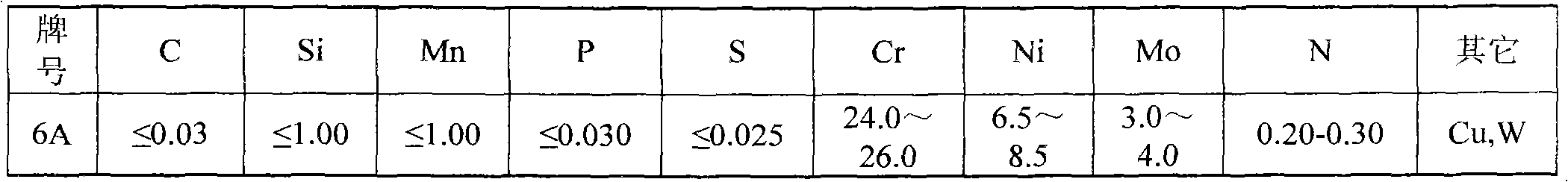

Repair welding wire for flaws of cast two-phase stainless steel 6A

A duplex stainless steel, defect technology, applied in the direction of welding medium, manufacturing tools, welding equipment, etc., can solve the problems of reducing erosion corrosion resistance and cavitation corrosion resistance, high scrap rate, scrapping of original parts, etc. Achieve good erosion corrosion resistance and cavitation corrosion resistance, stable and reliable welding process, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: The overall composition of the repair welding wire of the present invention is shown in the following table by weight percentage.

[0047] Fe

[0048] After batching according to the above table and according to the above-mentioned production method, a φ2mm repair welding wire is finally formed, and the repair welding wire meets the mechanical performance indicators of fracture strength, yield strength and reduction of area.

[0049] The specific welding parameters are shown in the table below:

[0050] Welding current (A)

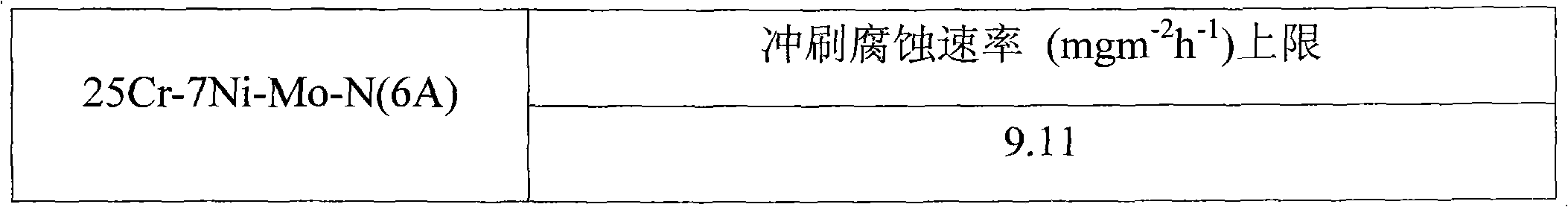

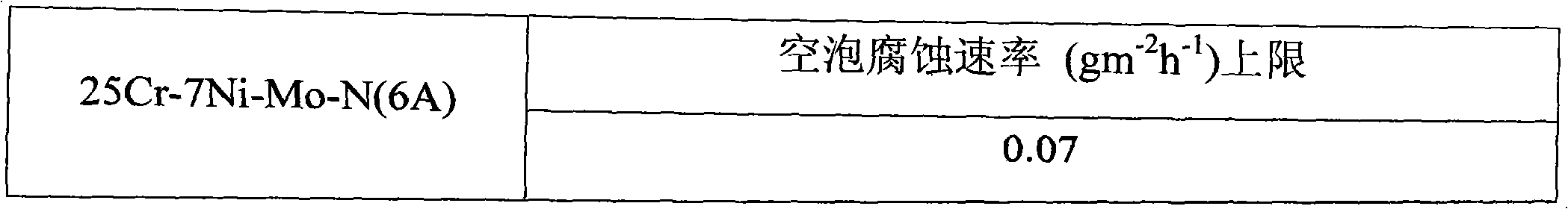

[0051] A complete repair welding repair part includes the weld seam and heat-affected zone. Usually, the percentage of the ferrite phase in the repair welding repair part of duplex stainless steel, including the weld seam, heat-affected zone and base metal, to all phases is determined. The phase structure of repaired parts can be determined more comprehensively. Adopt repair welding welding wire of the present inve...

Embodiment 2

[0058] Embodiment 2: The overall composition of the repair welding wire of the present invention is shown in the following table by weight percentage.

[0059] Fe

[0060] After batching according to the above table and according to the above-mentioned production method, a φ2mm repair welding wire is finally formed, and the repair welding wire meets the mechanical performance indicators of fracture strength, yield strength and reduction of area.

[0061] The specific welding parameters are as follows:

[0062] Welding current (A)

[0063] A complete repair welding repair part includes the weld seam and heat-affected zone. Usually, the percentage of the ferrite phase in the repair welding repair part of duplex stainless steel, including the weld seam, heat-affected zone and base metal, to all phases is determined. The phase structure of repaired parts can be determined more comprehensively. Adopt repair welding welding wire of the present invention after re...

Embodiment 3

[0069] Embodiment 3 The overall composition of the repair welding wire according to the present invention is shown in the table below.

[0070] Fe

[0071] After batching according to the above table and according to the above-mentioned production method, a φ2mm repair welding wire is finally formed, and the repair welding wire meets the mechanical performance indicators of fracture strength, yield strength and reduction of area.

[0072] The specific welding parameters are as follows:

[0073] Welding current (A)

[0074] A complete repair welding repair part includes the weld seam and heat-affected zone. Usually, the percentage of the ferrite phase in the repair welding repair part of duplex stainless steel, including the weld seam, heat-affected zone and base metal, to all phases is determined. The phase structure of repaired parts can be determined more comprehensively. Adopt repair welding welding wire of the present invention after repairing 25Cr-7Ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com