Method for reinforcing post-earthquake bridge pier through super-toughening fiber concrete

A concrete reinforcement and ductile fiber technology, which is applied in bridge reinforcement, bridges, bridge parts, etc., can solve the problems of excessive strength, low strength utilization rate, transfer, etc., and achieve good fatigue resistance, good economic benefits, interlayer good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

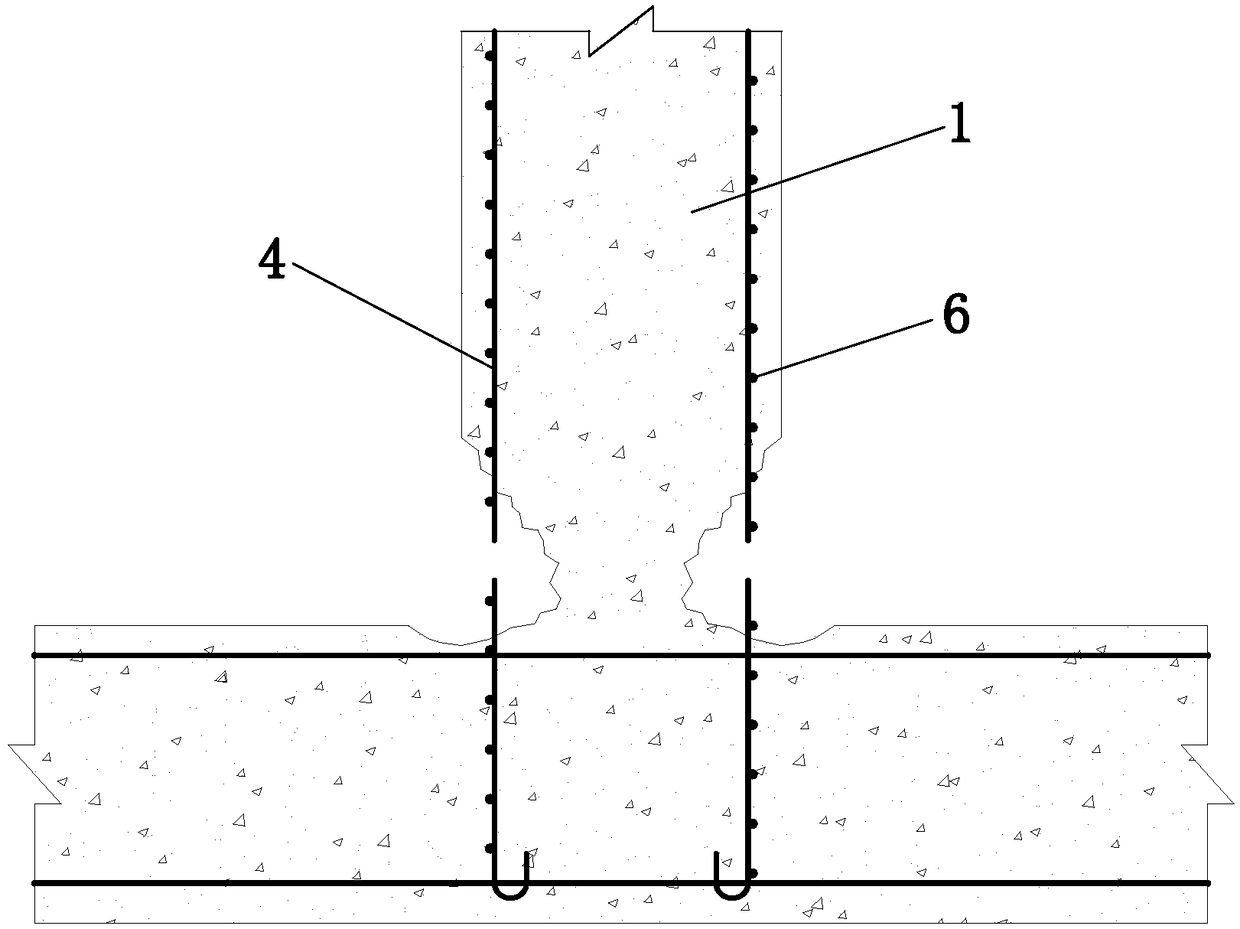

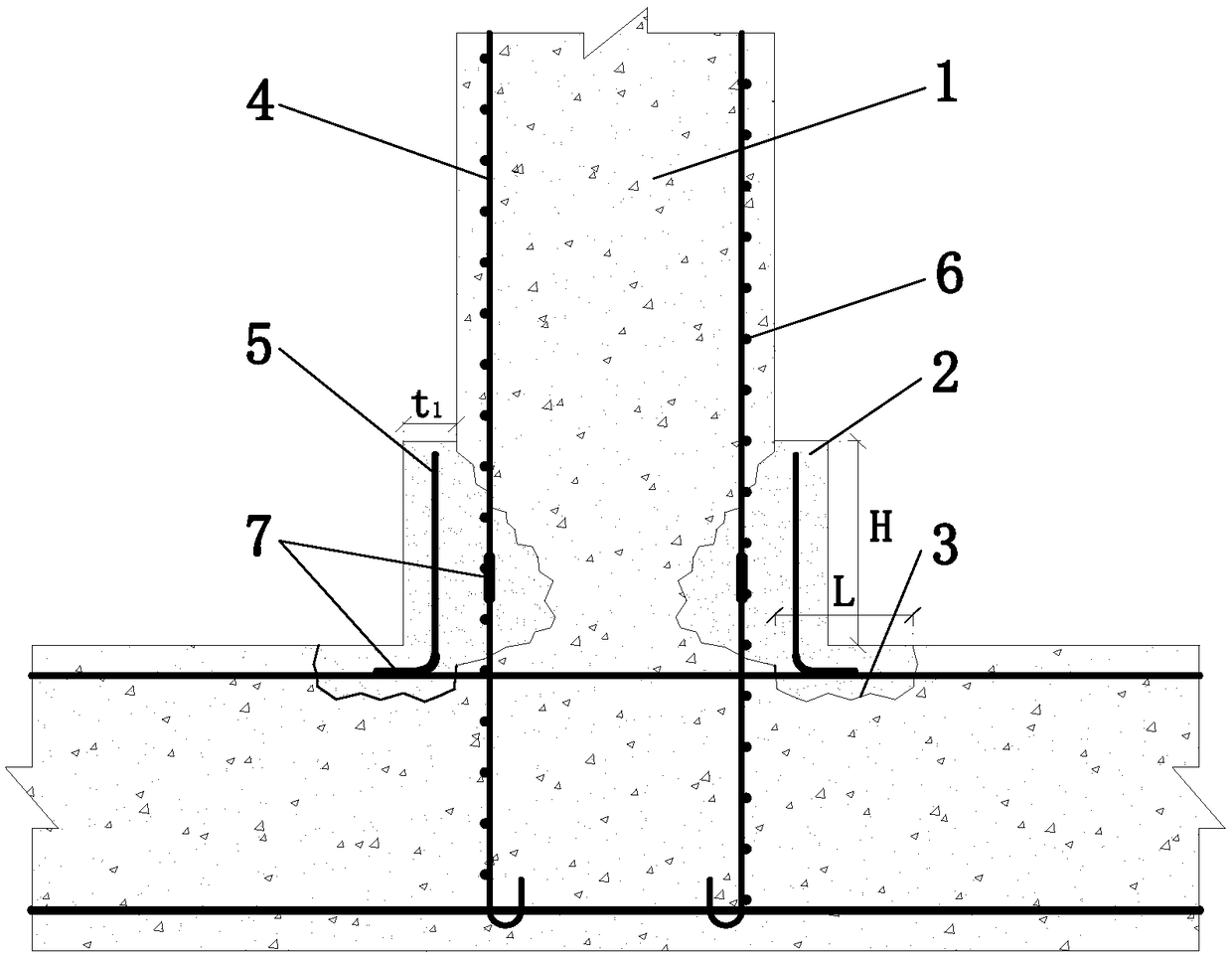

[0038] Such as figure 1 , figure 2 Shown is a method of using super-tough fiber concrete to strengthen post-earthquake pier, the reinforced pier includes ordinary concrete 1, super-tough fiber concrete 2, such as image 3 Shown, the former reinforcing bar is provided with stirrup 6 outside, is equipped with anchoring reinforcing bar 5 in the ultra-tough fiber concrete 2, and anchoring reinforcing bar 5 is welded with former reinforcing bar 4. The bonding surface between ordinary concrete 1 and super-tough fiber concrete 2 is a rough surface that has been chiseled.

[0039]The chisel height H on the pier column is 2.5L P , the chiseling width L of the platform surface is 0.25b.

[0040] L P ——Equivalent plastic hinge length (cm), which may take the smaller value of the calculation results of the following two formulas;

[0041] L P =0.08h+0.022f y d s ≥0.044f y d s

[0042]

[0043] Bark - the height of the cantilever pier or the distance from the plastic hinge s...

Embodiment 2

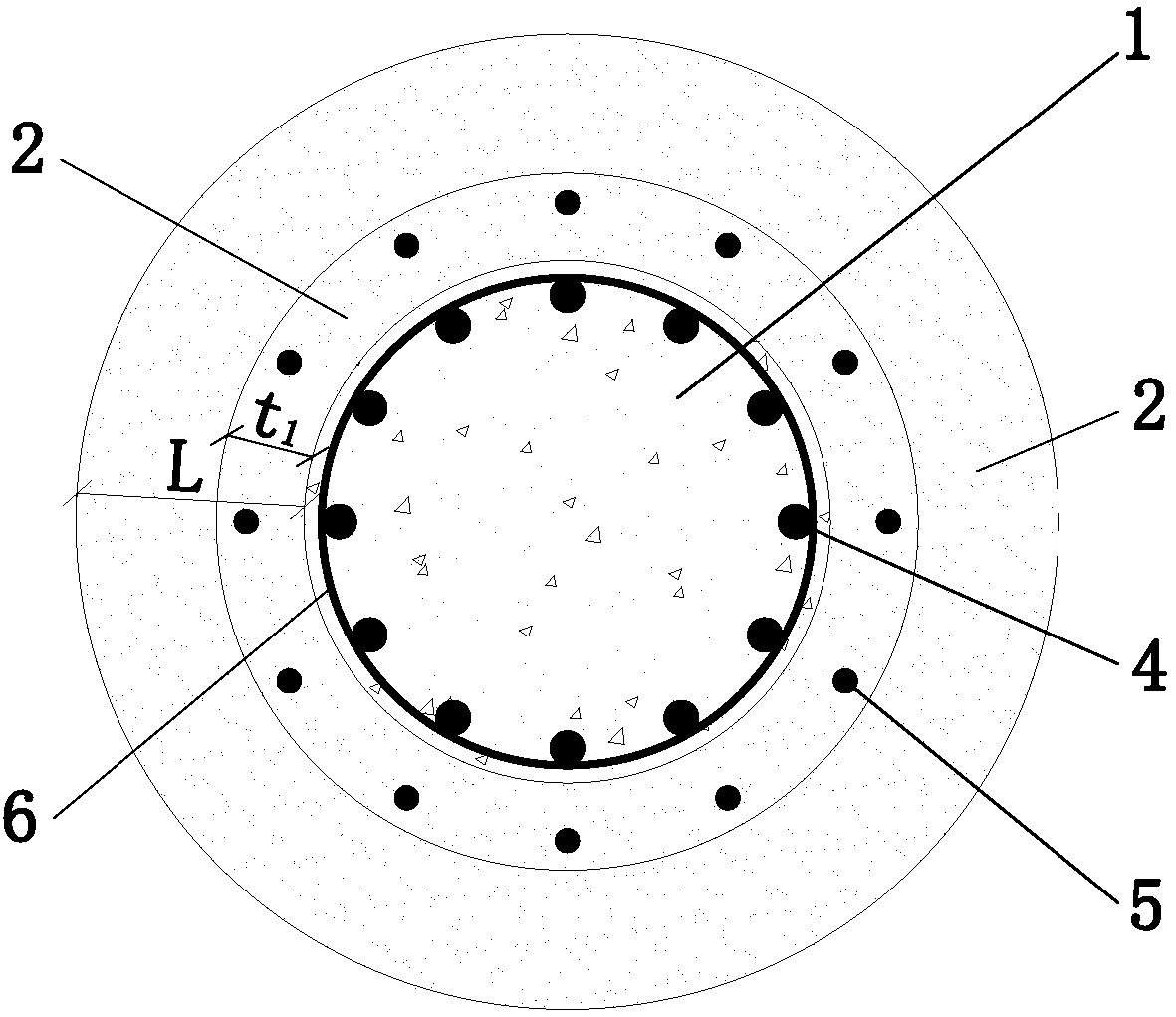

[0055] Such as figure 1 , Figure 5 Shown is a method of using super-tough fiber concrete to strengthen post-earthquake pier, the reinforced pier includes ordinary concrete 1, super-tough fiber concrete 2, such as Image 6 Shown, the former reinforcing bar is provided with stirrup 6 outside, is equipped with anchoring reinforcing bar 5 in the ultra-tough fiber concrete 2, and anchoring reinforcing bar 5 is welded with former reinforcing bar 4. The bonding surface between ordinary concrete 1 and super-tough fiber concrete 2 is a rough surface that has been chiseled.

[0056] The chisel height H on the pier column is 2.5L P , the chiseling width L of the platform surface is 0.25b.

[0057] L P ——Equivalent plastic hinge length (cm), which may take the smaller value of the calculation results of the following two formulas;

[0058] L P =0.08h+0.022f y d s ≥0.044f y d s

[0059]

[0060] Bark - the height of the cantilever pier or the distance from the plastic hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com