Bellows used for polytetrafluoroethylene compensator and manufacturing method thereof

A technology of polytetrafluoroethylene and its manufacturing method, which is applied in the direction of expansion compensation devices, hoses, pipes, etc. used in pipelines, and can solve the problems of inability to install open reinforcement rings with polytetrafluoroethylene anti-corrosion coatings, compensator scrapping, and loss of support Function and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

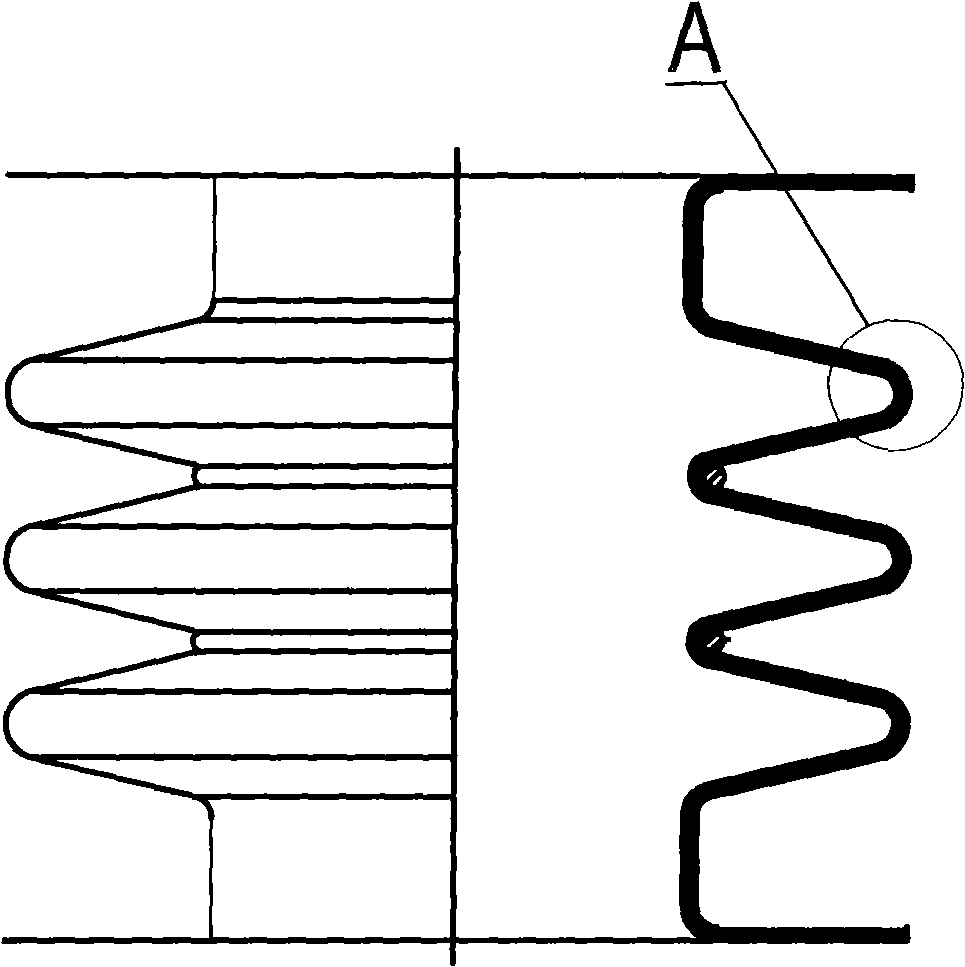

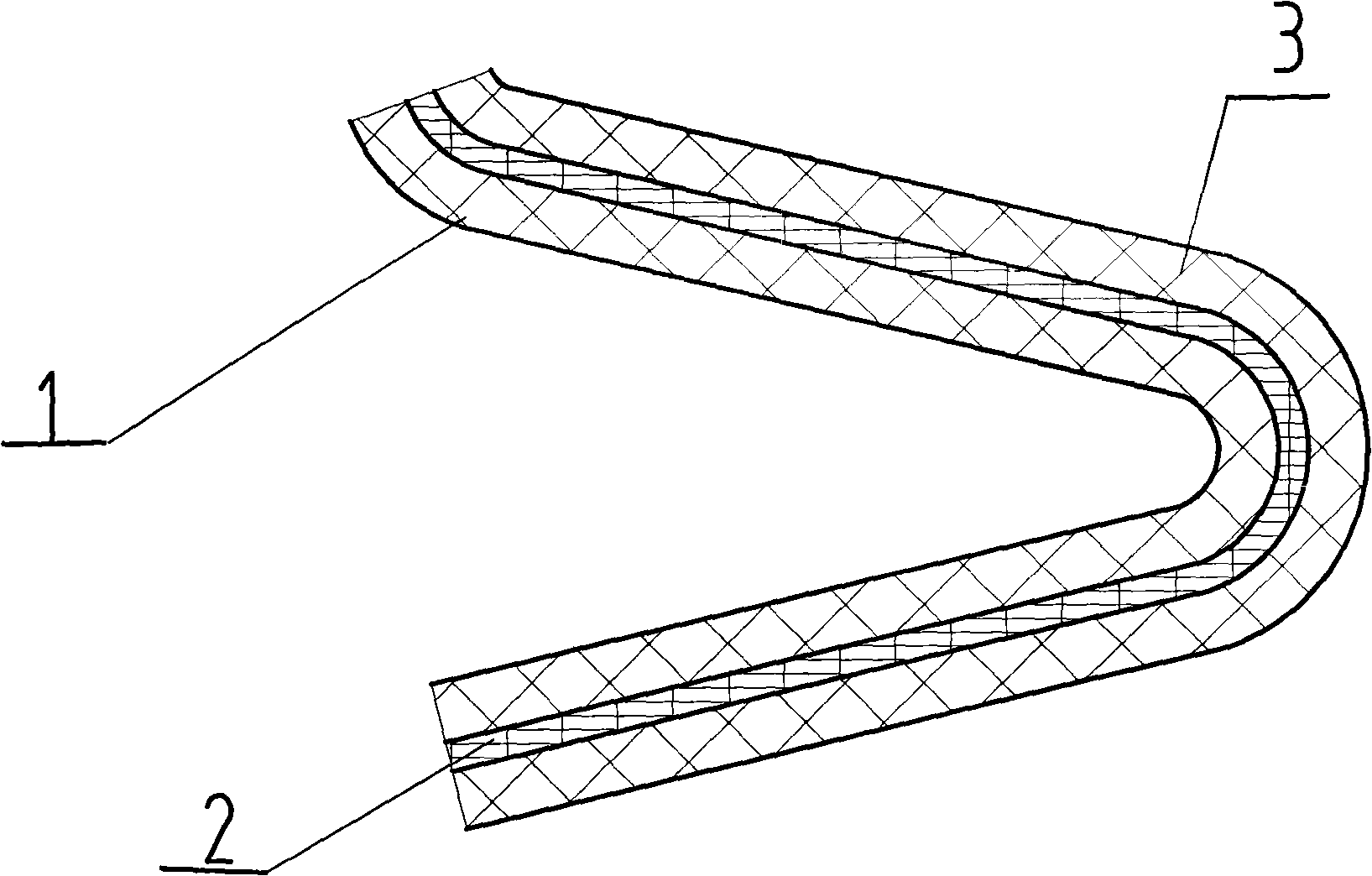

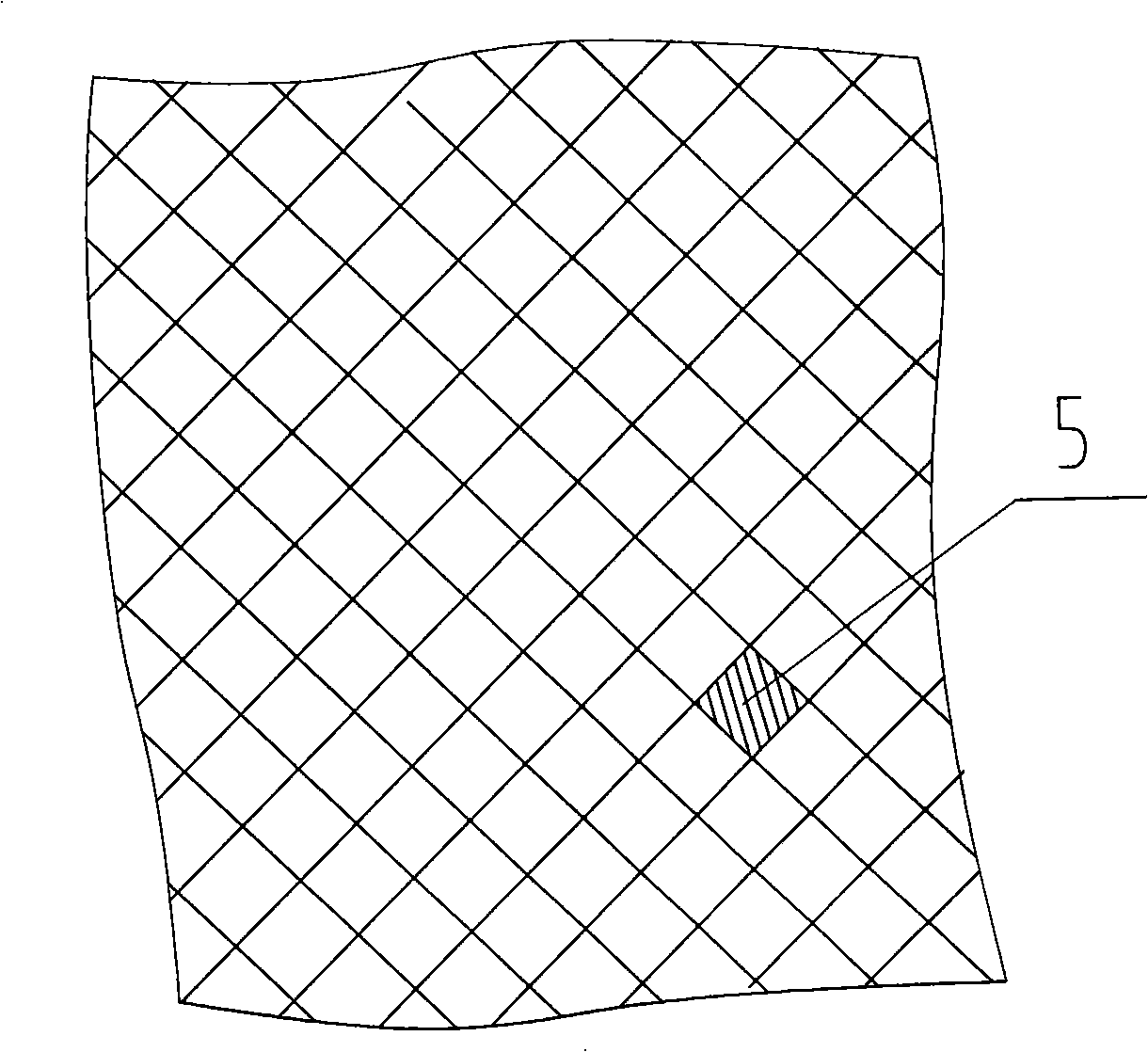

[0021] Such as figure 1 and figure 2 As shown, the corrugated pipe is sequentially fused together by the inner polytetrafluoroethylene corrugated layer 1, the metal mesh corrugated layer 2, and the outer polytetrafluoroethylene corrugated layer 3. The unit grid 4 in the metal mesh corrugated layer 2 is a quadrilateral structure (such as Figure 4 As shown), the directions of the two diagonals of the quadrilateral are respectively consistent with the axial and radial directions of the bellows.

[0022] Its manufacturing method is as follows:

[0023] ① Wrap the polytetrafluoroethylene film on the cylindrical mold;

[0024] ②Wrap the flat metal mesh on the polytetrafluoroethylene film in the direction that the two diagonals of the quadrilateral unit grid in the flat metal mesh are respectively consistent with the axial and radial directions of the cylindrical mold;

[0025] ③ Wrap the polytetrafluoroethylene film on the metal mesh;

[0026] ④ Wrap the glass fiber tape on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com