Low-frequency sound absorption metamaterial

A metamaterial and sound absorption technology, applied in the field of sound absorption metamaterials, can solve the problems of large structure thickness, poor sound absorption effect, narrow sound absorption frequency, etc., and achieve the effect of small structure thickness, convenient adjustment and improvement of absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

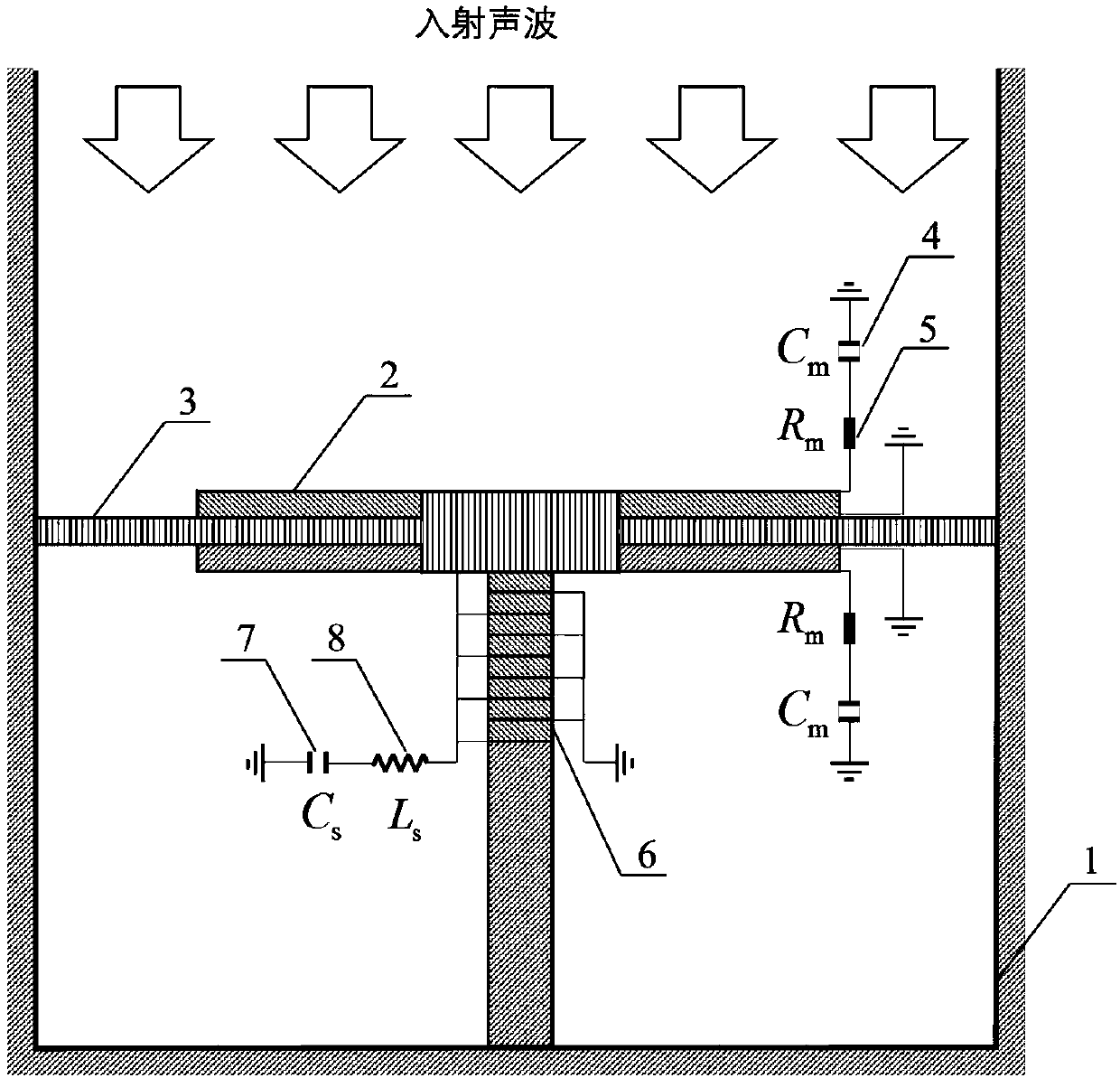

[0121] Such as figure 1 As shown, a wide and low-frequency sound-absorbing metamaterial includes a back cavity 1, a composite film, a piezoelectric film circuit, a piezoelectric stack, and a piezoelectric stack circuit;

[0122] The back cavity 1 is a cavity structure with one end open, and its thickness h c 3cm;

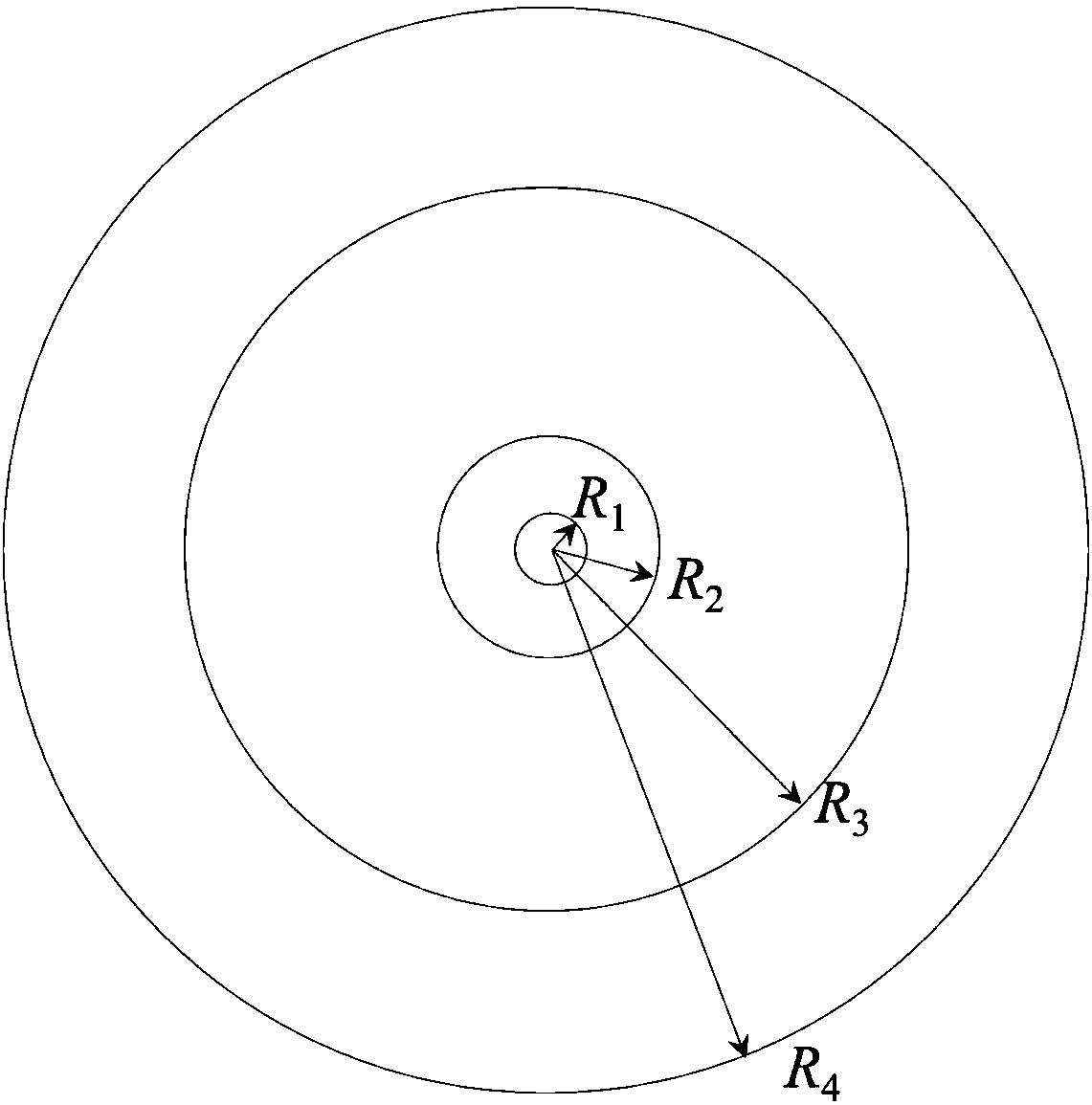

[0123] The composite film is a composite structure formed by bonding the piezoelectric film 2, the metal film 3 and the piezoelectric film 2 in order; wherein the piezoelectric film 2 is a ring structure, and the center of the metal film 3 is processed with a convex platform structure, the piezoelectric film 2 is nested on the boss structure of the metal film 3; the material of the piezoelectric film 2 is a PZT-5H piezoelectric ceramic material, and the other metal film 3 is an aluminum film; in addition, figure 2 R in 1 =1mm, R 2 =20mm, R 3 = 40mm and R 4 = 60mm, the thickness of the piezoelectric film 2 inside and outside the cavity of the back cavity 1 is ...

Embodiment 2

[0130] On the basis of Example 1, modify the negative capacitance I4 to -350nF, the resistance 5 to 180Ω, the negative capacitance II7 to -1.4503nF, and the negative inductance 8 to -1.4H. Other structural components and parameter settings of the material are the same as those of the wide and low frequency sound-absorbing metamaterial in Example 1.

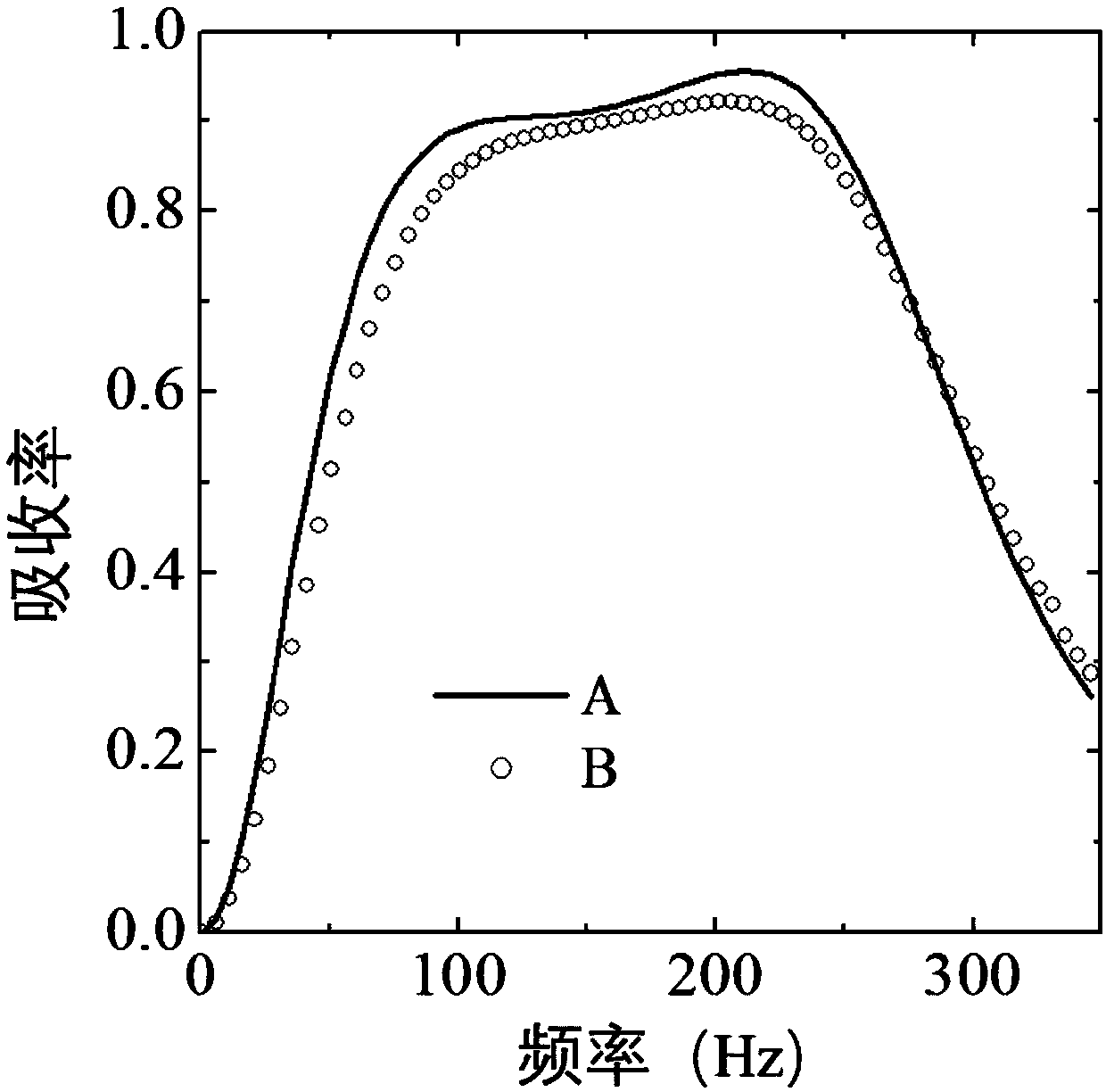

[0131] Apply a normal incident sound wave within 300 Hz to the wide and low frequency sound-absorbing metamaterial described in this example, and evaluate the sound-absorbing effect through theoretical calculation and simulation in the finite element software Comsol. The theoretical calculation and simulation results are detailed in Figure 4 . Through theoretical calculation, it can be seen that the sound-absorbing metamaterial can achieve an absorption rate of more than 0.9 in the range of 91Hz-250Hz, such as Figure 4 As shown in the middle curve A; through the simulation, it can be known that the sound-absorbing metamaterial ...

Embodiment 3

[0133] On the basis of Example 1, modify the negative capacitance I4 to -400nF, the resistance 5 to 55Ω, the negative capacitance II7 to -1.4496nF, and the negative inductance to 0H. In this embodiment, the adjustable narrow low-frequency sound-absorbing metamaterial Other structural components and parameter settings are the same as those of the wide and low frequency sound-absorbing metamaterial in Example 1.

[0134] Apply normal incident sound waves within 300 Hz to the adjustable narrow low-frequency sound-absorbing metamaterial described in this example, and evaluate the sound-absorbing effect through theoretical calculation and simulation in the finite element software Comsol, the results of theoretical calculation and simulation simulation See details Figure 5 . According to theoretical calculations, the absorption rate of the sound-absorbing metamaterial is 0.88 at 81 Hz, as Figure 5 As shown in the middle curve I-A; through simulation, it can be seen that the abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com