Galvalized aluminum magnesium steel plate and manufacture method thereof

A manufacturing method and hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve problems such as large scum, reduce energy consumption, reduce equipment loss, and good adhesion ability and welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0031] Manufacture the hot-dip galvanized aluminum-magnesium steel sheet of the present invention according to the following steps, the steel sheet includes a substrate and a coating coated on the substrate, and the substrate adopts a common IF steel with a thickness of 0.7mm:

[0032] (1) Manufacture substrate:

[0033] (2) Degrease and clean the surface of the substrate;

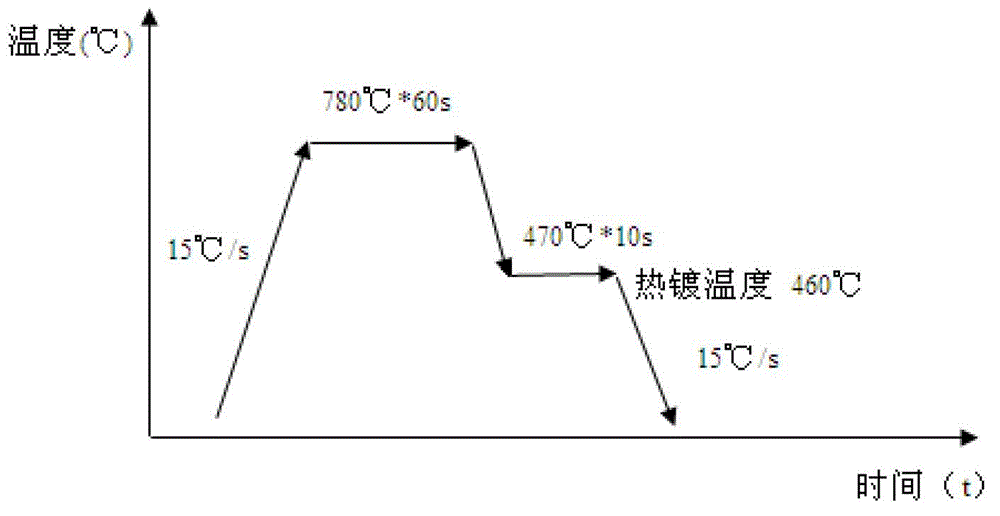

[0034] (3) The heating rate is 15°C / s, the continuous annealing temperature is 780°C, and the reducing atmosphere is 10vol%H 2 +N 2 , the dew point is -30℃, and the reduction time is 60s;

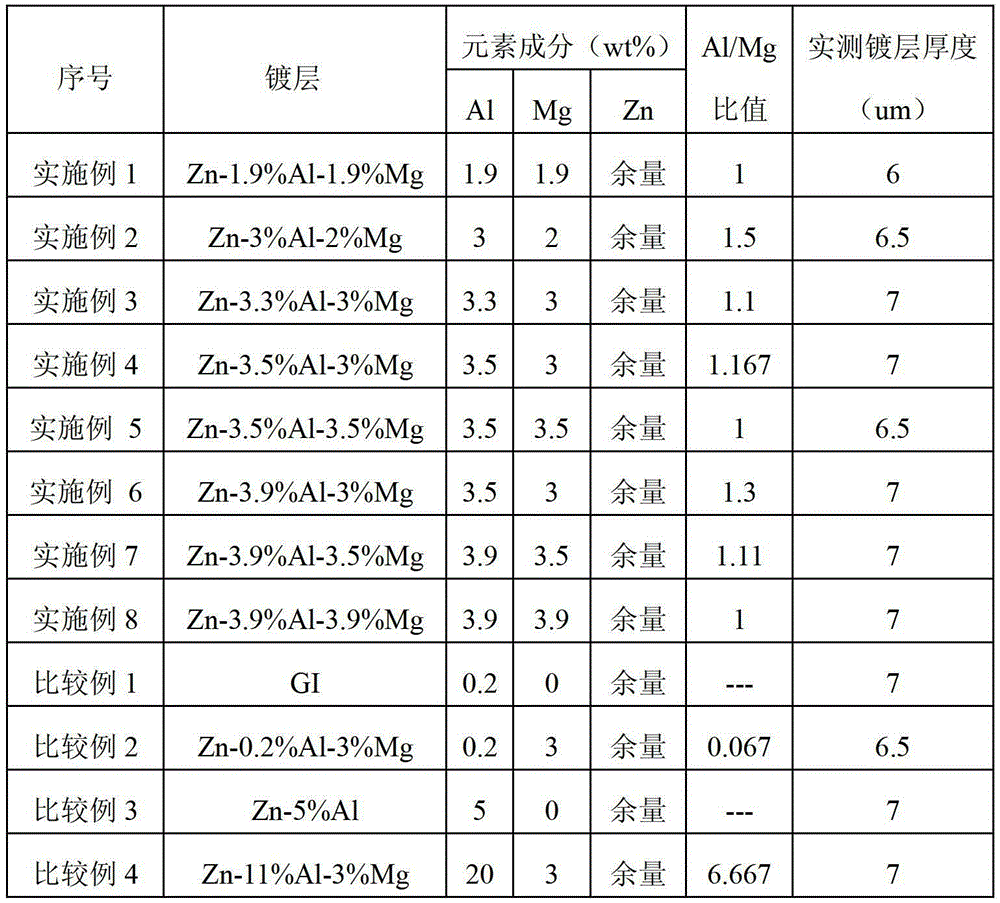

[0035] (4) Before immersion plating, keep warm at a temperature 10°C higher than the plating solution for 10s to make the temperature of the substrate uniform. , the immersion plating time is 3-10s, wherein, the composition ratio of each chemical element in the plating solution is shown in Table 1, and the plating solution temperature and immersion plating time are shown in Table 2;

[0036] (5) Control the cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com