Tear-resistant packing material structure manufacture method and tear-resistant product

A manufacturing method and anti-tearing technology, applied in chemical instruments and methods, packaging, wrapping paper, etc., can solve problems such as low recovery rate, random discarding, loss of sellers, etc., to reduce material development and manufacturing costs, and reduce manpower cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

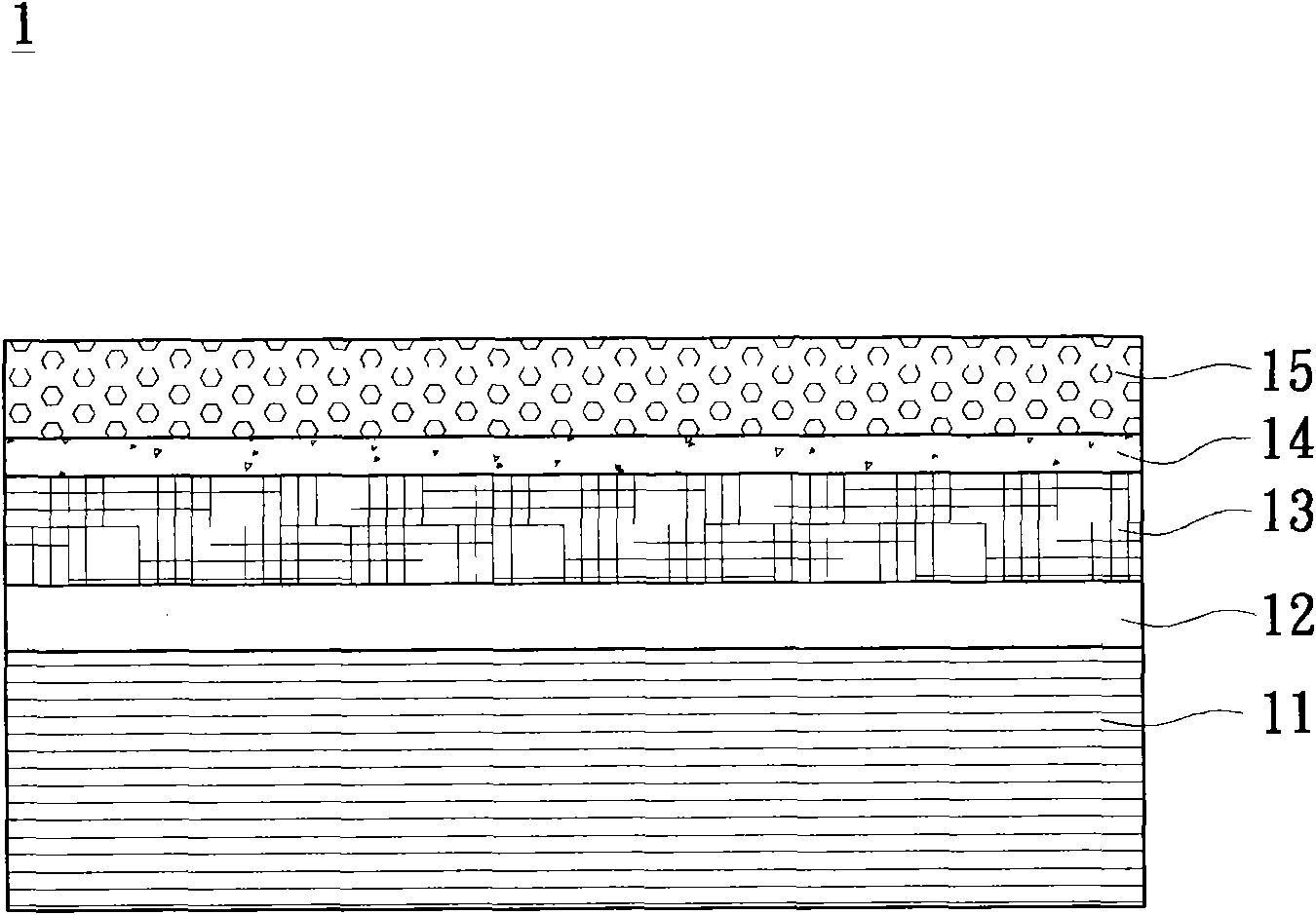

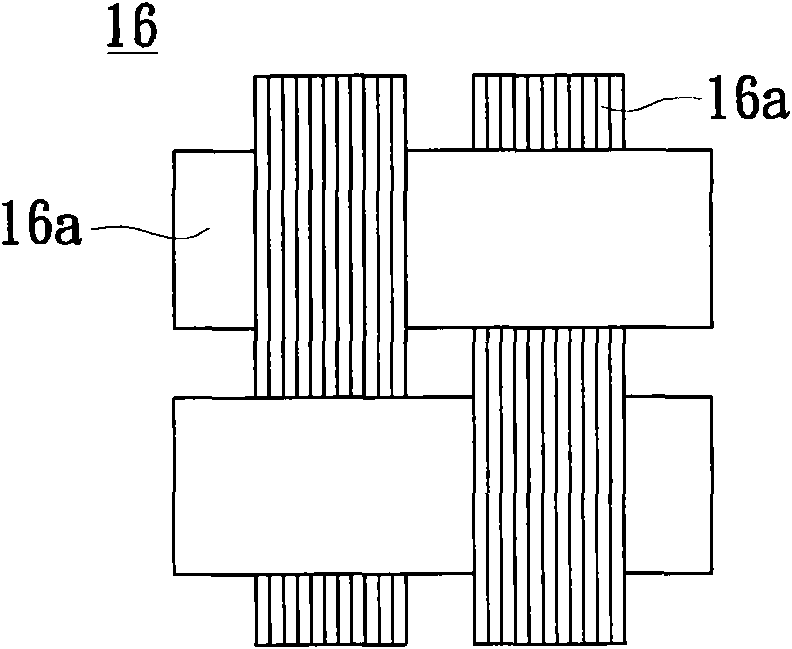

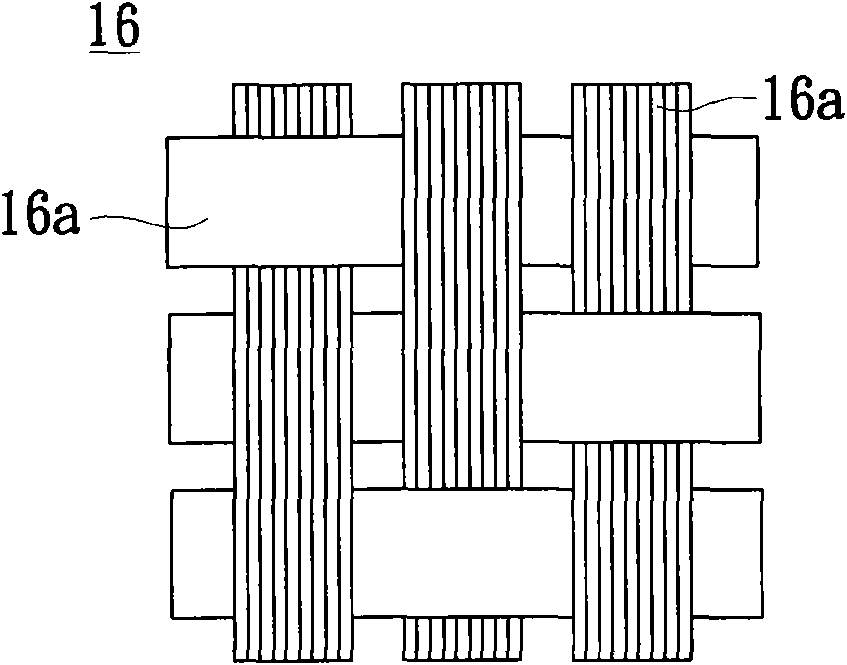

[0060] see Figure 1 to Figure 6 As shown, the present invention provides a method for manufacturing a tear-resistant packaging material structure and tear-resistant packaging material products, such asfigure 1 It is a side view sectional view of the tear-resistant packaging material structure of the present invention; the present invention provides a tear-resistant packaging material structure 1, figure 1 It is a side view sectional view of the tear-resistant packaging material structure 1 of the present invention; the tear-resistant packaging material structure 1 of the present invention may include a paper layer 11, a connecting layer 12, and a type of film-based tear-resistant material in order from top to bottom. Crack layer 13, a transition layer 14 and a heat-sealing layer 15; wherein, the quasi-thinning tear-resistant layer 13 can be made of a braided fiber layer structure after weaving warp and weft fiber bundles and then undergo a thinning treatment. Since the tear-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com