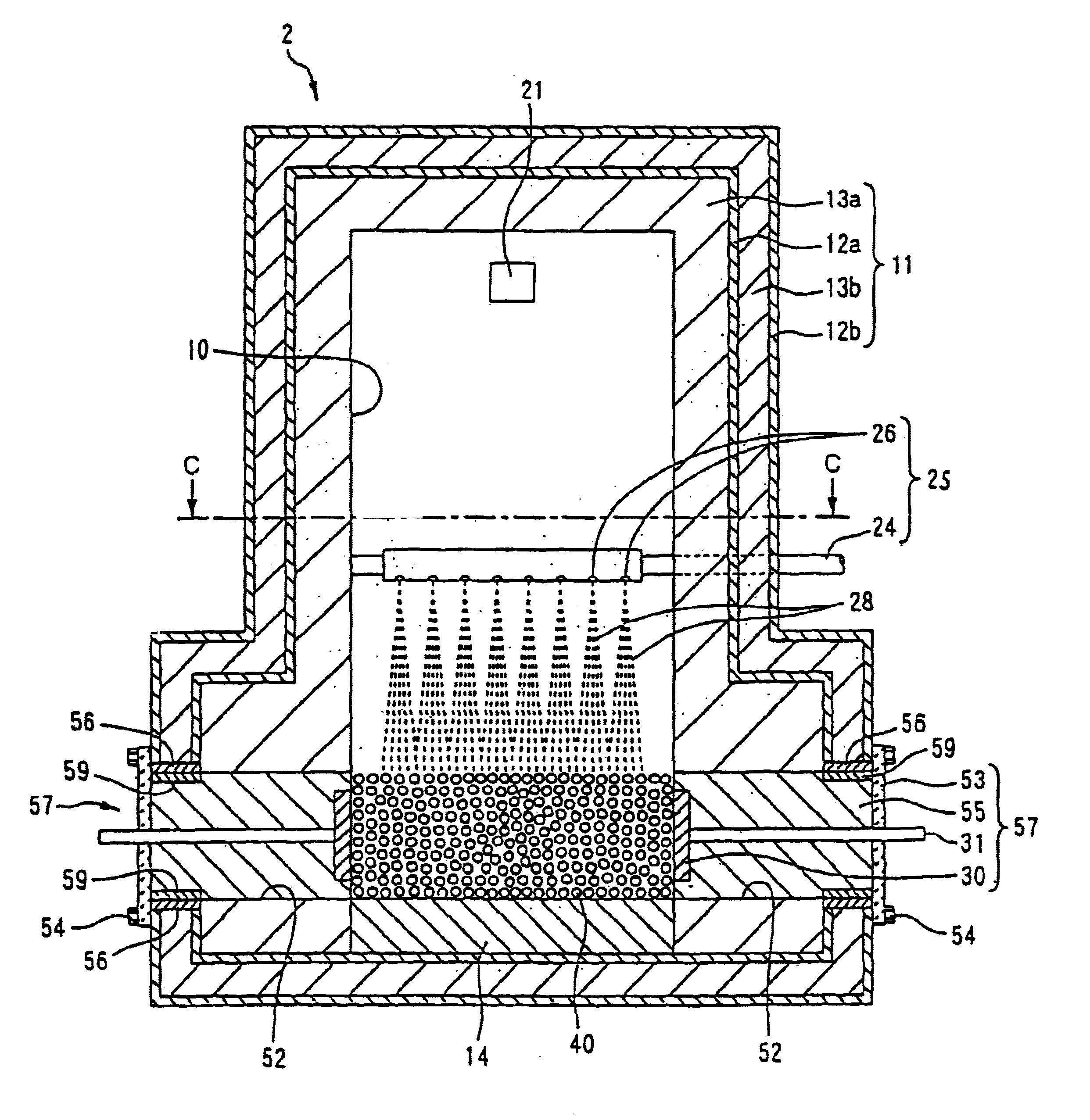

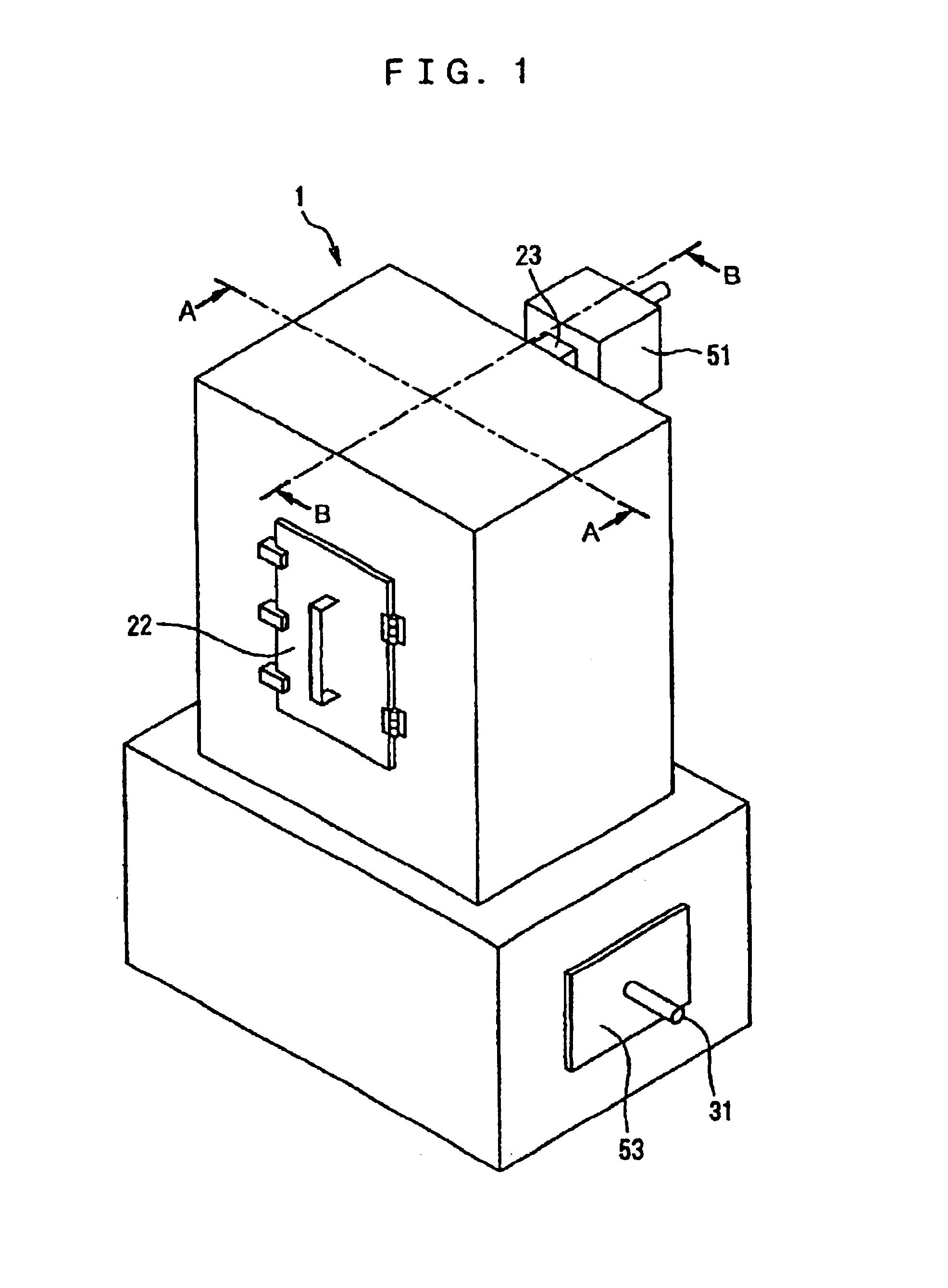

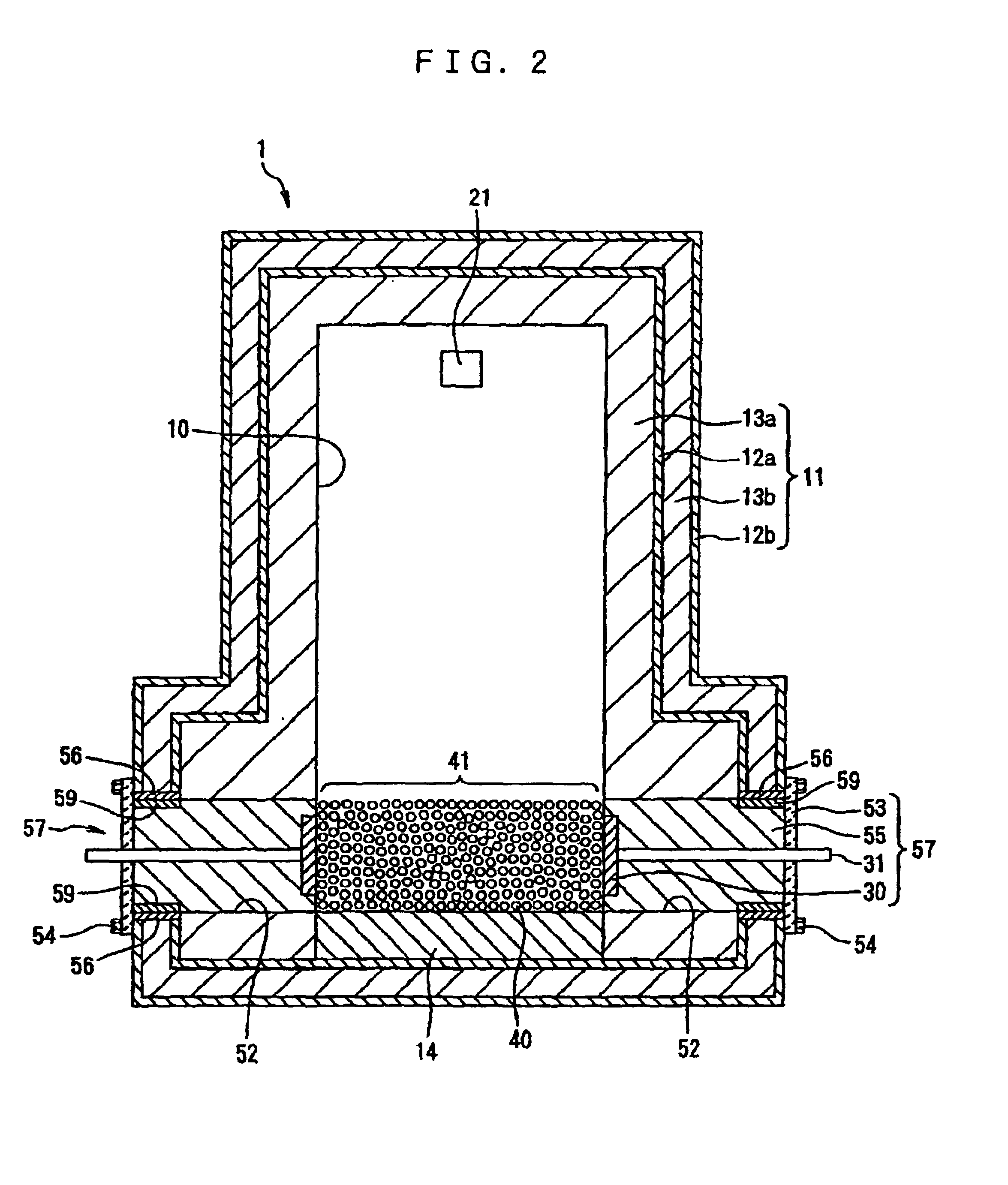

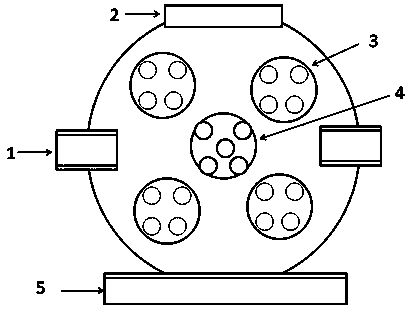

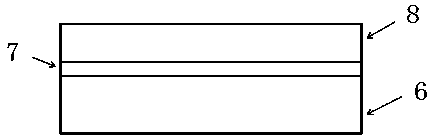

Thermal decomposer for waste

InactiveUS7005112B1Improved strengthExcellent corrosion resistanceElectrical coke oven heatingSolid waste disposalDecomposerVoltage

A thermal decomposition apparatus for wastes comprises: a heating chamber; an inlet port; at least one pair of electrodes provided within the heating chamber; a plurality of balls each taking the shape of a sphere whose primary ingredient is carbon, provided between the at least one pair of electrodes so as to produce an electric discharge when a voltage is applied across the at least one pair of electrodes; an outlet port for discharging the gases into which the wastes are thermally decomposed; oxygen free or vacuum environment forming means or evacuating means.According to the present invention, an inexpensive thermal decomposition apparatus for wastes is provided which thermally decomposes almost all wastes at a high temperature of not lower than about 3000° C. without producing harmful substances such as soot, dust, chlorine compounds; nitrogen compounds and / or dioxin.

Owner:KYOWA LTD

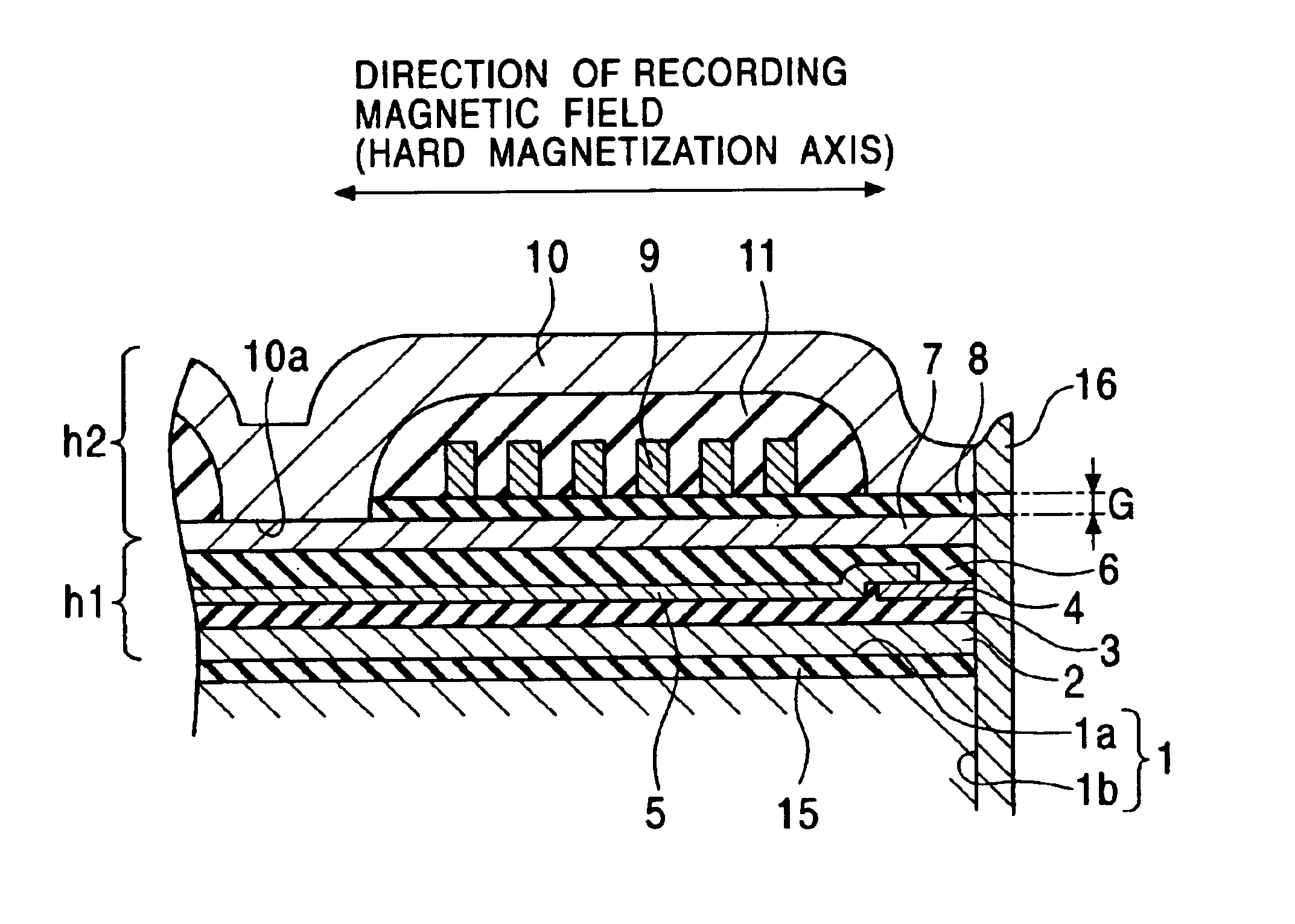

Corrosion-resistant soft magnetic film, method of producing the same, thin film magnetic head using the same and method of manufacturing the thin film magnetic head

InactiveUS6898054B2High magnetic flux densityExcellent corrosion resistanceConstruction of head windingsLiquid applicationRecording densityCorrosion resistant

A lower pole layer and / or an upper pole layer is formed by plating a soft magnetic film represented by the formula FeXNiYαZ (wherein element α is at least one of Tc, Ru, Rh, Pd, Re, Os, Ir and Pt), wherein the composition ratio X of Fe is 65% by mass to 74% by mass, the composition ratio Y of Ni 25% by mass to 34% by mass, the composition ratio Z of the element α is 1% by mass to 7% by mass, and X+Y+Z=100% by mass. Therefore, a thin film magnetic head adaptable to a higher recording density and having excellent corrosion resistance can be manufactured.

Owner:TDK CORPARATION

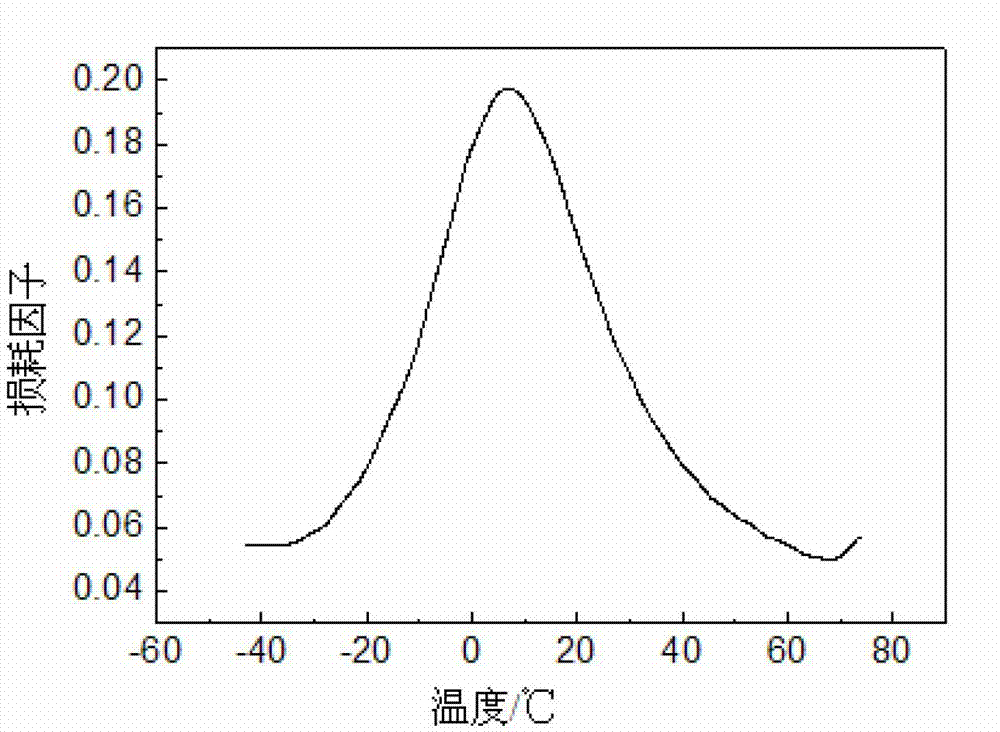

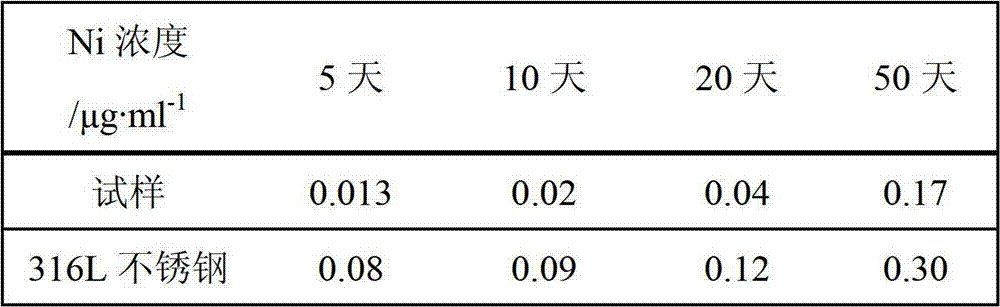

Nickel titanium memory alloy/polyurethane compound damping panel and preparation method thereof

InactiveCN102896836AHigh strengthHigh hardnessLamination ancillary operationsLaminationSurface layerTitanium

The invention provides a nickel titanium memory alloy / polyurethane compound damping panel and a preparation method thereof and relates to a compound damping panel and the preparation method thereof. The invention aims to solve the technical problems that the present surface layer is a 316L stainless steel compound steel panel, the tensile strength is low, the corrosion resistance is inferior and the present compound damping material has inferior damping effect. The preparation method according to the invention comprises the following steps: placing a nickel titanium memory alloy panel and a polyurethane panel into a hot press, and then pressing for 5-20min under the conditions of 185-195 DEG C temperature and 40-50N pressure, and taking out and cooling in air. The tensile strength of the compound damping panel provided by the invention is 600-800MPa; the precipitation volume of nickel ions in Nacl solution is 0.17ug / ml; the tensile strength is high; the corrosion resistance is excellent; a damping loss factor can reach 0.2; the vibration-reducing and noise-reducing effects are good; and the compound damping panel can be widely applied to passenger cars, trains, ships and buildings.

Owner:HARBIN ENG UNIV

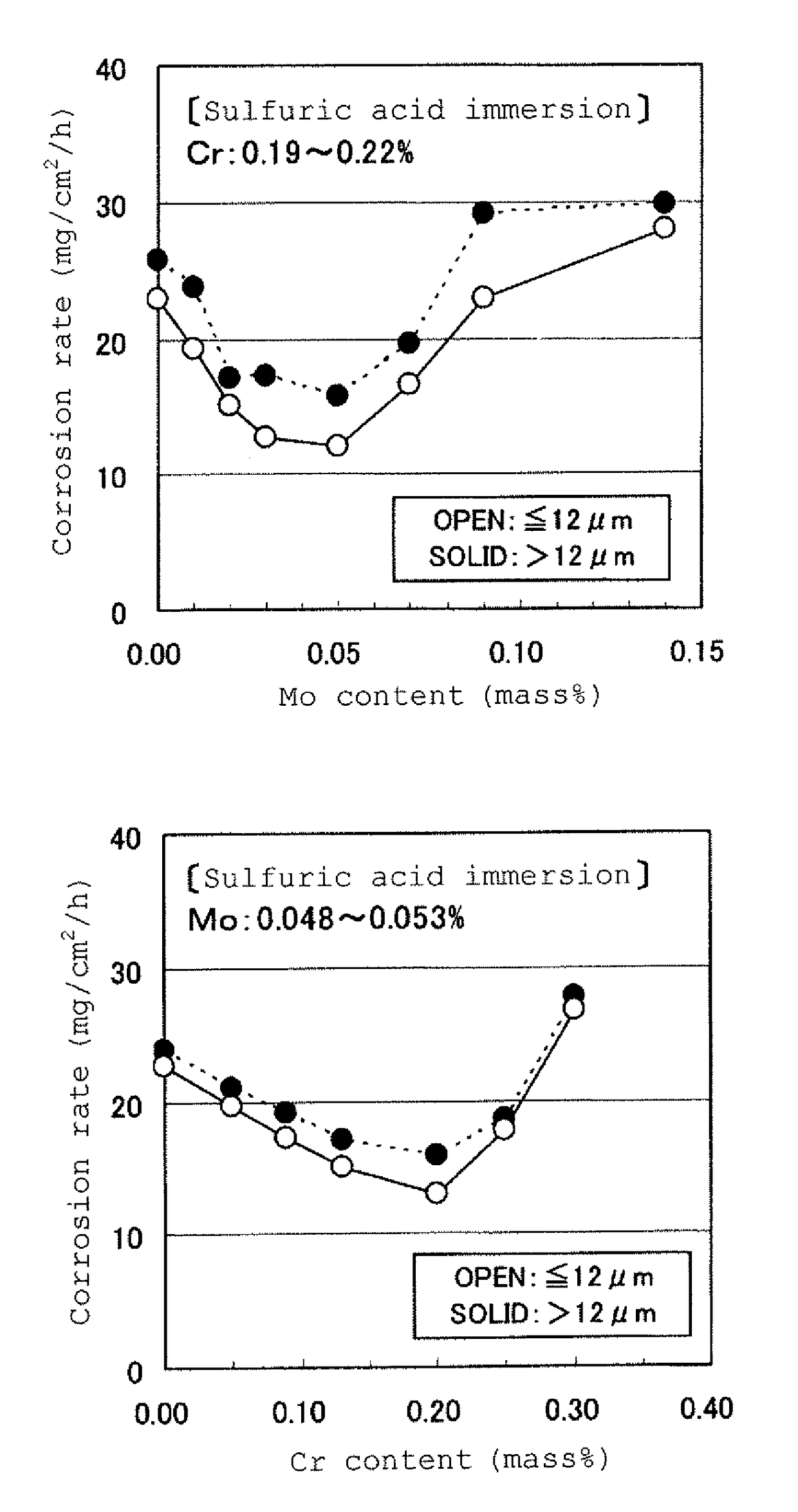

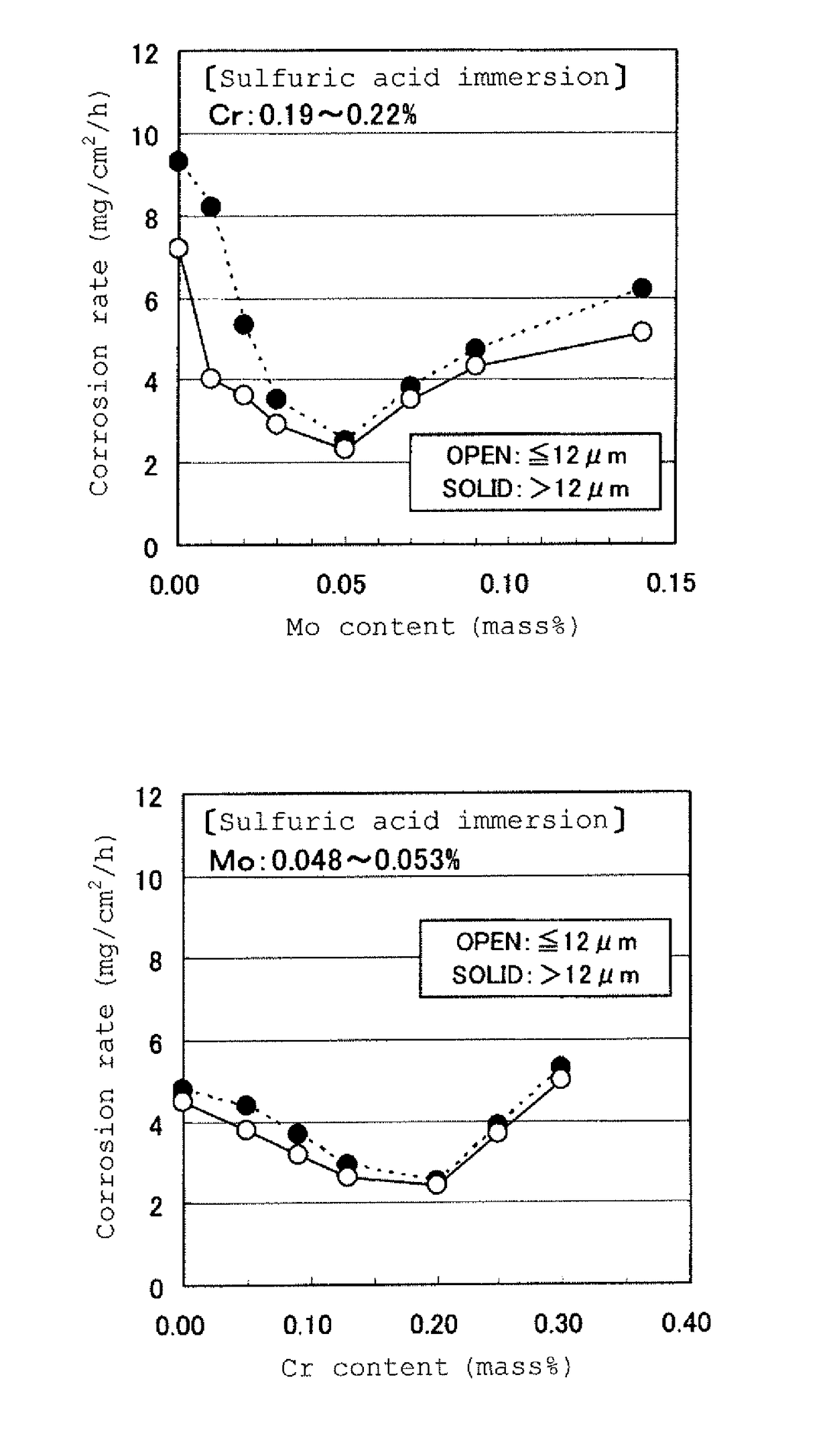

Steel plate having excellent acid dew point corrosion resistance, method of production, and exhaust gas channel constituent member

ActiveUS20170114425A1Improve in sulfuric acid dew point corrosion resistanceExcellent corrosion resistanceFurnace typesHeat treatment furnacesPearliteDew point

A steel plate excellent in acid dew point corrosion resistance has a composition, in mass percent, from 0.001 to 0.15% of C, 0.80% or less of Si, 1.50% or less of Mn, 0.025% or less of P, 0.030% or less of S, from 0.10 to 1.00% of Cu, 0.50% or less of Ni, from 0.05 to 0.25% of Cr, 0.01 to 0.08% of Mo, 0.100% or less of Al, from 0 to 0.20% in total of Ti, Nb, and V, from 0 to 0.010% of B, from 0 to 0.10% in total of Sb and Sn, and a balance of Fe and unavoidable impurities, having a ferrite single phase structure, or a structure containing 30% by volume or less in total of one or more of cementite, pearlite, bainite, and martensite, with the balance ferrite phase. Ferrite crystal grains have an average crystal grain diameter of 12.0 mm or less.

Owner:NISSHIN STEEL CO LTD

Color steel tile with graphite coating and preparation method thereof

ActiveCN106893440AFast dryingProduct quality is lightFireproof paintsAnti-corrosive paintsEpoxyPolyvinyl alcohol

The invention discloses a color steel tile with a graphite coating and a preparation method thereof. The color steel tile comprises a base plate located in a middle layer, and the two sides of the base plate are coated with coatings formed by graphite slurry. The graphite slurry is made of, by weight parts, 50-200 parts of fine flake graphite micro powder, 40-160 parts of cashew-nut oil modified phenolic resin or epoxy resin, 10-50 parts of polyvinyl acetal, 40-160 parts of alcohol, 2-10 parts of coupling agent, 2-10 parts of defoamer, 1-10 parts of plasticizer and 2-10 parts of liquid acrylonitrile butadiene rubber. The service life of the obtained color steel tile with the graphite coating can be greatly prolonged, problems that a conventional resin tile ages easily and is low in strength toughness and not resistant to flame and the like are solved; a problem that a conventional color steel tile is heavy in weight and difficult to install is solved; indoor and outdoor heat exchange rate can also be effectively increased, and a problem of high-temperature poor working environments of conventional color steel tile plants is solved; and a problem that at present, on the market the fine flake graphite is massively accumulated and is low in additional value is solved.

Owner:YICHANG XINCHENG GRAPHITE

Grounding grid NiP-DLC composite corrosion resisting protection coating and preparing method

InactiveCN103956592AImprove wear resistanceExcellent corrosion resistanceLine/current collector detailsVacuum evaporation coatingGrounding gridChemical plating

The invention discloses a grounding grid NiP-DLC composite corrosion resisting protection coating and preparing method. The coating comprises an NiP alloy coating covering the grounding grid material and a pure carbon type diamond coating covering the NiP alloy coating, wherein the NiP alloy coating is a corrosion resisting coating, and the pure carbon type diamond coating is a high hardness oxidation resistant coating. The coating preparing method comprises the steps that the NiP alloy coating is deposited on the surface of the grounding grid material in a chemical plating mode, and the pure carbon type diamond coating is deposited on the surface of the NiP alloy coating through an anode layer ion source in a vacuum cavity. The coating is more superior in abrasion resistance, corrosion resistance and oxidation resistance, and friendly to the environment. The method is simple in technology and high in deposition efficiency, and the coating is suitable for being produced on a large scale. The thick composite coating can be obtained based on the method, the service life of the coating can be greatly prolonged, and cost can be reduced.

Owner:WUHAN UNIV

Hot-dip galvanized steel sheet and manufacturing method thereof

ActiveUS20110253263A1Excellent corrosion resistanceExcellent anti-powdering propertyHot-dipping/immersion processesFurnace typesCorrosionOxide

A galvanized steel sheet includes a zinc plating layer which is disposed on a steel sheet containing 0.01% to 0.15% C, 0.001% to 2.0% Si, 0.1% to 3.0% Mn, 0.001% to 1.0% Al, 0.005% to 0.060% P, and 0.01% or less S on a mass basis, the remainder being Fe and unavoidable impurities, and which has a mass per unit area 20 g / m2 to 120 g / m2. An oxide of at least one selected from the group consisting of Fe, Si, Mn, Al, and P is present in a surface portion of the steel sheet that lies directly under the zinc plating layer and that extends up to 100 μm from the surface of a base steel sheet. The amount of the oxide per unit area is 0.05 g / m2 or less in total. The steel sheet has excellent corrosion resistance, anti-powdering property during heavy machining, and strength.

Owner:JFE STEEL CORP

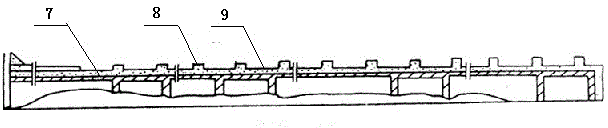

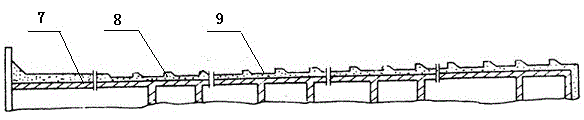

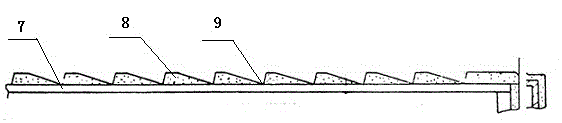

Bed-top of concentrating table

The invention relates to parts for gravity concentration equipment, in particular to a bed-top of a concentrating table. The bed-top is of novel material. By modifying the structure and material of the bed-top, the grade of finished ores is greatly increased, and the service life of the bed-top is greatly prolonged. The bed-top comprises a face plate, an ore feeding trough and a water feeding rough; the bed-top is characterized in that the face plate is provided with rifle strips, at least two deep and shallow grooves are provided between every two rifle strips, the section of the deep and shallow grooves is trapezoidal, and the ore feeding trough and the water feeding trough are made of environmental material. The bed-top is applicable to concentration of fine materials and is widely applicable to concentration of tin, tungsten, gold and silver, lead, zinc, titanium, iron, manganese, ferrotitanium, coal and the like.

Owner:江西省浩燃冶金设备有限责任公司

Dissolved oxygen electrode

InactiveCN1789999AExcellent corrosion resistanceHigh sensitivityMaterial electrochemical variablesPhysicsCorrosion

The invention discloses a dissolved oxygen electrode, which consists of working electrode (2) and silver-silver chloride reference electrode (3), wherein two electrodes connect the electrode lead; the working electrode (2) is metal gold, which is packed by polyetheretherketone electrode chip (10) with part of electrode chip (10) outsides; encircling the reference electrode (3) on the surface of electrode chip (10); connecting the top of electrode chip (10) with the electrode cap (5) with the bottom in the oxygen penetration film sleeve (1) and connecting; placing the working electrode (2) and reference electrode (3) in the oxygen penetration film sleeve (1); setting the oxygen penetration film (8) at the bottom of oxygen penetration film sleeve (1). The invention improves the corrosion-proof property and sensibility, which is fit for on-line measurement of dissolved oxygen density.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com