Subminiature integrated servo joint

An ultra-small, joint technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of inability to meet complex and changeable environments and tasks, poor modularity and replaceability, large joint diameter and volume, etc., and achieve light weight , reduce weight, simplify the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

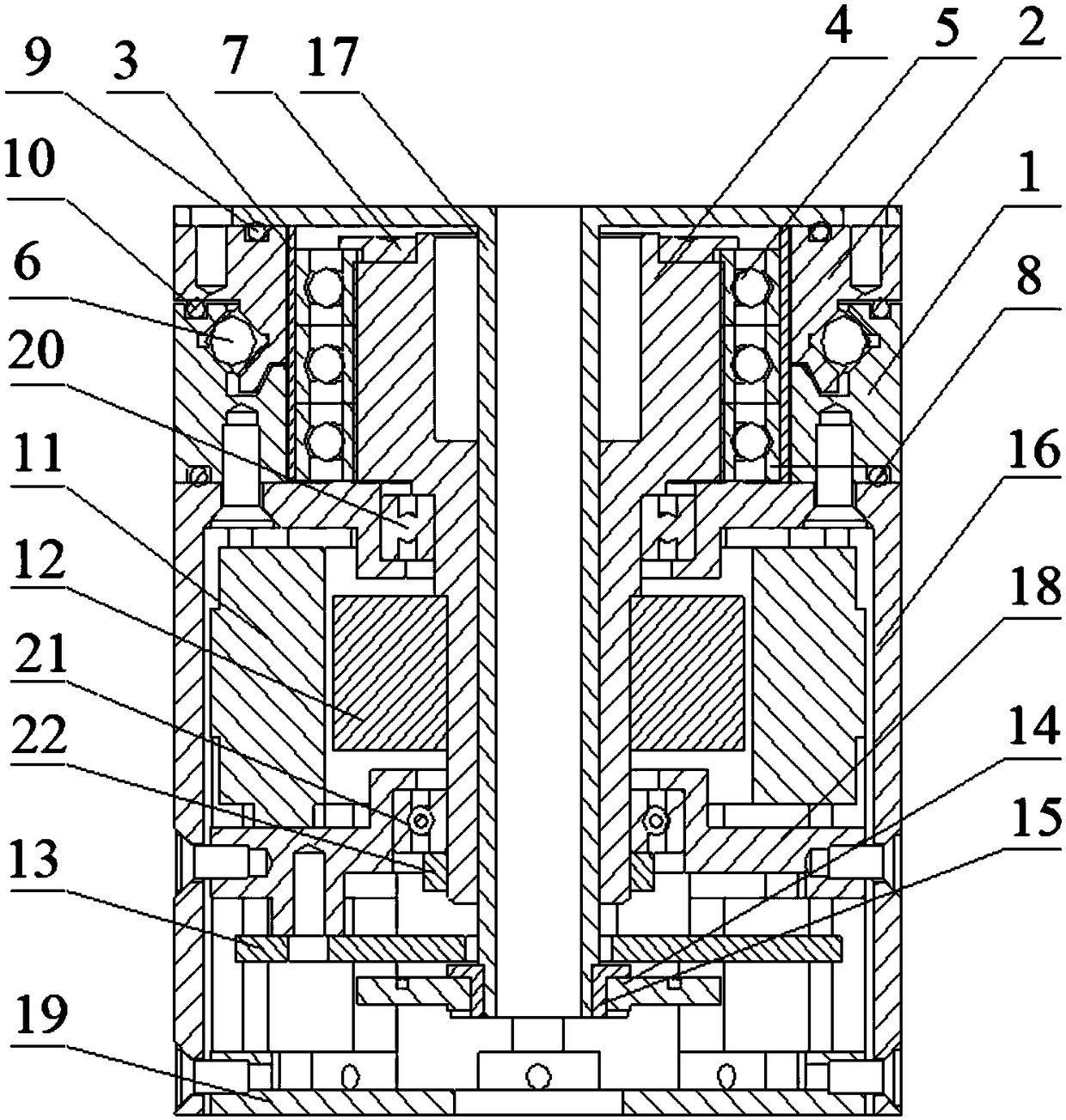

[0025] Such as figure 1 As shown, an ultra-small integrated servo joint provided by the present invention includes: an ultra-small harmonic reducer, a hollow torque motor and a drive unit.

[0026] Among them, the ultra-small harmonic reducer mainly includes: steel wheel a1, steel wheel b2, flexible wheel 3, cam 4, flexible bearing 5, roller 6 and bearing ring 7. In addition, the ultra-small harmonics also include seal ring a8, seal ring b9 and seal ring c10.

[0027] The hollow torque motor mainly includes: a motor stator 11 and a motor rotor 12 .

[0028] The drive unit mainly includes: a drive control board 13 , a code wheel 14 and a code wheel mounting plate 15 .

[0029] The ultra-small integrated servo joint also includes a housing 16, an output collection shaft 17, a pressure plate 18, a blocking cover 19, a bearing a20, and a bearing b21. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com