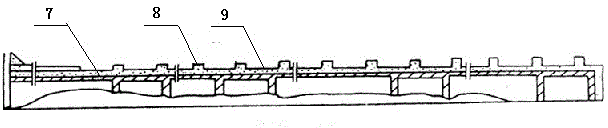

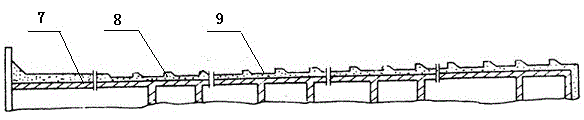

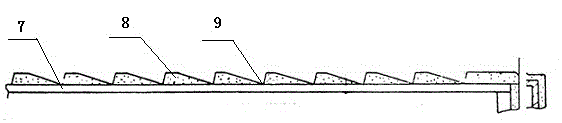

Bed-top of concentrating table

A panel and ore trough technology, applied in the field of gravity beneficiation equipment accessories, can solve the problems of high processing and repair costs, easy deformation and damage of the bed surface, short service life, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The length of the shaking table surface 4 made of PVC laminated board material is 450 centimeters, width (big head is: 180 centimeters / small head is: 150 centimetres, 60 big grooves of equidistant distribution, between adjacent rafters The width of the stepped platform is 8 mm, and there are 6 steps, that is, 6 grooves; the depth of the 6 grooves is 6, 5, 4, 3, 2, and 1 mm respectively, and there are 360 small grooves in total.

Embodiment 2

[0021] The length of the shaking table surface 4 made of PVC laminated board material is 450 centimeters, width (big head is: 180 centimeters / small head is: 150 centimetres, 60 big grooves of equidistant distribution, between adjacent rafters The width of the stepped platform is 6 mm, and there are 4 steps, that is, 4 grooves; the depth of the 4 grooves is 6, 4.5, 3, and 1.5 mm respectively, and there are 240 small grooves in total.

Embodiment 3

[0023] The length of the shaking table surface 4 made of PVC laminated hard board material is 450 centimeters, the width (large head is: 180 cm / small head is: 150 cm, 60 large grooves distributed equidistantly, adjacent rifling strips The width of the step table is 3 mm, and there are 10 steps, that is, 10 grooves; the depth of the 10 grooves is 6, 5.5, 5, 4.5, 4, 3.5, 3, 2.5, 2, 1.5 mm, a total of 600 small grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com